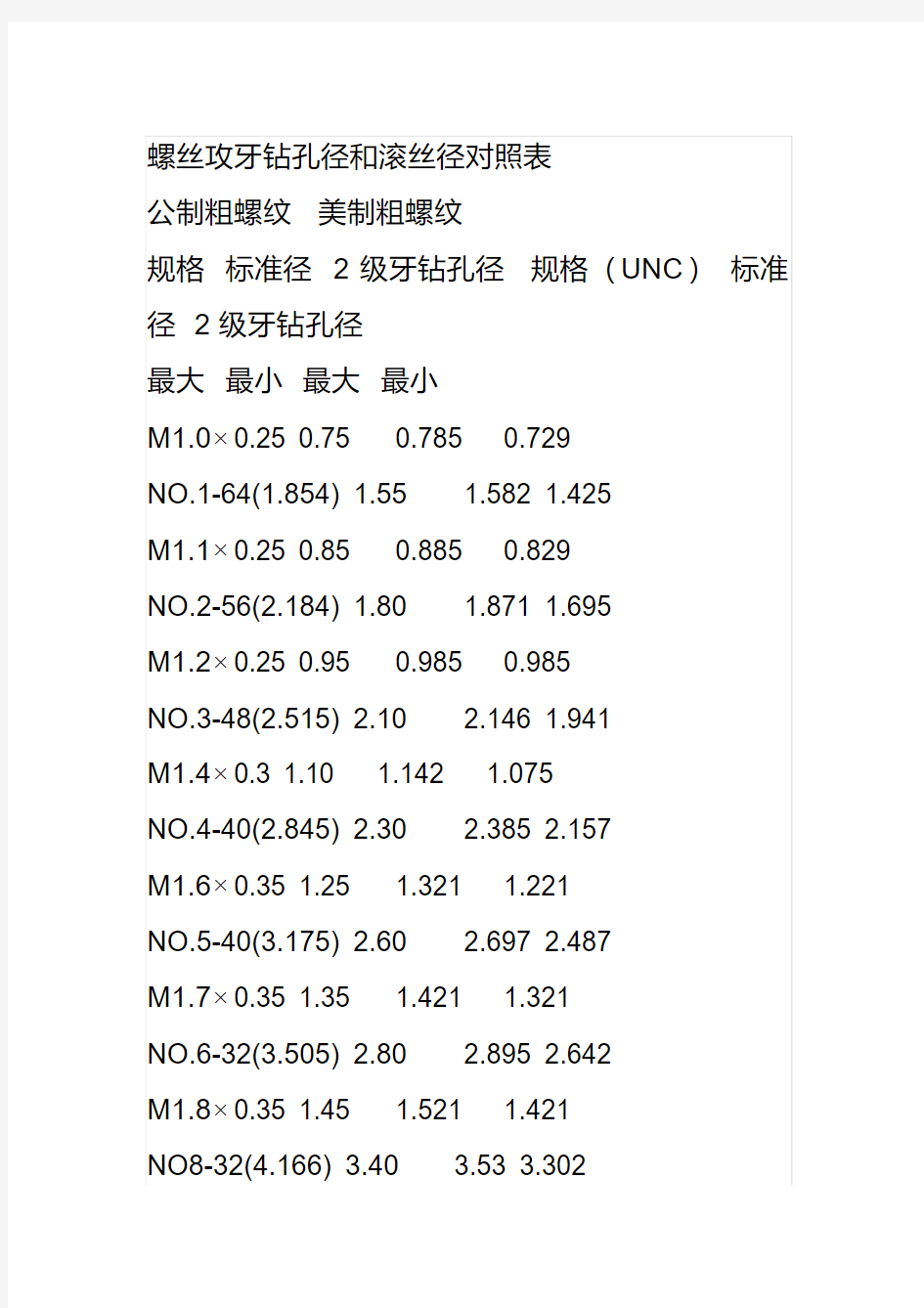

螺丝攻牙钻孔径和滚丝径对照表

螺丝攻牙钻孔径和滚丝径对照表

螺丝攻牙钻孔径和滚丝径对照表

公制粗螺纹美制粗螺纹

规格标准径2级牙钻孔径规格(UNC)标准径2级牙钻孔径

最大最小最大最小

M1.0×0.25 0.75 0.785 0.729

NO.1-64(1.854) 1.55 1.582 1.425

M1.1×0.25 0.85 0.885 0.829

NO.2-56(2.184) 1.80 1.871 1.695

M1.2×0.25 0.95 0.985 0.985

NO.3-48(2.515) 2.10 2.146 1.941

M1.4×0.3 1.10 1.142 1.075

NO.4-40(2.845) 2.30 2.385 2.157

M1.6×0.35 1.25 1.321 1.221

NO.5-40(3.175) 2.60 2.697 2.487

M1.7×0.35 1.35 1.421 1.321

NO.6-32(3.505) 2.80 2.895 2.642

M1.8×0.35 1.45 1.521 1.421

NO8-32(4.166) 3.40 3.53 3.302

M2.0×0.4 1.60 1.679 1.567

NO.10-24(4.826) 3.90 3.962 3.683

M2.2×0.45 1.75 1.838 1.713

NO.12-24(5.486) 4.50 4.597 4.344

M2.3×0.4 1.90 1.979 1.867 1/4-20 5.10 5.257 4.979

M2.5×0.45 2.10 2.138 2.013 5/16-18 6.60 6.731 6.401

M2.6×0.45 2.20 2.238 2.113 3/8-16 8.00 8.153 7.798

M3.0×0.5 2.50 2.599 2.459 7/16-14 9.40 9.55 9.144

M3.0×0.6 2.40 2.440 2.280 1/2-13 10.80 11.023 10.592

M3.5×0.6 2.90 3.010 2.850 9/16-12 12.20 12.446 11.989

M4.0×0.7 3.30 3.422 3.242 5/8-11 13.60 12.868 13.386

M4.0×0.75 3.25 3.326 3.106 3/4-10 16.50 18.840 16.307

M4.5×0.75 3.80 3.878 3.688 7/8-9 19.50 19.761 19.177

M5.0×0.8 4.20 4.334 4.134 1 22.20

22.606 21.971

M5.0×0.9 4.10 4.170 3.930 1-1/8-7 25.00 25.349 24.638

M6.0×1.0 5.00 5.153 4.917 1-1/4-7 28.20 28.524 27.813

M7.0×1.0 6.00 6.153 5.917 1-3/8-6 30.80 31.115 30.353

M8.0×1.25 6.80 6.912 6.647 1-1/2-6 34.00 34.290 33.528

M9.0×1.25 7.80 7.912 7.647 1-3/4-5 39.50 39.827 38.964

M10×1.5 8.50 8.676 8.376 2-4-1/2 45.20 45.593 44.679

M11×1.5 9.50 9.676 9.376

M12×1.75 10.30 10.441 10.106

M14×2.0 12.00 12.210 11.835

M16×2.0 14.00 14.210 13.835

M18×2.5 15.50 15.744 15.294

M20×2.5 17.50 17.744 17.294

M22×2.5 19.50 19.744 19.294

M24×3.0 21.00 21.252 20.752

M27×3.0 24.00 24.252 23.752

M30×3.5 26.50 26.771 26.211

螺丝攻牙钻孔径和滚丝径对照表

公制细螺纹美制细螺纹

规格标准径2级牙钻孔径规格(UNC)标准径2级牙钻孔径

最大最小最大最小

M1.0×0.2 0.80 0.821 0.783 NO.0-80(1.524) 1.25 1.305 1.182

M1.1×0.2 0.90 0.921 0.883 NO.1-72(1.854) 1.55 1.612 1.474

M1.2×0.2 1.00 1.021 0.983 NO.2-64(2.184) 1.85 1.912 1.756

M1.4×0.2 1.20 1.221 1.183 NO.3-56(2.515) 2.10 2.197 2.025

M1.6×0.2 1.40 1.421 1.383 NO.4-48(2.845) 2.40 2.458 2.271

M1.7×0.2 1.45 1.500 1.460

NO.5-44(3.175) 2.70 2.740 2.551

M1.8×0.2 1.60 1.621 1.583

NO.6-40(3.505) 2.90 3.022 2.820

M2.0×0.25 1.75 1.785 1.729

NO.8-36(4.166) 3.50 3.606 3.404

M2.2×0.25 1.95 1.985 1.929

NO.10-32(4.826) 4.10 4.165 3.963

M2.3×0.25 2.05 2.061 2.001

NO.12-28(5.846) 4.60 4.724 4.496

M2.5×0.35 2.20 2.221 2.121 1/4-28 5.50 5.588 5.360

M2.6×0.35 2.20 2.246 2.186 5/16-24 6.90 7.035 6.782

M3.0×0.35 2.70 2.721 2.621 3/8-24 8.50 8.636 8.382

M3.5×0.35 3.20 3.221 3.121 7/16-20 9.90 10.033 9.729

M4.0×0.5 3.50 3.599 3.459 1/2-20 11.50 11.607 11.329

M4.5×0.5 4.00 4.099 3.959 9/16-18 12.90 13.081 12.751

M5.0×0.5 4.50 4.599 4.459 5/8-18 14.50 14.681 14.351

M5.5×0.5 5.00 5.099 4.959 3/4-16 17.50 17.678 17.323

M6.0×0.75 5.30 5.378 5.188 7/8-14 20.50 20.675 20.270

M6.0×0.5 5.50 5.550 5.400 1-12 23.20 23.571 23.114

M7.0×0.75 6.30 6.378 6.188 1-1/8-12 26.50 26.746 26.289

M7.0×0.5 6.50 6.550 6.400 1-1/4-12 29.50 29.921 29.464

M8.0×1.0 7.00 7.153 6.917 1-3/8-12 32.80 33.096 32.639

M8.0×0.75 7.30 7.378 7.188 1-1/2-12 36.00 36.271 35.814

M8.0×0.5 7.50 7.520 7.400

M9.0×1.0 8.00 8.153 7.917

M9.0×0.75 8.30 8.378 8.188

M10×1.25 8.80 8.912 8.647

M10×1.0 9.00 9.153 8.917

M10×0.75 9.30 9.378 9.188

M10×0.5 9.50 9.520 9.400

M11×1.0 10.00 10.153 9.917

M11×0.75 10.30 10.378 10.188

M12×1.5 10.50 10.676 10.376

M12×1.25 10.80 10.912 10.647

M12×1.0 11.00 11.153 10.917 M12×0.5 11.50 11.520 11.400 M14×1.5 12.50 12.676 12.376 M14×1.0 13.00 13.153 12.917 M15×1.5 13.50 13.676 13.376 M15×1.0 14.00 14.153 13.917 M16×1.5 14.50 14.676 14.376 M16×1.0 15.00 15.153 14.917 M17×1.5 15.50 15.676 15.376 M17×1.0 16.00 16.153 15.917 M18×2.0 16.00 16.210 15.835 M18×1.5 16.50 16.676 16.376 M18×1.0 17.00 17.153 16.917 M20×2.0 18.00 18.210 17.835 M20×1.5 18.50 18.676 18.376 M20×1.0 19.00 19.153 18.917 M22×2.0 20.00 20.210 19.835 M22×1.5 20.50 20.676 20.376 M22×1.0 21.00 21.153 20.917

M24×2.0 22.00 22.210 21.835 M24×1.5 22.50 22.676 22.376 M24×1.0 23.00 23.153 22.917 M25×2.0 23.00 23.210 22.835 M25×1.5 23.50 23.676 23.376 M25×1.0 24.00 24.153 23.917 M26×1.5 24.50 24.676 24.376 M27×2.0 25.00 25.210 24.835 M27×1.5 25.50 25.676 25.376 M27×1.0 26.00 26.153 25.917 M28×2.0 26.00 26.210 25.835 M28×1.5 26.50 26.676 26.376 M28×1.0 27.00 27.153 26.917 M30×3.0 27.00 27.252 26.752 M30×2.0 28.00 28.210 27.835 M30×1.5 28.50 28.676 28.376 M30×1.0 29.00 29.153 28.917 M32×2.0 30.00 30.210 29.835 M32×1.5 30.50 30.676 30.376

M33×3.0 30.00 30.252 29.752

M33×2.0 31.00 31.210 30.835

M33×1.5 31.50 31.676 31.376

M35×1.5 33.50 33.676 33.376

M36×3.0 33.00 33.252 32.752

M36×2.0 34.00 34.210 33.835

M36×1.5 34.50 34.676 34.376

螺丝攻牙钻孔径和滚丝径对照表

公制挤压丝攻钻孔径美制挤压丝攻钻孔径

规格精度等级规格(UNC)精度等级

G4-G6 G7-G8 G9 G4-G6 G7-G8 G9

M1.0×0.25 0.86 0.88 -NO.2-56UNC 1.94

--

M1.1×0.25 0.96 0.98 -NO.3-48 2.23 --M1.2×0.25 1.06 1.08 -NO.4-40 2.50 --M1.4×0.3 1.24 1.25 -NO.5-40 2.83 --M1.6×0.35 1.41 1.43 -NO.6-32 3.07 --

M1.7×0.35 1.51 1.53 -NO.8-32 3.73 3.77 -

M1.8×0.35 1.61 1.63 -NO.10-24 4.24 4.3 -

M2.0×0.4 1.78 1.80 -NO.12-24 4.90 4.96 -

M2.2×0.45 1.95 1.98 -1/4-20 - 5.72 -M2.3×0.4 2.08 2.10 -5/16-18 -7.24 -M2.5×0.45 2.25 2.28 -3/8-16 -8.74 8.81 M2.6×0.45 2.35 2.38 -7/16-14 -10.20 10.30

M3.0×0.5 2.73 2.75 -1/2-13 -11.27 11.82

M3.5×0.6 3.17 3.20 -NO.2-64UNF 1.97

--

M4.0×0.7 3.62 3.65 3.69 NO.3-56 2.27 --

M5.0×0.8 4.56 4.60 4.64 NO.4-48 2.56 --

M6.0×1.0 5.45 5.50 5.55 NO.5-44 2.86 --

M7.0×1.0 6.45 6.50 6.55 NO.6-40 3.16 --

M8.0×1.25 7.31 7.38 7.44 NO.8-36 3.78 --

M10×1.5 9.18 9.25 9.32 NO.10-32 4.39

4.43 -

M10×1.25 9.31 9.38 9.44 NO.12-28 4.99

5.04 -

M12×1.75 11.04 11.12 11.21 1/4-28 5.85

5.90 -

M12×1.25 11.31 11.38 11.44 5/16-24 7.36 7.41 -

3/8-24 -9.00 -

7/16-20 -10.48 10.54

1/2-20 -12.07 12.13

美制特细螺纹英制电器螺纹

规格标准径2级牙钻孔径规格钻孔径

最大最小

NO.12-32 4.70 4.826 4.623 2BA 4.0-4.2 1/4 -32 5.60 5.690 5.486 3BA

5/16 -32 7.10 7.264 7.087 4BA 3.0-3.2 3/8 -32 8.70 8.865 8.661 5BA 2.7-2.8 7/16 -28 10.20 10.338 10.135 6BA 2.4-2.5

1/2 -28 11.80 11.938 11.709

9/16 -24 13.20 13.386 13.132

5/8 -24 14.80 14.986 14.732

3/4 -20 17.80 17.958 17.678

7/8 -20 21.00 21.133 20.853

1 -20 24.00 24.308 24.028

螺丝攻牙钻孔径和滚丝径对照表

英制螺纹公制螺纹针车用螺纹

规格(UNEF) 钻孔径规格滚丝径规格滚丝径

硬材软材

W 1/8 - 40 2.65 2.60 M3×0.5 2.63-2.60

SM1/8-40 2.735-2.688

W 5/32 - 32 3.25 3.20 M3.0×0.6 2.56-2.53 SM1/8-44 2.769-2.722

W 3/16 - 24 3.75 3.70 M3.5×0.6 3.06-3.03 SM9/64-40 3.128-3.083

W 1/4 - 20 5.10 5.00 M4.0×0.7 3.49-3.45 SM11/64-40 3.855-3.805

W 5/16 - 18 6.60 6.50 M4.0×0.75 3.45-3.41 SM3/16-32 4.205-4.155

W 3/8 - 16 8.00 7.90 M4.5×0.75 3.96-3.92 SM3/16-28 4.143-4.093

W 7/16 - 14 9.40 9.30 M5.0×0.8 4.43-4.38 SM7/32-32 5.003-4.955

W 1/2 - 12 10.70 10.50 M5.0×0.9 4.36-4.31 SM15/64-28 5.325-5.570

W 9/16 - 12 12.30 12.00 M6.0×1.0

5.30-5.25 SM1/4-40 5.890-5.735

W 5/8 - 11 13.70 13.50 M7.0×1.0 6.30-6.25 SM1/4-28 5.721-5.366

W 3/4 - 10 16.70 16.50 M8.0×1.0 7.28-7.23 SM9/32-28 6.508-6.648

W 7/8 - 9 19.50 19.30 M8.0×1.25 7.12-7.07 SM11/32-28 8.092-8.432

W1 - 8 22.40 22.00 SM3/8-28

8.880-8.015

W 1-1/8 - 7 25.00 24.80 SM7/16-28 10.466-10.401

W 1 - 1/4 - 7 28.30 28.00 SM7/16-16 10.037-9.967

SM1/2-20 11.819-11.749

SM9/26-20 13.400-13.425

英制管螺纹英制管螺纹美制管螺纹

规格标准径钻孔径规格标准径有交牙部之长度(最小)中之毋螺牙内径标准长度(最小)中之毋螺牙内径规格钻孔径

最大最小使用绞刀时不用绞刀时NPT NPS 使用绞刀时不用绞刀时

PS 1/16 - 28 6.50 6.632 6.490 PT 1/16 - 28 6.10 6.20 6.244 6.384 1/16 - 27 6.10 6.25 6.35

PS 1/8 - 28 8.50 8.637 8.495 PT 1/8 - 28 8.10 8.20 8.249 8.388 1/8 - 27 8.33 8.43 8.74

PS 1/4 - 19 11.40 11.549 11.341 PT 1/4 - 19 10.70 11.00 10.962 11.174 1/4 - 18

10.72 11.13 11.13

PS 3/8 - 19 15.00 15.054 14.846 PT 3/8 - 19 14.20 14.50 14.448 14.658 3/8 - 18

14.27 14.27 14.68

PS 1/2 - 14 18.50 18.773 18.489 PT 1/2 - 14 17.60 18.00 17.979 18.263 1/2 - 14

17.48 17.86 18.26

PS 3/4 -14 24.00 24.259 23.975 PT 3/4 - 14 23.00 23.50 23.378 23.663 3/4 - 14 22.63 23.01 23.42

PS 1 - 11 30.20 30.471 30.111 PT 1- 11 29.00 29.50 29.459 29.822 1 - 11-1/2 28.58 28.98 29.36

PS 1-1/4 - 11 38.80 39.132 38.772 PT 1-1/4 - 11 37.50 38.00 37.976 38.339

1-1/4-11-1/2 37.31 37.69 38.10

PS 1-1/2 - 11 44.80 45.025 44.665 PT 1-1/2 - 11 43.40 44.00 43.869 44.232

1-1/2-11-1/2 43.66 44.04 44.45

PS 2 - 11 56.50 56.836 56.476 PT 2 - 11 54.90 55.50 55.412 55.844

2 - 11 - 1/2 55.58 55.96 56.36

螺纹底孔对照表(技巧学习)

螺纹底孔直径公制普通粗牙螺纹 螺纹代号 钻头直径HSS 硬质合金 M2×0.4 1.6 1.65 M3×0.5 2.5 2.55 M4×0.7 3.3 3.4 M5×0.8 4.2 4.3 M6×1.0 5.0 5.1 M8×1.25 6.8 6.9 M10×1.5 8.5 8.7 M12×1.75 10.3 10.5 M14×2.0 12.0 12.2 M16×2.0 14.0 14.2 M18×2.5 15.5 15.7 M20×2.5 17.5 17.7 M24×3.0 21.0 ……M30×3.5 26.5 ……M36×4.0 32.0 ……M42×4.5 37.5 ……M45×4.5 40.5 ……M48×5.0 43.0 ……

公制细牙螺纹 螺纹代号 钻头直径HSS 硬质合金 M2×0.25 1.75 1.75 M3×0.35 2.7 2.7 M4×0.5 3.5 3.55 M5×0.5 4.5 4.55 M6×0.75 6.3 6.35 M8×1.0 7 7.1 M8×0.75 7.3 7.35 M10×1.0 9 9.1 M10×1.25 8.8 8.9 M10×0.75 9.3 9.35 M12×1.5 10.5 10.7 M12×1.25 10.8 10.9 M12×1.0 11 11.1 M14×1.5 12.5 12.7 M14×1.0 13.0 13.1 M16×1.5 14.5 14.7 M16×1.0 15.0 15.1 M18×1.5 16.5 16.7 M18×1.0 17 17.1

M20×2.0 18 18.3 M20×1.5 18.5 18.7 M20×1.0 19 19.1 M24×2.0 22.0 ……M24×1.5 22.5 ……M24×1.0 23.0 ……M30×3 27 ……M30×2 28 ……M30×1.5 28.5 ……M30×1.5 29 ……M36×3.0 33.0 ……M36×2 34.0 ……M36×1.5 34.5 ……M42×4 38 ……M42×3 39 ……M42×2 40 ……M42×1.5 40.5 ……M45×4 41 ……M45×3 42 ……M45×2 43 ……M45×1.5 43.5 ……

最全的螺纹孔径对照表

最大最小最大最小G4-G6G7-G8G9M1.0*0.250.750.7850.729M12*1.011.0011.15310.917M1.0*0.250.860.88M1.1*0.250.850.8850.829M12*0.511.5011.52011.400M1.1*0.250.960.98最大M1.2*0.250.950.9850.929M14*1.512.5012.67612.376M1.2*0.25 1.06 1.08G 1/167.72 6.84M1.4*0.3 1.10 1.142 1.075M14*1.013.0013.15312.917M1.4*0.3 1.24 1.25G(PF)1/89.738.85M1.6*0.35 1.25 1.321 1.221M15*1.513.5013.67613.376M1.6*0.35 1.41 1.431/413.1611.89M1.7*0.35 1.35 1.421 1.321M15*1.014.0014.15313.917M1.7*0.35 1.51 1.533/816.6615.40M1.8*0.35 1.45 1.521 1.421M16*1.514.5014.67614.376M1.8*0.35 1.61 1.631/220.9619.17M2.0*0.4 1.60 1.679 1.567M16*1.015.0015.15314.917M2*0.4 1.78 1.805/822.9121.13M2.2*0.45 1.75 1.838 1.713M17*1.515.5015.67615.376M2.2*0.45 1.95 1.983/426.4424.66M2.3*0.4 1.90 1.979 1.867M17*1.016.0016.15315.917M2.3*0.4 2.08 2.107/830.2028.42M2.5*0.45 2.10 2.138 2.013M18*2.016.0016.21015.835M2.5*0.45 2.25 2.28133.2530.93M2.6*0.45 2.20 2.238 2.113M18*1.516.5016.67616.376M2.6*0.45 2.35 2.38 1.12537.9035.58M3.0*0.5 2.50 2.599 2.459M18*1.017.0017.15316.917M3.0*0.5 2.73 2.75 1.2541.9139.59M3.0*0.6 2.40 2.440 2.280M20*2.018.0018.21017.835M3.5*0.6 3.17 3.20 1.37544.3242.01M3.5*0.6 2.90 3.010 2.850M20*1.518.5018.67618.376M4.0*0.7 3.62 3.65 3.69 1.547.8049.02M4.0*0.7 3.30 3.422 3.242M20*1.019.0019.15318.917M5.0*0.8 4.56 4.60 4.64 1.62551.9150.79M4.0*0.75 3.25 3.326 3.106M22*2.020.0020.21019.835M6.0*1.0 5.45 5.50 5.55 1.7553.7556.66 M4.5*0.75 3.80 3.878 3.688M22*1.520.5020.67620.376M7.0*1.0 6.45 6.50 6.552 59.61 M5.0*0.8 4.20 4.334 4.134M22*1.021.0021.15320.917M8.0*1.257.317.387.44M5.0*0.9 4.10 4.170 3.930M24*2.022.0022.21021.835M10*1.59.189.259.32M6.0*1.0 5.00 5.153 4.917M24*1.522.5022.67622.376M10*1.259.319.389.44M7.0*1.0 6.00 6.153 5.917M24*1.023.0023.15322.917M12*1.7511.0411.1211.21M8.0*1.25 6.80 6.912 6.647M25*2.023.0023.21022.835M12*1.25 11.3111.3811.44 M9.0*1.257.807.9127.647M25*1.523.5023.67623.376最大M10*1.58.508.6768.376M25*1.024.0024.15323.917PS 1/16 - 28 6.50 6.632M11*1.59.509.6769.376M26*1.524.5024.67624.376PS 1/8 - 288.508.637M12*1.7510.3010.44110.106M27*2.025.0025.21024.835PS 1/4 - 1911.4011.549M14*2.012.0012.21011.835M27*1.525.5025.67625.376PS 3/8 - 1915.0015.054M16*2.014.0014.21013.835M27*1.026.0026.15325.917PS 1/2 - 1418.5018.773M18*2.515.5015.74415.294M28*2.026.0026.21025.835PS 3/4 - 1424.0024.259M20*2.517.5017.74417.294M28*1.526.5026.67626.376PS 1 - 1130.2030.471M22*2.519.5019.74419.294M28*1.027.0027.15326.917规格PS 1-1/4 - 1138.8039.132M24*3.021.0021.25220.752M30*3.027.0027.25226.752(UNC) 最大最小PS 1-1/2 - 1144.8045.025M27*3.024.0024.25223.752M30*2.028.0028.21027.835 (螺丝牙外径) PS 2 - 11 56.50 56.836 M30*3.5 26.50 26.771 26.211 M30*1.528.5028.67628.376No.1-64(1.854) 1.55 1.582 1.425M30*1.029.0029.15328.917No.2-56(2.184) 1.80 1.871 1.695M32*2.030.0030.21029.835No.3-48(2.515) 2.10 2.146 1.941M32*1.530.5030.67630.376No.4-40(2.845) 2.30 2.385 2.157M33*3.030.0030.25229.752No.5-40(3.175) 2.60 2.697 2.487M33*2.031.0031.21030.835No.6-32(3.505) 2.80 2.895 2.642最大最小M33*1.531.5031.67631.376No.8-32(4.166) 3.40 3.530 3.302M1.0*0.20.800.8210.783M35*1.533.5033.67633.376No.10-24(4.826) 3.90 3.962 3.683M1.1*0.20.900.9210.883M36*3.033.0033.25232.752No.12-24(5.486) 4.50 4.597 4.344PT 1/16 -28 6.10 6.20 6.244 6.384M1.2*0.2 1.00 1.0210.983M36*2.034.0034.21033.8351/4 - 20 5.10 5.257 4.979PT 1/8 -288.108.208.4298.388M1.4*0.2 1.20 1.221 1.183M36*1.5 34.50 34.67634.376 5/16 - 18 6.60 6.731 6.401PT 1/4 -1910.7011.0010.96211.174M1.6*0.2 1.40 1.421 1.3833/8 - 168.008.1537.798PT 3/8 -1914.2014.5014.44814.658M1.7*0.2 1.45 1.500 1.4607/16 - 149.409.5509.144PT 1/2 -1417.6018.0017.97918.263M1.8*0.2 1.60 1.621 1.5831/2 - 1310.8011.02310.592PT 3/4 -1423.0023.5023.37823.663M2.0*0.25 1.75 1.785 1.7299/16 - 1212.2012.44611.989PT 1 -1129.0029.5029.45929.822M2.2*0.25 1.95 1.985 1.929规格5/8 - 1113.6012.86813.386PT 1-1/4 -1137.5038.0037.97638.339M2.3*0.25 2.05 2.061 2.001(UNF) 最大最小3/4 - 1016.5018.84016.307PT 1-1/2 -1143.4044.0043.86944.232M2.5*0.35 2.20 2.221 2.1217/8 - 919.5019.76119.177PT 2 -11 54.9055.5055.41255.844 M2.6*0.35 2.20 2.246 2.186No.0-80(1.524) 1.25 1.305 1.182 1 - 822.2022.60621.971M3.0*0.35 2.70 2.721 2.621No.1-72(1.854) 1.55 1.612 1.4741-1/8 - 725.0025.34924.638M3.5*0.35 3.20 3.221 3.121No.2-64(2.184) 1.85 1.912 1.7561-1/4 - 728.2028.52427.813M4.0*0.5 3.50 3.599 3.459No.3-56(2.515) 2.10 2.197 2.0251-3/8 - 630.8031.11530.353M4.5*0.5 4.00 4.099 3.959No.4-48(2.845) 2.40 2.458 2.2711-1/2 - 634.0034.29033.528M5.0*0.5 4.50 4.599 4.459No.5-44(3.175) 2.70 2.740 2.5511-3/4 - 5 39.5039.82738.964M5.5*0.5 5.00 5.099 4.959No.6-40(3.505) 2.90 3.022 2.820 2 - 4-1/245.20 45.593 44.679 使用绞刀时不用绞刀时 M6.0*0.75 5.30 5.378 5.188No.8-36(4.166) 3.50 3.606 3.4041/16 - 27 6.10 6.25M6.0*0.5 5.50 5.550 5.400No.10-32(4.826) 4.10 4.165 3.9631/8 -278.338.43M7.0*0.75 6.30 6.378 6.188No.12-28(5.846) 4.60 4.724 4.4961/4 -1810.7211.13M7.0*0.5 6.50 6.550 6.4001/4 - 28 5.50 5.588 5.3603/8 -1814.2714.27M8.0*1.07.007.153 6.9175/16 - 24 6.907.035 6.782规格1/2 -1417.4817.86M8.0*0.757.307.3787.1883/8 - 248.508.6368.382(UNEF)最大最小3/4 -1422.6323.01M8.0*0.57.507.5207.4007/16 - 209.9010.0339.729No.12 - 32 4.70 4.826 4.623 1 -11-1/228.5828.98M9.0*1.08.008.1537.9171/2 - 2011.5011.60711.3291/4 - 32 5.60 5.690 5.4861-1/4 -11-1/237.3137.69M9.0*0.758.308.3788.1889/16 - 1812.9013.08112.7515/16 - 327.107.2647.0871-1/2 -11-1/243.6644.04M10*1.258.808.9128.4675/8 - 1814.5014.68114.3513/8 - 328.708.8658.661 2 -11-1/2 55.5855.96 M10*1.09.009.1538.9173/4 - 1617.5017.67817.3237/16 - 2810.2010.33810.135M10*0.759.309.3789.1887/8 - 1420.5020.67520.2701/2 - 2811.8011.93811.709M10*0.59.509.5209.400 1 - 1223.2023.57123.1149/16 - 2413.2013.38613.132M11*1.010.0010.1539.9171-1/8 - 1226.5026.74626.2895/8 - 2414.8014.98614.732M11*0.7510.3010.37810.1881-1/4 - 1229.5029.92129.4643/4 - 2017.8017.95817.678M12*1.510.5010.67610.3761-3/8 - 1232.8033.09632.6397/8 - 2021.0021.13320.853M12*1.25 10.80 10.91210.647 1-1/2 - 1236.0 36.271 35.814 1 - 20 24.00 24.30824.028 规 格使用绞刀时不用绞刀时 有效牙部之长度(最小)中之母螺牙内径 标准长度(最小)中之母螺牙内径 螺 纹 攻 牙 钻 孔 径 和 滚 造 径 对 照 表 英制平行管用螺紋PF(G) (單位:mm) 大 径钻孔径 规格公 制 细 螺 纹 规格 标准径2级牙钻孔径标准径 2级牙钻孔径美 制 特 细 螺 纹 规 格 (螺丝牙外径) 美 制 细 螺 纹 美 制 管 螺 纹 钻 孔 径 标准径 美 制 粗 螺 纹 标准径2级牙钻孔径公 制 粗 螺 纹 公 制 迫 牙 丝 攻 钻 孔 径 规 格精 度 等 级公 制 细 螺 纹 2级牙钻孔径标准径规格14.95 18.6320.5924.12最小6.568.5711.4541.3745.4949.6751.4327.8830.2934.9438.958.49511.341英 制 管 螺 纹 钻孔径 最小规格标准径N P T 14.84623.97530.11138.77218.48944.66556.476 英 制 管 螺 纹 规格18.2623.4229.366.3511.1314.68N P S 44.4556.36 38.108.7457.30 6.490注:迫牙丝攻之钻孔径,在上表所列之数值,由于被加工 材料之材质、硬度、形状、尺寸等之影响,多少会有所变动,因此于参考上表之同时,亦请增减若干。 标准径2级牙钻孔径标准径 2级牙钻孔径

螺纹底孔直径对照表

螺纹: 螺纹指的是在圆柱或圆锥母体表面上制出的螺旋线形的、具有特定截面的连续凸起部分。螺纹按其母体形状分为圆柱螺纹和圆锥螺纹;按其在母体所处位置分为外螺纹、内螺纹,按其截面形状(牙型)分为三角形螺纹、矩形螺纹、梯形螺纹、锯齿形螺纹及其他特殊形状螺纹。 螺纹底径: 螺纹底径=公称直径—1.08252*螺距。 底孔直径的确定丝锥在攻螺纹的过程中,切削刃主要是切削金属,但还有挤压金属的作用,因而造成金属凸起并向牙尖流动的现象,所以攻螺纹前,钻削的孔径(即底孔)应大于螺纹内径。 底孔直径: 丝锥在攻螺纹的过程中,切削刃主要是切削金属,但还有挤压金属的作用,因而造成金属凸起并向牙尖流动的现象,所以攻螺纹前,钻削的孔径(即底孔)应大于螺纹内径。 底孔的直径可查手册或按下面的经验公式计算: 脆性材料:钻孔直径d0=d(螺纹外径)-1.1p(螺距) 塑性材料(钢、紫铜等):钻孔直径d0=d(螺纹外径)-p(螺距)钻孔深度: 攻盲孔(不通孔)的螺纹时,因丝锥不能攻到底,所以孔的深度要大于螺纹的长度, 盲孔的深度可按下面的公式计算:

孔的深度=所需螺纹的深度+0.7d 公制螺纹的计算方法: 底径=大径-1.0825*螺距 英制螺纹的计算方法: 底径=大径-1.28*螺距 攻螺纹: 攻螺纹是钳工金属切削中的重要内容之一,包括划线、钻孔、攻螺纹等环节。攻螺纹只能加工三角形螺纹,属连接螺纹,用于两件或多件结构件的连接。螺纹的加工质量直接影响到构建的装配质量效果,所以实习教学非常重视攻螺纹各环节的教学。 简介: 工作部分是一段开槽的外螺纹。丝锥的工作部分包括切削部分和校准部分。 手用丝锥一般由两支组成一套,分为头锥和二锥。两支丝锥的外径、中径和内径均相等,只是切削部分的长短和锥角不同。头锥较长,锥角较小,约有6个不完整的齿,以便切入。二锥短些,锥角大些,不完整的齿约为2个。 铰杠是扳转丝锥的工具。常用的是可调节式,以便夹持各种不同尺寸的丝锥。 划孔位线: 划线时,钻孔是攻螺纹的基础。划线准确,孔位尺寸就能得到保证。划线前,首先要看懂图样和工艺要求,明确工作任务。然后,清

无屑丝攻下孔径表(公制)

100%90%80%70%100%90%80%70%M1.00.25 40.860.870.890.90M9.0 1.578.298.368.438.500.230.890.900.910.92178.438.498.558.60M1.10.25 40.960.970.99 1.000.7578.578.628.668.700.230.99 1.00 1.01 1.020.568.728.748.778.80M1.20.25 4 1.06 1.07 1.09 1.10M10 1.579.159.239.329.400.23 1.09 1.10 1.11 1.12 1.2579.299.369.439.50M1.40.3 4 1.23 1.2 5 1.2 6 1.28179.439.499.559.600.23 1.29 1.30 1.31 1.320.7579.579.629.669.70M1.60.35 4 1.40 1.42 1.44 1.460.569.729.749.779.800.23 1.49 1.50 1.51 1.52M11 1.51010.1510.2310.3210.40M1.70.35 4 1.50 1.52 1.54 1.561810.4310.4910.5510.600.24 1.59 1.60 1.61 1.620.75810.5710.6210.6610.70M1.80.35 4 1.60 1.62 1.64 1.66M12 1.75811.0111.1111.2111.310.23 1.69 1.70 1.71 1.72 1.5811.1511.2311.3211.40M2.00.4 4 1.77 1.80 1.82 1.84 1.25811.2911.3611.4311.500.254 1.86 1.87 1.89 1.911811.4311.4911.5511.60M2.20.45 4 1.94 1.97 2.00 2.02M1421012.8712.9813.0913.210.54 2.06 2.07 2.09 2.10 1.5913.1513.2313.3213.40M2.30.4 4 2.07 2.10 2.12 2.14 1.25813.2913.3613.4313.500.254 2.16 2.17 2.19 2.201813.4313.4913.5513.60M2.50.45 4 2.24 2.27 2.30 2.32M1 5 1.5914.1514.2314.3214.400.354 2.30 2.32 2.34 2.361814.4314.4914.5514.60M2.60.45 4 2.34 2.37 2.40 2.42M1621014.8714.9815.0915.210.35 5 2.40 2.42 2.44 2.4 6 1.5915.1515.2315.3215.40M3.00.6 5 2.6 6 2.69 2.73 2.761815.4315.4915.5515.600.55 2.72 2.74 2.7 7 2.80M17 1.51116.1516.2316.3216.400.355 2.80 2.82 2.84 2.861916.4316.4916.5516.60M3.50.6 5 3.1 6 3.19 3.23 3.26M18 2.51116.5816.7216.8717.010.355 3.30 3.32 3.34 3.3621116.8716.9817.0917.21M4.00.75 6 3.5 7 3.62 3.66 3.70 1.51017.1517.2317.3217.400.76 3.60 3.64 3.6 8 3.721917.4317.4917.5517.600.56 3.72 3.74 3.77 3.80M20 2.51118.5818.7218.8719.01M4.50.75 6 4.0 7 4.12 4.16 4.2021118.8718.9819.0919.210.56 4.22 4.24 4.27 4.30 1.51019.1519.2319.3219.40M5.00.9 6 4.49 4.54 4.59 4.641919.4319.4919.5519.600.86 4.55 4.59 4.64 4.68M22 2.51120.5820.7220.8720.010.56 4.72 4.74 4.7 7 4.8021120.8720.9821.0921.21M5.50.9 6 4.99 5.04 5.09 5.14 1.51021.1521.2321.3221.400.56 5.22 5.24 5.2 7 5.301921.4321.4921.5521.60M6.01 7 5.43 5.49 5.55 5.60M2421122.8722.9823.0923.210.756 5.57 5.62 5.66 5.70 1.51023.1523.2323.3223.400.56 5.72 5.74 5.77 5.801912.4323.4923.5523.60M7.01 7 6.43 6.49 6.55 6.60 0.756 6.57 6.62 6.66 6.70 0.56 6.72 6.74 6.77 6.80 M8.01.25 77.297.367.437.50 177.437.497.557.60 0.7577.577.627.667.700.5 6 7.727.747.777.80 【注】1.本表的寸法为参考用,请先试着加工 再决定下孔径。饱和率 下孔径 (mm) 2级用精 度番号 2.精度番号是以母螺纹的公差80%为目标 做决定。无屑丝攻下孔径表 公制螺纹的下孔径和无屑丝攻的精度番号 外径牙距外径牙距2级用精度番号 饱和率 下孔径 (mm)