供应商风险评估表范例

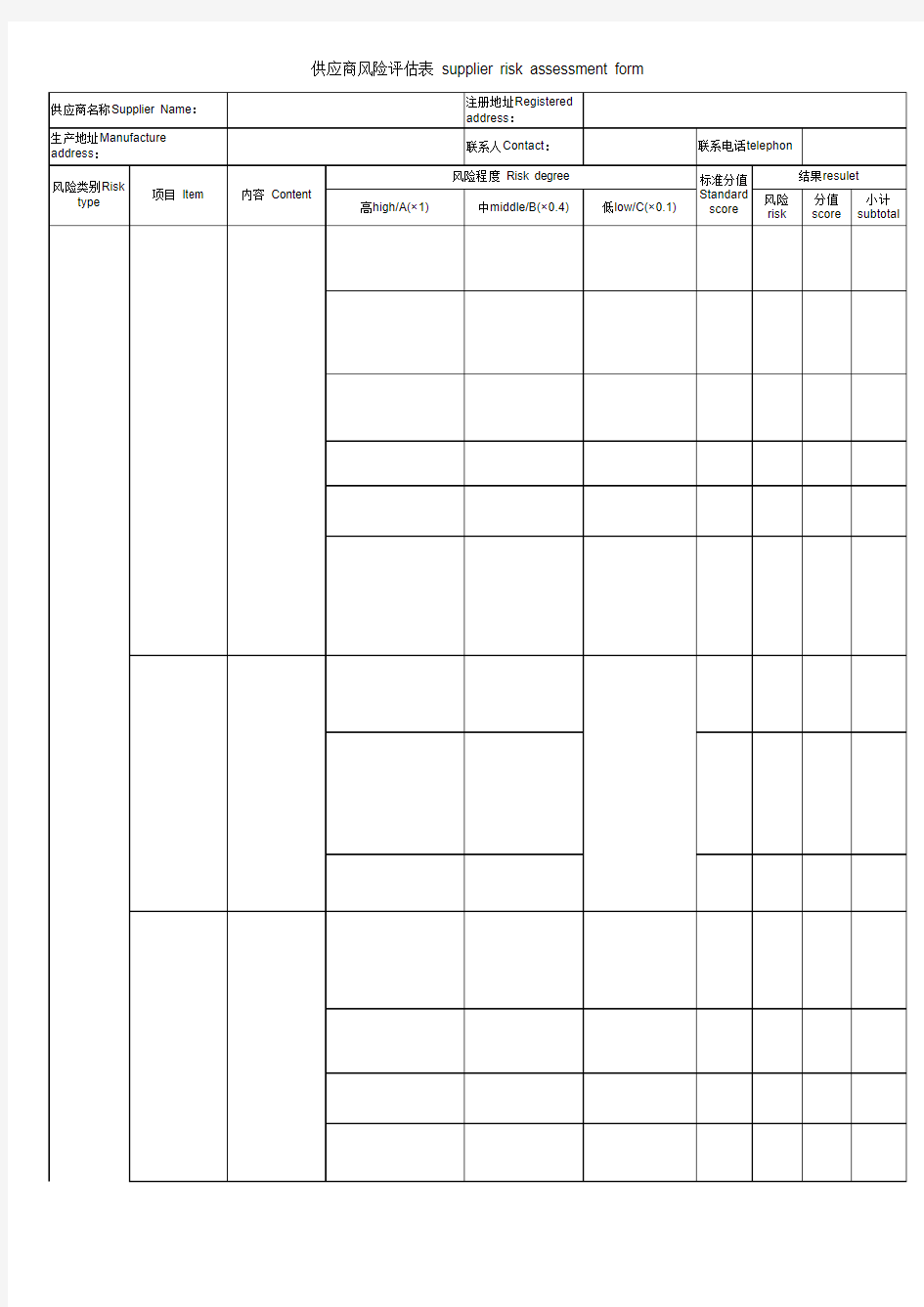

供应商风险评估表 supplier risk assessment form

风险程度Risk degree

备注:所有风险评估应基于事实的依据,对于新入册供应商不适用的项目可以按中等风险打分

note: All risk evaluation is based on the actual , for new supplier, some item which could not be evalued shall evaluate as middle risk.

◇必要时,可对供应商每两年执行1次现场考察或书面审查 if necessary, should do on-site visit or writted review every two years.中风险

middle risk

低风险

low risk ◇每批次物料需严格进行检验 Each batch of material shall be inspected strictly.◇所有采购材料实时跟踪状态 Real-time tracking of all purchasing materials ◇每半年年至少对供应商进行1次实地考察或书面调查 one time on-site visit or written review every half a year at least.◇对每批次物料进行检验 Each batch of material shall be inspected.◇每年跟踪一至二批材料的供料状态 Track of one or two batch of material yearly ◇每年对供应商进行1次实地考察或书面审查 one time on-site visit or written review every year ◇对每批次物料进行检验,若供应商的历史交货质量状况良好,可降低抽样检验频率 Each batch of material should be inspected, if the supplier's historical delivery quality is in good condition, could reduce the sampling frequency ◇不跟踪材料的供应状态the supply status of the material is not tracked

评估结论:评估分值在15分以下为低风险,15-30分范围内为中等风险,30分以上为高风险(代理商得分5分以下为低风险,5-8分为中风险,8分以上为高风险)evaluation result: low risk when the evaluated score not more than 15, middle risk when the evaluated score between 15-30, high risk when the evaluated score more than 30(agents scoring 5 point or less is low risk, 5-8 is middle risk, 8 or more is high risk)

高风险

High risk

管理措施 Management method 备注:代理商仅考虑商务风险、物流风险和交货风险,不考虑其质量风险。

Note: Agents only consider business risk, logistics risk and delivery risk, without quality risk.