WLCO HDMI 规格书---中英文

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No:

A

TITLE:

HDMI TYPE A REC.CONN. 1 of 7

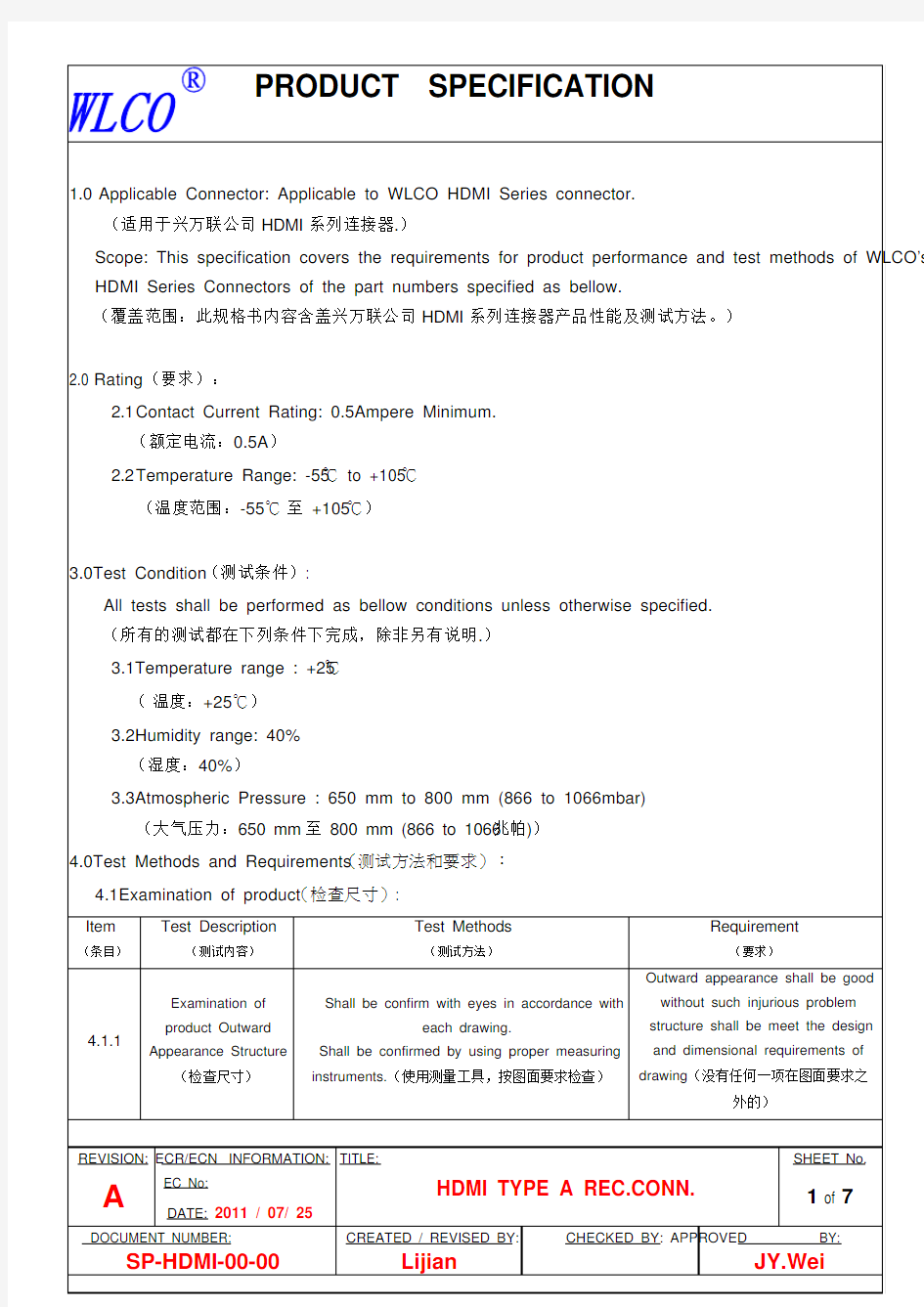

1.0 Applicable Connector: Applicable to WLCO HDMI Series connector.

(适用于兴万联公司HDMI 系列连接器.)

Scope: This specification covers the requirements for product performance and test methods of WLCO’s HDMI Series Connectors of the part numbers specified as bellow.

(覆盖范围:此规格书内容含盖兴万联公司HDMI 系列连接器产品性能及测试方法。)

2.0 R ating (要求):

2.1 C ontact Current Rating: 0.5Ampere Minimum. (额定电流:0.5A )

2.2 T emperature Range: -55℃ to +105℃

(温度范围:-55℃ 至 +105℃)

3.0Test Condition (测试条件):

All tests shall be performed as bellow conditions unless otherwise specified. (所有的测试都在下列条件下完成,除非另有说明.)

3.1Temperature range : +25℃ ( 温度:+25℃) 3.2Humidity range: 40% (湿度:40%)

3.3Atmospheric Pressure : 650 mm to 800 mm (866 to 1066mbar) (大气压力:650 mm 至 800 mm (866 to 1066兆帕))

4.0Test Methods and Requirements (测试方法和要求):

4.1Examination of product (检查尺寸):

Item

(条目)

Test Description

(测试内容)

Test Methods

(测试方法)

Requirement

(要求)

4.1.1

Examination of

product Outward Appearance Structure

(检查尺寸)

Shall be confirm with eyes in accordance with

each drawing.

Shall be confirmed by using proper measuring instruments.(使用测量工具,按图面要求检查)

Outward appearance shall be good

without such injurious problem structure shall be meet the design and dimensional requirements of drawing (没有任何一项在图面要求之

外的)

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No:

A

TITLE:

HDMI TYPE A REC.CONN. 2 of 7

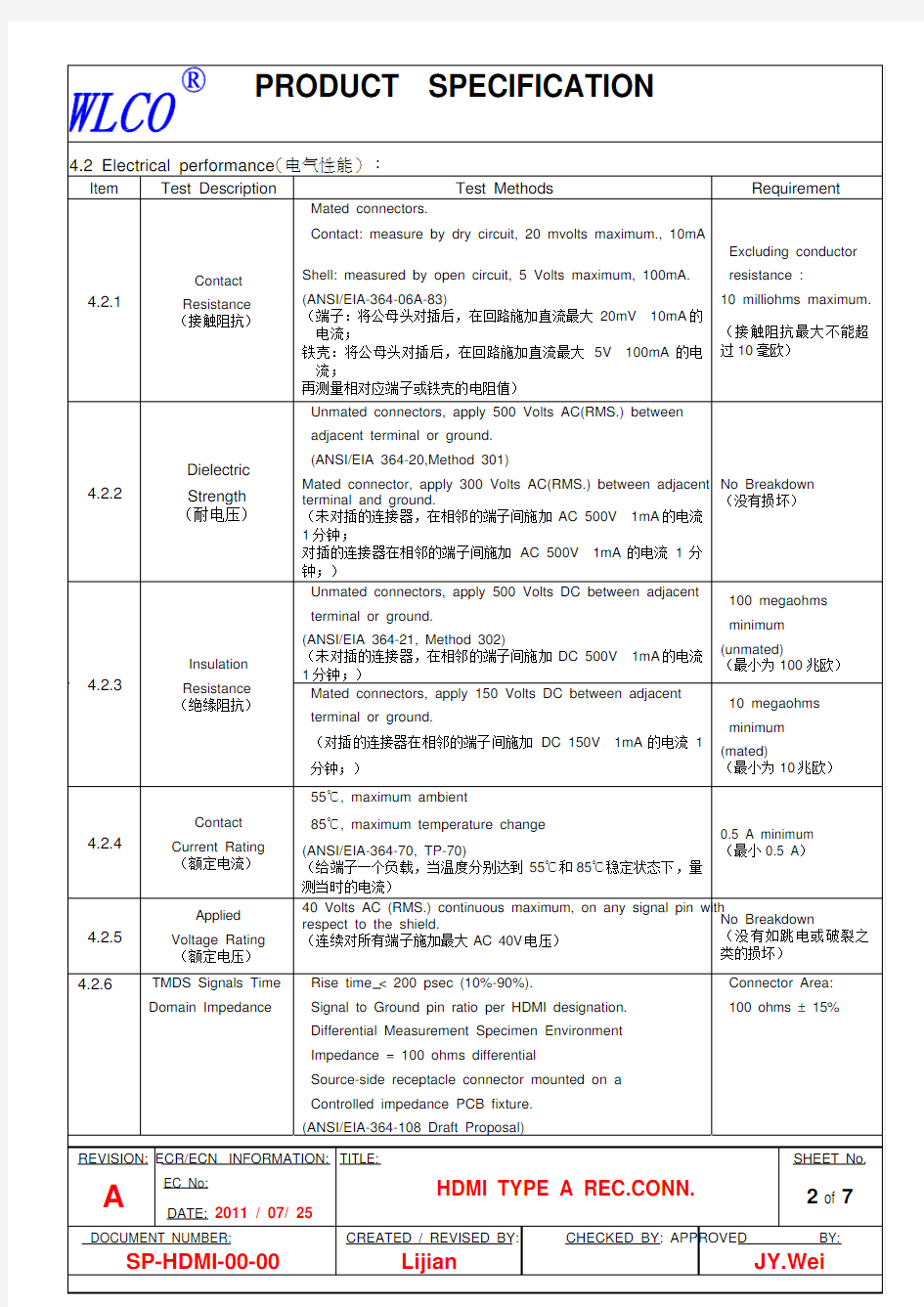

4.2 Electrical performance (电气性能):

Item

Test Description

Test Methods Requirement

4.2.1

Contact

Resistance (接触阻抗)

Mated connectors.

Contact: measure by dry circuit, 20 mvolts maximum., 10mA

Shell: measured by open circuit, 5 Volts maximum, 100mA. (ANSI/EIA-364-06A-83)

(端子:将公母头对插后,在回路施加直流最大20mV 10mA 的电流;

铁壳:将公母头对插后,在回路施加直流最大5V 100mA 的电流;

再测量相对应端子或铁壳的电阻值)

Excluding conductor

resistance :

10 milliohms maximum.

(接触阻抗最大不能超过10毫欧)

4.2.2

Dielectric

Strength (耐电压)

Unmated connectors, apply 500 Volts AC(RMS.) between adjacent terminal or ground. (ANSI/EIA 364-20,Method 301)

Mated connector, apply 300 Volts AC(RMS.) between adjacent terminal and ground. (未对插的连接器,在相邻的端子间施加AC 500V 1mA 的电流1分钟;

对插的连接器在相邻的端子间施加AC 500V 1mA 的电流1分钟;)

No Breakdown (没有损坏) Unmated connectors, apply 500 Volts DC between adjacent

terminal or ground.

(ANSI/EIA 364-21, Method 302)

(未对插的连接器,在相邻的端子间施加DC 500V 1mA 的电流

1分钟;)

100 megaohms

minimum

(unmated)

(最小为100兆欧)

4.2.3

Insulation

Resistance (绝缘阻抗)

Mated connectors, apply 150 Volts DC between adjacent

terminal or ground.

(对插的连接器在相邻的端子间施加DC 150V 1mA 的电流1

分钟;)

10 megaohms

minimum

(mated)

(最小为10兆欧) 4.2.4

Contact

Current Rating (额定电流)

55℃, maximum ambient

85℃, maximum temperature change

(ANSI/EIA-364-70, TP-70)

(给端子一个负载,当温度分别达到55℃和85℃稳定状态下,量测当时的电流)

0.5 A minimum (最小0.5 A )

4.2.5 Applied

Voltage Rating (额定电压) 40 Volts AC (RMS.) continuous maximum, on any signal pin with

respect to the shield.

(连续对所有端子施加最大AC 40V 电压)

No Breakdown (没有如跳电或破裂之类的损坏) 4.2.6

TMDS Signals Time Domain Impedance

Rise time < 200 psec (10%-90%).

Signal to Ground pin ratio per HDMI designation. Differential Measurement Specimen Environment Impedance = 100 ohms differential

Source-side receptacle connector mounted on a Controlled impedance PCB fixture. (ANSI/EIA-364-108 Draft Proposal)

Connector Area: 100 ohms ± 15%

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No:

A

TITLE:

HDMI TYPE A REC.CONN. 3 of 7

4.2.7

TMDS Signals Time Domain Cross talk FEXT

Rise time < 200 psec (10%-90%)

Signal to Ground pin ration per HDMI designation. Differential Measurement Specimen Environment Impedance = 100 ohms differential.

Source-side receptacle connector mounted on Controlled impedance PCB fixture. Driven pair and victim pair. (ANSI/EIA-364-90 Draft Proposal)

5 % maximum

4.3 Mechanical Performance:

Item Test Description

Test Methods

Requirement

Appearance (外观) No Damage (没有损坏) Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

4.3.1

Vibration (振动测试)

Amplitude:1.52 mm P-P or 147m/s 2

{15G} (振幅:1.52mm ) Sweep time:50-2000-50Hz in 20

minutes.(频率:20分钟内变换50-2000-50Hz )

Duration:12 times in each

(total of 36 Times) X, Y, Z axes.(持续时间:每个方向12小时,共36小时)

Electrical load: DC100mA current shall be Flowed during the test. (负载:施加DC 100mA 电流测试)

(ANSI/EIA-364-28 Condition Ⅲ Method 5A)

Discontinuity (断讯)

1 μsec maximum. (不能超过1微秒)

Appearance (外观) No Damage (没有损坏)

4.3.2

Shock

(冲击测试) Pulse width: 11 m sec., Waveform: half sine,

490m/s 2

{50G}, 3 strokes in each

(将对插后的连接器固定于冲击实验机上,并施加下列测试条件: 冲击时间:11毫秒 波形:半正弦波

加速度最大50G ,沿3个互相垂直的方向)

Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No:

A

TITLE:

HDMI TYPE A REC.CONN. 4 of 7

Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

Discontinuity (断讯)

1 μsec maximum. (不能超过1微秒) 4.3.3

Durability (寿命测试)

Measure contact and shell resistance after Following. Automatic cycling:

10,000 cycles at 100 + 50 cycles per hour

(将公座及母座焊接在PCB 上,然后以每小时100±50次的速度沿轴向插拔10000次)

Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

Withdrawal Force

(拔出力)

Initial:9.8N {1.0kgf} minimum 39.2N{4.0kgf} maximum After 2000 cycles: 4.9N {0.5kgf} minimum

39.2N{4.0kgf} maximum 初始:最小 9.8N {1.0kgf} 最大39.2N{4.0kgf} 插拔2000次后:

最小 4.9N {0.5kgf}

最大39.2N{4.0kgf}

4.3.4

Insertion/ Withdrawal Force

(插入/拔出力)

Insertion and withdrawal speed: 25mm/mminute.

(ANSI/EIA-364-13)

(将公座或母座焊接在PC 板上,然后以每分钟25mm 的速度沿轴向插拔3次后再测量其插入和拔出力)

Insertion force (插入力)

44.1N{4.5kgf} maximum (最大44.1N{4.5kgf})

4.3.5

Terminal retention (端子保持力)

Assembled in the housing at a rate of 25±3mm per minute.

(沿胶芯组装面,用每分钟25+3mm 的速度拔出端子)

pull-out force (拔出力)

2.94N Minute Min (0.3Kgf Min )

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No:

A

TITLE:

HDMI TYPE A REC.CONN. 5 of 7

4.4 Environmental Performance:

Item Test Description

Test Methods

Requirement

Appearance (外观) No Damage (没有损坏)

4.4.1

Thermal Shock (冷热冲击)

10 cycles of: –55℃ for 30 minutes +85℃ for 30 minutes

(ANSI/EIA-364-32, Condition I)

(将连接器焊在PCB 上后将其暴露在下列环境条件中循环10次:

置于–55℃±3℃温度中30分钟,再转换标准温度条件10-15分钟,再转换至+85℃±2℃下30分钟,再换至标准温度条件10-15分钟;)

Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

Appearance (外观) No Damage (没有损坏)

A 4.4.2 Humidity

(恒温恒湿)

Mate connectors together and perform the test as Follows. Temperature: +25℃ to +85℃ Relative Humidity: 80 to 95% Duration: 4 cycles (96 hours) Upon completion of the test, specimens shall be conditioned at ambient room conditions for 24 hours,

After which the specified measurements shall be performed.

(ANSI/EIA-364-31)

(将公母座配对后,放入下列环境中测试:

温度:+25℃-+85℃ 湿度:80-95%

时间:4天(96小时)

测试后产品应置于标准大气条件中24小时后再进行测量;)

Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

REVISION: ECR/ECN INFORMATION: SHEET No.

EC No:

A

TITLE:

HDMI TYPE A REC.CONN. 6 of 7

Appearance (外观)

No Damage (没有损坏)

B

Unmated each connectors and perform the test as follows. Temperature: +25℃ to +85℃ Relative Humidity: 80 to 95% Duration: 4 cycles (96 hours) Upon completion of the test, specimens shall be conditioned at ambient room conditions for 24 hours,

After which the specified measurements shall be performed.

(ANSI/EIA-364-31)

(将单个连接器,放入下列环境中测试:

温度:+25℃-+85℃ 湿度:80-95%

时间:4天(96小时)

测试后产品应置于标准大气条件中24小时后再进行测量;)

Dielectric Withstanding Voltage and Insulation Resistance (耐电压和绝缘阻抗)

Conform to item of Dielectric Withstanding Voltage and Insulation Resistance

(符合耐电压和绝缘阻抗测试要求)

Appearance

(外观) No Damage (没有损坏)

4.4.3

Thermal Aging (热老化测试)

Mate connectors and expose to + 105℃ + 2℃

for 250 hours. Upon completion of the exposure period, the test specimens shall be conditioned at ambient room conditions for 1 to 2 hours, after which the specified measurements shall be performed.

(ANSI/EIA-364-17, Condition 4, Method

A)

(将连接器放在+ 105℃ + 2℃的环境中250小时,然后再移至标准温度条件下1-2小时,再进行测量;)

Contact Resistance (接触阻抗)

Contact: Change From initial value: 30 Milliohms maximum. (端子:测试后不得大于30毫欧)

Shell Part: Change From initial value:50 Milliohms maximum.

(外壳:测试后不得大于50毫欧)

4.4.4

Solder ability (焊锡性)

Immerse the solder pin of the connector in the solder bath at 245℃±3℃ for 3±0.5seconds.

After dipped the pin in the flux for 5 seconds.

(将端子脚浸入助焊剂中5秒,然后将端子脚浸入245℃±3℃的锡炉中3±0.5秒.)

Solder wetting (粘锡面积)

95% of immersed area must show no voids ,Pin holes. (锡附着的面积应超过浸入表面积的95%以上)

4.4.5

Resistance to soldering heat (耐焊性)

Place the connector on the PCB,then immerse the solder pin up to the

surface of the board in the solder bath at 260℃±5℃ for 10 seconds.

(将产品置于PCB 上,然后将Pin 脚部分浸入260±5℃的锡炉中10秒)

1、 Without deformation of case or excessive

lossen.(塑胶不得有明显变形或损坏) 2、 Electrical characteristics shall be

satisfied.(电气特性必须符合规格)

电机技术参数中英文对照

Rated output 额定输出 Rated armature voltage 额定电枢电压 Rated torque 额定转矩 Rated armature current 额定电枢电流 Rated rotating speed 额定转速 Continuous stall torque 连续失速(堵转)转矩 Instantaneous maximum torque 瞬时最大转矩 Stall armature current 失速电枢电流 Instantaneous maximum armature current瞬时最大电枢电流Maximum rotating speed最大转速 Friction torque 摩擦转矩 Rated power rate 额定功率比 Instantaneous maximum angular acceleration 瞬时最大角加速度Viscous braking constant 粘性制动常数 Torque constant 转矩常数 Voltage constant 电压常数 Rotor inertia 转动惯量 Armature winding resistance 电枢绕组电阻 Armature inductance 电枢电感 Mechanical time constant 机械时间常数 Electrical time constant 电气时间常数 Thermal time constant 热时间常数 Thermal resistance 热阻 Heatup limit 热上限 Mass 质量 Coefficient of voltage generated 再生电压系数 Effective (rms) ripple 有效脉动 Peak-to-peak ripple 峰-峰纹波 Linearity 线性 Minimum load resistance 最小负载电阻 Holding torque 保持转矩自锁转矩

产品规格书 BL-4C-英文

ShenZhen CHY Battery Technology Co.,LTD Page Number:1st of 15 Core Model:TMB433450AR Specifications of Product Specifications of Product Customer Name SHANGHAI HUAQIN TELECOM TECHNOLOGY CO.,LTD. Product Name Cell Phone Lithium-ion Battery Product Model (Customer): ZL20A57 Product Model CHY-ZL20A57 (Manufacturer): Product Size 433450AR/800mAh Material Number(Manufacturer) Material Number(Customer) Prepared Checked approved Customer Confirmation Contents Decision Outcome Signature Date Appearance Structure Electrical Property Company address: Buillding A3, Jindida T echnological Park, Langkou Village, Longhua T own, Shenzhen Tel:(86-0755)61564565/66/67/69 Fax:(86-0755)61564568

ShenZhen CHY Battery Technology Co.,LTD Page Number: 2nd of 15 Core Model:TMB433450AR Specification of Product Content Historical Recording of Date of Change Eidtion The Content Being Modification Edition Modification 00/01 2011-1-1 A0 New Edition Released 00/02 2011-6-21 A1 New Edition Released 1. Applicable Scope 2. Reference S tandard 3. T echnical Parameters 4. Batteries Work Principle Diagram 5. Material List 6. Reliability T est Specifications 7. T ransportation 8. S torage 9. Instructions and Safety Procedures 10. Packages and Marking 11. Warranty 12. Interpretation of Product Change Appendix : 1.PCM Work Principle Diagram 2.BOM of PCM 3.PCB Layout Diagram 4.Dimension Diagram 5.Label Diagram

技术规格书(中英文)

NPC-National Petro Co. 3600t Revolving/Engineering Crane Technical Specification (Project Plan) Shanghai Zhenhua Port Machinery (Group) Co., Ltd. 2005-12-10 Table of Content

1.1 General Description 总则 1.1.1Consist of the Specification 本规格书组成 The specification including general, hull structure, outfitting, machinery, electrical, refrigerating, air conditioning, ventilating, pipelaying, DP, and crane parts describes the 3600t CRANE PIPELAYING VESSEL based on scheme design. 本规格书由船舶总体、舾装、轮机、电气、通风冷藏空调、动力定位、起重机及铺管设备估价等部分组成,表述3600 t全回转起重工程船的主要技术规格方案。 1.1.2Construction Explanation建造说明 The BUILDER’s supply covers the item described in this specification, anything excluding from the scope of the specification will be supplied by the OWNER. 本船的建造估价,所有规格书所规定的项目均由建造方提供。超过规格书部分船东提供。 1.1.3Language and Measuring Unit文种与计量单位 The drawings, instructions, instruments, display, caution sign and nameplate shall be written in English and kept down the foreign nameplate of the importation of machine and equipments. Metric system is used for designing and fabricating of hull, crane and equipment etc. unless otherwise specialized in specification or instruction. 本船的图纸、使用说明书、仪表、显示、警示牌和铭牌等均以英文书写。进口机械、设备保留原来外文铭牌。 船体、起重机、机电设备等设计和建造,除非在规格书或说明书中特别表明,均采用公制计量单位。 1.2General Description船舶航区及用途 1.2.1The Sailing Area and Functions船舶航区及用途 The vessel is designed as a large-scale all revolving self-propelled vessel. The vessel is used for offshore projects. 本船是一艘自航大型全回转起重工程船,航行于无限航区。 本船主要用于海上海洋工程等作业。 1.2.2Type of Vessel船型 The vessel will be a steel, all welded crane ship with streamline bow, round bilge and bilge keel. A helicopter platform will be situated at forecastle deck. One (1) full revolving crane to be installed in the after area of deck. The vessel will be equipped with two (2) 2000kW tunnel thrusters at bow, two (2) 2500kW retractable azimuthing thrusters at the foreship, two (2) 4500kW azimuthing thrusters at the aftship. The dynamic positioning system is GL DYNPOS–AUTR class. 本船是一艘钢质、全电焊起重工程船。设流线型首,尾部纵向及舭部有圆角,设舭龙骨。船首设居住区及直升飞机起降平台。 船尾设置一台全回转吊机。 首部设2台轴隧式侧推装置,功率2×2000kW;设2台伸缩式全回转螺旋桨推进器,功

诺瓦科技LED控制器MCTRL600规格书英文版

Specifications Independent Controller MCTRL600 V2.1.0 NS110100121 X i ’a n N o v a S t a r T e c h C o ., L t d .

Overview MCTRL600 is an advanced model of Nova controllers, which supports extra-large resolution. With HDMI/DVI video input and four Ethernet port outputs, a single unit is able to load 2560×960. Multiple units can be cascaded for uniform control. Feature 1) HDMI/DVI input; 2) HDMI/external audio input; 3) 12bit/10bit/8bit HD video source; 4) Resolution supported: 2048×1152,1920×1200,2560×960; 5) Resolution supported: 1440×900 (12bit/10bit); 6) 1 light sensor interface; 7) Cascading supported; 8) 18bit gray scale processing and presentation; 9) Video format: RGB, YCrCb4:2:2, YCrCb4:4:4; 10) Standard 1U housing and independent power supply. X i ’a n N o v a S t a r T e c h C o ., L t d .

机械类常用技术要求中英文

常用技术要求 before the feeding control and the wind meets the tube welding, to the good center, in the hole guaranteed that ¢204 the pipeline can pass through. the 进料接管和出风接管焊前对好中心,内孔保证¢204管道能穿过。 welding uses the manual arc welding, welding rod trademark J420G. before the 焊接采用手工电弧焊,焊条牌号J420G。 painting, must carry on the superficial stain removal, the elimination welding residual and so on, its quality scale sees JB/T5000.12 the stipulation; Prime, in Huang He the blue color (according to color model) the polyurethane finishes two. Besides various laps spread the yellow paint, other spread the blue color. In the paint does not allow to contain the lead. Does not allow to have leaks flaws and so on paint, wrinkle paint. 涂装前要进行表面除锈、清除焊接残渣等,其质量等级见JB/T5000.12的规定;涂底漆一层、中黄和中蓝色(按颜色样板)聚氨酯面漆二层。除各盖板涂中黄漆外,其余均涂蓝色。漆中不允许含铅。不允许有漏漆、皱漆等缺陷。 sealants and so on lap like seal lax available CH107, JLC-1 spread in the slit main point. on 盖板如密封不严可用CH107,JLC-1等密封胶涂在缝隙大处。

诺瓦科技LED接收卡MRV220-15规格书英文版

Specifications Receiving Card MRV220-15 Product images provided in this file are for reference only , and the actual products shall prevail. Rev1.0.1 NS110100270 X I ' A N N O V A S T A R T E C H C O ., L T D .

Features MRV220 is the receiving card of Nova with 28-group data mode. It has the following features: 1) Single card outputs 24-group of RGB data; 2) Single card outputs 28-group of RGB data; 3) Single card outputs64-group of serial data; 4) Single card support resolution 256x226; 5) Configuration fileread back; 6) Temperature monitoring; 7) Ethernet cable communication status detection; 8) Power supply voltage detection; 9) Pixel-by-pixel brightness and chromaticity calibration, Brightness and chromaticity calibration coefficients for each LED; 10) Supports dual power backup function: It supports two-way power detection and screen brightness will be adjusted automatically when power failure occurs in any way of the power. NOTE: PWR1_S and WR2_S default to normal. Power shall be guaranteed to be pulled down to GND after power failure occurs; 11) Comply with RoHS standard; 12) Comply with EU CE-EMC Class A standard. X I 'A N N O V A S T A R T E C H C O ., L T D .

PA全系列端子台规格书(中英文对照本)

东莞市铄徕电子有限公司KINGLION ELECTRONICS CO.,LTD HTTP ://WWW.KINGLIONGROUP .COM PA 系列 端子台 平底型和凹槽型(底部加高1.2mm) 高脚型端子台(底部加高4.3mm) 規格尺寸(Dimensions & Data 尺 寸 Dimensions 型 号 Model 线 径 mm2 安 培 Amp 电 压 Volt. 螺 丝 Screw Unit A B C D E F 包 装 Packing PA7F PA7 FDS 1.5 1.5 17.5 17.5 450 450 M2.6×5 M2.6×5 (mm)(mm)96.2096.2017.0017.0014.5014.508.20 8.20 2.90 2.90 2.80 2.80 50pcs/bag 10bags/carton PA8F PA8 FDS 1.5 1.5 17.5 17.5 450 450 M2.6×5 M2.6×5 (mm)(mm)95.8095.8016.3016.3012.7012.708.00 8.00 2.90 2.90 2.80 2.80 50pcs/bag 10bags/carton PA8H PA8HDS 1.5 1.5 17.5 17.5 450 450 M2.6×5 M2.6×5 (mm)(mm)96.2096.2017.0017.0014.5014.508.00 8.00 2.90 2.90 2.80 2.80 50pcs/bag 10bags/carton PA8HT PA8HTDS 1.5 1.5 17.5 17.5 450 450 M2.6×5 M2.6×5 (mm)(mm)96.0096.0016.3016.3017.6017.608.00 8.00 2.90 2.90 2.80 2.80 50pcs/bag 10bags/carton PA9H PA9HDS 2.5 2.5 24.0 24.0 450 450 M3.0×6 M3.0×6 (mm)(mm)116.0116.020.2020.2016.7016.7010.0010.00 3.60 3.60 3.40 3.40 50pcs/bag 10bags/carton PA10F PA10 FDS 2.5 2.5 24.0 24.0 450 450 M3.0×6 M3.0×6 (mm)(mm)117.5117.520.2020.2015.8015.8010.0010.00 3.60 3.60 3.20 3.20 50pcs/bag 10bags/carton PA10H PA10HDS 2.5 2.5 24.0 24.0 450 450 M3.0×6 M3.0×6 (mm)(mm)117.5117.520.2020.2017.0017.0010.0010.00 3.60 3.60 3.20 3.20 50pcs/bag 10bags/carton PA10HT PA10HTDS 2.5 2.5 24.0 24.0 450 450 M3.0×6 M3.0×6 (mm)(mm)117.5117.520.2020.2020.1020.1010.0010.00 3.60 3.60 3.20 3.20 50pcs/bag 10bags/carton PA12H PA12HDS 6.0 6.0 41.0 41.0 500 500 M3.5×7 M3.5×7 (mm)(mm)140.7140.723.8023.8019.0019.0012.0012.00 3.90 3.90 4.20 4.20 50pcs/bag 8bags/carton PA14H PA14HDS 10.0 10.0 57.0 57.0 500 500 M4.0×9 M4.0×9 (mm)(mm)158.0158.025.6025.6025.2025.2013.5013.50 4.40 4.40 5.00 5.00 25pcs/bag 10bags/carton PA16H PA18H 16.0 25.0 76.0 101.0 500 500 M4.0×9 M5.0×11 (mm)(mm)169.8194.4 28.0036.90 23.0028.70 14.5016.50 4.20 4.20 6.00 7.50 10pcs/bag 10bags/carton 内容(Description): ◆底部(base):F 为平底型(Fwith flat base)\H 型底部加高1.2mm(Hwith 1.2mm elevated base)\ HT 型底部加高4.3mm(HTwith 4.3mm elevated base) ◆材质(housing material):高级尼龙66工程塑胶,防火等级UL 94V-2,94V-0(nylon66,natural)。 ◆温度(working temperature):110℃。 ◆弹片(wire protector DS):PA8FDS,PA8HDS,PA10FDS,PA10HDS,PA12HDS,PA14HDS 附加弹片。 (PA8FDS&PA8HDS&PA10FDS&PA10HDS&PA12HDS&PA14HDS with wire protector.) ◆接线排数(poles available) :12排(12poles) 第2.0版2007-05-30

技术规格书模板

技术规格书模板 -标准化文件发布号:(9456-EUATWK-MWUB-WUNN-INNUL-DDQTY-KII

中国石油大庆炼化公司 技术规格书 (物资名称:) 编制人:(专业厂或业务管理部门签字)年月日审核人:(专业厂单位领导签字)年月日 审批人:(业务管理部门领导签字)年月日

目录 1.总则 2. 执行标准 3. 主要技术要求 4. 检验和试验 5. 包装及运输 6. 资料交付 7. 技术服务及售后保证 8. 其它 附件供货范围 1.总则

1.1 本技术规格书适用于大庆炼化公司物资招标,提出了该物资生产、检验、试验、验收、运输、试用和售后服务等方面的基本技术要求; 1.2 投标人所供物资的材料、制造、检验和试验,按标准的最新版本要求执行;其它未列出的与本产品有关的规范与标准,投标人有义务在投标文件中列出。投标人应对所供产品质量承担全部责任。 1.3 在所有技术文件中的文字和计量单位,采用中文(中英文对照)和国际SI单位。 1.4 投标人所采用的专利涉及到的全部费用均被认为已经包含在报价中,投标人承担所提供的设计、制造过程中所涉及的各类专利技术的法律责任。投标人保证所采用技术不侵犯 任何第三方权益,如引发知识产权方面相关的法律纠纷,由投标人负全责。 2. 执行标准: 标准名称:下列标准或规范应为国家标准、行业标准或集团公司标准(不能为供应商企业标准)。 例:GB/T 14976 液体输送用不锈钢无缝钢管 GB/T 14975 结构用不锈钢无缝钢管 ………… 3. 主要技术要求(如有) 针对于标的物的具体要求,在本条列出。 例如具体参数要求,形式形状要求,特殊材质要求等。 4. 检验和试验(如有) 有标准的执行标准 例:执行GB/T 14976检验标准) 4.1 生产过程检验要求(如有) 例:需提供生产过程检验报告 4.2 出厂检验要求(如有) 例:需提供出厂合格证 4.3 第三方检验要求(如有) 例:需提供省级以上质量监督部门检测机构报告 4.4 购买招标文件后递交投标样品要求、试验要求(如有) 填写详细的递交样品方式、数量、包装、检验流程、报告出具等详细要求。 例:需提供样品一份。0.5L瓶装,开标前送至招标管理中心负责人处。 4.5 到货验收要求(如有)

电力电缆技术规格书 正式

电力电缆技术规格书 编制: 目次 1.概述....................................................................................... 错误!未指定书签。 2.标准....................................................................................... 错误!未指定书签。 3.设计....................................................................................... 错误!未指定书签。 3.1使用环境 ................................................................ 错误!未指定书签。 3.2 导体.................................................................... 错误!未指定书签。 3.3 绝缘.................................................................... 错误!未指定书签。 3.4 缆芯、填充及内衬层........................................... 错误!未指定书签。 3.5 铠装.................................................................... 错误!未指定书签。 3.5 外护套 ................................................................ 错误!未指定书签。 4.检查和试验........................................................................... 错误!未指定书签。 5.标记....................................................................................... 错误!未指定书签。 6.其它....................................................................................... 错误!未指定书签。 7.供货方式............................................................................... 错误!未指定书签。……1.概述 本规格书为电力电缆的的最基本的技术要求。 2.标准 高、低压电缆应符合本规格书及以下最新版法规及规范的要求。 2.1国家标准 GB/T2951.1-7-1997 电缆绝缘和护套材料通用试验方法 GB5013.1~4-97 额定电压450V/750V及以下橡皮绝缘电缆(IEC60245) GB/T3956-1997 电缆的导体 GB/T12666.1-7-89 电线电缆燃烧试验方法 GB/T2706.1-3-91 额定电压35kV及以下铜芯、铝芯塑料绝缘电力电IEC60502

QX7137英文版规格书

Typical Application R CS 1 V IN V IN (a)Low V oltage Application (b) High V oltage Application Figure 1:Typical Application Circuit Diagrams of QX7137 General Description QX7137 is a constant current regulator for LED driver with low quiescent current and low dropout voltage. The LED current ranges from 100mA to 3.0A. In addition to LEDs, QX7137 also needs the external connection of a NMOS and a resistor to set the LED current. QX7137 uses SOT23-5 package Features Power Supply Voltage: 2.7~5.5V Extremely Low Quiescent Current: 26uA Sink Current: 100mA~3.0A Current Accuracy: ±5% Extensible Power Supply: Above 400V Extensible LED Current: Up to 3.0A Applications Power LED Driver

Ordering Information Type Number QX7137 Package Marking 7137X Lot Number Pin Assignments SOT23-5 7137X GND CS VDD DRV EN 1325 4

电子产品中英文规格书完整版

Page 1 Of 12 ShenZhen C&D Electronics CO.Ltd. Add: Building 2, X iayousong Mountaintop Industrial District,Yousong Village,LongHua T own, Baoan District ShenZhen China Zip 518109 Tel: 86-755- 28142422 Fax: 86-755-28142699 E-mail: export@https://www.360docs.net/doc/f318780130.html, Remote control specification (Rev. A0) Seller Customer Part Name :Remote control Part No. : Part Name : Part No. : Seller approval Customer approval Prepared By: Date:Received by: Date: Checked By: Date: Checked by: Date: Approved By: Date:Approved by: Date: company chop:company chop: Change history Version Date Description Author Page 2 Of 12 2、目录Index

NO. appellation Page 1 规格书封面(Approval Sheet Cover) 1/12 2 目录(Index) 2/12 3 检验内容及要求(Verification content & Requirement) 3/12~6/12 4 码表(Code table) 7/12 5 产品效果图(Product Cosmetics drawing) 8/12 6 原理图(Schematic diagram) 9/12 7 爆炸图(Explosion drawing) 10/12 8 产品尺寸图(Dimension drawing) 11/12 9 包装尺寸图(Packaging drawing) 12/12

登船梯技术规格书 (英文版)

MARITIME TERMINAL OF COMPLEX Technical Specification of Gangway (CHEC NO:13303) (CLIENT NO:013) China Engineering Co. Ltd. (C) September, 2015 Issue status:

CONTENTS 1GENERAL.......................................................................... 错误!未定义书签。 1.1FIELD OF APPLICATION ............................................ 错误!未定义书签。 1.2DEFINITION OF ITEMS............................................... 错误!未定义书签。2REFERENCE DOCUMENTS.......................................... 错误!未定义书签。 2.1APPLICABLE CODES AND STANDARDS............... 错误!未定义书签。 2.2APPLICABLE PROJECT DOCUMENTS .................. 错误!未定义书签。 2.3EXCEPTIONS TO REFERENCE DOCUMENTS .... 错误!未定义书签。 2.4DOCUMENTS ORDER OF PRECEDENCE............. 错误!未定义书签。3SCOPE OF SUPPLY ........................................................ 错误!未定义书签。 3.1EQUIPMENT SUPPLY ................................................. 错误!未定义书签。 3.2EXCLUSIONS................................................................ 错误!未定义书签。 3.3BOUNDARY LIMITS ..................................................... 错误!未定义书签。 3.4ERECTION WORKS..................................................... 错误!未定义书签。4INSTALLATION DATA ..................................................... 错误!未定义书签。 4.1SITE LOCATION AND ENVIRONMENTAL CONDITIONS. 错误!未定义书签。 4.2AREA CLASSIFICATION ............................................. 错误!未定义书签。5GENERAL SERVICE CONDITIONS ............................. 错误!未定义书签。 5.1PROCESS...................................................................... 错误!未定义书签。 5.2OPERATING AND DESIGN CONDITIONS .............. 错误!未定义书签。6DESIGN AND CONSTRUCTION ................................... 错误!未定义书签。 6.1MATERIALS ................................................................... 错误!未定义书签。 6.2DESIGN REQUIREMENTS......................................... 错误!未定义书签。 6.3SWIVEL JOINTS AND STRUCTURAL BEARINGS错误!未定义书签。 6.4QUICK-CONNECT/DISCONNECT CARGO COUPLERS (QCDC)错误!未定义书签。 6.5SPOOL PIECES ............................................................ 错误!未定义书签。 6.6POWERED EMERGENCY RELEASE COUPLINGS (PERC)错误!未定义书签。 6.7ACCESSORIES............................................................. 错误!未定义书签。 6.8OPERATING AND CONTROL SYSTEM DESIGN .. 错误!未定义书签。

技术规格书

技术规格书 产品名:氢热分析仪系统 数量:1套 1.概要 主要用于测定无机气体的升温脱离分析装置,对升温过程中,从钢材中所逃逸的氢含量进行高精密度定量分析,可为高强度钢以及大型锻件焊接组织的氢脆敏感性以及储氢合金的分析评价提供重要分析数据。 2.系统构成 (1)分析室 (2)样品加热室 (3)样品导入室 (4)排气控制系统(包括烘烤系统) (5)氢含量数据采集系统 3.主要技术规格 3.1分析室 ·检出器:四重极质谱仪 质量测量范围:1~100amu 质量分析精度:0.01ppm wt以下(5g试样中) ·排气性能: 氢背景值:5×10-9Pa以下(产品保证值·、包括样品加热炉心管) 真空泵:两段涡轮分子泵(320L/s磁悬浮型涡轮分子泵,50L/s涡轮分子泵)机械泵 ·可烘烤温度:200℃(带烘烤保护罩) ·真空脱气处理:450℃/10h以上超高真空脱气处理(出場付真空脱气处理 分析数据) ·真空计:UHV規格电离真空计 ·隔离装置:与样品加热室采用全金属超高真空闸阀隔离 ·氢气校正

标准4点氢气校正:4.99×10-6atm?cc/sec 2.0×10-5atm?cc/sec 5.0×10-5atm?cc/sec 1.0×10-4atm?cc/sec 可实施至1.0×10-4atm?cc/sec=1atm的氢气校正,高精度(±0.5%)绝对压力计裝備,可对应规定压力值准确填充校正氢气。 填充氢气前实施真空排气,绝对压力计的原点复位每次校正。 氢气填充后,可通过开启阀门操作在超高真空下将标准校正氢气导入至炉心管。整个校正步骤,包括真空排气,2点校正线生成,氢气填充操作以及校正后的预备排气使用提示画面功能执行自动操作。 3.2样品加热室 ·加热方式:外加热式3区高温电气炉(管式) ·炉心管体:石英(超高真空金属法兰焊接规格,氢背景值5×10-9Pa) ·样品导入:磁耦合样品传输,无需使用样品架,低放出气体规格 ·可加热样品尺寸:φ20mm×50mm以下(形状不限) ·最高加热温度:Max.1000℃(均热长200mmm/±5℃) ·升溫速度:50℃/h~600℃/h任意可调,可设定保溫时间 溫度经时数据以及升溫結束信号输出功能 3.3样品导入室 ·排气性能:大气压~超高真空(5×10-5Pa)只需15分 ·真空泵:涡轮分子泵,辅助机械泵 ·可烘烤溫度:150℃ ·真空计:超高真空电离真空计 ·隔离装置:与样品加热室采用超高真空全金属闸阀隔离 3.4排气控制系统 ·触摸式PLC自动控制 分析室,样品导入室的真空排气/停止自动操作 样品交换时的真空排气以及阀门自动操作

英文技术规格书

Description: BA TTERY LiB-909YHNC(Z)for ZTE CORPORATION Battery Specifications: 3.8V/400mAh Rechargeable Lithium-ion cell: NEC IMP300540-1 DESAY LITHIUM-ION BATTERY SPECIFICATIONS ( LiB-909YHNC(Z)) DRW: CHK: APP: DESAY POWER TECH. CO., LTD. April 2002

1.Extent of the application This specification applied to the prismatic Lithium-ion rechargeable inter cell and battery pack for the mobile phone of ZTE CORPORATION. 2.Battery Classification and Type 2.1 Battery Classification Prismatic Lithium-ion Rechargeable Battery Park 2.2 Battery Type LiB-909YHNC(Z) 3.Structure Prismatic Li-ion Rechargeable Bare Cell/ protecting plate and Temperature Fuse ①Rated discharge: Discharge at constant current (80mA=0.2C) down to end voltage at 20±2℃. ②Rated charge: charge at CC-CV(400mA-4.2V) at 20±2℃.

技术规格书模板

技术规格书模板

中国石油大庆炼化公司 技术规格书 (物资名称:) 编制人:(专业厂或业务管理部门签字)年月日 审核人:(专业厂单位领导签字)年月日 审批人:(业务管理部门领导签字)年月日

目录 1.总则 2. 执行标准 3. 主要技术要求 4. 检验和试验 5. 包装及运输 6. 资料交付 7. 技术服务及售后保证 8. 其它 附件供货范围

1.总则 1.1 本技术规格书适用于大庆炼化公司物资招标,提出了该物资生产、检验、 试验、验收、运输、试用和售后服务等方面的基本技术要求; 1.2 投标人所供物资的材料、制造、检验和试验,按标准的最新版本要求执行;其它未列出的与本产品有关的规范与标准,投标人有义务在投标文件中列出。投标人应对所供产品质量承担全部责任。 1.3 在所有技术文件中的文字和计量单位,采用中文(中英文对照)和国际SI单位。 1.4 投标人所采用的专利涉及到的全部费用均被认为已经包含在报价中,投标人承担所提供的设计、制造过程中所涉及的各类专利技术的法律责任。投标人保证所采用技术不侵犯 任何第三方权益,如引发知识产权方面相关的法律纠纷,由投标人负全责。 2. 执行标准:

标准名称:下列标准或规范应为国家标准、行业标准或集团公司标准(不能为供应商企业标准)。 例:GB/T 14976 液体输送用不锈钢无缝钢管 GB/T 14975 结构用不锈钢无缝钢管 ………… 3. 主要技术要求(如有) 针对于标的物的具体要求,在本条列出。 例如具体参数要求,形式形状要求,特殊材质要求等。 4. 检验和试验(如有) 有标准的执行标准 例:执行GB/T 14976检验标准) 4.1 生产过程检验要求(如有) 例:需提供生产过程检验报告 4.2 出厂检验要求(如有) 例:需提供出厂合格证 4.3 第三方检验要求(如有) 例:需提供省级以上质量监督部门检测机构报告 4.4 购买招标文件后递交投标样品要求、试验要求(如有) 填写详细的递交样品方式、数量、包装、检验流程、报告出具等详细要求。 例:需提供样品一份。0.5L瓶装,开标前送至招标管理中心负责人处。 4.5 到货验收要求(如有) 如执行到货验收程序,需明确送检主责单位,检