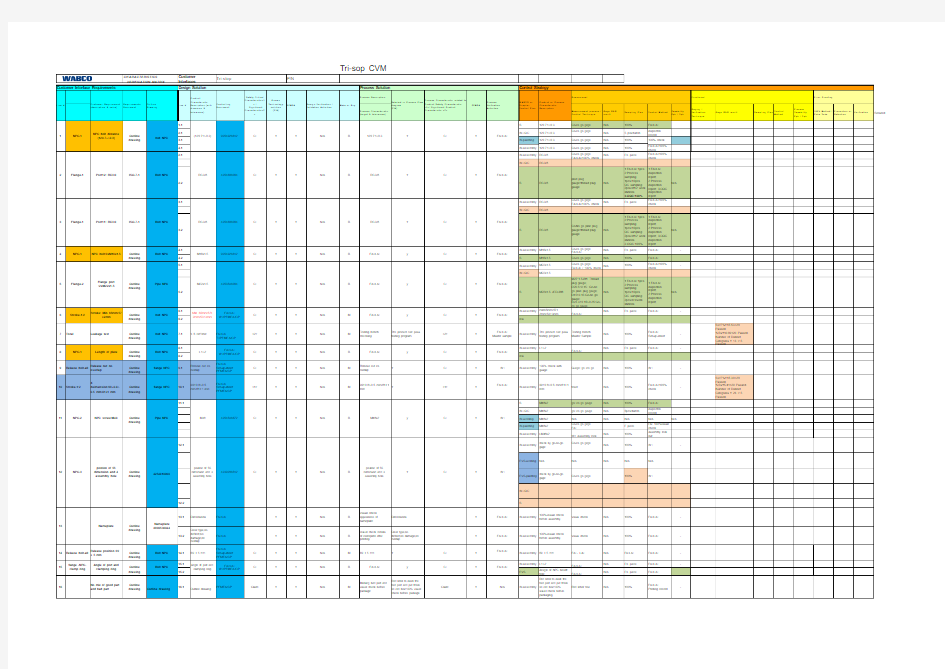

特殊特性矩阵

P/N Process Description Process Characteristic (target & tolerances)Measurement process /Control Technique Gage R&R result Sampling Plan Control Method Capability

Ppk / Cpk Gaging /Verification

Technique Gage R&R result Sampling Plan Control Method Process Capability

Ppk / Cpk 100% Method /Poka Yoke Prevention or Detection Verification Secured

1.1

S 120.7+/-0.3Go-no go gage N/A 100%FAI/LAI 2.1W-IQC 120.7+/-0.3Go-no go gage N/A 5 pcs/batch inspecton record 3.1

W-painting 120.7+/-0.3Go-no go gage N/A 100%100% check 4.1

W-assembly 120.7+/-0.3Go-no go gage N/A 100%FAI/LAI/100%check 2.1W-assembly RC3/8

Go-no go gage

FAI/LAI/100% check N/A F/L piece FAI/LAI/100%

check W-IQC RC3/8

2.2S RC3/8plain plug gauge+thread plug

gauge N/A 1.FAI/LAI:1pcs 2.Process sampling:1pcs/10pcs QC sampling:

2pcs/4H/2 work

stations

3.OQC:100%

1.FAI/LAI inspection report;

2.Process inspection report;

3.OQC inspection report N/A

3.1W-assembly RC3/8

Go-no go gage FAI/LAI/100% check N/A F/L piece FAI/LAI/100%check W-IQC RC3/83.2S RC3/8Go-No go plain plug gauge+thread plug

gauge N/A 1.FAI/LAI:1pcs 2.Process sampling:1pcs/10pcs QC sampling:

2pcs/4H/2 work

stations

3.OQC:100%

1.FAI/LAI inspection report;

2.Process inspection report;

3.OQC inspection report N/A

4.1W-assembly M16x1.5Go-no go gage FAI/LAI N/A F/L piece

FAI/LAI -4.2S M16x1.5Go-no go gage N/A 100%

FAI/LAI 5.1W-assembly M22x1.5

Go-no go gage FAI/LAI / 100% check N/A 100%FAI/LAI/100%

check -

W-IQC M22x1.55.2S M22x1.5 JED-388

M22*1.5-6H: Thread plug gauge;D20.5+0.15: Go-no go plain plug gauge;D15+0.15:Go-no go gauge;D23.3+0.15/-0.25:Go-no go gauge N/A 1.FAI/LAI:1pcs 2.Process sampling:1pcs/10pcs QC sampling:2pcs/4H/work stations 1.FAI/LAI inspection report;2.Process inspection report;N/A 6.1W-assembly min65mm/57±2mm/53+3mm FAI/LAI N/A F/L piece FAI/LAI -

6.2n/a 7Total Leakage test Outline

drawing bolt NPC 7.1≤ 8 cm3/min FAI/LAI TI/PFMEA/CP <2>Y Y N/A M Testing bench checking The product can pass testing program <2>Y FAI/LAI

Master sample W-assembly The product can pass testing program Testing bench Master Sample N/A 100%FAI/LAI

Set-up-sheet -SV/T%=15.53<20Passed.%SV=10.69<20 Passed.

Number of Distinct

Categories = 13>5

Passed.

8.1

W-assembly L+/-2FAI/LAI N/A F/L piece FAI/LAI -8.2

n/a 9Release bolt-all Release nut no

overlap Outline

drawing flange NPC 9.1Release nut no

overlap FAI/LAI Set-up-sheet

PFMEA/CP CI Y Y N/A M Release nut no overlap Y CI Y WI W-assembly 100% check with guage Guage: go /no go N/A 100%WI -

10Stroke-1/2X deimension:99+0.8/-0.5 mm/81±1 mm Outline drawing flange NPC 10.199+0.8/-0.5mm/81±1 mm FAI/LAI Set-up-sheet PFMEA/CP <1>Y Y N/A M 99+0.8/-0.5 mm/81±1mm Y <1>Y FAI/LAI W-assembly 99+0.8/-0.5 mm/81±1mm teser N/A 100%FAI/LAI/100%check -

SV/T%=15.30<20

Passed.

%SV=5.41<20 Passed.

Number of Distinct

Categories = 26>5

Passed.11.1S

M48x2go/ no go gauge N/A 100%FAI/LAI W-IQC M48x2

go/ no go gauge N/A 5pcs/batch inspecton record W-welding M48x2

N/A N/A N/A N/A N/A W-painting M48x2Go-no go gage

FAI

F piece FAI 100%visual check W-assembly LM48x2WI/ Assembly lock

N/A 100%Assembly lock nut 12.1W-assembly check by go-no-go

gage Go-no go gage N/A 100%

WI -EVS-welding N/A

N/A N/A N/A N/A EVS-painting check by go-no-go

gage Go-no go gage 100%WI

W-IQC

12.2

S 13.1Dimensions FAI/LAI

appearance of

nameplate

Dimensions

overlap

FAI/LAI

of nameplate after

printing Clear type,no deflect,no damage,no overlap

± 5 mm

Outline drawing Bolt NPC 14.169 ± 5 mm FAI/LAI Set-up-sheet PFMEA/CP CI Y Y N/A M 69 ± 5 mm Y CI Y FAI/LAI W-assembly 69 ± 5 mm FAI 、LAI N/A FAILAI FAI/LAI -15.1W-assembly L+/-2FAI/LAI N/A F/L piece FAI/LAI -15.2EVS

Anagle of NPC breath hole FAI/LAI N/A F/L piece FAI/LAI 16No mix of good part and bad part Outline drawing Outline drawing 16.1Outline drawing PFMEA/CP Claim Y Y N/A M Marking bad part and visual check before package Red label to mark the bad part and put them on red box/100% visual check before package Claim Y N/A W-assembly Red label to mark the bad part and put them on red box/100%visual check before

packaging Red label/ box N/A 100%FAI/LAI Printing record -

NPC-2NPC-3flange -NPC-

clamp ring NPC-1Flange-1Flange-1NPC-1Flange-215Angle of port and

clamping ring Outline

drawing Bolt NPC

Angle of port and clamping ring FAI/LAI WI/PFMEA/CP CI Y Y N/A B Y Y B Y CI B N/A Y Y CI postion of 55dimension and 4assembly hole B CI 11NPC screw:M48Outline drawing Pipe NPC M484254546672CI CI N/A FAI/LAI WI/PFMEA/CP CI Y Y N/A Nameplate 13Nameplate 8990538044Outline drawing Outline drawing 8Length of plate Outline

drawing Bolt NPC NPC-1FAI/LAI WI/PFMEA/CP Outline drawing Outline

drawing Outline

drawing 12postion of 55

dimension and 4

assembly hole 4254810090L+/-2postion of 55dimension and 4assembly hole 4239206512CI CI 92549266124254606004Outline

drawing ISO-7-1Y Y 2Port12: RC3/8Bolt NPC

RC3/892549266124253546004Y ISO-7-1Y Y Y Y Y Y Y Y RC3/8CI 4254606004M16x1.5CI CI CI Y N/A B N/A B N/A B N/A B N/A B N/A M 6Stroke: Min 65mm/57

±2mm bolt NPC Min 65mm/57±2mm/53+3mm 5Flange port

:2xM22x1.5Pipe NPC

M22x1.5Stroke-1/2Dimensional Functional Error Proofing WABCO or Supplier Control Plan 4NPC bolt:3xM16x1.5Bolt NPC 3Port11: RC3/8Bolt NPC

Known Technology solution (Y/N)PFMEA Process Verfication Activities Design Verification /Validation Activities NPC bolt distance

(120.7+/-0.3)bolt NPC 1(120.7+/-0.3)

Control Strategy Product

Characteristic

Description (with

dimesion &

tolerances)Controlling Document Line #DFMEA Product or Process Characteristic Description Process Solution Detailed in Process Flow diagram (Y/N)Process Characteristic related to Product Safety Characteristic <1>/ Significant Product Characteristic <2>Make or Buy Safety Critical Characteristic<1> / Significant Characteristic<2

>Line #Customer Requirement (description & value)CHARACTERISTICS

VERIFICATION MATRIX Tri-stop Customer Interface Requirements Customer Interfaces

Design Solution

Requirements Document Outline Drawing 120.7+/-0.3Y Y FAI/LAI RC3/8Y Y FAI/LAI CI CI RC3/8Y Y FAI/LAI FAI/LAI y Y FAI/LAI CI CI FAI/LAI y Y FAI/LAI FAI/LAI y Y FAI/LAI

CI CI FAI/LAI y Y FAI/LAI M48x2y Y WI Y WI

FAI/LAI y Y FAI/LAI

CI