碟形弹簧计算公式

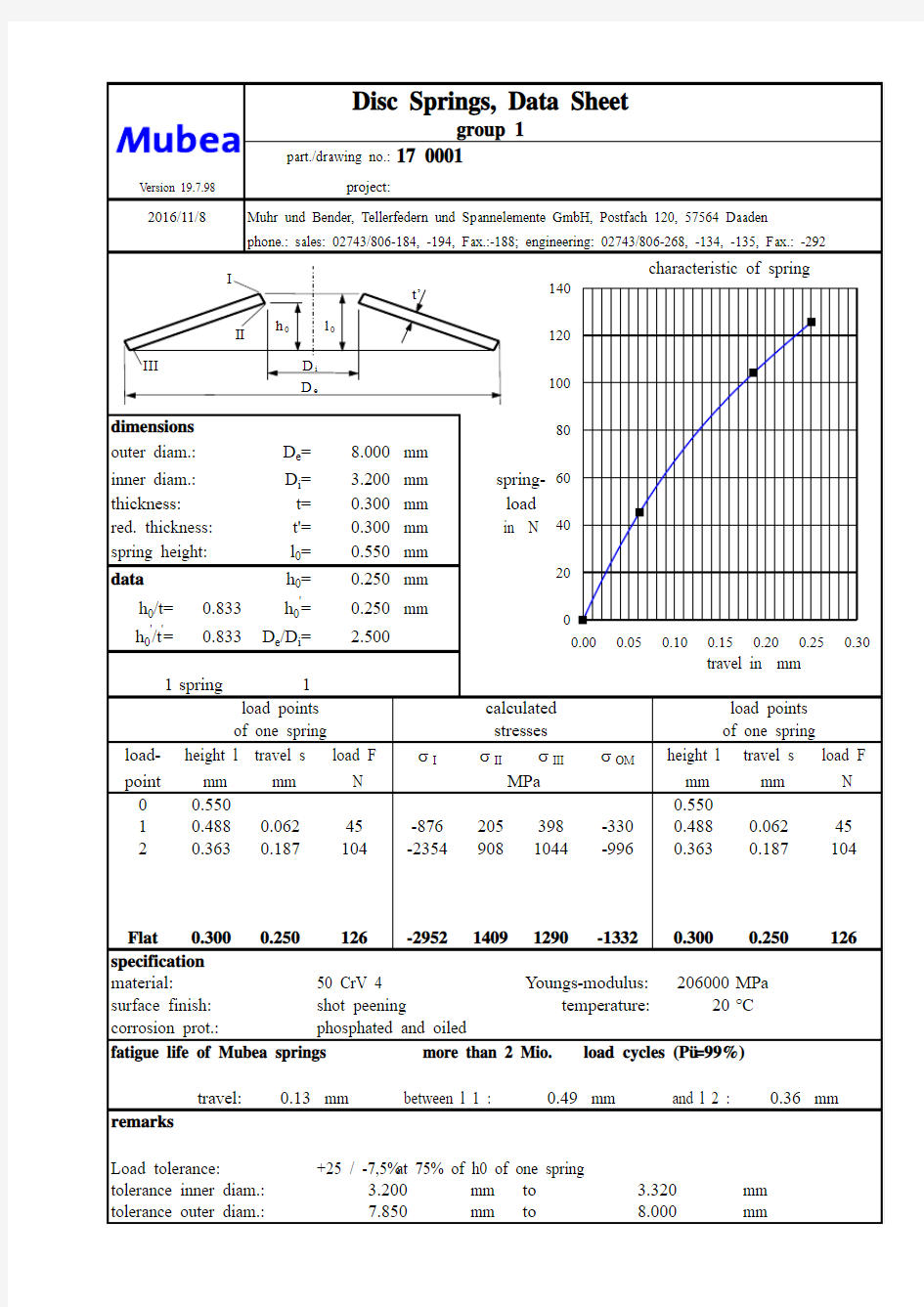

part./drawing no.:17 0001

Version 19.7.98project:0

2016/11/8Muhr und Bender, Tellerfedern und Spannelemente GmbH, Postfach 120, 57564 Daaden 0phone.: sales: 02743/806-184, -194, Fax.:-188; engineering: 02743/806-268, -134, -135, Fax.: -292

load points calculated load points

of one spring stresses of one spring

height l travel s load F s I s II s III s OM height l travel s load F stiffness mm mm N MPa mm mm N N/mm 0.550.000000000.550.0000851 0.540.0108-1482768-530.540.0108810 0.530.02016-29356134-1070.530.02016770 0.520.03024-43688199-1600.520.03024733 0.510.04031-576122263-2130.510.04031697 0.500.05038-714158325-2660.500.05038663 0.490.06044-849197386-3200.490.06044630 0.480.07050-982239446-3730.480.07050599 0.470.08056-1113283504-4260.470.08056570 0.460.09062-1241329561-4790.460.09062542 0.450.10067-1366378616-5330.450.10067516 0.440.11072-1489430671-5860.440.11072492 0.430.12077-1610484724-6390.430.12077469 0.420.13081-1728540775-6930.420.13081448 0.410.14086-1843599826-7460.410.14086429 0.400.15090-1956660875-7990.400.15090411 0.390.16094-2067724922-8520.390.16094396 0.380.17098-2175790968-9060.380.17098381 0.370.180102-22818591013-9590.370.180102369 0.360.190105-23849301057-10120.360.190105358 0.350.200109-248510041099-10660.350.200109349 0.340.210112-258310801140-11190.340.210112341 0.330.220116-267911581180-11720.330.220116335 0.320.230119-277312391218-12250.320.230119331 0.310.240122-286413231255-12790.310.240122329 0.300.250126-295214091290-13320.300.250126328

1spring1

dimensions load points

outer diam.:D e=8.00 mm of one spring

inner diam.:D i= 3.20 mm load-height l travel s load F thickness:t=0.30 mm point mm mm N red. thickness:t'=0.30 mm00.5500.0000 spring height:l0=0.55 mm10.4880.06245 material:50 CrV 420.3630.187104 Youngs-modulus:206000MPa at20°C Flat0.3000.250126

part./drawing no.:17 0001

Version 19.7.98project:0

2016/11/8Muhr und Bender, Tellerfedern und Spannelemente GmbH, Postfach 120, 57564 Daaden 0phone.: sales: 02743/806-184, -194, Fax.:-188; engineering: 02743/806-268, -134, -135, Fax.: -292

remarks

max upper stress:1300MPa

max compress. stress:-3600MPa

setting at 20°C:0.3 % after 48h 1.0 % after 1000h

setting at 100°C: 4.8 % after 48h 6.4 % after 1000h

calculated data

disc-angle at L0: 6.607°

De at flat:7.984 mm

Di at flat: 3.221 mm

center of rotation: 5.239 mm

tolerances concerning Mubea-disc-spring-handbook

Load tolerance:+25 / -7,5 %at 75% of h0 of one spring

rel. min. load at disloading:90 %at 75% of h0 of the stack

tolerance inner diam.: 3.200 mm to 3.320 mm

tolerance outer diam.:7.850 mm to8.000 mm

gap at inner diam.:0.200 mm

gap at outer diam.:0.200 mm

tolerance of thickness:0.240 mm to0.320 mm

tolerance of spring height:0.500 mm to0.650 mm please contact Mubea!