制造业工厂用专业版产品品质系统稽核全表

Quality System Audit

Information and

Instructions

PURPOSE 目的

This document was purposed as an Audit Tool to assess a supplier's Quality Systems that should satisfy Lite-On’s Quality Systems Requirements. The

LITE-ON Quality Systems Audit (QSA) is built upon the ISO-9000 Quality Systems Standard, but with additional LITEON specific requirements included.

本文件的目的是作為評估供應商品質系統的工具,以滿足光寶之品質系統要求。此「品質系統稽核」是以ISO 9000 品質系統標準為基礎,再參酌光寶之特定品質系統要求。

SCOPE 範圍

The LITEON Quality Systems Audit is not commodity specific; therefore it may be used to assess the Quality Systems deployed by a supplier/manufacture.「品質系統稽核」的評估範圍是限定於供應商所展現之一般性品質系統實際執行情形,而非針對某一製品或產品的特定製程。

DEFINITION 定義

The roles definition of supplier chain in QSA schecklist as follwoing

sub-tier supplier(e.g. GE resin) >> supplier(e.g. MaeTay) >> customer(LiteOn)

AUDIT BY SELF ASSESSMENT 供應商自我稽核

A supplier's facility is required to complete a self assessment using this tool in advance of the LITEON Audit. (One QSA is required per facility.) By doing this, a facility will be able to prepare for the audit and seek advance help and guidance from LITEON SQE to be best positioned to succeed.

It is also expected that based on self audit results, a supplier will inform the LITEON team of their readiness for a formal LITEON audit. A self assessment is completed by scoring the relevant column in each worksheet.

光寶供應商品質工程師(以下簡稱SQE) 正式執行「品質系統稽核」的業務前,供應商應先行依照此查核表完成自我稽核。一份「品質系統稽核」查核表(以下簡稱QSA查核表)僅適用一座供應商之廠區。藉此自我稽核,供應商可適時地做好稽核準備、諮詢光寶SQE提供幫助和QSA查核表內容解釋。

當供應商妥善完成自我稽核后,應通知光寶SQE前往進行實地稽核。自我稽核之查核表應展現稽核結果分數。

AUDIT BY LITEON 光寶稽核

During the audit process, the LITEON SQE may wish to review every question/criterion listed on the audit document, or alternatively the SQE may choose to focus only on those questions for which the supplier awarded themselves a score of 1 by self-assessment. The path taken is left to SQE discretion. The score awarded by the SQE Auditor will be entered in the 'Score' column on each worksheet.

當光寶SQE進行實地稽核,若可行時,應依照此QSA查核表內容逐一完成稽核,或是僅僅針對自我稽核結果分數為”1”之項目進行實地稽核。對此,光寶SQE應適當地自行決定。實地稽核完成后,應確實在查核表上填入評分。

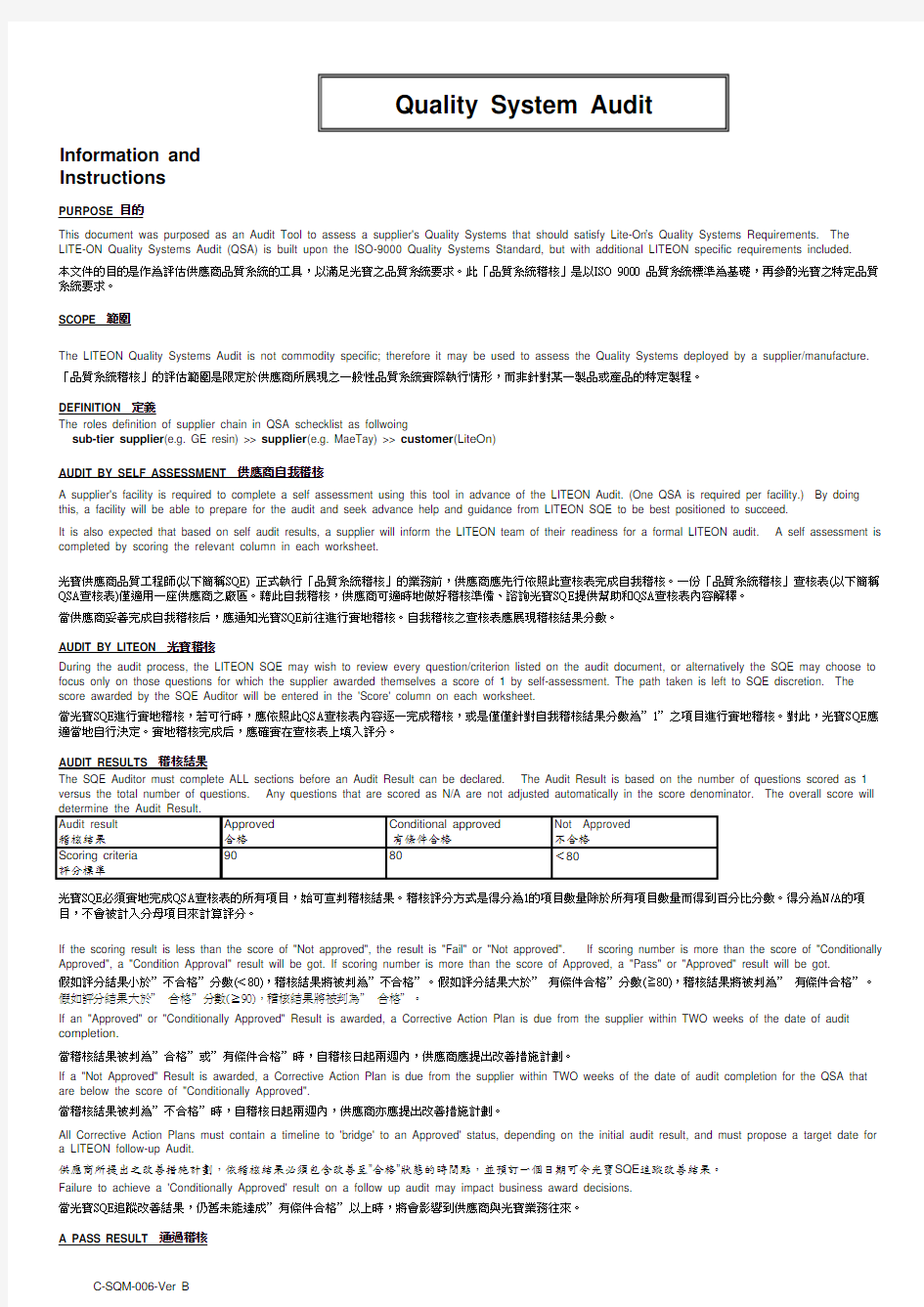

AUDIT RESULTS 稽核結果

The SQE Auditor must complete ALL sections before an Audit Result can be declared. The Audit Result is based on the number of questions scored as 1 versus the total number of questions. Any questions that are scored as N/A are not adjusted automatically in the score denominator. The overall score will

光寶SQE必須實地完成QSA查核表的所有項目,始可宣判稽核結果。稽核評分方式是得分為1的項目數量除於所有項目數量而得到百分比分數。得分為N/A的項目,不會被計入分母項目來計算評分。

If the scoring result is less than the score of "Not approved", the result is "Fail" or "Not approved". If scoring number is more than the score of "Conditionally Approved", a "Condition Approval" result will be got. If scoring number is more than the score of Approved, a "Pass" or "Approved" result will be got.

假如評分結果小於”不合格”分數(<80),稽核結果將被判為”不合格”。假如評分結果大於” 有條件合格”分數(≧80),稽核結果將被判為” 有條件合格”。假如評分結果大於” 合格”分數(≧90),稽核結果將被判為” 合格”。

If an "Approved" or "Conditionally Approved" Result is awarded, a Corrective Action Plan is due from the supplier within TWO weeks of the date of audit completion.

當稽核結果被判為”合格”或”有條件合格”時,自稽核日起兩週內,供應商應提出改善措施計劃。

If a "Not Approved" Result is awarded, a Corrective Action Plan is due from the supplier within TWO weeks of the date of audit completion for the QSA that are below the score of "Conditionally Approved".

當稽核結果被判為”不合格”時,自稽核日起兩週內,供應商亦應提出改善措施計劃。

All Corrective Action Plans must contain a timeline to 'bridge' to an Approved' status, depending on the initial audit result, and must propose a target date for a LITEON follow-up Audit.

供應商所提出之改善措施計劃,依稽核結果必須包含改善至”合格”狀態的時間點,並預訂一個日期可令光寶SQE追蹤改善結果。

Failure to achieve a 'Conditionally Approved' result on a follow up audit may impact business award decisions.

當光寶SQE追蹤改善結果,仍舊未能達成”有條件合格”以上時,將會影響到供應商與光寶業務往來。

A PASS RESULT 通過稽核

TRAINING 訓練REVISION HISTORY

Doc Number

Rev. Date Revised content Revised by C-SQM-006-01Ver A

A 2005/7/13Roger Lin C-SQM-006-01Ver B

B 2007/04/30Edward A Liu C-SQM-006-01Ver

C C 2009/06/12Edward A Liu

Insert: (1) conclusion area in audit summary page,(2) supplier self survey in each item.Update to ISO 9001:2008 compliance The QSA is very technical in content with regard to Quality Systems and Engineering Techniques. An internal training session will be provided to the SQEs who use this checklist. SQEs who properly use this tool are considered within LITEON as being sufficiently qualified to conduct this audit.

QSA查核表含有技術性之品質系統與工程技術內容,SQE 使用此查核表之前必須事先接受訓練,一位正確使用此查核工具的SQE,在光寶集團內是被視為足以擔當此稽核業務。

The Audit may be used as and when the need arises. However, LITEON will conduct an official audit at least annually for key suppliers. Before conducting an audit, the auditor must ensure the LITEON commodity management teams responsible for the relationship are advised of the audit schedule. It is also intended for suppliers to conduct internal audits by self assessment every half year so progress may be reported to LITEON SQE.

QSA AUDIT CHECKLIST 稽核查核表

當稽核需求被提出時,稽核活動應被執行。然而,針對主要供應商必須每年至少稽核一次。執行稽核前,須知會該供應商的光寶採購人員正確的稽核日程。排定此稽核日程表,其用意也是期望供應商每半年自我內部稽核一次,並將結果過程知會光寶SQE.

The Lite-on SQE should imitate a QSA annual audit plan/schedule. When a quality systematic failure in supplier site, Lite-On SQE should lead auditing supplier or audit with relative department, it should be performed in a scheduled date.

光寶SQE應事先擬妥QSA年度稽核計劃與日程,當供應商發生品質系統之失效時,光寶SQE應該排定一個日期,偕同相關部門前往供應商執行稽核並主導稽核工作。

the template of QSA audit checklist. It will be managed and maintained by the Corp. SQM Program office.

Initial Because of the closed nature of the questions, there can only be one of three answers to any question, i.e. Yes (1), No (0), or N/A (x). If the Criterion is fully met, a score of 1 is obtained. If the Criterion is not met, a score of 0 is obtained.

因採封閉式問答,所以僅可由三種答案中選擇一項回答:例如: Yes (1), No (0), or N/A (x). 假如問題要項被滿足,則Yes可得到1分;否則No,得到0分。

A score of N/A (x) may be awarded if the SQE believes that any particular question is truly Not Applicable in the case of the supplier facility under review. In any cases the total number of N/A should be kept as minimum as possible. If there is any doubt as to the score to award for any given Criterion, a score of zero shall be awarded by default. Any Criterion that scores 1 shall be clearly demonstrated, followed, and be beyond reproach. In the event that a supplier clearly meets the intent of the audit question, a score of 1 shall be given.

當SQE認定某一特定問題要項是真正不適用於該次稽核時,則不給予1分或0分,應給N/A。在任何情形下,儘可能減少給N/A。 當懷疑某一問題要項是否真正被滿足時,應給予0分。當某一問題要項在被給1分之前,必須確認真正答案證據被呈現或滿足問題要項之意圖。

AUDIT FREQUENCY 稽核頻率

當供應商通過SQA稽核,也僅限定於被稽核之廠區而非供應商所屬全面廠區。通過SQA稽核,不表示一定有業務訂單,卻是取得技術性合格的第一步。此外,各項產品有其特定的”製程品質稽核” (以下簡稱QPA) 要求,亦須被稽核合格,始可正式取得技術性合格。

AUDIT MECHANICS and QUESTIONS 稽核作業與問題要項

The Audit breaks down the Quality System into individual sections, each of which is represented by an individual worksheet. Within each worksheet is

contained a series of questions specifically pertaining to the section being examined. The questions were devised and developed as closed questions with every attempt to avoid ambiguity.

本QSA查核表被分為個別的查核表,各查核表含有多個相關問題項目,每一問題項目採封閉式問答以避免模稜兩可。

AUDIT SCHEDULE 稽核排程

Once a supplier's facility has passed the Audit, the Quality Systems are approved for the facility audited not all supplier facilities. Passing the QSA does not guarantee a business award, but is the first step towards winning technical approval for a site. In addition, many commodities have a commodity specific Quality Process Audit (QPA), which also requires to be passed before technical approval may be obtained.