多壁碳纳米管功能化

方法一:

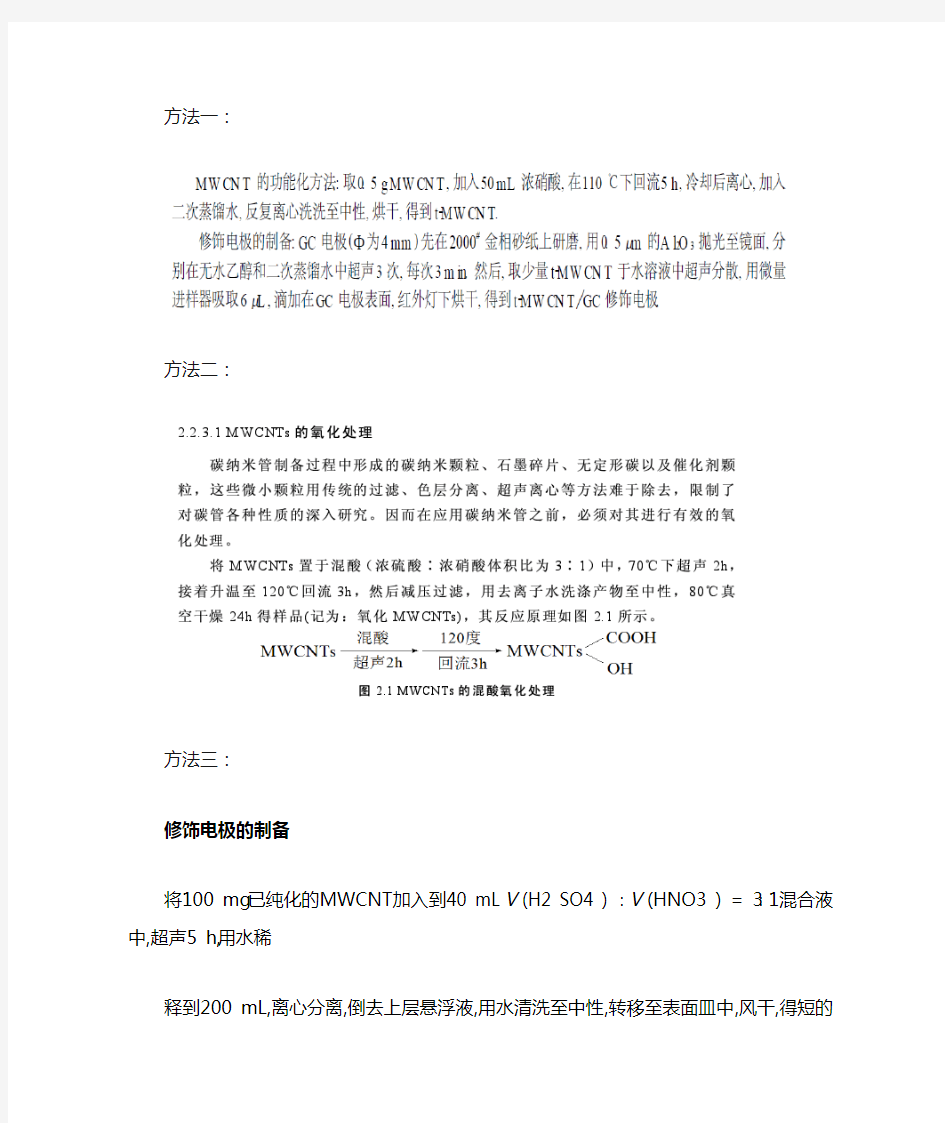

方法二:

方法三:

修饰电极的制备

将100 mg已纯化的MWCNT加入到40 mL V (H2 SO4 ) ∶V (HNO3 ) = 3∶1混合液中,超声5 h,用水稀

释到200 mL,离心分离,倒去上层悬浮液,用水清洗至中性,转移至表面皿中,风干,得短的羧基化的

MWCNT,备用。

将碳黑与固体石蜡按3 ∶1 (质量比)在研钵中研磨后,于90 ℃加热使固体石蜡熔融,迅速装进< 1 mm玻璃毛细管中,压紧后上端插入铜丝,电极表面在称量纸上抛光。将1. 0 mg经羧基化处理后的

MWCNT加入1 mL水中,超声振荡2 min,用微量注射器取适量滴加到CPE表面,置于空气中干燥备用。

方法四:

方法五:

112多壁碳纳米管的酸化处理

将500mg多壁碳纳米管在250mL H2 SO4 /HNO3(体积比为3: 1)的混合酸中水浴加热回流数小时,用5倍的去离子水冲洗,并用直径为0122μm的混合纤维膜和膜过滤器真空过滤,再用去离子水反复洗涤直至PH > 5,将滤出物放在真空干燥箱中烘干待用,将该样品记为MWNTCOOH。

碳纳米管的羧基化

Carbon-Nanotube-Templated and Pseudorotaxane-Formation-Driven Gold Nanowire Self-Assembly Toby Sainsbury and Donald Fitzmaurice* Department of Chemistry,University College Dublin,Belfield,Dublin4,Ireland Received December22,2003.Revised Manuscript Received March15,2004 A cation-modified multiwalled carbon nanotube is used to template the noncovalent self-assembly in solution of a gold nanowire from crown-modified gold nanoparticles.The driving force for self-assembly is formation of the surface-confined pseudorotaxane that results from the electron-poor cation threading the electron-rich crown. Introduction The demand for integrated circuits that will allow information to be processed at even faster speeds remains undiminished.This is despite the fact that the density of the wires and switches that comprise such circuits has doubled every eighteen months for nearly four decades,giving rise to Moore’s Law.1 It is clear that Moore’s Law will hold true until2012; it is not clear that it will hold true thereafter.2The responses of the relevant technological and scientific communities have been two-fold:first,to continue to develop existing fabrication and materials technologies; and second,to consider alternative fabrication and materials technologies. When considering alternative fabrication technolo-gies,one is attracted to the self-assembly in solution and self-organization at a conventionally patterned silicon wafer substrate of nanoscale wires and switches.3 When considering alternative materials technologies, one is attracted to the use of the growing number of nanoscale condensed-phase and molecular building blocks that are becoming available.4 Specifically,one is attracted to the use of nanoscale condensed-phase and molecular building blocks to self-assemble in solution and self-organize at a patterned silicon wafer substrate metal nanowires.5 It was in this context that Fullam et al.previously reported the multiwalled carbon nanotube(MWNT) templated self-assembly of gold nanowires from gold nanoparticles.6Briefly,unmodified MWNTs added to a stable dispersion of tetraoctylammonium bromide (TOAB)-modified gold nanoparticles templated the as-sembly in solution of gold nanowires comprised of discrete gold nanoparticles.It was suggested that the driving force for self-assembly was charge transfer from the conduction band states of the gold nanoparticle to theπ*states of the carbon nanotubes.7 It is noted that there has been a large number of subsequent reports describing the preparation of metal-and metal-oxide-coated carbon nanotubes.8It is also noted that there has been a large number of reports describing the chemical modification of carbon nano-tubes.Initially,these reports focused on the covalent introduction of carboxy groups at the surface of the carbon nanotubes.9Subsequently,these reports have focused on the covalent coupling of an increasingly wide range of functional molecules and biomolecules to the surface of carboxy-modified carbon nanotubes.10 Reported herein is the preparation of cation-modified (dibenzylammonium)MWNTs and crown-modified(di-benzo[24]crown-8)gold nanoparticles(Scheme1).It was expected that the above cation-modified MWNTs would *To whom correspondence should be addressed.E-mail: donald.fitzmaurice@ucd.ie. (1)Moore,G.Electronics1965,38,114. (2)International Technology Roadmap for Semiconductors,2002 (https://www.360docs.net/doc/30126399.html,/). (3)Parviz,B.;Ryan,D.;Whitesides,G.IEEE Trans.Adv.Pac.2003, 26,233. (4)Parak,W.;Gerion,D.;Pellegrino,T.;Zanchet,D.;Micheel,C.; Williams,S.;Boudreau,R.;Le Gros,M.;Larabell,C.;Alivisatos,A. Nanotechnology2003,14,15. (5)Richter,J.Physica E2003,16,157. (6)Fullam,S.;Rensmo,H.;Cottell,D.;Fitzmaurice,D.Adv.Mater. 2000,12,1430. (7)(a)Brust,M.;Kiely,C.;Bethell,D.;Schiffrin,D.J.Am.Chem. Soc.1998,120,12367.(b)Maxwell,A.;Bruhwiler,P.;Nilsson,A.; Martensson,N.Phys.Rev.B1994,49,10717.(c)Hunt,M.;Modesti, S.;Rudolf,P.;Palmer,R.Phys.Rev.B1995,51,10039. (8)(a)Satishkumar,B.;Vogl,E.;Govindaraj,A.;Rao,C.J.Phys. D:Appl.Phys.1996,29,3173.(b)Zhang,Y.;Franklin,N.;Chen,R.; Dai,H.Chem.Phys.Lett.2000,331,35.(c)Banerjee,S.;Wong,S.Nano Lett.2002,2,195.(d)Li,Y.;Ding,J.;Chen,J.;Cailu,X.;Wei,B.;Liang, J.;Wu,D.Mater.Res.Bull.2002,1847,1.(e)Azamian,B.;Coleman, K.;Davis,J.;Hanson,N.;Green,https://www.360docs.net/doc/30126399.html,mun.2002,366.(f) Fu,Q.;Lu,C.;Liu,J.Nano Lett.2002,2,329.(g)Choi,H.;Shim,M.; Bangsaruntip,S.;Dai,H.J.Am.Chem.Soc.2002,124,9058.(h) Haremza,J.;Hahn,M.;Krauss,T.;Chen,S.;Calcines,J.Nano Lett. 2002,2,1253.(i)Han,W.-Q.;Zettl,A.J.Am.Chem.Soc.2003,125, 2062.(j)Ellis,A.;Vijayamohanan,K.;Goswami,R.;Chakrapani,N.; Ramanathan,L.;Ajayan,P.;Ramanath,G.Nano Lett.2003,3,279. (k)Jiang,K.;Eitan,A.;Schadler,L.;Ajayan,P.;Siegel,R.;Grobert, N.;Mayne,M.;Reyes-Reyes,M.;Terrones,H.;Terrones,M.Nano Lett. 2003,3,275.(l)Ravindran,S.;Chaudhary,S.;Colburn,B.;Ozkan, M.;Ozkan,C.Nano Lett.2003,3,447.(m)Han,W.-Q.;Zettl,A.Nano Lett.2003,3,681. (9)(a)Hiura,H.Mol.Cryst.Liq.Cryst.1995,267,267.(b)Hiura, H.;Ebbesen,T.;Tanigaki,K.Adv.Mater.1995,7,275.(c)Ebbesen, T.;Hiura,H.;Bisher,M.;Tracey,M.;Shreeve-Keyer,J.;Haushalter, R.Adv.Mater.1996,8,155.(d)Dujardin,E.;Ebbesen,T.;Krishnan, A.;Treacy,M.Adv.Mater.1998,10,611.(e)Burghard,M.;Krstic,V.; Duesberg,G.;Philipp,G.;Muster,J.;Roth,S.Synth.Met.1999,103, 2540.(f)Satishkumar,B.;Govindaraj,A.;Mofokeng,J.;Subbanna, G.;Rao,C.J.Phys.B:At.Mol.Opt.1996,29,4925.(g)Dillon,A.; Gennett,T.;Jones,K.;Alleman,J.;Parilla,P.;Heben,M.Adv.Mater. 1999,11,1354. 2174Chem.Mater.2004,16,2174-2179 10.1021/cm035368k CCC:$27.50?2004American Chemical Society Published on Web05/01/2004

碳纳米管的性质性能及其应用前景

碳纳米管的性质性能其应用前景 The Properties and Applications of Carbon Nano-Tubes 张雅坤北京师范大学化学学院201411151935 摘要:从1991年被正式认识并命名至今,碳纳米管凭借其特殊的结构及异常的力学、电学和化学性能获得了材料、物理、电子及化学界的广泛关注。近些年随着碳纳米管及纳米材料研究的深入,其广阔的应用前景也不断地展现出来。本文主要对碳纳米管目前的性质性能及其应用前景进行了系统详细的介绍【8】。 关键词:碳纳米管、无机化学、性质性能、应用前景 一、综述 1.发展历史与研究进程 在1991年日本NEC公司基础研究实验室的电子显微镜专家饭岛(Lijima)在高分辨透射电子显微镜下检验石墨电弧设备中产生的球状碳分子时,意外发现了由管状的同轴纳米管组成的碳分子,这就是现在被称作的“Carbon nanotube”,即碳纳米管,又名巴基管。 1993年,S. Lijima等和D. S. Bethune等同时报道了采用电弧法,在石墨电极中添加一定的催化剂,可以得到仅仅具有一层管壁的碳纳米管,即单壁碳纳米管产物。

1997年,A. C. Dillon等报道了单壁碳纳米管的中空管可储存和稳定氢分子,引起广泛的关注。相关的实验研究和理论计算也相继展开。据推测,单壁碳纳米管的储氢量可达10%(质量比)。此外,碳纳米管还可以用来储存甲烷等其他气体。但该猜测在后来被证实是错误的,碳纳米管无法用于储氢的主要问题有两个:一是假如作为容器进行储氢,则无法对其进行可控的封闭和开启;二是假如用于氢气吸附,则其吸附率不超过1%(质量分数)。 能否控制单壁碳纳米管的生长是近二十余年来一直困扰着碳纳米管研究领域科学家们的难题,能否找到控制方法也成为碳纳米管应用的瓶颈。2014年,这道世界性难题被北京大学李彦教授研究团队攻克,该团队在全球首次提出单壁碳纳米管生长规律的控制方法,研究成果已于2014年6月26日发表在国际权威学术期刊《自然》杂志上,这是碳纳米管研究方面的又一大突破。 2.碳纳米管的制备方法 常用的碳纳米管制备方法主要有:电弧放电法、激光烧蚀法、化学气相沉积法(碳氢气体热解法)、固相热解法、辉光放电法、气体燃烧法以及聚合反应合成法等。 2.1电弧放电法 电弧放电法是生产碳纳米管的主要方法。1991年日本物理学家饭岛澄男就是从电弧放电法生产的碳纤维中首次发现碳纳米管的。电弧放电法的具体过程是:将石墨电极臵于充满氦气或氩气的反应容器中,在两极之间激发出电弧,此时温度可以达到4000度左右。在这种条件下,石墨会蒸发,生成的产物有富勒烯(C60)、无定型碳和单壁或多壁的碳纳米管。通过控制催化剂和容器中的氢气含量,可以

多壁碳纳米管的纯化及其表面含氧基团的表征

多壁碳纳米管的纯化及其表面含氧基团的表征 周金梅 李海燕 林国栋 张鸿斌* (厦门大学化学化工学院,固体表面物理化学国家重点实验室,醇醚酯化工清洁生产国家工程实验室,福建厦门 361005) 摘要:用兼具酸性和氧化性的HNO 3水溶液可方便地除去残留在原生态多壁碳纳米管(CNT)上的Ni ?MgO 催化剂组分,同时在其表面产生某些含氧官能团,使原生态多壁碳纳米管的疏水性表面变为亲水性表面.采用Boehm 中和滴定法以及X 射线衍射(XRD)、热脱附谱(TPD)、傅里叶变换红外(FTIR)光谱和X 射线光电子能谱(XPS)等技术对HNO 3处理过的多壁碳纳米管的相组成和表面含氧官能团进行测量和表征.结果表明:所生成表面含氧官能团的总量以经7.0mol ·L -1硝酸378K 处理24h 的CNT 为最高;3种主要表面含氧官能团的含量高低顺序为,羧基>内酯型羧基>酚型羟基.关键词:多壁碳纳米管;纯化; 表面含氧官能团; 表面修饰 中图分类号:O647 Purification of Multiwalled Carbon Nanotubes and Characterization of Their Oxygen 鄄Containing Surface Groups ZHOU Jin ?Mei LI Hai ?Yan LIN Guo ?Dong ZHANG Hong ?Bin * (College of Chemistry and Chemical Engineering,State Key Laboratory of Physical Chemistry for Solid Surfaces,National Engineering Laboratory for Green Chemical Productions of Alcohols ?Ethers ?Esters,Xiamen University,Xiamen 361005, Fujian Province,P.R.China )Abstract :We conveniently removed the Ni ?MgO catalyst components from an as ?grown multiwalled carbon nanotube (CNT)using an aqueous HNO 3solution with strong acidity and oxidizability as a purifying reagent.Some oxygen ?containing surface groups were generated at the CNT surface,which converted the hydrophobic surface into a hydrophilic surface.The phase composition and the oxygen ?containing surface groups of the CNTs treated by nitric acid were determined and characterized using Boehm ′s neutralizing titration method and X ?ray powder diffraction (XRD),temperature ?programmed desorption (TPD),Fourier transform infrared (FTIR)spectroscopy,and X ?ray photoelectron spectroscopy (XPS)techniques.The results indicated that the total content of the formed oxygen ?containing surface groups was the highest for the CNTs treated with 7.0mol ·L -1aqueous HNO 3at 378K for 24h.The content of the three major oxygen ?containing surface groups was:carboxyl>lactonic carboxyl>phenolic hydroxyl.Key Words :Multiwalled carbon nanotubes; Purification; Oxygen ?containing surface group; Surface modification [Article] https://www.360docs.net/doc/30126399.html, 物理化学学报(Wuli Huaxue Xuebao ) Acta Phys.?Chim.Sin .,2010,26(11):3080-3086 多壁碳纳米管(CNT)是一类新奇纳米碳素材料[1].典型的CNT 具有由sp 2?C 组成的类石墨平面并按一定方式组合而成的纳米级管状结构.这类材料具 有一些独特的物理化学性质,诸如高的机械强度、 类石墨结构的管壁、纳米级的管腔、sp 2?C 构成的表面、高中等级的表面积、优良的导电导热性以及对H 2的 吸附活化能力等,预期在复合材料、 电子器件、场发射、吸波、吸附分离和催化等诸多领域有现实或潜在 November Received:May 17,2010;Revised:July,24,2010;Published on Web:September 13,2010.? Corresponding author.Email:hbzhang@https://www.360docs.net/doc/30126399.html,. The project was supported by the National Key Basic Research Program of China (973)(2009CB939804)and Fujian Provincial Key Scientific & Technical Project,China (2009HZ0002?1). 国家重点基础研究发展规划项目(973)(2009CB939804)和福建省重大科技专项专题项目(2009HZ0002?1)资助 ?Editorial office of Acta Physico ?Chimica Sinica 3080

羧基化多壁碳纳米管修饰电极循环伏安法测定过氧化氢

羧基化多壁碳纳米管修饰电极循环伏安法测 定过氧化氢 【摘要】目的:研究用羧基化多壁碳纳米管修饰电极伏安法测定过氧化氢的浓度。方法:采用涂布法制成羧基化多壁碳纳米管修饰电极;在pH=7.0 KH2PO4-Na2HPO4缓冲溶液中,采用该修饰电极伏安法测定H2O2。结果:该修饰电极对H2O2有着显著的电催化作用,与裸玻碳电极相比,其灵敏度大大提高,在 1.2×10-6~1.0×10-3 mol/L 浓度范围内,过氧化氢的氧化峰电流与其浓度呈良好的线性关系,检测限为3.1×10-7 mol/L,将该修饰电极用于医用过氧化氢的测定,相对平均偏差为1.2%,平均回收率为97.6%,结果满意。结论:该修饰电极响应快,灵敏度高,稳定性好,寿命长,适合于具有电活性生物分子的测定。 【关键词】碳纳米管学修饰电极伏安法过氧化氢 Abstract: Objective: To study a quantitative method for determination of hydrogen peroxide (H2O2) by voltammetry with multi-wall carbon nanotubes functionalized with carboxylic group modified electrode (CME). Method: The CME was fabricated, which based on the immobilization of multi-wall carbon nanotubes functionalized with carboxylic group. In a medium of KH2PO4-Na2HPO4 buffer solution with pH=7.0,the CME was

碳纳米管的改性研究进展

碳纳米管的改性研究进展 摘要:碳纳米管因其独特的结构与优异的性能,在许多领域具有巨大的应用潜力而引起了广泛的关注。由于碳纳米管不溶于水和有机溶剂,极大地制约了其性能的应用,因此碳纳米管的功能化改性 就成为目前研究的热点。本文简要介绍了碳纳米管及其性质作,详细阐述了碳纳米管的改性研究进展,并对今后的研究方向进行了展望。 关键词:碳纳米管;结构与性能;功能化;共价改性;非共价改性 1. 碳纳米管及其性能简介 1.1碳纳米管的结构 碳纳米管(Carbon Nanotubes,CNTs)是1991年由日本筑波NEC公司基础研究实验室的Iijima在高分辨透射电子显微镜下检验石墨电弧设备中产生的球状碳分子时意外发现的一种具有一维管状结构的碳纳米材料。因其独特的准一维管状分子结构、优异的力学、电学和化学性质及其在高科技领域中潜在的应用价值,引起了世界各国科学家们的广泛关注,由此引发了碳纳米管的研究热潮和十多年来纳米科学和技术的飞速发展。 碳纳米管是单层或多层石墨片围绕中心轴按一定的螺旋角卷曲而成的无缝、中空的 微管,每层纳米管是一个由碳原子通过SP2杂化与周围3个碳原子完全键合后所构成的 六边形平面组成的圆柱面。根据构成管壁碳原子层数的不同,CNTs可以分为:单壁碳纳 米管(single-walled carbon nanotube,SWNT)和多壁碳纳米管(multi-walled carbon nanotube, MWNT)两种形式。MWNTs的层间接近ABAB堆垛,其层数从2~50不等,层间距为0.34±0.01nm,与石墨层间距(0.34nm)相当。MWNTs的典型直径和长度分别为2~30nm 和0.1~50μm;SWNTs典型的直径和长度分别为0.75~3nm和1~50μm。与MWNTs 比,SWNTs是由单层圆柱型石墨层构成,其直径的分布范围小,缺陷少,具有更高的 均匀一致性。无论是MWNTs还是SWNTs都具有很大的长径比,一般为100~1000, 最大可达到1000~10000,可以认为是一维分子。CNTs有直形、弯曲、螺旋等不同外形。在MWNTs中不同石墨层的螺旋角各不相同,由Euler定理可知,在CNTs的弯曲处,一定要有成对出现的五元环和七元环才能使碳纳米管在弯曲处保持光滑连续,而封 闭的两端半球形或多面体的圆拱形是由五元环参与形成的。但是实际制备的CNTs或多 或少存在这样那样缺陷,主要缺陷有三种类型:拓扑学缺陷,重新杂化缺陷和非完全键

多壁碳纳米管的磺酸基功能化(英文)

硅酸盐学报 · 1614 ·2007年 多壁碳纳米管的磺酸基功能化 卢志华1,2,孙康宁2,任帅2 (1. 济宁学院物理系,山东济宁 273155;2. 山东大学,液态结构及其遗传性教育部重点实验室,济南 250061) 摘要:磺酸基官能团可以改善碳纳米管的化学性质,促进其在复合材料以及涂层中的应用。介绍一种用十二烷基磺酸钠和羧基化碳纳米管相互反应制备磺酸基修饰碳纳米管的简便方法。紫外吸收强度及透射电镜分析表明:磺酸基修饰后的多壁碳纳米管在水中分散均匀且稳定存在。红外光谱分析表明:经过修饰的碳管表面带有丰富的磺酸基官能团。zeta电位分析表明:在所有pH值考察范围内,经过修饰的碳纳米管胶体溶液的zeta电位均低于–32mV,根据胶体稳定理论,低于该值的溶液在水中可以稳定存在。 关键词:碳纳米管;功能化;分散;磺酸基 中图分类号:TB332 文献标识码:A 文章编号:0454–5648(2007)12–1614–04 FUNCTIONALIZATION OF MULTI-WALLED CARBON NANOTUBES CONTAINING SULFONIC GROUPS LU Zhihua1,2,SUN Kangning2,REN Shuai2 (1. Department of Physics, Jining University, Jining 273155, Shandong; 2. Key Laboratary for Liquid Struture and Heredity of Materials of Ministry of Education, Shandong University, Jinan 250061, China) Abstract: Functionalized carbon nanotubes containing sulfonic groups can improve the chemical property of nanotube, and may promote their many potential applications such as in composites and coatings. A facile method to prepare functionalized carbon nano-tubes containing highly reactive sulfonic groups on its surface via the reaction between sodium dodecyl sulfate and carboxylated car-bon nanotubes is described. Ultraviolet absorbance intensity analysis and transmission electron microscope confirmed that the func-tionalized multi-walled carbon nanotubes can be individually dispersed and retain a long uniform state in water. Fourier trans-formed-infrared spectroscopy showed that reactive sulfonic groups were covalently attached to carbon nanotubes. The zeta potentials of the colloid solution of functionalized multi-walled carbon nanotubes decrease to less than –32mV under all studied pH values, which indicate that they are stable in water according to the theory of colloid stabilization. Key words: carbon nanotube; functionalization; dispersion; sulfonic group Ever since carbon nanotubes (CNTs) have become available in quantities,[1] a continuous interest has grown in many diverse and interdisciplinary fields, owing to the unique and novel structural, electronic, mechanical and physical properties of CNTs.[2] Because many applications need CNTs that have good dispersibility and chemical ac-tivity, surface modification and/or functionalization of their surface have attracted increasing attention in recent years.[3–5] Modification of CNTs by covalent or non-covalent molecules can improve their dispersibility in liquid media[6–8] and their compatibility with polymer matrixes.[9–11] The tested covalent modification of CNTs has been well summarized in several review papers.[12–14] In general, major approaches include: (1) amidation or esterification of carboxylated CNTs and (2) side-wall co-valent attachment of functional groups directly to pristine CNTs. In this paper, we are mainly concerned with the functionalization of multi-walled carbon nanotubes (MWCNTs) containing sulfonic groups. Carboxylated multi-walled carbon nanotubes (MWCNT—COOH) were 收稿日期:2006–06–06。修改稿收到日期:2007–09–22。基金项目:国家自然科学基金(50672051;30540061)资助项目。第一作者:卢志华(1979~),女,博士研究生。 通讯作者:孙康宁(1955~),男,教授,博士研究生导师。Received date:2006–06–06. Approved date: 2007–09–22. First author: LU Zhihua (1979—), female, postgraduate student for doctor degree. E-mail: zlhsky@https://www.360docs.net/doc/30126399.html, Correspondent author: SUN Kangning (1955—), male, professor. E-mail: sunkangning@https://www.360docs.net/doc/30126399.html, 第35卷第12期2007年12月 硅酸盐学报 JOURNAL OF THE CHINESE CERAMIC SOCIETY Vol. 35,No. 12 December,2007

碳纳米管综述

碳纳米管综述 摘要:本文主要介绍碳纳米管的发现及发展过程,并说明碳纳米管的制备方法及其制备技术。同时也叙述碳纳米管的各种性能与应用。 引言:在1991年日本NEC公司基础研究实验室的电子显微镜专家饭岛在高分辨透射电子显微镜下检验石墨电弧设备中产生的球状碳分子时,意外发现了由管状的同轴纳米管组成的碳分子,这就是现在被称作的“Carbon nanotube”,即碳纳米管,又名巴基管。 正文: 碳纳米管的制备: 碳纳米管的合成技术主要有:电弧法、激光烧蚀(蒸发)法、催化裂解或催化化学气相沉积法(CCVD,以及在各种合成技术基础上产生的定向控制生长法等。电弧法 利用石墨电极放电获得碳纳米管是各种合成技术中研究得最早的一种。研究者在优化电弧放电法制取碳纳米管方面做了大量的工作。 T. W. Ebbeseo[2]在He保护介质中石墨电弧放电,首次使碳纳米管的合成达到了克量级。为减少相互缠绕的碳纳米管在阴极上的烧结,D.T.Collbert[3]将石墨阴极与水冷铜阴极座连接,大大减少了碳纳米管缺陷。C. Journet[4]等在阳极中填人石墨粉末和铱的混合物,实现了SWNTs的大量制备。研究发现,铁组金属、一些稀土金属和铂族元素或以单个金属或以二金属混合物均能催化SWNTs 合成。 近年来,人们除通过调节电流、电压,改变气压及流速,改变电极组成,改进电极进给方式等优化电弧放电工艺外,还通过改变打弧介质,简化电弧装置。 综上所述,电弧法在制备碳纳米管的过程中通过改变电弧放电条件、催化剂、电极尺寸、进料方式、极间距离以及原料种类等手段而日渐成熟。电弧法得到的碳纳米管形直,壁簿(多壁甚至单壁).但产率偏低,电弧放电过程难以控制,制备成本偏高其工业化规模生产还需探索。 催化裂解法或催化化学气相沉积法(CCVD) 催化裂解法是目前应用较为广泛的一种制备碳纳米管的方法。该方法主要采用过渡金属作催化剂,适于碳纳米管的大规模制备,产物中的碳纳米管含量较高,但碳纳米管的缺陷较多。 催化裂解法制备碳纳米管所需的设备和工艺都比较简单,关键是催化剂的制备和分散。目前用催化裂解法制备碳纳米管的研究主要集中在以下两个方面:大规模制备无序的、非定向的碳纳米管;制备离散分布、定向排列的碳纳米管列阵。一般选用Fe, Co、Ni及其合金作催化剂,粘土、二氧化硅、硅藻土、氧化铝及氧化镁等作载体,乙炔、丙烯及甲烷等作碳源,氢气、氮气、氦气、氩气或氨气作稀释气,在530℃~1130℃范围内,碳氢化合物裂解产生的自由碳离子在催化剂作用下可生成单壁或多壁碳纳米管。1993年Yacaman等人[5]采用此方法,用Fe催化裂解乙炔,在770℃下合成了多壁碳纳米管,后来分别采用乙烯、聚乙烯、丙烯和甲烷等作为碳源,也都取得了成功。为使碳离子均匀分布,科研人员还用等离子加强或微波催化裂解气相沉积法制备碳纳米管。 激光蒸发法

多壁碳纳米管的改性

CVD 法不同条件下制备的多壁碳纳米管的Fenton 氧化改性 李伟 成荣明* 徐学诚 陈奕卫 孙明礼 何为凡 (华东师范大学纳米功能材料和器件应用研究中心 上海 200062) 李伟 男,24岁,硕士生,现从事碳纳米管的改性研究。 *联系人,E -mail :ys 02122048@student .ecnu .edu .cn 上海纳米科技专项基金资助项目(0252nm011)2004-08-27收稿,2005-01-31接受摘 要 碳纳米管经焙烧和稀硝酸纯化处理后,在相同的实验条件下,采用Fenton 试剂产生的·OH 分别对C VD 法合成的两种制备条件不同的多壁碳纳米管进行氧化改性处理。红外光谱(FT -IR )表明,改 性后的两种碳管结构中都引入了羟基、羰基和羧基等含氧官能团。此外,由于制备条件不同,导致它们 的石墨化程度、缺陷含量和抗氧化能力等性质也不同,因此CVD 法制备条件能够对碳管Fenton 氧化改 性结果产生重要影响。机理分析表明,这些含氧官能团可以看作是具有强亲电性和强氧化性的·OH 对 碳管上缺陷位置和不饱和键进行攻击的结果。 关键词 多壁碳纳米管 Fenton 试剂 ·OH 机理 Fenton Oxidation Modification of Multi -walled Carbon Nanotubes Prepared in Different Conditions by C VD Method Li Wei ,Cheng Rongming * ,Xu Xuecheng ,Chen Yiwei ,Sun Mingli ,He Weifan (Center of Functional Nanomaterials and Devices ,East China Normal Universit y ,Shanghai 200062) A bstract After purification pretreatment by heating in air and in dilute HNO 3,in the same experimental conditions two kinds of multi -walled carbon nanotubes (MWNTs )were treated with Fenton 's reagents ,which were s ynthesized in different preparation conditions by chemical vapor deposition (CVD )method .The results of FT -IR spectra indicated that the oxygen -containing functional groups such as hydroxyl groups ,carbon y l groups and carboxyl groups could be brought into two kinds of MWNTs after Fenton oxidation modification treatment .In addition ,the properties such as graphitization degree ,defects ′content and antioxidation ability are also different for the different preparation conditions .So the preparation conditions of MWNTs could affect intens ively the results of Fenton oxidation modification .Finally ,we discussed the possible mechanisms of reaction between hydroxyl radical and MWNTs by FT - IR spectral changes before and after Fenton modification treatments were discussed .The possible mechanisms indicated that the existence of oxygen -containing functional groups could be viewed as outcome of attacks of h ydroxyl radical (·OH )with both the properties of oxidizabilit y and electrophilic addition on defect sites and unsaturated bonds in the MWNTs sample . Key words Multi -walled carbon nanotubes (MWNTs ),Fenton 's reagents ,Hydroxyl radical ,Mechanis ms 1991年日本科学家Iijima [1] 用高分辩透射电镜(HRTE M )发现了纳米尺寸的多壁碳纳米管(multi -walled car bon nanotubes ,MWNTs )。由于其独特的结构和物理化学性质,在许多新领域都可望得到应用,如在纳米电子器件[2]、超强度复合材料[3]等领域都显示了巨大的潜力。目前碳纳米管的制备方法主要有三种:电弧法(arc discharge ,AD )、激光蚀刻法(laser alblation ,LA )和化学气相沉积法(c hemical vapor deposition ,CVD )。其中CVD 法产量大,成本低,易于实现工业化大批量连续生产, ·618·化学通报 2005年第8期 http : www .hxtb .org DOI :10.14159/j .cn ki .0441-3776.2005.08.009