AATCC 150-2003 服装经家庭洗涤后的尺寸稳定性

Developed in 1977 by AATCC Commit-tee RA42; editorially revised and reaf-firmed 1979, 1984, 1992; editorially revised 1983, 1985, 1989, 1990, 1991, 1996, 1997, 2004, 2005, 2006; revised 1987, 1995, 2001, 2003 (with title change); reaffirmed 2000. Related to ISO 3759.

1. Purpose and Scope

1.1 This test method is for the determi-nation of dimensional changes of gar-ments when subjected to home launder-ing procedures used by consumers. Four washing temperatures, three agitation cy-cles, two rinse temperatures and four dry-ing procedures cover the common home care options available to consumers using current laundering machines.

1.2 The dimensional changes of gar-ments subjected to home laundering care procedures are measured using bench-marks placed on designated areas of the garments. Measured dimensional changes may be affected by garment construction, tensions, sewing threads or trims in addi-tion to fabric dimensional change.

1.3 As an optional procedure, fabric dimensional changes may be determined by using benchmarks placed on the fabric in areas of the garment that contains no seams or sewing.

1.4 This method may not be applicable for garments made of certain stretch fabrics.

2. Principle

2.1 The dimensional changes of gar-ment specimens subjected to home laun-dering care procedures are measured us-ing benchmarks applied to the garment before laundering.als, a process intended to remove soils

and/or stains by treatment (washing) with

an aqueous detergent solution and nor-

mally including rinsing, extraction and

drying.

3.5 shrinkage, n.—a dimensional

change resulting in a decrease in the

length or width of a specimen.

4. Safety Precautions

NOTE: These safety precautions are

for information purposes only. The pre-

cautions are ancillary to the testing proce-

dures and are not intended to be all inclu-

sive. It is the user’s responsibility to use

safe and proper techniques in handling

materials in this test method. Manufac-

turers MUST be consulted for specific

details such as material safety data sheets

and other manufacturer’s recommenda-

tions. All OSHA standards and rules

must also be consulted and followed.

4.1 Good laboratory practices should

be followed. Wear safety glasses in all

laboratory areas.

4.2 The 1993 AATCC Standard Refer-

ence Detergent may cause irritation. Care

should be taken to prevent exposure to

skin and eyes.

4.3 Manufacturer’s safety recommen-

dations should be followed when operat-

ing laboratory testing equipment.

5. Apparatus and Materials

5.1Automatic washing machine (see

12.1).

5.2Automatic tumble dryer (see 12.2).

5.3Conditioning/drying racks with

pullout screens or perforated shelves (see

12.3).

5.4Facilities for drip drying and line

drying.

5.51993 AATCC Standard Reference

Detergent (see 12.8 and 12.9).

5.6Ballast of 920 × 920 ± 30 mm (36

5.9 Balance with at least 5.0 kg (10.0

lb) capacity.

6. Test Specimens

6.1 Sampling and Preparation.

6.1.1 Each garment will be considered

a specimen. Garments used as specimens

should be representative of the produc-

tion lot. When possible, three specimens

should be used. One or two specimens

may be used when insufficient garments

are available.

6.1.2 Garments that are distorted in

their unlaundered state due to faulty fab-

ric finishing, garment assembly, or pack-

ing may give deceptive dimensional

change results when laundered by any

procedure. In such cases, it is recom-

mended that a garment not be tested or, if

used, the results be considered as indica-

tive only.

6.1.3 Prior to marking, condition test

specimens as directed in ASTM D1776,

Standard Practice for Conditioning and

Testing Textiles. Condition each garment

for at least 4 h, in an atmosphere of 21 ±

1°C (70 ± 2°F) and 65 ± 2% RH by hang-

ing it on an appropriate hanger. If the gar-

ment would not normally be hung on a

hanger; i.e., t-shirts, boxer shorts, etc., lay

each test specimen separately on a screen

or perforated shelves of a conditioning

rack.

6.2 Marking.

6.2.1 Using Table I as a guide for the

selection of garment specimen areas to

use as measurement sites, place bench-

marks on the garment at the selected lo-

cations. Use at least three length and

three width locations for marking bench-

marks on each garment specimen. Loca-

tion of benchmarks should be as agreed

upon by the buyer and seller. If garment

areas are sufficient, place 460 mm (18

in.) benchmarks on the garment. Bench-

AATCC Test Method 150-2003

Dimensional Changes of Garments after Home Laundering

benchmark lengths may not be compara-ble.

6.2.4 Benchmark distances used should be indicated on the report.6.3 Original Measurements.

6.3.1 To improve the accuracy and pre-cision of the dimensional change calcula-tions based on the benchmarks applied to the garment in 6.2, measure and record the distance between each pair of bench-marks with suitable tape or rule to nearest millimeter or eighth or tenth of an inch.This is measurement A.

7. Test Procedure

7.1 Tables II, III and IV summarize al-ternative washing, rinsing and drying conditions and settings. Additional infor-mation on the machine and laundering conditions may be found in the mono-graph, Standardization of Home Laundry Test Conditions , elsewhere in this T ECH -NICAL M ANUAL .7.2 Washing.

7.2.1 Weigh garment test specimens and enough ballast to make a 1.8 ± 0.1 kg (4.00 ± 0.25 lb) load. An alternative load size of 3.6 ± 0.1 kg (8.00 ± 0.25 lb) may be used. Dimensional change results ob-tained using a 1.8 kg (4 lb) load weight may not be equal to those obtained with a 3.6 kg (8 lb) load weight and should not be compared.

7.2.2 Select the specified water level,the desired water temperature for the

washing cycle and a rinse temperature of less than 29°C (85°F). If this rinse tem-perature is not attainable, record available rinse temperature. Fill the washing ma-chine to the 18 ± 0.5 gal water level. For alternate load size, fill washing machine to the 22.0 ± 0.5 gal water level.

7.2.3 Add 66.0 ± 1 g of 1993 AATCC Standard Reference Detergent to an 18 ±0.5 gal wash load. For alternative load size of 22.0 ± 0.5 gal, add 80 ± 1 g of 1993 AATCC Standard Reference Deter-gent. Agitate water briefly to dissolve de-tergent. Stop the machine agitation. It should be noted that in soft water areas,the amount of detergent used may be re-duced to avoid excessive sudsing.

7.2.4 Add garment test specimens and ballast to machine. Set the washer for the selected washing cycle and time (see Ta-bles II and III).

7.2.5 For garment specimens to be dried by procedures A, B or D, allow washing to proceed through the final spin cycle. Remove the garment specimens immediately after the final spin cycle,separate tangled garments, taking care to minimize distortion, and dry by proce-dure A, B or D (see Tables II and IV).7.2.6 For garment specimens to be dried by procedure C, Drip Dry, allow washing to proceed through to the final rinse cycle. Remove the specimens from the washer just before the water begins to drain for the final rinse cycle. Remove specimens soaking wet.

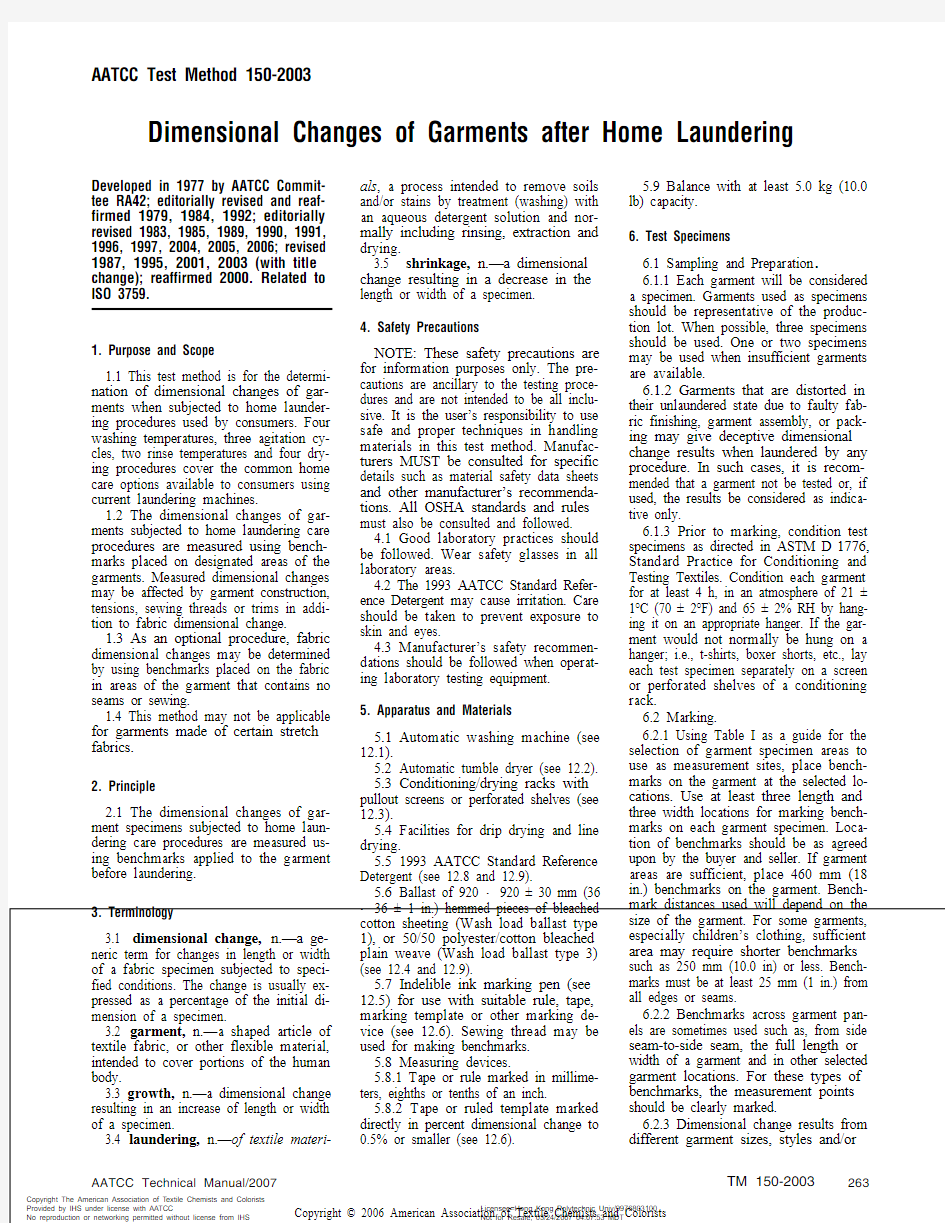

Table II—Alternative Washing and Drying Conditions (see 7.1)

Machine Cycle Washing Temperatures Drying Procedures (1) Normal/Cotton Sturdy (II) 27 ± 3°C (80 ± 5°F)(A) Tumble:

(2) Delicate

(III) 41 ± 3°C (105 ± 5°F)i. Cotton Sturdy (3) Permanent Press

(IV) 49 ± 3°C (120 ± 5°F)ii. Delicate

(V) 60 ± 3°C (140 ± 5°F)

iii. Permanent Press (B) Line (C) Drip (D) Screen

Table III—Washing Machine Setting Conditions Without Load (see 7.1)

Table I—Examples of Bench Mark Locations

Type of Garment

Bench Mark Locations

Shirt

Collar

Collar Band Body Lengths Sleeve Lengths Width at Chest Cuffs Trousers

Front Rise Back Rise Inseams Outseams Waist Seat

Coveralls

Body Lengths Front Rise Back Rise Inseams

Underarm Lengths Sleeve Lengths Shoulder Waist Chest Seat Width Boxer Shorts

Overall Lengths Front Rise Back Rise Waist Pajama Top

Lengths Sleeves Hem Chest Pajama Bottom

Inseams Lengths Hip Waist Shorts

Lengths Front Rise Back Rise Leg Width Inseam Width Seat Width Waist Sweater

Lengths

Sleeve Lengths Chest Waist Shoulders Slip

Lengths Hem Waist Hip Blouse

Lengths

Sleeve Lengths Shoulders Chest Waist Skirt

Lengths

7.3 Drying.

7.3.1 For drying procedures B, C and

D do not blow air directly on specimens as it may cause fabric distortion within the garment.

7.3.2 (A) Tumble Dry. Place the washed load (garment test specimens and ballast) in the tumble dryer, and set the temperature control to generate the cor-rect exhaust temperatures as specified in Table IV. For fibers that are heat sensi-tive, lower temperatures consistent with producer’s care recommendations should be used and reported. Allow the dryer to operate until the total load is dry. Remove the load immediately after the dryer stops.

7.3.3 (B) Line Dry. Hang each garment on an appropriate hanger, straightening and smoothing facings, seams, etc. Allow the garment to hang in still air at room temperature, not greater than 26°C (78°F) until dry.

7.3.4 (C) Drip Dry. Hang each dripping garment on an appropriate hanger, straightening and smoothing facings, seams, etc. Allow the specimens to hang in still air at room temperature, not greater than 26°C (78°F) until dry.

7.3.5 (D) Screen Dry. Spread each gar-ment on a horizontal screen or perforated surface removing wrinkles without dis-torting or stretching it. Allow the speci-men to dry in still air at room tempera-ture, not greater than 26°C (78°F).

7.3.6 Repeat the selected washing and drying cycle two more times or to an agreed number of cycles.

7.4 Conditioning and Restoration.

7.4.1 After the last washing and drying cycle, garments must be conditioned be-fore being remeasured. All garments need to be completely dry before they are conditioned. Condition garments (see 6.1.3) for at least 4 h by hanging each completely dry garment on a hanger or by laying each completely dry garment sepa-rately on a screen or perforated shelf of a conditioning rack in an atmosphere at 21± 1°C (70 ± 2°F) and 65 ± 2% RH.

7.4.2 For garments that are intended to be used as a form fitting garment, a resto-ration technique is sometimes used prior ric being ironed. See Table I, Safe Ironing

Temperature Guide, in AATCC Method

133, Colorfastness to Heat: Hot Pressing.

Exert only that pressure during pressing

which is necessary to remove wrinkles.

7.4.3.1 Due to the extremely high vari-

ability of hand ironing procedures per-

formed by individual operators (no stan-

dard test method exists for hand ironing

procedures), the reproducibility of di-

mensional change results after hand iron-

ing has been found to be extremely poor.

Consequently, caution is advised when

comparing dimensional change results af-

ter laundering and hand ironing, reported

by different operators.

7.4.3.2 Hand ironing, is intended pri-

marily for the evaluation of fabrics used

in garments, which require ironing to re-

move wrinkles prior to wearing. Use safe

ironing temperatures appropriate to the

fibers in the fabric being ironed. See Ta-

ble I, Safe Ironing Temperature Guide, in

AATCC Method 133, Colorfastness to

Heat: Hot Pressing. Exert only that pres-

sure during pressing which is necessary

to remove wrinkles.

7.4.3.3 After ironing, condition gar-

ments for at least 4 h (see 6.1.3) by hang-

ing each garment on a hanger or by lay-

ing each specimen separately on the

screen or perforated shelf of a condition-

ing rack in an atmosphere at 21 ± 1°C (70

± 2°F) and 65 ± 2% RH.

8. Measurement

8.1 After conditioning, lay each gar-

ment without tension on a flat smooth,

horizontal surface. Measure and record

the distance between benchmarks or be-

tween marks made across garment panels

such as, from side seam-to-side seam, the

full length or width of a garment and

other selected garment locations, to the

nearest millimeter, or eighth or tenth of

an inch. This is measurement B. Or, if us-

ing a scale calibrated in percent dimen-

sional change, measure to nearest 0.5%

or smallest increment on the scale and

record the percent dimensional change

directly.

where:

DC=Dimensional change

A=Original dimension

B=Dimension after laundering

Average the dimensional change for

each measurement location made on all

test garments. If desired, calculate length

and width averages separately to nearest

0.1% (12.7).

9.1.3 A final measurement smaller

than the original measurement results in a

negative dimensional change which is

shrinkage. A final measurement larger

than the original measurement results in a

positive dimensional change which is

growth.

9.2 Interpretation.

9.2.1 If the dimensional change after

one washing and drying cycle as calcu-

lated in 9.1, is within a specification pre-

viously agreed on, continue test proce-

dure as directed in 7.2, 7.3 and 7.4 until

an agreed upon number of cycles has

been completed.

9.2.2 If the dimensional change after

one washing, drying, and, if used, hand

ironing cycle as calculated in 9.1 exceeds

a specification previously agreed on, ter-

minate the test.

10. Report

10.1 Report for each sample test:

(a) Dimensional change, length and

width for each garment locations (i.e.

body length, sleeve length, body width,

collar width) to the nearest 0.1% with a

minus sign (-) for shrinkage or a plus (+)

sign for growth (see 9.1.3).

(b) Washing procedure (include type of

washing, cycle and temperature) and dry-

ing procedure (include type of drying, cy-

cle and temperature).

(c) Size of load; i.e., 1.8 kg (4 lb) or 3.6

kg (8 lb).

(d) Number of complete washing and

drying cycles (see 9.2.1).

(d) If garments are distorted in unlaun-

dered state.

(e) If garments were hand ironed.

(f) If garments were restored and a res-

toration technique.

12. Notes

12.1 Contact AATCC, P.O. Box 12215, Re-search Triangle Park NC 27709; tel: 919/ 549-8141; fax: 919/549-8933; e-mail: or-ders@https://www.360docs.net/doc/2d10127071.html,, for model number(s) and source(s) of current approved washer(s). Any other washer, which is known to give compa-rable results, can be used. Washing machine conditions given in Table III represent the ac-tual speeds and times available on the current specified model(s). Other washers may vary in one or more of these settings.

12.2 Contact AATCC, P.O. Box 12215, Re-search Triangle Park NC 27709; tel: 919/ 549-8141; fax: 919/549-8933; e-mail: or-ders@https://www.360docs.net/doc/2d10127071.html,, for model number(s) and source(s) of current approved dryer(s). Any other dryer which is known to give compara-ble results can be used. Dryer machine condi-tions given in Table IV represent the actual temperatures and cool-down times available on the current specified model(s). The dryers may vary in one or more of these settings. 12.3 Screen or perforated conditioning/dry-ing racks available from Somers Sheet Metal Inc., 5590 N. Church St., Greensboro NC 27405; tel: 336/643-3477; fax: 336/643-7443. Rack drawings available from AATCC, P.O.Box 12215, Research Triangle Park NC

27709; tel: 919/549-8141; fax: 919/549-8933;

e-mail: orders@ https://www.360docs.net/doc/2d10127071.html,.

12.4 Ballast are available from Testfabrics

Inc., P.O. Box 26, 415 Delaware St., W.

Pittston PA 18643; tel: 570/603-0432; fax:

570/603-0433; and Textile Innovators Corp.,

div. of SDL Atlas L.L.C., P.O. Box 8, 101

Forest St., Windsor NC; tel: 252/794-9703;

fax: 252/794-9704; e-mail: tic@https://www.360docs.net/doc/2d10127071.html,.

12.5 Marking pens with different size tips

are available from Mark-Tex Corp., Box 681,

Englewood NJ 07631; and AATCC, P.O. Box

12215, Research Triangle Park NC 27709;

tel:919/549-8141; fax: 919/549-8933; e-mail:

orders@https://www.360docs.net/doc/2d10127071.html,.

12.6 A ruled template marked in percent di-

mensional change is available from AATCC,

P.O. Box 12215, Research Triangle Park NC

27709; tel: 919/549-8141; fax: 919/549-8933;

e-mail: orders@https://www.360docs.net/doc/2d10127071.html,. A mechanical

marking device and measuring tape marked

in percent dimensional change is available

from Benchmark Devices Inc., 3305 Eques-

trian Trail, Marietta GA 30064; tel: 770/795-

0042; fax: 770/421-8401; e-mail: bmarkers@

https://www.360docs.net/doc/2d10127071.html,.

12.7 If information on the dimensional

change variability between specimens is

needed, calculate dimensional change based

on the individual pairs of benchmarks.

12.8 Available from AATCC, P.O. Box

12215, Research Triangle Park NC 27709;

tel:919/549-8141; fax: 919/549-8933; e-mail:

orders@https://www.360docs.net/doc/2d10127071.html,.

12.9 The AATCC Technical Center con-

ducted a study to compare the 1993 AATCC

Standard Reference Detergent, AATCC Stan-

dard Reference Detergent 124 and two differ-

ent types of fabrics (current and proposed) to

be used as ballast, under the following test

conditions:

Machine cycle:(1)—Normal/Cotton

Sturdy

Washing Temp:(V)—60 ± 3°C (140 ± 5°F)

Drying Procedure:(A)i—Tumble dry, cotton

sturdy cycle

Fabrics tested:White Twill (100% cotton)

Beige Twill (100% cotton)

Grey Poplin (100% cotton)

Blue Twill (50/50 poly/

cotton)

No significant differences were found in the

results using either detergent or ballast load

fabrics.

服装尺寸术语中英对照

服装尺寸表(中英文对照)服装尺寸表(中英文对照) 一些不是很常用的词汇 HEM EDGE 拖曳部分(具体视衣服的设计图-在底部下摆边缘FRONT YOKE HEIGHT FROM HPS 前约克长-从肩顶量起 ACROSS BACK-PLACEMENT FRM HPS 后胸宽-在肩膀处量 ACROSS FRONT-PLACEMENT FRM HPS 前胸宽-在肩膀处量 COLLAR LENGTH AT NECK SEAM 领高-后颈缝量 FRONT POCKET WIDTH-AT TOP EDGE 前口袋宽-在最顶部 FRONT POCKET OPENING ALONG THE EDGE 前口袋边缘的开口 FRONT POCKET FROM HPS TO POCKET EDGE 前口袋从衣肩顶点到口袋边 FRONT POCKET FRM CTR FRT 前口袋拉链xx

FRONT POCKET HEIGHT @ OUTER SIDE 前口袋外侧高 COVER PLACKET WIDTH 口袋盖片宽 ARMHOLE DROP-FRM HPS 袖长-从肩顶量起 LENGTH-HPS TO HEM xx-肩顶至下摆 Bottoms下装 back rise后直裆长,[粤]后浪长 back yoke height后约克高,[粤]后机头高 fly length(裤)门襟长,[粤]钮牌长 fly width(裤)门襟宽,[粤]钮牌宽 front rise前直裆长,[粤]前浪长 high hipxx臀围,xx坐围 hip,hip width臀围,坐围 inseam length内长 knee膝围 leg opening裤脚围 side seam,outseam length外长,[粤]侧骨长sweep(裙)下摆,[粤](裙)脚围

服装术语中英文对照

服装术语中英文对照24L BUTTON 24号钮 6 FEED PIQUE 6模珠地 以A开头的常用服装外贸术语: ACCESSORY 辅料 BACK ACROSS 后背宽 ACROSS MEASURE 横量 ACRYLIC 腈纶 ADHESIVE / FUSIBLE INTERLINING 粘衬 ANTIQUE BRASS COA TING 镀青古铜 ANTISTA TIC FINISH 防静电处理 APPAREL 成衣 APPEALING LOOK 吸引人的外表 APPROV AL SAMPLE 批办 APPROVED SAMPLE WITH SIGNING NAME 签名批办 ARMHOLE 夹圈 ASSEMBLING OF FRONT & BACK PART 前后幅合并 ASSEMBLING SECTION 合并部分 ATTACH COLLAR 上领 ATTACH LABEL 上商标 ATTACHMENT (车缝)附件 以B开头的常用服装外贸术语

BACK COVER FRONT 后搭前 BACK MID-ARMHOLE 后背宽 BACK STITCH 返针,回针BACKLESS DRESS 露背装 BAR CODED STICKER 条形码贴纸BARGAINING 讨价还价 BAR-TACK 打枣 BASTE 假缝 BA TILK 蜡染 BEARER 袋衬 BEARER & FACING 袋衬袋贴BEDFORD CORD. 坑纹布,经条灯心绒BELL BOTTOM 喇叭裤脚 BELLOWS POCKET 风琴袋 BELT 腰带 BELT-LOOP 裤耳 BIAS CUT 斜纹裁,纵纹裁BIFURCATE 分* BINDER 包边蝴蝶,滚边蝴蝶BINDING 包边 BINDING OF SLV. OPENING R折BINDING OF TOP VENT 面*包边

衣服尺寸对照表

衣服尺寸对照表 女款上装 上衣S M L XL XXL XXXL 服装384042444648胸围(cm)78-8182-8586-8990-9394-9798-102腰围(cm)62-6667-7071-7475-7980-8485-89 肩宽(cm)363840424446适合身高(cm)153/157158/162163/167168/172173/177177/180, 女裤 尺码24 26 27 28 29 30 31 对应臀围(市 2尺4 2尺6 2尺7 2尺8 2尺9 3尺3尺1 尺) 对应臀围 80 87 90 93 97 100 103 (cm) 对应腰围(市 1尺8 1尺9 2尺2尺1 2尺2 2尺3 2尺4 尺) 对应腰围 59 63 67 70 74 78 82 (cm) 女式背心 尺码S M L XL 3XL

胸围72-80 79-87 86-94 94-97 98-102 腰围58-64 64-70 69-77 77-85 85-93 臀围82-90 87-95 92-100 97-105 102-110 女式内裤 尺码S M L XL 3XL 型号150-155 155-160 160-165 165-170 170-175 腰围55-61 61-67 67-73 73-79 79-85 臀围80-86 85-93 90-98 95-103 100-108 女式泳装 尺码XS/32 S/34 M/36 L/38 XL/40 腰围63-70 70-76 80-86 86-93 93-100 女鞋 光脚长度 22.0 22.5 23.0 23.5 24.0 24.5 25.0 (cm) 鞋码(中国) 34码35码36码37码38码39码40码 鞋码(美国) 4.5 5 5.5 6 6.5 7 7.5 鞋码(英国) 3.5 4 4.5 5 5.5 6 6.5 女裙 尺码24 26 27 28 29 30 31 对应臀围 2尺4 2尺6 2尺7 2尺8 2尺9 3尺3尺1 (市尺)

中英文服装尺码表

服装尺寸表(中英文对照) 一些不是很常用的词汇 HEM EDGE 拖曳部分(具体视衣服的设计图-在底部下摆边缘FRONT YOKE HEIGHT FROM HPS 前约克长-从肩顶量起 ACROSS BACK-PLACEMENT FRM HPS 后胸宽-在肩膀处量 ACROSS FRONT-PLACEMENT FRM HPS 前胸宽-在肩膀处量 COLLAR LENGTH AT NECK SEAM 领高-后颈缝量 FRONT POCKET WIDTH-AT TOP EDGE 前口袋宽-在最顶部 FRONT POCKET OPENING ALONG THE EDGE 前口袋边缘的开口 FRONT POCKET FROM HPS TO POCKET EDGE 前口袋从衣肩顶点到口袋边 FRONT POCKET FRM CTR FRT 前口袋拉链长度 FRONT POCKET HEIGHT @ OUTER SIDE 前口袋外侧高 COVER PLACKET WIDTH 口袋盖片宽 ARMHOLE DROP-FRM HPS 袖长-从肩顶量起 LENGTH-HPS TO HEM 长度-肩顶至下摆 Bottoms 下装 back rise 后直裆长,[粤]后浪长 back yoke height 后约克高,[粤]后机头高 fly length (裤)门襟长,[粤]钮牌长 fly width (裤)门襟宽,[粤]钮牌宽 front rise 前直裆长,[粤]前浪长 high hip 上臀围,上坐围 hip,hip width 臀围,坐围 inseam length 内长 knee 膝围 leg opening 裤脚围

服装各部位的英文术语

样板SAMPLE 布封幅宽FABRIC WIDTH 侧骨侧缝,摆缝SIDE SEAM 插竹领插角片COLLAR STAY 车花绣花EMBROIDERY 打枣打结BARTACK 担干过肩YOKE 耳仔裤带袢BELTLOOP 返针回针BACK STITCH 狗牙车牙FEED DOG 挂卡吊牌HANGTAG 后浪后档BACK RISE 蝴蝶车缝附件SEWING MACHINE ATTACHMENTS 及骨锁边OVERLOCK 及骨车包缝机,锁边机OVERLOCK MACHINE 急钮四合扣SNAP FASTENER

夹圈袖窿ARMHOLE 间棉绗缝QUILT 肩棉肩垫,垫肩膊头棉SHOULDER PAD 介英,鸡英袖口,袖级CUFF 拉冚车绷缝机COVERING STITCH MACHINE 拉裤头上裤头WAISTBANDING 拉筒车门襟机PLACKET MACHINE 辘脚车脚口卷边机BOTTOM HEMMING MACHINE 唛架排料图MAKER 唛头商标LABEL 埋夹缝合袖底骨和侧缝JOIN THE UNDER ARM SEAM AND SIDE SEAM 魔术贴尼龙搭扣VELCRO 纳膊缝合小肩JOIN THE SMALL SHOULDER 纳膊位肩缝SHOULDER SEAM 钮门扣眼BUTTON HOLE 钮牌门袢FLY

钮子钮门搭位BUTTON STAND 排唛排料LAYOUT 啤机冲压裁剪机DIE CUTTING MACHINE 脾围横档THIGH 平车平缝机NORMAL SEWING MACHINE 朴衬布INTERLINING 前浪前档FRONT RISE 生褶省PLEAT 死褶褶DART 梭仔梭芯BOBBIN 烫斗熨斗IRON 挑脚车暗缝机BLIND STITCHING MACHINE 乌蝇扣钩棒扣EYES & HOOKS 靴压脚PRESSER FOOT 针步线步STITCHES 止口,子口缝头SEAM ALLOWANCE

服装专业术语中英文对照

少年易学老难成,一寸光阴不可轻。 服装专业术语中英文对照 购衣点吧 目录 一、成品上装术语 (1) 二、成品裙子术语 (2) 三、成品裤子术语 (3) 四、成品全身装术语 (3) 五、领子的造型名称 (4) 六、口袋的造型名称 (5) 七、小部件造型名称 (5) 八、上装前身的部位名称 (6) 九、上装后身的部位名称 (6) 十、服装袖子术语 (7) 十一、服装标准术语 (7) 十二、下装的部位名称 (8) 十三、包装物料、车缝物料 (9) 十四、辅料 (9) 十五、颜色 (10) 十六、纺织品与服装测试项目 (12) 十七、洗涤 (15) 十八、样板 (15) 一、成品上装术语 〔西服Western-style clothes〕又称西装,即西式上衣的一种形式。按钉纽扣的左右排数 不同,可分为单排扣西服和双排扣西服;按照上下粒数的不同,分为一粒扣西服、两粒扣西 服、三粒扣西服等。粒数与排数可以有不同的组合,如单排两粒扣西服、双排三粒扣西服等; 按照驳头造型的不同,可分为平驳头西服、枪驳头西服、青果领西服等。西服已成为国际通 行的男士礼服。 〔背心Vest〕也称为马甲或坎肩,是一种无领无袖,且较短的上衣。主要功能是使前后 胸区域保温并便于双手活动。它可以穿在外衣之内,也可以穿在内衣外面。主要品种有各种 造型的西服背心、棉背心、羽绒背心及毛线背心等。 〔牛仔服Cowboy's Clothes〕原为美国人在开发西部、黄金热时期所穿着的一种用帆布 制作的上衣。后通过影视宣传及名人效应,发展成为日常生活穿用的服装。1970 年代曾风靡全世界,现已成为全球性的定型服装。其面料多用坚固呢制作,款式已发展到牛仔茄克、牛 仔裤、牛仔衬衫、牛仔背心、牛仔马甲裙、牛仔童装等各种款式。牛仔服以其坚固耐用、休 闲粗犷等特点深受各国人民喜爱,虽然它的整体风格相对模式化,但其细部造型及装饰则伴 随着流行时装的周期与节奏,不断演绎和变化。 〔中山服Zhongshan coat〕又称中山装。根据孙中山先生曾穿着的款式命名。主要特点 是立领、前身四个明贴袋,款式造型朴实而干练。 〔军便服〕仿军服式样的上衣。

服装各部位基本尺寸测量中英文表示法

上衣的尺寸: 一,身长(Body Length) 1,一般上衣的衣长: (1)从后领中量至下摆(From CB Neck to bottom edge of hem)。 (2)从肩高点量至下摆(From HPS to bottom edge of hem)。 2,特殊上衣的衣长: (1)后长(Back Length): 在大多数情况下,是记作:后中量(from CB),在服装的后身,量取后领中至下摆的距离。 但是也有可能要求其他的测量位置线,例如肩高点量(from HPS)。 (2)前长(Front Length): 在大多数情况下,是记作:肩高点量(from HPS),在服装的前身,量取肩高点至下摆的距离。 但是也有可能要求其他的测量位置线,例如从前领中量(from C. F. Neck)。 二,胸围(Chest Width) 在大多数情况下,测量位置点是在袖笼下1英寸,从一侧的侧缝水平地量到另一侧,在客户的尺寸表上记作:at 1”below the AH。 三,腰围(Waist Width) 1,上衣腰围:一般在客户的尺寸表上会注明一个测量位置点,指出是在肩高点下多少距离测量,记作“X”down from HPS。2,下装腰围:下装,如裙、裤。测量时只需测量下装的腰头开口长度即可。 如果是带有橡筋的裙或者裤,其腰围测量就有松量尺寸(relaxed)和拉量尺寸(extended)之分。 四,下摆围(Bottom Width) 从下摆的一侧量到另一侧。如果下摆是带有橡筋,则需要分别测量松量尺寸(relaxed)和拉量尺寸(extended)。五,下摆罗纹宽(Rib/ Bottom Hem Height) 从下摆罗纹起头的一侧量到下摆罗纹结束处。 六,肩宽(Cross Shoulder) 从一侧与袖窿接缝的肩点量到另一侧的对应肩点。 另一种肩宽的测量为单肩宽(Side Shoulder)。 七,前胸宽(Cross Front) 在大多数情况下,客户的尺寸表上会注明一个测量位置点,指出是在肩高点下多少距离测量,记作“X”down from HPS。测量是按照此位置点,从一侧袖窿缝水平地量到另一侧。 八,后背宽(Cross Back) 与测量前胸宽类似。 九,袖窿、挂肩(Armhole)、(AH) 袖窿的测量有两种方法: 1,一是沿着袖窿缝的曲线进行测量,尺寸表上会记作(Along the Curve)。 2,另一是在袖窿缝的上下两点作直线测量,尺寸表上会记作(Straight)。 还有一种斜袖(Raglan)的款式,其袖窿的测量法基本上也是沿着袖窿缝的曲线进行测量的。 十,袖长(Sleeve Length) 袖长的测量方法有三种,在客户的尺寸表上一般会提示测量的方法。 1,从肩点测量(from the shoulder point)。 2,从肩高点测量(from the HPS)。 3,从后中量(from the C. B.)。 十一,袖宽、臂围或袖肥(Muscle) 使尺平行与袖罗纹或袖克夫,并在袖笼下1英寸处测量,其测量位置线记作:(from 1”below the armhole)。 十二,下臂围(Lower Sleeve Width)

中英服装尺寸对照表

服装缝纫专用术语(中日英) 尺寸表サイズ表 measurement 身长身长body length 前身长前丈 front body length 后身长後丈back length 上围,胸围胸囲(バスト)bust (chest) 胸宽前身巾bust width 肩宽背肩巾shoulder width 背宽背巾back width 袖长袖丈Sleeve length 总袖长裄丈Neck to sleeve 袖宽袖巾Sleeve width

袖笼,袖根围アーム.ホールArm hole 插肩袖长ラグランスリーブ丈raglan sleeve length 袖口罗纹宽袖口リブ巾cuffs rib width 袖口罗纹长袖口リブ丈cuffs rib length 袖口宽袖口巾.カフス巾cuffs width ,sleeve hem width 袖口长カフス巾cuffs length 后领宽天巾(ニット)back neck width 前领深前衿下がりfront neck depth 后领深後衿下がりback neck depth 后领宽(高)衿巾(後)collar height 外领宽上衿巾collar width

领下盘宽下领宽台衿巾under collar width 门襟宽前立て巾front placket width 下摆下围宽hem width 下摆罗纹宽裾リブ巾hem rib width 下摆罗纹长裾リブ丈hem rib length 衣袋(位置)ポケット(位置)pocket (position) 衣袋宽.长ポケット巾. 丈pocket width 腰围ウエストwaist size 腰围松紧带宽长ウエストゴム巾.丈elastic belt width. length 臀围ヒップhip size 上臀围中ヒップhigh hip size

中英文服装尺码表

服装尺寸表(中英文对照) 一些不就是很常用得词汇 HEM EDGE 拖曳部分(具体视衣服得设计图在底部下摆边缘FRONT YOKE HEIGHT FROM HPS 前约克长从肩顶量起 ACROSS BACKPLACEMENT FRM HPS 后胸宽在肩膀处量 ACROSS FRONTPLACEMENT FRM HPS 前胸宽在肩膀处量 COLLAR LENGTH AT NECK SEAM 领高后颈缝量 FRONT POCKET WIDTHAT TOP EDGE 前口袋宽在最顶部 FRONT POCKET OPENING ALONG THE EDGE 前口袋边缘得开口 FRONT POCKET FROM HPS TO POCKET EDGE 前口袋从衣肩顶点到口袋边 FRONT POCKET FRM CTR FRT 前口袋拉链长度 FRONT POCKET HEIGHT OUTER SIDE 前口袋外侧高 COVER PLACKET WIDTH 口袋盖片宽 ARMHOLE DROPFRM HPS 袖长从肩顶量起 LENGTHHPS TO HEM 长度肩顶至下摆 Bottoms 下装 back rise 后直裆长,[粤]后浪长 back yoke height 后约克高,[粤]后机头高 fly length (裤)门襟长,[粤]钮牌长 fly width (裤)门襟宽,[粤]钮牌宽 front rise 前直裆长,[粤]前浪长 high hip 上臀围,上坐围 hip,hip width 臀围,坐围 inseam length 内长 knee 膝围 leg opening 裤脚围

服装尺寸中英对照

服装尺寸中英对照

FRONT LENGTH FROM HPS 前衣长,肩点量 SHOULDER SLOPE 肩斜 ACROSS SHOULDER SEAM TO SEAM 肩宽,骨位至骨位缝到缝 ACROSS FRONT 6" DOWN FROM HPS 前胸宽,肩点下6" ACROSS BACK 6" DOWN FROM HPS 后背宽,肩点下6" CHEST 1" BELOW UNDERARM(夹下) 胸宽,袖夹底下1" WAIST 16 1/2" FROM HPS 腰围,肩点下16 1/2" SWEEP STRAIGHT 弧形脚宽,直量 SWEEP HEM HEIGHT 车脚高 ARMHOLE CIRCUMFERENCE (夹圈) 袖笼,沿一周弯量袖笼周长 ARMHOLE DROP (RAGLAN SLEEVE) 袖笼,(套袖衣袖)(插肩袖) BICEP/MUSCLE 1" STRAIGHT FM UNDERARM 袖肥,袖夹底下1" SLEEVE OPENING - SHORT SLEEVE 袖口宽- 短袖 SHORT SLEEVE LENGTH FROM CB NECK SEAM-3 PTS 短袖袖长,从后中领窝缝3点量 ELBOW WIDTH 11" ABOVE CUFF OPENING ( HALF ) 袖肘宽,(克夫)袖口开口上11" SLEEVE OPENING - LONG SLEEVE 袖口宽- 长袖 LONG SLEEVE LENGTH FROM CB NECK SEAM-3 PTS 长袖袖长,从后中领窝骨位3点量 SLEEVE CUFFS HEIGHT 袖克夫高 SLEEVE PLACKET LENGTH EXCL CUFF 袖叉长不包含袖袖口 SLEEVE PLACKET WIDTH 袖叉宽 NECK WIDTH SEAM TO SEAM 领宽,骨位至骨位 FRONT NECK DROP FROM HPS TO SEAM 前领深,肩点至骨位

服装面料中英文对照表

C:Cotton 棉 W:Wool 羊毛 M:Mohair 马海毛 RH:Rabbit hair 兔毛 AL:Alpaca 羊驼毛 S:Silk真丝 J:Jute 黄麻 L:linen 亚麻 Ts:Tussah silk 柞蚕丝 YH:Yark hair 牦牛毛 Ly:lycra莱卡 Ram:Ramine 苎麻 Hem:Hemp 大麻 T:Polyester 涤纶 WS:Cashmere 羊绒 N:Nylon 锦纶(尼龙) A:Acrylic 腈纶 Tel:Tencel 天丝,是Lyocell莱赛尔纤维的商品名 La:Lambswool 羊羔毛 Md:Model 莫代尔 CH:Camel hair 驼毛 CVC:chief value of cotton涤棉倒比(涤含量低于60%以下)Ms:Mulberry silk 桑蚕丝 R:Rayon 粘胶

Fibers,Yarn | 纖維,紗 ?C=Cotton | 棉 ?L=Linen | 亞麻 ?W=Wool | 羊毛 ?S=Silk | 蠶絲 ?N=Nylon, Polya mid | 尼龍,錦綸 ?T=Polyester | 聚酯,滌綸 ?R=Rayon | 人造棉,人造絲?A=Acrylic | 人造毛,亞克力紗?Viscose | 人造絲,粘膠纖維?OP=Spandex | 彈性纖維,氨綸 ?Lycra | 萊卡(杜邦彈性紗) ?Tactel | 特達(杜邦彈性紗) ?Spun | 短纖(捻成絲狀) ?Filament | 長纖,絲 ?Micro fiber | 超細纖維 ?Tencel | 天絲棉 ?Recycled fibers | 環保纖維?Metallic yarn | 金屬紗 ?Sea lands cotton | 海島棉?Carbon Fibers | 碳纖維 Dyeing | 染色整理 ?Grey inspecting | 胚檢 ?Singeing | 燒毛 ?Desizing | 退漿 ?Scouring | 精鍊 ?Bleaching | 漂白 ?Mercerizing | 絲光 ?Setting | 定型 ?Exhaustion | 浸染 ?Padding | 軋染 ?Cold batch | 冷捲固色 ?Drying | 烘乾 ?Steaming | 汽蒸(固色) ?Chem pad | 化學浸軋(固色) ?Thermofixation | 烘乾固色?Baking | 熱焙固色 ?Oxidizing | 氧化顯色 ?Reduction | 還原洗 ?Soaping & Rinsing | 皂洗?Resin finishing | 樹脂加工?Curing | 烘焙 ?Calendering | 軋光 ?Sanforizing | 預縮 ?Finished inspection | 成檢?Packing | 包裝 Fabric Finishing | 布料加工?Printing | 印花 ?Flocking | 植絨Knitted Fabrics | 針織布料 ?Jersey | 單面平紋緯編布 ?Rib | 羅(菱)紋布 ?Single Jersey | 單面針織布?Double Jersey | 雙面針織布?Interlock | 雙羅紋組織,棉毛布 ?Jacquard Knit | 提花針織布?Pique | 凹凸組織織物 ?Warp knitted fabrics | 經編針織布 ?Weft knitted fabrics | 緯編針織布 ?Flat Knit | 橫編針織 ?Terry | 毛巾布,毛圈織物 ?Fleece | 抓毛布,起絨布 ?Terry fleece | 單面刷毛布 ?Polar fleece | 雙面刷毛布 ?Anti-pilling polar fleece | 搖粒絨布 ?Looped Pile, Pile Knit | 毛圈織物 ?Cut pile | 剪毛織物 ?Plush, Long pile | 長毛絨 ?Fur | 仿毛布 ?Plain knitting | 平紋針織布?Mesh fabric | 網眼織物 ?Lace | 蕾絲 ?Tricot | 特利可得經編布 ?Tricot jersey | 經編平紋布?Velour/Velvet | 絲絨/天鵝絨?Waffle pique | 蜂巢紋凹凸織物 Woven Fabrics | 梭織布料 ?Plain | 平紋 ?Twill | 斜紋 ?Satin | 經向緞紋布 ?Sateen | 緯向緞紋布 ?Pongee | 繭綢,府綢 ?Poplin | 細薄平紋梭織布,府綢?Rayon flocking | 人棉植絨布?Metallic woven fabric | 金蔥布 ?Bengaline | 羅緞,水兵布 ?Canvas | 帆布 ?Chambray | 有條紋格子的布?Check | 格子布 ?Corduroy | 燈芯絨 ?Crinkle | 皺皺布 ?Denim, Jean | 牛仔布 ?Flannel | 法蘭絨布 Functions | 功能性 ?Anti-Bacterial | 抗菌 ?Anti-Static | 抗靜電 ?Anti-fungus | 防霉 ?Breathable and waterproof | 透濕防水 ?Electromagnetic shielding | 防電磁波 ?Far infrared | 遠紅外線 ?Flame resistant | 防(火)焰?Flam retardant | 阻燃 ?Moisture absorbing & quick drying | 吸濕速乾 ?Oil repellency | 潑油 ?Soil release | 防油污 ?Sun protective | 抗紫外線?Water repellency | 潑水 ?Wrinkle free | 防皺 ?Wash and wear | 免燙 Inspection | 檢驗 ?Washing shrinkage | 水洗縮率 ?Steaming shrinkage | 燙縮?Color fastness | 色牢度 ?Washing color fastness | 水洗色牢度 ?Rubbing/Crocking color fastness | 耐摩擦色牢度 ?Light color fastness | 耐光色牢度 ?Perspiration color fastness | 耐汗色牢度 ?Water color fastness | 耐水色牢度 ?Phenolic Yellowing | 耐酚黃化 ?Tensile strength | 拉伸/抗張強度 ?Tearing strength | 撕裂強度 ?Bonding strength | 剝離強度 ?Seam slippage | 接縫滑裂?Pilling resistance | 抗起毛起球性 ?Abrasion resistance | 耐磨性 ?Water repellency | 拒水性?Water resistance | 抗水性?Water vapour permeability | 透溼度

服装尺寸表英语词汇

服装尺寸表英语词汇 across measure 横度,横量 armhole(curve/straight) 夹圈(弯度/直度) back cross 后背宽 back rise 后浪长 bicep 袖肥,袖髀宽 bust (女)胸围 bust width (女)胸宽,胸阔 center back length 后中长 chest (男)胸围 chest width (男)胸宽,胸阔 collar band height 下级领高 collar length 领长 collar point spread 领尖距 collar point 领尖长 cuff width 介英宽 elbow width 肘宽 fly length 钮牌长 fly width 钮牌宽 front cross 前胸宽 front neck drop 前领深 front rise 前浪长 hem, bottom 脚宽,脚阔 high hip 上坐围 hip 坐围 inseam length 内(骨)长 knee 膝围 leg opening 裤脚围 neck across, neck width 领宽 neck drop 领深 outseam length 外(骨)长,侧骨长overarm 上袖长placket width 门筒宽pocket high point 袋尖高(袋最长的高度) shoulder across 总肩宽,肩阔 sleeve crown height 袖山高 sleeve length 袖长 sleeve opening 袖口宽 small shoulder 小肩长 sweep 裙阔 thigh(under crotch) 脾围,大腿围underarm 下袖长 upper arm width 袖髀阔 upper collar height 上级领高 waist 腰围

服装尺寸术语中英对照

服装尺寸表(中英文对照) 服装尺寸表(中英文对照) 一些不是很常用的词汇 HEM EDGE 拖曳部分(具体视衣服的设计图-在底部下摆边缘FRONT YOKE HEIGHT FROM HPS 前约克长-从肩顶量起 ACROSS BACK-PLACEMENT FRM HPS 后胸宽-在肩膀处量 ACROSS FRONT-PLACEMENT FRM HPS 前胸宽-在肩膀处量 COLLAR LENGTH AT NECK SEAM 领高-后颈缝量 FRONT POCKET WIDTH-AT TOP EDGE 前口袋宽-在最顶部 FRONT POCKET OPENING ALONG THE EDGE 前口袋边缘的开口 FRONT POCKET FROM HPS TO POCKET EDGE 前口袋从衣肩顶点到口袋边 FRONT POCKET FRM CTR FRT 前口袋拉链长度 FRONT POCKET HEIGHT @ OUTER SIDE

前口袋外侧高 COVER PLACKET WIDTH 口袋盖片宽 ARMHOLE DROP-FRM HPS 袖长-从肩顶量起 LENGTH-HPS TO HEM 长度-肩顶至下摆 Bottoms 下装 back rise 后直裆长,[粤]后浪长 back yoke height 后约克高,[粤]后机头高 fly length (裤)门襟长,[粤]钮牌长 fly width (裤)门襟宽,[粤]钮牌宽 front rise 前直裆长,[粤]前浪长 high hip 上臀围,上坐围 hip,hip width 臀围,坐围 inseam length 内长 knee 膝围 leg opening 裤脚围 side seam,outseam length 外长,[粤]侧骨长 sweep (裙)下摆,[粤](裙)脚围 thigh(under crotch),thigh width 髀围,大腿围(裤浪底量)waist(relax)腰围(松量,[粤]松度) waist(stretched)腰围(拉量,[粤]拉度)

服装尺寸中英对照大全

服装尺寸中英文对照大全 FRONT LENGTH FROM HPS 前衣长,肩点量 SHOULDER SLOPE 肩斜 ACROSS SHOULDER SEAM TO SEAM 肩宽,骨位至骨位缝到缝ACROSS FRONT 6" DOWN FROM HPS 前胸宽,肩点下6" ACROSS BACK 6" DOWN FROM HPS 后背宽,肩点下6" CHEST 1" BELOW UNDERARM 胸宽,袖夹底下1" WAIST 16 1/2" FROM HPS 腰围,肩点下16 1/2" SWEEP STRAIGHT 弧形脚宽,直量 SWEEP HEM HEIGHT 车脚高 ARMHOLE CIRCUMFERENCE 袖笼,沿一周弯量袖笼周长ARMHOLE DROP (RAGLAN SLEEVE) 袖笼,(套袖衣袖)(插肩袖)BICEP/MUSCLE 1" STRAIGHT FM UNDERARM 袖肥,袖夹底下1" SLEEVE OPENING - SHORT SLEEVE 袖口宽- 短袖 SHORT SLEEVE LENGTH FROM CB NECK SEAM-3 PTS 短袖袖长,从后中领窝缝3点量 SLEEVE OPENING - LONG SLEEVE 袖口宽- 长袖 LONG SLEEVE LENGTH FROM CB NECK SEAM-3 PTS 长袖袖长,从后中领窝骨位3点量 SLEEVE CUFFS HEIGHT 袖克夫高 SLEEVE PLACKET LENGTH EXCL CUFF 袖叉长不包含袖袖口SLEEVE PLACKET WIDTH 袖叉宽

服装尺寸中英文对照

Weight 单耗 Body length 身长 "Chest Width 1""blw armhole 胸围" Waist Width AcrosS 腰围 Waist Location blw HPS 腰位 Bottom Width 摆宽 Across Chest 前上胸 Across Chest Location 前上胸位 Across Back 后上胸 Across Back Location 后上胸位 Armhole 袖笼 Front armhole 前袖笼 Back armhole 后袖笼 Front raglan length 前明收长 Back raglan length 后明收长 Position of raglan fr HPS肩顶至明收 "Muscle 1"" blw armhole袖庄" Sleeve Opening袖口 Armhole finish 袖笼边 Armhole finish width: FF to FF 袖笼明收宽 Cuff finish袖边Sleeve length 袖长 Underarm sleeve length 袖底长 Cap width at neck seam to seam 袖山宽 CAP HEIGHT 袖山高 Across shoulder 肩宽 Neck/Shoulder width 单肩宽 Neck width 领宽 Collar width across top edge 领顶宽 Front neck width across seam 前领缝宽 Back neck width across seam 后领缝宽 Front neck drop 前领深 Back neck drop 后领深 Ncck opening at base 领底宽 Back Neck opening at base 后领底宽 Neck finish 领边 FR/BK Neck finish:Width edge to FF 领边明收宽Neck Height 领高 Shoulder slope肩斜 Placket length门襟长 Placket width 门襟宽 Skirt CB length below W.B. 裙长 "High Hip 3"" Below WB 3”下臀围" "Low Hip 7"" Below WB 7“下臀围" Up Body Length 上身长 Waist Height(Roll Back Elastic) 腰头 Bottom finish 摆边 Bottom finish:Self start Solid 3x3 Rib摆边3X3素色 Turtle neck width edge to edge 高领领宽"Middle panel width,ribs 前中幅宽" V-points placement fr HPS 肩顶至V尖 Back panel width 后幅宽 FR panel width(incl trim)@neck tub 前幅宽 BK panel width(incl trim)@neck tub 后幅宽Shoulder Strap Width 肩带宽 Hood Length at CF Opening帽长(前中) Hood width帽宽 pocket LXW 袋长X宽 Pocket placement fr hem 摆上袋位 Pocket placement fr ss 袋至侧缝 Hood finish:Jersey Tub帽边空包 Zipper length拉链长 FN selvage width inside covering zip 拉链里贴宽Overlap height at side seam 侧缝高 Side point band fr HPS 侧位 Side seam length侧缝长 Crotch width at base浪底宽 Leg opening 腿位宽 Button ligne钮号 Shoulder slope:HSP to seam 肩斜 Total pattern height间色总高 Position of pattern fr btm edge摆上至间色Total pattern width at body间色总高 Total pattern width at cuff袖间色总高 Position of pattern on body大身间色位Position of pattern on cuff袖间色位 Stripe pattern height 间色高 Total pattern width on body 大身间色宽 Position fr bottom edge 摆上间色 Total pattern width on sleeve 袖间色宽 position fr cuff edge 袖口上间色 Stitch transfer on sleeve fr cuff edge 袖上翻针Stitch transfer placement fr hem 摆上翻针Minimum Elastin Stretch 橡筋最小拉长 Bottom finis:self start-solid 3x3 摆

服装尺寸英文

Length from HPS 身长-肩点量 Chest Width 1"Below Armhole 胸宽-夹下1"量 Across Shoulder –Shaped A/H 肩宽 Across Chest 5"below HPS-Shaped A/H 前上胸宽( 肩点下5"量) Across Back 5"below HPS-Shaped A/H 后背宽(肩点下5"量) Empire Wodth Sm to Sm Relaxed 公主线宽(线到线) 平铺量 Empire Wodth Sm to Sm Extended 公主线宽(线到线) 拉量 Empire Band frm HPS To top of band+ 公主线位置(从肩点下到公主线) Empire Sm From Armhole Advise+ 公主线位置(从夹圈下到公主线) Bottom Opening Width 下摆宽 Bottom Hem Height Scallop Lace 下摆高(狗牙蕾丝边) Armhole Width Straight Measure 夹圈(直量) Neck Drop Frt-lmag Line to Seam前领深(水平至线) Neck Drop BK-lmag Line to Seam后领深(水平至线) NK Width HPS-Edge to Edge at Lace 领宽(蕾丝边至边)

From Neck Width @ Bottom – edge to edge不是很清楚这个要说什么尺寸, 最好问一下客人 Neck Trim Height at F&B-Scallop Lace 领高(蕾丝边) Sleeve Length CB Neck –S/S w/Ruffle袖长(后中量,包括荷叶边) Sleeve Opening Width –S/S Relaxed袖口宽(平铺量) Sleeve Opening Width –S/S Extended袖口宽(拉量) Sleeve Ruffle Height袖口荷叶边高 Sleeve Shirring at Top of Cap sleeve+袖打褶 Shoulder Slope 肩斜 Shoulder Forward肩走前 Bust Shirring from C.Front+ 胸打褶(从前中计) Bust Shirring Length胸打褶长度 Minimum Neck Stretch 领最小拉量 Empire Wodth Sm to Sm Relaxed 公主线宽(线到线) 平铺量 Empire Wodth Sm to Sm Extended 公主线宽(线到线) 拉量

服装各部位的英文术语

布封幅宽FABRIC WIDTH 侧骨侧缝,摆缝SIDE SEAM 插竹领插角片COLLAR STAY 车花绣花EMBROIDERY 打枣打结BARTACK 担干过肩YOKE 耳仔裤带袢BELTLOOP 返针回针BACK STITCH 狗牙车牙FEED DOG 挂卡吊牌HANGTAG 后浪后档BACK RISE 蝴蝶车缝附件SEWING MACHINE ATTACHMENTS 及骨锁边OVERLOCK 及骨车包缝机,锁边机OVERLOCK MACHINE 急钮四合扣SNAP FASTENER 夹圈袖窿ARMHOLE

肩棉肩垫,垫肩膊头棉SHOULDER PAD 介英,鸡英袖口,袖级CUFF 拉冚车绷缝机COVERING STITCH MACHINE 拉裤头上裤头WAISTBANDING 拉筒车门襟机PLACKET MACHINE 辘脚车脚口卷边机BOTTOM HEMMING MACHINE 唛架排料图MAKER 唛头商标LABEL 埋夹缝合袖底骨和侧缝JOIN THE UNDER ARM SEAM AND SIDE SEAM 魔术贴尼龙搭扣VELCRO 纳膊缝合小肩JOIN THE SMALL SHOULDER 纳膊位肩缝SHOULDER SEAM 钮门扣眼BUTTON HOLE 钮牌门袢FLY 钮子钮门搭位BUTTON STAND

排唛排料LAYOUT 钮牌门袢FLY

啤机冲压裁剪机DIE CUTTING MACHINE 脾围横档THIGH 平车平缝机NORMAL SEWING MACHINE 朴衬布INTERLINING 前浪前档FRONT RISE 生褶省PLEAT 死褶褶DART 梭仔梭芯BOBBIN 烫斗熨斗IRON 挑脚车暗缝机BLIND STITCHING MACHINE 乌蝇扣钩棒扣EYES & HOOKS 靴压脚PRESSER FOOT 针步线步STITCHES 止口,子口缝头SEAM ALLOWANCE 纵纹斜纹BIOS CUT 坐围臀围HIP (Jandy 整理) 服装专业英语(辅料)