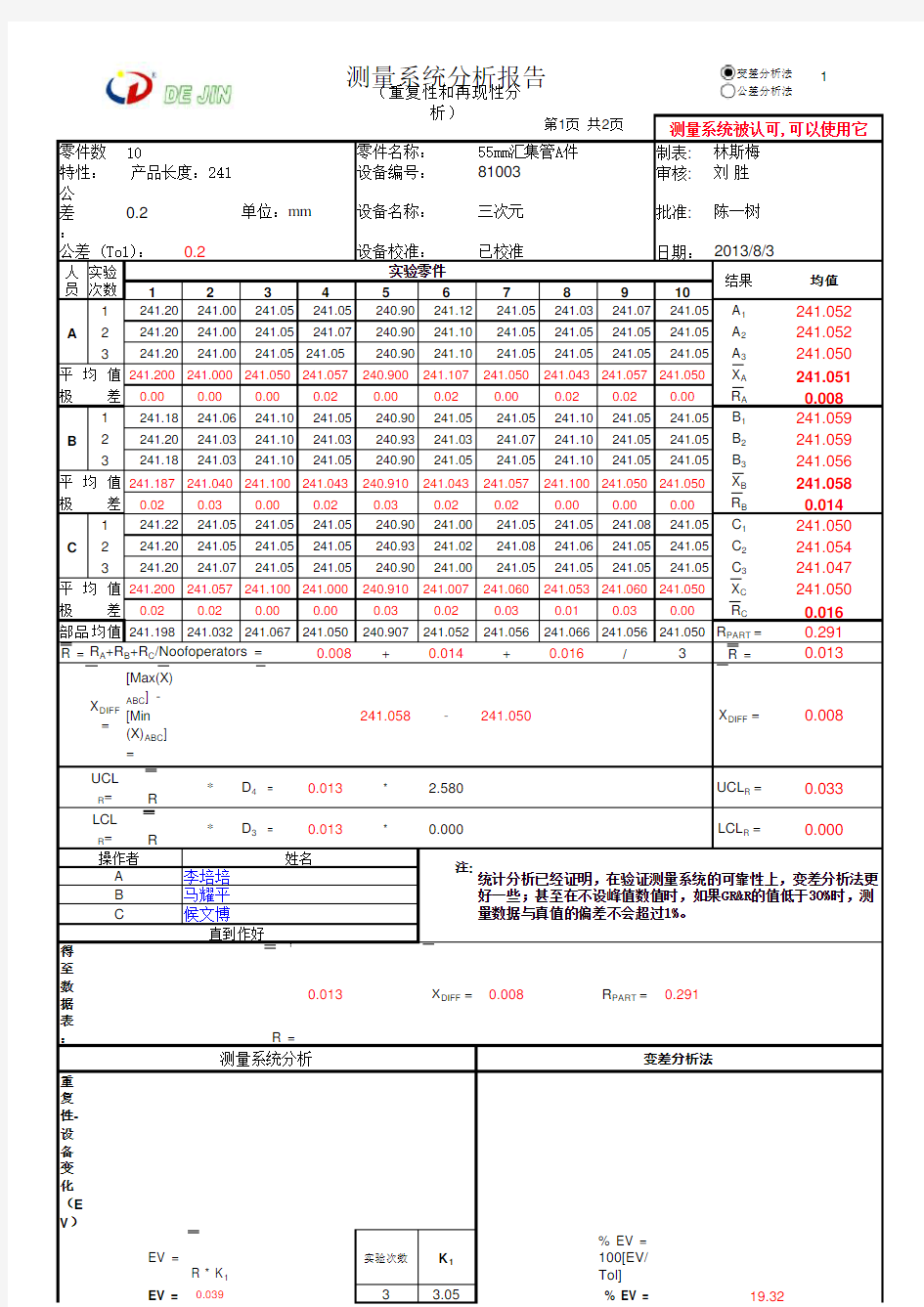

测量系统分析报告

1

10制表:审核:公差:0.2

批准:0.2日期:1

2

3

4

56

7

8

9

10

1241.20241.00241.05241.05240.90241.12241.05241.03241.07241.05A 1

241.052A

2241.20241.00241.05241.07

240.90241.10241.05241.05241.05241.05A 2241.0523

241.20

241.00

241.05

241.05

240.90

241.10

241.05

241.05

241.05

241.05

A 3241.050241.200241.000241.050241.057240.900241.107241.050241.043241.057241.050

X A 241.0510.00

0.000.000.020.000.020.000.020.020.00R A 0.0081241.18241.06241.10241.05240.90241.05241.05241.10241.05241.05B 1241.059B

2241.20241.03241.10241.03240.93241.03241.07241.10241.05241.05B 2241.0593241.18241.03241.10241.05240.90241.05241.05241.10241.05241.05B 3241.056241.187241.040241.100241.043240.910241.043241.057241.100241.050241.050

X B 241.0580.020.030.000.020.030.020.020.000.000.00

R B 0.0141241.22241.05241.05241.05240.90241.00241.05241.05241.08241.05C 1241.050C

2241.20241.05241.05241.05240.93241.02241.08241.06241.05241.05C 2241.0543241.20241.07241.05241.05240.90241.00241.05241.05241.05241.05C 3241.047241.200241.057241.100241.000240.910

241.007241.060241.053241.060241.050X C 241.0500.02

0.020.000.000.030.020.030.010.030.00R C 0.016241.198241.032241.067241.050240.907241.052

241.056

241.066

241.056

241.050

R PART =0.291R =0.008+

0.014+0.016/3

R =0.013X DIFF =[Max(X)ABC ] - [Min (X)ABC ] =241.058

-241.050

X DIFF =0.008UCL R =R *D 4 =0.013

* 2.580UCL R =0.033LCL R =R

*

D 3 =

0.013*

0.000

LCL R =

0.000

得至数据表:

R =

0.013

X DIFF =

0.008

R PART =

0.291

变差分析法

重复性-设备变化(EV )

EV =R * K 1实验次数

K 1% EV = 100[EV/Tol]EV =0.039

3

3.05

% EV =

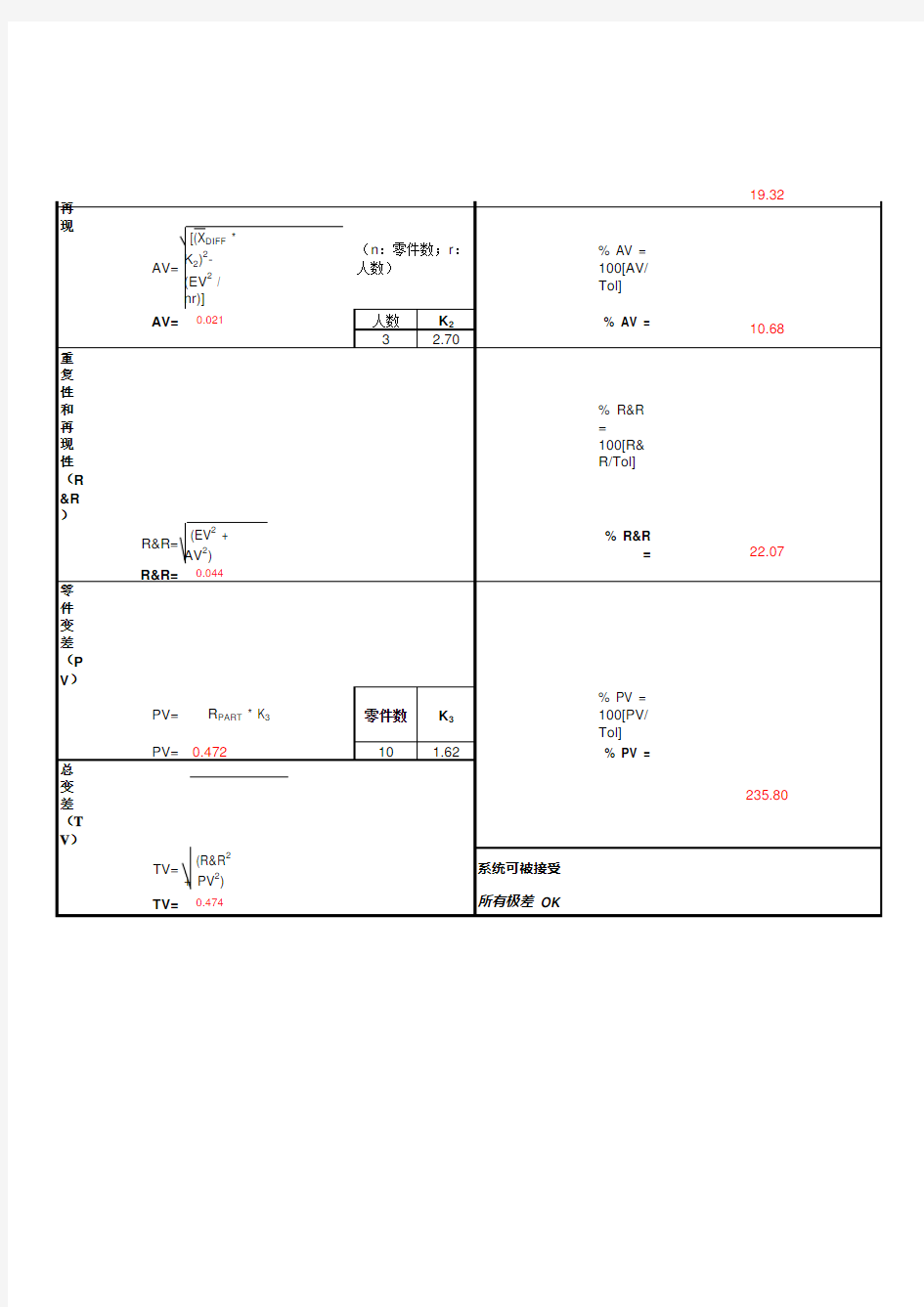

再现性-人员变化(AV )

AV= [(X DIFF * K 2)2-(EV 2 / nr)]% AV = 100[AV/Tol]AV=0.021人数

K 2% AV =

3 2.70

重复性和再现性(R&R )

% R&R = 100[R&R/Tol]R&R= (EV 2 + AV 2)% R&R =

R&R=0.044

零件变差(PV )

PV=

零件数K 3% PV = 100[PV/Tol]PV=0.472

10 1.62% PV =

总变差(TV )

基于方差分析

TV= (R&R 2 + PV 2)

TV=

0.474

林斯梅测量系统分析报告

测量系统被认可,可以使用它 特性:产品长度:241

设备编号:81003零件数量:零件名称:55mm汇集管A件2013-8-3

刘 胜单位:mm 设备名称:三次元陈一树实验零件平均值极差平均值公差 (Tol):

设备校准:

已校准

R A +R B +R C /Noofoperators =操作者

姓名

A 李培培极差平均值极差部品均值直到作好

测量系统分析

R PART * K 3系统可被接受

B 马耀平

C 候文博

所有极差 OK

人员实验

次数

注:

结果均值

#REF!

统计分析已经证明,在验证测量系统的可靠性上,变差分析法更好一些;甚至在不设峰值数值时,如果GR&R的值低于30%时,测量数据与真值的偏差不会超过1%。19.32

(n :零件数;r :人数)

10.68

22.07

235.80

第1页共2页

变差分析法公差分析法

BREAKPOINT =RPN #x %GRR/10031.79

=144.0x 0.22070.0327

0.0327

0.0327

0.0327

0.0327

0.0327

0.0327

0.0327

0.0327

0.0327

结论是 ... 测量系统被认可,可以使用它

从有关尺寸检测的DFMEA 中决定风险优先数(RPN ),把这个数填

入右表的RPN#区域,然后按下一步命令执行。

重复性和再现性(%R&R)实验结果分析原则:小于总变差的10%:测量系统可以接受;

10%和30%之间:考虑测量系统使用的重要性。计算breakpoint 值,如果小于37.8,可以接受。大于30%:系统需要改进,确认问题已被纠正。

测量系统分析报告

240.750

240.800 240.850 240.900

240.950 241.000 241.050

241.100 241.150 241.200

241.250 12345678910

平均值零件

平均值控制图

A B C

0.00 0.01 0.01 0.02

0.02 0.03

0.03 0.04 1

2345678910

极差零件

极差控制图

A

B

C

UCLr