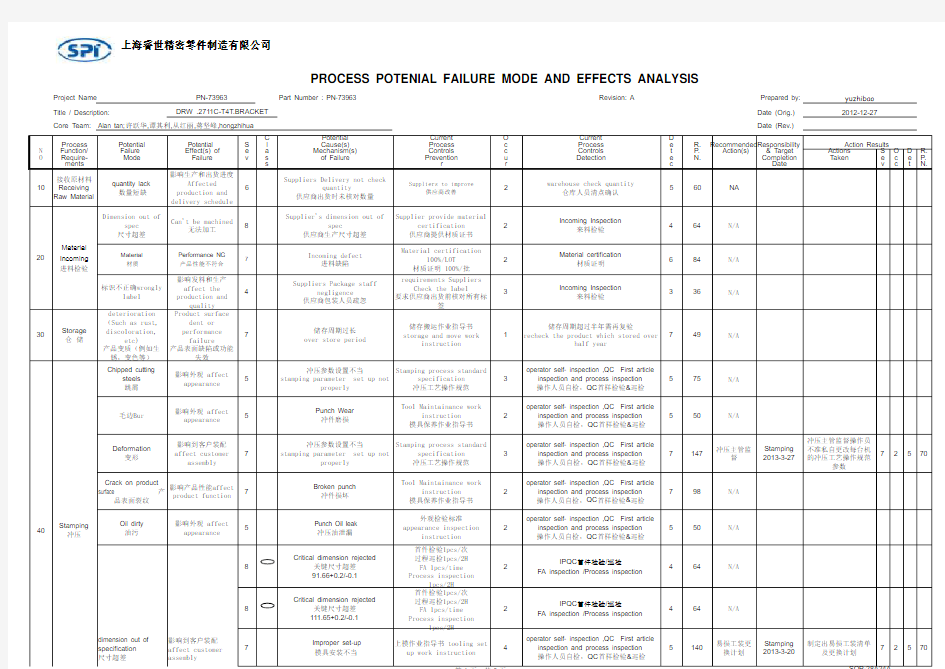

冲压_PFMEA中英文

PROCESS POTENIAL FAILURE MODE AND EFFECTS ANALYSIS

Project Name PN-73963

Part Number : PN-73963

Revision: A

Prepared by:yuzhibao Title / Description:

Date (Orig.)2012-12-27

Core Team:Alan tan;许跃华,谭其利,从红丽,蒋坚峰,hongzhihua Date (Rev.)

C Potential Current O Current

D Process Potential Potential S l Cause(s)Process c Process e R.RecommendedResponsibility Action Results N Function/Failure Effect(s) of e a Mechanism(s)Controls c Controls t P. Action(s)& Target

Actions S O D R.O

Require-Mode

Failure v

s of Failure

Prevention

u Detection

e N.

Completion Taken e c

e P.ments s

r

r c Date

v c

t N.

10

接收原材料Receiving Raw Material

quantity lack 数量短缺影响生产和出货进度

Affected production and delivery schedule 6

Suppliers Delivery not check

quantity

供应商出货时未核对数量Suppliers to improve

供应商改善

2

warehouse check quantity

仓库人员清点确认

5

60

NA

Dimension out of

spec 尺寸超差

Can't be machined

无法加工

8

Supplier's dimension out of

spec

供应商生产尺寸超差

Supplier provide material

certification 供应商提供材质证书2

Incoming Inspection

来料检验464N/A

Material 材质Performance NG 产品性能不符合

7Incoming defect

进料缺陷Material certification

100%/LOT

材质证明 100%/批2Material certification

材质证明684N/A

标识不正确wrongly

label 影响发料和生产affect the production and

quality

4Suppliers Package staff

negligence 供应商包装人员疏忽

requirements Suppliers

Check the label

要求供应商出货前核对所有标

签3Incoming Inspection

来料检验

336N/A

30

Storage 仓 储

deterioration (Such as rust,discoloration,

etc)

产品变质(例如生锈,变色等)Product surface

dent or performance failure

产品表面缺陷或功能

失效7

储存周期过长over store period

储存搬运作业指导书storage and move work

instruction

1

储存周期超过半年需再复验

recheck the product which stored over

half year

749N/A

Chipped cutting

steels 跳屑

影响外观 affect appearance

5

冲压参数设置不当stamping parameter set up not properly Stamping process standard

specification

冲压工艺操作规范

3

operator self- inspection ,QC First article

inspection and process inspection 操作人员自检,QC 首样检验&巡检575N/A

毛边Bur

影响外观 affect appearance 5Punch Wear 冲件磨损

Tool Maintainance work

instruction 模具保养作业指导书

2operator self- inspection ,QC First article

inspection and process inspection 操作人员自检,QC 首样检验&巡检550N/A

Deformation

变形

影响到客户装配affect customer

assembly

7

冲压参数设置不当stamping parameter set up not properly Stamping process standard

specification

冲压工艺操作规范

3operator self- inspection ,QC First article

inspection and process inspection 操作人员自检,QC 首样检验&巡检7147

冲压主管监

督Stamping 2013-3-27

冲压主管监督操作员不准私自更改每台机的冲压工艺操作规范

参数

72570

Crack on product

surface 产

品表面裂纹

影响产品性能affect

product function

7Broken punch 冲件损坏

Tool Maintainance work

instruction 模具保养作业指导书2operator self- inspection ,QC First article

inspection and process inspection 操作人员自检,QC 首样检验&巡检798N/A

Oil dirty 油污

影响外观 affect appearance

5

Punch Oil leak 冲压油泄漏

外观检验标准

appearance inspection

instruction 2operator self- inspection ,QC First article

inspection and process inspection 操作人员自检,QC 首样检验&巡检

550N/A

8

Critical dimension rejected

关键尺寸超差91.66+0.2/-0.1首件检验1pcs/次过程巡检1pcs/2H FA 1pcs/time Process inspection

1pcs/2H 2

IPQC 首件检验/巡检

FA inspection /Process inspection

464N/A

8Critical dimension rejected

关键尺寸超差111.65+0.2/-0.1

首件检验1pcs/次过程巡检1pcs/2H FA 1pcs/time Process inspection

1pcs/2H 2

IPQC 首件检验/巡检

FA inspection /Process inspection 464N/A

7

Improper set-up 模具安装不当

上模作业指导书 tooling set

up work instruction

4operator self- inspection ,QC First article

inspection and process inspection 操作人员自检,QC 首样检验&巡检

5140

易损工装更换计划Stamping 2013-3-20制定出易损工装清单

及更换计划

72570

DRW .2711C-T4T.BRACKET

20

40

影响到客户装配affect customer assembly

Material Incoming 进料检验

Stamping 冲压

dimension out of specification 尺寸超差上海睿世精密零件制造有限公司

C Potential Current O Current

D Process Potential Potential

S

l Cause(s)Process c Process e R.RecommendedResponsibility Action Results N Function/Failure Effect(s) of e a Mechanism(s)Controls c Controls t P. Action(s)& Target

Actions S O D R.O

Require-Mode Failure v

s of Failure Prevention

u Detection

e N.

Completion Taken e c

e P.ments

s

r

r c Date v c t N.affect customer assembly

out of specification 尺寸超差