硬盘知识-硬盘简介-hddharddiskdriveintroduction

HARD DISK DRIVE INTRODUCTION

硬盘大致分为,磁盘Media,读写头Read Write Head,马达Spindle Motor & V oice Coil Motor,底座Base,电路板PCBA等几大项,组合而成。

The Hard Disk Drive is made up of Media, Read Write Head, Spindle Motor, Voice Coil Motor, Base and PCBA.

Media的基板是金属或玻璃材质制成,为达到高密度高稳定的质量,基板要求表面光滑平整,不可有任何暇疵,然后再将磁粉Coating 溅渡到基板表面上,最后再涂上保护润滑层。此处有2项高科技,一为,如何制造出不含杂质极细微的磁粉二为,如何将磁粉均匀的Coating上去。

The Substrate of Media is made of metal or glass. To achieve the quality of high density and stability, the surface has to be very smooth without any defects. The magnetic coating is then layered on the substrate and after that the lubricant is covered on top. Two high-technologies procedure take place here: 1. To produce tiny particles of coating without impurities. 2. To coat the magnetic coating evenly.

以3.5"Media计算,其内径为25mm,需扣掉最外及最内圈不保存Data的部分,

实际只剩20mm,如换算成60GB Media以Bit为单位(1个Bit记录0或1,8Bit

只可记录一个A,B,C…事实上不是以Bit为单位,在此为求简单易懂,固以

Bit形容)

Using a 3.5" Media to calculate, the inner diameter is 25mm. The actual

diameter becomes 20mm with the deduction of outer and inner circle that does not store data. If a 60GB Media is being converted into Bit as unit (A 0 or 1 accounts for 1 Bit, 1 character, such as A, B, C?Ketc., accounts for 8 Bit. Bit is not the actual unit, but for the ease of comprehension, Bit is used.)

Media每面粗计密度为32,901,120,000 Bit,可见其密度相当高,所以Media不可有任

何污染,全程制造均需在Class 100高洁净度的Clean Room内,这也是硬盘机要求需在

Clean Room才能拆解的原因。

The density of each side of the Media is roughly 32,901,120,000 Bit, which is a very high density. So the Media can not be polluted anyhow. The whole manufacturing process of the Hard Disk must be in

a Class 100 highly purified Clean Room. This is also why the Hard Disk needs to be opened only in the Clean Room.

Media出厂时,是完全空白无任何讯号存在,需交由各硬盘厂组装时自行编码。

When the Media leaves the factory, it is blank and without any signals. It is encoded when the manufacturers of the Hard Disk is putting the Hard Disks together.

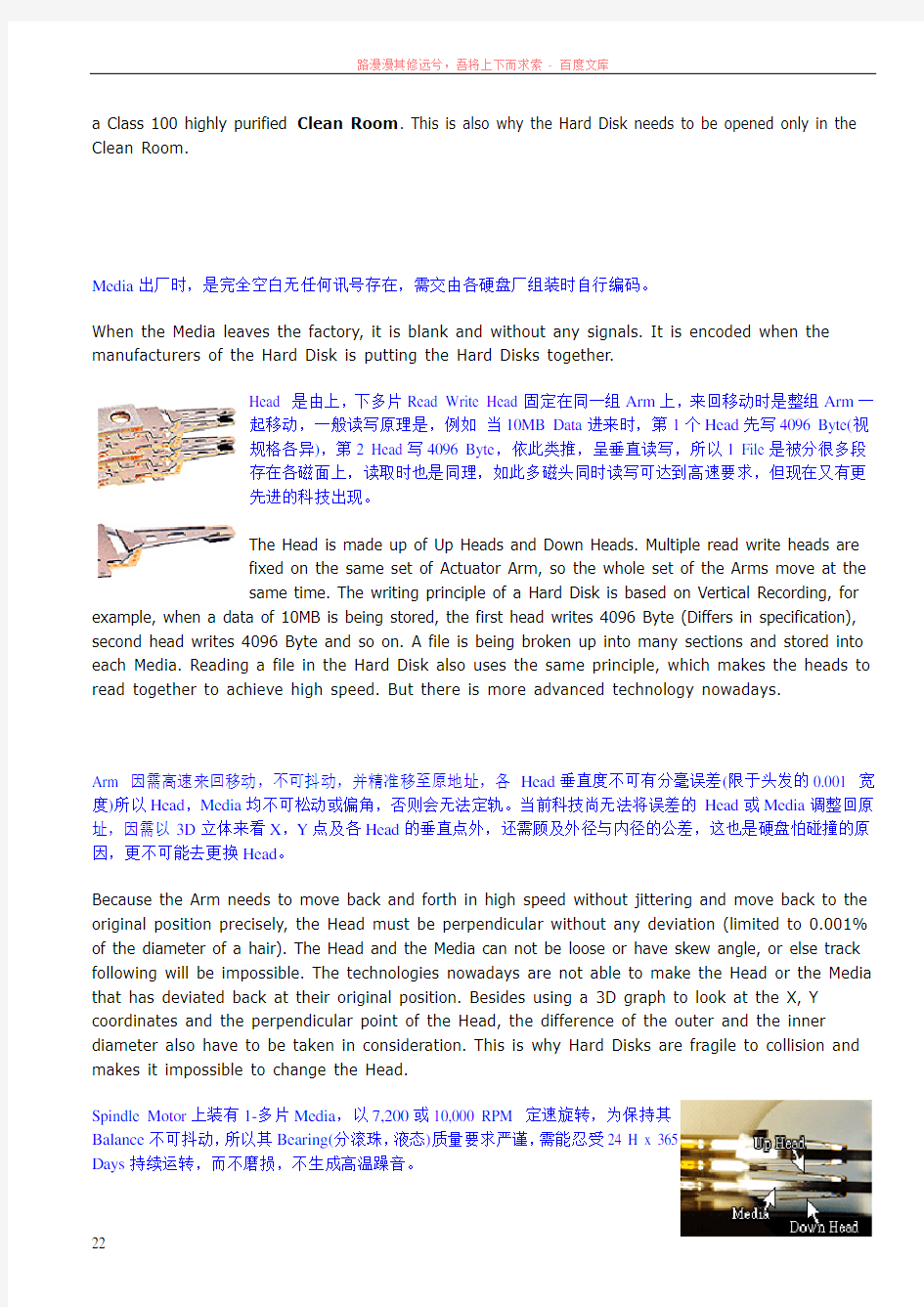

Head 是由上,下多片Read Write Head固定在同一组Arm上,来回移动时是整组Arm一

起移动,一般读写原理是,例如当10MB Data进来时,第1个Head先写4096 Byte(视

规格各异),第2 Head写4096 Byte,依此类推,呈垂直读写,所以1 File是被分很多段

存在各磁面上,读取时也是同理,如此多磁头同时读写可达到高速要求,但现在又有更

先进的科技出现。

The Head is made up of Up Heads and Down Heads. Multiple read write heads are

fixed on the same set of Actuator Arm, so the whole set of the Arms move at the

same time. The writing principle of a Hard Disk is based on Vertical Recording, for example, when a data of 10MB is being stored, the first head writes 4096 Byte (Differs in specification), second head writes 4096 Byte and so on. A file is being broken up into many sections and stored into each Media. Reading a file in the Hard Disk also uses the same principle, which makes the heads to read together to achieve high speed. But there is more advanced technology nowadays.

Arm 因需高速来回移动,不可抖动,并精准移至原地址,各Head垂直度不可有分毫误差(限于头发的0.001 宽度)所以Head,Media均不可松动或偏角,否则会无法定轨。当前科技尚无法将误差的Head或Media调整回原址,因需以3D立体来看X,Y点及各Head的垂直点外,还需顾及外径与内径的公差,这也是硬盘怕碰撞的原因,更不可能去更换Head。

Because the Arm needs to move back and forth in high speed without jittering and move back to the original position precisely, the Head must be perpendicular without any deviation (limited to 0.001% of the diameter of a hair). The Head and the Media can not be loose or have skew angle, or else track following will be impossible. The technologies nowadays are not able to make the Head or the Media that has deviated back at their original position. Besides using a 3D graph to look at the X, Y coordinates and the perpendicular point of the Head, the difference of the outer and the inner diameter also have to be taken in consideration. This is why Hard Disks are fragile to collision and makes it impossible to change the Head.

Spindle Motor上装有1-多片Media,以7,200或10,000 RPM 定速旋转,为保持其

Balance不可抖动,所以其Bearing(分滚珠,液态)质量要求严谨,需能忍受24 H x 365

Days持续运转,而不磨损,不生成高温躁音。

The Spindle Motor spins at as speed of 7,200 or 10,000 RPM (Revolution per minute) and has one to multiple Medias attached to it. To keep its balance without jittering, the qualities required for its bearings (ball or hydraulic) are strict and has to sustain 24H x 365 Days of operation continuously without wearing-out and making any bearing noise.

硬盘组装时,是依序将Spindle Motor,Media,V oice Coil Motor,Head装上固定后,

先测试各Head在其所处Media的Fly Height值,是否合格约为0.5 u in。

The Hard Disk is being assembled in the following order: Spindle Motor,

Media, Voice Coil Motor, and Head. With the parts being secured, the Fly

Height value of the Head with its Media is checked to see if it qualifies. (About

0.5 uin)。

因为Head是利用气流漂浮在Media上,不接触的原理,才可在各轨间高速来回移动,但太高读取讯号太弱,太低会磨损到Media表面,所以Media表面上须相当光滑平整,任何异物,尘埃均会造成Head打伤磁面而造成Data永久性伤害。所以硬盘的装配修复全程需在Class 100高洁净度的Clean Room 内进行。此项安装作业需用激光仪器完成无法使用人工。

The Head is using the principle of current to float on the Media without touching it to move at high speed back and forth between each track. If the Head is floating too high, the signal will be too weak. If the Head is floating too low, the surface of the Media will be scratched. The Media's surface must be very smooth, any particles or dust will cause the Head to damage the magnetic surface and cause permanent Data loss. So the Hard Disk's assembly and repair has to take place in a high-purified Clean Room. The Laser equipment is needed to assemble the Hard Disk and can not be done manually.

各大组件装毕后,此时Media因尚无任何Sector存在,硬盘还无法使用,需经各厂依其

规格用专用的Servo Writer,透过其Head在Media进行一圈一圈的Embedded Servo的编

码动作。若以60GB Media规格计每面其Sectors总数约为64,260,000 Sectors但因Media

是圆形,内径较小所以所编出的Sector数量会比外径少,这是所谓的Zone Bit Recording

编码法,这也是最困难的技术。

The Media has no Sectors after all the parts are assembled, so the Hard Disk is still unusable. The Hard Disk needs to be encoded through each manufacturer's Servo Writer with its own specifications. The Head of the Servo Writer does the Embedded Servo encoding action on the Media of the Hard Disk in a circular motion. Using a 60GB Media to estimate, each side of the Media has about 64,260,000 Sectors. Because the Media is a circle, the inner diameter is smaller, so the numbers of Sector will be lesser than the outer diameter. This is called Zone Bit Recording and it is the hardest technique.

Embedded Servo完成后,此时硬盘已可使用,接上计算机Power On后,Head已可正常定轨,BIOS已可Detect 其规格,出现Cylinder,Head,Sector等值。最后BIOS会将Controller交由操作系统,只需Create New Partition,Format,就可正式保存Data。

After Embedded Servo is completed, the Hard Disk is usable. When attached to a computer and Power On, the Head is able to stay on track normally. The BIOS can detect its specification and the values of Cylinder, Head and Sector are detected as well. Finally, the BIOS will send the Controller over to the operating system. The only steps need to be taken to start storing Data are to Create New Partition and Format.

以上基本原理介绍,读者应可得知几项问题需注意

1. Media不可污染,所以需在高洁净度的Clean Room拆解。

2. Head ,Media是唇齿相依,当初固定后,即用Servo Writer将各面Media作垂直性的Embedded Servo,就不

容许再有误差,只要稍有碰撞Head就无法定轨,所以更不可能将Head或Media拆下或装至另一同型硬盘。

3. Media是磁性媒介,就像录音带,只容许一种极性存在,所以只要Head有电流生成,是会去改变其原值,所

以一台受损的硬盘只要稍有不慎,是很容易再被写入,而破坏原Data。

There are some details for the readers to pay attention from the basic introduction of the Hard Disk:

1.Disk must be opened only in a Class 100 high-purified Clean Room.

2.The Head and the Media are part of each other. When they were assembled, the Servo Writer

did a perpendicular Embedded Servo on each side of the Media. No deviation is permitted.

If there is collision in the Head, the track will not be able to reposition anymore. It is also

impossible to take or put the Head or the Media into another Hard Disk of the same model.

3.The Media is a magnetic medium. Similar to the cassette tape, only one polarity is allowed.

Therefore, if there is electric current in the Head, the original value will be changed. If being careless, a damaged Hard Disk has a great chance of its Data being over write and destroys the original Data.