光学玻璃的折射率和色散

DATE May 2004 PAGE 1/15

TIE-29: Refractive Index and Dispersion

0. Introduction

The most important property of optical glass is the refractive index and its dispersion behavior.

This technical information gives an overview of the following topics:

- Dispersion

o Principal dispersion (page 2) o Secondary spectrum (page 3)

o Sellmeier dispersion equation (page 4)

- Temperature dependence of refractive index (page 6)

- Influence of the fine annealing process on the refractive index and Abbe number

(page 9)

- Tolerances (page 12)

- Refractive index measurement (page 13)

1. Refractive Index

If light enters a non-absorbing homogeneous materials reflection and refraction occurs at the boundary surface. The refractive index n is given by the ratio of the velocity of light in vacuum c to that of the medium v

v

c n =

(1-1)

The refractive index data given in the glass catalogue are measured relative to the refractive index measured in air. The refractive index of air is very close to 1.

Practically speaking the refractive index is a measure for the strength of deflection occurring at the boundary surface due to the refraction of the light beam. The equation describing the amount of deflection is called Snell’s law:

)sin()sin(2211αα?=?n n (1-2)

The refractive index is a function of the wavelength. The most common characteristic quantity for characterization of an optical glass is the refractive index n in the middle range of the visible spectrum. This principal refractive index is usually denoted as n d – the refractive index at the wavelength 587.56 nm or in many cases as n e at the wavelength 546.07 nm.

2. Wavelength Dependence of Refractive Index: Dispersion

The dispersion is a measure of the change of the refractive index with wavelength. Dispersion can be explained by applying the electromagnetic theory to the molecular structure of matter. If an electromagnetic wave impinges on an atom or a molecule the bound charges vibrate at the frequency of the incident wave.

DATE May 2004 PAGE 2/15

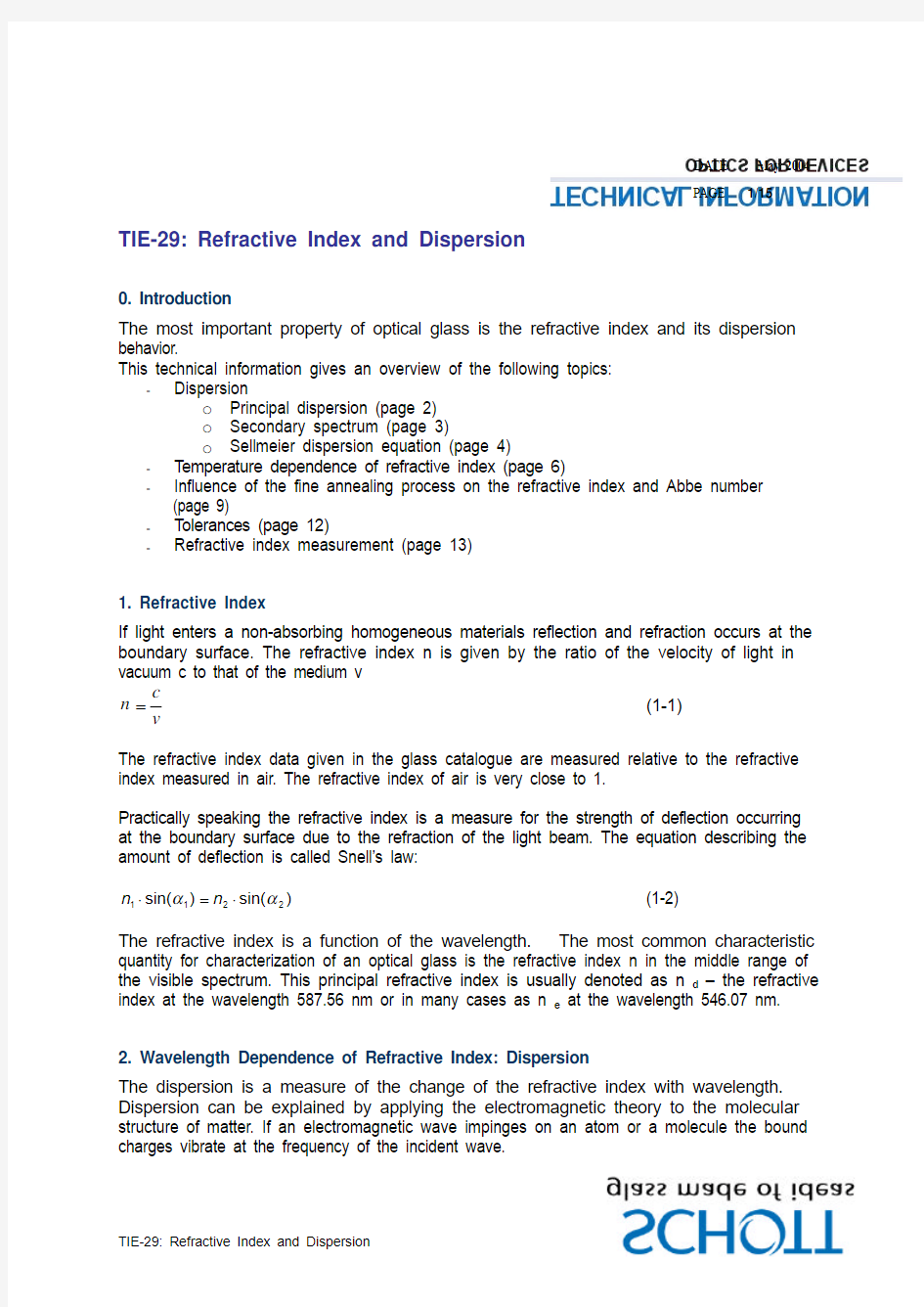

The bound charges have resonance frequency at a certain wavelength. A plot of the refractive index as a function of the wavelength for fused silica can be seen in Figure 2-1. It can be seen that in the main spectral transmission region the refractive index increases towards shorter wavelength. Additionally the dotted line shows the absorption coefficient as a function of the wavelength.

Figure 2-1: Measured optical constants of fused silica (SiO 2 glass) [1]

2.1 Principal Dispersion

The difference (n F – n C ) is called the principal dispersion. n F and n C are the refractive indices at the 486.13 nm and 656.27 nm wavelengths.

The most common characterization of the dispersion of optical glasses is the Abbe number. The Abbe number is defined as

)/()1(C F d d n n n ??=ν (2.1-1)

Sometimes the Abbe number is defined according to the e line as

)/()1(C F e e n n n ′′??=ν (2.1-2).

Traditionally optical glasses in the range of νd > 50 are called crown glasses, the other ones as flint glasses.

Glasses having a low refractive index in general also have a low dispersion behaviour e.g. a high Abbe number. Glasses having a high refractive index have a high dispersion behaviour and a low Abbe number.

DATE May 2004 PAGE 3/15

2.2. Secondary Spectrum

The characterization of optical glass through refractive index and Abbe number alone is insufficient for high quality optical systems. A more accurate description of the glass properties is achievable with the aid of the relative partial dispersions.

The relative partial dispersion P x,y for the wavelengths x and y is defined by the equation:

)/()(,C F y x y x n n n n P ??= (2.2-1)

As Abbe demonstrated, the following linear relationship will approximately apply to the majority of glasses, the so-called ”normal glasses”

d xy xy y x b a P ν?+≈, (2.2-2)

a xy and

b xy are specifi

c constants for the given relative partial dispersion.

In order to correct the secondary spectrum (i.e. color correction for more than two wavelengths) glasses are required which do not conform to this rule. Therefore glass types having deviating partial dispersion from Abbe’s empirical rule are especially interesting.

As a measure of the deviation of the partial dispersion from Abbe’s rule the ordinate difference ?P is introduced. Instead of relation (2.2-2) the following generally valid equation is used:

y x d xy xy y x P b a P ,,?+?+=ν (2.2-3)

The term ?P x,y therefore quantitatively describes a dispersion behavior that deviates from that of the ”normal glasses.”

The deviations ?P x,y from the ”normal lines” are listed for the following five relative partial dispersions for each glass type in the data sheets.

)/()()

/()()/()()/()()/,,,,C F g i g i C F F g F g C F e F e F C F s C s C C F t C C,t n n n n P n n n n P n n n n P n n n n P n (n )n (n P ??=??=??=??=??= (2.2-4)

The position of the normal lines is determined based on value pairs of the glass types K7 and F2. The explicit formulas for the deviations ?P x,y of the above-mentioned five relative partial dispersions are:

DATE May 2004 PAGE 4/15

)008382.07241.1()/()()

001682.06438.0()/()()000526,04884.0()/()()002331.04029.0()/()()004743.05450.0()/()(,,,,,d C F g i g i d C F F g F g d C F e F e F d C F s C s C d C F t C t C n n n n P n n n n P n n n n P n n n n P n n n n P ννννν?????=??????=??????=??+???=??+???=? (2.2-5)

Figure 2.2-1 shows the P g,F versus the Abbe number νd diagram.

Figure 2.2-1: P g,F as a function of the Abbe number for Schott’s optical glass sortiment.

Additionally the normal line is given.

The relative partial dispersions listed in the catalog were calculated from refractive indices to 6 decimal places. The dispersion formula (2.3-1) can be used to interpolate additional unlisted refractive indices and relative partial dispersions (see chapter 2.3).

2.3. Sellmeier Dispersion Equation

The Sellmeier Equation is especially suitable for the progression of refractive index in the wavelength range from the UV through the visible to the IR area (to 2.3 μm). It is derived from the classical dispersion theory and allows the description of the progression of refractive index over the total transmission region with one set of data and to calculate accurate intermediate values.

DATE May 2004 PAGE 5/15

)

()()(1)(32

2

3222212212

C B C B C B n ??+??+??=?λλλλλλλ (2.3-1)

The determination of the coefficients was performed for all glass types on the basis of precision measurements by fitting the dispersion equation to the measurement values. The coefficients are listed in the data sheets.

The dispersion equation is only valid within the spectral region in which refractive indices are listed in the data sheets of each glass. Interpolation is possible within these limits. The wavelengths used in the equation have to be inserted in μm with the same number of digits as listed in Table 2.3-1. For practical purposes Equation 2.3-1 applies to refractive indices in air at room temperature. The achievable precision of this calculation is generally better than 1·10-5 in the visible spectral range. The coefficients of the dispersion equation can be reported for individual glass parts upon request. This requires a precision measurement for the entire spectral region, provided the glass has sufficient transmission.

Table 2.3-1: Wavelengths for a selection of frequently used spectral lines

DATE May 2004 PAGE 6/15

3. Temperature Dependence of Refractive Index

The refractive indices of the glasses are not only dependent on wavelength, but also upon temperature. The relationship of refractive index change to temperature change is called the temperature coefficient of refractive index. This can be a positive or a negative value. The data sheets contain information on the temperature coefficients of refractive index for several temperature ranges and wavelengths. The temperature coefficients of the relative refractive indices ?n rel /?T apply for an air pressure of 0.10133·106 Pa. The coefficients of the absolute refractive indices dn abs /dT apply for vacuum.

The temperature coefficients of the absolute refractive indices can be calculated for other temperatures and wavelengths values with the aid of equation (3-1).

)232(),(21),(),(22102210002TK

abs T

E E T D T D D T n T n dT T dn λλλλλ????++???+???+???= (3-1)

Definitions:

T 0 Reference temperature (20°C) T Temperature (in °C) ?T Temperature difference versus T 0 λ Wavelength of the electromagnetic wave in a vacuum (in μm) D 0, D 1, D 2, E 0, E 1 and λTK : constants depending on glass type

This equation is valid for a temperature range from -40°C to +80°C and wavelengths between 0.6438 μm and 0.4358 μm. The constants of the dispersion formula are also calculated from the measurement data and listed on the test certificate.

The temperature coefficients in the data sheets are guideline values. Upon request, measurements can be performed on individual melts in the temperature range from -100°C to +140°C and in the wavelength range from 0.3650 μm to 1.014 μm with a precision better than ± 5·10-7/K. The accuracy at the limits of the measurement range is somewhat less than in the middle of this interval.

The temperature coefficients of the relative refractive indices ?n rel /?T and the values for ?n abs can be calculated with the help of the equations listed in Technical Information TI Nr. 19 (available upon request).

Figures 3-1 to 3-4 show the absolute temperature coefficient of refractive index for different glasses, temperatures and wavelengths.

DATE May 2004 PAGE 7/15

DATE May 2004

PAGE 8/15

SF 6.

DATE May 2004 PAGE 9/15

4. Influence of the Fine Annealing Process on the Refractive Index and Abbe number

The optical data for a glass type are chiefly determined by the chemical composition and thermal treatment of the melt. The annealing rate in the transformation range of the glass can be used to influence the refractive index within certain limits (depending on the glass type and the allowable stress birefringence). Basically slower annealing rates yield higher refractive indices. In practice, the following formula has proven itself.

)/log()()(00h h m h n h n x nd d x d ?+= (4-1) h 0 Original annealing rate h x New annealing rate m nd ? Annealing coefficient for the refractive index depending on the glass type

The refractive index dependence on annealing rate is graphically shown in Figure 4-1.

Figure 4-1: Dependence of refractive index on the annealing rate for several glass types. Reference annealing rate is 7 K/h

An analogous formula applies to the Abbe number.

)/log()()(00h h m h h x d d x d ?+=ννν (4-2) m νd ? Annealing coefficient for the Abbe number depending on the glass type

The annealing coefficient m νd can be calculated with sufficient accuracy with the following equation:

)/())((0C F nC nF d nd d n n m h m m ???=?νν (4-3)

The coefficient m nF-nC has to be determined experimentally.

DATE May 2004 PAGE 10/15

Figure 4-2 shows that individual glass types vary greatly in their dependence of t he Abbe number on the annealing rate. In general also the Abbe number increases with decreasing annealing rate. High index lead free glass types like N-SF6 show anomalous behavior. Anomalous behaviour means that the Abbe number decreases with decreasing annealing rate.

Figure 4-2: Abbe number as a function of the annealing rate for several glass types. Reference annealing rate is 7 K/h

Values for Annealing coefficients of some optical glasses are shown in Table 4-1. We will provide the values for the annealing coefficients of our glasses upon request.

m nd m nF-nc m ν

d

N-BK7 -0.00087 -0.000005 -0.0682 N-FK51 -0.00054 -0.000002 -0.0644 SF 6 -0.00058 +0.000035 -0.0464 N-SF6 -0.0025 -0.000212 0.0904

Table 4-1: Annealing coefficients for several selected glass types

The annealing rate can be used to adjust the refractive index and Abbe number to the desired tolerance range.

In practice the annealing rate influences the refractive index and the Abbe number simultaneously. Figure 4-3 shows a diagram of the Abbe number versus the refractive index for N -BK7. The rectangular boxes indicate the tolerance limits (steps) for the refractive index and the Abbe number. For example the largest box with a dotted frame indicates the tolerance borders for step 3 in refractive index and step 4 in Abbe number. The smallest box indicates step 1 in refractive index and Abbe number. In the center of the frames is the nominal catalog value.

DATE May 2004

PAGE 11/15 After melting the optical glass is cooled down at a high annealing rate. To control the refractive index during the melting process samples are taken directly from the melt after each casting. These samples are cooled down very fast together with a reference sample of the same glass. The reference sample has a known refractive index at an annealing rate of 2°C/h. By measuring the change in refractive index of the reference sample the refractive index of the sample can be measured with moderate accuracy in the range of ±10-4.

The annealing rate dependence of the Abbe number and refractive index of each glass is represented by a line in the diagram having a slope that is characteristic for the glass type. For a given melt the position of the line in the diagram is given by the initial refractive index / Abbe number measurement for a cooling rate of 2°C/h as a fix-point together with the glass typical slope. The refractive index and Abbe number for a given glass part can be adjusted by a fine annealing step along this characteristic line.

Glass for cold processing has to be fine annealed to reduce internal stresses. During this fine annealing the annealing rate is in general lower than 2°C/h. The initial refractive index has to be adjusted during melting in such a way that the desired tolerances can be reached during fine annealing. The initial refractive index of N-BK7 for example is in general lower than the target value.

Figure 4-3:The influence of the annealing rate on the refractive index and Abbe number

of N-BK7 for different initial refractive indices.

DATE May 2004

PAGE 12/15 Glass for hot processing i.e reheat pressing is subjected to much more rapid annealing. The heat treatment processes used by the customer in general use annealing rates much higher than 2°C/h. Therefore for N-BK7 pressings for example the initial refractive index needs to be higher than the target value. For a better visualization in figure 4-3 the annealing line for pressings was shifted to higher Abbe numbers. In general it is also possible to achieve step 1/1 for pressings after hot processing. We deliver an annealing schedule for each batch of glass for hot processing purpose. This annealing schedule contains the initial refractive index at 2°C/h and the limit annealing rates to stay within the tolerances.

5. Tolerances

The refractive indices, which are listed to 5 decimal places in the data sheets, represent values for a melt with nominal n d-νd position for the glass type in question. The refractive index data are exact to five decimal places (for λ > 2 μm: ± 2·10-5). The accuracy of the data is less in wavelength regions with limited transmission. All data apply to room temperature and normal air pressure (0,10133·10-6 Pa).

Defining tolerances for the refractive index of a glass the customer has to distinguish between the refractive index tolerance, the tolerance of refractive index variation within a lot and the refractive index homogeneity (figure 5-1).

Figure 5-1:Refractive index variation from within a production sequence.

DATE May 2004 PAGE 13/15

All deliveries of fine annealed block glass and fabricated glass are made in lots of single batches. The batch may be a single block or some few strip sections. More information on the new lot id system can be found in [3].

The refractive index and Abbe number tolerance is the maximum allowed deviation of a single part within the delivery lot from nominal values given in the data sheets of the catalog. The refractive index of the delivery lot given in the standard test certificates is given by the following formulae:

2/)(min max n n n lot += (5-1)

n max is the maximum and n min the minimum refractive index within the lot.

The refractive index variation from part to part within a lot is always smaller than ± 1*10-4. The refractive index homogeneity within a single part is better than ± 2*10-5 in general [4]. A short summary of the refractive index tolerance, variation and homogeneity grades can be found in table 5-1. More information is given in the optical glass catalogue [5].

Tolerance Grade Refractive Index [*10-5] Abbe Number

Step 4

-- ± 0.8% Step 3 ± 50 ± 0.5% Step 2 ± 30 ± 0.3% Absolute

Step 1

± 20 ± 0.2% SN

± 10 -- S0 ± 5 -- Variation S1

± 2 -- H1

± 2 -- H2 ± 0.5 -- H3 ± 0.2 -- H4 ± 0.1 -- Homogeneity H5 ± 0.05

--

Table 5-1: Refractive Index Tolerances

6. Refractive Index Measurement

For refractive index measurement two different measurement setups are used: the v -block refractometer (figure 6-2) and the spectral goniometer. Figure 6-1 shows the principle of the v-Block measurement. The samples are shaped in a nearly square shape. One sample is about 20x20x5 mm small. The sample will be placed in a v shaped block prism. The refractive index of this prism is known very precisely. The refraction of an incoming light beam depends on the refractive index difference between the sample and the v-block-prism. The advantage of this method is that up to 10 samples can be glued together into one v -block stack. Therefore many samples can be measured in a very short time. The relative measurement accuracy is very h igh, therefore differences in refractive index within one v -block stack can be measured very accurately.

DATE May 2004 PAGE 14/15

Figure 6-1: Refractive index variation from within a production sequence .

Figure 6-2: V-block refractometer.

The spectral goniometric method is based on the measurement of the angle of minimum refraction in a prism shaped sample. This is the most accurate absolute refractive index measurement method. In our laboratory we have standard manual spectral goniometers and automated improved spectral goniometer with higher accuracy and the ability to measure in the infrared and UV region (figure 6-3).

Figure 6-3: Manual spectral goniometer (left side), automated spectral goniometer (right

side).

sample with lower

refractive index

sample with higher refractive index sample

v-block-prism immersion oil

lightbeam

DATE May 2004

PAGE 15/15 Table 6-1 shows a summary of the refractive index measurements available at Schott.

Measurement accuracy

Measurement

Refractive index Dispersion

Wavelengths Method

V-block standard ± 30*10-6 ± 20*10-6g, F’, F, e, d, C’,

C

V-block enhanced ± 20*10-6± 10*10-6I, h, g, F’, F, e, d,

C’, C, r, t

v-block

refractometer

Precision

spectrometer

± 10*10-6± 3*10-6

Super precision spectrometer ± 5*10-6± 2*10-6

h, g, F’, F, e, d,

C’, C

spectral

goniometer

UV precision

spectrometer

± 10-20*10-6± 3*10-6

UV super precision spectrometer ± 2-5*10-6± 2*10-6

248.3 nm –

2325.4 nm

(about 30

spectral lines

possible)

automatic

spectral

goniometer

Table 6-1: Absolute refractive index measurement accuracies

The temperature coefficient of refractive index is measured using an automated spectral goniometer and a temperature controlled climate chamber with a temperature range from -100°C up to +140°C. The temperature coefficient can be measured with an accuracy of ± 0.5*10-6 K-1.

7. Literature

[1] The properties of optical glass; H. Bach & N. Neuroth (Editors), Springer Verlag 1998

[2] SCHOTT Technical Information No. 19 (available upon request).

[3] SCHOTT Technical Note No. 4: Test report for delivery lots

[4] SCHOTT Technical Information No. 26: Homogeneity of optical glass

[5] SCHOTT Optical Glass Pocket Catalogue

For more information please contact:

Optics for Devices

SCHOTT Glas

Germany

Phone: + 49 (0)6131/66-3835

Fax: + 49 (0)6131/66-1998

E-mail: info.optics@https://www.360docs.net/doc/a618684839.html,

https://www.360docs.net/doc/a618684839.html,/optics_devices

光学基础知识

Part1公司零件代号的含义以及材料代号和说明 公司零件代号一般由四部分组成:零件种类—尺寸—材料—说明 例:TPX-25.4K9-100FL(AR1064nm) 1、零件种类: (1) 透镜: TPX:平凸透镜TPC:平凹透镜TBX:双凸透镜TBC:双凹透镜 TML:弯月透镜TDA:胶合透镜TCM:平凹反射镜TXM:平凸反射镜 (2) 窗口: TWI:平面窗口TPW:平行窗口TPM:平面反射镜TGM:窗口毛坯 TWP:楔形窗口TPOF:平面标准镜TSM:振镜TEA:平面标准具 (3) 棱镜: TRAP:直角棱镜TPRP:波罗棱镜TRP:斜方棱镜TPTP:五角棱镜 TDVP:道威棱镜TRFP:屋脊棱镜TCCR:锥体棱镜TEQP:等边棱镜 TSP:特殊棱镜TCB:胶合(立方、分光)棱镜TPBP:佩林勃洛卡棱镜 2、尺寸: (1)直径,如TPX-25.4U-100FL (2)直径和厚度(高度),如TWI-25.4D2.5-U, (3)长、宽、高,如TPM-25x20x3-K9, TDVP-52.5 x 17 x 17K9(Al),TRAP-12.7B 3、材料: 光学玻璃(无色光学玻璃、有色光学玻璃、特殊玻璃) 无色光学玻璃(根据其化学组成及光学性能常数分):冕牌类和火石类 特点:K类,质轻、性硬、折射率低,一般n D=1.50~1.55,色散小 F 其它材料: U——UVFS——紫外石英,有级别之分,如0A级,0C级,0F级等 J——JGS1——国产紫外石英 SS——Suprasil——贺利氏公司石英,有型号之分,如Suorisil II, Suprasil III, Suprasil 300等UI——Infrasil——贺利氏公司石英,有型号之分,如Infrasil 301, Infrasil 302 Q——Quartz——石英晶体 C——CaF2

各种玻璃特性详细介绍

各种玻璃特性详细介绍文稿归稿存档编号:[KKUY-KKIO69-OTM243-OLUI129-G00I-FDQS58-

各种玻璃特性详细介绍 玻璃的制造已有五千年的历史,一般认为最早的制造者是古代的埃及人。我国在东周时代已能制造玻璃,玻璃组成中都含有氧化铅和氧化钡,与其他国家的古代玻璃有明显的区别。我国历史上有把玻璃称为琉璃、颇黎、假水晶料器、硝子等名称。 玻璃具有一系列非常可贵的特性:透明、坚硬、良好的化学稳定性;可通过化学组成的调整,大幅度调节玻璃的物理和化学性能,以适应各种不同的使用要求;可以用吹、压、拉、铸、槽沉、离心浇注等多种成形方法,制成各种形状的空心和实心制品;可以通过焊接和粉末烧结等加工方制成形状复杂、尺寸严格的器件。而且,制造玻璃的原料丰富,价格低廉。因此,作为结构材料和功能材料,玻璃在建材、轻工、交通、医药、化工、电子、航天、原子能等领域获得了极其广泛的应用。 B270/K9 K9玻璃是用K9料制成的玻璃制品,用于光学镀膜等领域 K9料属于光学玻璃,由于它晶莹剔透,所以衍生了很多以K9料为加工对象的工厂,他们加工出来的产品,在市面上称为水晶玻璃制品。 K9的组成如下: SiO2=69.13%B2O3=10.75%BaO=3.07%Na2O=10.40%K2O=6.29%As2O3=0.36% 它的光学常数为:折射率=1.51630色散=0.00806阿贝数=64.06。 无色光学玻璃--B270技术要求

石英玻璃 石英玻璃以其优良的理化性能,被大量广泛用于半导体技术,新型电光源,彩电荧光粉生产,化工过程,超高电压收尘、远红外辐射加热设备、航空航天技术、某些武器及光学仪器的光学系统、原子能技术、浮法玻璃及元碱玻璃窖的耐火材料,特种玻璃用坩埚,仪器玻璃成型部料碗,紫外线杀菌灯,各种有色金属的生产等诸多领域。石英玻璃SiO2含量大于99.5%,热膨胀系数低,耐高温,化学稳定性好,透紫外光和红外光,熔制温度高、粘度大,成型较难。多用于半导体、电光源、光导通信、激光等技术和光学仪器中。 石英玻璃在整个波长有特别好的透光性,在红外区(特殊的红外玻璃除外),光谱透射范围比普通玻璃大。在可见光区透过率达93%。在紫外光谱区,特别是在短波,紫外光谱区透过率比其他玻璃好的多。石英玻璃他的光学性能在很大程度上取决于它的化学性能。哪怕是0.001%的杂质就明显地影响产品质量。过度金属杂质会改变波长方向移动,羟基的存在会吸收2.73μm光带。国产光学石英玻璃有三个牌号:JGS1紫外光学石英玻璃,应用波段185-2000nm,用合成石制造,Sicl4为原料,JGS2紫外光学石英玻璃,应用波段220-2500nm,用水晶做原料,气炼法生产;JGS3红外光学石英玻璃,应用波段260-3500nm,采用水晶或

各种玻璃特性详细介绍

各种玻璃特性详细介绍玻璃的制造已有五千年的历史,一般认为最早的制造者是古代的埃及人。我国在东周时代已能制造玻璃,玻璃组成中都含有氧化铅和氧化钡,与其他国家的古代玻璃有明显的区别。我国历史上有把玻璃称为琉璃、颇黎、假水晶料器、硝子等名称。 玻璃具有一系列非常可贵的特性:透明、坚硬、良好的化学稳定性;可通过化学组成的调整,大幅度调节玻璃的物理和化学性能,以适应各种不同的使用要求;可以用吹、压、拉、铸、槽沉、离心浇注等多种成形方法,制成各种形状的空心和实心制品;可以通过焊接和粉末烧结等加工方制成形状复杂、尺寸严格的器件。而且,制造玻璃的原料丰富,价格低廉。因此,作为结构材料和功能材料,玻璃在建材、轻工、交通、医药、化工、电子、航天、原子能等领域获得了极其广泛的应用。 B270/K9 K9玻璃是用K9料制成的玻璃制品,用于光学镀膜等领域 K9料属于光学玻璃,由于它晶莹剔透,所以衍生了很多以K9料为加工对象的工厂,他们加工出来的产品,在市面上称为水晶玻璃制品。 K9的组成如下: SiO2=69.13%B2O3=10.75%BaO=3.07%Na2O=10.40%K2O=6.29%As2O3=0.36% 它的光学常数为:折射率=1.51630色散=0.00806阿贝数=64.06。 石英玻璃 石英玻璃以其优良的理化性能,被大量广泛用于半导体技术,新型电光源,彩电荧光粉生产,化工过程,超高电压收尘、远红外辐射加热设备、航空航天技术、某些武器及光学仪器的光学系统、原子能技术、浮法玻璃及元碱玻璃窖的耐火材料,特种玻璃用坩埚,仪器玻璃成型部料碗,紫外线杀菌灯,各种有色金属的生产等诸多领域。石英玻璃SiO2含量大于99.5%,热膨胀系数低,耐高温,化学稳定性好,透紫外光和红外光,熔制温度高、粘度大,成型较难。多用于半导体、电光源、光导通信、激光等技术和光学仪器中。 石英玻璃在整个波长有特别好的透光性,在红外区(特殊的红外玻璃除外),光谱透射范围比普通玻璃大。在可见光区透过率达93%。在紫外光谱区,特别是在短波,紫外光谱区透过率比其他玻璃好的多。石英玻璃他的光学性能在很大程度上取决于它的化学性能。哪怕是0.001%的杂质就明显地影响产品质量。过度金属杂质会改变波长方向移动,羟基的存在会吸收2.73μm光带。国产光学石英玻璃有三个牌号:JGS1紫外光学石英玻璃,应用波段185-2000nm,用合成石制造,Sicl4为原料,JGS2紫外光学石英玻璃,应用波段220-2500nm,用水晶做

常用晶体及光学玻璃折射率表图文稿

常用晶体及光学玻璃折 射率表 Company number【1089WT-1898YT-1W8CB-9UUT-92108】

注:n o 、n e 分别是晶体双折射现象中的“寻常光”的折射率和“非常光”的折射率。 资料来源:华东师大《光学教程》 注:“苏联钻”,立方氧化锆钻石 一般情况下,基础玻璃的折射率为—,而斜锆石的折射率为,锆英石的折射率为;SnO 2可以降低釉熔体的表面张力,且具有较高地折射率() CR-39即折射率单体 有机高分子化学 日开发出新型热固性树脂

-------------------------------------------------------------------------------- 2004-7-28 9:04:29 来源:中国化工网 日前,日本Nitto Denko Corp公司开发出一种折射系数为的芳香族热固性树脂,高于折射率的环氧树脂,且这种树脂的耐热性也比环氧树脂高30%。 该公司称,折射系数的提高是由于在其中添加了二氧化钛、二氧化锆及其它金属氧化物的纳米级粒子。据介绍,这种树脂主要用途在电器领域,包括用于涂料中可提高白色发光二极管(LEDs)的发光率和吸光率,液晶显示器(LCDs)和其它显示器的防反射膜,以及在电荷耦合器件(CCDs)中作为微透镜使其能接受大量光等。 金红石型和锐钛矿型TiO2颜料的平均折射率分别为和,用来计算, 氧化锌颜料的相对密度为 ~ ,吸油度量为10 ~ 25 g/100 g,折射率为 ~ 。 商业上98%颜料级硫化锌的相对密度为 ~ ,折射率为 三氧化锑颜料的折射率约为, 名称折射率透光范围蒸发温度(℃)蒸发源应用 三氧化二铝550n200~50002000-2200 电子枪增透膜多层膜 氟化铈 500nm300~5000 1429 钼,钽,电子枪增透膜、多层膜 氧化铈 500nm400~16000 1950 电子枪增透膜 冰晶石 500nm250~14000 1000 钼,钽,电子枪增透膜 氧化铪 500nm230~7000 2500 电子枪紫外-近红外多层膜 透明导电膜料500nm?400~800 1450 电子枪,Al2O3 透明导电膜 氟化钙 1280~1400 钼,钽,钨增透膜

光学石英玻璃的折射率

表7 光学石英玻璃的折射率(之一)波长(毫微米)水晶熔制石英玻璃合成石英玻璃185.41 1.57464 - 193.53 1.56071 - 202.54 1.54729 1.54717 206.20 1.54269 1.54266 213.85 - 1.53434 214.45 1.53385 - 226.50 1.52318 1.52299 23 2.94 1.51834 - 237.83 - 1.51473 248.20 - 1.50841 250.20 1.50762 - 257.62 1.50397 1.50351 265.36 - 1.49994 274.87 1.49634 - 280.35 - 1.49403 289.36 - 1.49098 298.06 1.48859 1.48837 307.59 - 1.48575 313.17 - 1.48433 328.36 1.48183 - 334.15 - 1.47976 340.36 1.47877 1.47860 346.69 1.47766 1.47748 361.17 1.47513 1.47503 365.48 - 1.47448 398.84 1.47028 - 404.65 - 1.46961 435.83 1.46679 1.46669 486.13 1.46324 1.46314 546.07 1.46021 1.46007 587.56 1.45857 1.45847 656.27 1.45646 1.45637 注:测量误差:±3×10-5 表7 光学石英玻璃的折射率(之二)波长λ(微米) 折射率波长λ(微米) 折射率0.67 1.456066 1.30 1.446980 0.68 1.455818 1.40 1.445845 0.69 1.455579 1.50 1.444687 0.70 1.455347 1.60 1.443492 0.80 1.453371 1.70 1.442250 0.90 1.451808 1.80 1.440954 1.00 1.450473 1.90 1.439957 1.10 1.440261 2.00 1.438174 1.20 1.448110 2.10 1.436680 2.20 1.435111 2.90 1.421684 2.30 1.433462 3.00 1.41937 2.40 1.431730 3.10 1.41694

光学材料大全

有色玻璃牌号 无色光学玻璃类型

光学晶体主要性能参数

常用光学塑料-聚甲基丙烯甲酯PMMA 密度(kg/m3):(1.17~1.20)×10E3 nD ν:1.49 57.2~57.8 透过率(%):90~92 吸水率(%):0.3~0.4 玻璃化温度:10E5 熔点(或粘流温度):160~200 马丁耐热:68 热变形温度:74~109(4.6 ×10Pa) 68~99(18.5×10Pa) 线膨胀系数:(5~9)×10E-5 计算收缩率(%):1.5~1.8 比热J/kgK:1465 导热系数W/m K:0.167~0.251 燃烧性m/min:慢 耐酸性及对盐溶液的稳定性:出强氧化酸外,对弱碱较稳定 耐碱性:对强碱有侵蚀对弱碱较稳定 耐油性:对动植物油,矿物油稳定 耐有机溶剂性:对芳香族,氯化烃等能溶解,醇类脂肪族无影响日光及耐气候性:紫外透过滤73.5%

常用光学塑料-苯乙烯甲基丙烯酸甲酯共聚物 密度(kg/m3):(1.12~1.16)×10E3 nD ν:1.533 42.4 透过率(%):90 吸水率(%):0.2 玻璃化温度: 熔点(或粘流温度): 马丁耐热:<60 热变形温度:85~99 (18.5×105Pa) 线膨胀系数:(6~8)×10E-5 计算收缩率(%): 比热J/kgK: 导热系数W/m K:0.125~0.167 燃烧性m/min:慢 耐酸性及对盐溶液的稳定性:除强氧化酸外,对酸盐水均稳定 耐碱性:对强碱有侵蚀,对弱碱较稳定 耐油性:对动植物油,矿物油稳定 耐有机溶剂性:对芳香族,氯化烃等能溶解,醇类脂肪族无影响 日光及耐气候性:紫外透过滤73.5%

常用晶体及光学玻璃折射率表

常用晶体及光学玻璃折射率表 注:no、ne分别是晶体双折射现象中的“寻常光”的折射率和“非常光”的折射率。资料来源:华东师大《光学教程》 一般情况下,基础玻璃的折射率为1.5—1.7,而斜锆石的折射率为2.2,锆英石的折 射率为1.94;SnO2可以降低釉熔体的表面张力,且具有较高地折射率(2.09) CR-39即折射率1.499单体 有机高分子化学 日开发出新型热固性树脂 -------------------------------------------------------------------------- ------ 2019-7-28 9:04:29 来源:中国化工网 日前,日本Nitto Denko Corp公司开发出一种折射系数为1.7的芳香族热固性树脂,高于折射率1.56的环氧树脂,且这种树脂的耐热性也比环氧树脂高30%。 该公司称,折射系数的提高是由于在其中添加了二氧化钛、二氧化锆及其它金属氧化 物的纳米级粒子。据介绍,这种树脂主要用途在电器领域,包括用于涂料中可提高白色发 光二极管(LEDs)的发光率和吸光率,液晶显示器(LCDs)和其它显示器的防反射膜,以及在 电荷耦合器件(CCDs)中作为微透镜使其能接受大量光等。 金红石型和锐钛矿型TiO2颜料的平均折射率分别为2.71和2.57,用2.71来计算, 氧化锌颜料的相对密度为5.45 ~ 5.65,吸油度量为10 ~ 25 g/100 g,折射率为 2.03 ~ 2.08。 商业上98%颜料级硫化锌的相对密度为4.0 ~ 4.1,折射率为2.37 三氧化锑颜料的折射率约为2.0, 名称折射率透光范围蒸发温度(℃) 蒸发源应用 三氧化二铝 1.62/550n 200~5000 2000-2200 电子枪增透膜多层膜氟化铈氧化铈 冰晶石氧化铪 1.63/500nm 300~5000 1429 钼,钽,电子枪增透膜、多层膜 2.35/500nm 400~16000 1950 电子枪增透膜 1.33/500nm 250~14000 1000 钼,钽,电子枪增透膜 1.95/500nm 230~7000 2500 电子枪紫外-近红外多层膜

红外光学玻璃与红外晶体材料光学特性

一、红外光学玻璃与红外晶体材料光学特性: 1.晶体材料 晶体材料包括离子晶体与半导体晶体离子晶体包括碱卤化合物晶体, 碱土—卤族化合物晶体及氧化物及某些无机盐晶体。半导体晶体包括Ⅳ族单元素晶体、Ⅲ~Ⅴ族化合物和Ⅱ~Ⅵ族化合物晶体等。离子型晶体通常具有较高的透过率, 同时有较低的折射率, 因而反射损失小, 一般不需镀增透膜, 同时离子型晶体光学性能受温度影响也小于非离子型晶体。半导体晶体属于共价晶体或某种离子耦合的共价键晶体。晶体的特点是其物理和化学特性及使用特性的多样性。晶体的折射率及色散度变化范围比其它类型材料丰富得多。可以满足不同应用的需要, 有一些晶体还具备光电、磁光、声光等效应, 可以用作探测器材料。 [1] 按内部晶体结构晶体材料可分为单晶体和多晶体 ①单晶体材料 表1.1 几种常用红外晶体材料[1] 名称化学组成透射长波限/ μm 折射率/4.3μ m 硬度/克氏密度/(g·cm-3)溶解度 /(g·L-3)H2O 金刚石C30 2.48820 3.51不溶锗Ge25 4.02800 5.33不溶硅Si15 3.421150 2.33不溶石英晶体SiO2 4.5 1.46740 2.2不溶兰宝石Al2O3 5.5 1.681370 3.98不溶氟化锂LiF8.0 1.34110 2.600.27氟化镁MgF28.0 1.35576 3.18不溶氟化钡BaF213.5 1.4582 4.890.17氟化钙CaF210.0 1.41158 3.180.002溴化铊TLBr34 2.35127.560.05金红石TiO2 6.0 2.45880 4.26不溶砷化镓GaAs18 3.34(8μm)750 5.31不溶氯化钠NaCl25 1.5217 2.1635 硒化锌ZnSe22 2.4150 5.27不溶锑化铟InSb16 3.99223 5.78不溶硫化锌ZnS15 2.25354 4.09不溶KRS-5TLBr-TLI45 2.38407.370.02 KRS-6TLBr-TLCl30 2.19357.190.01 ②多晶体材料

光学材料特性

光学材料特性表:

常用光学塑料-聚甲基丙烯甲酯PMMA 密度(kg/m3):(1.17~1.20)×10E3 nD ν:1.49 57.2~57.8 透过率(%):90~92 吸水率(%):0.3~0.4 玻璃化温度:10E5 熔点(或粘流温度):160~200 马丁耐热:68 热变形温度:74~109(4.6 ×10Pa) 68~99(18.5×10Pa) 线膨胀系数:(5~9)×10E-5 计算收缩率(%):1.5~1.8 比热J/kgK:1465 导热系数W/m K:0.167~0.251 燃烧性m/min:慢 耐酸性及对盐溶液的稳定性:出强氧化酸外,对弱碱较稳定 耐碱性:对强碱有侵蚀对弱碱较稳定 耐油性:对动植物油,矿物油稳定 耐有机溶剂性:对芳香族,氯化烃等能溶解,醇类脂肪族无影响日光及耐气候性:紫外透过滤73.5% 常用光学塑料-苯乙烯甲基丙烯酸甲酯共聚物 密度(kg/m3):(1.12~1.16)×10E3 nD ν:1.533 42.4 透过率(%):90 吸水率(%):0.2 玻璃化温度: 熔点(或粘流温度): 马丁耐热:<60 热变形温度:85~99 (18.5×105Pa) 线膨胀系数:(6~8)×10E-5 计算收缩率(%): 比热J/kgK: 导热系数W/m K:0.125~0.167 燃烧性m/min:慢

耐酸性及对盐溶液的稳定性:除强氧化酸外,对酸盐水均稳定 耐碱性:对强碱有侵蚀,对弱碱较稳定 耐油性:对动植物油,矿物油稳定 耐有机溶剂性:对芳香族,氯化烃等能溶解,醇类脂肪族无影响 日光及耐气候性:紫外透过滤73.5% 常用光学塑料-聚碳酸酯PC 密度(kg/m3):1.2 ×10E3 nD ν:1.586(25) 29.9 透过率(%):80~90 吸水率(%):23CRH50% 0.15 水中0.35 玻璃化温度:149 熔点(或粘流温度):225~250(267) 马丁耐热:116~129 热变形温度:132~141(4.6×105Pa) 132138(18.5×105Pa) 线膨胀系数:6×10-5 计算收缩率(%):0.5~0.7 比热J/kgK:1256 导热系数W/m K:0.193 燃烧性m/min:自熄 耐酸性及对盐溶液的稳定性:强氧化剂有破坏作用,在高于60水中水解,对稀酸,盐,水稳定 耐碱性:强碱溶液,氨和胺类能腐蚀和分解,弱碱影响较轻 耐油性:对动物油和多数烃油及其酯类稳定 耐有机溶剂性:溶于氯化烃和部分酮,酯及芳香烃中,不溶于脂肪族,碳氢化合物,醚和醇类 日光及耐气候性:日光照射微脆化 常用光学塑料-烯丙基二甘碳酸酯CR39 密度(kg/m3):25 1.32×10E3 nD ν:1.498 53.6~57.8 透过率(%):92 吸水率(%):0.2 24h 25 玻璃化温度:

光学玻璃对照表

光学玻璃牌号对照表一 CODE n d d CDGM SCHOTT OHARA HOYA SUMITA HIKARI QK 470668 1.4704766.83H-QK1FK1FSL1FC1 487700 1.4874670.04H-QK3 487704 1.4874970.44H-QK3L N-FK5S-FSL5FC5 E-FK5 K 500621 1.4996762.07K1K11 500660 1.5004766.02H-K2BK4BSL4BSC4 505647 1.5046364.72H-K3BK5 508611 1.5080261.05K4A ZKN7ZSL7ZNC7 ZK7 510634 1.5100763.36H-K5BK1BSL1BSC1 BK1 511605 1.5111260.46H-K6K7NSL7C7 K7 515606 1.5147860.63H-K7 516568 1.5160256.79K8 NSL2C2 K2 516642 1.516864.2H-K9L N-BK7S-BSL7BSC7 E-BK7 516642 1.5168 H-UK9L UBK7 518590 1.5181858.95H-K10 S-NSL3E-C3 E-K3 526602 1.5263860.61H-K11BALK1NSL21BACL1 534555 1.5335955.47H-K12ZK5ZSL5ZNC5 ZK5 519617 1.5187861.69H-K16 BACL3 BALK3 522595 1.5224959.48H-K50N-K5S-NSL5C5 E-K5 523586 1.5230758.64H-K51B270NSL51C12 KN1 BaK 530605 1.5302860.47H-BaK1 540597 1.5399659.72H-BaK2N-BAK2S-BAL12BAC2 E-BaK2 547628 1.5467862.78H-BaK3 BAL21 PSK1 552634 1.5524863.36H-BaK4N-PSK3BAL23PCD3 PSK3 561583 1.5606958.34BaK5 564608 1.5638860.76H-BaK6N-SK11S-BAL41BACD11 E-SK11 569560 1.5688356.04H-BaK7N-BAK4 S-BAL14BAC4 E-BAK4 573575 1.572557.49H-BaK8N-BAK1S-BAL11BAC1 E-BAK1 574565 1.5744456.45BaK9BAK6BAL16BAC6 560612 1.5596361.21BaK11SK20BAL50 SK20 ZK 569629 1.5688862.93H-ZK1PSK2BAL22PCD2 PSK2 583595 1.5831359.46H-ZK2SK12S-BAL42BACD12 SK12

光学玻璃产品对照表

光学玻璃产品对照表

代码CDGM 代码HOYA 代码OHARA 代码SCHOTT 497H-FK61 497-FCD1 4978S-FPL4978N-PK52A 457H-FK71 457-FCD10 618H-ZPK1 618-PCD4 618-S-PHM52 603H-ZPK2 6036 470H-QK1 471-FC1 4716FSL1 4716FK1 487H-QK3 487H-QK3L 487-FC5 4877S-FSL5 4877N-FK5 500H-K2 510-BSC4 5006BSL4 5006BK4 505H-K3 508K4A 508-ZNC7 5086ZSL7 5086ZKN7 510H-K5 510-BSC1 5106BSL1 5106BK1 5116H-K6 5116C7 5116NSL7 5116K7 515H-K7 517H-K9L 517-BSC7 5176S-BSL7 5176N-BK7 518H-K10 518-E-C3 5185S-NSL3 526H-K11 526-BACL1 5266NSL21 522H-K50 5225C5 5225S-NSL5 5225N-K5 523H-K51 5235C12 5235NSL51 530H-BaK1 540H-BaK2 540-BAC2 5405S-BAL12 5405N-BAK2 547H-BaK3 5486BAL21 552H-BaK4 552-PCD3 5526BAL23 5526N-PSK3 561H-BaK5 564H-BaK6 564-BACD11 5646S-BAL41 5646N-SK11 569H-BaK7 569-BAC4 5695S-BAL14 5695N-BAK4 573H-BaK8 573-BAC1 5735S-BAL11 5735N-BAK1

玻璃的光学性能

合肥学院 Hefei University 翻译文献:玻璃的光学性能 课程名称:金属学与热处理 指导教师:谢劲松 系别/班级:14粉体材料科学与工程一班 姓名(学号):罗成1403011012

摘要:无机材料指由无机物单独或混合其他物质制成的材料。通常指由硅酸盐、铝酸盐、硼酸盐、磷酸盐、锗酸盐等原料和/或氧化物、氮化物、碳化物、硼化物、硫化物、硅化物、卤化物等原料经一定的工艺制备而成的材料。 Abstract: inorganic materials by inorganic material alone or mixed with other materials. Usually made of silicate, aluminate, borate, phosphate and germanate and / or raw materials such as oxides, nitrides, carbides, borides, silicides, sulfides, halides as raw materials prepared by materials. 玻璃是由二氧化硅和其他化学物质熔融在一起形成的(主要生产原料为:纯碱、石灰石、石英)。在熔融时形成连续网络结构,冷却过程中粘度逐渐增大并硬化致使其结晶的硅酸盐类非金属材料。普通玻璃的化学组成是Na2SiO3、CaSiO3、SiO2或Na2O·CaO·6SiO2等,主要成分是硅酸盐复盐,是一种无规则结构的非晶态固体。广泛应用于建筑物,属于混合物。另有混入了某些金属的氧化物或者盐类而显现出颜色的有色玻璃,和通过物理或者化学的方法制得的钢化玻璃等。有时把一些透明的塑料(如聚甲基丙烯酸甲酯)也称作有机玻璃。 The glass is made of silicon dioxide and other chemical substances fused together to form (the main raw materials for the production of soda ash, limestone, quartz). The formation of a continuous network structure in the melt, silicate nonmetalmaterials cooling process viscosity increases gradually and hardening resulting in the crystallization. The chemical composition of glass is Na2SiO3, CaSiO3, or SiO2 Na2O - CaO - 6SiO2, is the main component of silicate, is an amorphous solid irregular structure. Widely used in buildings, to the mixture. Otherwise mixed with some metal oxides or salts and show the color of colored glass The glass and method by physical or chemical preparation of toughened glass. Some transparent plastic (such as PMMA) also called organic glass. 关键词:折射率、反射、对红外和紫外的吸收 Refractive index, reflection, infrared and ultraviolet absorption 一、玻璃的折射率 当光照射到玻璃时,一般产生反射、透过和吸收。这三种基本性质与折射率有关。玻璃的折射率可以理解为电磁波在玻璃中传播速度的降低(以真空中的光速为准)。如果用折射率来表示光速的降低,则:n=c/v When the light shines on the glass, generally have the reflection and absorption. Through these three kinds of basic properties and refractive index. The refractive index of the glass can be understood as to reduce the velocity of

光学镜片知识整理

镜片知识整理 一、光学材料 (4) 二、无色光学玻璃 (4) 1.系列、类型和牌号 (5) 1.1 系列 (5) 1.2 类型 (5) 1.2.1 光学玻璃牌号分类 (5) 1.2.2 光学玻璃牌号命名 (6) 1.2.3 无铅、砷、镉玻璃牌号的命名 (6) 1.2.4 低软化点玻璃牌号的命名 (6) 1.2.5 高透过玻璃牌号的命名 (6) 1.3 牌号 (6) 2.质量指标、类别和级别 (11) 2.1 质量指标 (11) 2.2分类分级 (11) 2.2.1 折射率、色散系数 (11) 2.2.2光学均匀性 (12) 2.2.3应力双折射 (13) 2.2.4 条纹度 (14) 2.2.5. 气泡度 (15) 2.2.6光吸收系数 (16) 2.2.7 耐辐射性能 (17) 3.光学性能 (18) 3.1 折射率 (18) 4.化学性能 (18) 4.1 抗潮湿大气作用稳定性RC(S)(表面法) (18) 4.2抗酸作用稳定性RA(S)(表面法) (18) 4.3 各种氧化物对玻璃性质的影响 (19) 5. 光学玻璃的物理参数 (19) 6.玻璃牌号对照表 (20) 三、其它光学玻璃 (26) 1.有色光学玻璃 (26) 1.1 有色玻璃的种类 (26) 1.1.1 截止型玻璃(硒镉着色玻璃) (27) 1.1.2 选择吸收玻璃(离子着色玻璃) (27) 1.1.3 中性玻璃 (27) 1.2 有色光学玻璃的特点和用途 (28) 1.3 有色玻璃牌号 (28) 2.特种光学玻璃 (29) 2.1 石英玻璃 (29) 四、微晶玻璃 (30) 1.概述 (30)

2.微晶玻璃的性能及应用 (30) 3.光学晶体主要性能参数 (31) 五、光学塑料 (31) 1.光学塑料大致分类 (31) 2.常用光学塑料 (32) 2.1 聚苯乙烯PS(火石塑料) (32) 2.2 聚碳酸酯PC (32) 2.3 聚甲基丙烯酸甲脂(Polymethyl methacrylate简称PMMA,也称Acrylic) (33) 2.4 烯丙基二甘醇碳酸酯(Allgl diglycol carbonate,简称ADC或CR-39) (34) 2.5 苯乙烯-丙烯腈共聚物NAS (35) 2.6 苯乙烯-丁二烯-丙烯酯ABS (35) 2.7 苯乙烯甲基丙烯酸甲酯共聚物 (36) 3.光学塑料的主要优缺点 (37) 4.光学塑料零件的镀膜技术 (38) 六.光学镜片镀膜技术 (39) 1.光学零件镀膜分类, 符号及标注 (39) 2.镀膜种类 (39) 3. 镀膜材料 (40)

光学材料折射率的测定

光学材料折射率的测定 Summary :Refractive index is one of the important parameters of optical materials, which often needs to be measured in scientific research and production practice. The method of measuring the refractive index can be divided into two categories: one is the application of refractive index and reflection, total reflection law, through the accurate measurement of the angle of the refractive index of the geometric optics method, such as the minimum deviation angle method, grazing incidence method, total reflection method and displacement method, etc. Another kind is the light passed the medium (or by a dielectric reflection) and the polarization state changes of the phase change of the transmitted light or reflected light) and refraction rate is closely related to the principle to measure the refractive index of the physical optics method, such as cloth Brewster angle method, interferometry, ellipsometry etc.. 摘要:折射率是光学材料的重要参数之一,在科研和生产实际中常需要测量它。测量折射率的方法可分为两类:一类是应用折射率及反射、全反射定律,通过准确测量角度来求折射率的几何光学方法,如最小偏向角法、掠入射法、全反射法和位移法等。另一类是利用光通过介质(或由介质反射)后,透射光的相位变化(或反射光的偏振态变化)与折射率密切相关的原理来测定折射率的物理光学方法,如布儒斯特角法、干涉法、椭偏法等。 关键词:最小偏向角 偏振 全反射 分光计 干涉 布儒斯特角 引言:本实验要求综合已学过的光学知识和基本实验操作,查阅有关资料,拟定实验方案,完成对各种待测样品的折射率测定,从而对光学材料折射率的测量,在原理和方法上有更全面的认识。加深对分光计、阿贝折射仪、迈克尔孙干涉仪等光学仪器使用方法的了解。 一、最小偏向角法 【实验原理】 由图1的三棱镜光路图,可以证明: 2 sin 2sin sin sin min 1 1 A A r i n +== δ 其中A 是三棱镜的顶角,δmin 是出射光在i 1=i 2时的最小偏向角。由上式可见,只要测得三棱镜的顶角A 和对钠黄光的最小偏向角δmin ,便可间接测出对该波长的光的折射率n 。 【实验步骤】 1. 调节分光计到使用状态,打开汞灯照明平行光管,找到折射光谱 2. 对准某条谱线,转动游标盘和望远镜跟踪此谱线,当其不再继续移动而反向移动时,记录游标盘读数θ1、θ2 3. 测定入射光方向,将望远镜对准平行光管,使分划板十字竖线对准狭缝中央,读出此时两游标的读数θ1'、θ2',则最小偏向角δmin 为: ()()[] '2 1 22'11min θθθθδ-+-= 4. 重复测量,求平均值 图1 三棱镜中的光路图

光学论文光学玻璃

光学玻璃 摘要:随着光子学技术的发展,光学玻璃的研究领域更加宽阔,光学玻璃的研究成为 各国一项重的项目,光学玻璃也越来越多普及到生活各个领域,本文着重介绍光学玻璃的一些特性、应用、研究、及其发展前景。 关键词:光学玻璃技术特性发展 引言: 玻璃技术经历了5000 多年的发展历史。直到近代, 为了适应军用光学仪器的发 展, SCHO TT 公司的创始人O t to Scho t t 于1884 年发展了现代光学玻璃熔炼技术, 制造出世界上第一块高质量光学玻璃。目前, 随着光学、信息技术、能源、航空航天技术、生物技术以及生命科学等学科的迅速发展, 光学玻璃由传统意义上的光学仪器用成像介质——透 镜(主要是应用几何光学原理进行成像) 逐渐向新的应用领域迅速发展。尤其是伴随着光子学技术的发展, 光子继电子之后成为信息的主要载体。 一、光学玻璃概念: 光学玻璃是制造光学镜头、光学仪器的主要材料。光学玻璃(在普通的硼硅酸盐玻璃原料中加入少量对光敏感的物质,如AgCl、AgBr等,再加入极少量的敏化剂,如CuO等,使玻璃对光线变得更加敏感。光学玻璃必须有高度精确的折射率、阿贝数和高透明度、高均匀度。光学玻璃是用高纯度硅、硼、钠、钾、锌、铅、镁、钙、钡等的氧化物按特定配方混合,在白金坩埚中高温融化,用超声波搅拌均匀,去气泡;然后经长时间缓慢地降温,以免玻璃块产生内应力。冷却后的玻璃块,必须经过光学仪器测量,检验纯度、透明度、均匀度、折射率和色散率是否合规格。合格的玻璃块经过加热锻压,成光学透镜毛胚。 二、光学玻璃的分类及其特性: B270/K9 K9玻璃是用K9料制成的玻璃制品,用于光学镀膜等领域 K9料属于光学玻璃,由于它晶莹剔透,所以衍生了很多以K9料为加工对象的工厂,他们加工出来的产品,在市面上称为水晶玻璃制品。 K9的组成如下: SiO2=69.13%B2O3=10.75%BaO=3.07%Na2O=10.40%K2O=6.29%As2O3=0.36% 它的光学常数为:折射率=1.51630色散=0.00806阿贝数=64.06。 无色光学玻璃--B270技术要求

汽车安全玻璃试验方法--光学性能试验

前言 GB/T 5137《汽车安全玻璃试验方法》分为四个部分: ——第1部分:力学性能试验; ——第2部分:光学性能试验; ——第3部分:耐辐照、高温、潮湿、燃烧和耐模拟气候试验; ——第4部分:太阳能透射比测定方法。 本部分为GB/T 5137的第2部分。 GB/T 5137的本部分修改采用ISO 3537:1999《道路车辆安全玻璃材料力学性能试验方法》(英文版)。 本部分与该国际标准的主要差异如下: ——删除了国际标准中的“定义”部分; ——将“破碎后的可视性试验”中冲击点的位置及示意图,改为与GB 9656-2003相一致。 本部分代替GB/T 5137.2—1996《汽车安全玻璃力学性能试验方法》。 本部分与GB/T 5137.2—1996相比主要变化如下: ——将“4.透射比试验”改为“4.可见光透射比试验”; ——4.1可见光透射比试验目的改为:“测定安全玻璃是否具有一定的可见光透射比”; ——5.1副像偏离试验的试验目的改为:“测定主像与副像间的角偏离”; ——将“7.破碎后的能见度试验目的改为“7.破碎后的可视性试验”; ——7.4.3中冲击点的位置及示意图保持与GB 9656-2002相一致; ——将“9.反射比试验”改为“9.可见光反射比试验”; 本部分附录A为资料性附录。 本部分由原国家建筑材料工业局提出。 本部分由全国汽车标准化技术委员会安全玻璃分技术委员会归口。 本部分主要起草单位:中国建筑材料科学研究院玻璃科学与特种玻璃纤维研究所。 本部分主要起草人:王乐、韩松、陈峥科。 本部分所代替标准的历次版本发布情况为: GB 5137.2—1985、GB/T 5137.2—1996。 汽车安全玻璃试验方法 第2部分:光学性能试验 1 范围 GB/T 5137的本部分规定了汽车用安全玻璃的光学性能试验方法。 本部分适用于汽车安全玻璃(以下简称“安全玻璃”)。这种安全玻璃包括各种类型的玻璃加工成的或玻璃与其他材料组合成的玻璃制品。 2 试验条件 除特殊规定外,试验应在下述条件下进行: a) 环境温度:20℃±5℃; b) 压力:8.60×104Pa~1.06×105Pa; c) 相对湿度:40%~80%。 3 试验应用条件 对某些类型的安全玻璃而言,如果试验结果可以根据其某些已知的性能所预测,则无须进行本标准规定的所有试验。 4 可见光透射比试验比 4.1 试验目的 测定安全玻璃是否具有一定的可见光透射比。 4.2 试样 应使用制品或试验片,试验片可以从制品上相应试验区域切取。 4.3 仪器 4.3.1 光源:白炽灯,其灯丝包含在1.5mm×1.5mm×3mm的平行六面体内。加于灯丝两端的电压应使色温为2856K±50K,该电压稳定在±0.1%内。用来测量电压的仪表应有相应的精度。

常用晶体及光学玻璃折射率表

常用晶体及光学玻璃折射率表常用晶体及光学玻璃折射率表

[绝对折射率]: 光从真空射入介质发生折射时,入射角i与折射角r的正弦之比n叫做介质的“绝对折射率”,简称“折射率”。它表示光在介质中传播时,介质对光的一种特征。 [公式]:n=sin i/sin r=c/v 由于光在真空中传播的速度最大,故其他媒质的折射率都大于1。同一媒质对不同波长的光,具有不同的折射率;在对可见光为透明的媒质内,折射率常随波长的减小而增大,即红光的折射率最小,紫光的折射率最大。通常所说某物体的折射率数值多少(例如水为1.33,水晶为1.55,金刚石为2.42,玻璃按成分不同而为1.5~1.9),是指对钠黄光(波长5893×10^-10米)而言。 [相对折射率]: 光从介质1射入介质2发生折射时,入射角θ1与折射角θ2的正弦之比n21叫做介质2相对介质1的折射率,即“相对折射率”。因此,“绝对折射率”可以看作介质相对真空的折射率。它是表示在两种(各向同性)介质中光速比值的物理量。 [公式]:n21=sinθ1/sinθ2=n2/n1=v1/v2 光学介质的一个基本参量。即光在真空中的速度c与在介质中的相速v之比 真空的折射率等于1,两种介质的折射率之比称为相对折射率。例如,第一介质的折射率为n1,第二介质的折射率为n2,则n21=n2/n1称为第二介质对第一介质的相对折射率。某介质的折射率也是该介质对真空的相对折射率。于是折射定律可写成如下形式. n1sinθi =n2sinθt两种介质进行比较时,折射率较大的称光密介质,折射率较小的称光疏介质。 折射率与介质的电磁性质密切相关。根据电磁理论,εr和μr分别为介质的相对电容率和相对磁导率。折射率还与波长有关,称色散现象。手册中提供的折射率数据是对某一特定波长而言的(通常是对钠黄光,波长为5893埃)。气体折射率还与温度和压强有关。空气折射率对各种波长的光都非常接近于1,例如空气在20℃,760毫米汞高时的折射率为1.00027。在工程光学中常把空气折射率当作1,而其他介质的折射率就是对空气的相对折射率。 介质的折射率通常由实验测定,有多种测量方法。对固体介质,常用最小偏向角法或自准直法;液体介质常用临界角法(阿贝折射仪);气体介质则用精密度更高的干涉法(瑞利干涉仪)。 引自:https://www.360docs.net/doc/a618684839.html,/hot/reflect.htm