Y型过滤器说明书

中文Y型过滤器说明书

Y型过滤器使用说明书中国·乐山市热工仪表有限公司一、用途及特点Y型过滤器是输送介质的管道系统不可缺少的一种过滤装置,Y型过滤器通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来清除介质中的杂质,以保护阀门及设备的正常使用。

Y型过滤器具有结构先进,阻力小,排污方便等特点。

二、主要技术参数公称压力:PN1.6MPa~4.0Mpa公称通径:DN15~200㎜适用介质:水、油、气体等过滤精度:通水网为18~30目,通气网为40~100目,通油网为100~480目。

工作温度:≤200℃法兰标准:JB、GB、HG壳体材质:WCB滤筐、滤网材质:304密封材质:耐油石棉橡胶、聚四氟乙烯、丁腈橡胶等执行标准:Q/20696377-7.4-2011三、安装与维护1、根据过滤器的使用范围合理地使用。

2、安装前应将管道内的焊渣、杂物清除干净,以免损坏过滤器。

3、安装时应按过滤器的箭头方向进行。

4、过滤器的运行及维护系统最初工作一段时间后(一般不超过一周),应进行清洗,以清除系统初始运行时积聚在滤网上的杂质污物。

在此后,须定期清洗。

清洗次数依据工况条件而定。

若过滤器不带排污丝堵,则清洗过滤器时要将滤网限位器以及滤网拆下。

警告:每次维护、清洗前,应将过滤器与带压系统隔离。

清洗后,重新安装时要使用新的密封垫。

5、过滤器使用中,应定期检查是否工作正常,发现异常情况,应立即消除,以免造成事故。

6、长期存放时,应置于通风干燥处,并定期检查和保养。

四、定货须知为了保证提供的产品能满足贵公司(厂)的使用要求,请按以下要求提供必要的参数:1、产品型号2、公称压力3、公称通径4、工作介质5、工作温度6、法兰标准7、结构长度(有要求时)五、简图。

Y型过滤器的排污及更换滤芯操作方法

Y型过滤器的排污及更换滤芯操作方法

1、检查与准备

1.1熟悉掌握过滤器的性能、原理及作用。

1.2检查过滤器进口阀、出口阀及排污阀应转动自如。

1.3观察过滤器压差表读数,当压差超过规定值时,应清洗或更换滤芯。

2、过滤器排污操作规程

2.1过滤器排污时须关闭其进口阀、出口阀,缓慢开启排污阀。

2.2当排污管内气体流动声音发生变化时,关闭排污阀门,排污结束。

3、滤芯更换操作规程

3.1清洗或更换滤芯前应开启备用管线,或停机。

3.2按照过滤器排污步骤对过滤器排污,观察压力表指示情况,当压力显示为零时,依次打开放散阀和截止阀对工艺管线放空,确保过滤器内没有剩余压力。

3.3使用正确工具拆卸过滤器,在指定区域内进行清洗。

3.4清洗后,按照拆卸的逆顺序依次安装并更换过滤器密封圈。

3.5通气前,关闭压差表两端的进出气阀,依次打开放散阀和截止阀,开启过滤器进口阀和出口阀。

3.6用检漏仪或泡沫水进行检漏,同时观察压力表指示情况,气压稳定后,开启压差表的进出气阀。

3.7填写相关记录。

4、注意事项

4.1排污时应平稳缓慢,以保证管线压力稳定,避免阀门损坏。

4.2定期检查及排污,防止污物积余过多进入燃气管线。

Y型过滤器手册说明书

TRANSPORTE E ARMAZENAGEMA. Os filtros deverão ser transportados sem retirar as proteções das partes internas.B. Evitar golpes que possam causar danos as partes internas.C. No armazenamento e na instalação, quando for solicitada, deverá ser preservada a plaquetade identificação.INSTALAÇÃOA. Proceder uma inspeção visual, afim de verificar se não houve danos com o filtro durante otransporte.B. Certificar se a conexão do filtro está compatível com a tubulação.C. Instalar o filtro sempre no sentido orientado pela seta indicativa fundida no corpo.D. Colocar o filtro na tubulação, preferivelmente na horizontal, com o alojador do elemento filtrantepara baixo.MANUTENÇÃOA. Remover a tampa do filtro.B. Retirar a junta de vedação.C. Retirar cuidadosamente o elemento filtrante (tela), fazendo a limpeza do mesmo, utilizandouma escova de aço.D. Remontar as partas retiradas.PEÇAS DE REPOSIÇÃOA. Recomenda-se Ter sempre em estoque as seguintes peças : Elemento filtrante e junta devedação.GARANTIA E ASSISTÊNCIA TÉCNICAA. As válvulas da Niagara tem garantia de 12 meses em uso ou 18 meses em estoque contradefeitos de fabricação, à partir da data da Nota Fiscal. A garantia não cobre o uso da válvula em condições inadequadas.Nota: Não aceitamos devoluções sem a prévia consulta com o nosso Departamento de Vendas._____________________________________________________________________________.brTel (11) 5660-4444Rev. 1 22/02/2018。

Y 型过滤器使用说明书

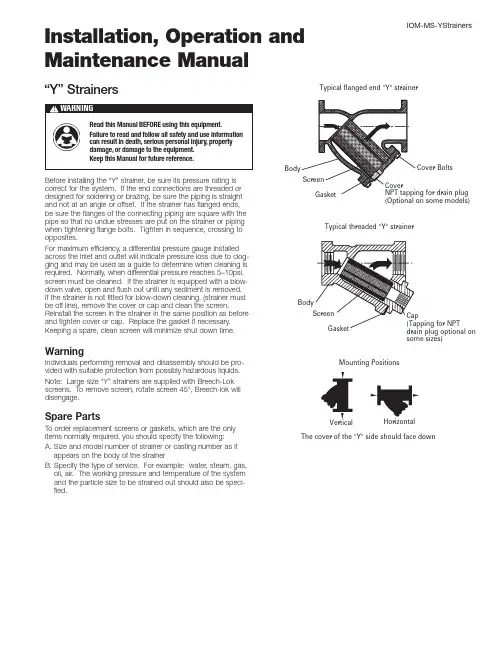

Before installing the “Y” strainer, be sure its pressure rating is correct for the system. If the end connections are threaded or designed for soldering or brazing, be sure the piping is straight and not at an angle or offset. If the strainer has flanged ends, be sure the flanges of the connecting piping are square with the pipe so that no undue stresses are put on the strainer or piping when tightening flange bolts. Tighten in sequence, crossing to opposites.For maximum efficiency, a differential pressure gauge installed across the inlet and outlet will indicate pressure loss due to clog-ging and may be used as a guide to determine when cleaning is required. Normally, when differential pressure reaches 5–10psi, screen must be cleaned. If the strainer is equipped with a blow-down valve, open and flush out until any sediment is removed. If the strainer is not fitted for blow-down cleaning, (strainer must be off line), remove the cover or cap and clean the screen.Reinstall the screen in the strainer in the same position as before and tighten cover or cap. Replace the gasket if necessary. Keeping a spare, clean screen will minimize shut down time.WarningIndividuals performing removal and disassembly should be pro-vided with suitable protection from possibly hazardous liquids.Note: Large size “Y” strainers are supplied with Breech-Lok screens. To remove screen, rotate screen 45°, Breech-lok will disengage.Spare PartsTo order replacement screens or gaskets, which are the only items normally required, you should specify the following:A. S ize and model number of strainer or casting number as it appears on the body of the strainer B. S pecify the type of service. For example: water, steam, gas,oil, air. The working pressure and temperature of the system and the particle size to be strained out should also be speci-fied.Installation, Operation and Maintenance Manual“Y” StrainersTypical flanged end "Y" strainerTypical threaded "Y" strainerMounting PositionsThe cover of the "Y" side should face down(Optional on some models)Vertical Horizontalsome sizes)Limited Warranty: Mueller Steam Specialty warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge. This shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Any implied warranties that are imposed by law are limited in duration to one year.Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to determine your rights.IOM-MS-YStrainers 1846 EDP# 1915978 © 2018 Mueller Steam SpecialtyUSA: T: (800) 334-6259 • F: (800) 421-6772 • Latin America:T: (52) 81-1001-8600 • Table ACap and Bolt Torques Torque noted is for threaded caps on small strainers, and for each bolt on larger strainers with bolted covers.。

永久媒体系统Y型过滤器简单双过滤器多篮式暂时标准漏管过滤器模型85Y过滤器说明书

Permanent Media Systems Y-StrainerSimplexDuplexMulti-basketTemporaryStandard cast pipeline strainersMODEL 85 Y-STRAINER• 1/4" to 10" threaded, flanged,or socket weld connections• Carbon steel and stainless steel• Compact design• Bolted or threaded covers • Standard stainless steel screens • Horizontal or vertical installationMODEL 72X SIMPLEX BASKET STRAINER• Flanged or threaded DIN and ANSI end connections • Ductile Iron models designed to 10 bar, 120°C • Stainless steel models designed to 16 bar, 120°C • Bolted cover• Machined basket seat with o-ring seal • Large capacity 316 stainless steel baskets, perforated or mesh • Bottom drain port • Mounting feet for stable installation for flanged units 2" and larger • Basket perforations from 1/32" to 1/2"• Basket mesh from 20 to 400• Optional: basket and seal materials, vent valves, gauge/vent taps, magnetic basket inserts, pressure differential gauge and switch• 1" to 8" flanged connections • Carbon steel or stainless steel • NPT steam connections • Up to 6.9 bar steam pressure • Quick open cover—no tools required • Large capacity basket • Threaded drain plug • Machined basket seat • Viton seals• Perforated or mesh 316 stainless steel basket • Basket perforations from 1/32" to 1/2"• Basket mesh from 20 to 400• Optional: vent valve and drain valves, gauge/vent taps, pressure differential gauge and switchesViton™, T efzel™ and Teflon™ are registered trademarks of The Chemours Company FC, LLC.Cross-section of a Y Strainer with blow off connection for quick and easy clean-out.Eaton standard cast pipeline strainers protect pumps, filters, nozzles, flow meters, valves, heat exchangers, condensers, oil burners, boilers, and other process system components from damaging pipeline debris. Eaton maintains the largest and broadest inventory of strainers in the industry, and can provide off-the-shelf delivery of simplex, duplex, and Y strainers in metals such as cast iron, carbon steel, bronze, and stainless steel. Eaton standard cast pipeline strainers meet customers’ expectations and the highest standards, including:• ISO 9001-2015 quality management • Properly sized components to meet anyspecified retention requirement and flow rate • NSF approved coatingsFor more than 50 years, Eaton has led the way with designs that meet the growing and vigorous demands of process and manufacturing industries, utilities, and municipalities around the world.The American Bureau of Shipping (ABS) has added Eaton’s Model 73 simplex strainers and the Model 53BTX duplex strainer to its list of Type Approved products.High performance systems for keeping debris out of your downstream equipmentStandard cast pipeline strainers• 10" to 18" flanged connections • Iron or bronze • Quick open cover• Straight through flow design • Low pressure loss • Convoluted basket design • Hand removable basket • Threaded drain • Buna-N O-ring seal • Low profile• No tools required for access• Perforated or mesh 316 stainless steel basket • Basket perforations from 1/32" to 1/2" • Basket mesh of 20, 40, or 60• Optional: vent valves, drain valves, gauge/vent taps, pressure differential gauge and switches• 1" to 6" flanged connections • Carbon steel with abrasion resistant 1/8" Tefzel liner • Excellent corrosion resistance • Tefzel-coated baskets • Service temperatures to 149 °C • Quick opening covers • Large capacity baskets • Flanged drain• Low cost alternative to exotic alloy strainers • Optional: MONEL orHASTELLOY C baskets• 3/4" to 4" threaded or flanged connections• Iron, bronze, carbon steel, or stainless steel • Dynamic sealing design for long life • Easy-to-operate lever handle—no gear box required • Unique seat and seal design requires no adjustments • Teflon seats for longer service life • Foot pads for rock solid installation• Double-stem O-rings for positive sealing • Easy to access body vent valve• Side drain plugs on each basket well • Piston seal strainer basket cover• Easy access for diverter cartridge removal •316 stainless steel ball designUnique diverter cartridge assures minimal leaks, if any to the basketchamber during cleaning. A double sealing system on the upper and lower stems guards against any possible leakage between fluid chambers and the environment. If service becomes necessary, just remove four bolts and the cartridge slides right out thetop of the strainer body.MONEL ® is a registered trademark of Special Metals Corporation group of Companies .HASTELLOY ® is a registered trademark of Haynes International Inc.• 5”, 6”, or 8” flanged connections• Iron, bronze, carbon steel, or stainless steel • Continuous flow, no shutdown for basket cleaning • Rugged tapered plug design • Lift jack prevents galling of the plug • Quick open cover—no tools needed • Large capacity baskets • Threaded drain • Machined basket seat• Perforated or mesh 316 stainless steel basket • Basket perforations from 1/32” to 1/2” • Basket mesh from 20 to 400• Optional: MONEL baskets, vent and drain valves, gauge/vent taps, pressure differential gauge and switches, cast iron and stainless steel diverter plug, magnetic basket inserts and a variety of seal materials• 10” to 18” flanged connections • Iron or bronze • Continuous flow - no shutdown for basket cleaning • Compact butterfly valve design • Quick opening covers • Convoluted-design bas-kets • Threaded drain• Perforated or mesh stainless steel baskets • Basket perforations from 1/32” to 1/2” • Basket mesh of 20, 40, or 60• Optional: Ductile iron construction, MONEL baskets, vent valve and drain valves, gauge/vent taps, pressure differential gauge and switches, and magnetic basket insertsMODEL 92 TEMPORARY STRAINER• Designed for use in new pipeline start-up service• Line flushing after any modification work • 2" to 24" flanged connection• Stainless steel or MONEL• ANSI Classes 150, 300, and 600• Perforations from 1/32" to 1/2" diameter • Mesh liners of 20, 40, 60, 80, and 100(best with basket type strainers)• Optional: Alloy construction,RT J-style connections Cone typeBaskettypeCone type temporary strainer is shownbolted between two pipe flangesADDITIONAL FABRICATED STRAINERS AVAILABLE• Custom fabricated pipeline strainers offer uniquedesigns that fit the exact requirements of anyapplication• Designed and constructed to meet worldwidequality standards and required codesModel 90simplexstrainerModel 950B duplexoffset strainer (BC/QOC)Model 91 T-typestrainer• Compact• Threaded drain• Perforated or meshstainless steel baskets• Basket perforationsfrom 1/32" to 1/2"• Basket mesh of 20, 40, or 60• Model 510:- Four baskets per strainer (two per side)• Model 570:- Sliding gate design- Continuous flow- no shutdown for basket cleaning- Eight baskets per strainer (four per side)• Optional: Ductile iron construction, MONEL baskets, vent valveand drain valves, gauge/vent taps, pressure differential gaugeand switches, and magnetic basket insertsModel 510simplexstrainerFor more information, pleaseemail us at********************or visit /filtration© 2023 Eaton. All rights reserved. All trademarksand registered trademarks are the property of theirrespective owners. All information and recommenda-tions appearing in this brochure concerning the use ofproducts described herein are based on tests believedto be reliable. However, it is the user’s responsibilityto determine the suitability for his own use of suchproducts. Since the actual use by others is beyond ourcontrol, no guarantee, expressed or implied, is madeby Eaton as to the effects of such use or the resultsto be obtained. Eaton assumes no liability arising outof the use by others of such products. Nor is the infor-mation herein to be construed as absolutely complete,since additional information may be necessary ordesirable when particular or exceptional conditions orcircumstances exist or because of applicable laws orgovernment regulations.North America44 Apple StreetTinton Falls, NJ 07724Toll Free: 800 656-3344(North America only)Tel: +1 732 212-4700Europe/Africa/Middle EastAuf der Heide 253947 Nettersheim, GermanyTel: +49 2486 809-0Friedensstraße 4168804 Altlußheim, GermanyTel: +49 6205 2094-0An den Nahewiesen 2455450 Langenlonsheim, GermanyTel: +49 6704 204-0Greater ChinaNo. 7, Lane 280,Linhong RoadChangning District, 200335Shanghai, P.R. ChinaTel: +86 21 2899-3687Asia-Pacific100G Pasir Panjang Road#07-08 Interlocal CentreSingapore 118523Tel: +65 6825-1620ENEF-SCPS-B05-2023。

Y型过滤器技术参数

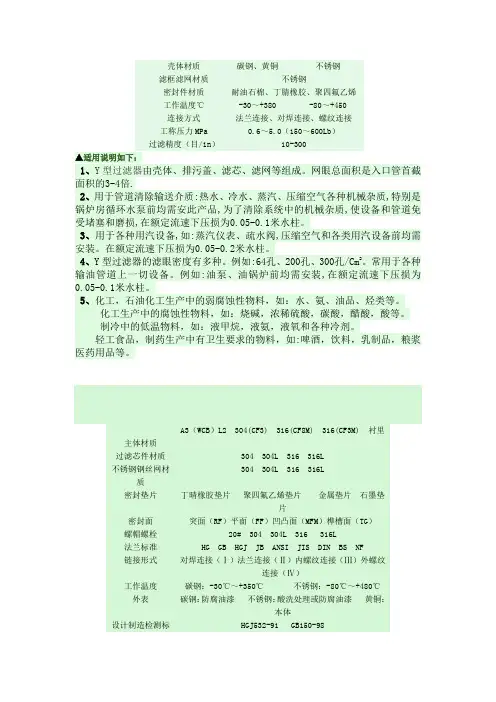

壳体材质碳钢、黄铜不锈钢滤框滤网材质不锈钢密封件材质耐油石棉、丁腈橡胶、聚四氟乙烯工作温度℃-30~+380-80~+450连接方式法兰连接、对焊连接、螺纹连接工称压力MPa0.6~5.0(150~600Lb)过滤精度(目/in)10-300▲适用说明如下:1、Y型过滤器由壳体、排污盖、滤芯、滤网等组成。

网眼总面积是入口管首截面积的3-4倍.2、用于管道清除输送介质:热水、冷水、蒸汽、压缩空气各种机械杂质,特别是锅炉房循环水泵前均需安此产品,为了清除系统中的机械杂质,使设备和管道免受堵塞和磨损,在额定流速下压损为0.05-0.1米水柱。

3、用于各种用汽设备,如:蒸汽仪表、疏水阀,压缩空气和各类用汽设备前均需安装。

在额定流速下压损为0.05-0.2米水柱。

4、Y型过滤器的滤眼密度有多种。

例如:64孔、200孔、300孔/Cm2。

常用于各种输油管道上一切设备。

例如:油泵、油锅炉前均需安装,在额定流速下压损为0.05-0.1米水柱。

5、化工,石油化工生产中的弱腐蚀性物料,如:水、氨、油品、烃类等。

化工生产中的腐蚀性物料,如:烧碱,浓稀硫酸,碳酸,醋酸,酸等。

制冷中的低温物料,如:液甲烷,液氨,液氧和各种冷剂。

轻工食品,制药生产中有卫生要求的物料,如:啤酒,饮料,乳制品,粮浆医药用品等。

A3(WCB)L2 304(CF3) 316(CF8M) 316(CF3M) 衬里主体材质过滤芯件材质304 304L 316 316L304 304L 316 316L不锈钢钢丝网材质密封垫片丁晴橡胶垫片聚四氟乙烯垫片金属垫片石墨垫片密封面突面(RF)平面(FF)凹凸面(MFM)榫槽面(TG)螺帽螺栓20# 304 304L 316 316L法兰标准HG GB HGJ JB ANSI JIS DIN BS NF链接形式对焊连接(Ⅰ)法兰连接(Ⅱ)内螺纹连接(Ⅲ)外螺纹连接(Ⅳ)工作温度碳钢:-30℃~+350℃ 不锈钢:-80℃~+480℃外表碳钢:防腐油漆不锈钢:酸洗处理或防腐油漆黄铜:本体设计制造检测标HGJ532-91 GB150-98准不锈钢钢丝技术特征(英制)SS Wire Gauze Parameter~目数∕in Mesh/in~孔数∕in2Hole/in2可截粒径ParticleDia(u)丝径Wire Dia(mm)有效过滤面积%EffectiveFiltrate Area1010020320.02000(0.510)64 204009550.01240(0.315)58 309006140.00921(0.224)54 4016004420.00760(0.206)48 5025003560.00598(0.152)46 6036003010.00480(0.122)44 8064002160.00402(0.102)421.00319(0.081)40▲Y型过滤器主要技术参数型号Model GLQ-SY环境温度AmbientTemperatureCS:–30℃~+350℃SS:-80℃~+480℃规格Size DN 15~600 GB81~59PN 0.6~5.0 FFRF螺帽螺栓Bolt/Nut20# 304 304L 316 316L壳体材质Body A3 304 304L PP316 316LH62 PTFE连接方式Joint Type法兰连接对焊连接螺纹连接Flange ButtWelding Threaded过滤精度Pore size 10~200(目/in)法兰标准FlangesHG GB SH HGJ JB ANSI JIS密封垫片Diaphragm(P/V)丁晴橡胶聚四氟乙烯金属垫片NBR PTFE MetalGasket设计检测标准ManufactureInspectionGB150-98 HGJ532-91滤芯材质Element 304 304L 316316L外表Coating CS:Paint SS:No Paint▲Y型过滤器安装尺寸参考:公称通径DN15DN20DN25DN32DN4DN5DN65DN8DN1DN125备注外型尺寸L12552350表格中的数字DN15至DN20为丝扣接口的尺寸,其他均为法兰接口尺寸H10212465公称通径DN15DN20DN25DN3DN35DN4DN45DN5DN6外型尺寸L386150 H53012。

Y型过滤器说明书

Y型过滤器Y型过滤器是输送介质的管道系列不可缺少的一种装置,通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来消除介质中的杂质,以保护阀门及设备的正常使用。

该过滤器具有结构先进,阻力小,排污方便等特点。

适用介质可为水,油、气。

可按用户要求制作滤网,其外型基本相同(Y型),内部件全部采用不锈钢,坚固耐用。

当需要清洗时,只要将可拆卸的滤筒取出,去除滤出的杂质后,重新装入即可,使用维护极为方便。

该过滤器体形小、滤眼细、阻力小、效果高、安装检修方便、成本低、并排污时间短,对一般小型号者,只需5-10分钟。

一般通水网为18-30目/cm2,通气网为40-100目/cm2,通油网为100-300目/cm2。

产品结构主要技术参数壳体材质黄铜碳钢不锈钢公称通径15~500mm滤框滤网材质不锈钢密封件材质耐油石棉、丁腈橡胶、聚四氟乙烯工作温度(℃)-30~380-80~425-80~450公称压力(MPa) 1.6~10(150Lb~600Lb)过滤精度(目10~300/in)外形尺寸DN"英寸L H H1参考重量kg15 1/212570150220 3/414570150325 116080160 3.832 1 1/418090180640 1 1/22001002407.250 22201302501065 2 1/22601653501780 328019539020100 432023045032125535030052053150 638033558066200 8495420690110250 10595500800165300 12640580950225350 147006401150312400 168007001360500450 188507901480700500 209008751650900分类说明本过滤器有壳体、排污盖、滤芯、滤网等组成。

网眼总面积是入口管首截面积的3-4倍。

Eaton Model 85 Y 过滤器说明书

Eaton Model 85 Y strainers areengineered to withstand aggressive industrial and commercial applications. Y strainers protect downstream process system components by mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element.To protect against any bypass, the Model 85 Y strainers are manufactured with a precision-machined screen seat on the body of the strainer and high-quality stainless steel screens fabricated to fit the strainer body perfectly. Model 85 Y strainers are available incarbon steel or stainless steelfor pipeline sizes from 1/4" to 10" with threaded, flanged or socket weld connections.For cost-effective straining solutions, Y strainers work well in applications in which the amount of material to be removed from the flow is relatively small--resulting in long intervals between screen cleanings. The strainer screen is manually cleaned by shutting down the line and removing the strainer cap. For applications with heavier dirt loading, Y strainers fitted with a “blow-off” connection permit cleaning of the screen without removing it from the strainer body.• Compact design• Bolted or threaded covers • Standard stainless steel screens• Horizontal or vertical installation Options• Basket perforations from 1/32" to 1/2" • Basket mesh from 20 to 400• MONEL ® screensMONEL ®is a registered trademark of Special Metals Corporation group of Companies .• 1⁄4" to 10"• Carbon steel and stainless steel • T hreaded, flanged or socket weld connectionsEaton Model 85 Y strainers 1/4" to 10"carbon or stainless steel-threaded, socket weld or flangedRating (WOG) Size Material End connection Cover non-shock* 1⁄4" to 2" Carbon steel Threaded or socket weld 600# Threaded 1480 psi (102 bar) 1⁄4" to 2" Stainless steel Threaded or socket weld 600# Threaded 1440 psi (99 bar) 1⁄2" to 10" Carbon steel Flanged 150# Bolted 285 psi (20 bar) 1⁄2" to 10" Carbon steel Flanged 300# Bolted 740 psi (51 bar) 1⁄2" to 10" Stainless steel Flanged 150# Bolted 275 psi (19 bar) 1⁄2" to 10" Stainless steelFlanged 300# Bolted 720 psi (50 bar)* @ 100 ˚F (38 °C)P i p e l i n e S t r a i n e rC a s t C o n s t r u c o nP e r m a n M e d i aModel 85Size A B C (Nom.) D Wt (lb / kg )1⁄43.00 / 76 3.00 / 76 3⁄84.00 / 102 2 / 0.93⁄8 3.00 / 76 3.00 / 76 3⁄8 4.00 / 102 2 / 0.9 1⁄2 3.00 / 76 3.00 / 76 3⁄8 4.00 / 102 2 / 0.9 3⁄43.75 / 95 3.50 / 89 3⁄84.75 / 121 4 / 1.814.63 / 118 4.00 / 102 1⁄25.75 / 146 6 / 2.7 1-1⁄4 5.00 / 127 4.63 / 118 3⁄46.50 / 165 8 / 3.6 1-1⁄2 5.63 / 143 5.25 / 133 3⁄47.50 / 191 10 / 4.527.00 / 1785.75 / 14618.75 / 22215 / 6.8Socket weld, threaded carbon steel or stainless steel – 600# (in/mm )Typical socket weld and threaded Y strainerABC (NPT)DClearance to remove screenConsult Eaton for 12" and larger size dimensions. Dimensions and weights are forreferences only. Contact Eaton for certified drawings.Cross-section of a Y strainer with "blow-off" connection forquick and easy clean-out.For more information, please email us at ********************or visit /filtration© 2020 Eaton. All rights reserved. All trademarks and registered trademarks are the property of their respective owners. All information and recommenda-tions appearing in this brochure concerning the use of products described herein are based on tests believed to be reliable. However, it is the user’s responsibility to determine the suitability for his own use of such products. Since the actual use by others is beyond our control, no guarantee, expressed or implied, is made by Eaton as to the effects of such use or the results to be obtained. Eaton assumes no liability arising out of the use by others of such products. Nor is the infor-mation herein to be construed as absolutely complete, since additional information may be necessary or desirable when particular or exceptional conditions or circumstances exist or because of applicable laws or government regulations.North America 44 Apple StreetTinton Falls, NJ 07724Toll Free: 800 656-3344 (North America only)Tel: +1 732 212-4700Europe/Africa/Middle East Auf der Heide 253947 Nettersheim, Germany Tel: +49 2486 809-0Friedensstraße 4168804 Altlußheim, Germany Tel: +49 6205 2094-0An den Nahewiesen 2455450 Langenlonsheim, Germany Tel: +49 6704 204-0ChinaNo. 3, Lane 280, Linhong RoadChangning District, 200335 Shanghai, P .R. China Tel: +86 21 5200-0099Singapore100G Pasir Panjang Road #07-08 Singapore 118523Tel: +65 6825-1668BrazilAv. Ermano Marchetti, 1435 - Água Branca, São Paulo - SP , 05038-001, Brésil Tel: +55 11 3616-8461USEF-SSEA-110-2020kg 1⁄2 5.00 / 127 2.75 / 70 3⁄8 3.50 / 89 5 / 2.3 3⁄45.63 / 143 3.00 / 76 3⁄8 4.00 / 102 7 / 3.216.38 / 162 3.64 / 92 1⁄2 5.00 / 127 9 / 4.1 1-1⁄47.25 / 184 4.25 / 108 3⁄4 5.75 / 146 14 / 6.3 1-1⁄28.88 / 226 5.75 / 146 3⁄46.50 /165 18 / 8.2 27.88 / 200 6.00 / 152 18.25 / 210 16 / 7.3 2-1⁄29.75 / 248 6.50 / 16519.25 / 235 25 / 11.4 3 10.00 / 254 7.25 / 184 1-1⁄4 10.50 / 267 35 / 16 4 12.13 / 308 9.75 / 248 1-1⁄2 14.75 / 375 70 / 32 6 18.50 / 470 14.25 / 362 2 21.00 / 533 130 / 59 8 21.63 / 549 18.00 / 457 2 26.75 / 679 240 / 1091026.00 / 66022.50 / 565233.75 / 857300 / 136Flanged carbon steel or stainless steel – 150# (in/mm ) kg 1⁄2 5.25 / 133 2.75 / 70 3⁄8 3.50 / 89 6 / 2.73⁄46.00 / 152 3.00 / 76 3⁄8 4.00 /102 9 / 4.1Flanged carbon steel or stainless steel – 300# (in/mm )Typical flanged Y strainerABDClearance to remove screen“C” NPTFlow rate (water) [GPM](B ) S U P E R H E A T E D S T E A M F L O W – 1,000 l b s . p e r h r .E temperature to obtain the point on this graph.Steam pressure drops。

黄铜 Y 型过滤器产品使用说明书

黄铜Y型过滤器产品使用说明书一、产品概述GLQ系列黄铜Y型过滤器(以下简称Y型过滤器)是输送介质的管道系统不可缺少的一种过滤装置,过滤器通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来清除介质中的杂质,以保护阀门及设备的正常使用。

二、结构特征和工作原理Y过滤器的结构为“Y”字型,支管内置过滤筒与滤网。

Y型过滤器在管道中的作用是滤除流体中的固体颗粒,以保护设备的正常工作。

当流体流入过滤器中,滤网会阻止比滤网孔径大的固体颗粒通过,从而保证通过过滤器的流体不含大尺寸的固体颗粒。

清洗滤网时,将过滤器阀盖旋开,取出滤网,清洗滤网后重新装入并旋紧阀盖即可。

维护过程比较简单。

三、产品命名规则四、外型尺寸及零件材质执行标准GB/T8464-2008《铁制和铜制螺纹连接阀门》公称通径DN15-DN50公称压力PN16适用介质水及60%以内的乙二醇水溶液介质温度0~120℃(液态)滤网目数16目(其它目数需要定制)主要零件材质阀体:黄铜;阀盖:黄铜;过滤网:不锈钢;密封垫片:PTFE五、保管、安装及使用说明1.安装前应清洗管道、清除管道内污垢和泥砂等异物,避免安装后过滤网被异物堵住。

2.过滤器的进水和回水管道最好安装压力表,如果进水回的压力表计数相差甚大,可能过滤网上已经有不少杂质,当有液体流经过滤器时,液体阻力比正常使用要大得多,此时需要即时清洗过滤网。

3.该阀通常安装于水平管路,但也可安装于垂直管路上或倾斜管路上,并注意介质流向与阀体上箭头方向相一致。

4.安装过滤器时要注意预留一定的维修空间,以便正常的日常维护。

5.使用工况要符合性能规范要求。

6.该阀应放在干燥的仓库内严禁露天存放,长期存放,应定期保养。

六、可能发生的故障及消除方法公称通径 L (mm ) H (mm ) GDN15 56.5 40 1/2” DN20 69 45 3/4” DN25 77 50 1” DN32 96.5 66 1 1/4” DN40 105 75 1 1/2” DN50 127 89 2”可能发生的故障 发生故障的原因 消除办法流量较小或者 水流阻力变大长期使用,过滤网被 杂质堵住清洗过滤网密封面渗漏1、端盖未拧紧。

Y型过滤器技术参数

Y型过滤器技术参数-标准化文件发布号:(9456-EUATWK-MWUB-WUNN-INNUL-DDQTY-KII壳体材质碳钢、黄铜不锈钢滤框滤网材质不锈钢密封件材质耐油石棉、丁腈橡胶、聚四氟乙烯工作温度℃-30~+380-80~+450连接方式法兰连接、对焊连接、螺纹连接工称压力MPa0.6~5.0(150~600Lb)过滤精度(目/in)10-300▲适用说明如下:1、Y型过滤器由壳体、排污盖、滤芯、滤网等组成。

网眼总面积是入口管首截面积的3-4倍.2、用于管道清除输送介质:热水、冷水、蒸汽、压缩空气各种机械杂质,特别是锅炉房循环水泵前均需安此产品,为了清除系统中的机械杂质,使设备和管道免受堵塞和磨损,在额定流速下压损为0.05-0.1米水柱。

3、用于各种用汽设备,如:蒸汽仪表、疏水阀,压缩空气和各类用汽设备前均需安装。

在额定流速下压损为0.05-0.2米水柱。

4、Y型过滤器的滤眼密度有多种。

例如:64孔、200孔、300孔/Cm2。

常用于各种输油管道上一切设备。

例如:油泵、油锅炉前均需安装,在额定流速下压损为0.05-0.1米水柱。

5、化工,石油化工生产中的弱腐蚀性物料,如:水、氨、油品、烃类等。

化工生产中的腐蚀性物料,如:烧碱,浓稀硫酸,碳酸,醋酸,酸等。

制冷中的低温物料,如:液甲烷,液氨,液氧和各种冷剂。

轻工食品,制药生产中有卫生要求的物料,如:啤酒,饮料,乳制品,粮浆医药用品等。

主体材质A3(WCB)L2 304(CF3) 316(CF8M) 316(CF3M) 衬里过滤芯件材质304 304L 316 316L不锈钢钢丝网材质304 304L 316 316L密封垫片丁晴橡胶垫片聚四氟乙烯垫片金属垫片石墨垫片密封面突面(RF)平面(FF)凹凸面(MFM)榫槽面(TG)螺帽螺栓20# 304 304L 316 316L法兰标准HG GB HGJ JB ANSI JIS DIN BS NF链接形式对焊连接(Ⅰ)法兰连接(Ⅱ)内螺纹连接(Ⅲ)外螺纹连接(Ⅳ)工作温度碳钢:-30℃~+350℃不锈钢:-80℃~+480℃外表碳钢:防腐油漆不锈钢:酸洗处理或防腐油漆黄铜:本体设计制造检测标准HGJ532-91 GB150-98~目数∕in Mesh/in ~孔数∕in2Hole/in2可截粒径ParticleDia(u)丝径Wire Dia(mm)有效过滤面积%Effective FiltrateArea1010020320.02000(0.510)64 204009550.01240(0.315)58309006140.00921(0.224)54 4016004420.00760(0.206)48 5025003560.00598(0.152)46 6036003010.00480(0.122)44 8064002160.00402(0.102)42 100100001730.00319(0.081)40▲型号Model GLQ-SY环境温度AmbientTemperatureCS:–30℃~+350℃SS:-80℃~+480℃规格Size DN 15~600 GB 81~59PN 0.6~5.0 FF RF螺帽螺栓Bolt/Nut20# 304 304L 316 316L壳体材质Body A3 304 304L PP 316316L H62 PTFE连接方式Joint Type法兰连接对焊连接螺纹连接Flange ButtWelding Threaded过滤精度Pore size 10~200(目/in)法兰标准FlangesHG GB SH HGJ JB ANSI JIS密封垫片Diaphragm(P/V)丁晴橡胶聚四氟乙烯金属垫片NBR PTFE MetalGasket设计检测标准ManufactureInspectionGB150-98 HGJ532-91滤芯材质Element304 304L 316 316L外表Coating CS:Paint SS:No Paint ▲公称通径DN15DN20DN25DN32DN4DN5DN65DN8DN1DN125备注外型尺寸L1251551618195215252853350表格中的数字DN15至DN20为丝扣接口的尺寸,其他均为法兰接口尺寸H10211314316618421333328385465公称通径DN15DN20DN25DN3DN35DN4DN45DN5DN6外型尺寸L384854565667885891150 H5366572858598929112。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

Y型过滤器

Y型过滤器是输送介质的管道系列不可缺少的一种装置,通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来消除介质中的杂质,以保护阀门及设备的正常使用。

该过滤器具有结构先进,阻力小,排污方便等特点。

适用介质可为水,油、气。

可按用户要求制作滤网,其外型基本相同(Y型),内部件全部采用不锈钢,坚固耐用。

当需要清洗时,只要将可拆卸的滤筒取出,去除滤出的杂质后,重新装入即可,使用维护极为方便。

该过滤器体形小、滤眼细、阻力小、效果高、安装检修方便、成本低、并

排污时间短,对一般小型号者,只需5-10分钟。

一般通水网为18-30目/cm2,通气网为40-100目/cm2,通油网为100-300目/cm2。

产品结构

主要技术参数

壳体材质黄铜碳钢不锈钢

公称通径15~500mm

滤框滤网材质不锈钢

密封件材质耐油石棉、丁腈橡胶、聚四氟乙烯

工作温度(℃)-30~380-80~425-80~450

公称压力(MPa) 1.6~10(150Lb~600Lb)

过滤精度(目/in)10~300

外形尺寸

分类说明

本过滤器有壳体、排污盖、滤芯、滤网等组成。

网眼总面积是入口管首截面积的3-4倍。

用于管道清除输送介质:热水、冷水、蒸汽、压缩空气各种机械杂质,特别是锅炉房循环水泵前均需安此产品,为了清除系统中的机械杂质,使设备和管道免受堵塞和磨损,在额定流速下压损为0.05-0.1米水柱。

用于各种用汽设备,如:蒸汽仪表、疏水阀,压缩空气和各类用汽设备前均需安装。

在额定流速下压损为

0.05-0.2米水柱。

油过滤器该主品滤眼密度有多种。

例如:64孔、200孔、300孔/Cm2。

用于各种输油管道上一切设备。

例如:油泵、油锅炉前均需安装,在额定流速下压损为0.05-0.1米水柱。

安装示例。