印刷机作业指导书

作 業 指 導 書 (WORKING INSTRUCTION )

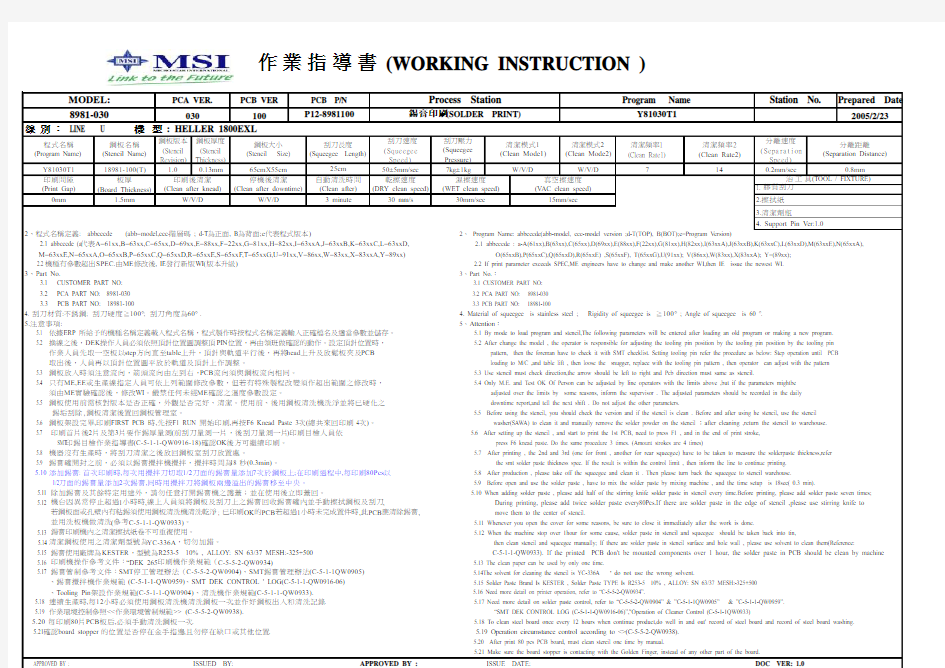

清潔頻率1(Clean Rate1)

清潔頻率2

(Clean Rate2)

7

14

2.擦拭紙

3.清潔劑瓶

2、程式名稱定義: abbcccde (abb=model,ccc-階層碼 ; d-T 為正面, B 為背面;e 代表程式版本)

2、 Program Name: abbcccde(abb-model, ccc-model version ;d-T(TOP), B(BOT);e=Program Version)

2.1 abbcccde (a 代表A=61xx,B=63xx,C=65xx,D=69xx,E=88xx,F=22xx,G=81xx,H=82xx,I=63xxA,J=63xxB,K=63xxC,L=63xxD, 2.1 abbcccde : a-A(61xx),B(63xx),C(65xx),D(69xx),E(88xx),F(22xx),G(81xx),H(82xx),I(63xxA),J(63xxB),K(63xxC),L(63xxD),M(63xxE),N(65xxA), M=63xxE,N=65xxA,O=65xxB,P=65xxC,Q=65xxD,R=65xxE,S=65xxF,T=65xxG,U=91xx,V=86xx,W=83xx,X=83xxA,Y=89xx) O(65xxB),P(65xxC),Q(65xxD),R(65xxE) ,S(65xxF), T(65xxG),U(91xx); V(86xx),W(83xx),X(83xxA); Y=(89xx); 2.2 機種有參數超出SPEC.由ME 修改後, IE 發行新版WI(版本升級) 2.2 If print parameter exceeds SPEC,ME engineers have to change and make another WI,then IE issue the newest WI.3、Part No.

3、Part No.: 3.1 CUSTOMER PART NO: 3.1 CUSTOMER PART NO: 3.2 PCA PART NO: 8981-030 3.2 PCA PART NO: 8981-030 3.3 PCB PART NO: 18981-100 3.3 PCB PART NO: 18981-100

4. 刮刀材質:不銹鋼; 刮刀硬度≧100°; 刮刀角度為60° . 4. Material of squeegee is stainless steel ; Rigidity of squeegee is ≧100° ; Angle of squeegee is 60 ° .

5.注意事項:

5、Attention :

5.1 依據ERP 所給予的機種名稱定義載入程式名稱,程式製作時按程式名稱定義輸入正確檔名及適當參數並儲存。 5.1 By mode to load program and stencil,The following parameters will be entered after loading an old program or making a new program. 5.2 換線之後,DEK 操作人員必須依照頂針位置圖調整頂PIN 位置,再由領班做確認的動作。設定頂針位置時, 5.2 After change the model , the operator is responsible for adjusting the tooling pin position by the tooling pin position by the tooling pin 作業人員先取一空板以step 方向直至table 上升,頂針與軌道平行後,再將head 上升及放鬆板夾及PCB pattern, then the foreman have to check it with SMT checklist. Setting tooling pin refer the procedure as below: Step operation until PCB 取出後,人員再以頂針位置圖平放於軌道及頂針上作調整。

loading to M/C ,and table lift , then loose the snugger, replace with the tooling pin pattern , then operator can adjust with the pattern 5.3 鋼板放入時須注意流向,箭頭流向由左到右,PCB 流向須與鋼板流向相同。

5.3 Use stencil must check direction,the arrow should be left to right and Pcb direction must same as stencil.

5.4 只有ME,EE 或生產線指定人員可依上列範圍修改參數,但若有特殊製程改變須作超出範圍之修改時, 5.4 Only M.E. and Test OK Of Person can be adjusted by line operators with the limits above ,but if the parameters mightbe 須由ME 實驗確認後,修改WI 。嚴禁任何未經ME 確認之溫度參數設定。

adjusted over the limits by some reasons, inform the supervisor . The adjusted parameters should be recorded in the daily 5.5 鋼板使用前需核對版本是否正確,外觀是否完好、清潔。使用前、後用鋼板清洗機洗淨並將已硬化之 downtime report,and tell the next shift . Do not adjust the other parameters.

錫垢刮除,鋼板清潔後置回鋼板管理室。

5.5 Before using the stencil, you should check the version and if the stencil is clean . Before and after using he stencil, use the stencil 5.6 鋼板架設完畢,印刷FIRST PCB 時,先按F1 RUN 開始印刷,再按F6 Knead Paste 3次(總共來回印刷 4次)。 washer(SAWA) to clean it and manually remove the solder powder on the stencil ;after cleaning ,return the stencil to warehouse. 5.7 印刷首片後2片及第3片要作錫厚量測(前刮刀量測一片,後刮刀量測一片)印刷目檢人員依 5.6 After setting up the stencil , and start to print the 1st PCB, need to press F1 , and in the end of print stroke, SMT 印錫目檢作業指導書(C-5-1-1-QW0916-18)確認OK 後方可繼續印刷。 press F6 knead paste. Do the same procedure 3 times. (Amount strokes are 4 times)

5.8 機器沒有生產時,將刮刀清潔之後放回鋼板室刮刀放置處。

5.7 After printing , the 2nd and 3rd (one for front , another for rear squeegee) have to be taken to measure the solderpaste thickness,refer 5.9 錫膏罐開封之前,必須以錫膏攪拌機攪拌,攪拌時間為18 秒(0.3min)。

the smt solder paste thickness spec. If the result is within the control limit , then inform the line to continue printing. 5.10 添加錫膏: 首次印刷時,每次用攪拌刀切取1/2刀面的錫膏量添加7次於鋼板上;在印刷過程中,每印刷80Pcs 以 5.8 After production , please take off the squeegee and clean it . Then please turn back the squeegee to stencil warehouse.

1/2刀面的錫膏量添加2次錫膏,同時用攪拌刀將鋼板兩邊溢出的錫膏移至中央。

5.9 Before open and use the solder paste , have to mix the solder paste by mixing machine , and the time setup is 18sec( 0.3 min).

5.11 除加錫膏及其餘特定用途外,請勿任意打開錫膏機之護蓋;並在使用後立即蓋回。

5.10 When adding solder paste , please add half of the stirring knife solder paste in stencil every time.Before printing, please add solder paste seven times;

5.12 機台因異常停止超過1小時時,線上人員須將鋼板及刮刀上之錫膏回收錫膏罐內,並手動擦拭鋼板及刮刀,

During printing, please add twice solder paste every80Pcs.If there are solder paste in the edge of stencil ,please use stirring knife to 若鋼板面或孔壁內有粘錫須使用鋼板清洗機清洗乾淨; 已印刷OK 的PCB 若超過1小時未完成置件時,此PCB 應清除錫膏, move them to the center of stencil.

並用洗板機做清洗(參考C-5-1-1-QW0933)。 5.11 Whenever you open the cover for some reasons, be sure to close it immediately after the work is done.

5.13 鍚膏印刷機內之清潔擦拭紙卷不可重複使用。

5.12 When the machine stop over 1hour for some cause, solder paste in stencil and squeegee should be taken back into tin,

5.14 清潔鋼板使用之清潔劑型號為YC-336A ,切勿加錯。

then clean stencil and squeegee manually; If there are solder paste in stencil surface and hole wall , please use solvent to clean them(Reference:

5.15 錫膏使用廠牌為KESTER ,型號為R253-5 10% , ALLOY: SN 63/37 MESH:-325+500 C-5-1-1-QW0933). If the printed PCB don't be mounted components over 1 hour, the solder paste in PCB should be clean by machine

5.16 印刷機操作參考文件:“DEK 265印刷機作業規範(C-5-5-2-QW0934)

5.13 The clean paper can be used by only one time.

5.17 錫膏管制參考文件:SMT 停工管理辦法(C-5-5-2-QW0904)、SMT 錫膏管理辦法(C-5-1-1QW0905) 5.14The solvent for cleaning the stencil is YC-336A ,do not use the wrong solvent.

、錫膏攪拌機作業規範 (C-5-1-1-QW0959)、SMT DEK CONTROL ' LOG(C-5-1-1-QW0916-06) 5.15 Solder Paste Brand Is KESTER , Solder Paste TYPE Is R253-5 10% , ALLOY: SN 63/37 MESH:-325+500 、Tooling Pin 架設作業規範(C-5-1-1-QW0904)、清洗機作業規範(C-5-1-1-QW0933). 5.16 Need more detail on printer operation, refer to “C-5-5-2-QW0934”.

5.18 連續生產時,每12小時必須使用鋼板清洗機清洗鋼板一次,並作好鋼板出入和清洗記錄. 5.17 Need more detail on solder paste control, refer to “C-5-5-2-QW0904” & ”C-5-1-1QW0905” & ”C-5-1-1-QW0959”. 5.19 作業環境控制參照<<作業環境管制規範>> (C-5-5-2-QW0938). “SMT DEK CONTROL LOG (C-5-1-1-QW0916-06)”,"Operation of Cleaner Control (C-5-1-1QW0933)

5.20 5.18 To clean steel board once every 12 hours when continue product,do well in and out' record of steel board and record of steel board washing. 5.21確認board stopper 的位置是否停在金手指邊,且勿停在缺口或其他位置.

5.19 Operation circumstance control according to <

5.21 Make sure the board stopper is contacting with the Golden Finger, instead of any other part of the board.

APPROVED BY : ISSUED BY: APPROVED BY :ISSUE DATE:25cm 50±5mm/sec 鋼板厚度(Stencil Thickness) 刮刀速度(Squeegee Speed)鋼板大小(Stencil Size)W/V/D

Program Name

Y81030T1

停機後清潔

(Clean after downtime)

濕擦速度(WET clean speed)Y81030T1分離距離

(Separation Distance)程式名稱(Program Name)鋼板名稱(Stencil Name)18981-100(T)

鋼板版本(Stencil Revision)0.13mm 1.065cmX55cm 刮刀長度(Squeegee Length)

清潔模式2(Clean Mode2)

刮刀壓力(Squeegee

Pressure)0.8mm

0.2mm/sec 分離速度

(Separation Speed)7kg±1kg W/V/D 清潔模式1(Clean Mode1)W/V/D MODEL:8981-030P12-8981100

Process Station

錫膏印刷(SOLDER PRINT)

PCA VER.030PCB P/N PCB VER 100

Prepared Date

2005/2/23

Station No.DOC VER: 1.0

4. Support Pin Ver:1.0

1. 膠質刮刀治 工 具(TOOL / FIXTURE)

線 別 : LINE U 機 型 : HELLER 1800EXL

真空擦速度(VAC clean speed)

每印刷80片PCB 板后,必須手動清洗鋼板一次.

乾擦速度(DRY clean speed)

0mm

印刷間隙(Print Gap)板厚

(Board Thickness)

1.5mm

15mm/sec

印刷後清潔(Clean after knead)

W/V/D

自動清洗時間(Clean after)3 minute

30mm/sec 30 mm/s