Atometal产品介绍手册

立亚化学产品手册

立亚化学产品手册立亚化学成立于2005年,是一家专业从事化学产品研发、生产和销售的企业。

在过去的几年里,立亚化学不断致力于推动科学创新和满足客户需求,以成为全球领先的化学品供应商为目标。

立亚化学产品手册分为三个主要部分:有机化工产品、无机化工产品和特种化工产品。

以下是产品手册的详细介绍:一、有机化工产品:1.有机溶剂:立亚化学提供各种有机溶剂,如乙醇、苯、甲醇等,广泛应用于化学实验室、医药制造和涂料工业等领域。

2.有机酸:我们提供多种有机酸,如乙酸、苯甲酸和柠檬酸等,用于染料、塑料和药品制造。

3.有机酯:立亚化学生产多种有机酯,例如乙酸乙酯、苯酸乙酯,用于香精、颜料和塑料等行业。

二、无机化工产品:1.碱类化学品:我们提供各种碱类化学品,如氢氧化钠、氢氧化铝等,广泛应用于制造肥料、玻璃和洗涤剂。

2.酸类化学品:立亚化学提供多种酸类化学品,如盐酸、硫酸和硝酸等,用于金属加工、陶瓷和玻璃工业等。

三、特种化工产品:1.表面活性剂:我们提供多种表面活性剂,如十二烷基苯磺酸钠、十二烷基硫酸钠等,用于制造洗涤剂和清洁剂。

2.助剂:立亚化学还生产各种特种助剂,如漂白剂、催化剂和固化剂等,用于改善产品性能和化学反应速率。

立亚化学的产品具有高纯度、稳定性和可靠性,得到了广大客户的认可与赞誉。

我们以严格的质量控制和标准化流程来确保产品的优良品质。

此外,我们还拥有一支专业的研发团队,不断探索创新技术并满足客户的不同需求。

在未来,立亚化学将继续秉持“诚信、品质、创新”的核心价值观,不断提升产品质量和服务水平。

我们将努力成为环保型和可持续发展化学行业的领导者,为客户创造更高的价值。

感谢您选择立亚化学的产品手册。

如需更多信息和详细资料,请联系我们的销售团队或访问我们的官方网站。

我们期待与您的合作!。

悦尔电子烟说明书

ALT E-Cigarette Instructions 悦尔电子香烟用户手册www.altecig 品味健康生活,从这里开始!Enjoy Healthy Lifestyle, Start Here!目录User Guide包装清单Contents of ALT pack 07 产品概述Introduction 11产品介绍Components 12使用指导Getting started 16操作指南Operating instructions 17充电指南Direction for charging battery 18注意事项Cautionary notes 21疑难排除Troubleshooting 23您已向更加健康的生活方式迈进了积极的一步,为您及您身边的人。

If you are already a smoker, you’ve just taken a positive first step on the road to a healthier lifestyle, not only for yourself but for those around you.注意:尼古丁使人上瘾,请慎重选择。

Nicotine is highly addictive. If you don't already smoke or use nicotine we strongly recommend you not to start with ALT .感谢您选择了悦尔电子烟!Congratulations on choosing ALT!包装配置Your ALT pack contains*Please check the model what you choose 请根据你所选择的型号进行核对尊享系列 ALT ⏹悦尔Luxury Series悦尔电子烟ALT e-cigarette备用电池Extra battery烟弹Pack of refill cartridges⏹ 悦尔尊享系列 ALT Luxury Series ⏹ 悦尔经典系列 ALT Classic Series ⏹悦尔标准系列 ALT Standard Series智能便携充电盒Smart Portable charger case转换插头及充电线Adapter/USB cable车载充电器Auto charger列 ALT悦尔经典系ClassicSeries悦尔电子烟ALT e-cigarette备用电池Extra battery烟弹Pack of refill cartridges便携盒Carry case转换插头AdapterUSB 充电器USB charger悦尔标准系列 ALT Standard Series产品概述Introduction悦尔电子烟ALT e-cigarette烟弹Pack of refill cartridges便携袋Leather pocket充电适配器AdapterUSB充电器USB charger悦尔电子烟介绍ALT e-cigarette Components 悦尔电子烟与普通香烟烟的本质区别在于:∙悦尔电子烟不含对人体有害的焦油成份,没有致癌物质;∙悦尔电子烟不燃烧,没有燃烧后所产生的多种有害化学物质;∙悦尔电子烟没有“二手烟”对他人造成的危害及对环境的污染;∙悦尔电子烟无火灾隐患,您可以在任何地方自由地享受;∙Important differences between ALT e-cigarettes and conventional cigarettes:• ALT e-cigarette contains no tar nor does it contain many of the carcinogenic substances found in traditional cigarettes, that are harmful to the human body.• No ignition is involved, so there is no real smoke – meaning none of the harmful chemicals contained in conventional cigarette smoke.• Eliminates “passive smoking”.• No possibility of fire risk.• ALT e-cigarettte can be used in most No Smoking situations.悦尔电子烟是一种采用高新微电子技术的微型雾化装置,是当前全球范围内最为成功的传统香烟替代品。

艾塔顿198893产品说明书

Eaton 198893Eaton Moeller® series Rapid Link - Speed controllers, 4.3 A, 1.5 kW, Sensor input 4, Actuator output 2, 180/207 V DC, Ethernet IP, HAN Q4/2, with manual override switch, STO (Safe Torque Off)General specificationsEaton Moeller® series Rapid Link Speed controller1988934015081969517157 mm 270 mm 220 mm 3.6 kg CEIEC/EN 61800-5-1 RoHS UL 61800-5-1 UL approvalProduct NameCatalog NumberEANProduct Length/Depth Product Height Product Width Product Weight Certifications Catalog Notes 3 fixed speeds and 1 potentiometer speedcan be switched over from U/f to (vector) speed control Connection of supply voltage via adapter cable on round or flexible busbar junction Diagnostics and reset on the device and via Ethernet IP480 VIs the panel builder's responsibility. The specifications for the switchgear must be observed.480 V AC, 3-phase400 V AC, 3-phaseMeets the product standard's requirements.1.5 kW500 VMeets the product standard's requirements.-40 °C380 VKey switch position AUTO2 Actuator outputsManual override switchSelector switch (Positions: REV - OFF - FWD)Control unitPTC thermistor monitoringInternal DC linkPC connectionIGBT inverterKey switch position OFF/RESETKey switch position HANDTwo sensor inputs through M12 sockets (max. 150 mA) for quick stop and interlocked manual operationThermo-click with safe isolation0 Hz200 %, IH, max. starting current (High Overload), For 2 seconds eaton-bus-adapter-rapidlink-speed-controller-dimensions-005.eps eaton-bus-adapter-rapidlink-speed-controller-dimensions-003.eps eaton-bus-adapter-rapidlink-speed-controller-dimensions-002.eps eaton-bus-adapter-rapidlink-speed-controller-dimensions-004.epsETN.RASP5-4421EIP-412R010S1.edzRapid Link 5 - brochureDA-SW-drivesConnect - installation helpDA-SW-USB Driver PC Cable DX-CBL-PC-1M5DA-SW-Driver DX-CBL-PC-3M0DA-SW-drivesConnect - InstallationshilfeDA-SW-drivesConnectDA-SW-USB Driver DX-COM-STICK3-KITMaterial handling applications - airports, warehouses and intra-logisticsIL034093ZUrasp5_v33.stpramo5_v33.dwgGeneration change from RA-MO to RAMO 4.0Generation change RAMO4 to RAMO5Generation Change RA-SP to RASP5Configuration to Rockwell PLC for Rapid LinkGeneration Change RASP4 to RASP5Generation change from RA-SP to RASP 4.0DA-DC-00003964.pdfDA-DC-00004184.pdfDA-DC-00004613.pdfDA-DC-00004612.pdfMains voltage - max10.11 Short-circuit ratingRated operational voltage10.4 Clearances and creepage distancesOutput at quadratic load at rated output voltage - max Output voltage - max10.2.3.1 Verification of thermal stability of enclosures Ambient storage temperature - minMains voltage - minFitted with:Output frequency - minStarting current - max DibujoseCAD modelFolletosInstrucciones de instalación mCAD modelNotas de aplicación Reportes de certificacionesevery 20 seconds, Power sectionRated conditional short-circuit current (Iq)10 kAAmbient operating temperature - max40 °CCommunication interfaceEthernet IP, built inAssigned motor power at 115/120 V, 60 Hz, 1-phase2 HPOutput frequency - max500 HzSwitching frequency8 kHz, 4 - 32 kHz adjustable, fPWM, Power section, Main circuitFeaturesParameterization: KeypadParameterization: FieldbusParameterization: drivesConnectParameterization: drivesConnect mobile (App)Ambient operating temperature - min-10 °CBraking current≤ 0.6 A (max. 6 A for 120 ms), Actuator for external motor brakeNumber of HW-interfaces (serial TTY)10.6 Incorporation of switching devices and componentsDoes not apply, since the entire switchgear needs to be evaluated.Nominal output current I2N4.3 A10.2.6 Mechanical impactDoes not apply, since the entire switchgear needs to be evaluated.10.3 Degree of protection of assembliesDoes not apply, since the entire switchgear needs to be evaluated.Product categorySpeed controllerRadio interference classC2, C3: depending on the motor cable length, the connected load, and ambient conditions. External radio interference suppression filters (optional) may be necessary.C1: for conducted emissions onlyHeat dissipation capacity Pdiss0 WRated control voltage (Uc)180/207 V DC (external brake 50/60 Hz)24 V DC (-15 %/+20 %, external via AS-Interface® plug)Assigned motor power at 460/480 V, 60 Hz, 3-phase2 HPNumber of HW-interfaces (RS-422)Mains current distortion120 %ProtocolEtherNet/IP10.9.2 Power-frequency electric strengthIs the panel builder's responsibility.Overvoltage categoryIIIDegree of protectionIP65NEMA 12Ambient storage temperature - max70 °CRated impulse withstand voltage (Uimp)2000 VConnectionPlug type: HAN Q4/2Overload currentFor 60 s every 600 sAt 40 °CFunctions1 potentiometer speedSTO (Safe Torque Off)For actuation of motors with mechanical brake3 fixed speedsOutput at linear load at rated output voltage - max1.5 kWMains voltage tolerance380 - 480 V (-10 %/+10 %, at 50/60 Hz)Leakage current at ground IPE - max3.5 mAConverter typeU converter10.2.2 Corrosion resistanceMeets the product standard's requirements.Supply frequency50/60 Hz10.2.4 Resistance to ultra-violet (UV) radiationMeets the product standard's requirements.10.2.7 InscriptionsMeets the product standard's requirements.Shock resistance15 g, Mechanical, According to IEC/EN 60068-2-27, 11 ms, Half-sinusoidal shock 11 ms, 1000 shocks per shaftApplication in domestic and commercial area permittedYesNumber of inputs (analog)Number of phases (output)310.12 Electromagnetic compatibilityIs the panel builder's responsibility. The specifications for the switchgear must be observed.10.2.5 LiftingDoes not apply, since the entire switchgear needs to be evaluated.Number of HW-interfaces (RS-485)1Number of HW-interfaces (industrial ethernet)2Efficiency98 % (η)System configuration typePhase-earthed AC supply systems are not permitted.Center-point earthed star network (TN-S network)AC voltage10.8 Connections for external conductorsIs the panel builder's responsibility.ProtectionFinger and back-of-hand proof, Protection against direct contact (BGV A3, VBG4)Braking voltage280/207 V DC -15 % / +10 %, Actuator for external motor brakeApplication in industrial area permittedYesClimatic proofing< 95 %, no condensationIn accordance with IEC/EN 5017810.9.3 Impulse withstand voltageIs the panel builder's responsibility.Overload current IL at 150% overload6.5 AInput current ILN at 150% overload4.1 ANumber of HW-interfaces (RS-232)Number of inputs (digital)4Current limitationAdjustable, motor, main circuit0.4 - 4.3 A, motor, main circuitCable lengthC1 ≤ 1 m, maximum motor cable lengthC2 ≤ 5 m, maximum motor cable lengthC3 ≤ 25 m, maximum motor cable length10.5 Protection against electric shockDoes not apply, since the entire switchgear needs to be evaluated.Mounting positionVerticalMains switch-on frequencyMaximum of one time every 60 seconds10.13 Mechanical functionThe device meets the requirements, provided the information in the instruction leaflet (IL) is observed.10.9.4 Testing of enclosures made of insulating materialIs the panel builder's responsibility.Heat dissipation per pole, current-dependent Pvid0 WElectromagnetic compatibility1st and 2nd environments (according to EN 61800-3)Resolution0.1 Hz (Frequency resolution, setpoint value)Assigned motor power at 460/480 V, 60 Hz2 HPRelative symmetric net voltage tolerance10 %Rated operational current (Ie)4.3 A at 150% overload (at an operating frequency of 8 kHz and an ambient air temperature of +40 °C)Number of outputs (analog)Rated operational power at 380/400 V, 50 Hz, 3-phase1.5 kWNumber of HW-interfaces (USB)Operating modeU/f controlSynchronous reluctance motorsSensorless vector control (SLV)BLDC motorsPM and LSPM motorsRated frequency - min45 HzDelay time< 10 ms, On-delay< 10 ms, Off-delayNumber of outputs (digital)2Power consumption46 W10.2.3.2 Verification of resistance of insulating materials to normal heatMeets the product standard's requirements.10.2.3.3 Resist. of insul. mat. to abnormal heat/fire by internal elect. effectsMeets the product standard's requirements.Number of HW-interfaces (other)Rated frequency - max66 HzVibrationResistance: According to IEC/EN 60068-2-6Resistance: 10 - 150 Hz, Oscillation frequencyResistance: 57 Hz, Amplitude transition frequency on accelerationResistance: 6 Hz, Amplitude 0.15 mmShort-circuit protection (external output circuits)Type 1 coordination via the power bus' feeder unit, Main circuit10.7 Internal electrical circuits and connectionsIs the panel builder's responsibility.Braking torque≤ 30 % (I/Ie)Adjustable to 100 % (I/Ie), DC - Main circuitRelative symmetric net frequency tolerance10 %10.10 Temperature riseThe panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices.Number of HW-interfaces (parallel)Assigned motor power at 230/240 V, 60 Hz, 1-phase2 HPInterfacesMax. total power consumption from AS-Interface® power supply unit (30 V): 250 mANumber of slave addresses: 31 (AS-Interface®) Specification: S-7.4 (AS-Interface®)Eaton Corporation plc Eaton House30 Pembroke Road Dublin 4, Ireland © 2023 Eaton. Todos los derechos reservados. Eaton is a registered trademark.All other trademarks areproperty of their respectiveowners./socialmedia332.3 W at 25% current and 0% speed 33.2 W at 25% current and 50% speed 35.2 W at 50% current and 90% speed 36.2 W at 50% current and 0% speed 37.6 W at 50% current and 50% speed 46.3 W at 100% current and 90% speed 48.7 W at 100% current and 0% speed 48.7 W at 100% current and 50% speed 0Max. 2000 mAbove 1000 m with 1 % performance reduction per 100 mNumber of phases (input)Heat dissipation at current/speed Number of interfaces (PROFINET)Altitude。

奥利满科学解决方案美国有限公司产品目录说明书

Shaft Size 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm) 0.125 in. (3.17 mm)

Eddy Current Probes

Table of Contents

- Flexible Shaft Surface Probes - Bent Shaft Surface Probes - Angle Shaft Surface Probes - Right Angle Surface Probes - Straight Shaft Surface Probes - Pencil Surface Probes - Other Surface Probes - Rotating Plastic Scanner Probes - Rotating Stainless Steel Scanner Probes - Other Scanner Probes - Manual Bolt Hole Probes - Ring / Donut Probes - Spot Probes - Sliding Probes - Conductivity Probes - Weld Probes - Cable & Adaptors - Standards

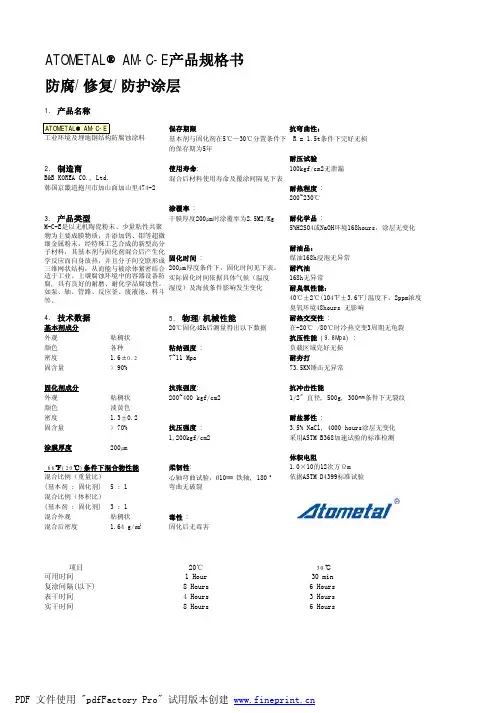

ATOMETAL AM-C-E防腐 修复 防护涂层 产品规格书

ATOMETAL ® AM-C-E 产品规格书防腐/修复/防护涂层1. 产品名称ATOMETAL ® AM-C-E保存期限抗弯曲性:基本剂与固化剂在5℃—30℃分置条件下 R = 1.5t 条件下完好无损的保存期为5年耐压试验2. 制造商使用寿命:100kgf/cm2无泄漏混合后材料使用寿命及覆涂间隔见下表耐热程度 :200~230℃涂覆率 :3. 产品类型干膜厚度200㎛时涂覆率为2.5M2/Kg 耐化学品 : 5%H2SO4或NaOH 环境168hours ,涂层无变化 耐油品:固化时间 :煤油168h 浸泡无异常200㎛厚度条件下,固化时间见下表。

耐汽油实际固化时间依据具体气候(温度168h 无异常湿度)及海拔条件影响发生变化耐臭氧性能:40℃±2℃(104℉±3.6℉)温度下,2ppm 浓度臭氧环境48hours 无影响5. 物理/机械性能耐热交变性 :20℃固化48h 后测量得出以下数据在-20℃ /80℃时冷热交变3周期无龟裂外观粘稠状抗压性能 (9.8Mpa) :颜色各种粘结强度 :负载区域完好无损密度 1.6±0.27~11 Mpa 耐夯打固含量> 90%73.5KN 锤击无异常固化剂成分抗张强度:抗冲击性能外观粘稠状200~400 kgf/cm21/2" 直径, 500g, 300㎜条件下无裂纹颜色淡黄色密度 1.3±0.2耐盐雾性 :固含量> 70%抗压强度 : 3.5% NaCl, 4000 hours 涂层无变化1,200kgf/cm2采用ASTM B368加速试验的标准检测涂膜厚度200㎛体积电阻68℉(20℃)条件下混合物性能柔韧性:1.0×10的12次方Ωm混合比例(重量比)心轴弯曲试验,Ø10㎜ 铁轴, 180˚依据ASTM D4399标准试验(基本剂 : 固化剂) 5 : 1弯曲无破裂混合比例(体积比)(基本剂 : 固化剂) 3 : 1混合外观粘稠状毒性 :混合后密度 1.64 g/㎤固化后无毒害项目20℃ 30℃可用时间1 Hour 30 min 复涂间隔(以下)8 Hours 6 Hours 表干时间 4 Hours 3 Hours 实干时间8 Hours6 Hours基本剂成分工业环境及埋地钢结构防腐蚀涂料B&B KOREA CO., Ltd.韩国京畿道抱川市加山面加山里474-24. 技术数据M-C-E 是以无机陶瓷粉末、少量粘性共聚物为主要成膜物质,并添加钨、钼等超微细金属粉末,经特殊工艺合成的新型高分子材料,其基本剂与固化剂混合后产生化学反应而自身放热,并且分子间交联形成三维网状结构,从而能与被涂体紧密结合适于工业、土壤腐蚀环境中的容器设备防腐, 具有良好的耐磨、耐化学品腐蚀性。

ATOM 婴儿保育箱 V-2100G 操作说明书

ATOM婴儿保育箱V-2100G操作说明书日本ATOM公司北京百世贸易有限公司简介本说明书介绍ATOM先进的V-2100G型婴儿保育箱的规格、操作和维修方法。

如因使用者忽视本说明书中有关操作和维修的说明而发生误操作,或因非ATOM公司所属人员,或非ATOM 公司授权人员进行修理而发生的事故,ATOM 公司不承担任何责任。

本说明书包括所有可用的功能,包括脉搏血氧计、氧气控制器和婴儿重量监视器。

无关部分可以跳过。

在操作本设备前要仔细阅读和完全熟悉本说明书内容。

将它保存在手边,以备随时查阅。

如发生任何技术问题,请与ATOM经销商联系。

用途ATOM先进的婴儿保育箱V-2100G是密闭式保育器,其设计意图是为新生儿和早产儿提供最佳临床环境。

它也是为了给临床医护人员提供最佳观察和检查条件、温度稳定性,便于他们管理和术后护理小病人。

该保育箱还有温度调节功能,便于调节婴儿体肤温度。

另外还有一些可选功能,如氧气控制器和体重监视器等。

安全事项有关安全操作的指示,在说明书中随处可见。

请在操作前仔细阅读它,并按指示操作。

[1] 基本指示1.Follow the instructions for safe use of the unit.按说明操作,以保安全。

2.Inspect the unit on a periodical basis.定期检查,以保持设备的最佳状态。

3.Never use the unit when faulty.如果发现设备损坏或功能不良,立即停止使用,并联系你处ATOM经销商。

[2] 警示标志解释[3] 标志定义1. 注意或警告标志标志 《标题》和指示内容《一般性注意事项》指示未特别说明的一般性小心和警示事项。

《小心:热表面》指示该表面是热的,可能造成危险。

2. 禁止标志标志 《标题》和指示内容《一般性禁止》指示未特别说明的一般性禁止事项。

《禁止拆卸》在可能引起触电或其它危险的地方,禁止拆卸。

《禁止用火》在某种条件下,外部火焰能使设备着火的地方,禁止用火。

atometal石油石化

公司介绍

安特爱涂(北京)国际科技有限公司三河工厂

产品介绍

附着力强,与多种材料均可附着(16~22 MPa )

抗冲击性能优异(英国Lloyd ’s 船级社耐夯打认证)

耐酸、碱、盐等化学腐蚀性能突出(CASS 盐雾加速试验:4000小时)半永久性防腐寿命(韩国建设防腐研究所,海洋环境22年)

不含VOC ,利于环保,对人体无毒无害(卫生部饮用水卫生安全产品)

附着力强,与多种材料均可附着(16~22 MPa )抗冲击性能优异(英国Lloyd ’s 船级社耐夯打认证)耐酸、碱、盐等化学腐蚀性能突出(CASS 盐雾加速试验:4000小时)半永久性防腐寿命(韩国建设防腐研究所,海洋环境22年)不含VOC ,利于环保,对人体无毒无害(卫生部饮用水卫生安全产品)

认证及专项实验

中石油管道局企业标准中石油管道局企业标准

应用实例。

芯力特别化化学产品说明书

Version 1 Honeywell Specialty Chemicals Seelze GmbH Brand:FlukaWunstorfer Strasse 40Product Number:E1120D-Seelze, 30926Lot Number:K064ATelefon: +49-5137-999-0Production Date:04.03.2020 Expiry date:04.04.2022Tin ICP Standard, 1000mg/L Sn in HNO3 1%, HF 1%This document is designed and the certified value(s) and uncertainty(ies) are determined in accordance with ISO Guide 31,ISO Guide 35, EA 4/02 and Eurachem / CITAC GuidesComponent Certified ValueMetrological traceabilityand uncertainty [mg/l]Sn1001.1 ± 3.9 (y) NIST SRM No 3161a Lot 140917Notes:(y) WQP 5.15.1.24 The certified value was obtained by a weighted mean of the results of two independent calibrationmethods among: Classical Volumetric,Primary Gravimetric, Instrumental (ICP/OES, ICP/MS or IC)Density*1.012 g/cm3at 20°CStarting Material, Purity* BatchSn 99.99% 82093211* These values are not certifiedStorage Conditions: Store under normal laboratory conditions, at temperatures between 15° to 25°CConcept of Certification and traceability statement:This certified reference material is produced using a high purity starting material, acid from sub-boiling and 18 MOhm deionized water.The reported expanded uncertainty of measurement is stated as the standard uncertainty of measurement multiplied by the coverage factor k = 2, which for a normal distribution corresponds to a coverage probability of approximately95%.The standard uncertainty of measurement has been determined in accordance with EA 4/02Property of the result of a measurement whereby it can be related to stated references, usually national or international standards, through an unbroken chainof comparisons all having stated uncertainties (ISO VIM)The metrological traceability is assured through calibration on ICP/OES . The calibration curve is drawn using a series of standard solutions prepared from a certified reference material traceable to SI of NIST (SRM) or BAM (CRM). All contributions in relation to the certification of standard solutions are considered when evaluating the uncertainty.The measurement results are traceable to SI.All analytical balances used for the preparation of the solution are calibrated yearly under an in-house procedure with analytical weights, traceable to DKD, and are checked daily.Class A laboratory glassware is used.The results from temperature measurement are traceable to SI. The thermometers used for solution's calibration are calibrated from an ISO 17025 accredited laboratory. The ambient conditions are controlled with a hygrometer calibrated from an ISO 17025 accredited laboratory.Intended use:For Laboratory Use OnlyCalibration of ICP/OES, AAS Validation of analytical methodsPreparation of “working reference samples”Detection limit and linearity studiesThis statement is not intended to restrict the use for other purposes.Instructions for the correct use of this reference material:This certified reference material can be used directly or can be diluted in an appropriate high purity matrix. Only a clean class A glassware should be used. Do not pipet from container. Obtained concentration (in mg/l) after dilution is a result from the multiplication of certified value of CRM concentration and the CRM's volume used for dilution and divided into the flask's volume used for dilution.Stability and storage:This CRM is with a guaranteed stability until ±0.5% of the certified concentration within its shelf life. Stability is guaranteed, provided that the solution is kept in its original packaging, tightly closed stored, as written in the section: Storage Conditions.The laboratory performs stability tests according to MQP 5.14.1 therefore solutions with one and the same bar-code number might have different expiration dates.Hazardous situation:The normal laboratory safety precautions should be observed when working with this CRM. Further details for the handling of this CRM are available as safety data sheet.Level of homogeneity:The material was tested for homogeneity by analyzing randomly selected samples according to an in-house procedure. The level of homogeneity proved satisfactory for a sample volume of 20 ml. The uncertainty incorporates the sample standard deviation combined with the uncertainty calculated from homogeneity and stability studies.To ensure sufficient homogeneity of the sample prior to use thoroughly mix by inversion.This document QF 5.17.1/1 version 1 is designed and the certified value(s) and uncertainty(ies) are determined in accordance with ISO Guide 31, ISO Guide 35,and Eurachem / CITAC GuidesThis certificate relates solely to the lot number given above.All processes (including generating of this certificate) are completely controlled by the specialized Computer-Aided-Manufacturing (CAM) software.This Certified Reference Material was produced under a quality management system that is:- Registered to ISO 9001 Quality Management System (Lloyd's Register Quality Assurance Ltd Cert No 0039638)- Accredited according to ISO/IEC 17025 – Testing (ANAB Cert No AT-1836)- Accredited according to ISO 17034 - Reference Material Producer (ANAB Cert No AR-1835)Trace impurities in the actual solution reported in ppm:(all values below are nominal and not certified)。

安利根系列产品使用指南说明书

• Agrilan ® 755High performance hydrophobically modified polyacrylate polymer when extra stabilization is needed. Adsorbsirreversibly to solid surfaces and oil droplets. Full potential is reached when combined with Morwet D-425. Soluble in both water and oil based systems. In addition, this polymer inhibits crystal growth.• Agrilan 700, Agrilan 789White polyacrylate copolymers. Can be used as primary dispersants or in combination with Morwet D-400/D-425. Agrilan 789 is the premium product for high loadings or extreme water hardness conditions.Liquid suspensionsExplore the full potential of your liquid suspensionFinding ways to enhance your crop protection formulations is what we do. Every day. We are a global company with a broad range of environmentally safe, biodegradable and cost effective solutions. This guide shows how our products can be used to explore the full potential of your liquid suspension.Key products for successful liquid suspensions• Morwet ® D-400, Morwet D-425Anionic naphthalene sulphonate condensates used asprimary dispersant. Benchmark to achieve short milling time and low viscosity premix. Brings electrostatic stabilization and makes the formulation stable towards temperature changes.• Morwet EFWAn anionic blend for excellent wetting of most powders. The best choice for actives with crystallization problems.• Ethylan ® NS-500LQBlock copolymer that provides steric stabilisation. Combine with Morwet D-425 for best performance. A liquid polymerthat is easy to handle.Agrochemical formulation guide for SC, SE and ODFormulations in this guide comply with the following CIPAC methods:Appearance CIPAC MT 148,1 Stability CIPAC MT 39.3, 46.3 Particle size CIPAC MT 187Suspensibility CIPAC MT 160, 184Suspension concentrate (SC)SC formulations are water based dispersions of fine particle active ingredients. The typical particle size is <5 μm. Due to their liquid nature SC formulations are easy and safe to handle. Suspension concentrates require efficient formulation additives to ensure long term stability. Due to their inherent stability issues their compositions are more complex compared to standard EC or WP formulations.Preparation•Prepare a base mill by adding active ingredient, dispersing agent (Morwet D-425/D-400, Agrilan 789, Agrilan 700), wetter if necessary (Morwet EFW) and defoamer in water •Homogenize the premix with high shear mixer or homogenizer (Ultra Turrax) for few minutes•Mill the slurry until desired particle size is achieved •Formulate by adding stabilizer (Agrilan 755,Ethylan NS-500LQ) and mix properly with mill base•Add other ingredients such as in-can adjuvant (Adsee AB 600, Adsee 611, Adsee 900), anti-freeze(propylene glycol, 5-8%), thickener (xanthan gum 0.1-0.3%) and biocide as necessaryActive ingredients Conc Base mill - step 1 (w/w)Formulation - step 2Additional additivesAclonifen Metobromuron 250 g/l250 g/l2.5% Morwet D-425 1.0% Ethylan NS-500LQ3.0% MEG + 0.2% Biocide +0.1% Defoamer + 0.2% Xanthan gum+ water to 100%Buprofezin250 g/l 2.5% Morwet D-4008.0% PG + 1% Biocide +0.1% Defoamer + 0.25% Xanthangum + water to 100% Epoxiconazole125 g/l 2.5% Morwet D-425 1.0% Ethylan NS-500LQ0.15% Xanthan gum + 5.0% PG +0.2% Antifoam + water to 100%Ethofumesate Phenmedipham 200 g/l200 g/l2.5% Morwet D-425 1.0% Ethylan NS-500LQ0.15% Xanthan gum + 5.0% PG +0.2% Antifoam + water to 100%Tebuconazole430 g/l 2.5% Morwet D-4251.0% Morwet EFW 0.5% Agrilan 7550.15% Xanthan gum + 5.0% PG +0.2% Antifoam + water to 100%White formulationsActive ingredients Conc Base mill - step 1 (w/w)Formulation - step 2AdditivesCyromazine30% w/w 2.5% Agrilan 700 2.0% Agrilan 755 3.0% Glycerin + 0.15% Biocide +0.1% Defoamer + 0.5% Bentonite +0.15% Xanthan gum + water to 100%Thiophanate-Methyl Azoxystrobin Metalaxyl 6% w/w3% w/w3% w/w2.0% Agrilan 789 1.0% Ethylan NS-500LQ3.0% Glycerin + 1.0% Citric acid +0.1% Biocide + 0.1% Defoamer +1.0% Bentonite + 0.2% Xanthan gum+ water to 100%Formulations containing adjuvantsActive ingredients Conc Base mill - step 1 (w/w)Formulation - step 2AdditivesBispyribac-Na10% w/w 3.0% Agrilan 700 1.0% Agrilan 75510.0% Adsee 6115.0% PG + 0.1% Biocide +0.1% Defoamer + 0.25% Xanthan gum + water to 100%Chlorfenapyr10% w/w 4.0% Agrilan 788 1.0% Adsee AB 615 3.0% Glycerin + 0.25% Biocide +0.1% Defoamer + 1.5% Bentonite +0.25% Xanthan gum + water to 100% Chlorfenapyr5% w/w 4.0% Agrilan 788 1.0% Adsee AB 615 3.0% Glycerin + 1.5% Magnesiumaluminometa-silicate + 0.2% Biocide+ 0.1% Defoamer + 0.25% Xanthangum + water to 100%Indoxacarb15% w/w 4.0% Agrilan 70010.0% Adsee AB 615 3.0% Glycerin + 0.1% Biocide +0.1% Defoamer + 0.5% Bentonite +0.2% Xanthan gum + water to 100% MEG = Mono Ethylene Glycol, PG = Propylene GlycolAn OD is a non-aqueous suspension concentrate. It can be used as replacement for EC, SC and WDG as it combinesgood biological efficacy with cost-effective and environmental friendly properties. A key benefit is that high amounts of adjuvants can be built into the formulation. OD formulation presents several challenges in production. To obtain a good and stable formulation over the time, optimal formulation additives are required in addition to optimum process.Preparation•Make a base mill by adding the actives, the emulsifier/ dispersant and the Bentone* to the solvent•Mill the content until the desired particle size is achieved •Add the stabilizer (Agrilan 755) and stir gentlyActive ingredients Conc Solvent Emulsifier/Dispersant Stabilizer AdditiveImidacloprid20% w/w Rape seed methylester, up to 100%5.0% Witconate P-1460EH5.0% Berol 2662% Bentone SD-3Pyridate Sulcotrione 40% w/w22.5% w/wRape seed methylester, up to 100%5.0% Witconate P-1460EH6.0% Berol 2662% Bentone SD-3Terbuthylazine30% w/w Coco methyl ester,up to 100%10.0% Witconate P-1460EH10.0% Berol 2662-4% Bentone SD-3Nicosulfuron4% w/w Soybean oil,up to 100%5.0% Ethylan NS-500LQ2.0% Ethomeen T/128.0% Berol 1922.0% Agrilan 7551-2% Bentone SD-3Azoxystrobin12% w/w Soybean oil,up to 100%5.0% Witconate P-1460EH5.0% Berol 2662.0% Agrilan 7550.5-1% Bentone SD-3Bentone is a trade name by Elementis SpecialtiesNouryon is a global, specialty chemicals leader. Markets and consumers worldwide rely on our essential solutions to manufacture everyday products, such as personal care, cleaning goods, paints and coatings, agriculture and food, pharmaceuticals, and building products. Furthermore, the dedication of more than 7,900 employees with a shared commitment to our customers, business growth, safety, sustainability and innovation has resulted in a consistently strong financial performance. We operate in over 80 countries around the world with a portfolio of industry-leading brands. Visit our website and follow us @Nouryon and on LinkedIn.All information concerning our products and/or allsuggestions for handling and use contained herein(including formulation and toxicity information) areoffered in good faith and are believed to be reliable.However, Nouryon makes no warranty express orimplied (i) as to the accuracy or sufficiency of suchinformation and/or suggestions, (ii) as to any product’smerchantability or fitness for a particular use or (iii) thatany suggested use (including use in any formulation)will not infringe any patent. Nothing contained hereinshall be construed as granting or extending any licenseunder any patent. The user must determine for itselfby preliminary tests or otherwise the suitability of anyproduct and of any information contained herein(including but not limited to formulation and toxicityinformation) for the user’s purpose. The safety of anyformulations described herein has not been established.The suitability and safety of a formulation should beconfirmed in all respects by the user prior to use. Theinformation contained herein supersedes all previouslyissued bulletins on the subject matter covered.Products mentioned are trademarks of Nouryonand registered in many countries.Contact us directly for detailed product information and sample requestwebsite | /markets/agricultureemail|****************December221SE formulations are water based dispersions of fine particles and oil droplets and can be used to combine water insoluble actives with oily/oil soluble actives as well as adjuvants. The development of suspo-emulsions needs careful consideration at the formulation stage as the dispersing and emulsifying agents can migrate between particles/oil droplets and create instability such as flocculation.SE offers the benefit of a broad spectrum of pest control due to mixed actives and in-can adjuvants.Preparation•Prepare SC part: Make a premix slurry by adding active ingredient, dispersing agent (Morwet D-425) and defoamer in water. Homogenize and wet mill until particle size is below5 μm (D50).•Prepare the oil phase by adding emulsifiers into the mineral oil•Mix both parts under high shear to form a suspo-emulsion.Add the EC under low shear to the SC. High shear mix toform a small droplet emulsion.Active ingredients Conc Dispersant Emulsifier Additive SolventIprodione250 g/l25 g/l Morwet D-42525 g/l Witconate P-1460EH25 g/l Berol 26610 g/l Lankropol KPH700.2% Thickener,defoamer200 g/l Mineral oil,Balance water。

亚马敦科学美国有限公司产品介绍书说明书

Yamato Scientific AmericaInnovating Science for Over 125 YearsYamato Scientific America Inc.Targeting Productivity ImprovementYamato offers customization of products based on customer requirementsCombination Forced Convection OvenLarge AutoclaveLarge Walk-in Forced Convection OvenLargeVacuum Drying OvenCustomized Industrial Products157CATV1-201701Use platform stands to combine one machine with several units to save spaceEquipped with set recorder (to record product temperature), timer and product running status indicator lampRepositioned air exhaust ports (facing backwards) to accommodate overlapping set of productEach door is equipped with an electromagnetic lock Customized chamber dimensionsEasy operation, available for fixed temperature, program, quick auto stop, auto stop and auto start operationsSelf-diagnostic circuit (abnormal temperature sensor, heater disconnection, auto overheat prevention, SSR short circuit), overheat protector, ELB to prevent overcurrent, key lock, etc.Large walk-in typeDouble door structure, anti lock mechanismEasy operation, available for fixed temperature, program, quick auto stop, auto stop and auto start operationsSelf-diagnostic circuit (abnormal temperature sensor, heater disconnection, auto overheat prevention, SSR short circuit), overheat protector, ELB to prevent overcurrent, key lock, etc.Yamato Scientific America Inc.C1-006, C4-008158CATV1-201701Operation and featuresVacuum pump can be installed inside the ovenQuick connect / disconnect of vacuum pipes for easy vacuum pump maintenanceBecause the exhaust system is improved to significantly shorten the time to reach vacuum, working efficiency is improvedUse specialized function menu key and ▲/▼ key to set. With program operation function, use submenu key to operate overheat protector, deviation correction, etc.Safety featuresSelf-diagnostic circuit (abnormal temperature sensor, heater disconnection, auto overheat prevention, SSR short circuit), overheat protector, ELB to prevent overcurrent, key lock, etc.For safety, resin protection panel is installed at the observation windowYamato Scientific America Inc.DP83C/103C 159CATV1-201701Application: Environmental test of various materials, partsFeaturesLow temperature: -20°CLarge capacity of 800L compared to standard models IN and INE which are up to 286LHigh airtight panel structure (thermal insulation panel) Door switch and other safety devices can be added Size can be specified according to customer’s needsOther optional specs can also be addedInteriorYamato Scientific America Inc.C1-007, YY-711process.Installed with a conveyor to improve efficiency of thermal treatment Adjustable conveyor speed with the ability to set multiple treatment processesProgram operation functionEquipped with a frequency converter, beacon, infrared switch, etc.Equipped with safety devices such as auto overheat protector, overheat protector, emergency stop switch, conveyor overload protection, over-current earth leakage circuit breaker, etc.160CATV1-201701InternaldimensionYYK500ø500×850mmYYK750ø750×1100mmYYK800ø800×1100mmYYK900ø900×1300mmOperation and featuresNo temperature overshoot, precision temperature uniformity available4 step working procedures:(1)Preheat: temperature rising, no pressurizing(2)Pressurizing: holding temperature, pressurizing(3)Deaeration: holding temperature, deaerating(4)End: temperature cooling, pressure droppingAdjustable air suction and exhaust speedCustomized chamber dimensionsSafety featuresDoor open / close detection, door lock / unlock detection, higher pressurealarm, air inlet pressure detection, safety valve, independent overheatprotector, ELB to prevent over-current Yamato Scientific America Inc.YYK500/750/800/900161CATV1-201701。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

0082-31-5432223ATOMETAL“爱涂”超陶防水防腐系列产品手册韩国爱涂防水防腐株式会社0082-31-5432223一、公司介绍公 司 介 绍韩国爱涂防水防腐株式会社位于韩国中部距汉城40公里的京畿道抱川市,最早成立于1982年,是专门研制和生产新型防腐防护涂料的高新技术企业。

经过近二十年的不懈努力,其ATOMETAL “爱涂”牌超陶系列产品已在韩国取得广泛应用。

先后取得韩国船级社、英国Lloyd’s 船级社以及韩国建设交通部的新技术认证、优秀产品认证、ISO 9001质量体系/14001环保体系认证等。

具体情况如下:公 司 全 称中文韩国爱涂防水防腐株式会社英文 B&B KOREA CO., LTD.公 司 地 址中文韩国京畿道抱川市加山面加山里474-2 (邮编487-811) 英文474-2 Gasan-ri, Gasan-myeon, Pocheon-si, Gyeonggi-do,487-811, KOREA工 厂 用 地 面 积 7,991㎡工 厂 建 筑面 积制造设施 492.8㎡ 配套设施 1,199.9㎡ 总 计 1,692.7㎡ 电 话 82-31-543-2223~5 F A X 82-31-543-2226 网 址 www.atometal.co.kr 邮 箱 khic@atometal.co.kr 注 册 资 本 2亿元 (韩币) 注册日期 1990. 12. 15 法 人 代 表申 铉 官注 册 号127-81-16183 产 品 名 称 ATO CERAMIC COATING爱涂牌超陶防腐涂料 注 册 商 标ATOMETAL经 营 范 围能广泛用于钢材、混凝土结构防腐防护及修补工程的新型环保无机材料ATOMETAL “爱涂”超陶产品的生产、销售及施工。

技 术 工 程 项 目ATO “爱涂”涂料在韩国已得到广泛应用,与现代重工、浦项制铁、LG化工、韩国电力等有着紧密的合作关系,并承接多项国家大型建设项目如西海闸门、釜山隧道、仁川大桥等,成为韩国道路建设交通部建筑防护设计标准中的指定新型涂料,同时还开辟了日本、南美、中东等海外市场,是国际无机超陶组 织 机 构 图设计科工程施工科技术支持科北京代表处日本代表处美国代表处社长(代表理事)技术咨询委员会副社长监事专务理事常务理事海外部海外发展部防腐技术研究所生产部技术部销售部销售服务部经营管理部海外分支企划科财务科总务科工程预算科代理管理科销售1科销售2科生产科管理科采购科ISO 认证科R &D 科质检科质 量 保 证 体 系:本社执行ISO 9001--2000 质量管理体系,企业内部由防腐技 术研究所、R&D试验开发部、质量检验部同时进行产品质量监控, 外部定期委托韩国建材料试验研究院等权威检验机构抽查,以确 保ATO产品性能。

0082-31-5432223二、产品介绍0082-31-5432223ATOMETAL 超 陶 产 品 介 绍由韩国爱涂防水防腐株式会社(B&B KOREA Co., Ltd.)自行研制开发的ATOMETAL 超陶防水防腐涂料及修补剂,属于一种新型高分子材料,是传统环氧树脂类防腐涂料的替代产品。

本系列产品合成后,其材料成分本身不会分解,物理特性不变,化学性能稳定。

具有以下鲜明特性:1、该涂料常态下分为基本剂与固化剂双组份储存;涂装时双组份混合并按一定比例加入稀释剂,涂于被涂体表面,一方面,溶剂挥发干燥的同时,膜层分子发生交联反应放热而固化成膜;另一方面,被涂金属表面经过喷砂处理后,具有一定粗慥度和活性,涂料分子通过机械嵌合锚固及化学吸附等作用,很快与被涂体紧密结合形成半永久性防护层。

因此对硬质基材如金属、混凝土等都能附着牢固(附着力160-222kgf/cm2),成膜后表面光亮如瓷釉(硬度HRR 112)设计理论寿命30~50年;2、成膜物质主要是无机系硅酸酯(Ceramic silicate,一种超细陶瓷粉末),及少量的共聚树脂(copolymer resin,粘性物质能够形成漆膜并粘结粉末)构成,经搅拌、均质混合等生产工艺后,产生化学反应最终形成黏稠膏体成品。

3、原料中添加了钨(W)、钼(Mo)等超微细金属粉末(纯度99.99%),不仅加强了涂膜的强度,且不会产生烧结,最大限度发挥流动性和粘结性,涂层可耐高温、耐老化,强耐蚀、耐化学药品性;4、单一涂层体系,厚度薄(平均200㎛)、水中可固化等施工特性,施工简便易行。

有利于管道现场的补口工艺,还可在水中、油中、漏气的部位及带压状态(采用适当的工艺配合)进行堵漏修补,固化后可耐水压(100kgf/ cm2)。

5、应用领域非常广泛。

不仅可满足桥梁、城建及一般工业设施的防腐,而且其绝缘性能与耐阴极剥离性能等均使其适用于长距离埋地油气管线的防护,而其水中可以固化、有效防止鱼贝类侵蚀、超强耐氯离子渗透等特点还可应用于海洋设施、船舶、码头等重防腐领域。

名 称 型 号 用 途涂布率AM-C-T海洋环境钢结构防腐:船舶、闸门、码头钢桩、桥墩(先涂装后夯打)、海上平台、井架、灯塔、化学罐等 2.5m 2/kgAM-C-E 工业环境钢结构的防腐耐温耐磨:电厂、化工厂、钢铁厂、污水厂、矿山、药厂等的各 种管道、容器、反应釜,以及泵、轴、阀等机电设备 2.5m 2/kgAM-C-O土壤环境钢结构的防腐防湿:石油天然气管道及储罐 2.5m 2/kg 钢 结构AM-C-I 大气环境钢结构的防腐:钢桥梁及铁路支架、塔架 2.5m 2/kg AM-C-C 混凝土防水防腐面漆:水厂, 污水池, 隧道, 堤坝, 灯 塔, 屋顶、地坪等2.5m 2/kg AM-C-CP 混凝土防水防腐底漆:同上,与面漆搭配 4m 2/kg 混 凝土AM-C-DP 混凝土地面填缝剂:涂装前对被涂体调整修复用 -- AM-C-U防紫外线面漆:露天钢结构及混凝土结构7m 2/kg 超陶防腐 涂 料 (AM-C 系)稀 释 剂 丁酮 ( 200ml/kg )--AM-A修补/强化/加固:各种腐蚀环境下,设备、机件构造 物的破损、裂缝、薄弱部位--超陶修补剂 (AM-A 系)Ceracot家庭日用品修补:锅炉、散热器、浴缸、大理石、 瓷器具的裂缝、破损修补堵漏,及各种物体固定和附着--产 品 种 类 及 用 途与热浸镀锌工艺对比对比项目热浸镀锌超陶涂装表面处理采用酸洗除锈,会残留有害离子,造成腐蚀隐患;且基材表面光滑,影响结合力;若酸洗时间控制不够,容易造成锌层跷起和开裂采用喷砂除锈,除锈彻底,且基材表面粗糙(45~75㎛),涂层以化学键形式与基材表面结合。

厚度镀层厚度不易控制,易流挂,不均匀,甚至引起架构变形采用高压无气喷涂,涂层厚度均匀,作业效率高,易于控制调整。

外观颜色单一,且受酸液、镀槽温度时间等参数影响,每批不同部位、批与批外观色泽不一致,常见色斑。

颜色可调,固化后如瓷釉,光泽度均匀,具有耐污自洁能力对钢结构内部应力影响镀液温度高,易使结构变形,产生内部应力,影响性能常温喷涂自然固化,无应力影响防腐性能对比锌可作牺牲阳极保护钢材,但易氧化,耐碱、耐酸雨腐蚀性能差。

需要外加面漆。

涂层致密,有效隔绝酸、碱、盐分等腐蚀介质。

耐盐雾CASS 4000H,耐紫外线老化 6000H ,满足一般环境防腐需求对现场安装的影响运输安装过程造成的磕碰,镀锌层无法补涂,严重影响整体防护效果补涂工艺简单(现场刷涂即可),涂层配套一致韩国新型Ceramic超陶防腐涂料的性能及工艺介绍(韩国爱涂防水防腐株式会社防腐研究所梁迪北京 100102)摘要:本文介绍了韩国目前防腐项目设计中常用的一种新型Ceramic超陶防腐涂料的特性、施工及发展趋势。

引用ASTM 、JIS、KSM等标准,根据Dolly Test、腐蚀电流密度、抗氯离子渗透性、CASS Test、UV照射-冷凝等实验结果,分析说明该产品具有无毒无害、高附着力,结构致密,抗冲击性强,长效防腐等特点,是一种较为理想的钢质管道防护涂料。

关键词:Ceramic超陶防腐涂料,腐蚀电流密度、氯离子渗透性、CASS Test、可靠性认证体系一、引言随着中国经济的高速发展,工业基础设施领域的投资也在急剧加大。

钢质管道,作为主要的物流渠道之一,其建造和管理方面也得到极大的发展。

最近,根据南开大学公布的《2007年中国钢管业详细评估报告》,至2020年管道应用的三大领域:石油天然气管线、城市燃气管网、机械和建筑结构钢管在今后13年间总需求量将达到34,650万吨。

详见表(一)。

其中,天然气长输管线平均年用钢管:100万t/a;油品管线中原油管线30万t/a,成品油管线40万t/a,城市燃气管网为90万t/a。

而随着中国核电装机容量大幅提升,高压锅炉管年均需求量将达到30~40万t/a左右。

表(一)8个项目2020年前用钢管重量估计表项目2020年前所需钢管量(15年)×104t年平均用量×104t百分比%天然气长输管线1500 100 4.33油品长输管线1050 70 3.03油井管2500 166 7.18城市天然气管线1400 93 4.03建筑18000 1200 51.97机械(压力管)7200 480 20.7石油化工1500 100 4.38轻工家具1500 100 4.38 总计34650 2309 100伴随管道建设的加速,相应的对管道品质,如焊接、防腐等工艺的要求也在迅速提升。

如大口径长距离输油气管、气液多相管、海洋平台架管、高压高温油井管、核岛用高压锅炉钢管、大口径城市污水排管等,愈来愈多复杂的应用环境需要新工艺新技术的出现。

今天,要向大家推荐一种韩国的新型钢质管道防护涂料Ceramic ---即由韩国B&B 株式会社自行研制开发的A TOMETAL“爱涂”超陶(Ceramic)重防腐涂料(以下简称“A TO”),在韩国目前该种产品已成为主流防腐设计,被韩国建设交通部、韩国水资源公社、住宅公社、道路公社等列入相关施工标准中,在所有拟在建项目中优先采用。

二、超陶(Ceramic)涂料性能超陶(Ceramic),以无机陶瓷粉末、少量粘性共聚物为主要成膜物质,并添加钨、钼(纯度99.99%,细度325Mash)等超微细金属粉末,一种经特殊工艺合成的新型高分子涂料。

双组分,其基本剂与固化剂混合后产生化学反应而自身放热,并且分子间交联形成三维网状结构,从而能与被涂体紧密结合,可以有效的对钢结构、混凝土结构进行防腐/防水保护。

与其他涂料的显著区别:1、固化后完全无毒无害其制造过程中不添加任何有机溶剂或其他介质,靠构成材料之间的合成反应而生成,完全无毒无害。