Localized corrosion of 6056 T6 aluminium alloy in chloride media

Localized corrosion of 6056T6aluminium alloy in chloride media

Vale

rie Guillaumin,Georges Mankowski*Laboratoire de Cristallochimie,Re ?activite ?et Protection des Mate ?riaux,UPRESA CNRS 5071,ENSCT,118route de Narbonne,31077,Toulouse Cedex 04,France

Received 30September 1998;accepted 19March 1999

Abstract

The corrosion behaviour of 6056T6aluminium alloy was investigated in 1M NaCl solution.Pitting and intergranular corrosion were found to be dependent on each other since intergranular corrosion nucleated on pit walls and spread from them.Coarse intermetallic Al±Si±Mg-containing particles were found to be nucleation sites for pits.Pits ?rst developed within the grains and grew up through microscopic crystallographic tunnels.The intergranular corrosion mechanism of 6056T6alloy appeared to consist of preferential dissolution of the anodic Si and Cu depleted zone along grain boundaries whereas Cu±Si±Mg rich intergranular precipitates functioned as local cathodes and stimulated the dissolution of the depleted zone.#1999Elsevier Science Ltd.All rights reserved.

1.Introduction

Aluminium 6013T6alloy is a high strength Al±Mg±Si±Cu alloy recently developed by Alcoa for replacement of the traditional 2024T3alloy in structural areas such as fuselage and door skins,formers and aft pressure bulkhead skin,dorsal ?n and trailing edge panels [1,2].Indeed,its mechanical properties are very attractive [1,3,4]:weldability is comparable to that of 6061alloy;good stretch forming characteristics in the T4temper,comparable to that in 2024W,helps in reducing the fabrication cost;three percent lower density than the 2024alloy;0010-938X/00/$-see front matter #1999Elsevier Science Ltd.All rights reserved.PII:S 0010-938X (99)00053-0

Corrosion Science 42(2000)

105±125

*Corresponding author.

higher tensile and compressive yield strengths when compared with the alclad 2024;fracture toughness and crack resistance higher than that of the alclad 2024.Moreover,6013T6alloy seems to be virtually immune to exfoliation and saltwater stress corrosion cracking [1,3,4].However,its lower resistance to fatigue corrosion when compared to both the bare 2024and alclad 2024seems to be due to intergranular corrosion [5,6].Indeed,6013T6alloy was found to be susceptible to intergranular corrosion,but very few investigations have studied its corrosion properties [7±10].In this study,the corrosion behaviour of 6056T6alloy,the French equivalent of the 6013T6alloy,was investigated in 1M NaCl solution.The purpose of this work was to understand the susceptibility of the alloy towards intergranular corrosion and other localized corrosion.Speci?c attention was given to coarse intermetallic particles whose corrosion behaviour inˉuenced the corrosion properties of the alloy.

2.Experimental method

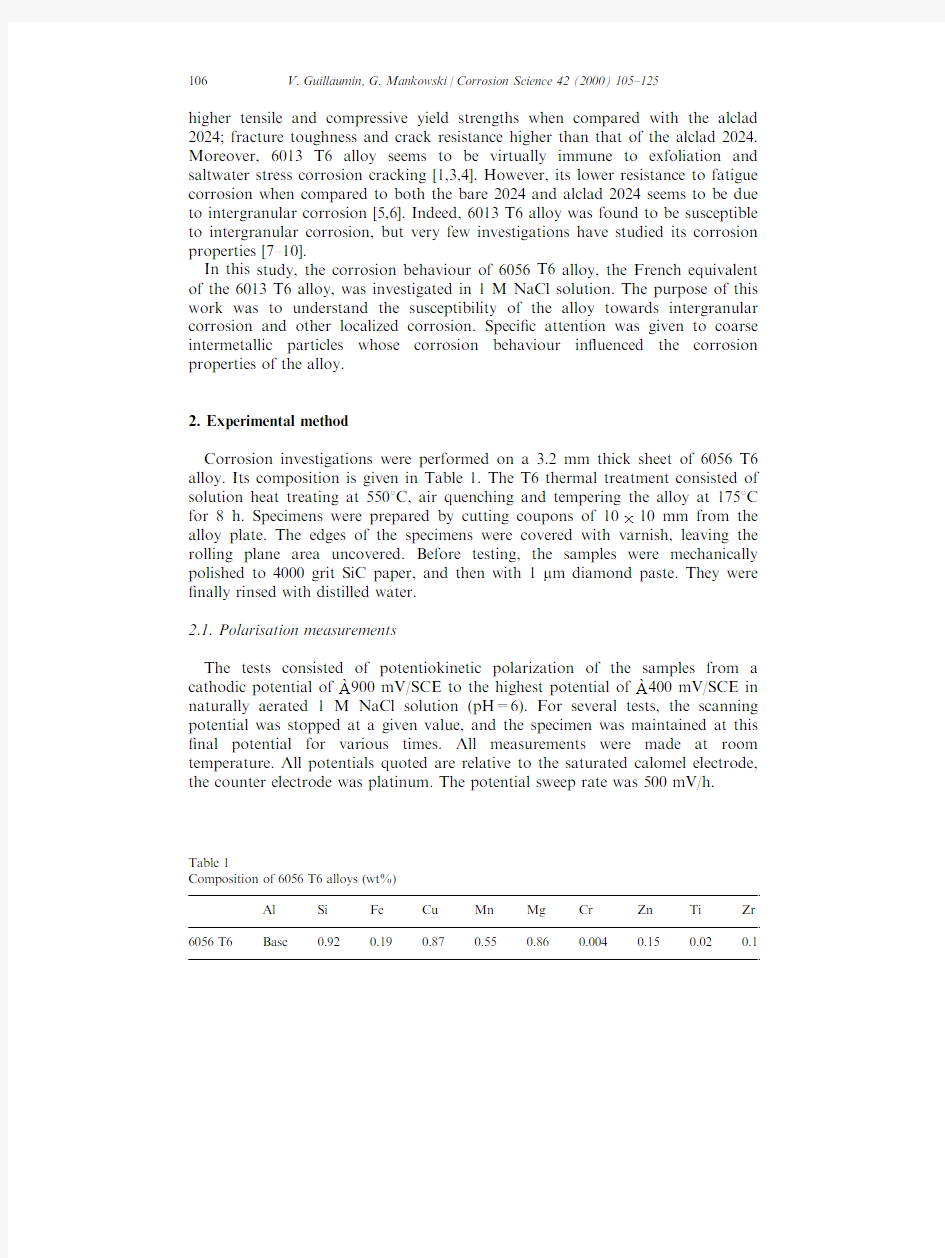

Corrosion investigations were performed on a 3.2mm thick sheet of 6056T6alloy.Its composition is given in Table 1.The T6thermal treatment consisted of solution heat treating at 5508C,air quenching and tempering the alloy at 1758C for 8h.Specimens were prepared by cutting coupons of 10?10mm from the alloy plate.The edges of the specimens were covered with varnish,leaving the rolling plane area uncovered.Before testing,the samples were mechanically polished to 4000grit SiC paper,and then with 1m m diamond paste.They were ?nally rinsed with distilled water.

2.1.Polarisation measurements

The tests consisted of potentiokinetic polarization of the samples from a cathodic potential of à900mV/SCE to the highest potential of à400mV/SCE in naturally aerated 1M NaCl solution (pH=6).For several tests,the scanning potential was stopped at a given value,and the specimen was maintained at this ?nal potential for various times.All measurements were made at room temperature.All potentials quoted are relative to the saturated calomel electrode,the counter electrode was platinum.The potential sweep rate was 500mV/h.Table 1Composition of 6056T6alloys (wt%)

Al

Si Fe Cu Mn Mg Cr Zn Ti Zr 6056T6Base 0.920.190.870.550.860.0040.150.020.1

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

106

V.Guillaumin,G.Mankowski/Corrosion Science42(2000)105±125107

2.2.Microscopic observations

After polarization,observations using optical microscopy and scanning electron microscopy(SEM)with a LEO435VP apparatus were performed on the samples in order to examine and locate pits or intergranular corrosion.The specimens were also observed using transmission electron microscopy(TEM)using a JEOL JM2010,in order to observe intergranular precipitation and very small precipitates.To study the intergranular corrosion mechanism,foils prepared by electropolishing for TEM observations were subsequently immersed in two di erent dilute HCl solutions.The?rst one was made by adding two drops of concentrated HCl(36%)per liter of distilled water(pH=3.3),the second one was made by adding8drops of concentrated HCl(36%)per liter of distilled water (pH=2.7).The foils were immersed for2min in the less concentrated HCl solution,and after,2min in the other solution.The TEM foils were?nally rinsed with methanol and dried in air.Energy dispersed spectrometery(EDS)analysis was also performed during TEM observations to determine the composition of intergranular and other small precipitates.

2.3.Phase shifting interferometric microscopy(PSIM)[11]

This method,based on classical interferometry,was used to study the reactivity of coarse intermetallic particles and to quantify the dissolution of these particles through2D and3D pro?les.The advantage of PSIM lies in the acquisition of4 images of the same surface,but with a di erence of l/4in optical path length between two consecutive images.As accurate repositioning of the samples was possible,the pro?les plotted before and after the test were compared.The technique was chosen since the lateral resolution was well suited to the dimensions of the intermetallic particles.Moreover,this technique a ords a very high vertical resolution of1nm.Consequently,even slight modi?cations occurring in the shape of the intermetallic particles or in the matrix around them can be measured.

3.Results and discussion

Intergranular corrosion is usually caused by the precipitation of second-phase precipitates in the grain boundary.During precipitation,an adjacent denuded zone free of precipitates(PFZ)is formed,which has a di erent solution potential than the matrix.The degree of susceptibility of an alloy to intergranular corrosion depends on its microstructure,in particular the amount,size and distribution of intergranular precipitates,and the composition and the width of the PFZ. Obviously,these characteristics result from the metallurgical history and thermal treatment of the alloy.Likewise,many studies have proved that coarse intermetallic particles inˉuence the corrosion behaviour of aluminium alloys. Indeed,corrosion properties of2024T351alloy were found to depend on the

behaviour of the coarse Al±Cu±Mg-containing particles [12,13].Thus,this investigation began with a microstructural characterisation of the 6056T6alloy.

3.1.Microstructure

The overall thermomechanical treatment led to the 6056T6alloy having an average grain size of 30±40m m.Both optical and SEM observations show the presence of a very irregular distribution of coarse intermetallic particles (Fig.1).Indeed,particles can be very close to each other,but sometimes they can be at very wide intervals.The global fraction of particles with an analysed surface area equal to 0.35mm 2was found to represent 2.7%of the total area.Two types of coarse intermetallic particles were distinguished:Dmore or less globular Al±Si±Mg-containing particles with a size between 2±20m m for the longest side.They appeared blue coloured by optical observation and represent 0.7%of the total area.Dmore irregularly shaped Al±Si±Mn±Fe-containing particles which size is between 2±20m m (for the longest side).Optical observations made them appear pink.They were more numerous and represented 2%of the total area.Such coarse intermetallic particles have also been observed by Blanc et al.[12]in the 6056T6alloy.Lectard et al.[14]and Conte and Sanders [15]have also observed a -(AlFeMnSi)particles in 6013alloy.TEM observations were performed to reveal smaller particles.EDS analysis was also used to determine their chemical composition.In the matrix:Dneedle shaped hardening Al±Cu±Si-containing precipitates with a long side of around 100nm were found (Fig.2).They are unlikely to be b 'or b 0which

are

Fig.1.Coarse intermetallic Si±Mg-rich and Si±Mn±Fe-rich particles in 6056T6alloy.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

108

the precursors of the stable b -Mg 2Si phase which is generally encountered in 6013alloy.As the wt%copper was higher than 0.25%,the precursors y 'or y 0of the y -Al 2Cu phase could also have been observed [16].However,the analysed copper concentration was so small that it seemed improbable that the hardening precipitates belonged to this chemical type.They most likely belong to

another

Fig.2.Hardening Al±Cu±Si-containing precipitates in the

matrix.

Fig.3.Round and rod shaped dispersoids in the matrix.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125109

chemical type but analyses on such small particles were not precise enough to make conclusions.Dtwo types of dispersoids were found (Fig.3).Some were rather round with a size range of 0.08±0.4m m,and contained Al (74.3wt%),Mn (14.4wt%),Si (7.2wt%),Cu (2.2wt%),and Fe (0.6wt%).Others were rod shaped with the longest size of 0.35±1.2m m and contained Al (81.3wt%),Mn (10.2wt%),Si (4.6wt%),Cu (2.2wt%),and Fe (0.3w%).These two dispersoid compositions seemed very close to each other so,it was assumed that these two types of dispersoid belonged to the same chemical type and that they were oriented in perpendicular two directions.At the grain boundaries,a large number of needle shaped precipitates with average dimensions 20?40nm were found (Fig.4)and they contained Al (89.7wt%),Si (5.8wt%),and Cu (3.3wt%).Some were longer:24?130nm and contained Al (62.9wt%),Si (15.3wt%),Mg (10.4wt%),and Cu (10wt%).The PFZ along grain boundaries was not very clear (Fig.5).Indeed,sometimes hardening precipitates were found up to twenty nanometers from the grain boundary (Fig.5a)and at other times,they seemed to be very close to it (Fig.5b).EDS analysis of a grain boundary showed that it contained 2.24wt%Cu and 0.09wt%Si,whereas the matrix contained 2.56wt%Cu and 0.51wt%Si (such local analysis was possible with the JEOL 2010apparatus which allows the utilization of a 7nm analysis spot).The same copper and silicon contents were found over a zone 40nm wide on both sides of the grain boundary.Consequently,the grain boundaries presented a slight depletion in copper and a strong depletion in silicon,in comparison with the rest of the matrix.As TEM polar pieces are made of copper,results obtained always showed a copper content higher than the real

one.

Fig.4.Needle shaped Al±Si±Cu-containing precipitates at grain boundary.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

110

Indeed,the matrix copper content was a little higher than that indicated in Table 1.The hardening precipitates of Al±Mg±Si alloys have been widely studied by TEM analysis [16±24].However,very little work has been devoted to the 6013alloy microstructure.Blanc et al.[12],who worked on the susceptibility of pitting corrosion of 6056T6alloy have found approximately the same

precipitate

Fig.5.(a)Hardening precipitates up to twenty nanometers from a grain boundary.(b)Hardening precipitates very close to a grain

boundary.

Fig.6.Potentiokinetic polarization curve of 6056T6alloy in 1M NaCl solution.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125111

distribution.Jeniski et al.[25]have found 0.1±0.3m m dispersoids of a Al 12Mn 3Si and a -(AlFeMnSi)in the 6013alloy,depending on the local iron content.

3.2.Polarizaion curve in sodium chloride solution

Fig.6shows a typical potentiokinetic polarization curve obtained in 1M NaCl for 6056T6alloy.The curve shows only one breakdown potential around à730mV,close to the corrosion potential (E corr =à720mV).On and after the breakdown potential,both pitting and intergranular corrosion developed.In the ?rst stage of attack,large pits were observed as well as intergranular corrosion which took place on pit walls.Indeed,Fig.7shows a pit of 20±30m m in diameter which developed on the surface of a 6056T6sample after potentiokinetic polarization to à700mV (i.e.,30mV higher than the breakdown potential).On both sides of the pit,two grain boundaries were attacked,and intergranular corrosion spread from the pit following the grain boundaries.Fig.8presents observations of a sample after potentiokinetic polarization to à400mV.This potential was very high,so the attack became more severe compared to polarization to à700mV.Indeed,intergranular corrosion was stronger and more extensive,but stayed concentrated around the pits.Intergranular corrosion still took place on pit walls and spread from them (Fig.8a).Zones where pits did not develop did not allow intergranular corrosion to develop,and remained unattacked.Thus,these two forms of corrosion seemed to be dependent on each other.Various authors [3±6,9,10]who studied the

corrosion Fig.7.Pit on 6056T6surface after potentiokinetic polarization to à700mV,the potential was maintained for 5min at à700mV.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

112

properties of 6013T6alloy have found that pitting and intergranular corrosion were often encountered together.Pits can reach a very large size (200±300m m)and can show crystallographic facets.A tendency to grow following certain crystallographic planes was observed in Fig.8b.Other authors [26,27]have previously observed crystallographic shaped pits in the matrix of di erent aluminium alloys.In Fig.8a,pits are signi?cantly rami?ed presenting a rough pro?le.They seemed to grow following the model

of Fig.8.6056T6surface after potentiokinetic polarization to à400mV/SCE.(a)Microscopic observation of the whole surface.(b)SEM observation of a pit.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125113

Reigada et al.[28].This model is based on the idea that microscopic crystallographic tunnels are randomly nucleated on the pit wall,and quickly penetrate the metal.The occurrence and size of the tunnels depends on the local chloride concentration and potential.Under mild conditions,tunnelling is a rare process,the size of the tunnels is small,so the pit pro?le becomes rough.With increasing aggressiveness,both the occurrence and the size of the tunnels increases,leading to the formation of smooth,hemispherical pits.Frankel [29]who studied pit morphology on pure aluminium in chloride solutions has shown that the pit shape depended on the pit growth potential.At low potentials,the pit current density increases linearly with potential and pit pro?le is extremely rough.At higher potentials,the pit current density is independent of potential and the pit pro?le becomes round and smooth.Fig.9a shows the microscopic observation of a sample surface after potentiokinetic polarization to à400mV.Pitting as well as intergranular corrosion were observed.Fig.9b presents the same zone of the sample surface,after a short polishing with 1m m diamond paste.The attack appears much more severe after polishing.Pits are more extensive and microscopic tunnels are conspicuous,much more than in Fig.9a.The pit propagation by microscopic tunnels is there very clear.The propagation of the attack spread under the passive ?lm but spread also in depth.Moreover,as tunnelling was also observed on both sides of the grain boundaries,it is assumed that once the grain boundaries were attacked,microscopic tunnels nucleated on the grain boundary walls,and penetrated the metal.Finally,tunnelling seems to be the way of propagation of pitting but also takes place during intergranular corrosion propagation.The question remains as to how pitting and intergranular corrosion are

related.Fig.9.Microscopic observation of 6056T6surface after potentiokinetic polarization to à400mV/SCE.(a)Just after the experiment.(b)After a short polishing with 1m m diamond paste.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

114

Fig.10shows a specimen surface after a potentiokinetic polarization to à400mV.This SEM observation was taken with a 608tilt.Across the corroded surface many voluminous corrosion products were observed.Many of them were circular shaped with a hole in their centre.It can easily be assumed that each hole beneath each circular shaped corrosion product is a pit.Thus,the pit environment was isolated from the bulk solution by the voluminous aluminium hydroxide corrosion products and it became acidic and high in chloride concentration.Indeed,local acidi?cation is one of the possible mechanism of pit propagation [30±33].It can then be assumed that once the pit formed and the pit environment acidi?ed because of the formation of the voluminous corrosion product,the microscopic tunnels nucleated on pit walls.They penetrated the metal and spread within the grain.They could also penetrate along grain boundaries which were in contact with the growing pit.Then,intergranular corrosion started on pit walls and spread from them.Burleigh et al.[9,10]who studied intergranular corrosion of 6013T6alloy in NaCl/H 2O 2corrosive medium,have found that tall chimneys of corrosion products could maintain the acidic environment of pits and subsequently caused intergranular corrosion.This argument strongly supports ?ndings of the present work.Finally,it was inferred from these results that the breakdown potential corresponds to the matrix breakdown potential.On and after this potential,pits developed in the matrix and led to the formation of voluminous corrosion products.Then,the pit environment becomes acidic and high in chloride concentration.In this aggressive medium,the pits grow up through microscopic tunnels.When some of them penetrate grain boundaries,intergranular corrosion starts,and tunnelling also takes part in intergranular

corrosion.

Fig.10.SEM observations of 6056T6surface taken with a 608tilt,after potentiokinetic polarization to à400mV/SCE.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125115

3.3.Intergranular corrosion mechanism

After immersion in dilute HCl solutions,foils were ?rstly examined by optical microscopy.On one of its sides,the foil hole was quite rami?ed,presenting a rough pro?le (Fig.11)such as the pit pro?le in Fig.8a.So,it could be assumed that a pit developed and spread from the hole to the grain interior by microscopic crystallographic tunnels.TEM observation of the foil showed that this zone was quite oxidized.It appeared rather black by TEM observation,and the attack was so strong it that it was not possible to observe matrix or dispersoids any longer.The rest of the foil remained completely undamaged,and no grain boundaries were found to be attacked.However,grain boundaries encountered in the oxidized zone were found to be seriously attacked (Fig.12).A 0.5m m wide band on both sides of the grain boundaries was dissolved whereas grain boundary precipitates remained undamaged and were still observed.Thus,it was assumed that the Si and Cu depleted zone along the grain boundaries was anodic in comparison to the grain boundary precipitates and dissolved preferentially leaving the grain boundary precipitates unattacked.It is important to highlight the fact that attacked grain boundaries were only observed in the oxidized zone.This result con?rms the previous hypothesis:intergranular corrosion nucleates on pit walls and spreads from them to the metal interior following the depleted zone along the grain boundaries.Indeed,outside the corroded zone (i.e.,the pit),grain boundaries were completely undamaged.From the literature [34],two intergranular corrosion mechanisms have been proposed:DThe ?rst one consists of preferential dissolution of grain

boundary

Fig.11.TEM foil of 6056T6sample after immersion in HCl dilute solutions.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

116

precipitates.If the initial grain boundary precipitate is b 'or b ,these particles could serve as anodic sites and dissolve preferentially.As these particles are quite anodic compared to aluminium,their dissolution shifts the alloy potential in the cathodic direction,thereby diminishing the intergranular corrosion driving force.DThe second one consists of preferential dissolution of the PFZ along grain boundaries.If silicon is the initial grain boundary precipitate,the particles could function as minute cathodes stimulating electrochemical attack of the PFZ

zone Fig.12.Grain boundary attack containing Cu±Si rich intergranular

precipitates.

Fig.13.3D pro?les of an Al±Cu±Mn±Fe containing particle.(a)After polishing.(b)After 5min at free potential in 1M NaCl solution.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125117

along grain boundaries.The Si depleted PFZ zone would tend to be slightly anodic to the grain centres.The intergranular corrosion mechanism of 6056T6alloy seems to correspond to the second proposed mechanism.Indeed,the Si and Cu depleted zone along grain boundaries seems to be anodic in comparison to both the Si±Mg±Cu rich precipitates and grain centres and consequently dissolves preferentially,whereas intergranular precipitates function as local cathodes.Moreover,pitting corrosion helps intergranular corrosion to develop since intergranular corrosion nucleates on pit walls.

3.4.Reactivity of coarse intermetallic particles in chloride solution

The role of coarse intermetallic particles in aluminium alloys has been previously stated in this study.Moreover,Blanc et al.[12]showed that coarse intermetallic particles in 6056T6alloy are reactive in sulphate media.Therefore,to study the behaviour of coarse intermetallic particles in detail,phase shifting interferometric microscopy was performed on 6056T6alloy.Firstly,the particle behaviour was studied after 5min immersion in 1M NaCl solution at free potential.Fig.13b shows the 3D pro?le plotted for an Al±Si±Mn±Fe-containing particle after 5min at free potential in 1M NaCl solution.Fig.14b and 15b show 3D pro?les plotted for two di erent Al±Si±Mg-containing particles after 5min immersion in 1M NaCl.The 3D pro?les plotted before the polarization are shown in Figs.13a,14a and 15a.In Fig.13a,the Al±Si±Mn±Fe-containing particle shows a more strongly marked relief than does the Al±Si±Mg-containing particle in Figs.14a and 15a.This is due to di erences of hardness between the matrix and the coarse intermetallic particles which leads to such relief after

polishing.

Fig.14.3D pro?les of an Al±Si±Mg-containing particle.(a)After polishing.(b)After 5min at free potential in 1M NaCl solution.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

118

Comparison of Figs.13a and b shows no signi?cant modi?cation of the Al±Si±Mn±Fe-containing particle.All the other 3D pro?les plotted for this type of particle led to the same result.Consequently,the Al±Si±Mn±Fe-containing particles were not reactive,and remained undamaged after 5min immersion in 1M NaCl at free https://www.360docs.net/doc/b512210029.html,parison of Figs.14a and b shows that the Al±Si±Mg-containing particle was largely dissolved.After immersion in the electrolyte,it appeared as a hole on the sample surface.Nevertheless,comparison of Figs.15a and b shows that

this Fig.15.3D pro?les of an Al±Si±Mg-containing particle.(a)After polishing.(b)After 5min at free potential in 1M NaCl

solution.

Fig.16.2D pro?les of the Al±Si±Mg-containing particle in the Fig.14before and after immersion for 5min in 1M NaCl solution at free potential.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125119

Al±Si±Mg-containing particle partly dissolved and still appeared in relief on the surface.Moreover,the attack was not homogeneous.Thus,this particle seemed to be less reactive than Fig.14particle.The other 3D pro?les plotted on this type of particle led to the same result.Some of them were slightly dissolved,others were completely dissolved.It can be inferred from these results that the Al±Si±Mn±Fe-containing particles are not reactive during immersion in 1M NaCl solution at free potential whereas,the Al±Si±Mg-containing particles are reactive.To compare the reactivity of Al±Si±Mg-containing particles in di erent electrolytes and at di erent potentials,the following experiments were conducted:5min in distilled water at free potential,5min in 1M NaCl solution at à900mV,and 5min in 1M NaCl solution at à750mV.However,3D graphic representation did not allow comparison of the dissolution of the Al±Si±Mg-containing particle according to the experimental conditions.Indeed,the hole masked by the surrounding surface could not be seen correctly,and it was not possible to measure its height,2D pro?les seemed to be more adapted to quantitative measurement of hole depth.Moreover,it was easier to make 2D pro?les coincide using the non-attacked surrounding matrix level as reference.Fig.16represents the 2D pro?les corresponding to the Al±Si±Mg-containing particle seen in Fig.14,before and after immersion in the electrolyte.As was done previously [12],to estimate the amount of material lost,the surface areas between the particle pro?les and the matrix level (S R before immersion and S A after immersion)were measured.This allowed the surface area lost,S L ,to

be Fig.17.Mean attack depth of Al±Mg±Si-containing particles after immersion for 5min in (a)Distilled water at free potential.(b)1M NaCl solution at free potential.(c)1M NaCl solution at à900mV.(d)1M NaCl solution at à750mV.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

120

V.Guillaumin,G.Mankowski/Corrosion Science42(2000)105±125121

Fig.18.Al±Si±Mg-containing particles after potentiokinetic polarization to10mV higher than the corrosion potential,the potential was maintained at this?nal value for5min.

calculated.Since,the particle sizes varied over a wide range,a parameter R was de?ned as follows:

R S L

d R

R took into account the size of the particles in the attack plane with d R ,being the dimension of the particle measured in the 2D pro?le plotted before immersion.The parameter R allowed better comparisons to be made between the lost material for particles for di erent sizes.R corresponded to a mean depth and was expressed in m m.When the attack was not homogeneous,like as in Fig.15b,the 2D pro?le was plotted at the maximum attack of the particle,R was calculated from this pro?le.Fig.17shows the di erent mean values of R obtained from 4to 6particles after the experiments.After 5min immersion at free potential in distilled water,the particles reacted as they reacted after 5min immersion at free potential in 1M NaCl solution:some of them were slightly dissolved,others were completely dissolved.For both immersions at free potential,the dissolution was very low,R was around 0.02m m.This may have been due to the fact that it took more than 5min for the potential to become stable,and this,whatever the electrolyte.At the beginning of immersion in 1M NaCl solution,the free potential was around à1300mV and it reached à730mV more than 5min later.Consequently,the dissolution of the particles at free potential was slight.After immersion for 5min in 1M NaCl at à900mV or at à750mV,all of the particles were much more dissolved and appeared like a hole on the sample surface.Also,R ,of around 0.05m m,was two times higher compared to R at free potential.Thus,cathodic polarization caused a greater dissolution of the particles.Whatever the applied potential,à900mV or à750mV,the values of R were rather equal.It can be inferred from these results that the Al±Si±Mg-containing particles are strongly reactive in 1M NaCl solution at a cathodic potential.After the breakdown potential,the dissolution of the particles was so strong that it was not possible to use PSIM any longer.Consequently,SEM observations were conducted to study the behaviour of the Al±Si±Mg-containing particles after the breakdown potential.Before the test,a large zone of a sample was examined by optical microscopy and all the Al±Si±Mg-containing particles were located.After polarization to 10mV higher than the corrosion potential,the same zone was again examined by SEM.All over this zone,all the pits encountered nucleated on,or just around,the Al±Si±Mg-containing particles (Fig.18).Thus,these particles can be considered as nucleation sites for pits,and consequently for intergranular corrosion.Besides,in the initial stages of the attack,as seen in Fig.7,the 20±30m m pit showed exactly the same size as the average size of the particles.Several hypotheses can be considered:Dif particle dissolution was strong,the particle could become the nucleation site for the pit (Fig.18a).

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

122

V.Guillaumin,G.Mankowski/Corrosion Science42(2000)105±125123Dif the particle was only partly dissolved,it grew hollow.It can then be assumed that in this hole,a local acidi?cation of the environment occurred, weaker than in the?rst hypothesis.If the particles were in contact with grain boundaries,it can be assumed,that intergranular corrosion started since the PFZ along the grain boundaries was anodic in comparison with the rest of the matrix. Following the PFZ in the core of the metal,if at a given moment,the attack reached the sample surface,a pit could develop.Then,the pit was a few micrometers from the particle as in Figs.18b±d.Figs.18e and f,where intergranular corrosion propagates under the surface of the metal from one particle to another,supports this hypothesis.

In both cases,pitting corrosion seems to be a consequence of preferential dissolution of the coarse intermetallic Al±Si±Mg-containing particles.The dissolution of these particles makes these zones fragile,and helps pitting corrosion to occur.In Fig.8a,the large zones where pitting and intergranular corrosion did not occur were free of Al±Si±Mg-containing particles.That is why they remained completely undamaged.

4.Conclusion

The potentiokinetic polarization curve of6056T6alloy in1M NaCl solution presents one breakdown potential which corresponds to the matrix breakdown potential.After it,both pitting and intergranular corrosion develop.These two forms of corrosion seem to be dependent on each other since intergranular corrosion starts on pit walls,spreads from them,but stays concentrated around them.

Pits?rstly develop within the grains leading to the formation of voluminous corrosion products.Then,the pit environment becomes acidic and high in chloride concentration.In this very aggressive medium,pits grow up through microscopic crystallographic tunnels.When some of them penetrate a grain boundary which is contact with the growing pit,intergranular corrosion starts.

Coarse intermetallic Al±Si±Mg-containing particles are strongly reactive in1M NaCl solution and seem to be nucleation sites for pits and consequently for intergranular corrosion.

Finally,the intergranular corrosion mechanism of6056T6alloy consists of preferential dissolution of the anodic Cu and Si depleted zone along grain boundaries whereas Si±Mg±Cu rich intergranular precipitates function as local cathodes and stimulate the electrochemical attack of this depleted zone.

Acknowledgements

This work was carried out in the framework of the``Laboratoire Re gional pour l'Ame lioration des Mate riaux Stucturaux pour l'Ae ronautique''with the?nancial support of the Re gion Midi-Pyre ne es.Special recognition goes to Michelle

Reversat and Djar Oquab for the SEM work and to Josette Poujardieu for TEM work.

References

[1]S.J.Cieslak,Alcoa Aluminium Alloy 6013,Alcoa Green Letter No.225,(1987).[2]R.S.Kaneko,L.Bakow,E.W.Lee,JOM (1990)16.[3]R.J.H.Wanhill,L.Schra,W.G.J.'t Hart,in:L.Arnberg,et.al.,(eds.),The 3rd International Conference on Aluminium Alloys,Trondheim,Norway.1992,p.357.[4]W.G.J.'t Hart,L.Schra,NLR Technical Publication TP 92315U.[5]J.Chaudhuri,Y.M.Tan, A.Eftekhari,K.Patni,NIAR Report 91-8,The Wichita State University,Wichita,Kansas,1991.[6]J.Chaudhuri,Y.M.Tan,V.Gondhalekar,K.M.Patni,J.Mater.Eng.Perf.3(1994)371.[7]C.Blanc,G.Mankowski,Corros.Sci.39(1997)949.[8]C.Blanc,G.Mankowski,Corros.Sci.40(1998)411.[9]T.D.Burleigh,E.Ludwiczak,R.A.Petri,Corrosion 51(1995)50.[10]T.D.Burleigh,in:L.Arnberg,et.al.,(eds.),3rd International Conference on Aluminium Alloys,Trondheim,Norway.1992,p.435.[11]R.Escalona,R.Devillers,G.Tribillon,J.Calatroni,P.Fievet,Y.Roques,F.Dabosi,J.Mater.Sci.28(1993)299.[12]C.Blanc,Y.Roques,G.Mankowski,Corros.Sci.40(1998)1019.[13]V.Guillaumin,G.Mankowski,Corros.Sci.41(1999)421.[14]E.Lectard,O.Sche er,E.Zschech,in:J.H.Driver et al.(Eds.),Aluminium Alloys,Their Physical and Mechanical Properties,217-222,Materials Science Forum,Transtec Publications,Switzerland,1996,p.1709.[15]A.Conte,T.H.Sanders Jr,in:J.H.Driver et al.(Eds.),Aluminium Alloys,Their physical and Mechanical Properties,242,Materials Science Forum,Transtec Publications,Switzerland,1997,p.119.[16]A.K.Gupta,P.H.Marois,D.J.Lloyd,in:J.H.Driver et al.(Eds.),Aluminium Alloys,Their physical and Mechanical Properties,217-222,Materials Science Forum,Transtec Publications,Switzerland,1996,p.801.[17]M.H.Jacobs,Phil.Mag.26(1972)1.[18]R.P.Wahi,M.Von Heimendahl,Phys.Stat.Sol.(a)24(1974)607.[19]J.P.Lynch,L.M.Brown,M.H.Jacobs,Acta Metall.30(1982)1389.[20]L.Sagalowicz,G.Hug,D.Bechet,P.Sainfort,https://www.360docs.net/doc/b512210029.html,passet,in:T.H.Sanders et al.(Eds.),Proc.4th International Conference on Aluminium Alloys,Atlanta,USA,1993,p.636.[21]K.Matsuda,S.Tada,S.Ikeno,J.Electron.Microsc.42(1993)1.[22]G.A.Edwards,K.Stiller,G.L.Dunlop,M.J.Couper,in:J.H.Driver et al.(Eds.),Aluminium Alloys,Their Physical and Mechanical Properties,217-222,Materials Science Forum,Transtec Publications,Switzerland,1996,p.713.[23]P.Donnadieu,A.Proult,in:J.H.Driver et al.(Eds.),Aluminium Alloys,Their Physical and Mechanical Properties,217-222,Materials Science Forum,Transtec Publications,Switzerland,1996,p.719.[24]M.Vivas,P.Lours,C.Levaillant,A.Couret,M.J.Casanove,A.Coujou,in:J.H.Driver et al.(Eds.),Aluminium Alloys,Their Physical and Mechanical Properties,217-222,Materials Science Forum,Transtec Publications,Switzerland,1996,p.1305.[25]R.A.Jeniski Jr.,B.Thanaboonsombut,T.H.Sanders Jr.,Metall.Mater.Trans.A 27A (1996)19.[26]I.L.Muller,J.R.Galvele,Corros.Sci.17(1977)179.[27]M.Baumga rtner,H.Kaesche,Corros.Sci.29(1989)363.[28]R.Reigada,F.Sague s,J.M.Costa,J.Chem.Phys.101(1994)2329.[29]G.S.Frankel,Corros.Sci.30(1990)1203.

V.Guillaumin,G.Mankowski /Corrosion Science 42(2000)105±125

124

奔驰7座mpv商务车大全

奔驰7座mpv 商务车大全 奔驰7座mpv 商务车大全。详情欢迎咨询南京亿海汽车,咨询有优惠!随着商务车的普及,奔驰七座商务车凭着自己的豪华优良血统,在国内得到了众多企业的认可。奔驰七座商务车作为时下受欢迎的7座商务车车型,具备空间大、外型动感豪华,配置科技感十足,无论是商务还是家用出门十分有面子。 下面主要来介绍一下奔驰V 级商务车的相关信息: 奔驰V 级外观时尚前卫,车身线条流畅,自带商务属性。多边形进气格栅,镀铬横条包围奔驰的大奔标志,凌厉的车灯设计令人燃起敬畏。整车修长有型,行驶时姿态十分优雅,是商务人士商务出行的理想选择。 奔驰V 级商务车的驾驶舱带着别致的华美,简约的中控台设计,使视觉感受到更豪华,精美,更富层次感,按键旋钮有序排列,十分便于操作。这辆奔驰V 级商务车无论是驾驶还是乘坐体验,都足以媲美迈巴赫这种豪华轿车的。

奔驰V级商务车采用前后无隔设计,全车用豪华皮革包裹,视觉感受华丽,触感舒适。地板则是游艇专用的柚木铺设而成的。棕色的配色更显商务的沉稳。白色的点缀则增添雅致简约感。奢华led氛围灯,随意调节车舱氛围,整车采用隔噪隔热处理。 MVP商务车必备的第二排豪华航空座椅(可通风,加热,按摩,带腿托功能)。第三排豪华连排座椅在车内人员困乏时可以一键躺平成双入床,为出行提供温暖舒适的休息。盘绕车内 的窗帘,为您在这纷扰的大千国际阻隔出一处豪华私享空间。全景天窗,营造通透大气的车内 空间,置身其间,环视或者仰望,360度风景随行。 南京亿海汽车集团总公司成立于1998年,是华东地区专业的豪华商务车、房车、SUV展销中心,旗下有奔驰、林肯、GMC、进口大众等品牌,为客户私人定制顶级的商务车、房车、保姆车。

suv汽车品牌其型号

A返回顶部↑ 奥迪一汽奥迪 奥迪Q5 报价图库论坛 进口奥迪 奥迪Q7 报价图库论坛 (进口)奥迪Q5 报价图库论坛 奥迪Q3 报价图库论坛 安驰安驰汽车 杰豹 报价图库论坛 雪豹 报价图库论坛 威豹 报价图库论坛 B返回顶部↑ 北汽北汽制造 北汽骑士 报价图库论坛 速威 报价图库论坛 陆霸 报价图库论坛 北汽吉普 报价图库论坛 战旗 报价图库论坛 北汽B40 报价图库论坛 勇士 报价图库论坛 域胜007 报价图库论坛 保时捷进口保时捷 卡宴 报价图库论坛 宝马进口宝马 宝马X1 报价图库论坛 宝马X5 报价图库论坛 宝马X6 报价图库论坛 宝马X3

报价图库论坛 奔驰进口奔驰 奔驰G级 报价图库论坛 奔驰ML级 报价图库论坛 奔驰GLK 报价图库论坛 奔驰GL 报价图库论坛 本田广汽本田 本田Pilot 报价图库论坛 东风本田 本田CR-V 报价图库论坛 进口本田 (进口)本田CR-V 报价图库论坛 别克进口别克 昂科雷 报价图库论坛 比亚迪比亚迪 比亚迪S6 报价图库论坛 比亚迪T6 报价图库论坛 比亚迪F4 报价图库论坛 标致进口标致 标致4007 报价图库论坛 标致3008 报价图库论坛 C返回顶部↑ 丰越一汽丰越 丰越-陆地巡洋舰 报价图库论坛 长城长城汽车 哈弗M1 报价图库论坛 哈弗CUV 报价图库论坛 赛影 报价图库论坛 哈弗M3 报价图库论坛 赛弗 报价图库论坛

哈弗H5 报价图库论坛 哈弗H7 报价图库论坛 赛骏 报价图库论坛 哈弗M2 报价图库论坛 哈弗H6 报价图库论坛 哈弗H3 报价图库论坛 哈弗SC60 报价图库论坛 长丰长丰猎豹 猎豹奇兵 报价图库论坛 猎豹CS6 报价图库论坛 帕杰罗 报价图库论坛 黑金刚 报价图库论坛 飞腾 报价图库论坛 长丰扬子 猎豹先锋 报价图库论坛 长安长安轿车 长安e301 报价图库论坛 D返回顶部↑ 大众上海大众 途观 报价图库论坛进口大众 途锐 报价图库论坛 Tiguan 报价图库论坛 大迪大迪汽车 大迪霸道 报价图库论坛 都市威菱 报价图库论坛

福特房车E350多少钱 福特房车E350报价参数

福特房车E350多少钱? 新款福特E350豪华商务车最大的亮点来自于iPad控制总线,可控制内容包括电视机开关、电脑开关、DVD娱乐系统、隔板与玻璃升降、氛围灯开关、夜间模式、隐私模式以及可透视天窗的开关。对于商务车房车来说,车内的座椅和空间等才是车主最重视的部分。 新款福特E350豪华商务车在马路上属于绝对的稀罕物,并非因为其长相古怪,而是作为一台MPV来说5972mm×2014mm×2450mm的体型确实算的上庞大,霸气十足的全镀铬庞克车头也几乎不会在国内的MPV车型中看到,大灯和保险杠也属于大块头,所有的设计都表现出2个字“气派”! 秉承美国车向来的设计思路,方向盘的造型势必不会太漂亮,但手感绝对是一流的。上下桃木加两侧打孔真皮的组合在美式豪华车上很普遍,多功能按键也带有定速巡航和蓝牙电话等功能。第二排座椅斜纹的意大利小牛皮不仅覆盖了座椅,当然也覆盖了整个后部车厢。皮质本身处理的非常细腻,并且座椅的填充物也非常柔软。

吧台的视觉效果和工艺都很棒,其中杯架来自意大利,ipad蓝牙键盘和鼠 标都可以看到。下方的BOSE音响主机可以直接连接iphone,现在似乎现在任 何时尚或奢华的玩意儿总要和苹果沾上一些边。吧台的灯光和音响主机等都可 以用ipad来控制开启。 福特商务车按摩功能也是异常强大,两个座椅均配有完整功能的遥控器, 可以提供4X4共16组不同的按摩方式,足以满足任何对座椅按摩功能挑剔的朋友。调节好座椅到一个舒适的位置,然后就打开按摩功能开始享受惬意的长途 旅程吧! 福特E350的市场售价从148万到258万之间不等,根据车型的选择,价位会有一定的差别。 南京亿海汽车集团,总公司成立于1998年。是华东地区专业的豪华商务车、房车、SUV展销中心,旗下有奔驰、林肯、GMC、进口大众等品牌,为尖端客户 私人定制顶级的商务车、房车、保姆车。现在咨询,立即享受折扣优惠!

奔驰V260商务车报价

奔驰V260商务车报价 奔驰V260商务车报价。奔驰V260采用的是全新奔驰家族化前脸设计,双横幅前进气格 栅搭配全LED大灯,整体风格庄重而肃穆。奔驰V260在近年来奔驰家族的诸多主打车型中,颇受偏爱,营造十足科技操控感的同时,也能提升驾驶舱视觉的流畅性。那奔驰V260商务车报价是怎样的呢? 关于奔驰V260商务车的详细报价,请咨询南京亿海汽车,咨询有优惠!或登录 https://www.360docs.net/doc/b512210029.html,查看详细信息。 奔驰v260商务车加高顶车身的打造类似于奔驰斯宾特商务车的前后舱全隔断式设计格局,使二者有相对独立的空间和氛围感,同时又具备了更佳完备的隔音防噪表现,集成了高清LED 液晶电视以及环绕式立体声音响套件,下设多功能一体式吧台,同时还配备了两个隐藏式秘书 座椅。

对于同价位竞品迈特威、埃尔法这些商务MPV 来说,奔驰V260是一台性价比非常高的豪华型MPV ,他把商务MPV 的豪华程度提升了一个级别。而且以它的价格来说还有一个更大的好处,那就是有关于后排的选择面更宽了,不仅局限于商务用途的它也可以很好的做一台家用MPV ,给父母、老婆、孩子、亲戚带来从未有过的尊贵体验。 奔驰 V260将电控自动化改装工艺深入融合,从车门到座椅、灯光、车窗以及隐私窗帘闭 合,都实现了电控一键操作,全车铺设的游艇级柚木地板也是具备了部分奔驰v260商务改装车难以比拟的豪华舒适度。 精致到无以复加的奔驰奔驰V260商务车总裁级航空首长席配备,除了高标准的视觉享受,更有完爆空乘贵宾舱的舒适体验,按摩、通风、加热、旋转八向舒适性调节,适用于各种身形的乘客消疲解乏,真正的坐享其成。

奔驰豪华房车价格及介绍

奔驰豪华房车价格及介绍 奔驰豪华房车价格及介绍,详情咨询南京亿海汽车,咨询有优惠!现如今房车生活逐渐从美国引入中国,房车旅游生活已经深入一部分人的生活中,各种豪华房车从国外引入到国内,奔驰豪华房车就是非常受欢迎的一款,奔驰豪华房车,让工作和休闲同时进行。下面就来看看奔驰豪华房车斯宾特的相关介绍。 关于奔驰豪华房车的价格,不同的改装在价格上都存在着差异,具体报价请咨询南京亿海汽车,咨询有优惠! 奔驰斯宾特豪华房车,兼具奢华内饰与实用性,是目前市场上主流的B 型豪华房车,一般都是设定在6米内,7 座以下,奔驰斯宾特前脸十分大气,前侧两层镀铬的进气格栅,两侧配有鹰眼式设计的氙气大灯,下侧配有大灯大灯清洗功能,以及感应雨刷,机盖上方 S 型镀铬空调进气口也是别具一格,双侧也配有镀铬反光镜,进一步提高了夜间行车的安全性。轮胎采用了17寸轮毂,胎壁加厚进一步缓解了车内的颠簸感,或者后期改为19寸轮毂加装一副空气悬挂,也是不错的选择。

作为一款豪华商务房车,奔驰斯宾特搭载3.5L排量的V6发动机,带电控喷射,配合5速自动变速箱,随时可以感受到那种强烈的推背感蠢蠢欲动,更由其重硕的体格,即使将近三米的车身高度,也能保持相当好的贴地感与平温度,让宾客乐享其“程”。斯宾特车内各项配备都力求尽善尽美,缤纷的氛围感,再现豪华影院级试听享受,极尽真实。全系配备Sony蓝光DVD影碟机作为图像、音源输入,32寸高清液晶电视给你身临其境的画面感,Bose5.1环绕式音响系统的表现力亦是可圈可点,斯宾特房车给我的感受更像是一个移动的家、行走的巨幕。 奔驰斯宾特豪华房车隐藏九座内饰雕琢上可谓是下足了功夫,全车游艇级柚木地板,纯手工真皮编织内饰,德式航海钟,环形立体式七彩氛围顶灯,后舱空气净化器,并于车顶预留了多个空调换气出风口,确保车内空气清新。扶手边的电控触摸屏几乎集成了后舱所有的电器操作:多媒体影音播放;车内全套氛围灯系统;前后排座椅旋转电动调节;更可下载手机APP实现掌间操控。后排电动沙发床是斯宾特房车的一贯标准配备,180度自由平躺,商务旅途中可算一处非常好的休憩场所,全家出行的话可当成小朋友的专属游乐王国。

大众商务车多少钱一辆

传承与历史不只属于奔驰和福特,大众在汽车历史的长河中也拥有众多经典车型,而“T”系列无疑是一笔浓墨重彩。大众商务车也因此吸引了众多的购买者,在选择车型的时候,大家都会对价格有所考量,那么大众商务车多少钱一辆呢,下面就来看看相关介绍,希望对大家有所帮助。 T型车不只是一款车或者一个车型,更代表了一种文化。T1和T2是20世纪60年代到 70年代的一个时尚符号。从T4开始,T 型车的身份发生了转变,变成了一款商务车。到了T5 的时候,大众开始强调其商务车的定位。而今天这款T6超乎想象的商务驾乘体验,展现较同级更强的动力、竞争力!前后驻车雷达系统停车时,若检测到车前方或后方有障碍物,会发出声音警告。同步在显示屏上会显示与障碍物的距离。倒车影像功能显示屏上显示车后方画面,使停车过程更加便捷。此外,指示线也能够对停车过程产生帮助。

外观方面,全新T6采用了大众新家族式的设计元素,前脸看上去比较有活力。车身侧面,全新T6采用了非常四平八稳的线条以及方方正正的车顶,为整车增添了些许大气、沉稳的气息。全新设计的LED 大灯,灵动中散发着睿智的光芒,与后方尾灯交相呼应,呈现出相得益彰的整体感。既有强大的驱动能力,又有强悍的保护能力,此为T6“攻防合一”的性格特质。源源不绝的动力来自于全系标配的2.0TSI 高性能汽油机, 150kW/350Nm 的动力输出配合7速DSG 双离合手自一体变速箱,将商务车鲜有的好动灵魂刻画得淋漓尽致。 大众商务车多少钱一辆?详情请咨询南京亿海汽车集团总公司。 南京亿海汽车集团总公司成立于1998年,是华东地区专业的豪华商务车、房车、SUV 展销中心,旗下有奔驰、林肯、GMC 、进口大众等品牌,为客户私人定制顶级的商务车、房车、保姆车。 我们始终坚持:“真情感动客户”、“专情服务客户”和“亲情维护客户”,奉行“您只管开车,剩下的事都是我们的!”销售和服务理念。以骄人的业绩、良好的口碑和先进的企业文化,在商务房车领域有着举足轻重的地位。 了解更多大众商务车相关信息欢迎致电咨询或登录南京亿海汽车网站: https://www.360docs.net/doc/b512210029.html,

福特 奔驰 丰田 gmc 大众房车各有什么优缺点

目前市面上的车,品牌很多,质量性能也是有所差异。根据车型不同又可以分为轿车,房车,商务车。国内房车市场上比较耳熟能详的有福特,宝马,丰田,GMC,大众等等。那么,福特奔驰丰田gmc 大众房车各有什么优缺点?下面就简单为大家介绍一下。 每个品牌的房车类型多样,性能参数不一。因此只能简单概括该品牌的部分特点,具体情况还是咨询经销商,以实际参数为主。 福特房车包括E350,E450,福特E350类型也分很多的,有黑色魅影版、铂金版、湾流版、游艇版,还有土豪金版,E350房车侧重商业化的出差,商务。而E450房车侧重旅游,基本明星会用到,报价也要贵一些。福特车型的优点是车子的空间大,乘坐舒服,回头率高,缺点是车子费油,价位贵,维修保养价格高。福特e350在定位上要更高,更具科技含量。 GMC跟福特E350外观差不多,GMC商务之星,乘坐舒服,空间宽阔。不过没有福特配置高,一般GMC都是在国内的改装的,油耗也比E350高。GMC以及福特e350都由内而外散发着美式的奢华与粗犷,而奔驰则是德系车,国外不管是把奔驰作为底盘改装还是直接购进,都比较常见。 奔驰的品牌价值高,优点是内里配置豪华,外型低调。核心为原装进口,内饰及配置经德国奔驰授权,同时售后网点多,维修方便;跟其他房车一样,有着车体大,进车库不方便的缺点。

丰田考斯特房车的外型跟中巴相似,比较适合企事业单位,机构,内里宽敞,多采用欧洲流行设计。丰田考斯特作为体积较大的车型(20-30座),司机所面临的视野盲区会是行车过程中的一个隐患,因此丰田考斯特的改装车一般会在车头上装置摄像将一切的视野所不能抵达的范围经过摄像头传抵达操作台上,以便当司机更好的把握路况。 大众商务车/房车比较常见的有凯路威和迈特威。有6/7座,8座款。乘客座椅可以360度旋转,配备洽谈桌椅,导航等。大众房车车身高大,开起来视野很开阔,外观也是普通的微面造型,不会太出众,比较低调。房车的优势就是可以定制,没有非常明确的价格区间,实惠点的房车价格在28-38万之间的,也有40万以上的房车,关键是看选什么配置。 南京亿海房车成立于1998年。是华东地区商务车、房车、SUV展-销-中-心,旗下有奔驰、林肯、GMC、进口大众等品牌,为客户私人定制商务车、房车、保姆车。如有需要,欢迎咨询!

上海大众7座商务车价格

上海大众7座商务车价格 上海大众7座商务车价格。上海大众七座商务车可以满足商旅人士各方面的驾乘需求。大众7座商务车相对简约坚挺的曲线,双面镀锌钢板车身板材,带来具有安全感的整车轮廓,同时,上海大众7座商务车的喷漆透着浓浓的商务质感,下面来看看上海大众7座商务车价格情况。 上海大众7座商务车价格,详细价格请咨询南京亿海汽车,咨询有优惠!亿海汽车房车种类多,让大家更省心,具体可登录https://www.360docs.net/doc/b512210029.html, 查看。下面主要为大家介绍大 众T6商务车。 大众T6商务车满足了消费者对商品外观、内部装修和空间、驾乘酣畅性以及人性化关怀的概括需求,完成了商品从办法与功用到拓宽与改造”质”的跨过,诠释了商品价值的重构与跋涉,成功完成了对原装进口的二次创造,为用户供应更加酣畅惬意的商旅领会。

大众T6商务车整车尺寸5304X1904X1990mm ,为内饰设计保留了更大尺度,电动侧滑门,在拥挤的城市中开启与关闭,更加节约空间。 大众T6商务车,搭载2.0TSI 涡轮增压发动机,4MOTION®四轮驱动系统,动力迅猛、运作安静;其配备的7速双离合变速箱,换挡平顺;350Nm 最大扭矩,魅力风范自然流露。 被动安全方面, T6商务车有高强度车体框架,主动安全方面,预碰撞安全系统涵盖了自动紧急制动系统,可以在行驶途中自动激活,当风险增大时产生声光提醒,甚至自动制动直至刹停。 进入车内,舒适感更加明显。经典的移动会议厅概念也同步提升,不仅仅来自那个熟悉的可拆卸老板桌,大面积高亮饰板与耐看的整体配色、真皮装饰、4 个全尺寸座位 +3人连排沙发(床),都营造了更具品质感的车内氛围。 以上就是关于大众7座商务车T6的介绍了,更多详情欢迎咨询南京亿海汽车。

大众t6商务车报价七座

大众t6商务车报价七座 暑表示炎热的意思,有句谚语是这么说的,“小暑不算热,大暑三伏天”。的确如此,小暑为小热,还不算十分热,但是南京的夏天,用热来形容是远远不够的。如此烦躁的夏天,想去体会一下世外桃源吗?大众t6商务车,帮您实现!在此大部分人产生的疑问就是作为进口大众t6商务车报价一定很贵吧,别着急,亿海这就带大家一起来了解一下下面几款大众t6商务车报价七座。 进口大众T6商务车-游艇(七座)技术参数如下: 动力参数:2.0T汽油7挡双离合生产地址:德国油箱容积:80L;整备质量:2247kg轴距参数:3400mm长*宽*高:5304*1904*1990/2150mm驱动轮胎:全时四驱 235/55R17座位牌照:7座蓝牌C照 型号类别:Volkswagen T6 豪华商务车/房车/保姆车 报价等更多信息欢迎致电咨询或登录南京亿海汽车网站:https://www.360docs.net/doc/b512210029.html,。 进口大众T6商务车-瑞航(七座)技术参数如下

动力参数:2.0T 汽油 7挡双离合油箱容积:80L长*宽*高:5304*1904*1990/2150mm 整备质量:2247kg轴距参数:3400mm驱动轮胎:全时四驱 235/55R17生产地址:德国油耗技术:直喷 10.3L/100KM型号类别:Volkswagen T6 豪华商务车/房车/保姆车座位牌照:7座蓝牌C照 报价等更多信息欢迎致电咨询或登录南京亿海汽车网站:https://www.360docs.net/doc/b512210029.html,。 进口大众T6商务车-豪驰(七座)如下技术参数 动力参数:2.0T 汽油7挡双离合油箱容积:80L长*宽*高:5304*1904*1990/2150mm 整备质量:2247kg轴距参数:3400(mm)驱动轮胎:全时四驱235/55R17生产地址:德国油耗技术:直喷 10.3L/100KM型号类别:Volkswagen T6 豪华商务车/房车/保姆车座位牌照:7座蓝牌C照 报价等更多信息欢迎致电咨询或登录南京亿海汽车网站:https://www.360docs.net/doc/b512210029.html,。 进口大众T6商务车-瑞驰(七座)技术参数

奔驰商务车七座多少钱

拥有百年造车精髓的梅赛德斯-奔驰是世界上历史悠久的汽车品牌,以豪华、舒适、等产品特点风靡全球,同时受到了热烈追捧。奔驰商务车不仅赋予产品强大的品牌魅力,更提供了超凡过硬的产品实力。那么奔驰商务车七座多少钱呢? 奔驰商务车七座多少钱?价格会根据车型的不同有所变动,所以购买者需要根据自己的购买需求咨询南京亿海汽车。咨询有优惠!下面为大家介绍奔驰商务车七座V-class的详细信息。 梅赛德斯—奔驰奢华而且时尚的车辆设计概念,在V-Class的车身上展露无遗。充满动感的车身前脸设计,炯炯有神的LED前车灯,镀铬进气格栅内镶嵌迈赛德斯—奔驰的星辉标,乘客舱深色隐私玻璃,空气动力学侧裙,合金轮毂以及尊贵的车身颜色,每一项皆诠释了梅赛德斯—奔驰对于设计的追求。 两种车长:1. 标准版车长5140mm(轴距3200mm) 2. 加长版车长5370mm(轴距3430mm)

三种车色:耀石黑、星辉银、皓雪白 M274 2.0T国五汽油发动机:对于V级豪华多功能车的引擎来说,敏捷的操控与高运行的速率不再是对立的存在。M274 2.0T直列四缸汽油发动机,采用缸内直喷和涡轮增压技术,相比于传统涡轮增压发动机其发动机最大优势在于能够克服涡轮迟滞效应,为驾驶者提供极度平顺感受。所有发动机皆配备ECO start/stop 发动机怠速节能启停功能,并且符合国五机动车排放标准。2.0T高功率发动机,最高时速185公里,扭矩350牛米,1250转就能爆发出最大扭矩,使提速不再有顿挫感。 增强版7速自动变速箱:与这款发动机匹配的是增强版7速自动变速箱7G-TRONIC 速自动变速箱增强版针对V级豪华多功能车发动机进行了调校。舒适或动感,一切尽在掌握。尊享平顺换挡,更配备多重降档功能体验加速快感。V-Class采用奔驰最拿手的后轮驱动方式,配合可变阻尼式敏捷操控悬挂系统依据路面情况及车速,调整底盘特性及车身姿态。配置动态操控控制器,4种驾驶模式:舒适、运动、经济、手动,尽供所需。

迈特威和埃尔法哪个好

迈特威和埃尔法哪个好 迈特威和埃尔法哪个好?详情咨询南京亿海汽车,咨询有优惠!丰田埃尔法令人印象深刻是经常出没在香港的电视剧中,其高频率的出现也影响了不少消费者。就迈特威而言,由于目前国内消费者接触到大众的MPV 多是途安L 和夏朗,再加上迈特威的售价并不便宜,所以很多人就自然而然将迈特威和商务联系在了一起。那么迈特威和埃尔法哪个好? 2018款埃尔法搭载一台型号为2GR-SKF 的全新3.5L V6自然吸气发动机,最大功率 221Kw,最大马力301Ps ,最大扭矩361Nm ,动力方面与上一代有着不小的提升,匹配全新的8AT 变速箱,在燃油经济上也有着不小的贡献。 埃尔法中控两边搭配金属饰条很好的划分出中控区域,但是视觉效果并不明显。不过埃尔法在车厢用料上从不吝啬,埃尔法座椅采用的材质手感很好,打孔皮革搭配柔软的填充物成就了如同头等舱的座椅。因为采用传统档杆设计,所以埃尔法不能像GL8那样直接从前排走到后排,这也许就如同车身侧面勾勒的线条一样为第二排乘客营造一种静谧的空间。

大众T6迈特威是一款不折不扣的MPV 车型,消费者们似乎对MPV 的要求仅停留在商务、空间、7座等词汇上,而大众T6迈特威确不仅仅停留在此。满足商务用途的内部空间和满足各类路况需求的四驱系统让全新上市的探索版进口大众迈特威更像一款具有SUV 功能的豪华商务车。 而且大众T6迈特威探索版还搭载了大众旗下的第五代Haldex 四驱系统,在车头进气格栅上标有4MOTION 标识。在这基础之上,大众T6迈特威探索版还增加了后桥机械差速锁,这是现在大部分MPV 车型里所没有的。 一款可以拥有SUV 越野性能的MPV 可以说是大众T6 迈特威探索版很大的卖点,不仅如此,在 MPV 车型中它的空间自由度和宽敞程度也是少见的。所以作为大众T 系列多功能车的继承人,迈特威探索版可谓是做足了“多功能”这三个字,在本就车型不多的MPV 市场里,能做到如此用途多样化的MPV 真的是少见了。

奔驰商务车报价及图片

奔驰商务车报价及图片 随着人们生活水平和质量的提高,普通的车型已经不能够满足人们的需求,奔驰下面亿海带给大家几款奔驰商务车报价及图片,我国国内的汽车在不断的成熟起来,一些豪车的价格也在上升,价格是人们非常关注的问题之一,下面就由亿海来给大家详细的介绍,仅供参考。 奔驰斯宾特—概述: 奔驰商务车"斯宾特"是专为商务人士开发的车型,是商务人士专业的商业伙伴。尊贵大气的外观、澎湃的动力以及坚实可靠的性能,再现了奔驰汽车对于车型的不懈追求。然而奔驰商务车"斯宾特 " 与其它商务车的不同之处就是后面可以根据车主的意愿进行改造,只要你能想到的,奔驰厂家也能为你做到。 报价等更多信息欢迎致电咨询或登录南京亿海汽车网站:https://www.360docs.net/doc/b512210029.html, 。 奔驰V-Class —概述:

奔驰商务车V-Class是兼顾商务和家庭用车的车型,是成功人士贴心伙伴。尊贵大气的外观、澎湃的动力以及坚实可靠的性能,再现了奔驰汽车对于车型的不懈追求。奔驰新V级上市有一段时间了,虽有心理准备,但火爆的订单量还是让厂家喜出望外,这足以说明全新奔驰V-Class的吸引力。同时,询问全新V-Class详细功能配置的呼声也日渐高涨,然而,奔驰商务车V-Class与其它商务车的不同之处就是可以根据车主的意愿进行升级改造,只要你能想到的,亿海都会尽所有能力为你做到。 报价等更多信息欢迎致电咨询或登录南京亿海汽车网站:https://www.360docs.net/doc/b512210029.html,。 奔驰斯宾特—概述: 奔驰商务车"斯宾特"是专为商务人士开发的车型,是商务人士专业的商业伙伴。尊贵大气的外观、澎湃的动力以及坚实可靠的性能,再现了奔驰汽车对于车型的不懈追求。然而奔驰商务车"斯宾特"与其它商务车的不同之处就是后面可以根据车主的意愿进行改造,只要你能想到的,奔驰厂家也能为你做到。 报价等更多信息欢迎致电咨询或登录南京亿海汽车网站:https://www.360docs.net/doc/b512210029.html,。 针对于奔驰商务车报价及图片小编就为大家先介绍到这里,如果还不能够满足大家的话请登录https://www.360docs.net/doc/b512210029.html,。南京亿海汽车集团总公司成立于1998年,是华东地区专业的豪华商务车、房车、SUV展销中心,旗下有奔驰、林肯、GMC、进口大众等品牌,为客户私人定制顶级的商务车、房车、保姆车。

奔驰V250商务车报价多少钱

奔驰V250在设计的档次感方面比之前有了非常大的进步,外观也许给人感觉变化并不是特别大,那么内饰则完全不一样了,近期的奔驰家族风格我们已经很熟悉了,而用在一款MPV 上还是让车内一下子变得高大上了很多。而且像一些细节之处的设计也向着轿车看起,比如仪表盘、方向盘和多媒体系统等,这也让它逐渐脱离之前很像是一款商用车的印象。奔驰V250商务车报价如何?下面我们一起来看看吧,希望对大家有所帮助。 这款奔驰V250内饰采用真皮与碳纤维拼接而成,座椅加上碳纤维使得车内更具有运动气息,让奔驰V250这款商务车的内饰摆脱了那些商务老大哥的身影。浓郁的运动气息更能激发想要驾驭它的冲动。家族化设计的LED 大灯非常漂亮,尖锐的轮廓视觉效果颇为犀利。总共由34颗LED 光源组成,光带式日行灯点亮后煞是好看。后视镜外壳上集成了转向灯,在底座下方还设有迎宾灯,而且还新增了变线辅助系统。中控台设计可以用惊艳来形容,整体风格与奔驰C 级以及S 级非常相似。采用了大面积搪塑工艺软性材质,符合奔驰惯有的风格。

内饰细节配备方面:高清仪表、中控独立悬浮液晶显示和三幅式多功能方向盘更加精致和实用。而为更好适应国内道路状况和交通问题,还特意采用了增强版的7速手自动变速箱来巩 固行车驾驶体验。普通奔驰 v级、奔驰v260等系列房车对比,这款进口奔驰v250改装内舱 定位不再局限于“载客”之上,“乘客”和“乘坐”的传统意识通过新概念的应用设计,进一步提升了乘员自身体验的重要性,而非房车奔驰尊贵品位上的面子工程。涵盖两座反响吧台座椅,乘客舱共四座真皮座椅,多功能扶手集合了小桌面、储物柜、座椅功能调节和精致酒柜等设备应用,让房车内舱设备的亮点,更加切合乘员实用便利的实际和享受。

林肯领航员2018款报价 领航员2018款最新报价多少钱

林肯领航员2018款报价 2018款林肯领航员接受定金预定,林肯领航员2018款报价158万,咨询有优惠!2018款林肯领航员接受预订。暂时不加价,咨询有优惠!敬请期待!2018款林肯领航员可以选择 亿海汽车,林肯领航员2018款报价158万,接受预订,不加价!更多车型可以咨询亿海汽车。 2018款林肯领航员配置 18款林肯领航员搭载3.5T双涡轮增压引擎,提供450马力335千瓦的动力自适应氙灯,方向盘电动调节,前排座椅加热,带加热功能前挡风感应雨刷,全景天窗,后排私密玻璃,自 动防眩目后视镜,氛围灯,电动尾门,前后驻车雷达,蓝牙USB连接,方向盘后视镜及座椅记忆、方向盘加热、后摄像头、定速巡航、电尾门触摸屏分辨率增强氛围灯、哈曼卡顿音响、20项座椅、四区空调、无钥匙进入、抬头显示、后排座椅加热、门把手灯、后排手动遮阳帘、电 吸门环影并道 M包(20轮黑色行李架 M套件 M真皮方向盘全景天窗陶瓷挡钯、电尾门加 热方向盘前座椅加热)NAPPA座椅、座椅通风、七座座椅 18款块头巨大的领航员,座椅采用2+2+3的布局,可以随意折叠调配,二三排折叠,立刻变身货车,车内空间扩升至2926升。领航员的第三排空间比很多7座MPV还要好。身高1.85米的体验者坐到第三排,无论头部还是腿部都有富余的空间。不过,遗憾的是第二排座椅并不能前后移动,所以第三排的腿部空间拓展性差一些。另外,领航员第三排座椅可以在行李 厢进行电动放倒和立起来,方便了有大体积行李时的装载。电动尾门的按键在左侧,而非尾门上,这会让刚接触的人有些不知所措。18款林肯领航员3.5TT 7座精雕细琢的内饰,结合了美国胡桃木和高级真皮材料、丝光镍饰件与白色发光二极管等组合一起,营造出一个豪华、浪漫 而又极具现代感的车内环境。方向盘和轿车一样的轻盈,周身散发出来的尊贵气息,让人肃然 起敬。

奔驰斯宾特房车报价单

奔驰斯宾特房车报价单 奔驰斯宾特房车报价单。奔驰斯宾特房车系列可以说是奔驰商务车房车中的经典热销车型了,外观的活力动感以及光鲜霸气和功能的实用性都是它能成为热销车型的主要原因。不仅是普通的商务人士会选择斯宾特,更有很多明星以及公众人物都选择斯宾特来作为他们出行的座驾。下面就来看看奔驰斯宾特房车报价的相关消息。 奔驰斯宾特房车报价单。详细价格请咨询南京亿海汽车,咨询有优惠!亿海汽车专业为客户定制各种车型,是您的理想选择。 进入奔驰斯宾特的驾驶室可以发现,斯宾特的驾驶室布局简约而不简单,中控台的按钮样式采用的是比较经典的款式,因为中控台的主要控制信息来源于大尺寸的触摸控制屏,驾驶室包括方向盘的皮质用料采用的是真皮,给驾驶员良好的手感和质感。 3.5升V6汽油发动机经过高效调校,随时即可迸发出最大功率258匹最大扭矩340扭米的强劲动力,搭配上5速手自一体变速箱,相信这是一辆司机朋友乐于驾驶的车。

斯宾特后舱不仅有着家庭影院的视觉享受,还有属于自己的小型吧台,吧台自带胶囊式咖啡机,闲暇之余冲泡上一杯醇香的咖啡,吧台的两侧还有两个隐藏式秘书座椅,一键展开这样 整个斯宾特房车就形成了 7+2式的座椅格局。 在车厢的各处还设置有多个电子控制屏,可以控制包括窗帘,空调,冰箱等车厢内多个电子产品和电子功能。奔驰斯宾特在电子智能控制方面也不输于其他竞品车型,这样的设计对于现在的电子信息和人工智能时代下的商务人士来说,可以事半功倍。 奔驰斯宾特房车在后排二坐采用的是航空级总裁席,座椅自带电动按摩,通风加热,等八项人性化功能,完全按照人体工学设计的航空级总裁座椅能够给后排乘客舒适的乘坐体验支持电动倾斜,给自己寻找一个舒服的姿势。

2019大众商务车T6价格多少

大众T6商务车是一款在商务接待领域有着广泛应用的汽车类型,颇受市场认可以及喜爱。大众商务车T6价格多少?这是广大车主都会比较关注的问题。本文中南京亿海汽车集团就针 对大众商务车T6的配置以及性能还有相关报价来进行详细介绍。 众T6从外观上来讲,比上一代的T5有了更多的改进,简洁平直的车身线条,但是线条的轮廓和清晰度比大众T5要好了很多,特别是车引擎盖上的两条棱线一直延伸,再加上高顶设计,一种从头到尾的凌厉几何感扑面而来;搭配上全新设计的LED大灯,让整个车头有了一种睿智沉稳的感觉。 走入驾驶室,大众T6的驾驶室中,首先吸引住我们视线的就是三幅式多功能方向盘,烤 漆材质,再加上方向盘上的多个功能键位,让整体的驾驶感有了很好的提升。整个中控台也采 用了大面积的烤漆饰板以及拉丝纹路饰板来装点, 新一代大众T6采用的是大家熟悉的2.0TSI发动机,350牛米的高扭矩输出,即使在满载 情况下也毫不逊色。更带有自动启停功能,减少油耗和尾气排放。

大众T6在后排三座的座椅选择上也有很多的人性化考量,大众T6的后排座椅采用电动三连坐沙发座椅,这款座椅拥有极高的座椅灵活性,支持一键电动平躺,可随时随地转换为一张柔软舒适的沙发床,不论是出差公干还是家庭出游,有这样方便的沙发座椅,能够增添更多的舒适度和生活乐趣。 目前,大众T6商务车的市场报价大概都在60万上下。如果您有实际的采购需求,欢迎致电联系南京亿海汽车集团。 南京亿海汽车集团,总公司成立于1998年。是华东地区专业的豪华商务车、房车、SUV 展销中心,旗下有奔驰、林肯、GMC、进口大众等品牌,为尖端客户私人定制顶级的商务车、房车、保姆车。现在咨询,立即享受折扣优惠!

上海大众七座商务车报价

上海大众七座商务车报价 上海大众七座商务车报价。七座商务车在我国的发展还是非常快的,七座商务车从自主品牌、合资品牌到进口品牌都有,各大厂家上市的7座商务车卖的都不错,当然上海大众七座商务车也不例外,大众T6商务车,更是凭借具有张力的性能表现、颇具优势的价格区间,吸引了众多购买者,那上海大众七座商务车报价如何呢? 上海大众七座商务车报价,详细价格请咨询南京亿海汽车,咨询有优惠!亿海汽车房车种类多,让大家更省心,下面主要来看看大众T6商务车的相关介绍。 大众( T6 )多功用商务车以原装进口为根底,遵从有用、内敛、理性安全的方案理念,经过外观形象的跋涉、精巧的内饰方案以及丰盛运用功用,创造精约、精巧、有用并具差异化的多功用移动商用空间。 外观方面,全新T6采用了大众家族式的方案元素,前脸看上去比照有活力。车身周围面,全新T6采用了十分深思远虑的线条以及方方正正的车顶,为整车增添了少数大气、沉稳的气

味。全新方案的LED 大灯,灵动中散发着睿智的光辉,与后方尾灯交相照料,呈现出相得益彰的整体感。 既有健旺的驱动才调,又有强悍的维护才调,此为T6“攻防合一”的性格特质。源源不绝的动力来自于全系标配的2.0TSI 高性能汽油机, 150kW/350Nm 的动力输出协作7速DSG 双聚散手自一体变速箱,将商务车鲜有的好动魂灵刻画得酣畅淋漓。此外,新一代 4MOTION? 还装备着第五代 Haldex 差速器,有用减轻车身重量,进一步加强了车辆的动力与操控性。 前进气格栅镀铬饰条与高穿透力晶钻式氙气大灯灯眉,完成一体式过渡并延伸至车身侧面腰线,流畅性十足。大面积隔热防紫外线前挡风玻璃、电动折叠防眩目功能后视镜,无一不在烘托着其外型的雍容典雅。 南京亿海汽车集团总公司成立于 1998年,是华东地区专业的豪华商务车、房车、SUV 展销中心,旗下有奔驰、林肯、GMC 、进口大众等品牌,为客户私人定制顶级的商务车、房车、保姆车。

著名房车品牌大全及报价表

房车品牌大全及报价表 房车品牌大全及报价表可以咨询亿海汽车。亿海汽车熟悉房车品牌以及报价。现在越来越多的人接受房车这种自驾游方式,各汽车厂商也推出自己的房车品牌和车型。中国的房车市场正在发展,很多房车生厂商和改装厂也逐渐涌现。今天对房车品牌做简单的说明介绍,让想要选购房车的你有一个参考。购房车选择亿海汽车,您只管开车,剩下的事都是我们的。 长城览众房车 览众房车为长城汽车唯一的房车战略合作伙伴,延续长城汽车十多年的房车研发成果及生产技术,采用长城房车专用底盘生产房车产品。 览众房车产品有览众风骏C型房车系列、赛拉维C型房车、拖挂房车等,览众风骏房车系列产品连续12年国内销量遥遥领先,并且远销美洲、澳洲、日本、韩国等多个国家和地区,是中国房车行业的销量领先品牌。 中天房车 中天房车隶属于北京中天行投资管理有限公司;专注房车源于2001年,中国房车旗舰品牌,是国内最早从事房生产、具有自主研发能力的特种车辆制造企业。 2001年中国第一辆拥有完全自主知识产权的自行式房车下线,彻底打破了中国没有自行研发生产旅居房车的历史,标志着中国企业自主创新能力的一次历史性跨越。 年生产能力6000余台,十多年来,中天房车赢得了社会各界的普遍赞誉,中天始终坚持技术立企的企业发展战略,截止到目前中天在房车领域已经取得技术发明专利近百余项,在业内高居领先地位。 江铃房车 江西江铃汽车集团旅居车有限公司成立于2010年7月16日,隶属于江铃汽车集团,企业性质:中外合资企业,注册资金:人民币2000万元; 企业信条:秉持“原厂改装”设计理念,引进欧美先进的汽车生活理念,引领中国国民汽车消费观念的使命,坚持成为“国内最优秀旅居车公司” 大通房车 上汽大通汽车有限公司(以下简称“上汽大通”),是上海汽车集团股份有限公司全资子公司,公司现拥有上汽大通MAXUS和LDV两大品牌,设有无锡生产基地,主要生产V80和G10两大平台产品,2017年,无锡基地将共线生产皮卡和SUV产品,年产能将达到20万台规模。