阀门遥控1113编辑

遥控浮球阀的型号标注方法

遥控浮球阀的型号标注方法

遥控浮球阀的型号标注方法主要包括以下步骤:

1. 确定阀门的类型:根据阀门的结构和功能,确定其类型,例如球阀、闸阀、截止阀等。

2. 确定阀门的主要参数:根据阀门的使用要求,确定其主要参数,例如公称通径、工作压力、工作温度等。

3. 确定阀门的特点:根据阀门的特点和特殊要求,确定其标注内容,例如是否带附件、特殊密封材料等。

4. 编写型号:根据上述信息,按照相应的标准或规定编写型号。

型号的编写方法可能因不同的阀门制造商而有所不同,但通常会包括阀门类型、主要参数和特点的代码或符号。

5. 校验:对所编写的型号进行校验,确保其准确性和完整性。

需要注意的是,具体的型号标注方法可能因不同的国家和地区或不同的阀门标准而有所不同。

因此,在选择和使用阀门时,应参照相关标准或规定,以确保正确的使用和维护。

遥控阀操作说明

遥控阀操作注意事项

领料前需要确认:

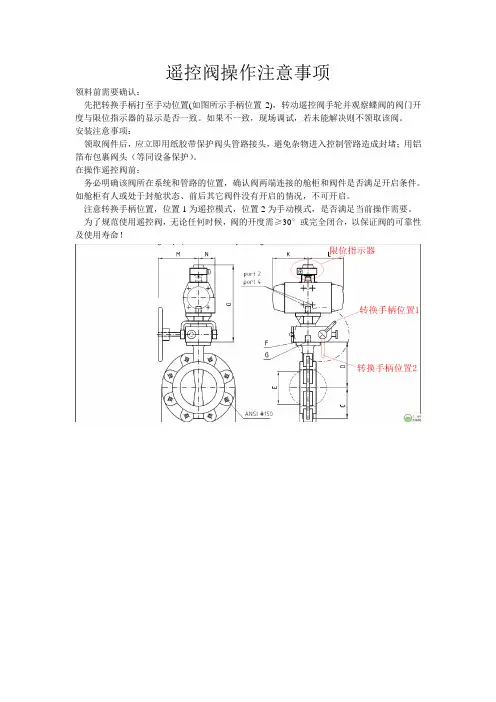

先把转换手柄打至手动位置(如图所示手柄位置2),转动遥控阀手轮并观察蝶阀的阀门开度与限位指示器的显示是否一致。

如果不一致,现场调试,若未能解决则不领取该阀。

安装注意事项:

领取阀件后,应立即用纸胶带保护阀头管路接头,避免杂物进入控制管路造成封堵;用铝箔布包裹阀头(等同设备保护)。

在操作遥控阀前:

务必明确该阀所在系统和管路的位置,确认阀两端连接的舱柜和阀件是否满足开启条件。

如舱柜有人或处于封舱状态、前后其它阀件没有开启的情况,不可开启。

注意转换手柄位置,位置1为遥控模式,位置2为手动模式,是否满足当前操作需要。

为了规范使用遥控阀,无论任何时候,阀的开度需≥30°或完全闭合,以保证阀的可靠性及使用寿命!。

卖阀门的幽默广告语

卖阀门的幽默广告语1. "我们的阀门,一关就停!连老板的嘴也关得住!"2. "我们的阀门,就像是乖乖地躺在地上的小狗,听话得不得了!"3. "买我们的阀门,你就能在慌乱的时候,轻松地关起门来给自己一个喘息的机会!"4. "我们的阀门,就像是一位保镖,护卫您的管道安全,不会让任何东西闯入!"5. "别再为突发的水浸事件烦扰,我们的阀门会给您一个干爽的家!"6. "我们的阀门,让您的管道无论是开还是关,都能像打击秋刀鱼那样轻松自如!"7. "买我们的阀门,您就能与管道独处,无需担心会有任何事情冒然闯入!"8. "我们的阀门,就像电视遥控器一样,指尖点击,管道随心驰骋!"9. "我们的阀门,可以说是管道界的'钢铁侠',绝对无敌保护您的水源!"10. "我们的阀门,它不仅能关,还能开,就像是来自未来的超级机器人一样!"1. "我们的阀门,让水流控制得比魔术师还精准!"2. "只要我们的阀门在,你就不用担心水灾肆虐,我们是水的守护神!"3. "你对我们的阀门是抱着开了头就没完没了的心态吗?别担心,我们的阀门能如你所愿,永不卡壳!"4. "和我们的阀门在一起,水管就像长长的舞蹈伴舞似的,优雅又顺畅!"5. "谁说阀门是冷酷无情的?我们的阀门可是温柔体贴,始终保持流量稳定,永远不让你受冷落!"6. "用我们的阀门,水管就像高速公路一样畅通无阻,再也不用为水流不通而困扰!"7. "我们的阀门就像一只贴心的管家,时刻为你维护水流的安全和舒适,你值得拥有!"8. "买了我们的阀门,不仅能控制水流,还能附带一个小小的快乐,让你开心每一天!"9. "我们的阀门是沉默的卫士,即使面对汹涌的水流,也能坚守岗位,绝不娇气!"10. "有了我们的阀门,水流自由畅通,如同你的人生一样,迎接无限可能!"。

液压阀门遥控系统的调试

阀门遥控系统简要调试步骤(甲板部分)QAA系统液压阀调试已结束的基础上,确认:1)液压动力单元正常工作;2)阀箱内部部件完整;3)三个蓄压单元完整;4)阀头上阀块完整且安装顺序正确;5)甲板上从阀箱到阀头间的液压油管路安装结束并且管路吹气已提交船东;6)各阀反馈完整,限位开关(如果有的话)完整,电缆接线完毕。

具体操作(参考所附原理图)ESD(Emergency Shut Down)以外的管路投油(参考所附原理图图一):1)确认液压泵单元正常工作,打开位于舵机室内液压主管路的阀门。

在液压系统启动之前检查通往各阀箱的截止阀应该处于关闭状态,防止阀箱漏油;2)打开阀箱外P,T,D主管路上截止阀,阀箱内部主管路阀块最底部的两个截止阀,以及阀箱内压力表管路上截止阀;此时,压力表有约为110bar的读数。

检查阀箱内部有无漏油,检查阀箱控制的各个阀门有无异常主要是看是否有漏油,有异常及漏油现象则马上关闭上述P,T,D主管路上截止阀。

3)阀箱正常情况下,在阀箱内拧出所要调试阀所对应阀块的P,T端;4)在阀头就地连接好旁通工具,即旁通软管,此时要保持旁通工具上手动截止阀处于关闭状态;5)拧开阀箱内P,T油管上的截止阀;6)用专用工具,操作阀箱内方向控制阀块一侧的操作按钮,将阀打开/关闭,开始往油管内投油。

此时,管子工要加强巡查液压油管路,以防有泄漏,若有异常,立刻关闭“5)”中所述两阀;7)等到阀完全动作到位后(开/关),缓慢打开旁通软管的手动截止阀,查看有无油流过旁通软,保持循环20分钟;同理,在此过程中阀头及管路漏油现象则马上关闭阀箱内该阀的阀块的P,T端。

8) 同样,操作阀箱内方向控制阀块另一侧的操作按钮,将阀关闭/打开,等到阀完全动作到位后,继续保持循环20分钟;9)结束后,关闭旁通软管中间的手动截止阀,拆掉调试旁通工具。

再次操作阀箱内的控制阀,看阀能否正常开/关。

调整各个阀的开/关时间:本操作以船东提供的时间表为操作依据,通过调整管路液压油流量来调整阀的开/关时间。

阀门遥控系统(液动)

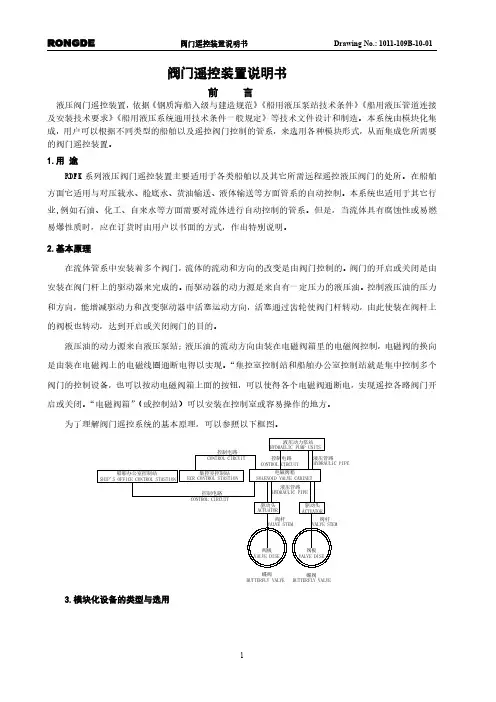

4 工作原理 阀门遥控装置的工作原理如图 2 所示。 阀门遥控装置的动力源由液压动力泵站产生,根据液压阀门开、关所要求的工作压力,由动力泵站

中的液压开关设定所需的压力范围,向电磁阀箱输送附合要求的液压动力。在正常运行状态下,操作设 在电磁阀箱面板上的带灯按钮,控制电磁阀箱中的电磁换向阀(二位四通或三位四通)的通路,实现对 设在各舱位中阀门开、关的遥控。

2# 液压泵 No.2 HYDRAULIC PUMP

CJ86/SC

HPU

容积 VOLUME

L

HPU Remote control & indication

AC V Φ Hz

DC V W IP

编号

日期

No.

DATE

CJ86/SC

Drawing No.: 1011-109B-10-01

集控室控制站 ECR CONTROL STATION

图 11 液压动力泵站的液压管路连接示意图

5.6.4 相邻管路和管件轮廓边缘的距离不应小于 10mm。同排管道法兰或活接头应相间错开 100mm 以上, 保证拆卸方便。 5.6.5 穿墙(舱壁)管应加套管,其接头位置宜距墙(舱壁)面 800mm 以上。 5.6.6 机体上的管道应尽量贴近机体,且不得妨碍机器动作。 5.6.7 管路敷设、安装时应防止元件和液压装置受到污染。 5.6.8 连接管道应选用Φ14×3 不锈钢管(耐酸钢),选择配管路线的原则应是管线最短、弯头少及易紧 固、维修的场所。

RDFK 系列液压阀门遥控装置主要适用于各类船舶以及其它所需远程遥控液压阀门的处所。在船舶

方面它适用与对压载水、舱底水、货油输送、液体输送等方面管系的自动控制。本系统也适用于其它行

业,例如石油、化工、自来水等方面需要对流体进行自动控制的管系。但是,当流体具有腐蚀性或易燃 易爆性质时,应在订货时由用户以书面的方式,作出特别说明。

舱底压载,阀门遥控系统介绍及其在船舶中的作用

舱底压载,阀门遥控系统介绍及其在船舶中的作用1. 压载系统作用是为了船舶正常的营运而进行入、排、调拨压载水(74000DWT散货轮无调拨压载水功能)。

为了船只的适航性,安全性,设计时要确定满载吃水,空载吃水等吃水线。

压载系统需要保持船只空载时的稳定性,适航性;重载时的适航性(比如航道经过距水面较低的固定式桥,则需要注意船舶在满压载时的高度能否保证顺利通过,否则要临时切割上层建筑)。

船舶经过大风浪的航区(如大西洋)时,一定要加压载保持稳定。

压载水的调拨目的是控制船只的纵、横倾。

比如江南厂造的火车渡轮,采用风机来实现左右调水以控制横倾(采用风机配紫铜管可以快速调水但管子的腐蚀量大);潜艇通过用泵前后调水以控制纵倾,实现姿态的调节。

在设计工作中,要求管系在船舶倾斜角5o的条件下,系统可以正常工作。

而对于主机则要求横倾15o,横摇22.5o的条件下可以工作。

应急消防泵要求横摇22.5 o,纵倾10 o时可用。

可见对于设备的要求比管系要高。

注意在压载舱中两套吸口,一般压载吸口较大,扫舱吸口较小。

吸口布置在舱的尾部,若舱的长度大于35m,则首尾均需要布置吸口。

由于压载泵的排量大,当吸口的吸水量大于舱中水流动到吸口的流动量时,就会由于大量空气混入而无法排水;这时需要用喷射泵扫舱。

压载系统与扫舱系统共用一根压载总管,而不需要另外设置扫舱总管。

尽管压载总管通径较大,但经过实践证明这种设计可以较好的发挥作用。

注意压载管要采用套筒焊接穿舱壁筒,而不可用法兰。

货舱,油舱(如散货轮的4号货舱)作压载舱用,则需要在压载管上装盲板或其他隔离措施。

(江南厂设2套截止阀,从4号货舱的污水井进入。

)注意压载管路中不能设止回阀。

通入艏压载舱的管子穿过防撞舱壁,需要将阀用座板直接装在防撞舱壁上,以前是将阀装在舱壁的前面,并引上艏楼甲板手动操作。

但是2004年4月之后,规范要求不能在航行时让船员经过危险区域去操作阀。

因此目前采用将阀装在舱壁的后面管弄中,通过遥控操作。

船舶阀门遥控系统电气设计优化与实践

电气元件的选择与优化效果:提高系统可靠性、安全性、经济性,降低维护成本

电气控制方案的优化

优化目标:提高系统稳定性、可靠性和效率 优化方法:采用先进的电气控制技术和算法 优化效果:降低系统能耗,提高响应速度 优化实例:某船舶阀门遥控系统的电气控制方案优化实践

易用性:系统应具 备易用性,方便船 员操作和维护

船舶阀门遥控系 统电气设计优化

电气设计优化的目标与原则

提高系统效率:降低能耗, 提高系统运行效率

降低成本:优化设计,降低 系统制造和维护成本

提高系统可靠性:减少故障 率,提高系统稳定性

遵循相关标准和规范:确保系 统符合相关行业标准和规范要

求

电气元件的选择与优化

船舶阀门遥控系统的未来发展方向与展望

智能化:实现阀门遥控系统的智能化,提高操作效率和准确性 网络化:实现阀门遥控系统与船舶其他系统的网络化连接,提高船舶整体运行效率 安全化:提高阀门遥控系统的安全性能,确保船舶运行安全 节能环保:优化阀门遥控系统设计,降低能耗,减少排放,实现绿色航行

感谢您的观看

升级改造的内容:包括硬件升级、软件 升级和系统优化

硬件升级:更换老旧设备,采用新型传 感器、控制器和执行器

软件升级:优化控制算法,提高系统的 响应速度和稳定性

系统优化:优化系统架构,提高系统的 可扩展性和可维护性

升级改造的效果:提高了船舶阀门遥控系统的性 能和可靠性,降低了故障率,提高了船舶的安全 性和运营效率。

组成:包括控制单元、执行 器、传感器等部分。

定义:船舶阀门遥控系统是一 种通过无线或有线方式控制船 舶阀门开闭的系统。

nordic阀门遥控样本

Nordic Flow Control Pte LtdSubsidiary of Nordic Group Limited, listed on the SGX 5 Kwong Min Road, Singapore 628708Tel: (65) 6848 4400 Fax: (65) 6848 4411 Customer Care Hotline: (65) 6425 2337Customer Care: customercare@Sales Enquiries: sales@Marketing & Communications: marketing@ Incorporated in 1998, Nordic Flow Control started out as a service agent.Through vision and determination, we have forged ahead to become aglobal manufacturer and system integration solutions provider for Marine,Oil and Gas control systems, with a sales and support network that spansAsia and Europe.To stay ahead of the competition, we are constantly raising the bar in qualityand technological creativity. Nordic Flow Control’s Integrated Control andManagement Systems, will meet any vessel automation needs. Fromproduction to installation, our professional and experienced engineers willbe there every step of the process to ensure customers get the mostreliable, user-friendly and technologically advanced control systems thatperform above their expectationsBacked by international accreditations from various marine classificationbodies, including ISO 9001:2000 by ABS, Nordic Flow Control’s one-stopintegrated solution has been installed in hundreds of vessels and drillingrigs across the globe. Made from the toughest materials and able to withstandthe most demanding of marine and offshore situations, our growing referencelist bears testament to the reliability of our systems.TECHNICAL SPECIFICATIONS – ACTUATOR DRAWINGSOur HPU is delivered as a one skid-mounted unit, and it contains thefollowing main components:s /IL RESERVOIR WITH A CAPACITY TO BE CALCULATED DEPENDING ON THEnumber of actuatorss %LECTRIC MOTORS TO BE CONTROLLED FROM SEPARATE STARTERSs (YDRAULIC PUMPs 6ALVES AND -ANIFOLDSs !CCUMULATOR AND CHARGING KITs 3TARTER #ONTROL 0ANEL AND #ONTROL 0ANELs 3IGHT 'LASSs ,EVEL 3WITCHESs 0RESSURE 3WITCHES FOR 34!24 34/0 OF PUMPS AT PRESET VALUESs 3AFETY 6ALVESs 0RESSURE 'AUGEs /IL TEMPERATURE MONITORINGThe HPU has been reviewed as an extremely reliable power unit. Fromstandard to customised units, they are very well designed. Our standardunits come with two motors, for back up purposes and to extend thelifespan of our HPU.!LL MOTORS THE ELECTRICAL CABINETS AND ALL OTHER EQUIPMENT COME WITHIP55 protection to ensure greater performance.TECHNICAL SPECIFICATIONSReservoir Volume 150l 250l 350l 0UMP #APACITY 0UMPS L MIN L MIN L MIN Max Working Pressure 170 bar%LECTRIC -OTOR NOS6OLTAGE 6 (Z 0H POLE0OWER #ONSUMPTION KW EACH KW EACH KW EACH "LADDER !CCUMULATOR L LX L Our HPU is designed to be user-friendly. The layout for the electricaland hydraulic components is placed systematically and the open designallows for easy access during maintenance.Featuress %XCELLENT DEPENDABILITYs ,OCAL AND REMOTE CONTROLs ,OW LEVEL HIGH PRESSURE HIGH TEMPERATURE ALARMSs !UTOMATIC AND MANUAL CONTROL FOR MOTOR 34!24 34/0s "ACKUP RESERVOIR ALLOWING FOR AUTO TRANSFER BETWEEN THE TWOreservoirs if neededs )0 PROTECTION ON MOTORS ELECTRICAL CABINET AND EQUIPMENTs#OMES IN THREE STANDARD SIZES OF AND LITRES RESERVOIRSHYDRAULIC SYSTEM ACCESSORIESDouble Pilot Block4HE $OUBLE 0ILOT $0 "LOCK IS DESIGNED TO BE USED ON BOTH OUR .2! AND .(2 SERIES OF DOUBLE ACTING ACTUATORS )T CONTAINS A THROTTLING VALVE WHICH IS USED FOR ADJUSTING SPEED WHEN REGULATING THE VALVE S OPENING AND CLOSING speeds.Featuress ! $OUBLE 0ILOT $0 #HECK 6ALVE WITH HYDRO LOCK FUNCTION TO PROVIDE FOR LOSS OF PRESSURE IN OIL CHAMBER CAUSED BY external factorss 4HROTTLING 6ALVE FOR SPEED ADJUSTMENT TO MINIMISE WATER HAMMERING EFFECTs ! PRESSURE RELIEF VALVE SET AT BARS TO PREVENT OVER PRESSURISING THE ACTUATORS BY RELEASING THE HYDRAULIC OIL FROM THE CHAMBER IF THE PRESSURE INSIDE GOES HIGHER THAN TO BARs ! HAND PUMP CONNECTION THAT ALLOWS EMERGENCY OPERATION BY MEANS OF A PORTABLE (AND 0UMP s 1UICK COUPLING TO CONNECT THE HAND PUMP FOR EMERGENCY OPERATION OF ACTUATOR DURING POWER FAILURE Operation&OR USE WITH .ORDIC $OUBLE !CTING !CTUATORSs $0 "LOCK CONSISTS OF A (YDRAULIC $0 #HECK 6ALVE QUICK CONNECTION FOR EMERGENCY HAND PUMP OPERATION PRESSURE RELIEF VALVES ATTACHMENT AND SPEED ADJUSTMENTs !BLE TO BE USED ON ALL .ORDIC ACTUATOR MODELSFor use with Submerged Actuators:s $0 IS -OUNTED ON THE $0#/ $ECK 0LATE "LOCK AT THE DECK FOR EASY MANUAL OVERRIDE OPERATIONS s ! 3UBMERGED #AP WILL BE ADDED ONTO THE ACTUATOR S INDICATORs 30#/ 3UBMERGED 0LATE "LOCK WILL BE PLACED ON THE ACTUATORTHROTTLE VALVESAC Block .ORDIC &LOW #ONTROL S 3!# "LOCK IS DESIGNED TO BE USED ON OUR .2! AND .(2 SERIES SINGLE ACTING ACTUATORS 4HE 3!# consists of a quick connection for emergency hand pump operation as well as a connection for throttle valves.! THROTTLING VALVE IS ALSO INCORPORATED FOR ADJUSTING SPEED WHEN REGULATING THE VALVE S OPENING CLOSING SPEED 4HISfeature also greatly reduces the water-hammering effect.Features s 4HROTTLING VALVES TO ADJUST THE SPEED OF THE HYDRAULIC OIL mOW s 1UICK COUPLING TO CONNECT THE HAND PUMP DURING EMERGENCY CONDITIONS OR HYDRAULIC POWER FAILURE TO OPEN OR close the valve Operation &OR USE WITH .ORDIC 3INGLE !CTING !CTUATORS s 4HE 3!# "LOCK CONSISTS OF A QUICK CONNECTION FOR EMERGENCY HAND PUMP OPERATION AND SPEED ADJUSTMENT s 3PRING ACTION BY MEANS OF DISC SPRINGS For use with Submerged Actuators:s 3!# "LOCK IS MOUNTED ON THE $0#/ $ECK 0LATE "LOCK AT THE DECK FOR EASY MANUAL OVERRIDE OPERATIONS s ! 3UBMERGED #AP WILL BE ADDED ONTO THE ACTUATOR S INDICATOR s 30#/ 3UBMERGED 0LATE "LOCK WILL BE PLACED ON THE ACTUATOR Deck Plate (DPCO)$0#/ IS THE DECK PLATE USED TO MOUNT THE $0 3!#block in the dry area for the actuator in submerged conditions.Submerged Applications AccessoriesSubmerge Plate (SPCO)"Y USING THE 30#/ 7E CAN COVER 0ORTS ! AND " WITH THEACTUATOR IN SUBMERGED CONDITIONS 4HERE WILL BE A $0 3!# "LOCK IN THE DRY AREASubmerged Cap The pinion gear is covered by the submerged cap whenthe actuator is in submerged conditions to prevent wateringress.DP BlockManifoldOur manifolds work with a stacked design that comes in 6-station blocks. The design allows placements behind each manifold in a solenoid valve cabinet and very compact hydraulic systems can be built upon each station."ESIDES THE ! AND " USER PORTS THERE ARE TWO THROTTLE STOP VALVES ON EACH station that regulates the flow and can be closed for repairs at the actuators.The manifolds are provided with screws and recesses for cabinet mounting.Featuress #OMPACT AND UNIQUE DESIGNs 4HROTTLE VALVES ON EACH STATIONs 3YSTEMS BLEED VALVE ON EACH MANIFOLDs(AND PUMPS CONNECTIONS FOR EMERGENCY OPERATIONTECHNICAL SPECIFICATIONSWorking Pressure 135 barMaximum Test Pressure 200 bar&ITTING #ONNECTION v "300Weight of Nordic 6-Station 6 kgWeight of Bottom Section 2 kgWeight of Top Section 1 kgMaterials-ANIFOLD "OTTOM AND 4OP "LOCK !LUMINIUM 4 4HROTTLE 3TOP 6ALVE "RASSHand Pump Connection SteelSeal RingNBRTop Block In the top block, a system bleed valve an d a pressure gauge TO BAR FOR 0 LINE PRESSURE ARE INCORPORATED When purging the pressure line P to the tank line T, the bleed valve is to be opened.Bottom Block In the bottom block, there are two han d pump connections on the P and T ports, which are incorporated for the emergency operation of the entire manifold.Before using the hand pump connection, the two stop valves that are incorporated in the P and T ports should be closed.Blank Plate The blank plate is used for blanking off connections that are not used on the manifold.! CHECK VALVE IS USED IN THE MANIFOLD 4 LINE IN ORDER to have flow moving in one direction, preventing back pressure.The check valve is a stan dard feature in our man ifold system.Check Valve 4HE THROTTLE VALVE IS USED FOR SPEED ADJUSTMENTS AND shut off.ValveComponentsFEEDBACK UNITSMODULATING LIMIT SWITCH.ORDIC &LOW #ONTROL S -ODULATING ,IMIT 3WITCH FOR MONITORING AND MODULATING VALVES IS SUITABLE FOR USE IN HAZARDOUS AREAS )TS ROBUST AND COMPACT DESIGN CONFORMS TO %. AND %. WHICH MAKES IT ALSO SUITABLE FOR :ONE AND :ONE APPLICATIONSFeaturess !LUMINIUM CASTING WITH POWDER COATING BODYs "OLTS ON VISUAL POSITION INDICATOR MAKING IT SECURE AND WEATHERPROOFs 1UICK SET CAMs $UAL CABLE ENTRYs #APTIVE COVER BOLTSs%ASY MOUNTING BRACKETON/OFF LIMIT SWITCH 4HE /. /&& ,IMIT 3WITCH IS A ROTARY POSITION INDICATOR USED TO MONITOR THE /0%. #,/3% POSITION OF THE VALVE The dome position indicator is constructed from high impact resistant polycarbonate material which offers instant recognition of valve position from up to 50 metres.Features s 6ISUAL 0OSITION )NDICATOR s 1UICK SET CAM s -ULTI POINT TERMINAL STRIP s $UAL WIRE POTTING s #APTIVE COVER BOLTS s %ASY MOUNTING BRACKET TECHNICAL SPECIFICATIONS %NCLOSURE 7EATHERPROOF )0 4EMPERATURE 2ANGE ª# TO ª# 4ERMINAL 3TRIP POINTS Position Indicator 0 to 90°C : Open – Yellow, Closed - Red 3HAFT STAINLESS STEEL -ICRO 3WITCHES 5SED IN 5, #3! APPROVED )NSERTS "RONZE / 2INGS .ITRILE 2UBBER Cams Polycarbo n ate 3PRING #OVER 3CREWS STAINLESS STEEL 6OLTAGE -AXIMUM 6 !# OR $##URRENT ! 6 OR $# ! b (0 !# ! 6 4 #ABLE %NTRY X b v 0& 04 .04 3WITCH 4YPE 30$4 -ECHANICAL SWITCHES 0ROXIMITY SENSORS Painting Polyester powder coating with black colour "RACKET 0LASTIC 0LATE STEEL TECHNICAL SPECIFICATIONS%NCLOSURE &LAMEPROOF %%XD ))" 4 AND %%XD ))#T6 Weatherproof0ROTECTION )0 )0#OATING %XTERNAL POWDER COATED!NODIZED SURFACE AGAINST CORROSION /PTIONAL !REA :ONE 'AS #LASSIlCATION %XD ))" # 4 4EMPERATURE 2ANGE ª# TO ª#(IGHER TEMPERATURE AVAILABLEUPON REQUEST#ABLE %NTRY X 04 b vX 0& b vX .04 b v2 x M20 X 1.5 upon request-AXIMUM4ERMINAL TERMINAL STRIPSFOR SWITCHES FOR SOLENOIDCONNECTIONPosition Monitoring Indicator 0°C to 90°CYellow - Open, Red - CloseSwitches 2 x mechanical switchesPotentiometer Position transmitter 0 to 1 K-OUNTING "RACKET 6$) 6$% .!-52TECHNICAL SPECIFICATIONSMaximum Working Pressure 135 barMaximum Test Pressure 200 barRotation Indication Pointer4EMPERATURE 2ANGE ª# TO ª#(YDRAULIC -EDIA !CID FREE HYDRAULIC OILViscosity 15 to 200 cSt-AXIMUM mOW RATE BAR L MINWeight 1.3kg&ILTRATION REQUIREMENTS «M ABSOLUTE OR lNER#ONNECTION &ACE #%4/0 2 ( SIZEMaterials (OUSING !LUMINIUMScrews Stai n less steel VALVE POSITION INDICATORWhen the actuator is submerged, the measurement of the actuator position by mean s of direct in dication is n ot feasible. Nordic Flow Con trol’s Valve 0OSITION )NDICATOR 60) CAN BE USED FOR BOTH NON SUBMERGED AND SUBMERGED applications, allowing accurate actuator measurement regardless of setup.The basic intention of the VPI is to receive and measure position feedback from the actuator. The working principle behind is through the measurement of the OIL DISPLACEMENT mOW ! GEAR WHEEL CONNECTED TO THE OIL mOW ROTATES WHEN the actuator is rotated. The rotation of the gear wheel is also connected to a 3-wire potentiometer. The output signal from the potentiometer ranges from 0 to 1 K ¾.Featuress %XCELLENT DEPENDABILITYs 7ELL CRAFTED TO SUIT MOST QUARTER TURN VALVESs %NGINEERED ESPECIALLY FOR -ARINE AND /FFSHORE APPLICATIONSs 2ECEIVE POSITION FEEDBACK FROM ACTUATORSs 2OTATIONAL GEAR WHEEL IS CONNECTED TO A WIRE POTENTIOMETERs /UTPUT SIGNAL FROM THE POTENTIOMETER RANGES FROM TO +¾VALVE POSITION INDICATORSIDE VIEWTOP VIEW VPI WITH SOLENOID LOCAL INDICATOR .ORDIC &LOW #ONTROL ,OCAL )NDICATOR IS USED TO DISPLAY THE POSITION OF THE VALVE /0%. #,/3% LOCALLY IF THE VALVE IS IN a submerged location. Once the incoming pressure exceeds the pressure setting on the pressure relief valve inside the local indicator, the oil would flow to a small chamber, causing the piston to move towards one side; as a result THE INDICATOR WOULD DEmECT AND GIVES THE /0%. #,/3% STATUS OF THE VALVE TECHNICAL SPECIFICATIONS (OUSING !LUMINIUM C W TYPE ANODIZING Screws Stai n less steel Working Pressure 135 bar Weight 0.7 kg (YDRAULIC -EDIA !CID FREE HYDRAULIC OIL Viscosity 15 to 200 cSt &ILTRATION 2EQUIREMENTS «M ABSOLUTE OR lNER 4EMPERATURE 2ANGE # TO #Local Indicator – Double Acting (Without Remote Signal)TECHNICAL SPECIFICATIONS (OUSING !LUMINIUM C W TYPE ANODIZING Screws Stai n less steel Working Pressure 135 bar Weight 0.7 kg (YDRAULIC -EDIA !CID FREE HYDRAULIC /IL Viscosity 15 to 200 cSt &ILTRATION 2EQUIREMENTS «M ABSOLUTE OR lNER4EMPERATURE 2ANGE # TO C Local Indicator – Single Acting (Without Remote Signal)。

浅析阀门遥控系统在海工船舶上的应用

浅析阀门遥控系统在海工船舶上的应用1. 引言1.1 阀门遥控系统概述阀门遥控系统是一种用于控制阀门开闭的自动化系统,通常通过远程控制设备实现。

这种系统能够帮助海工船舶实现对各种阀门的远程控制,保障船舶设备的安全运行和高效操作。

阀门遥控系统的概念最初来源于船舶工业,随着技术的不断进步,对阀门控制的要求也越来越高,因此阀门遥控系统逐渐成为海工船舶上必不可少的装备。

阀门遥控系统可以通过中央控制台或者远程控制器实现对船舶上各种阀门的控制,可以进行开启、关闭、调节等操作。

这种系统能够快速响应指令,提高操作效率,减少人为操作对设备的损坏风险。

阀门遥控系统具有自动报警和监控功能,能够及时发现问题并采取应对措施,确保船舶设备的安全稳定运行。

阀门遥控系统在海工船舶上扮演着至关重要的角色,是船舶操作和安全的关键保障。

随着技术的不断进步,相信阀门遥控系统在海工船舶上的应用范围将会进一步扩大,其在船舶行业中的重要性也将日益突显。

2. 正文2.1 海工船舶的特点海工船舶是指专门用于海洋勘探、海底作业、海洋科学研究、海洋资源开发等目的而设计建造的船舶。

与普通商业船舶相比,海工船舶具有以下几个特点:1. 海洋工作环境苛刻:海工船舶通常需要在恶劣的海洋环境中工作,如恶劣的天气、大浪、海浪等,因此需要具有较强的抗风浪能力和稳定性。

2. 多功能性:海工船舶需要具备多种功能,如搭载各种海洋勘探设备、作业设备等,并能够根据不同任务需求进行灵活调整。

3. 船体结构复杂:为了适应不同的海洋作业需求,海工船舶的船体结构通常比较复杂,如需要额外的设备支撑、结构加固等。

4. 特殊安全要求:海工船舶的安全要求较高,因为在海洋环境中发生事故后的救援难度大,因此需要具备完善的安全设备和紧急应对措施。

海工船舶具有特殊的工作环境和任务需求,因此对船舶本身的设计和设备配置有较高的要求。

阀门遥控系统作为其中重要的一部分,在海工船舶上的应用也显得格外重要。

2.2 阀门遥控系统的作用阀门遥控系统作为海工船舶上的重要设备之一,具有以下几项作用:1. 提高操作效率:阀门遥控系统能够实现对多个阀门同时进行远程控制,减少人力操作,并提高操作效率。

遥控阀原理

遥控阀原理

遥控阀原理是一种通过遥控操作来控制阀门开度的技术。

其基本原理是利用电磁或气动信号来调节阀门的开启程度,从而实现流体介质的控制。

遥控阀通常由执行机构、传感器和控制装置三部分组成。

执行机构是阀门的核心部件,通过接收来自控制装置的指令信号,控制阀门的启闭程度。

传感器用于感知阀门的开度情况,将阀门的实际开度信息反馈给控制装置。

控制装置则根据传感器的反馈信号和设定的控制要求,产生相应的控制信号,将其发送给执行机构,以调节阀门的开度。

在电磁式遥控阀中,执行机构通常由电磁阀和阀门构成。

电磁阀受到来自控制装置的电信号激励后,通过改变电磁场的强度,控制阀门的启闭程度。

而气动式遥控阀的执行机构则由气动驱动元件和阀门构成,通过气源产生的气压信号,调节阀门的开度。

遥控阀的原理基于控制装置对阀门的控制信号与传感器反馈信号之间的比较。

当控制装置的控制信号与传感器的反馈信号不一致时,控制装置会调整输出信号,以向执行机构发出正确的指令,使阀门的开度达到预期的要求。

通过遥控阀原理,可以实现对流体介质的准确控制,提高生产过程的自动化程度。

它广泛应用于工业生产中的流体控制系统,如石油、化工、冶金等领域,以及供暖、供水等民用工程中。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

液动阀门遥控系统的工作原理

• 液动阀门遥控: 以液压泵站提供动力源,通过控制台手动 开关控制,电磁阀换向相应的开闭阀管路, 驱动器驱动阀门进行开、闭阀动作。

电动阀门遥控工作原理

• 电动阀门遥控系统 以交流,直流电源为动力,通过控制台开 关控制电机的正反转及减速机构对阀门进 行开闭阀动作

电液动阀门遥控工作原理

11万吨油轮阀门遥控系统简介

• 11万吨油轮上的阀门遥控系统由以下五部 分组成 1 中央控制站 2 液压站 3 控制柜 4 液压管线 5 现场阀体及执行机构

1控制台

控制台是整套系统的核心,它一般安装在 货控室或驾控室。控制台应完全是按照用户要 求和习惯来进行设计,当阀门遥控系统处于自 动或遥控运行状态时,在中控控制台上可以控 制现场管线上的液压阀的开关状态,从而控制 相应管线内的流体的流向和流速。 为了控制和观察方便或者为了多位置来控 制系统,现在利用计算机技术,通过信号实时 采集与各种参数计算,在显示器上实时显示各 种阀门的运行状态、舱室的液位高度、四角吃 水等。

• 应急阀块

• 应急阀块采用一个阀对应一个应急阀块

• 接头

• 接头中间设置有虑片,能有效过滤管路中杂质, 防止电磁换向阀堵塞

阀门遥控系统

• 一 阀门遥控的基础知识 • 二 11万吨油轮阀门遥控系统简介 • 三

阀门遥控的基础知识

• 概述

• 阀门遥控装置是由控制台利用油压、气压、 电为动力对阀门的开启、动阀门遥控系统: 以0.5-0.7MPa的气源压力为动力,通过控 制台手动开关控制电磁阀换向相应的开、 闭阀管路,由驱动器驱动阀门进行开、闭 动作

控制台的其他主要功能: 液货舱污油舱液位遥测 液货舱与污油舱高位与高高位声光报警 压载舱液位测量 四角吃水测量 液货舱与污油舱温度显示与高温声光报警 货油泵、扫舱泵与压载泵进出口压力检测装置 专用压载泵、泵舱风机和扫舱泵起停、和闸按 钮及电源指示、运行指示 其他根据船东特殊要求安装的设备

液压站

• 动力泵站是整个系统的动力源,为阀门开 闭提供充足的动力。泵站安装两套互为备 用的泵-电动机组和其他必要的液压元件 及电控箱。液压元件包括液压滤器、溢流 阀、泻放阀、压力继电器组、压力表、压 力传感器、液位计等。

电磁阀箱

• 电磁阀箱包括了阀块组、电磁换向阀、压 力表、应急阀块、截止阀、快速接头、压 力开关、开度指示等。通过电磁阀改变油 路方向,达到启闭阀门的目的。应急操作 时,手摇泵站上的快速接头与应急阀块上 的快速接头对接,对每一只阀门进行应急 操作。

• 开度指示器

• 利用液压马达和等效容积原理,反映阀门的状态

• 电动阀门遥控 以液压为动力,通过控制台开关,控制电 液式驱动器电机正反转;使驱动器液压泵 将正向或反向的液压动力提供给开、闭油 路进行开、闭阀

11万吨油轮所采用的就所液压阀门遥控系统

• 液压阀门遥控系统是利用油压作为动力驱 动阀门,控制方式通常采用集中式,在控 制站处通过模拟板或计算机发出动作指令, 由安装于现场的执行机构来执行,最后将 位置信号反馈至控制站。这种控制系统可 以方便快捷的控制远程阀门并实时了解阀 门的状态。