模具常用语中英文对照解析

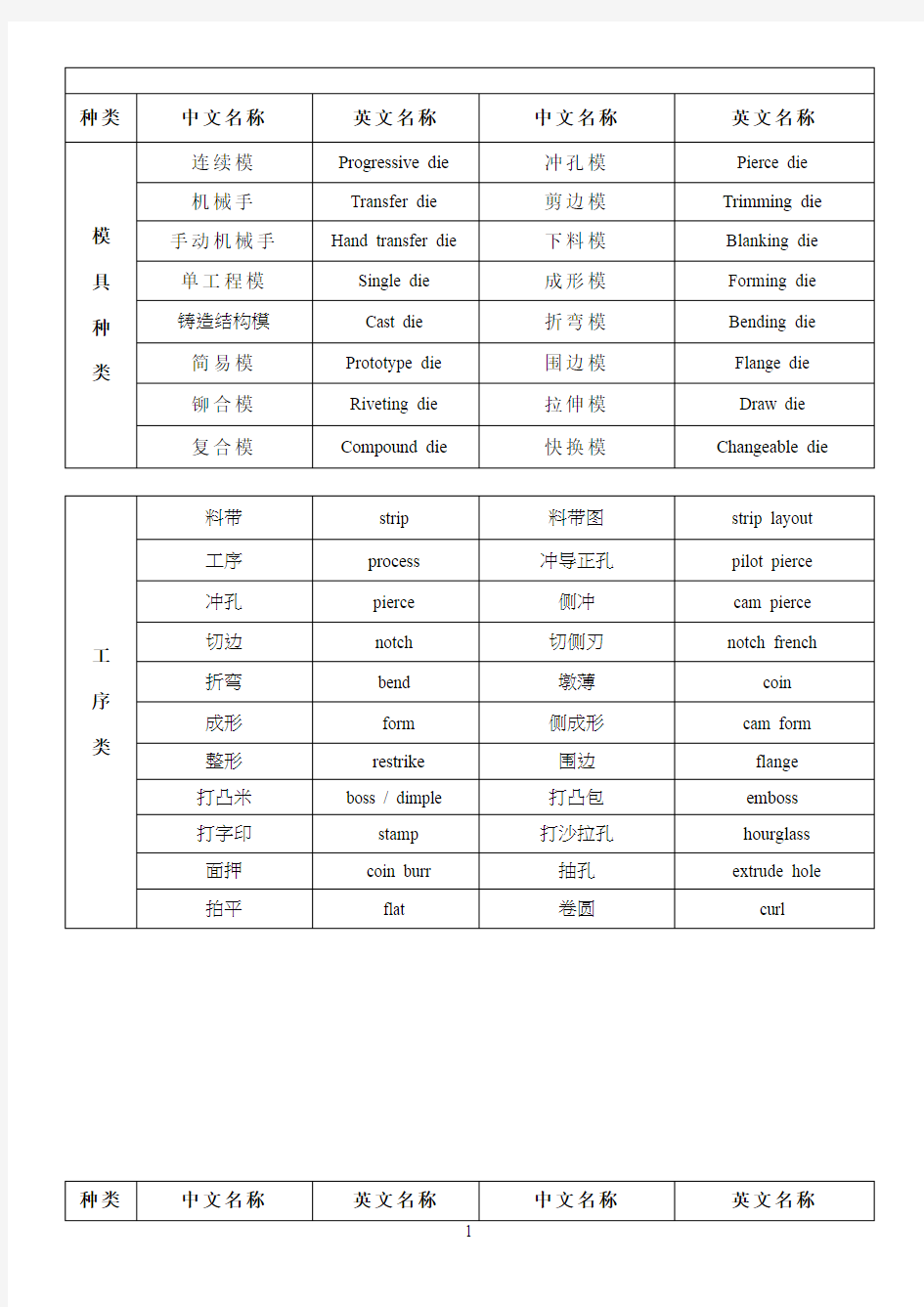

种类中文名称英文名称中文名称英文名称

模具种类

连续模Progressive die 冲孔模Pierce die 机械手Transfer die 剪边模Trimming die 手动机械手Hand transfer die 下料模Blanking die 单工程模Single die 成形模Forming die 铸造结构模Cast die 折弯模Bending die 简易模Prototype die 围边模Flange die 铆合模Riveting die 拉伸模Draw die 复合模Compound die 快换模Changeable die

工序类

料带strip 料带图strip layout 工序process 冲导正孔pilot pierce 冲孔pierce 侧冲cam pierce 切边notch 切侧刃notch french 折弯bend 墩薄coin

成形form 侧成形cam form 整形restrike 围边flange

打凸米boss / dimple 打凸包emboss

打字印stamp 打沙拉孔hourglass 面押coin burr 抽孔extrude hole 拍平flat 卷圆curl

种类中文名称英文名称中文名称英文名称

工序类

旋转rotate 铆接rivet

产品切边线trim line 铆螺母stake nut 切断cutoff 接刀口mismatch 料带带料处carrier tab 毛刺方向burr direction 压线groove 下料blanking

模板类

上托板top plate 下托板bottom plate 上垫脚upper parallel 下垫脚lower parallel 上模座upper die set 下模座lower die set 上垫板punch backup 下垫板lower backup 上夹板punch holder 下夹板die holder 上脱料板stripper 下模板die plate 冲头punch 凹模die

零件类

浮块lifter 浮料板lifter plate 成型公form punch 压料块pressure pad 切边冲头trim punch 刀口trim steel 沉头孔counter bore 冲孔入子button 顶针kick off / ejector 废料切断刀slug breaker 成型凹模forming die 整形公restrike punch 导尺rail 导尺顶杆lifter bolt 导料板rail plate 镶件/入子insert

侧冲组件cam 滑块slide

滑块上油槽oil groove 铲机driver

码模槽mounting slot 储运块storage block 限位柱stop block 起吊孔handing hole 起吊环eyebolt 靠块heel

脱料拉杆spool 模座导正块thrust heel

种类中文名称英文名称中文名称英文名称

零件类

耐磨片wear plate 垫片shim

压块keeper 初始管位first start pin

键槽key slot 键key

氮气弹簧nitrogen spring 螺旋弹簧coil spring

聚氨酯弹簧urethane

导柱

guide post 导套guide bushing 插针pilot pin

插针套pilot bushing 侧刃french

传感器sensor 销dowel

螺丝screw 拔牙jackscrew

垫圈washer 盲销blind dowel

压毛边冲头deburring punch 挡块stopping plate

压线冲头groove punch 定位块location block

字模冲头stamp punch 圆冲头round punch

压筋冲头ribbon punch 气垫板air cushion plate 异形冲头special shape punch 气垫顶杆air-cushion eject-rod 切边冲头trimming punch 上压块pressure block

加强筋冲头stiffening rib punch 弹簧箱spring box 定位板guide plate 弹簧箱顶杆spring-box eject-rod 压边圈binder 弹簧箱顶板spring-box eject-plate

公差类

公差tolerance 公差范围tolerance range 上公差upper tolerance 下公差lower tolerance 公差+/- 0.05 plus minus 0.05 形位公差图GD&T 平面度flatness 直线度

Straightness 倾斜度angularity 垂直度perpendicularity 平行度parallelism 圆度roundness

种类中文名称英文名称中文名称英文名称

公圆柱度cylindricity 面轮廓度surface profile

差类

线轮廓度line profile 位置度true position 同轴度concentricity 对称度symmetry 圆跳动runout 全跳动total runout 尺寸dimension 角度值angle degree 尺寸全检报告dimensional layout 三次元尺寸报告CMM report

冲床相关

机械冲床mechanical press 油压机hydraulic press 吨位tonnage 行程stroke / travel 冲床上台面ram 冲床下台面bolster

冲床台面布置图press layout 冲床上的快速对正QDC 冲床气垫air cushion 码仔stirrup 闭合高度shut height T型槽T-slot

送料机feeder 送料高度feeding height

工具

卡尺caliper 千分尺micrometer 直尺ruler 高度尺height gage 丝攻screw tap 起子screwdriver 拨牙器jacker 扳手wrench

风磨机hand grinder 油石oil stone

加工类

开料cutting material 钻drill (DR) 攻牙tap 铰ream

铣mill 车lathe

电脑锣NC mill 线切割wire cutting(W/C) 磨grind 刨planer

电火花EDM 镭射laser cutting 倒角chamfer xx的精加工finish XX

真空热处理

vacuum heat

treatment

镀钛TD coating 退磁demagnetization 烧焊weld

4.1.2 加工说明对照表:

加工说明Machining Note

注:有0.00的地方为数据填入处

外导套OUTER GUIDE BUISHING 起吊杆HANDING PIN

实数铣通MILL THRU 正反两面各铣TOP SIDE AND OPP SIDE MILL

X:-¢0.00(氮气弹弓过孔,锣穿)单+0.00

X:-¢0.00 (DR.THRU FOR GAS SPRING) S+0.00

X:-¢0.00(氮气弹弓沉头,正面CNC单+0.00,锣深0.00.)

X:-¢0.00 ( CNC C'BORE TOP SIDE FOR GAS SPRING, S+0.00, DP0.00)

X:-¢0.00(氮气弹弓沉头,反面CNC单+0.00,锣深0.00.)

X:-¢0.00 (CNC C'BORE OPP SIDE FOR GAS SPRING, S+0.00, DP0.00)

X:-¢0.00(合销孔,铰)

X:-¢0.00 (REAM FOR DOWEL)

X:-¢0.00(合销孔,割)单+0.00

X:-¢0.00 (W/C FOR DOWEL) S+0.00

(正面沉头¢0.00*0.00深,内攻M0.00*1.5牙)

(¢0.00*0.00 C'BORE DP0.00 TOP SIDE, TAP M0.00*1.5 THR)

(反面沉头¢0.00*0.00深,内攻M0.00*1.5牙)

(¢0.00*0.00 C'BORE DP.0.00 OPP. SIDE, TAP M0.00*1.5 THR)

X:-¢0.00(合销孔,钻穿)

X:-¢0.00 (DR.THRU FOR DOWEL)

X:-¢0.00(一般孔,钻穿)

X:-¢0.00 (DR.THRU HL)

X:-¢0.00(穿丝孔,钻穿)

X:-¢0.00 (DR.THRU FOR WEDM S.H.)

X:-¢0.00(漏油孔,钻穿) 按向视图加工

X:-¢0.00 (DR.THRU FOR DRAIN HL) ACCORDING VIEW DRAWING TO MACHINING X:-(漏油槽,反面CNC单+0.00,锣深0.00)

X:- (CNC POCKET OPP.SIDE FOR DRAIN, S+0.00, DP0.00)

X:-¢0.00(基准孔,铰)

X:-¢0.00 (REAM FOR DATUM HL)

X:-¢0.00钻穿(螺丝过孔)内攻M0.00牙

X:-¢0.00 (DR.THRU FOR CLEARANCE HL, TAP M0.00 THR)

(正面沉头¢0.00*0.00深)

(¢0.00*0.00 C'BORE DP0.00 TOP SIDE)

(反面沉头¢0.00*0.00深)

(¢0.00*0.00 C'BORE DP0.00 OPP. SIDE)

(侧面沉头¢0.00*0.00深)

(¢0.00*0.00 C'BORE DP0.00 EDGE SIDE)

X:-M0.00钻穿,反面攻深0.00,有效牙0.00

X:-M0.00 DR.THRU, TAP DP0.00 OPP.SIDE, THR DP0.00)

X:-M0.00钻穿,正面攻深0.00,有效牙0.00

X:-M0.00 DR.THRU, TAP DP0.00 TOP SIDE, THR DP0.00)

X:-M0.00钻穿,正反面攻深0.00,有效牙0.00

X:-M0.00 DR.THRU, TAP DP0.00 TOP&OPP. SIDE, THR DP0.00)

X:-M0.00盲孔,反面攻深0.00,有效牙0.00

X:-M0.00 BLIND HL, TAP WORK DP0.00 OPP. SIDE)

X:-M0.00盲孔,正面攻深0.00,有效牙0.00

X:-M0.00 BLIND HL, TAP WORK DP0.00 TOP SIDE, THR DP0.00)

X:-M0.00盲孔,正反面攻深0.00,有效牙0.00

X:-M0.00 BLIND HL, TAP DP0.00 TOP&OPP. SIDE, THR DP0.00)

X:-M0.00盲孔,侧面分中攻深0.00,组模自配

X:-M0.00 BLIND HL, TAP DP0.00 ON EDGE FROM CENTER , DIE MAKER FIT) (侧面沉头¢0.00*0.00深)

(¢0.00*0.00 C'BORE DP0.00 EDGE SIDE)

X:-M0.00盲孔,侧面分中钻深0.00

X:-M0.00 BLIND HL, DR. DP0.00 ON EDGE FROM CENTER

X:-M0.00(拨牙螺丝孔,攻穿)

X:-M0.00 TAP.THRU FOR JACK SCREW

X:-¢0.00(塞打过孔,钻穿)

X:-¢0.00 DR.THRU FOR SPOOL

X:-¢0.00(弹弓过孔,钻穿)

X:-¢0.00 DR.THRU FOR SPRING

X:-¢0.00(弹弓孔,反面沉深0.00)有效深0.00

X:-¢0.00 (C'BORE FOR SPRING DP.0.00 OPP.SIDE, USED DP.0.00)

X:-¢0.00(弹弓孔,正面沉深0.00)有效深0.00

X:-¢0.00 (C'BORE FOR SPRING DP.0.00 TOP.SIDE, WORK DP.0.00)

X:-(避空孔,锣穿)单+0.00

X:- (POCKET THRU)S+0.00

X:-(避空孔,正面CNC单+0.00,锣深0.00)

X:- (POCKET, CNC MILL S+0.00 DP0.00 TOP SIDE)

X:-(避空孔,反面CNC单+0.00,锣深0.00)

X:- (POCKET, CNC MILL S+0.00 DP0.00 OPP SIDE)

X:-¢0.00(避空孔,反面CNC单+0.00,锣深0.00)

X:-¢0.00 (POCKET, CNC MILL S+0.00, DP0.00 OPP.SIDE)

X:-¢0.00(避空孔,正面CNC单+0.00,锣深0.00)

X:-¢0.00 (POCKET, CNC MILL S+0.00, DP0.00 EDGE SIDE)

X:-¢0.00(两用销过孔,割)单+0.00

X:-¢0.00 (LIFTER PIN, W/C S+0.00)

X:-(导尺避空,CNC单+0.00锣穿)

X:- (POCKET FOR RAIL, CNC MILL THRU, S+0.00)

X:-(导尺避空,正面CNC单+0.00,锣深0.00)

X:- (POCKET FOR RAIL, CNC MILL DP.0.00 TOP SIDE, S+0.00) X:-(导尺避空,反面CNC单+0.00,锣深0.00)

X:- (POCKET FOR RAIL, CNC MILL DP.0.00 OPP. SIDE, S+0.00) X:-(浮块避空,正面CNC单+0.00,锣深0.00)

X:- (POCKET FOR LIFTER, CNC MILL DP.0.00 TOP SIDE, S+0.00) X:-(浮块孔,割)单+0.00

(反面避空单+0.00,锣深0.00)

X:-(LIFTER HL, W/C)S+0.00

(POCKET DP0.00 S+0.00 OPP.SIDE)

X:-(浮块孔,锣)单+0.00

(反面避空单+0.00,锣深0.00)

X:-(LIFTER HL, MILL)S+0.00

(POCKET DP0.00 S+0.00 OPP.SIDE)

X:-¢0.00(顶针孔,钻穿)

(反面沉头¢0.00*0.00深,内攻M0.00*1.5牙)

X:-¢0.00 (EJECT PIN, DR.THRU.)

(¢0.00 C'BORE DP0.00 OPP. SIDE, TAP M0.00*1.5 THR)

X:-¢0.00(顶针孔,钻穿)

(正面沉头¢0.00*0.00深,内攻M0.00*1.5牙)

X:-¢0.00 (EJECT PIN, DR.THRU.)

(¢0.00 C'BORE DP0.00 TOP SIDE, TAP M0.00*1.5 THR)

X:-¢0.00(导柱(导套)孔,CNC锣)单+0.00

X:-¢0.00 CNC MILL FOR GUIDE PIN(BUSHING) S+0.00

X:-¢0.00(导柱(导套)孔,割)单+0.00

X:-¢0.00 W/C FOR GUIDE PIN(BUSHING) S+0.00

X:-M0.00*1.5(止付螺丝,正面攻深0.00)

X:-M0.00*1.5(SET SCREW, TAP DP0.00 TOP SIDE)

X:-M0.00*1.5(止付螺丝,反面攻深0.00)

X:-M0.00*1.5(SET SCREW, TAP DP0.00 OPP SIDE)

X:-(入子孔,CNC单+0.00,锣穿)

X:-(INSERT HL, CNC MILL THRU S+0.00)

(阴影部分正面沉头单+0.00,锣深0.00)

(SHADE AREA, MILL DP0.00 S+0.00 TOP SIDE)

(阴影部分反面沉头单+0.00,锣深0.00)

(SHADE AREA, MILL DP0.00 S+0.00 OPP SIDE)

X:-(入子孔,割)单+0.00

X:-(INSERT HL, W/C S+0.00)

(阴影部分扣位正面锣深0.00)

(SHADE AREA FOR HEAD POCKET, MILL DP0.00 TOP SIDE)

(阴影部分扣位反面锣深0.00)

(SHADE AREA FOR HEAD POCKET, MILL DP0.00 OPP. SIDE)

(正面沉头单+0.00,锣深0.00)

(POCKET, MILL DP0.00 TOP SIDE)注: 此处的沉头不能用C'BORE, 只有圆形的沉头才用C'BORE.

(反面沉头单+0.00,锣深0.00)

(POCKET, MILL DP0.00 TOP SIDE)

X:-(入子孔,CNC单+0.00,锣穿)

X:- (INSERT HL, CNC MILL THRU. S+0.00)

X:-(入子孔,正面CNC单+0.00,锣深0.00)

X:- (INSERT HL, CNC MILL DP0.00 S+0.00 TOP SIDE)

X:-(入子孔,反面CNC单+0.00,锣深0.00)

X:- (INSERT HL, CNC MILL DP0.00 S+0.00 OPP. SIDE)

X:-¢0.00(插针孔,铰)单+0.00

X:-¢0.00(REAM S+0.00 FOR PILOT PIN)

X:-¢0.00(插针孔,割)单+0.00

(正面沉头¢0.00*0.00深)

X:-¢0.00(W/C FOR PILOT PIN)

(¢0.00 C'BORE DP0.00 TOP SIDE)

X:-¢0.00(插针孔,钻穿)

(正面沉头¢0.00*0.00深)

X:-¢0.00(DR.THRU FOR PILOT PIN)

(¢0.00 C'BORE DP0.00 TOP SIDE)

X:-(冲头过孔,割)单+0.00

(正面避空,CNC单+0.00,锣深0.00)

(阴影部分扣位正面锣深0.00)

X:-(W/C S+0.00 FOR PUNCH CLEARANCE HL)

(POCKET, CNC DP 0.00 S+0.00 TOP SIDE)

(POCKET SHADE FOR HEAD, DP0.00 TOP SIDE)

X:-(冲头过孔,锣穿)单+0.00

(正面避空,CNC单+0.00,锣深0.00)

X:-(MILL THRU.FOR PUNCH CLEARANCE HL)

(POCKET DP0.00 CNC S+ TOP SIDE)

X:-(异形冲孔,直x斜x,割)单+0.00

(双线部分,割)单+0.00

X:-(W/C FOR SPECIAL HL, 0.00 LAND 0.00 TAPER, S+0.00) (W/C PER DOUBLE LINE S+0.00)

X:-(冲孔,直x斜x,割)单+0.00

X:-(W/C FOR PIERCE DIE HL, 0.00 LAND 0.00 TAPER S+0.00) X:-(冲孔,割)单+0.00

X:-(W/C FOR PIERCE DIE HL S+0.00)

X:-¢0.00(冲孔漏屎,钻穿)

X:-¢0.00 (DR. THRU FOR CHUTE)

X:-(异形冲孔漏屎,CNC单+0.00,锣穿)

X:-¢0.00 (MILL. THRU FOR SPECIAL CHUTE S+0.00)

X:-(产品落料斜度,实数斜30o锣)

X:-(MILL 30 TAPER FOR PART RAMP NO CLEARANCE)

X:-(漏屎斜度,直x斜45o锣)

X:-(MILL FOR CHUTE 0.00 LAND 45 TAPER)

反面沉深底面留0.00

MILL UNTIL DP

正面沉深底面留

MILL UNTIL DP

五金模具单词总结模具种类:

连续模progressive die

机械手transfer die

手动机械手hand transfer die

单工程模single die/line die

复合模compound die

铆接模riveting die

铸造结构模cast die

能快换的模changeover die

泡沫模pattern

互换性:

公差tolerance

上公差upper tolerance

下公差lower tolerance

公差范围tolerance range

公差+/- 0.05 plus minus 0.05

形位公差图GD&T

平面度flatness

直线度straightness

倾斜度angularity

垂直度perpendicularity / squareness

平行度parallelism

圆度roundness / circularity

圆柱度cylindricity

面轮廓度surface profile

线轮廓度line profile

位置度true position

同轴度concentricity

对称度symmetry

圆跳动runout

全跳动total runout

尺寸dimension

角度angle degree

全尺寸报告dimensional layout

工艺性:

料带strip

料带图strip layout

工序process

冲导正孔pilot pierce

冲孔pierce

侧冲cam pierce

切边notch

成形后的切边trim

切侧刃french trim / fringe trim 厚料切边后的精修边shave

折弯bend

墩薄coin

折弯处压筋gusset

成形form

侧成形cam form

整形restrike / rehit

围边flange

压线/压长条状筋ribbon

打凸米boss / dimple

打凸包emboss

打字印stamp

打沙拉孔hourglass

面押coin burr

抽孔extrude hole

拍平flat / spanking

包边hem edge

压角cone

张角flare

切舌lance

半剪knockout

卷圆curl/热恶劣

旋转rotate

铆接rivet

铆螺母stake nut

切断cutoff

接刀口mismatch

料带带料处carrier tabs

毛刺方向burr direction

产品切边线trim line

模具零件:

模具die / tool

上托板upper mounting plate 上垫脚upper parallel

上模座upper die set

上垫板punch backup

上夹板punch holder

止挡板traveling stop

脱料板stripper

下模板die plate

下垫板die backup plate

下模座lower die set

下垫脚lower parallel

上托板base mounting plate

浮块lifter

浮料板lifter plate

成型公form punch

压料块pressure pad

切边冲头trim punch

刀口trim steel

刀口直身位land

直5斜1 5mm Land 1 taper 刀口上沉头的深度die life 沉头counter bore

冲头倒斜shear

高低冲stagger punch

球锁冲头ball-lock punch

球锁座ball-lock retainer

冲孔入子button

顶针kick off / ejector

废料切断刀slug breaker

成型凹模form die

整形公restrike form punch 导尺rail /stock guidance

导尺顶杆lifter bolt

导料板rail plate

镶件/入子insert

侧冲组件cam

滑块slide

滑块上油槽oil groove

铲机driver

码模槽mounting slot

储运块storage block

限位柱stop block

起吊孔handing hole

起吊环eyebolt

模柄shank

靠块heel

摆块rocker bender

脱料板拉杆stripper bolt

模座导正块thrust

耐磨片wear sheet

耐磨板wear plate

垫片shim

两用销lifter pin

初始管位first start pin

内限位standoff

压块keeper

导柱导套压块keeper/ boss 键槽key slot

键key

塑胶模具类中英文对照专业术语

塑胶模具类中英文对照专业术语工程部/ Design department: 1) Designer - 设计师。 2) Assembly drawing - 模具组装图。 3) Mold layout - 模具结构图。 4) 2D product drawing - 2D产品图。 5) 3D product data - 3D产品数据。 6) Part drawing - 散件图。 7) Insert molding - 镶件模。 8) 2 color mold / Double injection tool - 双色模。 9) Hydraulic system - 油/水压系统。 10) Parting line - 分模线。 11) Air venting - 排气槽。 12) Cooling system - 冷却系统。 13) Screw - 镙丝。 14) Hot runner system - 热流道。 15) Valve gate - 伐针入水口。 16) Fan gate - 扇型入水口。 17) Pin point gate - 针点进胶。 18) Moon gate / Banana gate - 香蕉,象牙入水口。 19) Submarine gate - 潜水口。 20) Injection machine tonnage - 注塑机吨数。 21) Number of cavity - 穴数。 22) Steel - 钢材。 23) Copper - 铜。 24) Tungsten copper - 钨铜。 25) Beryllium copper - 铍铜。 26) Hardening - 加硬/淬火。 27) Tempering - 回火。

冲压模具专业词汇中英文翻译

Counter bored hole 沉孔 Chamfer 倒斜角 Fillet 倒圆角 padding block垫块 stepping bar垫条 upper die base上模座 lower die base下模座 upper supporting blank上承板 upper padding plate blank上垫板 spare dies模具备品 spring 弹簧 bolt螺栓 document folder活页夹 file folder资料夹 to put file in order整理资料 spare tools location手工备品仓 first count初盘人 first check初盘复棹人 second count 复盘人 second check复盘复核人 equipment设备 waste materials废料 work in progress product在制品 casing = containerization装箱 quantity of physical inventory second count 复盘点数量 Quantity of customs count 会计师盘,点数量 the first page第一联 filed by accounting department for reference会计部存查 end-user/using unit(department)使用单位 Summary of year-end physical inventory bills 年终盘点截止单据汇总表 bill name单据名称 This sheet and physical inventory list will be sent to accounting department together (Those of NHK will be sent to financial department) 本表请与盘点清册一起送会计部-(NHK厂区送财会部) Application status records of year-end physical inventory List and physical inventory card 年终盘点卡与清册使用-状况明细表 blank and waste sheet NO. 空白与作废单号

常用模具零件中英文对照表

常用模具零件中英文对照表 2005-12-19 14:51:17中国注塑网 一、入水:gate 进入位:gate location 水口形式:gate type 大水口:edge gate 细水口:pin-point gate 水口大小:gate size 转水口:switching runner/gate 唧嘴口径:sprue diameter 二、流道: runner 热流道:hot runner,hot manifold 热嘴冷流道: hot sprue/cold runner 唧嘴直流: direct sprue gate 圆形流道:round(full/half runner 流道电脑分析:mold flow analysis 流道平衡:runner balance 热嘴:hot sprue 热流道板:hot manifold 发热管:cartridge heater 探针: thermocouples 插头:connector plug 插座:connector socket 密封/封料:seal 三、运水:water line 喉塞:line lpug 喉管:tube 塑胶管:plastic tube 快速接头:jiffy quick connector plug/socker 四、模具零件:mold components 三板模:3-plate mold 二板模:2-plate mold 边钉/导边:leader pin/guide pin 边司/导套:bushing/guide bushing 中托司:shoulder guide bushing 中托边:guide pin 顶针板:ejector retainner plate 托板:support plate 螺丝:screw 管钉:dowel pin

模具术语(中英文对照)

AD-Diameter The tread diameter at the centerline of the tread (EU); also: "T-Diameter"(GT) AD直径:指胎面中心线直径(EU)。又叫T直径(GT) Auto-lock Ear A Lug on the cone ring used to mount the mold/container in the top half of a 60“ NRM Auto-lock press. 导环上的突缘,用于和60“ NRM Auto-lock 硫化机上半部连接。 Bead Ring The tire bead forming ring (also: toe ring) 钢圈,也称toe ring Bead Ring Register The landing and tapered seat that the bead ring fits into 钢圈配合:侧板上,和钢圈配合的平面及锥面 Bottom Container Plate The plate that the bottom sidewall plate is bolted to 模壳底座 Bottom Container Plate Lifting Lug A lug attached to the Bottom Container Plate with Horizontal holes used for lifting. 模壳底座吊耳:装配在底座上、有水平的孔,用来吊装的吊耳 Bottom Container Plate Dowel Pin Lug A lug attached to the Bottom Container Plate that supports the Dowel Pin Bushing. 装配在底座上,用来支承定位销套的突缘 Bottom Container Plate Hold Down A lug that is used to fix the Bottom Plate in the Press. 用来将底座装配在硫化机上的突缘 Breaker Hook A hook fixed to the bottom of the tread segment that catches the bottom container plate only when the segment will not release from the tire during de-molding. 分离钩:固定在花纹块底部的钩子,轮胎硫化完后若花纹块不能跟轮胎分离,就用此钩抓住模壳底座帮助花纹块和轮胎进行分离。

塑料注塑模具中英文对照外文翻译文献

外文翻译及原文 (文档含英文原文和中文翻译) 【原文一】 CONCURRENT DESIGN OF PLASTICS INJECTION MOULDS Abstract The plastic product manufacturing industry has been growing rapidly in recent years. One of the most popular processes for making plastic parts is injection moulding. The design of injection mould is critically important to product quality and efficient product processing. Mould-making companies, who wish to maintain the competitive edge, desire to shorten both design and manufacturing leading times of the by applying a systematic mould design process. The mould industry is an important support industry during the product development process, serving as an important link between the product designer and manufacturer. Product development has changed from the traditional serial process of design, followed by manufacture, to a more organized concurrent process where design and manufacture are considered at a very early stage of design. The concept of concurrent engineering (CE) is no longer new and yet it is still applicable and relevant in today’s manuf acturing environment. Team working spirit, management involvement, total design process and integration of IT tools are still the essence of CE. The application of The CE process to the design of an injection process involves the simultaneous consideration of plastic part design, mould design and injection moulding machine selection, production scheduling and cost as early as possible in the design stage.

模具DFM常用中英文对照

DFM常用中英文对照 1、这个红色面在前模方向/后模方向/行位方向有倒扣。 This red surface is undercut at cavity side / core side / slider side. 2、这些红色面在前模方向/后模方向/行位方向有倒扣。 These red surfaces are undercut at cavity side / core side / slider side. 3、产品的这个位置太小,导致模具在前模方向/后模方向/行位方向有薄钢位。 This position is too small and it will bring the thin steel at cavity side / core side / slider side. 4、这些红色线是前后模/镶件/行位/斜顶分型线。 These red lines are the parting line of cavity and core / insert / slider / lifter. 5、此产品使用推板/推块顶出。 Use the stripper plate / ejector block to eject this part. 6、前模/后模斜内行位。 Inner angle slider at cavity / core side. 7、为了简化模具结构建议改变此处出模方向。 Suggest to change the draft direction of this position to make the mold structure simply. 8、最终的进胶位置根据模流分析。 Finally gate position according the mold flow analysis. 9、斜顶与后面的柱位空间太小,斜顶在运动时会干涉到柱子,请考虑移动这个柱子的位置。 This lifter intervene with the pole during ejection, please consider changing the position of the pole. 10、此处有薄钢位,强度不足而且不容易冷却。 The strength of this area is too weak and it is hard to cool because the thin steel. 11、此处有尖角,填充困难。 It is hard to fill for this area because the sharp feature. 12、此处料位太厚,会有缩水,建议减胶改善。 We suggest to reduce some wall thickness to avoid the sink mark for this position. 13、此处的行位夹线在外观面上,请确认是否接受? Please confirm whether it is acceptable to have a slider line on the visible surface? 14、建议加大拔模角,以便脱模顺利。 We suggest to enlarge the draft angle to help release the tool. 15、如果分型面此处,模具上会有尖角和刀口,对模具寿命有影响。 There are sharp edges if we set the parting line here, it will reduce the tool life. 16、此处料厚段差很大,成品表面会有应力痕,建议修改如图示。 The thickness is not equal and it will bring the stress lines on the surface, suggest to improve the part as the picture shown. 17、此大行位上有小行位,开模时小行位需先退,大行位做延时,合模时则相反。 The small slider is inside the big slider, when the mold open, the small slider need to recede first and the big slider have to postpone. When the mold close, it is contrary. 18、此处需做强顶。 This position need to force ejection. 19、由于此处没有足够空间下热咀,所以需做一个柱子进胶。 This position need to make a pole for gating because there have no enough space for hot sprue. 20、沾模, stick

模具中英文对照表

landed plunger mold 有肩柱塞式模具burnishing die 挤光模 landed positive mold 有肩全压式模具button die 镶入式圆形凹模 loading shoe mold 料套式模具 center-gated mold 中心浇口式模具loose detail mold 活零件模具 chill mold 冷硬用铸模 loose mold 活动式模具 clod hobbing 冷挤压制模 louvering die 百叶窗冲切模composite dies 复合模具 manifold die 分歧管模具 counter punch 反凸模 modular mold 组合式模具 double stack mold 双层模具 multi-cavity mold 多模穴模具electroformed mold 电铸成形模 multi-gate mold 复式浇口模具expander die 扩径模 offswt bending die 双折冷弯模具extrusion die 挤出模

palletizing die 叠层模 family mold 反套制品模具 plaster mold 石膏模 blank through dies 漏件式落料模porous mold 通气性模具duplicated cavity plate 复板模positive mold 全压式模具 fantail die 扇尾形模具 pressure die 压紧模 fishtail die 鱼尾形模具 profile die 轮廓模 flash mold 溢料式模具progressive die 顺序模 gypsum mold 石膏铸模 protable mold 手提式模具 hot-runner mold 热流道模具prototype mold 雏形试验模具ingot mold 钢锭模 punching die 落料模 lancing die 切口模 raising(embossing) 压花起伏成形re-entrant mold 倒角式模具

模具常用术语中英文对照表

"R,L Co.,Ltd" 模具常用术语中英文对照 模芯Parting Core 局部视图Partial View 冷料# Cold Slag 线切割 Wire 轮廊Contour 螺纹孔 Tapping Hole 连接件 Fittings 斜针Angle Pin 接合Engage 替换镶件Interchangeable Mold Inserts 指定吨位的注塑机Specific Press 水嘴接头Water Fittings 螺纹Eyebolt Thread 回针Stop Pin 二级顶出针Sub-Leaderd Pin 镶件Mold Insert 加硬Harden 唧嘴Sprue 设计筒图Design Preliminary 名称块表Title Block 版本标识Revision Level 材料清单Stock List 制模Build Mold 手动滑块Hand Slide 漏水测试Leak Test 流道排气Runner Vents 抛光Draw Polish 侧抽芯 Side Action 加强筋 Reinforcing

三角撑 Gusset 柱子Bossed 出模斜度Draft 外廊Contour 落单会议Kick-Off Meeting 装卸孔 Handling Hole 运输安全带Moldstrap 码模槽 Clamp Slot 撑头Support Pillar 螺牙1/2-13 Eye Bolt 1/2-13Tap 导柱位 Leader Pin Location 耐落胶 Teflon Paste 偏移量 Offset 水塞Water Line Plug 撬模脚 Ppy Slot 重新加工Reworked 配件Components 补偿Compensation 平面度 Parallel 倒角Chamfer 模胚Mold Base 热嘴Hotnozzle 火花机 Edm 熔接线 Weildline 压机Press 晒纹Texturing 梯形Trapezoid 凸缘、法兰Flange 方铁Spacer Block 顶针板Ejector Plate 顶针底板Ejector Retainer Plate 垫板Retainer Plate

冷冲压模具术语中英文对照

冲模stamping die 冲裁模blanking die 落料模blanking die 冲孔模piercing die 修边模trimming die 切口模notching die 切口模lancing die 剖切模parting die 精修模shaving die 精冲fine blanking die 切断模cut-off die 弯曲模bending die 预弯模pre-bending die 卷边模curling die 扭曲模twisting die 拉伸模drawing die 反拉伸模reverse redrawing die 正拉伸模obverse redrawing die 变薄拉伸ironing die 成形模forming die 胀形模bulging die 压筋模stretching die 翻边模flanging die 翻孔模burring die 缩口模necking die 扩口模flaring die 整形模restriking die 压印模printing die 复合模compound die 正装复合模obverse…倒装复合模inverse… 级进模progressive die 单工序模single-operation die 无导向模open die 导板模guide plate die 导柱模guide pillar die 通用模universal die 自动模automatic die 组合冲模combined die 传递模transfer die 镶块模insert die 柔性模flexible die 多功能模multifunction die 简易模low-cost die 橡胶冲模rubber die 钢带模steel strip die 低熔点合金模low-melting-point al 薄板模laminate die 夹板模template die 校平模planishing die 齿形校平模roughed.. 硬质合金模carbide die 上模upper die 下模lower die 模架die set 通用模架universal die set 快换模架quick change die set 后侧导柱模架back-pillar die set 对角导柱模架diagonal-pillar die set 精冲模架fine blanking die set 滑动导向模架sliding guide die set 滚动导向模架ball-bearing die set 工作零件working component 凸模punch 定距侧刃pitch punch 凸凹模main punch 镶件insert 拼块section 软模soft die 定位零件locating component 定位销locating pin 定位板locating plate 挡料销stop pin 始用挡料销finger stop pin 导正销pilot pin 抬料销Lifter pin 导料板stock guide rail 侧刃挡块stop block for pitch punch 止退键stop key 侧压板Side-push plate . 限位块limit block 限位柱limit post 压料clamping 卸料stripping 送料feeding 卸料版stripper plate 固定卸料板fixed stripper plate 弹性卸料板spring stripper plate 推件块ejector block 顶件块kicker block 顶杆kicker pin 推板ejector plate 推杆ejector pin 连接推杆ejector tie rod 打料杆knock-out pin 卸料螺钉stripper bolt 拉杆tie rod 托杆cushion pin 托板support pin 废料切刀scrap cutter 顶料器cushion 承料板stock-supporting plate 压料板pressure plate 压边圈blank holder 齿圈压板vee-ring plate 推件板slide feed plate 自动送料装置automatic feeder 导向零件guide component 导柱guide pillar 导套guide bush 滚柱导柱ball-bearing.. 滚柱导套ball-bearing.. 钢球保持圈cage 制动件retainer 导板guide plate 滑块slide block 耐磨板wear plate 凸模保护套punch-protecting Bushing 固定零件retaining component 上模座punch holder 下模座die holder 凸模固定板punch plate 预应力圈shrinking ring 垫板bolster plate 模柄die shank 浮动模柄self-centering shank 斜楔cam driver 模具间隙clearance 模具闭合高度die shut height 最大闭合高度maximum shut heigt 闭合高度调节量adjustable distance 冲模寿命die life 压力中心load center 冲模中心die center 冲压方向pressing direction 送料方向feed direction 排样blank layout 搭边web 步距feed pitch 切边余量trimming allowance 毛刺burr 塌角die roll 光亮带smooth cut zone 冲裁力blanking force 弯曲力bending force 拉深力drawing force 卸料力stripping force 推件力ejecting force 顶件力kicking force .

各式模具分类用语中英文对照

Landed plunger mold有肩柱塞式模具Burnishing die 挤光模 Landed positive mold 有肩全压式模具Button die镶入式圆形凹模 Loading shoe mold料套式模具Center-gated mold中心浇口式模具Loose detail mold 活零件模具 Chill mold 冷硬铸模 Loose mold 活动式模具 Cold hobbing冷挤压制模 Louvering die百叶窗冲切模Composite dies 复合模具 Manifold die分歧管模具 Counter punch反凸模 Modular mold 组合式模具 Double stack mold 双层模具 Multi-cavity mold多模穴模具Electroformed mold电铸成形模 Multi-gate mold复式浇口模具Expander die 扩径模 Offswt bending die双折冷弯模具Extrusion die 挤出模 Palletizing die 叠层模 Family mold反套制品模具 Plaster mold 石膏模 Blank through dies漏件式落料模Porous mold 通气性模具Duplicated cavity plate复板模Positive mold全压式模具 Fantail die扇尾形模具 Pressure die压紧模 Fishtail die鱼尾形模具 Profile die轮廓模 Flash mold 溢料式模具Progressive die顺序模 Gypsum mold 石膏铸模 Protable mold 手提式磨具 Hot-runner mold热流道模具Prototype mold 雏形试验模具 Ingot mold钢锭模 Punching die 落料模 Lancing die 切口模 Raising (embossing) 压花起伏成形Re-entrant mold 倒角式模具

大底模具技术术语中英文对照

LN3--PU/Phylon/Rubber Process Contents for these three sections of English Version PFC: ?Phylon Work Sheet PH数据表 ?Components Specification Sheet(Phylon) 部件明细单(Phylon)?Component Specification Sheet Set Up(Phylon) (此部分无中文) ?Phylon Midsole Specifications PH全插规格 ?Phylon Preform Specifications PH粗胚规格 ?Preform Drawing 粗胚图 ?Component Specification Sheet Set Up(PU) (此部分无中文) ?PU Midsole Specifications PU全插规格 ?PU Midsole Specifications II PU数据表 ?Components Specification Sheet(PU) 部件明细单(PU) ?PU Midsole Pouring Specification PU灌注明细 ?Outsole Color Schedule 本底颜色明细 ?Outsole Preform Specifications 本底粗胚规格 ?Outsole Pressing Process 本底压制流程 ?Outsole Degreasing Process 本底水洗流程 ********************************************************************* ΦPU Section ΦPU部分 ********************************************************************* air bag schedule 空气袋分段 specific instructions 特别说明 air bag diagram 空气袋图示 hardness(skin on) 硬度(带皮) density 密度 elongation 延伸率 tear 撕力 tensile 拉力 split tear 撕裂 painting 喷漆 MCS number 材料编号 mold release agent 脱模剂 polyurethane 聚安脂 polyester 聚脂 Density must be within NIKE spec and follow weight chart 密度必须符合NIKE要求及重量表 No dirty midsole sidewalls yellowing or poor cosmetics due to mold condition. 无因模具造成的边墙黄变及外观不良。 Correct molded or painted colors per NIKE confirmation. 根据NIKE的确认,成型材料及喷漆颜色正确。 Correct top/bottom edge trimming within 1mm width allowance. 正确修边上部及底部边缘,允许1mm余量。 No larger than 5mm diameter internal air voids.(checked by light table)

模具术语翻译

模具名词中英文对照表序号中文名英文名 1一、水口gate 2进水位gate location 3水口形式gate type 4大水口edge gate 5细水口pin-point gate 6水口大小gate size 7转水口switching gate 8唧嘴口径sprue diameter 9二、流道runner 10热流道hot runner 11冷流道cold runner 12唧嘴直流direct sprue gate 13圆形流道round runner 14模流分析mold flow analysis 15流道平衡runner balance 16热嘴hot sprue 17热流道板hot manifold 18发热管cartridge heater 19探针thermocouples 20插头connector plug 21插座connector socket 22密封/封料seal 23三、运水water line 24喉塞line pug 25喉管tube 26塑胶管plastic tube 27快速接头jiffy quick connector plug 28四、模具零件mold components 29三板模three-plate mold 模具名词中英文对照表 序号中文名英文名 30二板模two-plate mold 31边钉/ 导边leader pin /guide pin

32边司/ 导套bush in g/guide bush ing 33顶针板ejector retainer plate 34托板support plate 35螺丝screw 36管钉dowel pin 37开模槽ply bar score 38内模管位core/cavity inter-lock 39顶针ejector pin 40司筒ejector sleeve 41司筒针ejector pin 42推板stripper plate 43缩呵movable core 44扣机(尼龙拉勾)n yl on latch lock 45斜顶lifter 46模胚(架)mold base 47母模cavity in sert 48公模core insert 49行位(滑块)slide 50 镶件in sert 51压座/斜鸡wedge 52耐磨板/ 油板wedge wear plate 53压条plate 54撑头support pillar 55唧嘴sprue bushing 56挡板stop plate 57定位圈locating ring 58锁扣latch 模具名词中英文对照表 序号中文名英文名 59扣鸡parti ng lock set 60推杆push bar 61栓打螺丝S.H.S.B 62顶板ejector plate 63活动臂lever arm

模具DFM常用中英文对照

DFM常用中英文对照 15、如果分型面此处,模具上会有尖角和刀口,对模具寿命有影响。 There are sharp edges if we set the parting line here, it will reduce the tool life. 16、此处料厚段差很大,成品表面会有应力痕,建议修改如图示。 The thickness is not equal and it will bring the stress lines on the surface, suggest to improve the part as the picture shown. 17、此大行位上有小行位,开模时小行位需先退,大行位做延时,合模时则相反。 The small slider is inside the big slider, when the mold open, the small slider need to recede first and the big slider have to postpone. When the mold close, it is contrary. 18、此处需做强顶。 This position need to force ejection. 19、由于此处没有足够空间下热咀,所以需做一个柱子进胶。 This position need to make a pole for gating because there have no enough space for hot sprue. 20、沾模, Stick 1.High shrinkage values could indicate sink marks or voids at gate location 高缩水率的产品容易产生缩印,但 在浇口附近可以避免。 2.Welding line on the cosmetic surface 熔接线在外表面 3.Two banana gate was to being confluent in the end of melt flow. 两个香蕉浇口在流动未端熔合。 4.Venting insert here has flash 排气镶件处有飞边 5.Venting gap between inserts is too big 镶件处的排气槽过大 6.Stress mark on the cosmetic surface 产品外表面上有压痕 7.Uneven thickness 不平均的产品壁厚 8.Unreasonable product structure 不合理的产品结构 9.Injection speed is high 注塑压力过高 10.There is black spot on the cosmetic surface 产品外表面上有黑色点 11.There is flash on the product 产品有飞边 12.there is sink mark on the cosmetic surface 产品外表面上有缩痕 13.Gate size is not reasonably 浇口尺寸不合理 14.There is argent spot 这里有亮点(银色斑点) 15.The plastic of first shot didn't meet high temperature. 塑料的第一胶不会有很高的温度。 16.Make sure the core float plate was closed before lifter completely return to correct position 确认 lifter完全回位时core侧浮动板已经复位 17.Make sure the ejector system is smooth 确认顶针系统移动平稳 18.Add early return structure to protect lifter return to correct position 增加先复位机构保护lifter回到正确 位置。 19.Propose to add draft on slider side wall and draw polish. 建议增加 slider的角度和抛光角度。 20.It is too thin and very difficult to inject fully, and weakness wall will have risk of the part function 该 处壁厚过薄而造成很难去填充完整,薄壁将会有产品功能上的风险。 21.These are will have sink marks due to uneven thickness, propose to reduce plastic. 壁厚不均匀容易产生缩印, 建议在该处减胶。 22.These are will have sink marks due to ribs opposite. 正面的筋位易导致背面产生缩印。 23.Please confirm the 3D part thickness whether has including painting thickness or not? 请确认产品的设计是否

模具术语翻译

模具名词中英文对照表 序号中文名英文名 1 一、水口gate 2 进水位gate location 3 水口形式gate type 4 大水口edge gate 5 细水口pin-point gate 6 水口大小gate size 7 转水口switching gate 8 唧嘴口径sprue diameter 9 二、流道runner 10 热流道hot runner 11 冷流道cold runner 12 唧嘴直流direct sprue gate 13 圆形流道round runner 14 模流分析mold flow analysis 15 流道平衡runner balance 16 热嘴hot sprue 17 热流道板hot manifold 18 发热管cartridge heater 19 探针thermocouples 20 插头connector plug 21 插座connector socket 22 密封/封料seal 23 三、运水water line 24 喉塞line pug 25 喉管tube 26 塑胶管plastic tube 27 快速接头jiffy quick connector plug 28 四、模具零件mold components 29 三板模three-plate mold

模具名词中英文对照表 序号中文名英文名 30 二板模two-plate mold 31 边钉/导边leader pin/guide pin 32 边司/导套bushing/guide bushing 33 顶针板ejector retainer plate 34 托板support plate 35 螺丝screw 36 管钉dowel pin 37 开模槽ply bar score 38 内模管位core/cavity inter-lock 39 顶针ejector pin 40 司筒ejector sleeve 41 司筒针ejector pin 42 推板stripper plate 43 缩呵movable core 44 扣机(尼龙拉勾)nylon latch lock 45 斜顶lifter 46 模胚(架)mold base 47 母模cavity insert 48 公模core insert 49 行位(滑块)slide 50 镶件insert 51 压座/斜鸡wedge 52 耐磨板/油板wedge wear plate 53 压条plate 54 撑头support pillar 55 唧嘴sprue bushing 56 挡板stop plate 57 定位圈locating ring 58 锁扣latch 模具名词中英文对照表 序号中文名英文名