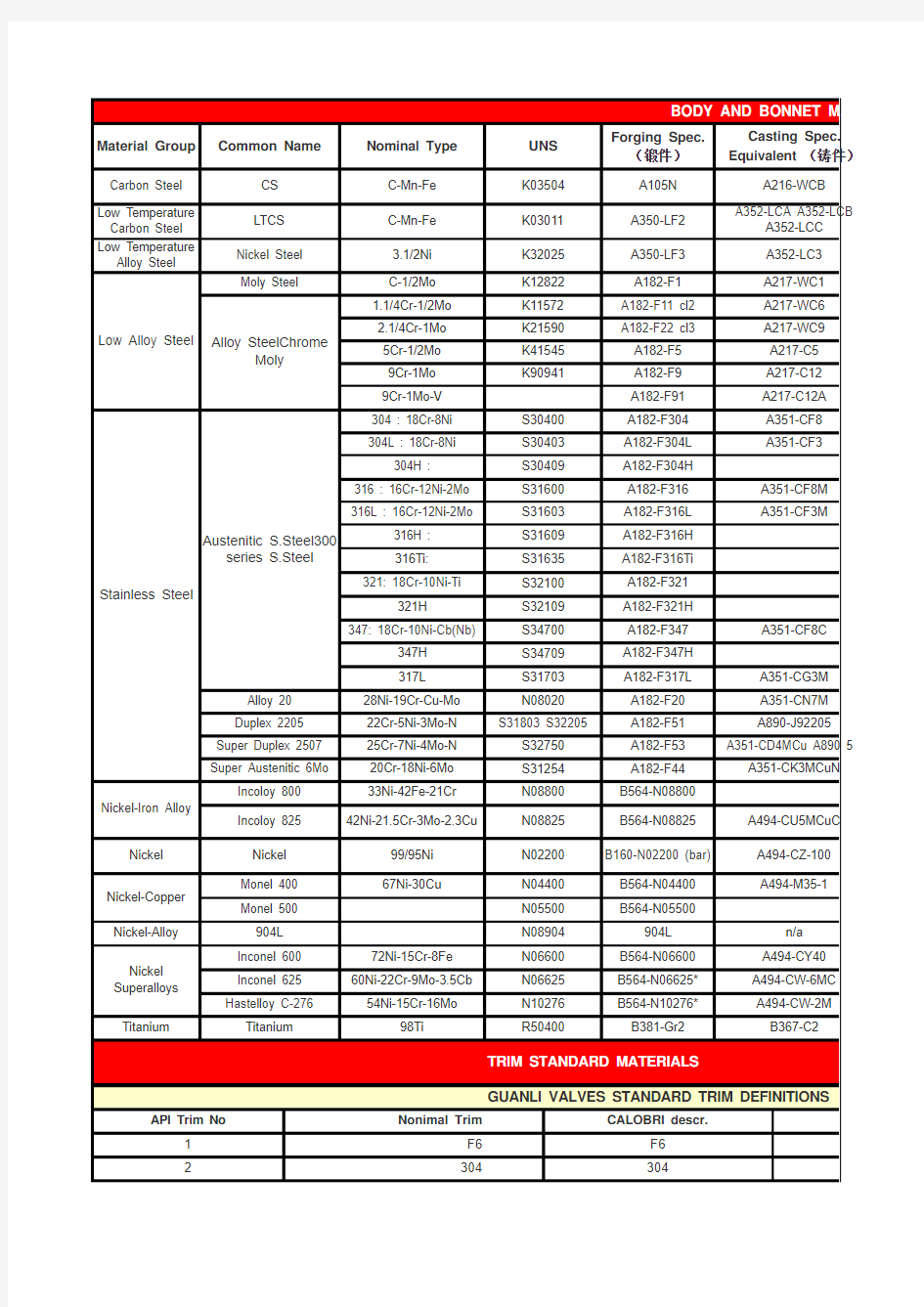

GUANLI阀门常见材料对照表ASME-DIN

Nickel-Copper Nickel Superalloys TRIM STANDARD MATERIALS

Low Alloy Steel

Alloy SteelChrome

Moly

Stainless Steel

Austenitic S.Steel300

series S.Steel

Nickel-Iron Alloy

2

304

304

1F6F6API Trim No

Nonimal Trim

CALOBRI descr.

GUANLI VALVES STANDARD TRIM DEFINITIONS

Titanium

Titanium

98Ti

R50400

B381-Gr2

B367-C2

Hastelloy C-276

54Ni-15Cr-16Mo

N10276B564-N10276*A494-CW-2M Inconel 62560Ni-22Cr-9Mo-3.5Cb N06625B564-N06625*A494-CW-6MC Inconel 600

72Ni-15Cr-8Fe N06600B564-N06600A494-CY40Nickel-Alloy

904L N08904

904L n/a Monel 500N05500B564-N05500

Monel 40067Ni-30Cu

N04400B564-N04400A494-M35-1

Nickel Nickel 99/95Ni N02200B160-N02200 (bar)A494-CZ-100Incoloy 82542Ni-21.5Cr-3Mo-2.3Cu

N08825B564-N08825A494-CU5MCuC Incoloy 800

33Ni-42Fe-21Cr N08800B564-N08800Super Austenitic 6Mo

20Cr-18Ni-6Mo S31254A182-F44A351-CK3MCuN

Super Duplex 250725Cr-7Ni-4Mo-N S32750A182-F53A351-CD4MCu A890 5

Duplex 220522Cr-5Ni-3Mo-N S31803 S32205

A182-F51A890-J92205Alloy 2028Ni-19Cr-Cu-Mo N08020A182-F20A351-CN7M 317L

S31703A182-F317L A351-CG3M 347H S34709A182-F347H 347: 18Cr-10Ni-Cb(Nb)

S34700A182-F347A351-CF8C

321H

S32109A182-F321H 321: 18Cr-10Ni-Ti

S32100A182-F321316Ti:S31635A182-F316Ti 316H :S31609A182-F316H 316L : 16Cr-12Ni-2Mo

S31603A182-F316L A351-CF3M

316 : 16Cr-12Ni-2Mo S31600A182-F316A351-CF8M 304H :

S30409A182-F304H 304L : 18Cr-8Ni

S30403A182-F304L A351-CF3

304 : 18Cr-8Ni S30400A182-F304A351-CF89Cr-1Mo-V A182-F91

A217-C12A 9Cr-1Mo K90941

A182-F9A217-C125Cr-1/2Mo K41545A182-F5A217-C52.1/4Cr-1Mo

K21590A182-F22 cl3A217-WC91.1/4Cr-1/2Mo

K11572A182-F11 cl2A217-WC6Moly Steel

C-1/2Mo K12822A182-F1A217-WC1Low Temperature

Alloy Steel

Nickel Steel 3.1/2Ni K32025A350-LF3A352-LC3Low Temperature Carbon Steel LTCS C-Mn-Fe K03011A350-LF2A352-LCA A352-LCB

A352-LCC

Carbon Steel CS C-Mn-Fe K03504A105N A216-WCB Material Group

Common Name

Nominal Type

UNS

Forging Spec.(锻件)

Casting Spec.Equivalent (铸件)

BODY AND BONNET MAT

CALOBRI

F6304316321347MONEL(R)ALLOY 20ALLOY 625C276St. Gr6

GUANLI VALVES TRIM MA

DESIGN AND MANUFACTURING STANDARDS

UNS R30006

Co Cr-A

AMS 5894

UNS N0662560Ni-22Cr-9Mo-3.5Cb ASTM B564-N06625UNS N1027654Ni-15Cr-16Mo

ASTM B564-N10276

UNS N0440067Ni-30Cu ASTM B564-N04400UNS N0802028Ni-19Cr-Cu-Mo ASTM A182-F20UNS S3210018 Cr-10 Ni-Ti ASTM A182 F321UNS S3470018 Cr-10 Ni-Cb ASTM A182 F347UNS S3040018-8 Cr-Ni ASTM A182 F304UNS S3160018-8 Cr-Ni (18-10-2)ASTM A182 F316UNS TYPE Grade (forged)UNS S4100013Cr ASTM A182 F6a n/a

Alloy 625

Alloy 625

18Hardfaced (Alloy 20)

Alloy 20-HF A

17Hardfaced (347)347-HF 16Hardfaced (316)316-HF 15Hardfaced (304)304-HF 14Alloy 20 and Hardfaced

Alloy 20HFS 13Alloy 20

Alloy 2012316 and Hardfaced

316HFS 11Monel and Hardfaced MonelHFS 10316

3169Monel Monel 8F6 and Hardfaced

F6HFS 5Hardfaced

F6HF

0.04% min. carbon (grade F321H) and heat treat at 2000F(1100C) for service temps.>1000F(538C)0.04% min. carbon (grade F347H) and heat treat at 2000F(1100C) for service temps.>1000F(538C)

304

304

304

Seat 410F6410Stem Disc/Wedge

Ti 2

3.7035

S

2.4856*Difficult to forge in close dye M

NiMo 16 Cr 15 W

2.4819*Difficult to forge in close dye

MC DIN 17742

2.48162.4375

Z2 NCDU 25-20 1.45391

DIN 17730

2.4362.4858service to 600F(316C) for N02200, 1200F(648C)

for N02201

0NW2200 1.774uC DIN 17744 1.4547service to 600F(316C)

X10NiCrAlTi32-20

1.4876service to 1000F(538C)

uN

X1CrNiMoCuN20-18-7 DIN 10088-1

(95)

1.4462service to 600F(316C) -The original S31803 UNS designation has been supplemented by S32205

890 5A X2CrNiMoN25-7-4 DIN 10088-1 (95) 1.4501service to 600F(316C)

5X2CrNiMON22-5-3 DIN 10088-1 (95)M DIN 1.4500

2.466service to 600F(316C)

M X2CrNiMo18-16-4 1.4438n/a

n/a DIN 8556 1.455n/a n/a X 6 CrNiTi 18 10

1.4541X 6 CrNiMoTi 17 12 2 1.4571Up to 800F(427C)

n/a

n/a M

X 5 CrNiMo 17 12 2

1.4404M DIN X5CrNiMo 18 10 1.44010.04% min. carbon for temp.>1000F(538C)

n/a

n/a 0.04% min. carbon for temp.>1000F(538C)

X 2 CrNi 19 11

1.4306Up to 800F(427C)

DIN X5CrNi 18 9 1.4301High temp erosive refinery service

X 10 CrMoVNb 9 1 1.4903High pressure steam

X 12 CrMo 9 1 1.7386Up to 1100F(593C), HP steam 12CRMO195 1.7362High temp refinery service 10CRMO910 1.7381.5415Up to 875F (468C)

13CRMO44 1.7335Up to 1100F (593C)15MO3General non-corrosive service from -50F (-46C) to 650F(340C), LF2 to 800F(427C).10Ni14 1.5637-150F(-101C) to 650F(340C)1.046General non-corrosive service from -20F(-29C) to 800F(427C)

-LCB

A352-LCC

TSTE 355 DIN 18103

1.0566DIN

DIN W. No

Application Notes

C22.8 DIN 17243

ec.

uivalent (铸件)

MATERIALS

DIN W NO.14,00614,30114,4011.45411.4552.4362.4662.486524,819

M MATERIAL

Stellite(R) Gr6

ASTM B564-N06625DIN 17361ASTM B574-N10276

DIN NiMo 16 Cr 15 W

B164-N04400DIN 17743ASTM B473DIN 14500A276-321DIN X6CrNiTi 18 10A276-347DIN X6CrNiNb18 10

A276-304DIN X5CrNi 18 10A276-316DIN X5CrNiMo 18 10ASTM wrought DIN A276-410DIN X12Cr13Alloy 20 + St Gr6

Alloy 625

Alloy 625

Alloy 625

Alloy 20 HF Alloy 20 + St Gr6

316 + St Gr6347 HF 347 + St Gr6347 + St Gr6316 HF 316 + St Gr6Alloy 20304304 + St Gr6304 + St Gr6Alloy 20Alloy 20316 + St. Gr6Alloy 20Alloy 20Alloy 20316316316Monel Monel Monel 316316410 + St Gr6Monel Monel Monel 410F6410F6 + St Gr6

410 + St Gr6