GM常用术语中英对照

gm专门用语

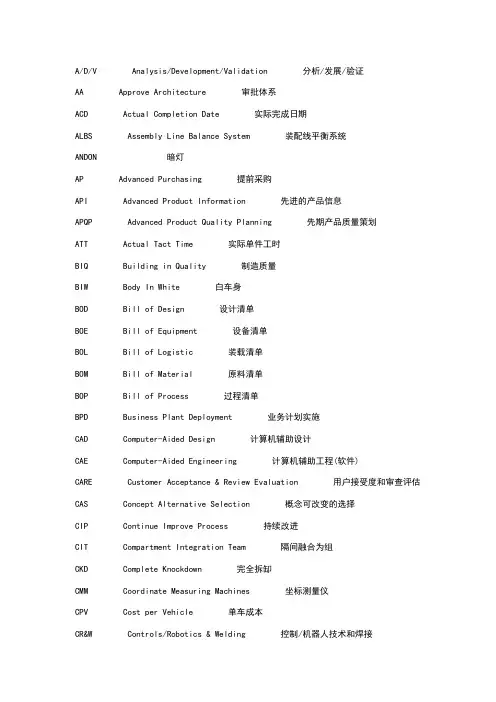

A/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时BIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施CAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程(软件)CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CAS Concept Alternative Selection 概念可改变的选择CIP Continue Improve Process 持续改进CIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准D/PFMEA Design/process failure mode & effects analysis 设计/过程失效模式分析DAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line-Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FL 听FMEA Failure Mode and Effects Analysis 失效形式及结果分析FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率GA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作GMIQ General Motors Initial Quality 通用汽车初始质量GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统GSB Global Strategy Board 全球战略部HVAC Heating, Ventilation ,and Air Conditioning 加热、通风及空调I/P Instrument Panel 仪表板IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心IPTV Incidents Per Thousand Vehicles 每千辆车的故障率IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUVA International Uniform Vehicle Audit 国际统一车辆审核JES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程MIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统MMSTS Manufacturing Major Subsystem Technical Specifications 制造重要子系统技术说明书MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范MVSS Motor Vehicle Safety Standards 汽车发动机安全标准NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案OSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDC Portfolio Development Center 证券发展中心PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution Team 项目执行小组PGM Program Management 项目管理PI People Involement 人员参与PIMREP Project Incident Monitoring and Resolution Process 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求PMT Product Management Team 产品车管理小组POMS Production Order Management System 产品指令管理小组POP Point of Purchase 采购点PP Push - Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability,andDurability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理SDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Stansardized Inspection Process 标准化检验过程SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期SMARTSMBP Synchronous Math-Based Process 理论同步过程SME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验SOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织SPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充SSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境TAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级VAE Vehicle Assembly Engineer 车辆装配工程师VAPIR Vehicle & Progress Integration Review Team 汽车发展综合评审小组VASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC Voice of Customer 顾客的意见VOD Voice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle Technical Specification 汽车技术说明书WBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购COMMWIP Correction 纠错浪费Overproduction 过量生产浪费Material Flow 过度物料移动浪费Motion 过度移动浪费Waiting 等待浪费Inventory 过度库存浪费 Processing 过度加工浪费。

岗位职位中英文对照版本

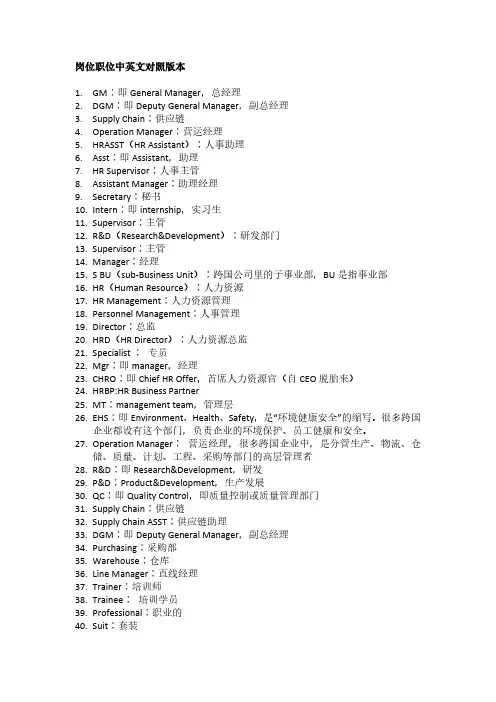

岗位职位中英文对照版本1.GM∶即General Manager,总经理2.DGM∶即Deputy General Manager,副总经理3.Supply Chain∶供应链4.Operation Manager∶营运经理5.HRASST(HR Assistant)∶人事助理6.Asst∶即Assistant,助理7.HR Supervisor∶人事主管8.Assistant Manager∶助理经理9.Secretary∶秘书10.Intern∶即internship,实习生11.Supervisor∶主管12.R&D(Research&Development)∶研发部门13.Supervisor∶主管14.Manager∶经理15.S BU(sub-Business Unit)∶跨国公司里的子事业部,BU是指事业部16.HR(Human Resource)∶人力资源17.HR Management∶人力资源管理18.Personnel Management∶人事管理19.Director∶总监20.HRD(HR Director)∶人力资源总监21.Specialist∶专员22.Mgr∶即manager,经理23.CHRO∶即Chief HR Offer,首席人力资源官(自CEO脱胎来)24.HRBP:HR Business Partner25.MT∶management team,管理层26.EHS∶即Environment、Health、Safety,是“环境健康安全”的缩写。

很多跨国企业都设有这个部门,负责企业的环境保护、员工健康和安全。

27.Operation Manager∶营运经理,很多跨国企业中,是分管生产、物流、仓储、质量、计划、工程、采购等部门的高层管理者28.R&D∶即Research&Development,研发29.P&D∶Product&Development,生产发展30.QC∶即Quality Control,即质量控制或质量管理部门31.Supply Chain∶供应链32.Supply Chain ASST∶供应链助理33.DGM∶即Deputy General Manager,副总经理34.Purchasing∶采购部35.Warehouse∶仓库36.Line Manager∶直线经理37.Trainer∶培训师38.Trainee∶培训学员39.Professional∶职业的40.Suit∶套装41.Internal Control∶内控42.Internal Audit∶内审43.MBA∶工商管理硕士,Master of Business Administration,目的在培养优秀的企业管理者。

游戏运营常用英文简称术语要点

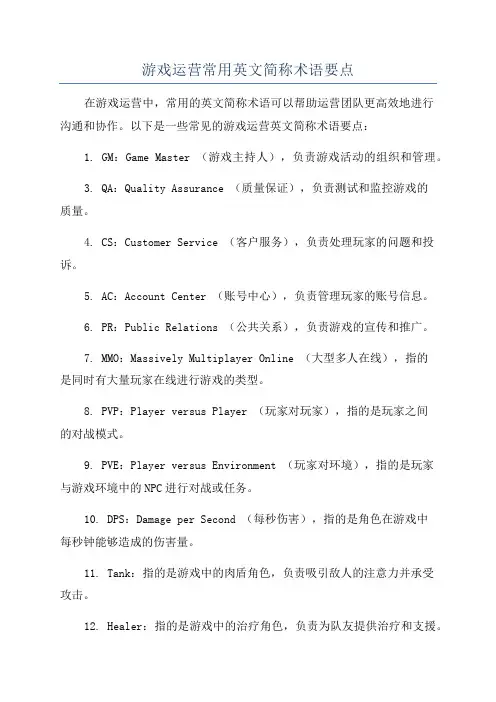

游戏运营常用英文简称术语要点在游戏运营中,常用的英文简称术语可以帮助运营团队更高效地进行沟通和协作。

以下是一些常见的游戏运营英文简称术语要点:1. GM:Game Master (游戏主持人),负责游戏活动的组织和管理。

3. QA:Quality Assurance (质量保证),负责测试和监控游戏的质量。

4. CS:Customer Service (客户服务),负责处理玩家的问题和投诉。

5. AC:Account Center (账号中心),负责管理玩家的账号信息。

6. PR:Public Relations (公共关系),负责游戏的宣传和推广。

7. MMO:Massively Multiplayer Online (大型多人在线),指的是同时有大量玩家在线进行游戏的类型。

8. PVP:Player versus Player (玩家对玩家),指的是玩家之间的对战模式。

9. PVE:Player versus Environment (玩家对环境),指的是玩家与游戏环境中的NPC进行对战或任务。

10. DPS:Damage per Second (每秒伤害),指的是角色在游戏中每秒钟能够造成的伤害量。

11. Tank:指的是游戏中的肉盾角色,负责吸引敌人的注意力并承受攻击。

12. Healer:指的是游戏中的治疗角色,负责为队友提供治疗和支援。

13. Mob:Mobile (移动),指的是游戏中的敌对生物。

14. NPC:Non-Player Character (非玩家角色),指的是由游戏控制的非玩家的角色。

15. RNG:Random Number Generator (随机数生成器),指的是在游戏中用来生成随机事件或随机数的算法。

16. MMORPG:Massively Multiplayer Online Role-Playing Game (大型多人在线角色扮演游戏),指的是在线多人角色扮演游戏。

GM基本命令

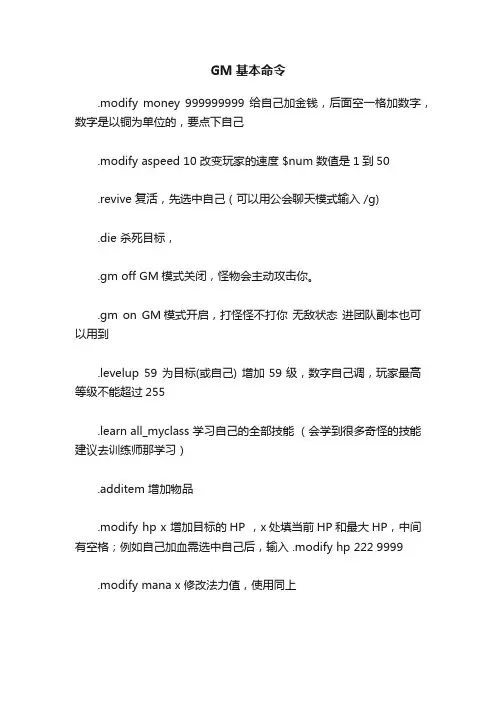

GM基本命令.modify money 999999999 给自己加金钱,后面空一格加数字,数字是以铜为单位的,要点下自己.modify aspeed 10 改变玩家的速度 $num 数值是1到50.revive 复活,先选中自己(可以用公会聊天模式输入 /g).die 杀死目标,.gm off GM模式关闭,怪物会主动攻击你。

.gm on GM模式开启,打怪怪不打你无敌状态进团队副本也可以用到.levelup 59 为目标(或自己) 增加59级,数字自己调,玩家最高等级不能超过255.learn all_myclass 学习自己的全部技能(会学到很多奇怪的技能建议去训练师那学习).additem 增加物品.modify hp x 增加目标的HP ,x处填当前HP和最大HP,中间有空格;例如自己加血需选中自己后,输入 .modify hp 222 9999.modify mana x 修改法力值,使用同上.npc KILL 杀死所选中的NPC(声望点数要受影响).npc DEL 删除所选中物件(声望点数不受影响).gps 显示角色或生物的坐标(x,y,z) 地图标号和地区.announce 发布公告.go 16222.1 16252.1 12.5872 1 传送自己到GM岛.bank 打开仓库.maxskill (所有技能熟练度增加满点).explorecheat 1 地图全开.taxicheat on 飞行点全开[post]騎乘術 .learn 34091提昇騎乘到300 .setskill 762 300 300.additem 23162 36格包包.quest complete +(shift键+右键点击任务名字)直接完成任务解决一些BUG任务.learn 44140 鱼叉冲浪哪都可以飞.add 49464 49488 好东西把等级改低用效果更佳。

GM中英文对照表

设计质量指标 设计发放,差异报告,要求的文件 每一小时的设计进程 决议回顾板 设计可信赖的分 白天运行灯光 包装 设计负责单位 资料放置次序 设计人员行为要求 数字科学公司 设计支持设备 设计人员信息发布 部门高级管理委员会 指定就座位置 详细送货记录 门开关传导模式 工艺分割决定 二级晶体管逻辑 放电温度保持 三维技术规范 双床下变换器 催促者和布拉德斯特里特数 耐力 微分真空延迟阀 三维变化管理 经久和确认计划编制系统 背离零件号码 动态汽车实验(在测力计上) 数字声音交流 „(软件) 设计工作定单 环境和动力谱 例如 每辆车的事件 能量吸收;工程管理;工程分配;工 程授权;出口行为 电子空气控制 电子空气控制转换阀 电子空气控制阀 发动机装配手册 工程战用办公室 员工援助项目 工程行为要求,高效动作要求 电子可变只读 环境行为人员 ,电子空气开关 电子空气开关阀 工程行动组,发动机/轮轴/传动 电子刹车控制 扩展二进制码十进制转换码 税&利息前利润 工程变换 工程变换认可 工程比较建议小组 电子气候控制

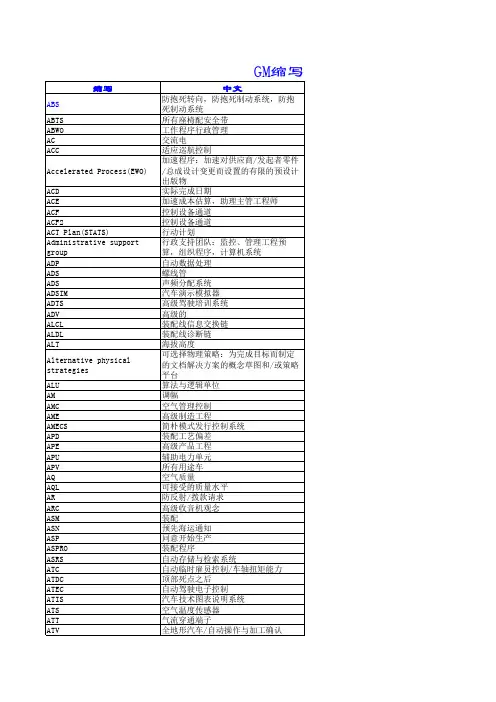

中文

防抱死转向,防抱死制动系统,防抱 死制动系统 所有座椅配安全带 工作程序行政管理 交流电 适应巡航控制 加速程序:加速对供应商/发起者零件 /总成设计变更而设置的有限的预设计 出版物 实际完成日期 加速成本估算,助理主管工程师 控制设备通道 控制设备通道 行动计划 行政支持团队:监控、管理工程预 算,组织程序,计算机系统 自动数据处理 螺线管 声频分配系统 汽车演示模拟器 高级驾驶培训系统 高级的 装配线信息交换链 装配线诊断链 海拔高度 可选择物理策略:为完成目标而制定 的文档解决方案的概念草图和/或策略 平台 算法与逻辑单位 调幅 空气管理控制 高级制造工程 简朴模式发行控制系统 装配工艺偏差 高级产品工程 辅助电力单元 所有用途车 空气质量 可接受的质量水平 防反射/拨款请求 高级收音机观念 装配 预先海运通知 同意开始生产 装配程序 自动存储与检索系统 自动临时雇员控制/车轴扭矩能力 顶部死点之后 自动驾驶电子控制 汽车技术图表说明系统 空气温度传感器 气流穿通端子 全地形汽车/自动操作与加工确认

GM缩写词汇总表

Action Center

Action Center template

行动中心指合工作进程可视的部门 。提供在交付计划中的精益工程行 为的节点,提供场所展示与改进主 动相关联的图表及信息,推进完成 当地精益目标,进行定义、跟踪交 付进程。 行动中心模板包含进程可视化的三 部分:-交付名字进程-交付进程分 析-其它信息 解决评估完成日期/实际完成日期 与要求完成日期不符所需采取的措 施。描述如何进行改进或消除障碍 。 实际完成日期:交付计划完成批准 日期 实际开始日期:明确的计划开始日 期

中文

空调 空气滤清器 模拟/数字,数字/模拟 空燃比 空气泵 自动排序 自动三档变速器 自动四档变速器 美国汽车协会 汽车广告理事会 装配辅助设备 美国汽车制造协会 外观认证报告 建造α 协议 建造β 协议 装配分类清单 原型车制造协议 商业程序 防抱死转向,防抱死制动系统,防 抱死制动系统 所有座椅配安全带 工作程序行政管理 交流电 适应巡航控制 加速程序:加速对供应商/发起者 零件/总成设计变更而设置的有限 的预设计出版物 实际完成日期 加速成本估算,助理主管工程师 控制设备通道 控制设备通道 关联构件组,行政认证团 空调控制模块 行动中心管理组 空气垫约束系统 装配元件跟踪 行动计划

ATSA ATT ATV ATWO AU AUR Automotive Technical lllusstration System(ATIS) Autoseque AUX MEM AVA AVE AVI AVIP AVO Avoid Verbal Orders(AVO) AVR AWD AWDA AWDIT AWO AWS B-I-W BAPS BCR BDS BIAT BIRG BPV B.I. B/P Qty B15 BA BACT BAI Balance

GM300写频软件中英文对照

GM300写频软件中英文对照表F1 HELP 帮助F2 SERVICE 服务F3 GET/SAVE Codeplug Data 读出/保存数据F4 CHANGE/VIEW Codeplug Data 编辑数据F5 PRINT Codeplug Data 打印数据F6 FILE Maintenance 文件维护F7F8F9 SETUP Computer Configuration 计算机配置F10 EXIT Radio Service Software,Return to DOS 退出软件F1 HELP 帮助F2 ALIGNMENT:Transmitter and Rceiver 路线:发射机和话筒F3F4F5F6 BOARD REPLACEMENT:Logic,RF,PA 更换-频率功率等F7F8F9F10 EXIT/Return To MAIN Menu 返回主菜单F1 HELP 帮助F2F3 DEVIATTON Adjustment 调整F4F5 REFERENCE OSCILLATOR WARP Adjustment 参考振荡器偏差调整F6F7 TX POWER Adjustment 发射功率调整F8F9F10 EXIT/Return To SERVICE Menu 返回服务菜单TRANSMITTER FREQUENCY WARP 发射机频率偏差Relative Value = 1-55 相对值TRANSMITTER FREQUENCY WARP 发射机功率偏差Relative Value = 1-102 相对值不能打开显示F2退出F1 HELP 帮助F2 READ Radio 读出数据F3 GET Archive File 获取存档文件F4F5 CLONE(copy)Codeplug Data 克隆(复制)codeplug数据F6 CHANGE to Repeater mode 改变中继模式F7 SAVE Archive File 保存数据文件F8 PROGRAM Radio 电台频道F9F10 EXIT/Return To MAIN Menu 返回主菜单READ RADIO CODEPLUG 主机数据读出Reading Codeplug Block 14 of 20 读取中F1 HELP 帮助F2 READ Repeater 读中继F3 GET Archive File 获取存档文件F4F5 CLONE(copy)Codeplug Data 克隆(复制)codeplug数据F6 CHANGE to Repeater mode 改变中继模式F7 SAVE Archive File 保存数据文件F8 PROGRAM Repeater 程序中继器F9F10 EXIT/Return To MAIN Menu 返回主菜单READ RADIO CODEPLUG 主机数据读出Reading Codeplug Block 14 of 20 读取中F1 HELP 帮助F2 RADIO CONFIGURATION:Radio-Wide,Mode 电台配置电台模式F3F4 PHONE LIST SUMMARY 列表?F5 ALIGNMENT SUMMARY 路线综述?F6 ARCHIVE FILE LIST For A Specified Path 存档文件列表指定路径F7 SIGNALLING CONFIGURAITON:Radio-Wide,SELECT V,Systems F8F9 CALL LIST SUMMARY 呼叫列表F10 EXIT/Return To MAIN Menu 返回主菜单F1 HELP 帮助F2 RADIO WIDE Configuration 无线电广泛配置F3F4 MODE Configuration:Summary 模式配置F5 MODE Configuration:All Parameters 模式配置所有参赛F6F7F8F9F10 Return to MAIN Menu 返回主菜单F5-F4 Printer Not Ready 打印机未准备好F5-F5 Print Aborted 打印终止F5-F6 PRINT:ARCHIVE FILE 打印:档案文件Archive Path:D:\GM300 存档路径F1 HELP 帮助F2 SIGNALLING RADIO-WIDE SUMMARY 信号radio-wide总结F3F4F5F6F7 SIGNALLING SYSTEM SUMMARY 信令系统综述F8F9F10 EXIT/Return To PRINT Menu 退出/返回打印菜单F1 HELPF2F3F4 CREATE Directory Path 创建目录路径F5F6 DELETE Archive File 删除存档文件F7 RESTORE Archive File From Backup 恢复文件从备份档案F8 UPDATE Backup From Aachive File 更新备份存档文件F9F10 EXIT 退出Path Name:D:\GM300 路径名Archive Path:D:\GM300 存档路径Source Path:------------------------- 源路径Target Path:--------------------------- 目标路径Source Path:------------------------- 源路径Target Path:--------------------------- 目标路径RADIO SERIAL NUMBERS 电台序号F1 HELP 帮助F2F3 PC Configuration:Drives,Paths,Etc 电脑配置:驱动器、路径F4F5F6F7 COLOR Configuration 色彩配置F8F9F10 EXIT/Return To MAIN Menu 返回主菜单DEFAULT PATH NAMES 默认路径名Archive D:\GM300 档案Backup 备份Repeater 复制SERIAL PORTS 串行端口 1MONITOR TYPE...........................Color 显示器类型Text....................................................Yellow 文本-黄色Status Line........................................White 状态Message Line........................................White 信息Highlight........................................White 高亮Background........................................Blue 背景Screen Outline........................................Lt Red 屏幕轮廓。

术语词汇表(GM)

术语词汇表先期产品质量策划——APQP目标工装能力——PpkDFMEA、PFMEA——过程潜在失效模式DFMEA是一份动态的文件,它是在概念设计阶段或之前发布的,并且在产品开发的过程中随着变化的发生获得更多的信息得到不断的更新。

它通过以下方式减少设计的失效风险:1)帮助评估设计要求,DFM和DFA;2)增加发现潜在失效模式的概率;3)明确设计的优先等级。

PFMEA的目的是确保已考虑并记录了过程可能产生的失效模式以降低RPN及缺陷的发生风险。

这是一个不断降低每个新零件风险的必须不断更新的动态文件。

生产件批准——PPAP生产件批准的目的是确定供应商是否完全理解所有的客户工程设计记录和规范要求,通过按照报价生产速率进行的正式生产,以验证其过程有能力生产出符合以上要求的产品。

AAR:Appearance Approval Report 外观批准报告ADV: Analysis/Development/Validation 分析/开发/验证ADV-DV:ADV Design Validation ADV 设计验证A/D/V P&R: Analysis/Development/Validation Plan and Report. This form is used to summarize the plan and results for validation testing. Additional information can be found inthe GP-11 procedure. 分析/ 开发/ 验证计划和报告AIAG:Automotive Industries Action Group, an organization formed by General Motors, Ford and Daimler-Chrysler to develop common standards and expectations for automotive suppliers.汽车工业行动集团AP:Advanced Purchasing 先期采购APQP:Advanced Product Quality Planning 产品质量先期策划APO:(General Motors)Asian Pacific Operations (通用)亚太分部APQP Project Plan: A one-page summary of the GM APQP process that describes the tasks and the timeframe in which they occur. APQP项目策划ASQE:Advanced Supplier Quality Engineer 先期供应商质量工程师BOM:Bill of Materials 材料清单BOP:Bill of Process 过程清单Brownfield Site: An expansion of an existing facility. 扩建场地CMM:Coordinate Measuring Machine 三坐标测试仪M Complex System / Subassembly: An assembly of sub-components delivered to the GM main production line for installation to the vehicle as a single unit. M复杂系统/分总成Cpk:Capability Index for a stabile process 过程能力指数CTS:Component Technical Specifications 零件技术规范Defect outflow detection: A phrase used in the Supplier Quality Statement of Requirements that refers to in-process or subsequent inspection used to detect defects in parts. 缺陷检测DFM/DFA: Design for Manufacturability / Design for Assembly 可制造性/ 可装配性设计DFMEA:Design Failure Modes and Effects Analysis. It is used to identify the potential failure modes of a part, associated with the design, and establish a priority system for design improvements. 设计失效模式分析MPC:Material Production Control 物料生产控制MPCE: Material Production Control Europe 欧洲物料生产控制MRD:Material Required Date; date material must be delivered in order to allow a build event to begin (Pilot, SOR, etc.)物料需求日期MSA:Measurement Systems Analysis 测量系统分析MVBns: Manufacturing Validation Build non-saleable 非销售车制造验证MVBs: Manufacturing Validation Build saleable 销售车制造验证NAO:(General Motors)North American Operations (通用)北美分部NBH:New Business Hold 停止新业务N.O.D.: Notice of Decision 决议通知OEM: Original Equipment Manufacturer 主机客户PAD: Production Assembly Documents 生产装配文件PC&L: Production Control & Logistics 生产控制&物流PDT:Product Development Team 产品开发小组PFMEA:Process Failure Modes and Effects Analysis. It is used to identify potential failure modes associated with the manufacturing and assembly process. 潜在失效模式分析PPAP: Production Part Approval Process 生产件批准程序PPM:1)Program Purchasing Manager 项目采购经理2)Parts per Million(rejects and returns to suppliers) 每百万件的产品缺陷数Ppk: Perfomance index for a stable process 过程能力指数PQC:Product Quality Characteristic 产品质量特性PR/R:Problem Reporting & Resolution 问题报告及解决PSA: Potential Supplier Assessment, a subset of the Quality System Assessment(QSA) 潜在供应商评审QSA:Quality System Assessment 质量系统评审QTC:Quoted Tool Capacity 工装报价能力RASIC:Responsible, Approve, Support, Inform, Consult 负责,批准,支持,通知,讨论RFQ:Request For Quotation 报价要求RPN: Risk Priority Number relater to FMEA development 风险顺序数RPN Reduction Plan: An action plan that describes what is being done to reduce the risk priority number for items listed in the DFMEA or PFMEA. 降低RPN值计划DPV:Defects per vehicle 每辆车缺陷数DRE:Design Release Engineer 设计发放工程师Error Occurrence Prevention: A phrase used in the Supplier Quality Statement of Requirement that refers to poke yoke or error-proofing devices used to prevent errors in the manufacturing process from occurring. 防错EWO:Engineering Work Order 工程更改指令FE 1,2,3: Functional Evaluations 1,2, and 3 功能评估GD&T: Geometric Dimensioning & Tolerancing 几何尺寸&公差GM: General Motors 通用汽车公司GME:General Motors Europe 通用汽车欧洲分部GM 9000:A document provided through Boise Cascade that houses GM specific requirements (General Procedures-GPs) that are referenced in QS 9000.GP: General Procedure 总体步骤GPDS:Global Purchasing System 全球采购系统GQTS:Global Quality Tracking System 全球质量跟踪系统G R&R: Gage Repeatability and Reproducibility 量具的重复性与再现性Greenfield Site: A new supplier facility that is built to support a program. 新建工厂GVDP:Global Vehicle Development Process 全球车辆开发过程IPTV:Incidents per Thousand Vehicles 每千辆车缺陷数KCC:Key Control Characteristics. It is a process characteristic where variation can affect the final part and/or the performance of the part. 关键控制特性KCDS: Key Characteristic Designation System 关键特性指示系统Kick-Off Meeting: The first APQP supplier program review. 启动会议KPC: Key Product Characteristic. It is a product characteristic for which reasonably anticipated variation could significantly affect safety, compliance to governmental regulations, or customer satisfaction. 关键产品特性LAO:(General Motors)Latin American Operations (通用)拉丁美洲分部LCR:Lean Capacity Rate. It is the GM daily capacity requirement. 最低生产能力MCR:Maximum Capacity Rate. It is the GM maximum capacity requirement. 最大生产能力MOP:Make or Purchase 制造/采购SDE:Supplier Development Engineer 供应商开发工程师SCC: Standard Control Characteristics 关键控制特性SFMEA:System Failure Mode and Effects Analysis 系统失效模式分析SMT:System Management Team 系统管理小组SOA:Start of Acceleration 加速开始SOP:Start of Production 正式生产SOR:Statement of Requirements 要求声明SPC:Statistical Process Control 统计过程控制SPC: Standard Product Characteristic 标准产品特性SPO:(General Motors)Service and Parts Operations (通用汽车)零件与服务分部SQ:Supplier Quality 供应商质量SQE:Supplier Quality Engineer 供应商质量工程师SQIP:Supplier Quality Improvement Process 供应商质量改进过程SSF:Start of System Fill 系统填充开始SSTS:Sub-system Technical Specifications 分系统技术规范S.T.E.P: Sourcing Team Evaluation Process, a supplier assessment focused on a specific technology or process at a supplier’s facility. 采购定点小组评估过程M Subcontractor: The supplier of a sub-component to a Complex System/ Subassembly supplier(Tier 2,3,etc). M分供方Team Feasibility Commitment: An AIAG APQP form that is provided with the Request for Quotation. It is the supplier’s concerns with the feasibility of manufacturing the part as specified. 小组可行性承诺UG:Unigraphics UG工程绘图造型系统VDP:Vehicle Development Process 车辆开发过程VLE:Vehicle Line Executive 车辆平台负责人WWP:Worldwide Purchasing 全球采购Supplier DUNS No.: 供应商邓氏编码Commodity:产品Engineering Change Level: 工程更改级别Model Year: 年型----应用于哪年的车型MPC:Main product characteristic 主要产品特性MCC:Main control characteristic 主要过程特性ME:Manufacturing engineer 制造工程师PE:Project engineer 项目工程师PQE:Project quality engineer 项目质量工程师TM:Technical manager 技术经理DRE: Design release engineer 设计发放工程师GP-12 Early Production Containment GP-12早期生产遏制Error proofing:防错Pre-Launch Control Plan: 试生产控制计划PRR:Problem Report and Resolution 问题报告与解决CS:Controlled Shipping 受控发运Appearance Approval Report 外观件批准报告Design engineering approval: 工程设计批准N/A:NOT Applicable 不适用的Conforming: 合格数Non-conforming: 不合格数Product Specification : 产品规格书PCR: Problem Communication Report 问题交流报告Trial mould 软模(试验模),Formal mould硬模(正式模)IMDS : International Material Data SystemCoaxial tolerance: 同轴度,Round corner :圆角环保要求:Environment requirementRetention/contact force:固定力未注尺寸:unspecified dimension/non specified dimension DR:Dimension requirement 尺寸要求APQP 和PPAP过程专业术语AAR Appearance Approval Report 外观批准报告ADV Analysis/Development/Validation 分析/开发/验证ADV-DV ADV Design Validation A D V 设计验证A/D/V P&R Analysis/Development/Validation Plan and Report, This from is used to summarize the plan and results for validation testing. Additional informationCan be found in the GP-11procedure. 分析/开发/验证计划和报告AEC Additional Engineering Changes 附加工程更改ADV-PV ADV product Validation A D V产品验证AIAG Automotive Industries Action Group, an organization formed by General Motors, Ford and Daimler Chrysler to develop common standards and expectationsfor automotive suppliers.汽车工业行动集团AP Advanced Purchasing 先期采购APO (General Motors) Asian Pacific Operations (通用)亚太分部APQP Advanced Product Quality Planning 产品质量先期策划AQE Advanced Quality Engineer 先期质量工程师ASQE Advanced Supplier Quality Engineer 先期供应商质量工程师ANOVA Analysis of Variance方差分析法ASDE Advanced Supplier Development Engineer 高级供应商开发工程师BOM Bill of Materials 材料清单BOP Bill of Process 过程清单CCAR Concern ed and Corrective Action Report 相关整改报告CAR Corrective Action Request 整改需求CFT Cross function Team 多方论证小组CMM Coordinate Measuring Machine三坐标测试仪CPV Weekly Production Volume 周产能CPK Capability Index for a Stabile process 过程能力指数CR Customer Requirements 客户要求CM Commodity Manager 产品经理CCM Corporate Commodity Manager 公司产品经理CS Customer Satisfaction 客户满意度CS 1/2 Level 1/2 Controlled Shipping 1/2级受控发运CTS Component Technical Specifications 零件技术规范DFM/DFA Design for Manufacturability/Design for Assembly 可制造性/可装配性设计DCP Dimension Control Plan (Dynamic Control Plan) 尺寸控制计划(动态控制计划) DOE Design of Experiment试验设计DPV Daily Production Volume 日产量DVP&R Design Validation Plan and Report 设计验证计划和报告DV Design Validation 设计验证DRE Design Release Engineer设计发放工程师DFMEA Design Failure Mode and Effects Analysis设计失效模式及后果分析EWO Engineering Work Order 工程更改指令EDI Electronic Data Interchange 电子数据交换FE1,2,3 Functional Evaluations1,2,and 3 功能评估ES Engineering Specification工程规范EPC Early Production Containment 早期生产遏制FAI First Article Inspection 首件检验FCR Field Call of RateFE Function Evaluation 功能评估FTA Failure Tree Analysis 故障树状分析FTC First Time Capability 试生产能力FTQ First Time Quality 直通率(一次合格率)GR&R Gage Repeatability and Reproducibility 量具的重复性与再现性GD&T Geometric Dimensioning & Tolerancing 几何尺寸&公差GM General Motors 通用汽车公司GME General Motors Europe 通用汽车欧洲部分GP General Procedure 总体步骤GPDS Global Product Description System 全球产品描述系统GPS Global Purchasing System 全球采购系统GQTS Global Quality Tracking System 全球质量跟踪系统GVDP Global Vehicle Development Process 全球车辆开发过程ISIR initial Sample Inspection Report 首次样品检验报告IPTV Incidents per Thousand Vehicles 每千辆车缺陷数IAA Interim Approval Authorization 临时批准授权ICAL Integral Corrective Action List 整体整改列表LCL Lower Control Limit 下控制限控制下限LSL Lower Specification Limit工程规范下限KCC Key Control Characteristic 关键控制特性KCDS Key Characteristics Designation System 关键特性指示系统KPC (GM)Key Product Characteristic关键产品特性LAO (General Motors) Latin American Operations (通用)拉丁美洲分部LCR Lean Capacity Rate, It is the GM daily capacity requirement 最低生产能力MCR Maximum Capacity Rate, It is the GM maximum capacity requirement 最大生产能力MPP Modified Production Part (Nissan Form) 改良生产零件MOP Make or Purchase 制造/采购MRP Manufacturing / Materials Resource Planning 加工/物料资源计划MRR Material Reject Report 物料拒收报告MPC Material Production Control 物料生产控制MPCE Material Production Control Europe 欧洲物料生产控制MRB Material Review Board物料评审MRD Material Required Date 物料需求日期MSA Measurement Systems Analysis 测量系统分析NAO (General Motors) North American Operations (通用)北美分部NCC Non Conformity Cost不良品成本NBH New Business Hold 停止新业务NDA/O Non Disclosure Agreement/Obligation保密协议/和约N.O.D Notice of Decision 决议通知OEE Operating Equipment Effectiveness 操作装置效率OEM Original Equipment Manufacturer原始设备制造商(整车厂)OTS Off Tooling Sample 正式工装/模具生产样品PPAP Production Part Approval Process 生产件批准程序PAD Production Assembly Documents 生产装配文件PC&L Production Control & Logistics 生产控制&物流PSW Part Submission Warrant 零件提交保证书PDT Product Development Team 项目开发组PFMEA Process Failure Modes and Effects Analysis 过程失效模式及后果分析PPM Parts per Million 每百万PSA Potential Supplier Assessment 潜在供应商评审PPK Performance index for a stable process 过程能力指数PFC Process Flow Chart 过程流程图PQC Product Quality Characteristic 产品质量特性PFD Process Flow Diagram 过程流程图PTC Pass Through Characteristic 过程特性?PTR Production Trial Run 生产试行PVP&R Production Validation Plan and Report 产品验证计划与报告PR/R Problem Reporting & Resolution 问题报告及决策PV Production Validation 生产产品验证PRR Problem Resolution Report 问题决策报告QSA Quality System Assessment 质量系统评审QSB Quality System Base 质量体系基础QSR Quality System Requirement质量体系要求QTC Quotes Tool Capacity 工装报价能力QFD Quality Function Deployment质量功能展开QOS Quality Operating System 质量运行体系QR Quality Reject/Report 质量拒收/报告?R@R Run at Rate 产能审核(产能审核指的是按照正常的生产状态进行审核,其中包括人员,设备,工装,材料和工艺。

GM音色表中英文对照

v1.0可编辑可修改GM音色表中英文对照钢琴0 Acoustic Grand Pia no 大钢琴(声学钢琴)1 Bright Acoustic Pia no 明亮的钢琴2 Electric Grand Pia no 电钢琴3 Hon ky-t onk Pia no 酒吧钢琴4 Rhodes Pia no 柔和的电钢琴5 Chorused Pia no 加合唱效果的电钢琴6 Harpsichord 羽管键琴(拨弦古钢琴)7 Clavichord 科拉维科特琴(击弦古钢琴)色彩打击乐器8 Celesta 钢片琴9 Glocke nspiel 钟琴10 Music box 八音盒11 Vibrapho ne 颤首琴12 Marimba 马林巴13 Xyloph one 木琴14 Tubular Bells 管钟15 Dulcimer 大扬琴风琴16 Hammond Orga n 击杆风琴17 Percussive Orga n 打击式风琴18 Rock Orga n 摇滚风琴19 Church Orga n 教堂风琴20 Reed Orga n 簧管风琴11v1.0可编辑可修改 40 Violin小提琴 41 Viola中提琴 42 Cello大提琴21 Accordia n2222 Tango Accordia n吉他23 Acoustic Guitar (n ylon)24 Acoustic Guitar (steel) 25 Electric Guitar (jazz)26 Electric Guitar (clea n) 27 Electric Guitar (muted) 28 Overdriven Guitar29 Distortion Guitar30 Guitar Harmo nics贝司31 Acoustic Bass32 Electric Bass(fi nger)33 Electric Bass (pick)34 Fretless Bass35 Slap Bass 136 Slap Bass 237 Synth Bass 138 Syn th Bass 2弦乐手风琴 口琴 探戈手风琴 尼龙弦吉他 钢弦吉他 爵士电吉他 清音电吉他 闷音电吉他 加驱动效果的电吉他 加失真效果的电吉他 吉他和音 大贝司(声学贝司) 电贝司(指弹) 电贝司(拨片) 无品贝司 掌击Bass 1 掌击Bass 2 电子合成Bass 1 电子合成Bass 2v1.0可编辑可修改合奏/合唱簧管64 Sopra no Sax 43 Con trabass44 Tremolo Strings45 Pizzicato Strings46 Orchestral Harp47 Timpa ni低音大提琴 弦乐群颤音音色 弦乐群拨弦音色 竖琴 定曰或 48 Stri ng En semble149 Stri ng En semble250 Synth Strings 151 Synth Strings 252 Choir Aahs53 Voice Oohs54 Syn th Voice弦乐合奏音色1 弦乐合奏音色2 合成弦乐合奏音色1 合成弦乐合奏音色 2 人声合唱“啊” 人声“嘟” 合成人声 管弦乐敲击齐奏铜管56 Trumpet小号 57 Tromb one58 Tuba 大号 59 Muted Trumpet 加弱音器小号 60 French Horn 法国号(圆号) 61 Brass Section 铜管组(铜管乐器合奏音色) 62 Syn th Brass163 Syn th Brass合成铜管音色1 合成铜管音色2 高音萨克斯风v1.0可编辑可修改65 Alto Sax 次中音萨克斯风66 Tenor Sax 中音萨克斯风67 Barit one Sax 低音萨克斯风68 Oboe 双簧管69 En glish Horn 英国管70 Bassoon 巴松(大管)71 Clari net 单簧管(黑管)笛72 Piccolo 短笛73 Flute 长笛74 Recorder 竖笛75 Pan Flute 排箫76 Bottle Blow [ 中文名称暂缺]77 Shakuhachi 日本尺八78 Whistle 口哨声79 Ocari na 奥卡雷那合成主音80 Lead 1 (square) 合成主音1 (方波)81 Lead 2 (sawtooth) 合成主音2 (锯齿波)82 Lead 3 (caliope lead) 合成主音383 Lead 4 (chiff lead) 合成主音484 Lead 5 (chara ng) 合成主音585 Lead 6 (voice) 合成主音6 (人声)86 Lead 7 (fifths) 合成主音7 (平行五度)87 Lead 8 (bass+lead) 合成主音8 (贝司加主音)合成音色1 (新世纪) 合成音色2 (温暖) 合成音色3 合成音色4 (合唱) 合成音色5合成音色6 (金属声) 合成音色7 (光环) 合成音色8 合成效果1雨声 合成效果2音轨 合成效果3水晶 合成效果4大气 合成效果5明亮 合成效果6鬼怪 合成效果7回声 合成效果8科幻 西塔尔(印度) 班卓琴(美洲) 三昧线(日本) 十三弦筝(日本)卡林巴 风笛合成音色88 Pad 1 (new age)89 Pad 2 (warm)90 Pad 3 (polysy nth)91 Pad 4 (choir) 92 Pad 5 (bowed)93 Pad 6 (metallic)94 Pad 7 (halo)95 Pad 8 (sweep)合成效果96 FX 1 (rain)97 FX 2 (sou ndtrack)98 FX 3 (crystal)99 FX 4 (atmosphere)100 FX 5 (brightn ess)101 FX 6 (gobli ns)102 FX 7 (echoes)103 FX 8 (sci-fi)民间乐器104 Sitar105 Banjo106 Shamise n107 Koto108 Kalimba109 Bagpipe110 Fiddle111 Sha nai 打击乐器Sound Effects 声音效果 120 Guitar Fret Noise吉他换把杂音 121 Breath Noise呼吸声 122 Seashore海浪声 123 Bird Tweet鸟鸣 124 Telepho ne Ring电话铃 125 Helicopter直升机 126 Applause鼓掌声 127 Gun shot枪声 Gen eral MIDI 打击乐器音色排列表MIDI 音高 打击乐声音35 Acoustic Bass Drum36 Bass Drum 1113 Agogo [ 中文名称暂缺] 114 Steel Drums钢鼓 115 Woodblock木鱼 116 Taiko Drum太鼓 117 Melodic Tom通通鼓 118 Syn th Drum合成鼓 119 Reverse Cymbal铜钹 112 Tin kleBell叮当铃 民族提琴 山奈37 Side Stick38 Acoustic Sn are39 Hand Clap40 Electric Snare41 Low Floor Tom42 Closed Hi-Hat43 High Floor Tom44 Pedal Hi-Hat45 Low Tom46 Open Hi-Hat47 Low-Mid Tom48 Hi-Mid Tom49 Crash Cymbal 150 High Tom51 Ride Cymbal 152 Chi nese Cymbal53 Ride Bell54 Tambouri ne55 Splash Cymbal56 Cowbell57 Crash Cymbal 258 Vibraslap59 Ride Cymbal 260 Hi Bongo61 Low Bongo62 Mute Hi Conga63 Open Hi Conga64 Low Conga65 High Timbale66 Low Timbale67 High Agogo68 Low Agogo69 Cabasa70 Maracas71 Short Whistle72 Long Whistle73 Short Guiro74 Long Guiro75 Claves76 Hi Wood Block77 Low Wood Block78 Mute Cuica79 Open Cuica80 Mute Tria ngle81 Ope n Tria ngle。

玛氏销售常用术语(中英对照)

玛氏销售常用术语(中英对照)销售常用术语及释义1.时间英语缩写英语全称中文释义举例YAG Year ago与去年同期相比Oct YAG Gr%十月同比增长YTD Year to date今年至今09P11 YTD09年P1-P11累计YTG Year to go今年剩下的时间09P11YTD 09年P12-P13累计MAT Movingannual total 往前滚动一年09P11MAT08年P12-09年P11P Period段P3, 第3段2.生意衡量指标1) 销售指标GSV Gross Sales Value Sell-in的销售额NSV Net Sales Value Sell-in的销售额减去TPDistribution 分销率 (ACN数据库可以查)2) 市场表现Sales Value 消费者购买POS金额(offtake), 销售额Sales Volume 消费者购买数量(offtake), 销量Market share市场份额(可以是销售额的份额Value share, 也可以是销量的份额Volume share)3) 财务指标MAC margin after conversion 公司计算毛利, NSV减去制造成本OP Operating profit 运营利润(看最后赚钱不赚…)4) 客户角度case-fill rate 订单满足率Category Management 品类管理Shopper traffic 客流量Basket value 客单价5) 品牌角度Awareness 品牌认知度Trail 尝试率Repeat 重复购买率Loyalty 忠诚度SOV 线上广告份额(在嘈杂的竞争品牌广告中, 我们的声音占了多少)* 从Awareness 一直到Loyalty, 是层层递进的6) 比较基数Benchmark 基准Vs. target 和目标相比Vs LY 和去年同期相比Vs competitor 和竞品相比3.渠道1) Mega 大型Hyper 超大型(收银台Checkout超过20个)Cash & Carry 仓储式(如麦德龙, 收银台Checkout超过20个) Large supermarket 大超市(收银台Checkout 7-19个)2) Middle 中型Smaller supermarket (ss) 小超(收银台Checkout7-19个) CVS 连锁便利店(一个收银台, 20家单店以上)Counter store 柜台店OSDO 批发市场Special channel 特渠, 如加油站, 火车站…3) IC Impulse channel 冲动渠道NCVS 非连锁便利店Small store 夫妻老婆店4) B2B 团购4.销量分类同样是销量, 在公司的衡量指标中有很多不同的名称和定义, 具体如下:Sell-in, Offtake, DTS5. 产品分类1)Brand 分品牌Dove, SNK, Crispy, M&M ’s2)Sub-Category 分品类Bulk 散装 Sharing分享装 Self-consumption 独享装Gifting礼盒6. 销售人员BDS Business development supervisor 销售主管MarsW/S,NKA, national key accountRetailerConsumerSellSell-DTSOfftakOfftaFOTG Feet on the ground 一线同事BDR Business development representative 业务代表JBDR Junior business development representative初级业务代表FLS Front Line Sales前线实地销售MER Merchandise executive representative理货员7. 合作部门Franchise 品牌市场部 (品牌建设和开发, 更多是线上的投入, 以及新品开发)Consumer Insight 消费者洞察部(为市场部提供消费者研究结果以及尼尔森等外部数据源)Trade marketing 市场推广部 (设计线下推广策略) Channel marketing 渠道推广部 (负责具体到活动SOP以及与销售同事沟通)Logistic 后勤 (物流)Finance 财务8. 价格表中的常见语RSP (Retail selling price) 零售价如43g, 元Listing Price 供价如43g, 元Margin 利润如, 43g, 20%Configuration 箱柜如心随 8*16, 一箱8盒, 每盒16个Excl VAT 不含增值税Incl VAT 含增值税9. 城市分类fortress city 堡垒城市 (BJ, TJ, SH, HZ, GZ, SZ)developing city 发展中城市(全国共38个)conversion city 转化城市10. 费用TP trade expense 投入给渠道的费用, 渠道受益CP consumer promotion expense 投入给消费者促销的费用, 消费者受益TTR trade term rebate 合同返点ATL Above the line 线上投入(如电视广告, 平面媒体, 楼宇广告, 赞助…)BTL Below the line 线下投入(如店内促销, 派发, 形象…)11. 必胜战役 Must Win Battle公司MTP中期计划中的策略方向, 资源分配和结果追踪都围绕这四大战役, 我们销售也应该了解我们为何而战…今年为四大战役, 缩写连起来是SIGN(标语)MWB S (SNK) 士力架战役MWB I (Impulse Channel) 冲动渠道战役MWB G (Gifting) 礼盒战役MWB N (New needs) 开发新需求(包括M&M’s以及新品)12. 销售衡量指标 Sales MetricsUniverse 存在店数Coverage 覆盖店数Distribution Points 分销点Hero SKU 英雄SKUAverage product line 平均产品线A-Display A陈列Activity evaluation 活动评估Turnover 人员流动NSV Gr NSV增长率Channel P&L 渠道的财务状况13. 其他POP point of promotion 促销点(咱老说贴POP, 其实就是通过张贴促销信息让消费者认识到这个是促销点)POS point of sales 销售点。