加工中心精度检验规范

MCV F01 S001Q301000003 940331-7

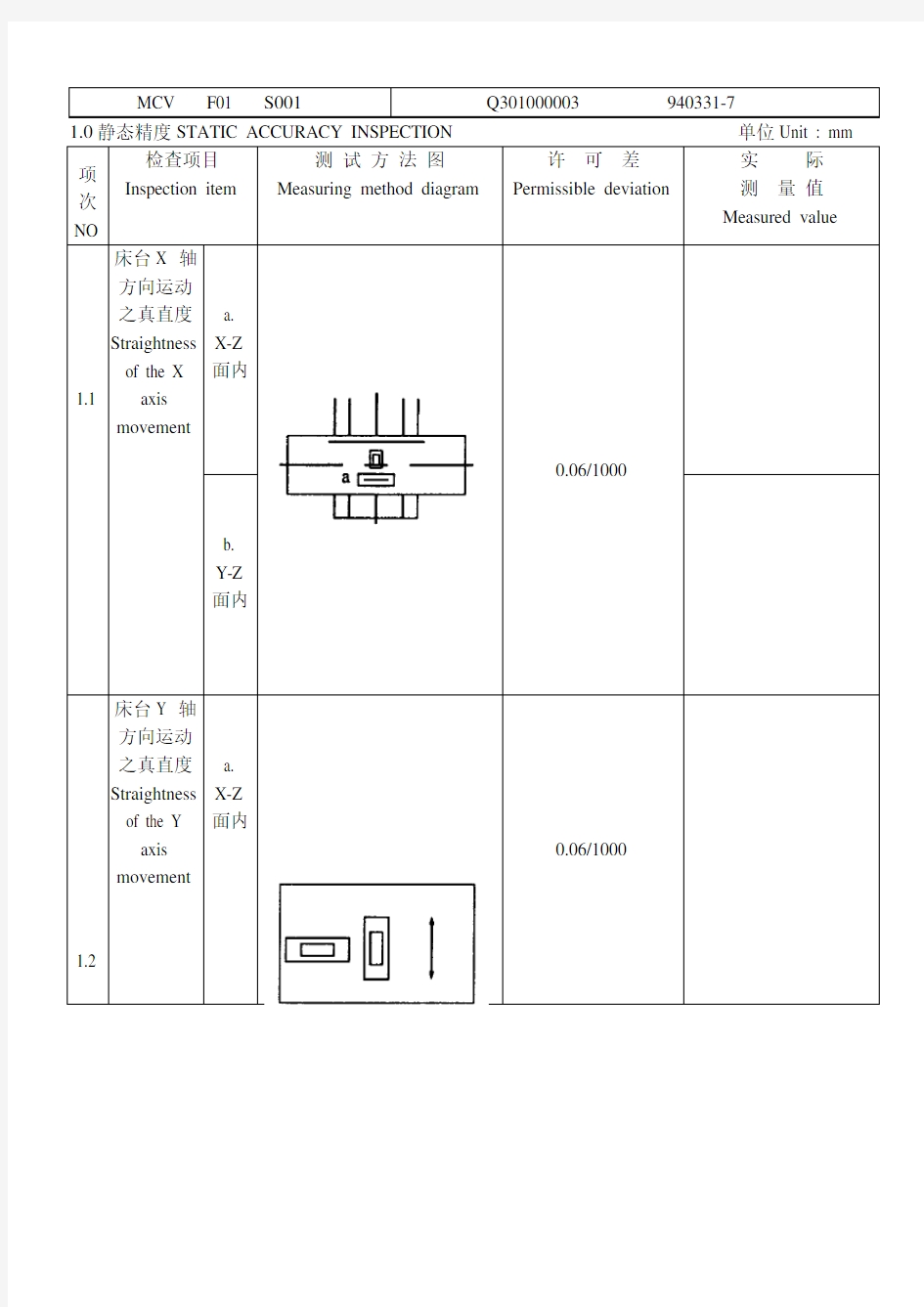

1.0静态精度STATIC ACCURACY INSPECTION 单位Unit : mm

项次NO

检查项目

Inspection item

测试方法图

Measuring method diagram

许可差

Permissible deviation

实际

测量值

Measured value

1.1 床台X 轴

方向运动

之真直度

Straightness

of the X

axis

movement

a.

X-Z

面内

0.06/1000

b.

Y-Z

面内

1.2 床台Y 轴

方向运动

之真直度

Straightness

of the Y

axis

movement

a.

X-Z

面内

0.06/1000

b.

Y-Z

面内

1-1

项次NO

检查项目

Inspection item

测试方法图

Measuring method diagram

许可差

Permissible deviation

实际

测量值

Measured value

1.3 床台X轴方向之

运动与其上面之

平行度

Parallelism

between

movement in X

axis direction and

table upper surface

X≦500 0.02

500<X≦800 0.025

800<X≦1250 0.03

1250<X≦2000 0.04

1.4 床台Y轴方向之

运动与其上面之

平行度

Parallelism

between

movement in Y

axis direction and

table upper surface

Y≦500 0.02

500<Y≦800 0.025

800<Y≦1250 0.03

1250<Y≦2000 0.04

1.5 X轴方向运动与

床台基准沟侧面

之平行度

Parallelism

between

movement in X

axis direction and

Side surface of

table reference slot

每300mm的量测距离下

许可差为0.015mm

0.015for a measuring

length of 300

1-2

单位Unit : mm

项次NO

检查项目

Inspection item

测试方法图

Measuring method diagram

许可差

Permissible

deviation

实际

测量值

Measured value

1.6

各轴方向

相互运动

之直角度

Perpendicu

larity

Between

movement

in X axis

direction

and Y axis

direction

and Z axis

direction

a.

X-Y

轴

Place

0.012/300

b.

X-Z

轴

Place

0.012/300

c.

Y-Z

轴

Place

0.012/300

1.7 主轴中心线与床

台面之直角度

Perpendicularity

between centerline

of main spindle

and table surface.

旋径每300

Per300

0.015

1-3

单位Unit : mm

项次NO

检查项目

Inspection item

测试方法图

Measuring method diagram

许可差

Permissible deviation

实际

测量值

Measured value

1.8 主轴孔内面之偏

摆

Run out of spindle

taper hole

固定端

At spindle side end of test

bar

0.005

固定端300处

At 300 position

0.015

1.9 主轴轴线与Z轴

轴线运动间的平

行度

Parallelism

between the

spindle axis and

the Z-axis motion

a:0.015/300

b:0.015/300

1.10 主轴在Z轴方向

之移(松)

动量

Movement of main

spindle in Z axis

direction

0.005

1.11 主轴端面之偏摆

Run out of main

spindle outer

surface

0.01

1.12 主軸外面之偏擺

Run out of main

spindle outer

surface

0.01mm

1-4

1.13 床檯X軸方向運

動之直線度

Straightness of

table movement in

the X axis.

1.Apply a fixed indicator to the straight

0.01/300

edge as the figure shown.

2.Adjust to get reading at both ends of the

straight edge.

2.Move the table 300 mm in X-axis

direction.

3.Record the largest value difference as the

measurement value.

1.14 床檯Y軸方向運

動之直線度

Straightness of

table movement in

the Y axis

1.Apply a fixed indicator to the straight

edge as the figure shown.

0.01/300

2.Adjust to get reading at both ends of the

straight edge.

2.Move the table 300 mm in X-axis

direction.

3.Record the largest value difference as the

measurement value.

1.15 旋轉檯旋轉偏擺

Table runout(XY)

0.015mm/300

1-5

1.16 旋轉檯旋轉偏擺

Table runout(Z)

0.005mm

1.17 車刀角度換刀後

重複定位精度

Repeatability of

0.001mm

tool angle after

tool change.

1.18 車刀角度停止後

重複定位精度

Repeatability of

0.001mm

tool angle after

tool stop.

1.20 車刀加工後定位

精度

Repeatability of

0.001mm

tool angle after

machining part

1.21 主軸振動檢測

Spindle vibration

detection ≦0.6mm/s

(Ref)

2.0定位精度检查Positioning accuracy inspection 单位Unit : mm

项次NO

检查项目

Inspection item

测试方法图

Measuring method diagram

许可差

Permissible deviation

实际

测量值

Measured value

2.1 直线运动之

定位精度

ISO230-2

循环次数:

2次

Positioning

accuracy of

straight line

movement

By

ISO230-2

Cycle times

: Two times

X

L≦1000

0.01

1000<L≦2000

0.015

L≧2000

0.02

Y

Z

2.2

回转运动

之定位精

度

Positioning

accuracy

of straight

line

movement

By

ISO230-2

Cycle

times

: Two

times

C

15〞

1-7