20136fu261

瓦房店光达轴承制造有限公司2-3月份轧机库存

1 3 8 2 0,5 2 2 5 6 8 9

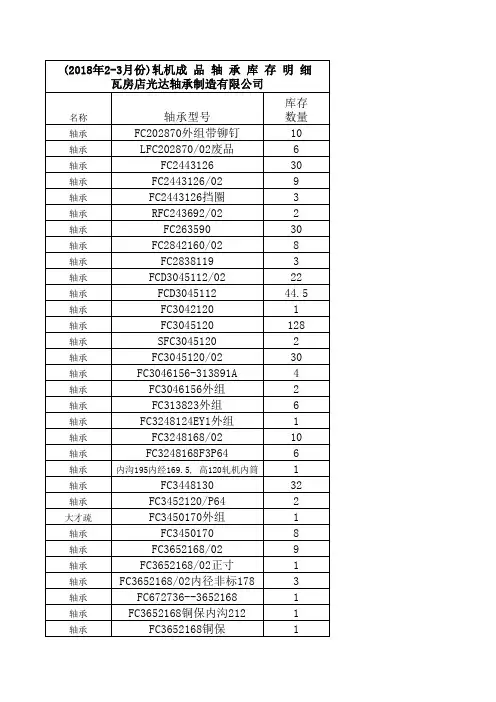

(2018年2-3月份)轧机成 品 轴 承 库 存 明 细 瓦房店光达轴承制造有限公司

名称 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承 轴承

轴承型号 FC202870外组带铆钉 LFC202870/02废品 FC2443126 FC2443126/02 FC2443126挡圈 RFC243692/02 FC263590 FC2842160/02 FC2838119 FCD3045112/02 FCD3045112 FC3042120 FC3045120 SFC3045120 FC3045120/02 FC3046156-313891A FC3046156外组 FC313823外组 FC3248124EY1外组 FC3248168/02 FC3248168F3P64

FC3652168铁保 SFC3652168铁保 FC3652168 FC3658192/02 FC3658192 FC3852168外组 FC3852168EY1外组 FC3854168外组内沟212 FC3854168/02 FC4056170外组 FC4056170 FC4056188内沟222 FC4056188/02内沟222 FC4058202 FC4058202外组 FC4058202/02 FC4058202M/P64 FC4054170外组 FC4054170 FC4054170/02 FC4056200 FC4056200/02 FC4058192 FC4260170外组 FC4260170 FC4460192 FC4460192/02 FC4462192外组 FC4462192/02间包 FCD4462192/02 FCDP4462192 FC4462225/02 SFCD4462225 FC4464210/02 FC4666206 FC4866220外组

ADP-101-G1 通用多功能保护测控装置技术和使用说明书

装置初始操作密码是 001。

序号 1

版本号 V1.00

文档修改摘要 第一版

修改日期 2012-11-05

目录

1 概述 .........................................................................................................................................1 1.1 应用范围 ..........................................................................................................................1 1.2 保护配置和功能 ..............................................................................................................1 1.2.1 保护配置 ...................................................................................................................1 1.2.2 测控功能 ...................................................................................................................1 1.2.3 保护信息功能 ...........................................................................................................1 1.3 性能特征 ..........................................................................................................................2

219322933_新型硼烷偶联剂B-69在商用车轮胎低滚动阻力胎面胶中的应用研究

新型硼烷偶联剂B-69在商用车轮胎低滚动阻力胎面胶中的应用研究陈建军1,薛彬彬1,孙保泉2,李培生1,倪海超1,张 鸣1[1.山东华盛橡胶有限公司,山东东营257300;2.启润轮胎(德州)有限公司,山东德州253699]摘要:研究新型硼烷偶联剂B-69在商用车轮胎低滚动阻力胎面胶中的应用。

结果表明:与硅烷偶联剂TESPT胶料相比,用硼烷偶联剂B-69替代50%硅烷偶联剂TESPT且配方微调后的胶料加工性能和物理性能改善,抗切割性能、耐磨性能、耐热老化性能和耐臭氧老化性能提高,生热和滚动阻力降低;成品轮胎耐久性能满足国家标准要求,滚动阻力更低,且生产成本降低。

关键词:硼烷偶联剂;硅烷偶联剂;胎面胶;抗切割性能;耐磨性能;滚动阻力;成本中图分类号:TQ330.38+7;TQ336.1 文章编号:2095-5448(2023)06-0277-05文献标志码:A DOI:10.12137/j.issn.2095-5448.2023.06.0277基金项目:山东省重点研发计划/重大科技创新工程项目(2020CXGC010312)作者简介:陈建军(1977—),男,重庆人,山东华盛橡胶有限公司高级工程师,学士,主要从事轮胎配方设计与研发管理工作。

E-mail :19468815@ OSID开放科学标识码 (扫码与作者交流)20世纪90年代初,由米其林公司率先提出“绿色轮胎”概念到全填充白炭黑“绿色轮胎”的成功研制,白炭黑作为橡胶工业有效的环保材料逐渐应用推广[1-4]。

白炭黑用于胎面胶中可以有效降低滚动阻力,但白炭黑表面含有大量羟基,易团聚、不易分散。

为改善该问题,轮胎企业采用硅烷偶联剂对白炭黑表面改性,以提高白炭黑的分散性,改善白炭黑胶料的加工性能和物理性能[5-7]。

硅烷偶联剂TESPT是一种由双-[3-(三乙氧基硅)丙基]-四硫化物与炭黑混合的有机硅化合物,含4个硫键。

为保证在胶料混炼过程中硅烷偶联剂TESPT的乙氧基与白炭黑的硅醇基发生有效的硅烷化反应,混炼温度一般应控制在不低于150 ℃。

诺基亚电动自行车 Electropak 技术数据说明书

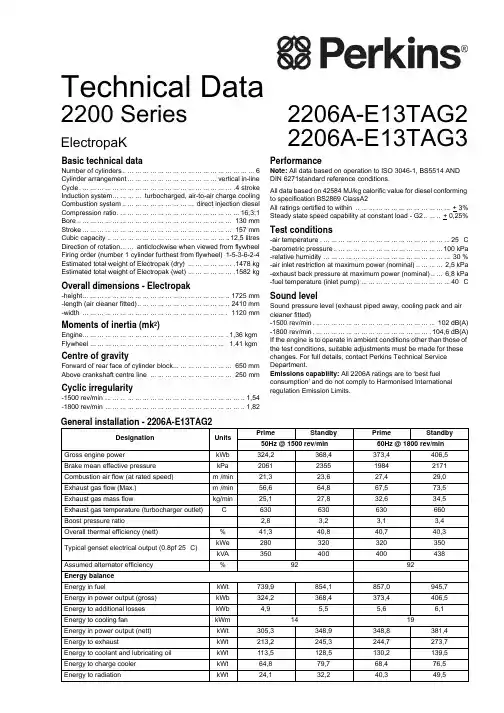

Technical DataBasic technical dataNumber of cylinders.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6 Cylinder arrangement... ... ... ... ... ... ... ... ... ... ... ...vertical in-line Cycle. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .4 stroke Induction system... ... ... ... turbocharged, air-to-air charge cooling Combustion system.. ... ... ... ... ... ... ... ... ... direct injection diesel Compression ratio. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...16,3:1Bore.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 130 mm Stroke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 157 mm Cubic capacity .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..12,5 litres Direction of rotation... ... anticlockwise when viewed from flywheel Firing order (number 1 cylinder furthest from flywheel)1-5-3-6-2-4Estimated total weight of Electropak (dry) ... ... ... ... ... ... .1478 kg Estimated total weight of Electropak (wet) ... ... ... ... ... ... .1582 kgOverall dimensions - Electropak-height... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1725 mm -length (air cleaner fitted).. ... ... ... ... ... ... ... ... ... ... ... ..2410 mm -width ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 1120 mmMoments of inertia (mk²)Engine... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .1,36 kgm²Flywheel ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1.41 kgm²Centre of gravityForward of rear face of cylinder block... ... ... ... ... ... ... ... 650 mm Above crankshaft centre line ... ... ... ... ... ... ... ... ... ... ... 250 mmCyclic irregularity-1500 rev/min ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,54-1800 rev/min ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..1,82PerformanceNote:All data based on operation to ISO 3046-1, BS5514 AND DIN 6271standard reference conditions.All data based on 42584 MJ/kg calorific value for diesel conforming to specification BS2869 ClassA2All ratings certified to within .. ... ... ... ... ... ... ... ... ... ... ... ... + 3%Steady state speed capability at constant load - G2.. ... .. + 0,25%Test conditions-air temperature . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...25 °C -barometric pressure.. ... ... ... ... ... ... ... ... ... ... ... ... ... ...100 kPa -relative humidity ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30 %-air inlet restriction at maximum power (nominal).. ... ... ... 2,5 kPa -exhaust back pressure at maximum power (nominal).. ... 6,8 kPa -fuel temperature (inlet pump) ... ... ... ... ... ... ... ... ... ... ... ...40 °CSound levelSound pressure level (exhaust piped away, cooling pack and air cleaner fitted)-1500 rev/min. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 102 dB(A)-1800 rev/min. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .104,6 dB(A)If the engine is to operate in ambient conditions other than those of the test conditions, suitable adjustments must be made for these changes. For full details, contact Perkins Technical Service Department.Emissions capability: All 2206A ratings are to ‘best fuel consumption’ and do not comply to Harmonised International regulation Emission Limits.General installation DesignationUnits Prime Standby Prime Standby 50Hz @ 1500 rev/min60Hz @ 1800 rev/minGross engine powerkWb 324,2368,4373,4406,5Brake mean effective pressure kPa 2061235519842171Combustion air flow (at rated speed)m³/min 21,323,627,429,0Exhaust gas flow (Max.)m³/min 56,664,867,573,5Exhaust gas mass flowkg/min 25,127,832,634,5Exhaust gas temperature (turbocharger outlet)°C630630630660Boost pressure ratio2,83,23,13,4Overall thermal efficiency (nett)%41,340,840,740,3Typical genset electrical output (0.8pf 25 °C)kWe 280320320350kVA 350400400438Assumed alternator efficiency %9292Energy balance Energy in fuelkWt 739,9854,1857,0945,7Energy in power output (gross)kWb 324,2368,4373,4406,5Energy to additional losses kWb 4,95,55,66,1Energy to cooling fan kWm 1419Energy in power output (nett)kWt 305,3348,9348,8381,4Energy to exhaustkWt 213,2245,3244,7273,7Energy to coolant and lubricating oil kWt 113,5128,5130,2139,5Energy to charge cooler kWt 64,879,768,476,5Energy to radiationkWt24,132,240,349,5 - 2206A-E13TAG22200 Series2206A-E13TAG2 2206A-E13TAG3ElectropaKGeneral installationDesignation Units Prime Standby Prime Standby50Hz @ 1500 rev/min60Hz @ 1800 rev/min Gross engine power kWb368,4412,5373,4406,5 Brake mean effective pressure kPa2344263719842171 Combustion air flow (at rated speed)m³/min24,326,427,429,0 Exhaust gas flow (Max.)m³/min64,672,567,573,5 Exhaust gas mass flow kg/min28,130,932,634,5 Exhaust gas temperature (turbocharger outlet)°C630630660660 Boost pressure ratio3,23,53,13,4 Overall thermal efficiency (nett)%41,440,940,740,3Typical genset electrical output (0.8pf 25 °C)kWe320360320350 kVA400450400438Assumed alternator efficiency%9292Energy balanceEnergy in fuel kWt842,6958,2857,0945,7 Energy in power output (gross)kWb368,4412,5373,4406,5 Energy to additional losses kWb5,56,25,66,1 Energy to cooling fan kWm1419Energy in power output (nett)kWt348,9392,3348,8381,4 Energy to exhaust kWt252,6290,4244,7273,7 Energy to coolant and lubricating oil kWt127,3139,9130,2139,5 Energy to charge cooler kWt60,375,568,476,5 Energy to radiation kWt34,039,840,349,6 - 2206A-E13TAG3Rating definitionsPrime powerVariable load. Unlimited hours usage with an average load factor of 70% of the published Prime Power rating over each 24 hour period.A 10% overload is available for 1 hour in every 12 hours of operationStandby powerVariable load. Limited to 500 hours annual usage up to 300 hours of which may be continuous running, No overload is permittedCooling systemRadiatorFace area . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...1,238 m²Number of rows and materials . ... ... ... ... ... ... .1rows, aluminium Matrix density and material .. ... ... ... ..12 fins per inch, aluminium Width of matrix . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 1048 mm Height of matrix ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 1100 mm Weight of radiator (dry). ... ... ... ... ... ... ... ... ... ... ... ... ... ..132 kg Pressure cap setting (min) ... ... ... ... ... ... ... ... ... ... ... ... ..70 kPa Charge coolerFace area.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...1,006 m²Number of rows and materials . ... ... ... ... ... ... .1rows, aluminium Matrix density and material .. ... ... ... ..12 fins per inch, aluminium Width of matrix . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 915 mm Height of matrix ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 1100 mm Coolant pumpSpeed @ 1500 rev/min. ... ... ... ... ... ... ... ... ... ... ... 2056 rev/min Speed @ 1800 rev/min. ... ... ... ... ... ... ... ... ... ... ... 2468 rev/min Drive method. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Gear FanDiameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 927 mm Drive ratio.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...0,92:1 Number of blades.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 9 Material. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .composite Type.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . pusher Cooling fan air flow @ 1500 rev/min. ... ... ... ... ... ... ...654 m³/min Cooling fan air flow @ 1800 rev/min. ... ... ... ... ... ... ...788 m³/min CoolantTotal system capacity ... ... ... ... ... ... ... ... ... ... ... ... ... . 51,4 litres Max. top tank temperature ... ... ... ... ... ... ... ... ... ... ... ... ..104 °C Temperature rise across engine... ... ... ... ... ... ... ... ... ... ... 10 °C Max. pressure in engine cooling circuit. ... ... ... ... ... ... ... ..70 kPa Max. permissible external system resistance ... ... ... ... ... ..30 kPa Max. static pressure head on pump.. ... ... ... ... ... ... ... ... ..30 kPa Coolant flow (min) against 30 kPa rstriction@ 1500 rev/min. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .5,3 litres/sec @ 1800 rev/min. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .6,7 litres/sec Thermostat operation range.. ... ... ... ... ... ... ... ... ... ... 87 to 98°C For details of recommended coolant specifications, refer to the Operation and Maintenance Manual for this engine model Duct allowanceDuct allowance 2206A-E13TAG2 - standbyMaximum additional retsriction (duct allowance) to cooling airflow and resultant minimum airflowEngine speedrev/minAmbient clear-ance inhibitedcoolant °CDuctallowancePam³/min 150059200563180059200716Duct allowance 2206A-E13TAG3 - standbyMaximum additional retsriction (duct allowance) to cooling airflow and resultant minimum airflowEngine speedrev/minAmbient clear-ance inhibitedcoolant °CDuctallowancePam³/min 150055200563180059200716Electrical system-type... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .24 Volt negative earth Alternator type ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .22SI -alternator voltage.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..24V -alternator output ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..70A Starter motor type.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...39MT -starter motor voltage. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..24V -starter motor power... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .7,8 kW Number of teeth on flywheel.. ... ... ... ... ... ... ... ... ... ... ... ... ..113 Number of teeth on starter pinion.. ... ... ... ... ... ... ... ... ... ... (11)Minimum cranking speed... ... ... ... ... ... ... ... ... ... ... 106 rev/min Starter solenoid maximum-pull-in current @ 0°C ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 200A -hold-in current @ 0°C... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..25A Cold start recommendations-5°C to -10°Coil... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..SAE grade 15W40 Starter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...42MT Battery ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24 volts Max. breakaway current. ... ... ... ... ... ... ... ... ... ... ... ..1311 amps Cranking current ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 588 amps Starting aids (ECM controlled)... ... ... ... ... ... ... ... ... ... ... ... none Min. mean cranking speed. ... ... ... ... ... ... ... ... ... ... .106 rev/min -11°C to -25°Coil... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... SAE grade 5W40 Starter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...42MT Battery ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24 volts Max. breakaway current. ... ... ... ... ... ... ... ... ... ... ... ..1585 amps Cranking current ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 828 amps Starting aids (ECM controlled)... block heater 1,5kW (110V/240V) Min. mean cranking speed. ... ... ... ... ... ... ... ... ... ... .106 rev/min Notes:z Battery capacity is defined by the 20 hour ratez The oil specification should be for the minimum ambient temperature as the oil will not be warmed by the immersion heaterz Breakaway current is dependent on the battery capacity available. Cables should capable of handling transient current twice that of cranking current.Exhaust systemMaximum back pressure-1800 rev/min . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .10,0 kPa Exhaust outlet, internal diameter. ... ... ... ... ... ... ... ... ... . 123 mm Fuel systemInjection system... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..MEUI Injector type. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..MEUI Governor type.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... electronic Governing conforms to ... ... ... ... ... ... ... ... .ISO 8528-5 Class G2 Injector pressure.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .207 MPa Fuel lift pump-lift pump type.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .gear driven -lift pump delivery @1500 rev/min... ... ... ... ... ... ... 480 litres/hour -lift pump delivery @1800 rev/min... ... ... ... ... ... ... 600 litres/hour -lift pump delivery pressure. ... ... ... ... ... ... ... ... ... ... ... ..621 kPa -max. suction head at pump inlet ... ... ... ... ... ... ... ... ... ... ... .3 m -max. static pressure head.. ... ... ... ... ... ... ... ... ... ... ... ... ... .4 m -max. fuel inlet temperature. ... ... ... ... ... ... ... ... ... ... ... ... ..55 °C -fuel filter spacing primary... ... ... ... ... ... ... ... ... ... ... .10 microns -fuel filter spacing secondary... ... ... ... ... ... ... ... ... ... ...2 microns Fuel specificationBS2869 Class A2 or BSEN590ASTM D975 Class 1D and class 2DNote:For further information on fuel specifications and restrictions, refer to the OMM, “Fluid Recommendations” for this engine model. Induction systemMaximum air intake restriction-clean filter... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...2,5 kPa -dirty filter. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...6,4 kPa -air filter type ... ... ... ... ... ... ... . paper element - 15 inch diameterLubrication systemMaximum total system oil capacity ... ... ... ... ... ... ... ... ... .40 litres Minimum oil capacity in sump... ... ... ... ... ... ... ... ... ... ..32,5 litres Maximum oil capacity in sump.. ... ... ... ... ... ... ... ... ... ... .38 litres Maximum engine operating angles -front up, front down, right side, left side ... ... ... ... ... ... ... ... ... 7 °Lubricating oil-oil flow @ 1500 rev/min... ... ... ... ... ... ... ... ... ... ... 140 litres/min -oil flow @ 1800 rev/min... ... ... ... ... ... ... ... ... ... ... 172 litres/min -oil pressure at bearings @ 1500 rev/min. ... ... ... ... ... ... 310 kPa -oil pressure at bearings @ 1800 rev/min. ... ... ... ... ... ... 358 kPa -oil pressure at bearings (min).. ... ... ... ... ... ... ... ... ... ... 270 kPa -oil temperature (continuous operation) ... ... ... ... ... ... ... ..113 °C -oil consumption at full load as a % of fuel consumption.. ...0.15% Oil filter screen spacing. ... ... ... ... ... ... ... ... ... ... ... ... 30 microns Oil consumption as % of fuel consumption... ... ... ... ... ... ... ... 0,1 Sump drain plug tapping... ... ... ... ... ... ... ... ... ... ... ... .1 1/8 UNF Lubricating oil specification... ... ... ... ... ... API-CH4 - SAE15W-40 Recommended SAE viscosityEngine Oil ViscosityEMA LRG-1API CH-4 Viscosity GradeAmbient Temperature Minimum MaximumSAE 0W20-40 °C10 °CSAE 0W30-40 °C30 °CSAE 0W40-40 °C40 °CSAE 5W30-30 °C30 °CSAE 5W40-30 °C40 °CSAE 10W30-20 °C40 °CSAE 15W40-10 °C50 °C MountingsMaximum static bending moment at rear face of block. ...1356 Nm Fuel consumption2206A-E13TAG2 - 1500 rev/minLoad g/kWhr l/hr Standby19580 110% Prime power19577 100% Prime power19671 75% of Prime power19854 50% of Prime power203372206A-E13TAG3 - 1500 rev/minLoad g/kWhr l/hr Standby19490 110% Prime power19689 100% Prime power19781 75% of Prime power19962 50% of Prime power202422206A-E13TAG2 - 1800 rev/minLoad g/kWhr l/hr Standby19387 110% Prime power19588 100% Prime power19681 75% of Prime power19962 50% of Prime power205432206A-E13TAG3 - 1800 rev/minLoad g/kWhr l/hr Standby19387 110% Prime power19588 100% Prime power19681 75% of Prime power19962 50% of Prime power20543All fuel consumption figures are based on Nett powerAll information in the document is substantially correct at the time of printing but may be subsequently altered by the company.Distributed by2200 Series2206A-E13TAG22206A-E13TAG3Load acceptance TAG2 (cold) Initial load application: When engine reaches rated speed(15 seconds maximum after engine starts to crank)DescriptorUnits 50 Hz 60Hz % of prime power %6680Load (nett)kWm 184,8256Transient frequency deviation%<10<10Frequency recoverySeconds55Second load application: When engine reaches rated speed(5 seconds after initial load application)DescriptorUnits 50 Hz 60Hz % of prime power %7385Load (nett)kWm 204,4272Transient frequency deviation%<10<10Frequency recoverySeconds55TAG3 (cold) Initial load application: When engine reaches rated speed(15 seconds maximum after engine starts to crank)DescriptorUnits 50 Hz 60Hz % of prime power %5880Load (nett)kWm 185,6256Transient frequency deviation%<10<10Frequency recoverySeconds55Second load application: When engine reaches rated speed(5 seconds after initial load application)DescriptorUnits 50 Hz 60Hz % of prime power %6585Load (nett)kWm 208272Transient frequency deviation%<10<10Frequency recoverySeconds55The information shown above complies with the requirements of classification 3 and 4 of ISO 8528-12 and G2 operating limits stated in ISO 8528-5The above figures were obtained under the following test conditions:-minimum engine block temperature.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 45 °C -ambient temperature. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..15 °C -governing mode ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... isochronous -alternator efficiency... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 92%-alternator inertia ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6,9 kgm²-under frequency roll off (UFRO) point set to. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1 Hz below rated -UFRO rate set to... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2% voltage / 1% frequency LAM on/off.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...off All tests were conducted using an engine which was installed and serviced to Perkins Engines Company Limited recommendations.Note:The general arrangement drawings shown in this data sheet are for guidance only. For installation purposes, latest versions should be requested from the Applications Dept., Perkins Engines Stafford, ST16 3UB United Kingdom.P u b l i c a t i o n N o . T P D 1687E 2. O c t o b e r 2008 P e r k i n s E n g i n e s C o m p a n y L i m i t e dPerkins Engines Company LimitedPeterborough PE1 5NA United Kingdom Telephone +44 (0) 1733 583000Fax +44 (0) 1733 。

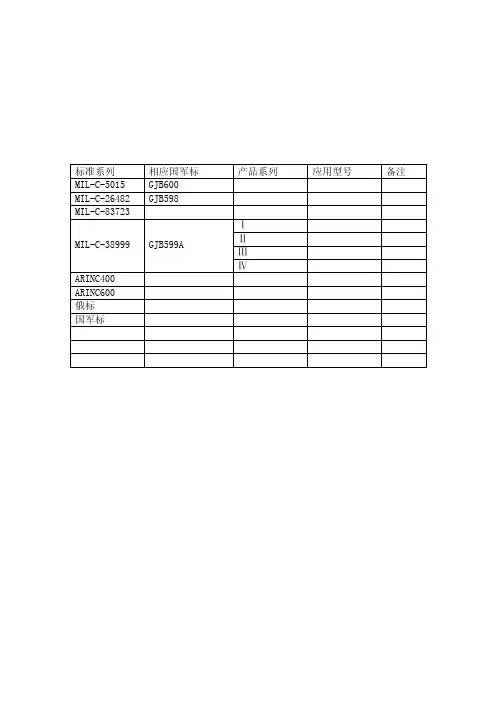

航空电连接器

文案编辑词条B 添加义项?文案,原指放书的桌子,后来指在桌子上写字的人。

现在指的是公司或企业中从事文字工作的职位,就是以文字来表现已经制定的创意策略。

文案它不同于设计师用画面或其他手段的表现手法,它是一个与广告创意先后相继的表现的过程、发展的过程、深化的过程,多存在于广告公司,企业宣传,新闻策划等。

基本信息中文名称文案外文名称Copy目录1发展历程2主要工作3分类构成4基本要求5工作范围6文案写法7实际应用折叠编辑本段发展历程汉字"文案"(wén àn)是指古代官衙中掌管档案、负责起草文书的幕友,亦指官署中的公文、书信等;在现代,文案的称呼主要用在商业领域,其意义与中国古代所说的文案是有区别的。

在中国古代,文案亦作" 文按"。

公文案卷。

《北堂书钞》卷六八引《汉杂事》:"先是公府掾多不视事,但以文案为务。

"《晋书·桓温传》:"机务不可停废,常行文按宜为限日。

" 唐戴叔伦《答崔载华》诗:"文案日成堆,愁眉拽不开。

"《资治通鉴·晋孝武帝太元十四年》:"诸曹皆得良吏以掌文按。

"《花月痕》第五一回:" 荷生觉得自己是替他掌文案。

"旧时衙门里草拟文牍、掌管档案的幕僚,其地位比一般属吏高。

《老残游记》第四回:"像你老这样抚台央出文案老爷来请进去谈谈,这面子有多大!"夏衍《秋瑾传》序幕:"将这阮财富带回衙门去,要文案给他补一份状子。

"文案音译文案英文:copywriter、copy、copywriting文案拼音:wén àn现代文案的概念:文案来源于广告行业,是"广告文案"的简称,由copy writer翻译而来。

多指以语辞进行广告信息内容表现的形式,有广义和狭义之分,广义的广告文案包括标题、正文、口号的撰写和对广告形象的选择搭配;狭义的广告文案包括标题、正文、口号的撰写。

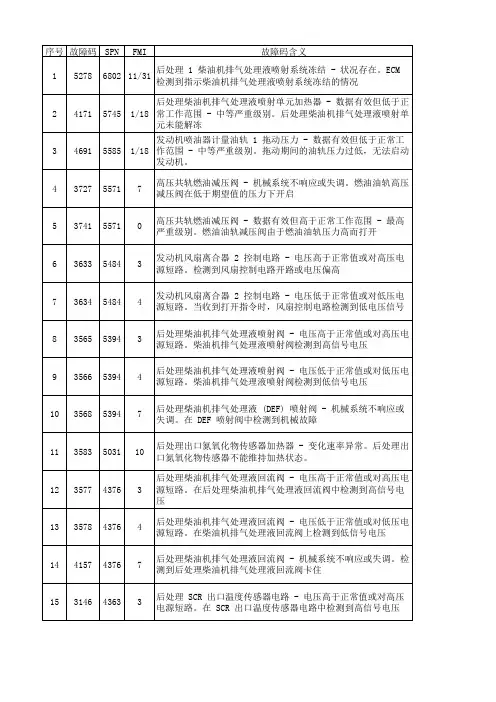

福康故障代码中文版

后处理 1 SCR 喷射空气辅助绝对压力传感器 - 电压低于正常 27 4173 4335 4 值或对低压电源短路。后处理 SCR 喷射空气辅助压力传感器电

路中检测到低信号电压

后处理 1 SCR 喷射空气辅助绝对压力 - 数据有效但低于正常 28 4238 4335 1/18 工作范围 - 中等严重级别。喷射单元中检测到低喷射空气辅助

11

3583 5031

10

后处理出口氮氧化物传感器加热器 - 变化速率异常。后处理出 口氮氧化物传感器不能维持加热状态。

后处理柴油机排气处理液回流阀 - 电压高于正常值或对高压电 12 3577 4376 3 源短路。在后处理柴油机排气处理液回流阀中检测到高信号电

压

13

3578 4376

4

后处理柴油机排气处理液回流阀 - 电压低于正常值或对低压电 源短路。在柴油机排气处理液回流阀上检测到低信号电压

后处理 1 SCR 喷射空气辅助阀 - 机械系统不响应或失调。当 25 4271 4336 7 喷射空气辅助阀断开时,柴油机排气处理液喷射单元内检测到

高喷射空气辅助压力。

后处理 1 SCR 喷射空气辅助绝对压力传感器 - 电压高于正常 26 4172 4335 3 值或对高压电源短路。后处理 SCR 喷射空气辅助压力传感器电

序号 故障码 SPN FMI

故障码含义

1

5278

6802

11/31

后处理 1 柴油机排气处理液喷射系统冻结 - 状况存在。ECM 检测到指示柴油机排气处理液喷射系统冻结的情况

后处理柴油机排气处理液喷射单元加热器 - 数据有效但低于正 2 4171 5745 1/18 常工作范围 - 中等严重级别。后处理柴油机排气处理液喷射单

雨润商品资料查询

商品条码商品编码商品名称商品简称商品类别类别名称65165669186雨润奥尔良烤鸡雨润奥尔良烤鸡62010301烧烤类80117722108雨润奥尔良烤鸡雨润奥尔良烤鸡62010303卤味80136722269雨润黑椒烤鸡雨润黑椒烤鸡62010303卤味80138722271雨润奥尔良烤鸡雨润奥尔良烤鸡62010301烧烤类80140722273雨润奥尔良烤鸡腿雨润奥尔良烤鸡腿62010301烧烤类80141722274雨润奥尔良烤鸡翅雨润奥尔良烤鸡翅62010301烧烤类80146722286雨润奥尔良烤鸭雨润奥尔良烤鸭62010301烧烤类22214950000011090808雨润普罗旺斯烤鸭腿雨润普罗旺斯烤鸭腿62010301烧烤类121131马鞍山雨润食品有限公司区域标识商品品牌品牌名称经营类型编码类型价格档销项税率价格因子当前合同最低进价银座1424雨润联营称重码未知17110银座1424雨润联营称重码未知17100 2.5944银座1424雨润联营称重码未知17113.912银座1424雨润联营称重码未知17112.972银座1424雨润联营称重码未知171 6.392银座1424雨润联营称重码未知171 4.512银座1424雨润联营称重码未知17118.612银座1424雨润联营称重码未知1711建档进价毛利率建档售价商品类型开始日期结束日期基本码类型季节因素销售规格销售单位12.9720.0613.8普通商品正常123456789ABC只只2.59440.06 2.76普通商品正常123456789ABC100g100g13.9120.0614.8普通商品正常123456789ABC只只12.9720.0613.8普通商品正常123456789ABC只只6.3920.06 6.8普通商品正常123456789ABC只只4.5120.06 4.8普通商品正常123456789ABC只只23.3120.0624.8普通商品正常123456789ABC只只186.117.2普通商品正常123456789ABC280-350g只原料成分商品产地入库预留天数出库预留天数SKU规格深SKU规格宽SKU规格高保质期山东滕州01112山东济南01111山东济南01111山东济南01111山东济南01111山东济南01111山东济南01111安徽马鞍山0000030最低储存温度最高储存温度建档时间试销期试销金额试销数量实际销售数量特殊码编码特价码编码152804-16-2010152806-28-2008152806-30-2008152806-30-2008152806-30-2008152806-30-2008152806-30-2008152807-28-2011。

中国人民解放军联勤保障部队第九二五医院直接挂网议价结果

常用低价药 血液制品

国基药 非基药

化学药

盐酸地尔硫

G014934

卓片

化学药 G004942 人血白蛋白

74 第925医院 YJ012029 75 第925医院 YJ012030 76 第925医院 YJ012031

5145 5217 5217

采购金额占比 低于80%的药

品

常用低价药

非基药 国基药

常用低价药 国基药

品

6 第925医院 YJ011924

7 第925医院 YJ011925

8 第925医院 YJ011927 9 第925医院 YJ011928 10 第925医院 YJ011929 11 第925医院 YJ011930

383

采购金额占比 低于80%的药 非基药

品

化学药

盐酸奥洛他 G031127 定滴眼液

急(抢)救药 品

非基药

常用低价药 省基药

中成药 G025352 天麦消渴片

注射用两性 化学药 G019882 霉素B脂质

体

中成药 G026037 消肿止痛酊

中成药

蜜炼川贝枇

G010607

杷膏

中成药 G017102 化风丹

中成药 G027179 安胃止痛片

中成药 G011977 乳宁胶囊

中成药 G012195 津力达颗粒

化学药 G008366 氟哌啶醇片 马破伤风免

化学药 G001407 疫球蛋白 (F(ab’)2)

化学药 G002867 鲨肝醇片

3952 4513 4177 4177 4636

常用低价药

采购金额占比 低于80%的药

品 采购金额占比 低于80%的药

品 采购金额占比 低于80%的药

奥索凌阳方案适用屏编码和驱动对照

奥索凌阳方案适用屏编码和驱动对照奥索凌阳方案适用屏编码和驱动对照2011-10-4 08:27阅读(26)转载自风的味道2.8寸屏:5408B----FPCHL2401 07CV05408------H2801 FPCHL2401.14A SXD0017 2401QQ AO24QN029325------12N 17N 154000 SAT28S01A05 SXD0002 SAT24000 37H 12A05 2803 HW240320F-2L-0A-20 HJ2810AO-AOFPC 0000000024-0019325C----3225LS2088A SAT28009A05 DST280AU006 4N 88N V029325B----LS24XD 22N 17N9320------19E TS028HA 1N 07N 9N SR779028-AO DST28014L037 CMS21019331-----FTM280F17N 17E FTM280F6W 7N 6E FTM280F10E 7NV 8Q 8A18 21N FPC2802-VO TTPHJ07NVO1289-----JS28ND603C-FPC WST240320S280AV02 1298-----SK001V02 HL2802 36B 10N M30111A197 CMS2101-03A SX2.8C98-4_3-37C T28-A T28-B FPC4218-V0123225-----AU28 036 SXD0006 001 7C SAT2400 12A FPC2803-VO 28A03-VO 12A05 KK240037 0039-C 280NP04-04 3728E SX2.8T28-4_3-37H SXD0001PNL9328------T-0028-A61505V---LS28XD 21N 21E 07NVO A18 FPC1A0027-01-A SYM280T01-A093116----15400053909335IH----24008C18 0367781-----21VO 24N 11N 4N 10N 18V2 FPC-TTHJ07CVO CM012 81-36A 8B26 SY280CM0204535-----SXD00179331LG----Q365205----17V0 YSD FPC 28A03-V0 18V21505C----2.4TE8347-----46E FPC-FTM280C05N 61N 80E TP65K9320LG----SAT28008A18 8K1304 KFM529B21 SR7790928-A061505W----SAT28008A18-Q337502----16N 13N 16E 17E 13E 12N SXD00651297----SAT28009A1161505U-FTM----B21 FPA-SH9873-01A_56-PCB RO61505R(3062主控上用)S6D04M0----TF28001A68070-----NT4PTM3728B MHJ101V1 ZBH028GT-01 SXD00688347D-----ZBH028GT-06 FPC-FTM280C58W-008367-----ZBH028GT-02V18230----XY-2405-HSD10-V2 LC2803.1R61509----QXD028-1000-FB9328LG----07V9338-----91N TFT028E001 EY028CMIL-001-V029335LG----LS28003ILI9320----826709341-----T-280A03-B-16 YQ24TM41-36CLCM0154------2805-PR112-V22.4屏5408-----A024QN025408B----FPCHL2401 SAT24001005 NOATS-V019325-----FPC-S2 TM240320C1NFWCWC FP-29325C----25N3225----Q36 154002660 FTP240F17N FTP240F22N 8C 24N 25W V1 66N 3624A9328----SPT-024-0061298----SK001V02 10N M30111A1978347----FTP240C61N 46E 5N FTP240C65N 3624F 240C29N 240C09N M403A1079325B----22N LS24XD FPC-JTBJ05JUO1505C----XY-2.4TE-V161580----FTP240H25N FTO240HO 32N 04N 25N9335HY----AST24011C19 091110S61505BOE----AST24011C19L LS-100810背面7781----24N 11N 81-36A61505W----LS24Q35 24036095205----53F F240253F 17V09320----01-1D FPC-FTS240W01 JC T24-E T24-A29340----T24BDHJ71V1 240A28-A-16 40-36A 134 240A37-A FPC-FTM240C179N-00S6D04H0----36PIN SXD0066HX8230------LC32002.1 XY-2405 HSDIO-V34535------SXD00249341-----YQ24TM41-36C T-240A82-D-16261卡屏的屏驱动----32063.5寸ST2102----KR035PA5S VT320240S70-A350TMT035---15400T4500 HW320 158000300 S805037535C R0HS 3.5_FPC_10FTS350----735M2 SN570 FMFU-2F 413450017002 513450006002LQ035----8501显示屏编号与屏驱动对应表1 排线丝印侧面丝印驱动IC2 024-22V1 93203 24WIT36-FPC01 93204 1540001660 TS024HAADD04-00 5408B5 1540002660 9325C6 24008C05-V1 93257 AF240B-36B V1.0 AL240EI-3501 77878 AF-240B-2V4.1 AL-240B-S1 77879 AF283E1-37A V1.2 9320-2.810 AF240E1-36C V1.0 778511 AF240E1-36C V2.0 778512 AF283P3-37A V1.0 9325-2.813 CMS2101-03A 080815 080918-2801A背光片 540814 CMS2101-03A 080815 CMS2101 HCT003-280-41F背光片1298CMT304-1(1)-08 8 30 5408B15 CMS2101-3 932516 FPC-FTS240F01 FTS240H03 150517 FPC-FTS240D03 129818 FPC-FTS240D14 129819 FPC-FTP240CO9N FTS240B03 834720 FPC-FTS240W01 FTP240W47N 129821 FPC-FTM280P04N M30111A150 9325C-2.822 FPC-FTM280C05N 8347-2.823 FPC-FTM280F01N FTM280F01N-00 9320-2.824 FPC-FTM280F06W FPC-FTM280F06N-00 090313(背面)933125 FPC-FTM280F07N R61505-2.826 FPC-FTM280C13N 932527 FPC-FTM280P05N M403A486 9325C28 FPC-Y80032 V01 N0711-14-04 9325-2.829 FTP240D10N-01 0703 129830 FTP240D24N-00 090307 778131 FPC-FTP280P05N FTP280P14N-01背面 778132 FTP240W17N-03 080807 9325B33 FG0280FLW-0802-1 8347-2.834 FPC_HL_2401 540835 HL2801 5408-2.836 HL2402B 5408B CMO37 HL2402A 5409B CMO38 LDH240*320F08M 778539 LS2288A 6813-2.840 M30111A116 129841 M30111A059 932542 MFC-S07024 V02 834743 MT321TLLKJ-13 排线接口不同 9320B-2.844 SX-2.4CPT-9325 9325B45 SAT28009A5 9325C-2.846 STA28008A18 9331-2.847 XJ2402-V01 834748 XD028-V01 9325-2.849 XSY LL240-003-081024 R61505(2.4)50 ZCT-24FPC-S1 778551 ZCT-24FPC-S2 9325xp024cp25-36v0 9325hw240320f-0j-0c-10 9325m403a545 1298hw240400f-3a 5420ygg000240ns04-03 9325zc24t04m 9320kfm281e01 9320truly-c tft8k1081fpc-a1-e 9320cf024lgg31-36av1 9320huaruit-0033-a-fpc 9325huaruit-0012-b 9325af240B-36b 7787af-283e1-37av1.2 9320GIANTPLUS KFM281E01-1D 9320 GIANTPLUS KFM281E01-1B 9320CF024LGG31-36AV1 9320 GIANTPLUS KFM281101-1A 9320JLST24PV25-36A 9325ZC24T02 9325DST280CPT003 9325 2.8寸 13SX-2.8CPT-932502 9325 2.8寸 13BX280V003(B0XIANTICH) 9325 2.8寸 13NT4SGP3T28A 5408B 2.8寸 10NT4SGP3T28A AU9325 2.8寸 17NT4PC36728A-BL AU9325 2.8寸 17FPC-TGG000280NP04-07 9325 2.8寸 24LEB-DO428000028C1 9325 2.8寸 24CMS210-03 9325 2.8寸 12HW240320F-2D-0B-10 9325 2.8寸 12HW240320F-2D-0B-20 9325 触摸 13SAT28009A05 9325 2.8寸 13LS2288A 9325 2.8寸 13LS2289A 1505 2.8C寸 9LS2288A 9328 2.8寸 13FPC-FTP280P04N-00 9325 2.8C寸 13FPC-FTM280F0TN-00 61505 2.8寸 27FPC-FTPM280F09N-01、FTM240D17N-00 61505 2.8寸 27 FPC-FTM280F06W-00(FTM280F06N-00) 9331 2.8寸 32NTSAU3624A 5408B 2.4寸 10NT4SHY3624A 3225+HY 2.4寸 35024HAADD04 9325 2.4寸 13FPC-T240BQC 9325 2.4寸 13AF240E3-36D 9325 2.4寸 13(AL240E1-3S01) 9325 2.4寸SX-TGS240STCPYB00-00 7785 2.4寸 15(TGS240STCP-8V1,LDH240X320F008M)SX-2.4CPT-9325 9325 2.4寸 18(SX-TGS2.4CPT)FPC-FTS240D03-02 1298 2.4寸 6(FTP240D10N-02) 9325 2.4寸 13SX-TGS24C98-4:3-36B 1298 2.4寸 6FPC-BKS2401 1298 2.4寸 6SAT24009C05 9325 2.4寸 13SAT24009C05L 9325 2.4寸 13(18)KTM377A01-1A 1298 2.4寸 6SAT24009C05 9325 2.4寸 13TGG000240NS04-03 9325 2.4寸 18(13)(LCM-TGG000240NS04-03)FPC-TTHJ05E00XA 9325 2.4寸 27 (FECHTKONCPT24-9325)24008CIT-Q29 1505 2.4寸 37 1540003250(FMARK) 9325 2.4寸 26 T-0033-B(HUARUI) 9325 2.4寸 26T-0053-A 1297 2.4寸 30T-0033-B 68B(CPT) 2.4寸 26T-0012-B(T-0024-A) 9325 2.4寸 18 (T-0059-A)T-0028-A(HUARUI) 9325 2.8寸2X-GT009BL 7783 2.4寸 25JLST24IH81-36A 7781 2.4寸 25JST24TM25-36A 9328 2.4寸 13SX24C98-413-36B 1298 2.4寸 6(SX-TGS240SDCPET00-00)CF024LCD87-36AVO 7787 2.4寸 4AF240B-36B V1.0 7787 2.4寸 4凌达所有屏 9320 1T-0030 9320 2.4寸 1KT240FC-003B 9320 2.4寸 1FPC-FTS240W01 9320 2.4寸 1FPC1032 9320 2.4寸 124WIT36-FPC01 9320 2.4寸 1FPC-FTS240F01 1505 2.4寸PF240320F-2C-OA-30 8347 2.4寸FPC24T49-A1 9325 2.4寸FPC-TGG000280NP04-07 9325 2.8寸TSA24002C05 9325 2.4寸ST24TM25-36A V1.0 9325 2.4寸FPC-0047A2 9320 2.4寸排线丝印侧面丝印驱动ICAF240B-36B V1.0 :AL240EI-3501 7787AF-240B-2V4.1 : AL-240B-S1 7787AF283E1-37A V1.2 9320-2.8AF240E1-36C V1.0 7785AF240E1-36C V2.0 7785AF283P3-37A V1.0 9325-2.8FPC-FTS240F01 FTS240H03 1505FPC-FTS240D03 1298FPC-FTS240D14 1298FPC-FTP240CO9N FTS240B03 8347FPC-FTM280C05N 8347-2.8FPC-FTM280F01N FTM280F01N-00 9320-2.8 FPC-Y80032 V01 N0711-14-04 9325-2.8 FTP240D10N-01 0703 1298FTP240W17N-03 080807 9325BJLST24PV25-36A V1.0 9325T-0033-B 9325024-22V1 9320FPC_HL_2401 5408HL2801 5408-2.8MFC-S07024 V02 8347MFC-S07001 V04 932024WIT36-FPC01 9320MFC-M240702-A 9320XJ2402-V01 8347XD028-V01 9325-2.8ZCT-24FPC-S1 7785ZCT-24FPC-S2 9325LDH240*320F08M 77851540001660 TS024HAADD04-00 5408B1540002660 9325C24008C05-V1 9325MT321TLLKJ-13 排线接口不同 9320B-2.8SX-2.4CPT-9325 9325BCMS2101-3 9325CMS2101-03A 080815 080918-2801A背光片 540834 M30111A116 1298HW240320F-oj-oc-10 9325FPC24T49-A1 9325ZCT-24FPC-S2 9325NOAIS NT4SAU3624A V01 5408CMS057-2 @ HX(8347)T028 0741Z HL240HYF 0803 7787Hantech HR24F11#02 7787JYD-G5060 GWIL36S03240A-A恻边号GXBL240-019LL240-003 08031141 9325FPC-Y80030 V01 恻边号yxd02436l09 je-c068(b) 9320FPC-Y80030 V01 9320M30111A055 8347M403A107 8347DM2432003-001 这个是2.8的,37线,驱动9320FPC24T49-A1 2.4 9325AF240E1-36B V2.0 7785FPC-Q90044-1 2.8 9325QD -24034Bo-1 2.4 9325NOAIS NT4SAU36 24A V01JLST24CP25-36A 2.4 9325板号:MP-763C-SL V1.1 2005.12.16上位屏CM50011ACT6-01AL 2006/03/06 20针1.5寸元件排列:由上到下整齐一行:C11-C7-C5-C12-R1-R2-C1-C6-C2-C3-C21-C22-C23-C31-C4-C0-D1可代换下位屏:CD50006ACT6-27PIN 2005/10/24 27针元件排列:由上到下整齐一行:RL-CVLCD-CVB0A-CVB1A(这是个利用同尺寸不同针数进行的代换)板号:SD008-V2 2006-07-25-MDLU (ROCKCHIPS 2606A)原屏:CMT027 V1.0 2006-08-09 29针可用屏:FPC-S95012-1 V01 SZSUCCESS 06.01 29针板号:JR040_MAIN_V3.1 2007.04.17 (2608a JXD858)原屏:TFT-2.4-S3D 36PIN IL9320可用屏:DZX2.4-S2 V06 (2608A JXD859)资源:GAUO GASP29P03200-002-A-FPC SA VER 1.3(即屏侧边的标记)板号:SG243 V2 0703140941P2原屏:GIANTPLUS KFM281E01-1D可用:CF024LGG31-36AV1(36P,2.4')可用:GIANTPLUS KFM281E01-1B可用:TRULY-C TFT8K1081FPC-A1-E适用机型:纽曼K8 (2.0版)-ANYKA-AK3225。

各种导线、导体电缆允许载流量表

注:表中系铝芯电缆数值;铜芯电缆的允许持续载流量值可乘以1.29。

2、6KV三芯电力电缆直埋敷设时允许载流量(引用电网改造常用标准汇编)注:表中系铝芯电缆数值;铜芯电缆的允许持续载流量值可乘以1.29。

3、10KV三芯电力电缆允许载流量(引用电网改造常用标准汇编)注:表中系铝芯电缆数值;铜芯电缆的允许持续载流量值可乘以1.29。

4、敷设条件不同时电缆允许持续载流量的校正系数(引用电网改造常用标准汇编)注:其他环境温度下载流量的校正系数K可按下式计算:不同土壤热阻系数时电缆载流量的校正系数注:1、本表适用于缺乏实测土壤热阻系数时的粗略分类,对110KV及以上电压电缆线路工程,宜以实测方式确定土壤热阻系数。

2、本表中校正系数适于各表中采取土壤热阻系数为1.2C・m/W的情况,不适用于三相交流系统的高压单芯电缆。

二、单芯电缆允许载流量(2)扁平型排列(相邻间距等于电缆外径)(XLPE绝缘)不同环境下载流量较正系数三、钢芯铝绞线的长期允许载流量(引用电网改造常用标准汇编)1974年我国曾制定了钢芯铝绞线国家标准,按此标准生产了各种规格的导线。

1983年我国又修订颁布了新的铝绞线及钢芯铝绞线国家标准(GB—1179—83)。

新标准的导线规格较老标准多(即铝钢比的范围大),导电性能较好(采用电工铝),制造工艺及机械强度亦较高,目前已有部分制造厂生产供应,但由于老标准产品价格较低,制造工艺及材质要求较易达到,故仍大量生产使用。

上海电缆研究所迄未正式提供新老标准各种规程钢芯铝绞线的长期允许载流量,现将经过计算得出的载流量数据列于附表1及附表2参考使用。

标称葡{mm2)i血积计算栽流鹹(A)+90 +70+8011V26678 8716/385 10011325/4HI131 14935/6134158 18050/8161191 21850/3()E6619521871V1U23226670/4019623025795/15252 3(X)35195/20 233 27731995/55230 270301120/7287 35()401120/20 285S4H399120/25265315365120/7025830] 365150/8323 3954M150/20326 4004^1150/25331407469150/35331 407 469185/10 372 1458 528185/25 379 468540185/30 373460531185/45 379 4695412W10 397 49()565210/25 4055015792W35 409507586210/50 405075S6注:最高允许温度分+70°C、+80°C、+90°C三种。