J Mater Chem 2007 17 1258-copolymerization of poluimide and polyoxometalates

Ultra-low-k polyimide hybrid films via copolymerization of polyimide and polyoxometalates {

Honggang Chen,Long Xie,Hongbin Lu *and Yuliang Yang

Received 2nd January 2007,Accepted 23rd February 2007

First published as an Advance Article on the web 5th March 2007DOI:10.1039/b618910e

Novel polyimide hybrid films in which nanoscale polyoxome-talates (POM)clusters are covalently linked with the polymer chains exhibit not only drastically reduced dielectric constants relative to neat polyimide film,as low as 1.22,but also improved thermal stability,and mechanical properties without sacrificing the transparency of the polymer films.

The interest in hybrid materials lies in their appealing properties,which result from the possibility to combine inorganic,organic,and biological functions in a tailored matrix or nanocomposite.1,2In particular,organic–inorganic hybrid materials have attracted remarkable attention for microelectronics and end use because their utilization in integrated circuits can lower line-to-line noise in interconnects,and alleviate power dissipation issues by reducing the capacitance between the interconnection conductor lines.3,4Although a great deal of effort has been made,it is still a considerable challenge to find an alternative to traditional insulators like silicon dioxide for future devices.5,6In view of the dielectric constant of air (k =1.01),the introduction of controlled porosity in materials,typically with pore sizes well below the

smallest device features,100A

?or less,has been envisioned as a promising method for developing ultra-low dielectric materials.7–9As an example,Lee et al.demonstrated the preparation of an ultra-low dielectric organosilicate film (polymethylsilsesquioxane,PMSSQ),where ethyl acrylate-terminated polypropyleneimine dendrimers were used as a porogen to yield narrow-distributed,closed spherical pores of radius ,2.0nm.8As the porosity of the films increased by 32%,their k value was decreased by 1.66.9However,the mechanical strength of the resulting nanoporous film is weak and the Young’s modulus is only 0.6GPa.

Polyimides are well known for their excellent mechanical properties and high-temperature durability and have been used as interlayer dielectrics in microelectrics by simple spin-coating techniques.10To balance their mechanical properties and dielectric constant,porous nanoparticles with stiff structures are attracting more attention.For example,porous polyhedral oligomeric silsesquioxane (POSS)10,11and silica nanotubes 12have been used in attempts to achieve simultaneous improvements in the mechanical and dielectric properties of polyimide films.

Polyoxometalates (POM)are also porous inorganic nano-particles or molecular clusters and have found wide applications in many fields.13As nanobuilding blocks,they have been embedded into some polymers and resulted in pronounced property improvements of the resulting materials.1a ,d ,2Due to the structural resemblance to semiconductor materials they have been used to fabricate composite materials for molecular switching devices.14This inspired us to explore the possibility of improving the dielectric properties of polyimides by incorporating organically modified POM clusters.

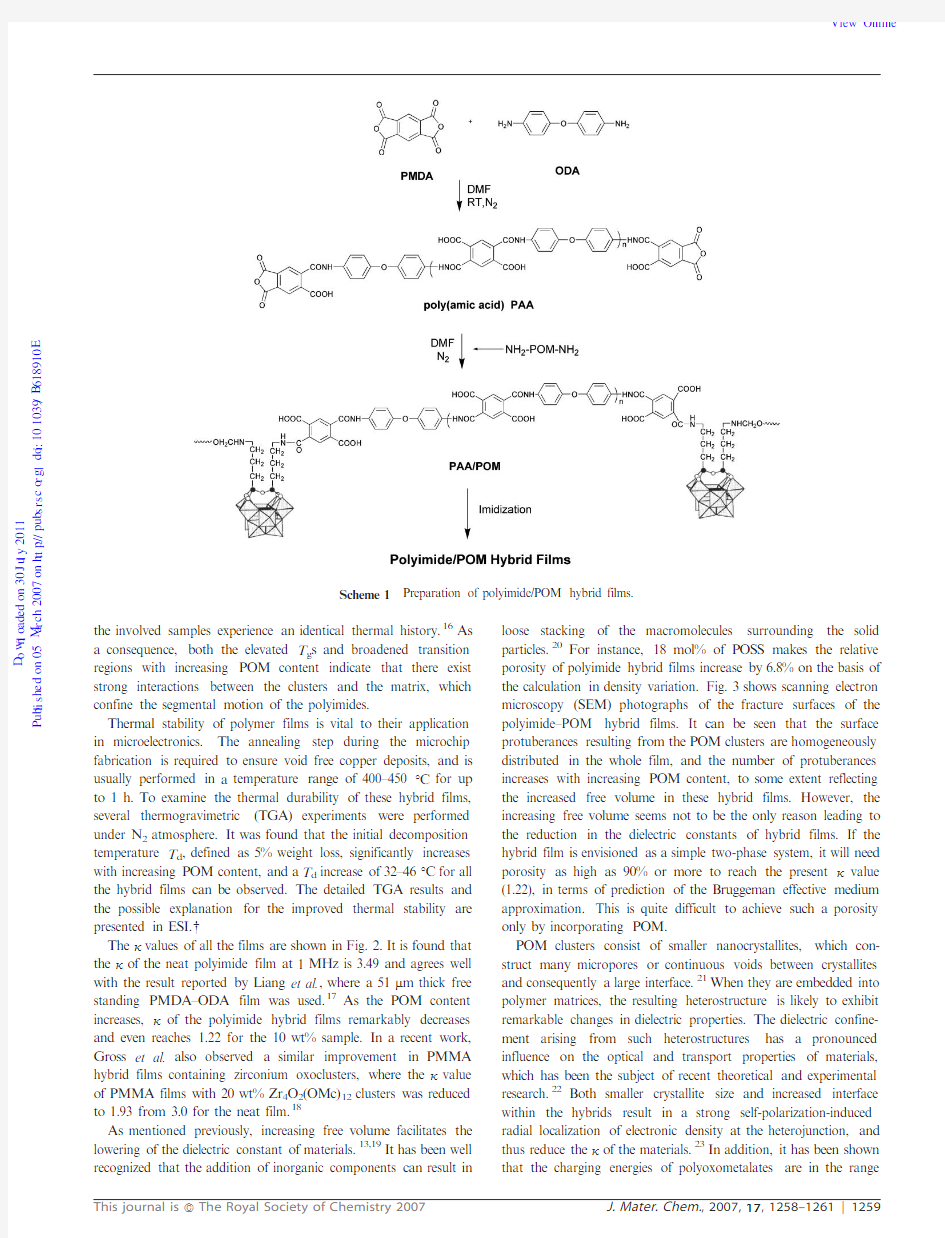

The POM cluster used in this work is a highly nucleophilic divacant lacunary decatungstosilicate with chemical formula K 8[c -SiW 10O 36]?12H 2O,synthesized following a procedure developed by Te ′ze ′et al.15In the present work,to carry out the copolymerization of POM clusters with pyromellitic dianhydride (PMDA)and 4,49-oxydianiline (ODA),two amine groups were attached to the lacunae of each tungstosilicate cluster by reaction with c -aminopropyltriethoxysilane.A representative synthesis procedure for polyimide/POM hybrids is illustrated in Scheme 1.Details of the experimental preparation and characterization for the organically modified POM and the hybrid films can be found in the electronic supplementary information (ESI).{

The dynamic mechanical behavior of the polyimide and its hybrid films with different POM contents is shown in Fig.1.All the measurements were performed in the temperature range 70–400u C with a frequency of 0.1Hz and a fixed sample size.The tensile modulus at 75u C (below T g )for the neat polyimide film is about 1.6GPa (see Fig.1a).The incorporation of POM clusters efficiently increases the storage modulus E 9of these polyimide films.For example,E 9at 75u C for the 10wt%POM hybrid film increased to 3.4GPa,an increase of 110%compared to that of the neat polyimide film.With increasing temperature,E 9of the hybrid film decreases but not very much,and is still 700MPa even at 390u C.In contrast,E 9of the neat polyimide film drastically decreases,especially starting from 300u C,and is only 24.5MPa at 390u C.Such a reinforcing effect can be attributed to the increasing stiffness of main chain in the polyimide containing POM clusters.The incorporated POM clusters elevate the activating threshold of segmental motion and reduce the response rate to the applied stress,which can be further verified from the change in glass transition temperature T g of the films.

The loss factor tan d curves in Fig.1(b)reveal a pronounced increase in T g ,defined as the peak temperature in the tan d curves,as high as 66u C (from 317to 383u C)as the POM content in polyimide films is increased by 10wt%.Furthermore,the peak width of tan d during the primary transition becomes broader with increasing POM content.Generally,the glass transition tempera-tures of polymers reflect their segmental mobility,especially when

Key Laboratory of Molecular Engineering of Polymers (Minister of Education)&Department of Macromolecular Science,Fudan

University,Shanghai,200433,China.E-mail:hongbinl@https://www.360docs.net/doc/0115495963.html,;Fax:+86-21-55664589;Tel:+86-21-55664589

{Electronic supplementary information (ESI)available:preparation procedures of the organo-POM and hybrid films;characterizations:1H and 29Si NMR,FTIR,XPS,UV-vis,dielectric loss and TGA data.See DOI:10.1039/b618910e

COMMUNICATION https://www.360docs.net/doc/0115495963.html,/materials |Journal of Materials Chemistry

D o w n l o a d e d o n 30 J u l y 2011P u b l i s h e d o n 05 M a r c h 2007 o n h t t p ://p u b s .r s c .o r g | d o i :10.1039/B 618910E

the involved samples experience an identical thermal history.16As a consequence,both the elevated T g s and broadened transition regions with increasing POM content indicate that there exist strong interactions between the clusters and the matrix,which confine the segmental motion of the polyimides.

Thermal stability of polymer films is vital to their application in microelectronics.The annealing step during the microchip fabrication is required to ensure void free copper deposits,and is usually performed in a temperature range of 400–450u C for up to 1h.To examine the thermal durability of these hybrid films,several thermogravimetric (TGA)experiments were performed under N 2atmosphere.It was found that the initial decomposition temperature T d ,defined as 5%weight loss,significantly increases with increasing POM content,and a T d increase of 32–46u C for all the hybrid films can be observed.The detailed TGA results and the possible explanation for the improved thermal stability are presented in ESI.{

The k values of all the films are shown in Fig.2.It is found that the k of the neat polyimide film at 1MHz is 3.49and agrees well with the result reported by Liang et al.,where a 51m m thick free standing PMDA–ODA film was used.17As the POM content increases,k of the polyimide hybrid films remarkably decreases and even reaches 1.22for the 10wt%sample.In a recent work,Gross et al.also observed a similar improvement in PMMA hybrid films containing zirconium oxoclusters,where the k value of PMMA films with 20wt%Zr 4O 2(OMc)12clusters was reduced to 1.93from 3.0for the neat film.18

As mentioned previously,increasing free volume facilitates the lowering of the dielectric constant of materials.13,19It has been well recognized that the addition of inorganic components can result in

loose stacking of the macromolecules surrounding the solid particles.20For instance,18mol%of POSS makes the relative porosity of polyimide hybrid films increase by 6.8%on the basis of the calculation in density variation.Fig.3shows scanning electron microscopy (SEM)photographs of the fracture surfaces of the polyimide–POM hybrid films.It can be seen that the surface protuberances resulting from the POM clusters are homogeneously distributed in the whole film,and the number of protuberances increases with increasing POM content,to some extent reflecting the increased free volume in these hybrid films.However,the increasing free volume seems not to be the only reason leading to the reduction in the dielectric constants of hybrid films.If the hybrid film is envisioned as a simple two-phase system,it will need porosity as high as 90%or more to reach the present k value (1.22),in terms of prediction of the Bruggeman effective medium approximation.This is quite difficult to achieve such a porosity only by incorporating POM.

POM clusters consist of smaller nanocrystallites,which con-struct many micropores or continuous voids between crystallites and consequently a large interface.21When they are embedded into polymer matrices,the resulting heterostructure is likely to exhibit remarkable changes in dielectric properties.The dielectric confine-ment arising from such heterostructures has a pronounced influence on the optical and transport properties of materials,which has been the subject of recent theoretical and experimental research.22Both smaller crystallite size and increased interface within the hybrids result in a strong self-polarization-induced radial localization of electronic density at the heterojunction,and thus reduce the k of the materials.23In addition,it has been shown that the charging energies of polyoxometalates are in the

range

Scheme 1Preparation of polyimide/POM hybrid films.

D o w n l o a d e d o n 30 J u l y 2011P u b l i s h e d o n 05 M a r c h 2007 o n h t t p ://p u b s .r s c .o r g | d o i :10.1039/B 618910E

0.1–4.0eV and the resolution of discrete electronic levels at room temperature is thus expected.The trapped electron and charge confinement increase the binding energy of the hybrid films and thus reduce the size-dependent static dielectric con-stant.24Apparently,the specific heterostructure and the induced variations in polarization effect and binding energy are also likely to be responsible for the prominently decreased k in the hybrid films.

In summary,a convenient route to the fabrication of polyimide hybrid films with ultra-low dielectric constant (k =1.22)has been proposed.On the basis of a simple copolymerization,the organically modified POM clusters are covalently incorporated into polyimide chains,and significantly improve the thermal and mechanical properties of the polymer films without sacrificing their optical transparency.This method can be extended to other polyoxometalate clusters and polymers and thus opens a new approach to develop ultra-low k hybrids or other functional materials.

Acknowledgements

This work was supported by the National Basic Research Program of China (Grant No.2005CB623800),NSF of China (Grant No.50573014),Shanghai Basic Research Program (Grant No.05JC14002)and partially supported by State Key Laboratory for Modification of Chemical Fibers and Polymer Materials.

Notes and references

1(a )C.Sanchez and F.Ribot,New J.Chem.,1994,18,1007;(b )S.I.Stupp and P.V.Braun,Science ,1997,277,1242;(c )R.Tamaki,Y.Tanaka,M.Z.Asuncison,J.Choi and https://www.360docs.net/doc/0115495963.html,ine,J.Am.Chem.Soc.,2001,123,12416;(d )U.Schubert,Chem.Mater.,2001,13,3487.

2For the state-of-the-art of hybrid materials,see:(a )C.Sanchez,B.Julian,P.Belleville and M.Popall,J.Mater.Chem.,2005,15,3559and other papers in this special issue on functional hybrids;(b )P.Gomez-Romero and C.Sanchez,Functional Hybrid Materials ,Wiley-VCH,Weinheim,2004;(c )G.J.A.A.Soler-Illia and P.Innocenzi,Chem.–Eur.J.,2006,12,

4478.

Fig.2Dielectric properties of the neat polyimide and POM hybrid films at room temperature:(A)neat polyimide;(B)1wt%POM;(C)3wt%POM;(D)5wt%POM;(E)10wt%

POM.

Fig.3Scanning electronic microscope photographs of the hybrid films containing (a)5wt%POM and (b)10wt%

POM.

Fig.1Dynamic mechanical properties of the neat polyimide and hybrid films:(a)tensile storage modulus E 9(MPa)and (b)loss factor tan d .Experimental conditions:temperature range 70–400u C,N 2atmosphere at flow rate 10cm 3min 21,frequency 0.1Hz.

D o w n l o a d e d o n 30 J u l y 2011P u b l i s h e d o n 05 M a r c h 2007 o n h t t p ://p u b s .r s c .o r g | d o i :10.1039/B 618910E

3(a )M.Ree,J.Yoon and K.Heo,J.Mater.Chem.,2006,16,685;(b )R.Q.Su,T.E.Muller,J.Prochazka and J.A.Lercher,Adv.Mater.,2002,14,1369;(c )B.Zhong,M.Spaulding,J.Albaugh and E.Moyer,Polym.Mater.Sci.Eng.,2002,87,440;(d )R.Ishii,T.Ikeda,T.Itoh,T.Ebina,T.Yokoyama,T.Hanaoka and F.Mizukami,J.Mater.Chem.,2006,16,4035;(e )T.H.Lee,J.H.Kim and B.-S.Bae,J.Mater.Chem.,2006,16,1657.

4(a )https://www.360docs.net/doc/0115495963.html,ler,Science ,1999,286,421;(b )J.L.Hedrick,K.R.Carter,R.Dipietro,https://www.360docs.net/doc/0115495963.html,ler,T.P.Russell,V.Flores,D.Mecerreyes,P.DuBois and R.Jerome,Chem.Mater.,1998,10,32;(c )G.D.Fu,W.C.Wang,S.Li,E.T.Kang,K.G.Neoh,W.T.Tseng and D.J.Liaw,J.Mater.Chem.,2003,13,2150.

5(a )K.Maex,M.R.Baklanov, D.Shamiryan, F.Iacopi,S.H.Brongersma and Z.S.Yanovitskaya,Appl.Phys.Rev.,2003,93,8793;(b )J.L.Hedrick,T.Magbitang,E.F.Connor,T.Glauser,W.Volksen,C.J.Hawker,V.Y.Lee and https://www.360docs.net/doc/0115495963.html,ler,Chem.–Eur.J.,2002,8,3309;(c )T.Homma,Mater.Sci.Eng.,R ,1998,R23,243.6(a )S.J.Martin,J.P.Godschalx,https://www.360docs.net/doc/0115495963.html,ls,E.O.Shaffer,II and P.H.Townsend,Adv.Mater.,2000,12,1769;(b )G.Maier,Prog.Polym.Sci.,2001,26,3.

7(a )Y.Q.Huang and J.Economy,Macromolecules ,2006,39,1850;(b )G.D.Fu,Z.Shang,L.Hong,E.T.Kang and K.G.Neoh,Adv.Mater.,2005,17,2622;(c )S.Li,Z.J.Li and Y.S.Yan,Adv.Mater.,2003,15,1528;(d )Q.R.Huang,W.Volksen,E.Huang,M.Toney,C.W.Frank and https://www.360docs.net/doc/0115495963.html,ler,Chem.Mater.,2002,14,3676;(e )B.Krause,G.H.Koops,N. F. A.van der Vegt,M.Wessling,M.Wubbenhorst and J.van Turnhout,Adv.Mater.,2002,14,1041;(f )C.M.Yang,A.T.Cho,F.M.Pan,T.G.Tsai and K.J.Chao,Adv.Mater.,2001,13,1099;(g )S.Baskaran,J.Liu,K.Domansky,N.Kohler,X.H.Li,C.Coyle,G.E.Fryxell,S.Thevuthasan and R.E.Williford,Adv.Mater.,2000,12,291.

8B.D.Lee,Y.H.Park,Y.T.Hwang,W.T.Oh,J.H.Yoon and M.H.Ree,Nat.Mater.,2005,4,147.

9S.Yang,P.A.Mirau,C.S.Pai,O.Nalamasu,E.Reichmanis,E.K.Lin,H.J.Lee,D.W.Gidley and J.Sun,Chem.Mater.,2001,13,2762.10(a )C.M.Leu,G.M.Reddy,K.H.Wei and C.F.Shu,Chem.Mater.,2003,15,2261;(b )L.Y.Jiang,C.M.Leu and K.H.Wei,Adv.Mater.,2002,14,426.11(a )J.C.Huang,P.C.Lim,L.Shen,P.K.Pallathadka,K.Y.Zeng and C.B.He,Acta Mater.,2005,53,2395;(b )C.M.Leu,Y.T.Chang and K.H.Wei,Chem.Mater.,2003,15,3721.

12Y.H.Zhang,S.G.Lu,Y.Q.Li,Z.M.Dang,J.H.Xin,S.Y.Fu,G.T.Li,R.R.Guo and L.F.Li,Adv.Mater.,2005,17,1056.

13(a )T.J.Barton,L.M.Bull,W.G.Klemperer,D.A.Loy,B.McEnaney,M.Misono,P.A.Monson,G.Pez,G.W.Scherer,J.C.Vartuli and O.M.Yaghi,Chem.Mater.,1999,11,2633;(b )Polyoxometalate Chemistry from Topology via Self-Assembly to Applications ,ed.M.T.Pope,Kluwer Academic Publishers,Dordrecht,2001.

14(a )C.Sanchez,B.Julian,P.Belleville and M.Papall,J.Mater.Chem.,2005,15,3559;(b )N.Glezos, D.Velessiotis,P.Chaidogiannos,P.Argitis,D.Tsamakis and X.Zianni,Synth.Met.,2003,138,267.15(a )J.Canny,A.Te ′ze ′,R.Thouvenot and G.Herve ′,Inorg.Chem.,1986,25,2114;(b )P.Judeinstein,Chem.Mater.,1992,4,4;(c )C.R.Mayer,I.Fournier and R.Thouvenot,Chem.–Eur.J.,2000,6,105.

16(a )H.B.Lu and S.Nutt,Macromolecules ,2003,36,4010;(b )H.B.Lu and S.Nutt,Macromol.Chem.Phys.,2003,204,1832.

17T.Liang,Y.Makita and S.Kimura,Polymer ,2001,42,4867.

18S.Gross,V.D.Noto and U.Schubert,J.Non-Cryst.Solids ,2003,322,154.

19T.M.Long and T.M.Swager,J.Am.Chem.Soc.,2003,125,14113.20(a )T.C.Merkel,B.D.Freeman,R.J.Spontak,Z.He,I.Pinnau,P.Meakin and A.J.Hill,Science ,2002,296,519;(b )C.M.Leu,Y.T.Chang and K.H.Wei,Macromolecules ,2003,36,9122.

21(a )H.Colfen and M.Antonietti,Angew.Chem.,Int.Ed.,2005,44,5576;(b )D.L.Long and L.Cronin,Chem.–Eur.J.,2006,12,3698.

22(a )R.Tsu and D.Babic,Appl.Phys.Lett.,1994,64,1806;(b )Z.Y.Deng,J.K.Guo and https://www.360docs.net/doc/0115495963.html,i,J.Phys.:Condens.Matter ,1994,6,5949;(c )A.Franceschetti,A.Williamson and A.Zunger,J.Phys.Chem.B ,2000,104,3398;(d )V.A.Fonoberov,E.P.Pokatilov and A.A.Balandin,Phys.Rev.B ,2002,66,085310.

23(a )J.L.Movilla and J.Planelles,Phys.Rev.B ,2006,74,125322;(b )P.S.Alegaonkar,V.N.Bhoraskar,P.Balaya and P.S.Goyal,Appl.Phys.Lett.,2002,80,640.

24(a )N.Glezos,P.Argitis,D.Velessiotis and C.D.Diakoumakos,Appl.Phys.Lett.,2003,83,488;(b )A.Szymczyk,M.Sbai,P.Fievet and A.Vidonne,Langmuir ,2006,22,3910;(c )J.L.Movilla and J.Planelles,Phys.Rev.B ,2005,71,075319.

D o w n l o a d e d o n 30 J u l y 2011P u b l i s h e d o n 05 M a r c h 2007 o n h t t p ://p u b s .r s c .o r g | d o i :10.1039/B 618910E