MP Lift directive certificate.pdf

百思维洗衣机使用说明书

Correct Use After installation, the appliance must be positioned so that the plug is accessible.

• Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

• Children

should

be

supervised to ensure that

• The final part of a washer dryer cycle occurs without heat (cool down cycle) to ensure that the items are left at a temperature that ensures that the items will not be damaged.

- Farm houses;

- By clients in hotels, motels and other residential type environments;

- Bed and breakfast type environments.

- Area for communal use in blocks of flats or in launderettes.

• The maximum load capacity of dry clothes depends on the model used (see control panel).

95_54_EC(1995) 防范当引擎火星点火时的电波干扰

COMMISSION DIRECTIVE 95/54/ECof 31 October 1995adapting to technical progress Council Directive 72/245/EEC on the approximation of the laws of the Member States relating to the suppression of radio interference produced by spark-ignition engines fitted to motor vehicles and amending Directive 70/156/EEC on the approximation of the laws of the Member States relating to the type-approval of motor vehicles and their trailers THE COMMISSION OF THE EUROPEAN COMMUNITIES,Having regard to the Treaty establishing the European Community,Having regard to Council Directive 70/156/EEC of 6 February 1970 on the approximation of the laws of the Member States relating to the type-approval of motor vehicles and their trailers (1), as last amended by Commission Directive 93/81/EEC (2), and in particular Article 13 (2) thereof,Having regard to Council Directive 72/245/EEC of 20 June 1972 on the approximation of the laws of the Member States relating to the suppression of radio interference produced by spark-ignition engines fitted to motor vehicles (3), as amended by Commission Directive 89/491/EEC (4), and in particular Article 4 thereof,Whereas Directive 72/245/EEC is one of the separate directives of the EEC type-approval procedure which was established pursuant to Directive 70/156/EEC; whereas, consequently, the provisions laid down in Directive 70/156/EEC relating to vehicle systems, components and separate technical units apply to this Directive;Whereas, in particular, Articles 3 (4) and 4 (3) of Directive 70/156/EEC require each separate directive to have attached to it an information document incorporating the relevant items of Annex I to that Directive and also a type-approval certificate based on Annex VI thereto in order that type-approval may be computerized;Whereas Directive 72/245/EEC contained the earliest measures endeavouring to bring about a basic electromagnetic compatibility regarding radio interference, since which time technical progress has increased the complexity and diversity of electrical and electronic equipment; Whereas, in view of the increasing concern about the technological developments in electrical and electronic equipment and the need to ensure the general compatibility of different electrical and electronic equipment, Council Directive 89/336/EEC (5), as last amended by Directive 93/68/EEC (6), laid down general provisions regarding electromagnetic compatibility for all products;Whereas Directive 89/336/EEC established the rule that, in so far as protection requirements specified in that Directive were harmonized, its general provisions would not apply or would cease to apply with regard to apparatus covered by specific directives;(1) OJ No L 42, 23. 2. 1970, p. 1.(2) OJ No L 264, 23. 10. 1993, p. 49.(3) OJ No L 152, 6. 7. 1972, p. 15.(4) OJ No L 238, 15. 8. 1989, p. 43.(5) OJ No L 139, 23. 5. 1989, p. 19.(6) OJ No L 220, 30. 8. 1993, p. 1.Whereas in the field of vehicles, their components and separate technical units, it is necessary to envisage a specific directive within the framework of the system for European type-approval which provides for approvals granted by designated national authorities to harmonized technical requirements;Whereas Directive 72/245/EEC should become such a specific directive;Whereas reference is made to electromagnetic compatibility in other directives relating to vehicles, their components and separate technical units, within the framework of Directive 70/156/EEC;Whereas the technical requirements relating to the radio interference (electromagnetic compatibility) of vehicles, their components and systems should be governed from 1 January 1996 solely by the provisions of Directive 72/245/EEC;Whereas it is necessary to amend Directive 70/156/EEC to reflect the extension of Directive 72/245/EEC to all vehicle categories;Whereas it is necessary to refer to Council Directive 72/306/EEC (1), as amended by Directive 89/491/EEC, in order to distinguish between spark and compression ignition engines;Whereas the measures provided for in this Directive are in accordance with the opinion of the Committee for Adaptation to Technical Progress established by Directive 70/156/EEC,HAS ADOPTED THIS DIRECTIVE:(1) OJ No L 190, 20. 8. 1972, p. 1.Article 1Directive 72/245/EEC is hereby amended as follows:1. the title shall be replaced by the following:'Council Directive 72/245/EEC of 20 June 1972 relating to the radio interference (electromagnetic compatibility) of vehicles';2. Article 1 shall be replaced by the following:'Article 1For the purpose of this Directive, "vehicle" means any vehicle as defined in Directive 70/156/EEC.';3. Article 2 shall be replaced by the following:'Article 2No Member State may refuse to grant EEC type-approval or national type-approval of a vehicle, component or separate technical unit on grounds relating to electromagnetic compatibility if the requirements of this Directive are fulfilled.';4. Article 3 shall be replaced by the following:'Article 31. This Directive shall constitute a "specific directive" for the purposes of Article 2 (2) of Council Directive 89/336/EEC (*) with effect from 1 January 1996.2. Vehicles, components or separate technical units approved pursuant to this Directive shall be considered to fulfil the provisions of other directives, cited in Annex IV to Council Directive 92/53/EEC (**), which refer to electromagnetic compatibility.(*) OJ No L 139, 23. 5. 1989, p. 19.(**) OJ No L 225, 10. 8. 1992, p. 1.';5. The Annexes shall be replaced by the Annex to this Directive.Article 21. With effect from 1 December 1995, Member States may not, on grounds relating to electromagnetic compatibility:- refuse, in respect of any given type of vehicle, to grant EEC type-approval or national type-approval,- refuse, in respect of any given type of component or separate technical unit, to grant EEC component or technical unit type-approval, or- prohibit the registration, sale or entry into service of vehicles,- prohibit the sale or use of components or separate technical units,if the vehicles, components or separate technical units comply with the requirements of Directive 72/245/EEC as amended by this Directive.2. With effect from 1 January 1996, Member States:- shall no longer grant EEC vehicle type-approval, EEC component type-approval or EEC separate technical unit type-approval, and- may refuse to grant national type-approval,for any type of vehicle, component or separate technical unit on grounds relating to electromagnetic compatibility, if the requirements of Directive 72/245/EEC, as amended by this Directive, are not fulfilled.3. Paragraph 2 shall not apply to vehicle types approved before 1 January 1996 pursuant to Directive 72/306/EEC nor to any subsequent extensions to these approvals.4. With effect from 1 October 2002, Member States:- shall consider certificates of conformity which accompany new vehicles in accordance with the provisions of Directive 70/156/EEC to be no longer valid for the purposes of Article 7 (1) of that Directive,- may refuse the registration, sale or entry into service of new vehicles which are not accompanied by a certificate of conformity in accordance with Directive 70/156/EEC, and- may refuse the sale and entry into service of new electrical/electronic sub-assemblies as components or separate technical unit,if the requirements of this Directive are not fulfilled.5. With effect from 1 October 2002 the requirements of Directive 72/245/EEC, relating to electrical/electronic sub-assemblies as components or separate technical units, as amended by this Directive, are applicable for the purposes of Article 7 (2) of Directive 70/156/EEC.6. Notwithstanding paragraphs 2 and 5, for the purposes of replacement parts, Member States shall continue to grant EEC type approval and to permit the sale and entry into service of components or separate technical units intended for use on vehicle types which have been approved before 1 January 1996 pursuant to either Directive 72/245/EEC or Directive72/306/EEC and, where applicable, subsequent extensions to these approvals.Article 3Item No 10 of Part I of Annex IV to Directive 70/156/EEC shall be amended to include an 'X' in each of the columns for vehicle category 0 under the heading 'Applicability'.Article 41. Member States shall bring into force the laws, regulations and administrative provisions necessary to comply with this Directive before 1 December 1995. They shall forthwith inform the Commission thereof.When Member States adopt these provisions, these shall contain a reference to this Directive or shall be accompanied by such reference at the time of their official publication. The procedure for such reference shall be adopted by Member States.2. Member States shall communicate to the Commission the texts of the main provisions of national law which they adopt in the field covered by this Directive.Article 5This Directive shall enter into force on the 20th day following its publication in the Official Journal of the European Communities.Article 6This Directive is addressed to the Member States.Done at Brussels, 31 October 1995.For the CommissionMartin BANGEMANNMember of the CommissionLIST OF ANNEXESANNEX 1 Requirements to be met by vehicles and electrical/electronic sub-assemblies fitted to a vehicle.ANNEX IIA Model information document for EEC type-approval of a vehicle with respect to electromagnetic compatibility.ANNEX IIB Model information document for EEC type-approval of an electrical/electronic sub-assembly with respect to electromagnetic compatibility.ANNEX IIIA Model: EEC type-approval certificate (vehicle)ANNEX IIIB Model: EEC type-approval certificate (electrical/electronic sub-assembly) ANNEX IV Method of measurement of radiated broadband electromagnetic emissions from vehicles.ANNEX V Method of measurement of radiated narrowband electromagnetic emissions from vehicles.ANNEX VI Method of testing for immunity of vehicles to electromagnetic radiation. ANNEX VII Method of measurement of radiated broadband electromagnetic emissions from electrical/electronic sub-assemblies.ANNEX VIII Method of measurement of radiated narrowband electromagnetic emissions from electrical/electronic sub-assemblies.ANNEX IX Method (s) of testing of immunity of electrical/electronic sub-assemblies to electromagnetic radiation.ANNEX IREQUIREMENTS TO BE MET BY VEHICLES AND ELECTRICAL/ELECTRONIC SUB-ASSEMBLIES FITTED TO A VEHICLE1. Scope1.1. This Directive applies to the electromagnetic compatibility of vehicles covered in Article 1, being vehicles or trailers (hereinafter referred to as vehicle(s)) as supplied by the vehicle manufacturer and to components or separate technical units intended for fitment in vehicles.2. Definitions2.1. For the purposes of this Directive:2.1.1. 'Electromagnetic compatibility' means the ability of a vehicle or component(s) or separate technical unit(s) to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment.2.1.2. 'Electromagnetic disturbance' means any electromagnetic phenomenon which may degrade the performance of a vehicle or component(s) or separate technical unit(s). An electromagnetic disturbance may be electromagnetic noise, an unwanted signal or a change in the propagation medium itself.2.1.3. 'Electromagnetic immunity' means the ability of a vehicle or component(s) or separate technical unit(s) to perform without degradation of performance in the presence of specified electromagnetic disturbances.2.1.4. 'Electromagnetic environment' means the totality of electromagnetic phenomena existing at a given location.2.1.5. 'Reference limit' means the nominal level to which type approval and conformity of production limit values are referenced.2.1.6. 'Reference antenna' for the frequency range 20 to 80 MHz: means a shortened balanced dipole being a half wave resonant dipole at 80 MHz, and for the frequency range above 80 MHz: means a balanced half wave resonant dipole tuned to the measurement frequency.2.1.7. 'Broadband emission' means an emission which has a bandwidth greater than that of a particular measuring apparatus or receiver.2.1.8. 'Narrowband emission' means an emission which has a bandwidth less than that of a particular measuring apparatus or receiver.2.1.9. 'Electrical/electronic system' means (an) electrical and/or electronic device(s) or set(s) of devices together with any associated electrical connections which form part of a vehicle but which are not intended to be type approved separately from the vehicle.2.1.10. 'Electrical/electronic sub-assembly' (ESA) means an electrical and/or electronic device or set(s) of devices intended to be part of a vehicle, together with any associated electrical connections and wiring, which performs one or more specialized functions. An ESA may be approved at the request of a manufacturer as either a 'component' or a 'separate technical unit (STU)' (see Directive 70/156/EEC, Article 2).2.1.11. 'Vehicle type' in relation to electromagnetic compatibility means vehicles which do not differ essentially in such respects as:2.1.11.1. the overall size and shape of the engine compartment;2.1.11.2. the general arrangement of the electrical and/or electronic components and the general wiring arrangement;2.1.11.3. the primary material of which the body or shell (if applicable) of the vehicle is constructed (for example, a steel, aluminium or fibreglass body shell). The presence of panels of different material does not change the vehicle type provided the primary material of the body is unchanged. However, such variations must be notified.2.1.12. An 'ESA type' in relation to electromagnetic compatibility means ESAs which do not differ in such essential respects as:2.1.12.1. the function performed by the ESA;2.1.12.2. the general arrangement of the electrical and/or electronic components, if applicable.3. Application for EEC type-approval3.1. Approval of a vehicle type3.1.1. The application for approval of a vehicle type, with regard to its electromagnetic compatibility pursuant to Article 3 (4) of Directive 70/156/EEC shall be submitted by the vehicle manufacturer.3.1.2. A model for the information document is given in Annex IIA.3.1.3. The vehicle manufacturer shall draw up a schedule describing all projected combinations of relevant vehicle electrical/electronic systems or ESAs, body styles (1), variations in body material (1), general wiring arrangements, engine variations, left-hand/right-hand drive versions and wheelbase versions. Relevant vehicle electrical/electronic systems or ESAs are those which may emit significant broadband or narrowband radiation and/or those which are involved in the driver's direct control (see paragraph 6.4.2.3 of this Annex) of the vehicle.3.1.4. A representative vehicle shall be selected from this schedule for the purpose of being tested, in mutual agreement between the manufacturer and the competent authority. This vehicle shall represent the vehicle type (see Appendix 1 to Annex IIA). The choice of vehicle shall be based on the electrical/electronic systems offered by the manufacturer. One more vehicle may be selected from this schedule for the purpose of being tested if it is considered by mutual agreement between the manufacturer and the competent authority that different electrical/electronic systems are included which are likely to have a significant effect on the vehicle's electromagnetic compatibility compared with the first representative vehicle.3.1.5. The choice of the vehicle(s) in conformity with paragraph 3.1.4 is limited to vehicle/electrical/electronic system combinations intended for actual production.3.1.6. The manufacturer may supplement the application with a report from tests which have been carried out. Any such data provided may be used by the approval authority for the purpose of drawing up the type-approval certificate.(1) If applicable.3.1.7. If the technical service responsible for the type-approval test carries out the test itself, then a vehicle representative of the type to be approved, according to paragraph 3.1.4 shall be provided.3.2. Approval of a type of ESA3.2.1. The application for approval of a type of ESA with regard to its electromagnetic compatibility pursuant to Article 3 (4) of Directive 70/156/EEC shall be submitted by the vehicle manufacturer or by the manufacturer of the ESA.3.2.2. A model for the information document is given in Annex IIB.3.2.3. The manufacturer may supplement the application with a report from tests which have been carried out. Any such data provided may be used by the approval authority for the purpose of drawing up the type-approval certificate.3.2.4. If the technical service responsible for the type-approval test carries out the test itself, then a sample of the ESA system representative of the type to be approved shall be provided, if necessary, after discussion with the manufacturer on, for example, possible variations in the layout, number of components, number of sensors. If the technical service deems it necessary, it may select a further sample.3.2.5. The sample(s) must be clearly and indelibly marked with the manufacturer's trade name or mark and the type designation.3.2.6. Where applicable, any restrictions on use should be identified. Any such restrictions should be included in Annexes IIB and/or IIIB.4. Type-approval4.1. Routes to type-approval4.1.1. Type-approval of a vehicleThe following alternative routes to type-approval of a vehicle may be used at the discretion of the vehicle manufacturer.4.1.1.1. Approval of a vehicle installationA vehicle installation may achieve type-approval directly by following the provisions laid down in paragraph 6 of this Annex. If this route is chosen by a vehicle manufacturer, no separate testing of electrical/electronic systems or ESAs is required.4.1.1.2. Approval of vehicle type by testing of individual ESAsA vehicle manufacturer may obtain approval for the vehicle by demonstrating to the approval authority that all the relevant (see paragraph 3.1.3 of this Annex) electrical/electronic systems or ESAs have individually been approved in accordance with this Directive and have been installed in accordance with any conditions attached thereto.4.1.1.3. A manufacturer, if he wishes, may obtain approval to this Directive if the vehicle has no equipment of the type which is subject to immunity or emission tests. The vehicle shall have no systems as specified in paragraph 3.1.3 (immunity) and no spark ignition equipment. Such approvals do not require testing.4.1.2. Type-approval of an ESAType-approval may be granted to an ESA to be fitted either to any vehicle type or to a specific vehicle type or types requested by the manufacturer. ESAs involved in the direct control of vehicles will normally receive type-approval in conjunction with a vehicle manufacturer.4.2. Granting of type-approval4.2.1. Vehicle4.2.1.1. If the representative vehicle fulfils the requirements of this Directive, EEC type-approval pursuant to Article 4 (3), and if applicable, Article 4 (4) of Directive 70/156/EEC shall be granted.4.2.1.2. A model for the EEC type-approval certificate is given in Annex IIIA.4.2.2. ESA4.2.2.1. If the representative ESA system(s) fulfil(s) the requirements of this Directive, EEC type-approval pursuant to Article 4 (3), and if applicable, Article 4 (4) of Directive 70/156/EEC shall be granted.4.2.2.2. A model for the EEC type-approval certificates is given in Annex IIIB.4.2.3. In order to draw up the certificates referred to in paragraph 4.2.1.2 or 4.2.2.2, the competent authority of the Member State granting the approval may use a report prepared by an approved or recognized laboratory or in accordance with the provisions of this Directive.4.3. Amendments to approvals4.3.1. In the case of amendments to approvals granted pursuant to this Directive, the provisions of Article 5 of Directive 70/156/EEC shall apply.4.3.2. Amendment of a vehicle type-approval by ESA addition or substitution.4.3.2.1. Where a vehicle manufacturer has obtained approval for a vehicle installation and wishes to fit an additional or substitutional electrical/electronic system or ESA which has already received approval pursuant to this Directive, and which will be installed in accordance with any conditions attached thereto, the vehicle approval may be amended without further testing. The additional or substitutional electrical/electronic system or ESA shall be considered as part of the vehicle for conformity of production purposes.4.3.2.2. Where the additional or substitutional part(s) has (have) not received approval pursuant to this Directive, and if testing is considered necessary, the whole vehicle shall be deemed to comply if the new or revised part(s) can be shown to comply with the relevant requirements of paragraph 6 or if, in a comparative test, the new part can be shown not to be likely to adversely affect compliance of the vehicle type.4.3.2.3. The addition by a vehicle manufacturer to an approved vehicle of standard domestic or business equipment, other than mobile communication equipment (*) which complies with Directive 89/336/EEC, and is installed according to the recommendations of the equipment and vehicle manufacturers, or the substitution or removal thereof, shall not invalidate the vehicle approval. This shall not preclude vehicle manufacturers fitting communication equipment with suitable installations guidelines developed by the vehicle manufacturer and/or manufacturer(s) of such communication equipment. The vehicle manufacturer shall provide evidence (if requested by the test authority) that vehicle performance is not adversely affected by such transmitters. This can be a statement that the power levels and installationare such that the immunity levels of this Directive offer sufficient protection when subject to transmission alone, i.e. excluding transmission in conjunction with the tests specified in paragraph 6. This Directive does not authorize the use of a communication transmitter when other requirements on such equipment or its use apply. A vehicle manufacturer may refuse to install in his vehicle standard domestic or business equipment which complies with Directive 89/336/EEC.(*) For example: radio telephone and citizens band radio.5. Marking5.1. Every ESA conforming to a type approved pursuant to this Directive shall bear an EEC type-approval mark.5.2. This mark shall consist of a rectangle surrounding the letter 'e' followed by the distinguishing number or letters of the Member State which has granted type-approval:1 Germany2 France3 Italy4 the Netherlands6 Belgium9 Spain11 the United Kingdom13 Luxembourg18 Denmark21 Portugal23 GreeceIRL IrelandIt must also include in the vicinity of the rectangle the four-digit sequential number (with leading zeros as applicable) - hereinafter referred to as 'base approval number' - contained in Section 4 of the type-approval number shown on the EEC type-approval certificate issued for the type of device in question (see Annex IIIB), preceded by the two figures indicating the sequence number assigned to the most recent major technical amendment to Directive 72/245/EEC on the date EEC component type-approval was granted. In this Directive the sequence number is 02.5.3. The EEC type-approval mark must be affixed to the main part of the ESA (e.g. the electronic control unit) in such a way as to be clearly legible and indelible.5.4. An example of the EEC type-approval mark is shown in Appendix 7.5.5. No marking is required for electrical/electronic systems included in vehicle types approved by this Directive.5.6. Markings on ESAs in compliance with paragraph 5.3 need not be visible when the ESA is installed in a vehicle.6. Specifications6.1. General specification6.1.1. A vehicle (and its electrical/electronic system(s) or ESAs) shall be so designed, constructed and fitted as to enable the vehicle, in normal conditions of use, to comply with the requirements of this Directive.6.2. Specifications concerning broadband electromagnetic radiation from vehicles fitted with spark ignition.6.2.1. Method of measurementThe electromagnetic radiation generated by the vehicle representative of its type shall be measured using the method described in Annex IV at either of the defined antenna distances. The choice shall be made by the vehicle manufacturer.6.2.2. Vehicle broadband reference limits6.2.2.1. If measurements are made using the method described in Annex IV using a vehicle-to-antenna spacing of 10,0 ± 0,2 m, the radiation reference limits shall be 34 dB microvolts/m (50 microvolts/m) in the 30 to 75 MHz frequency band and 34 to 45 dB microvolts/m (50 to 180 microvolts/m) in the 75 to 400 MHz frequency band, this limit increasing logarithmically (linearly) with frequencies above 75 MHz as shown in Appendix 1 to this Annex. In the 400 to 1 000 MHz frequency band the limit remains constant at 45 dB microvolts/m (180 microvolts/m).6.2.2.2. If measurements are made using the method described in Annex IV using a vehicle-to-antenna spacing of 3,0 ± 0,05 m, the radiation reference limits shall be 44 dB microvolts/m (160 microvolts/m) in the 30 to 75 MHz frequency band and 44 to 55 dB microvolts/m (160 to 562 microvolts/m) in the 75 to 400 MHz frequency band, this limit increasing logarithmically (linearly) with frequencies above 75 MHz as shown in Appendix 2 to this Annex. In the 400 to 1 000 MHz frequency band the limit remains constant at 55 dB microvolts/m (562 microvolts/m).6.2.2.3. On the vehicle representative of its type, the measured values, expressed in dB microvolts/m, (microvolts/m), shall be at least 2,0 dB (20 %) below the reference limits.6.3. Specifications concerning narrowband electromagnetic radiation from vehicles.6.3.1. Method of measurementThe electromagnetic radiation generated by the vehicle representative of its type shall be measured using the method described in Annex V at either of the defined antenna distances. The choice shall be made by the vehicle manufacturer.6.3.2. Vehicle narrowband reference limits6.3.2.1. If measurements are made using the method described in Annex V using a vehicle-to-antenna spacing of 10,0 ± 0,2 m, the radiation-reference limits shall be 24 dB microvolts/m (16 microvolts/m) in the 30 to 75 MHz frequency band and 24 to 35 dB microvolts/m (15 to 56 microvolts/m) in the 75 to 400 MHz frequency band, this limit increasing logarithmically (linearly) with frequencies above 75 MHz as shown in Appendix 3 of this Annex. In the 400 to 1 000 MHz frequency band the limit remains constant at 35 dB microvolts/m (56 microvolts/m).6.3.2.2. If measurements are made using the method described in Annex V using a vehicle-to-antenna spacing of 3,0 ± 0,05 m, the radiation reference limit shall be 34 dB microvolts/m (50 microvolts/m) in the 30 to 75 MHz frequency band and 34 to 45 dB microvolts/m (50 to 180 microvolts/m) in the 75 to 400 MHz frequency band, this limit increasing logarithmically (linearly) with frequencies above 75 MHz as shown in Appendix 4 to this Annex. In the 400 to 1 000 MHz frequency band the limit remains constant at 45 dB microvolts/m (180 microvolts/m).。

Sprint

Sprint Mag CapImportant Safety InstructionsImportant Safety InstructionsWHEN USING YOUR APPLIANCE, BASIC PRE-CAUTIONS SHOULD ALWAYS BE FOLLOWED, INCLUDING THE FOLLOWING:Read all instructions.Use appliance only for its intended use.To reduce the risk of electric shock, do not immerse the appliance in water or other liquids.Never pull cord to disconnect from outlet, instead grasp plug and pull to disconnect.Do not allow cord to touch hot surfaces, let appliance cool completely before putting away.Do not operate appliance with a damaged cord, or if the appliance has been dropped ordamaged. To reduce the risk of electric shock, do not disassemble or attempt to repair theappliance, take it to a qualified service person for examination and repair. Incorrect reassemblyor repair could cause a risk of fire, electric shock, or injury to persons when the appliance is used.Close supervision is necessary for any appliance being used by or near children.Do not leave appliance unattended while connected.Burns could occur from touching hot metal parts.To reduce the likelihood of circuit overload, do not operate another high voltage appliance onthe same circuit.If an extension cord is absolutely necessary, a 20 ampere rated cord should be used.Cords rated for less amperage may overheat, care should be taken to arrange the cord sothat the cord cannot be pulled or tripped over.SAVE THESE INSTRUCTIONS.Sprint Mag CapTable of Contents3 45-101112131415Digital Part Location Guide Sprint ® Mag Cap Control PanelOperating Instructions Replacement Parts List Parts Location GuideSprint ® Mag Cap electrical SchematicCE-Certification Terms of guaranteeLift Handle12V MagnetPower ON/OFFSwitchPressureAdjustmentKnobCap Hold Down LeverSIDE VIEWFRONT VIEWLED DisplayLocated on the opposite side of the pressPower SupplyCircuitBreakerSprint Mag CapCap Hold Down LeverON OFF Machine ViewThe Digital Sprint ® Mag Cap Operating Instructions are designed with you in mind.Carefully read and follow the step-by-step instructions for best results.If you experience any difficulty, carefully re-read the instructions and try again.Pay particular attention to the risk of burns which can be sustained by touching the heated platen during use.Keep hands clear from the platens of the press during platen lock down as the pressure can cause injury.Press should be placed on a sturdy suitable stand of at least 60x90cms (24"x36").Work area must be kept clean, tidy and free of obstructions to the movements of the heat press.Power supply cord must be disconnected before cleaning or servicing press.Connect the power cord into a properly grounded (earthed) electrical outlet with a sufficient amperage rating.Your Sprint ® Mag Cap requires a full 7,5 amp grounded circuit for 240 volt operation.Extension Cords, if used, should be as short as possible and not less than 12 gauge. Heavy duty cords are recommended.Circuits that have under 15 amps or other high demandequipment or appliances (especially more than one heat seal machine) should not be used.NOTE:If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or asimilarly qualified person in order to avold hazard. Use HSJ type, rated 250V-10 AMP for replacement.CAUTIONFAILURE TO FOLLOW THESE INSTRUCTIONS WILL CAUSE:1. Erratic controller functions.2. Inaccurate displays and slow heat-up.3. The circuit breaker to disengage.Connect the Power CordNow, locate the Power ON/OFF Switch on the side of the press,then turn the Power Switch on.Power ON/OFF SwitchSee the diagram below for switch placement.Locate the packaging bolt positioned on the top-centre of the press. Packaging bolt must be removed prior to turning the press on or operating the press.Turning the System OnON OFFLocate the LED Display on the Press.Press the Mode Select button located in the centre of the Control Panel.The (SET) and (TEMP) lights located next to the display will illuminate indicating you are in the adjust temperature mode.Next, press the (-) button located to the left of the Mode Select button to lower the temperature setting,or press the (+) button located to the right of the Mode Select button to raise the temperature setting.The temperature can be set from 170° F (76° C) to 430° F (220° C).The LED will display changes as you make them.Digital DisplayTemperature IndicatorTime Indicator Pressure IndicatorDecreaseMode Select Increase Set Indicator Adjust Temperature & TimeAdjusting the TemperatureThe Sprint ® Mag Cap has two time settings. This will allow you to set different times when a two step application is required. For single hit applications, you simply set both time settings the same.Once you have adjusted the temperature, press the Mode Select button again. This will advance you to the Time #1 mode. The set and time lights will illuminate, indicating that you are in the Time # 1 mode.Adjust the time in the same manner that you adjusted the temperature. Once you have the Time # 1 set,push the Mode Select button again to advance to the Time # 2 setting. All three red LED lights will illuminate indicating that you are in the Set Time # 2 Mode. Select the desired time and push the Mode Select button again to exit the time settings. All lights will be off and the press will return to the print mode.NOTE:Press the Mode Select button ONCE to advance to the Adjust Temperature Mode.Remember:Press the Mode Select button A SECOND TIME to advance to the Time #1 mode Press the Mode Select button A THIRD TIME to advance to the Time #2 Settings. Press the Mode Select button A FOURTH TIME to return to the Heat Up/Operating Mode.Adjust the TimeMode SelectAdjusting the TimeAdjust PressureAdjusting the PressureFirst, locate the LED Display on the Press.(see figure 1).The Pressure Adjustment Knob is located directlyunder the lower platen (see figure 2).Adjust the pressure by turning the knobclockwise to increase pressure and counterclockwise to decrease pressure.PRESSURE READOUTA visual Pressure Readout is located on the lowerright side of the LED Display. When the handle islocked into the Print Position, a pressure numberwill be displayed. Readout will be on a scale ofPressure Adjustment KnobCap Hold Down LeverPrint / PressPrinting / PressingOnce your equipment has reached the designated temperature:Pull the “Cap Hold Down Lever” up and towards the operatorand load the cap onto the lower platen.Pull out the sweatband and position the cap so that it clearsthe upper platen when the machine is closed.Push the “Cap Hold Down Lever” down and away from theoperator. This will stretch and hold the cap from moving.Position your application and lower and lock the heat plateninto the press position. This will start the automatic timing process.The timer will automatically count down andlift the heat platen into the “UP” position whenthe press cycle is complete.NOTE:Please be aware after time is complete, gasshocks will automatically release the platen intothe “UP” position.The time will automatically re-set and you areready to continue with the next application.Replacement Parts List = Wear Parts= Wear PartsElectrical SchematicCE-CertificationbatteryEC conformance explanation:For the purposes of the EC-Machine Guideline 98/37EU, Appendix 2A and the EC LowVoltage directive to 73/23 European Economic Community as well as the EC EMV-guideline 89/336. For the manufacturer STAHLS’ Hotronix Division, we state as EuropeanCommissioners, that our product:A Transfer Press for ironing of thermo application.Model: Sprint® Mag CapThe product supplied corresponds to the following appropriate regulations:EMC Directive (2014/30/EU), Machinery Directive (20069/42/EC), RoHS Directive (2011/65/EU)& Low voltage Directive (2006/95/EC)Applied Harmonized normsEN 55011:2007EN 61000-4-4:2004 EN 61000-3-2:2006 EN 61000-6-1:2007EN 61000-4-5:2006 EN 61000-3-3:1995EN 61000-4-2:1995EN 61000-4-6:1996 EEC 60335-2-44EN 61000-4-3:2006EN 61000-4-11:2004EN 61000-4-8:1993IEC 61000-3-3:1994It is possible that not all the listed norms apply to the above mentioned product.STAHLS’ Europe GmbH (Frank Brücker, Chief Executive STAHLS’ Europe GmbH)WEE and RoHS SymbolsSTAHLS’ Europe GmbH will take back ALL heat press machinesFREE OF CHARGE (inside the EU) that have been manufactured by them, even thosesold prior to the date stated above, subject to the heat press machine being deliveredto them at the owners costs.STAHLS’ Europe GmbH will break down the heat press machine and ensure that allrecyclable parts are correctly recycled, and non-recyclable parts will be disposed of inaccordance with legal requirements. In an e ort to make such transaction as smooth tocustomers as is possible, and to ensure that all STAHLS’ heat presses are identi able,all heat press machines supplied by STAHLS’ Europe GmbH will have the logo/brand ofSTAHLS’ Hotronix clearly marked upon them.Contact:STAHLS’ Europe GmbH, Dieselstraße 62, 66763 Dillingen, Germany Telefon:+49(0)6831/9733-0,Fax:+49(0)6831/973345,www.stahls.de,**************Terms of GuaranteePolicyWarrantySTAHLS’ Europe GmbH provides the following warranty for the Sprint® Mag Cap, subject to the following terms:DurationThe warranty period of 2 years commences from the date of receipt by the buyer of the heat press machine, which can be verified by the invoice or similar documents. The warranty does not cover any damage caused by normal wear and tear.RepairIf any parts are found to be defective, despite proper use, authorised use and not as a result of fair wear and tear, within the warranty period, then they will be replaced or repaired without question provided that STAHLS’ Europe GmbH have been informed of any such claim in writing within one week of the occurrence of the failure. The terms and conditions of the commercial transaction are specifically excluded from this warranty, especially §§377 et.seq. HGB. Following any claim under the warranty,the warranty period will not be extended for either the heat press machine or for any replaced parts.Any exchanged parts will be the property of STAHLS’ Europe GmbH. No charge will be made for any labour or components for any claim under the warranty. STAHLS’ Europe GmbH operates a “bring in”guarantee for the first six months from the date of the purchase, under which all delivery and return costs will be borne by STAHLS Europe GmbH. After the first six months from the date of purchase,all delivery and return costs will be borne by the customer.RectificationInitially the customer’s rights are limited to repair by STAHLS’ Europe GmbH. Should the repair or remedial works finally fail, it will become the customer’s right according to §462 BGB to receive a payment reduction, or to withdraw from the contract. In every case, any further claim would be excluded, especially indemnity claims (including consequential damages) and those resulting from defects, unless it can be proven that STAHLS’ Europe GmbH acted intentionally, grossly negligently, or there are requirements according to §463 BGB.ReturnsGoods may only be returned with express written authorisation from STAHLS’ Europe GmbH. Customers must ensure that the heat transfer machine is properly fixed to the supplied wooden panel, and returned in the original carton, which must include the contact details of the sender, together with details of any failure which requires remedying. STAHLS’ Europe GmbH will not be liable for any damages howsoever caused during transportation as a result of improper packaging.Acceptance of Returned machines manufactured by STAHLS’ for disposalSTAHLS Europe GmbH agrees to accept the return of all heat press machines manufactured by STAHLS’or with their genuine trademark for Free of Charge disposal, subject to the costs of delivery to STAHLS’Europe GmbH being borne by the sender. WEEE DE 54539730.PackagingThe original carton (box), packaging and wooden transport panel must be retained for any future transportation of the heat press machine.Circuit BreakerIf the circuit breaker should become dislodged, it can easily be reinstated after the heat press machine has cooled down. It is recommended to try and eliminate the source of any failure by using the error checklist.Set UpIt is important that the heat press machine is fixed securely to your worktop. To set up the press, it is necessary to fully open the press, and place the substrate that is to be printed flat on the lower platen.If the press is not fully open, there is a risk of being burnt. Always follow the supplied instructions for printing for every respective material.。

安规认证培训 全球认证介绍

全球各地区认证标志

标准体系

标准体系

认证类型

强制性产品认证(法律法规要求的-国家,州/省,监管目录)

中国:CCC认证 北美:FCC认证, IC认证 欧盟:CE认证,ROSH 日本:PSE菱形 韩国:KC认证 俄罗斯,白,哈海关联盟EAC认证 其他……

自愿性认证(市场要求的-分销商,零售店,消费者,工厂)

RoHS是由欧盟立法制定的一项强制性标准, (Restriction of Hazardous Substances)。主要用于规范电子电气产品的材料及 工艺标准,使之更加有利于人体健康及环境保护。

WEEE即Waste Electrical and Electronic Equipment (WEEE) Directive (2012/19/EU),报废的电子电气设备,报废实际上是针对WEEE指令中附件 Ⅰ中所有类别的产品,即使该产品并无达到使用寿命结束的阶段,只要被 消费者丢弃都视为废弃物

FCC认证即是由FCC(Federal Communications Commission,美国联邦通信委员会)于1934 年建立是美国政府的一个独立机构,直接对国会负责。

CSA是加拿大标准委员会的认証标志,它能对机械、建材、电器、电脑设备、办公设备、 环保、医疗防火安全、运动及娱乐等方面的所有类型的产品提供安全认证。

就可以让代理商帮忙出宣告。该产品就可以销售至澳洲并打上RCM Mark。 ◦ EMC Report --- 即可以是C-Tick Report (Test Standard: AS/NZS CISPR 22: 2002), 也

可以是CE EMC Report。

常见认证标志

认证机构介绍

TUV-德国技术监督协会

日本

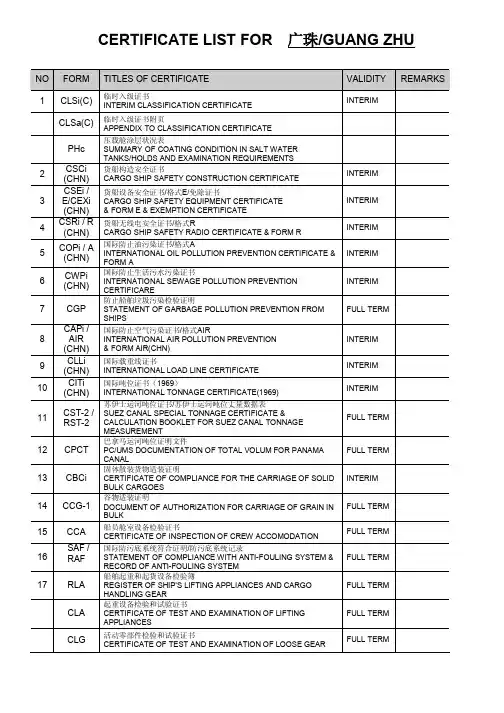

List of Certificate 最全船舶证书大全(中英文对照)

BULK CARGOES

谷物适装证明

14 CCG-1 DOCUMENT OF AUTHORIZATION FOR CARRIAGE OF GRAIN IN FULL TERM

BULK

15

CCA

船员舱室设备检验证书 CERTIFICATE OF INSPECTION OF CREW ACCOMODATION

connection with the services provided by this Society shall be submitted Arbitration Commission for arbitration which shall be conducted in accordance with the

INTERIM

6

CWPi (CHN)

国际防止生活污水污染证书

INTERNATIONAL SEWAGE POLLUTION PREVENTION CERTIFICARE

INTERIM

防止船舶垃圾污染检验证明

7

CGP STATEMENT OF GARBAGE POLLUTION PREVENTION FROM

INTERIM

10

CITi (CHN)

国际吨位证书(1969) INTERNATIONAL TONNAGE CERTIFICATE(1969)

INTERIM

苏伊士运河吨位证书/苏伊士运河吨位丈量数据表

11

CST-2 / SUEZ CANAL SPECIAL TONNAGE CERTIFICATE & RST-2 CALCULATION BOOKLET FOR SUEZ CANAL TONNAGE

重大改建部位

Major Portion:

PASSENGER PRO LIFT乘客电梯说明书

P A S S E N G E R P R O L I F TThese are possible min/max values, certain drive and building requirements may limitvalues. See brochures technical pages or contact a sales specialist for more information.*PASSENGER PRO LIFTPassenger Pro lift offers passengers a unique travel experiencecharacterised by smooth and silent travel with no abruptmovements. The result is a relaxed user experience and the capacity to shine, whatever the architectural setting.SPEED : 1 - 1.2 M/SThe Premier Home Lift offers smooth consistent speed betweenfloors and is in conformity with European standards.RATED LOAD: UP TO 630KG *Advanced traction drive system allows for a high maximum capacity with up to 8 people using the lift at a given time.TRAVEL: 60 M Suitable for most residential and public spaces.MACHINE - ROOM LESS TRACTION DRIVEDrive options that are suited to the user and building requirements. We work with you to provide the best option.MEETS ALL LEGISLATION REQUIREMENTSAll of our products comply with Europe’s strictest safety requirements. Ensuring safety with the latest EC directives.PIT & HEADROOM REQUIREMENTSPit requirements are a minimum of 1050mm. Minimum headroomfrom the top floor FFL is 3400mmPAGE 7Indicates the floor to which the lift is travelling and the time remaining before arrival, expressed in seconds.DESTINATION FLOOR & TIME REMAINING BEFORE ARRIVAL Sleek rounded design finished in AISI 304 stainless steel. Lift car is also available with handrails on all walls or without.HIGH QUALITY STAINLESS STEEL HANDRAILS Minimalist cabin design caters for our customers’ most demanding finishes right down to the last detail, both in terms of appearance and of function.ALL NEW MODERN DESIGN CABIN New 7” car and landing indicators that keep passengers up to date in realtime regarding the lift position.SMARTECH CAR AND LANDING INDICATORSSUPREME PRECISION ANDCOMFORTThe Passenger Pro Lift offers users a unique travel experiencecharacterised by smooth and silent travel with no abrupt movements.Our Direct Approach System allows the lift’s control system to calculatethe optimum speed curve for each trip, avoiding the delays typicallyexperienced with lifts that do not benefit from this function.As a result, lift travel and waiting times are drastically reduced andpassenger experience in terms of comfort, smoothness of travel and car-to-landing stopping accuracy are significantly improved.On top of that, the Direct Approach System gets rid of the need for aseries of sensors and devices inside the lift shaft, thereby simplifying,shortening and economising on the lift installation process and subsequent maintenance work.STATE OF THE ART DRIVE SYSTEMIn full compliance with:· 2014/33/EU Directive· EN 81-20/50 Standards · EN 81-28 Remote alarms Optional: EN81-73 · EN81-70Gearless machine: compact & energy efficient as well as easier to install due to its reduced weightState-of-the-art electronicoverspeed governor.The car platform, flooring,ceilings and sling arrangementmake for a robust andhard-wearing product.The robust c onventionalunder-slung sling arrangementallows for excellent ride quality. Amodernelectrically triggered safetygear replaces the traditional linkagebar mechanism whilst providing a lower tripping speed.The machined guide rails are of the highest quality and are delivered cut to size to suitthe particular project.Automatic fire-rated doors,side or central opening aresafe and reliable. Availablein brushed stainless steel or epoxy finish.In-shaft safety devices (limit switches, absolute positioning,door zone magnets, finallimits) are integrated into a LIMAX Safe device.VARISPEED TECHNOLOGY FASTER TRAVEL FOR OPTIMUM TRAFFIC MANAGEMENT.Our Passenger Pro lift incorporates innovative Varispeed technology that allows the lift to travel faster, cut passengers’ travel and waitingtimes and increase the building’s lift traffic capacity.WITHOUT VARISPEED WITH VARISPEED1 m/s 1.2 m/s Varispeed allows lifts to travel faster than their rated speed.When the weight of the lift car and counterweight are well balanced, depending on the number of passengers inside the lift car, the gearless machine may not require all of its power to move the lift at nominal speed. This unused power allows the lift to travel faster.* & ***: Based on traffic analysis during the late evening in a residential building with 24m travel, 9 floors and an occupation of 10people per floor.**: Based on data collected of random traffic in a residential building over 6 floorswith 15.5m travel.Travel up to 20% faster.Reduction of waiting times.*Reduced energy consumption.**Reduced travel time to destination.***REVOLUTIONARY ENERGY-EFFICIENCY Our Passenger Pro lifts have been awarded the maximum possible energy-efficiency ratings according to the VDI 4707 and ISO 25745-2 standard.VarispeedBrand-new technology that converts the Silens Pro Revolution ® in to the first lift on the market that travels faster that it’s nominal speed.SIRES (Shaft Intelligent Revolutionary Elevator System) A concept based on a PESSRAL devicewith an electronically activated over-speed governor, electromechanical safe-ty gear and absolute positioning that:· Guarantees maximum safety of pas-sengers.· Allows automatic shaft learning, dras-tically reducing commissioning costs.Revolutionary in its energy-efficiency The incorporation of Varispeed and the Direct Ap-proach System.The gearless drive unit significantly lowers energy consumption and does not require lubricants.Stand-by mode is activated whenever the lift is not in use.Energy-efficient lighting withLED spotlights .Designed and built in compliance withISO 14001, the international standard which sets the basis for anef-fective environmental management system.Approach System.Stand-by mode is activated whenever the lift is not in Designed and built in compliance with ISO 14001,STRUCTURES FOR INDOOR AND OUTDOOR USEOur lifts can be provided with highly customisable structures. They can be designed with different types of glass panelling to suit installations of all kinds and provide support when masonry work is unavailable. Our skilled engineering team ensures installation is completed quickly with great careto the surrounding environment.EASY TO FOLLOW & COMPREHENSIVE DRAWING Our visual site-specific drawing pack has been developed to provide clear- Electrical Requirements- Doors dimensions and fixing points- Scaffolding, lighting and safety requirements- Cabin and door finishesPAGE 20ADD INSTALLATION INFO We work to provide a speedy installation, with minimal interference to your building or the surrounding area, making sure that you get to carry on withyour daily life.PASSENGER LIFT SOLUTIONS ACROSS THE UK Premier Lift Group is a leading provider of passenger lifts in the UK. Our team of lift engineers and installation specialists have years of experience designing, manufacturing and installing tailor-madePAGE 23BOOK A NO OBLIGATIONCONSULTATIONStart a conversation with Premier today, we will asses yourrequirements, talk through our available options and ensure we meetyour lift solution needs.***********-London 0161 820 3716 – Manchester************************.ukF I N I S H E S& A C C E S S O R I E S10La línea 210 ofrece cabinas ideales paraintegrarse en cualquier proyecto de edificio;hemos buscado un diseño funcional basadoen una construcción modular plana, unapaleta de colores fresca y actual y una altacalidad en los materiales orientada a su mayordurabilidad y resistencia.• Paneles de cabina acabados en laminadosplásticos (skinplates) de distintos colores.• Suelo de alta resistencia en caucho, vinilo,mármol o granito.• Iluminación directa mediante focos LEDs oindirecta mediante fluorescentes a travésde sobretechos de diferentes diseños.Línea 210200 SERIES200 Revolution Series lift cars are built with galvanisedsteel sheeting and clad with plastic laminatesavailable in a wide range of colours or with stainlesssteel in a choice of different patterns.IN-CAR LIGHTINGDirect, using LED spotlights from either range.LIFT-CAR DOORS AND FRONT RETURNS:Finished in stainless steel.CAR OPERATING PANEL:BCR 1 model which includes the 7” TFT colour indicator.FLOORINGHard-wearing cabin floors available in a range of rubberfinishes.HANDRAILS (OPTIONAL)Finished in AISI 304 stainless steel. Lift car is also availablewith handrails on all walls or without.MIRROR (OPTIONAL)Covering half of the back wall of the car.Design in full accordance with 2014/33/EUDirective, EN 81-20:2014, EN 81-50:2014 and EN81/70:2018300 Series lift cars are built with galvanised steelsheeting and clad with high-pressure laminates in awide range of colours.12La línea 210 ofrece cabinasideales paraintegrarse en cualquier proyecto de edificio;hemos buscado un diseño funcional basadoen una construcción modular plana, unapaleta de colores fresca y actual y una altacalidad en los materiales orientada a su mayordurabilidad y resistencia.• Paneles de cabina acabados en laminadosplásticos (skinplates) de distintos colores.• Suelo de alta resistencia en caucho, vinilo,mármol o granito.• Iluminación directa mediante focos LEDs oindirecta mediante fluorescentes a travésde sobretechos de diferentes diseños.Línea 210300 SERIESIN-CAR LIGHTINGDirect, using LED spotlights from either range.LIFT-CAR DOORS AND FRONT RETURNS:Finished in stainless steel.CAR OPERATING PANEL:BCR 2 model which includes the 7” TFT colour indicator.SKIRTINGSFinished in aluminium.FLOORINGHard-wearing cabin floors available in a range of rubberfinishes.HANDRAILS (OPTIONAL)Finished in AISI 304 stainless steel. Lift car is also availablewith handrails on all walls or without.MIRROR (OPTIONAL)covering two-thirds of the car’s back wall.Design in full accordance with 2014/33/EUDirective, EN 81-20:2014, EN 81-50:2014 and EN81/70:2018PB 10PM 10PM 35S45GN Pearl GreyBlack LabradorS101PB 40Stainless SteelPB 20PM 20PM 45PB 50PSRCAR WALL PANELSSkinplate200 SERIES FINISHESLANDING INDICATORS300 SERIES FINISHESStainless steelRubber Granite MarbleHigh pressure laminatesFLOORINGCAR OPERATING PANELS, LANDING PUSHSTATIONS & INDICATORSL.E.D Spotlights Square L.E.D SpotlightsStainless WavesPB 30PM 30BER1*FERVSmartech HR 7” indicator.EN81-70 option: Includes fordirection of travel arrow and gong.HLER - Car doorjamb(EN81-70)BER2**BER3***PM 55PB 15PM 15PM 40S42GB White ItaliaClear LabradorS102Brown PortuguesePB 45Stainless SquarePB 25PM 25PM 50PB 35LANDING SMARTECHHR DISPLAY**OPTIONALStainless steel push-buttonswith tactile legend and braille(EN81-70 compliant).DIFFERENT DOOROPTIONS FOR ANYSPACELANDING & CABIN DOORSWhether you are limited on space or require a certain aesthetic we provide a range of door options that offer different opening and usage. They can be configured with different finishes and RALpainted to match any environment.Our telescopic doors are available with a smoke and fire rating of up-to 120 minutes under European standard.PAGE 30TELESCOPIC WITHSOLID PANELSTELESCOPIC WITHPARTIAL FRAMED GLASSTELESCOPIC WITHPINNED GLASSTELESCOPIC WITHFRAMED GLASSTELESCOPIC (LANDING & CABIN)AVAILABLE IN 2,3 AND 4 PANEL OPTIONSFIRE RATED SMOKE RATED***********-London 0161 820 3716 – Manchester************************.uk。

社会责任审核所要准备的文件(中国)

社会责任审核所需之文件(中国)Document Checklist for CSR Audit (China)以下正本文件烦请准备,并恳请允许复印样本,谢谢!Please prepare the original documentation listed below for verification and sample photocopying, Thanks!1. 工卡或考勤记录 (过去十二个月)。

如果是使用电子考勤,审核员可能需要在计算机直接审阅考勤记录,审阅是会在工厂职员协助下进行如果是使用手工考勤,员工需每月最少签名一次以作确认。

Timecards or Attendance Records (Last 12 Months). If electronics time card is used, the auditor may need to review the time record directly from the computer, with the assistance from the factory staff.If manual attendance record is used, employees’ signature is required at least once a month for verification.2. 工资表 (过去十二个月)Payroll Records (Last 12 months)3. 员工花名册及员工个人档案(含身份证复印件)Employee Roster and Employee Personnel Records (including I.D. card copy)4. 劳动合同Labor Contract5. 社会保险收据、参保人员花名册,当地参保要求文件,或合格证明文件等Social Insurance Receipts, Name List, Social Insurance Local Policy or Qualified Certificate, etc.6. 工商营业执照RegistrationBusiness7. 建筑工程消防验收意见书/ 消防检查报告Construction Project Fire Safety Acceptance Document or Fire Safety Inspection Certificate8. 消防演习记录、紧急疏散计划及工伤记录等Fire Drill Record, Emergency Evacuation Plan1 Work Accident Records and Work-related Injury Record9. 特种设备注册登记及检验文件,如电梯、起重机械、铲车、锅炉及压力容器(含气瓶,压力表及安全阀)等Special Appliance Safety Operation Certificate/ Calibration Report such as Lift, Lifting Appliance, Forklift, Boiler and Compressing Equipment including Gas Cylinders, Gauge and Safety Valve).10. 特种作业人员操作证,如电梯工、起重机械操作工,叉车司机,电工及焊接工等。

电梯国标学习1-机房和滑轮间

6 机房和滑轮间注意机房的空间要求,强度要求,通风,驱动主机,控制柜的放置要求,机房照明电源插座等解说:本章将被EN81-1的一个修改件—A2(机器设备与滑轮空间)所取代。

由于欧洲(芬兰的通力公司)率先推出了无机房电梯。

同时欧盟的电梯法规(Lift Directive)95/16/EC 也不禁止无机房的电梯的存在。

因此,EN81-1所规定的“机房”的概念和6.1.1条所规定的“电梯驱动主机及其附属设备和滑轮应设置在一个专用房间内”在技术上已经技术发展的要求。

因此CEN/TC10对其进行了修改,由于并不需要全面修订EN81-1(加之新的EN81-1 1998刚刚施行等原因)因此已修改件(或叫修正案)的方式进行修改,就是所谓的A2。

A2中以“机器设备空间”的概念替代了“机房”的概念。

因此一般视A2为无机房电梯的规定,但实际上A2不仅适用于无机房电梯,同样适用于有机房电梯。

6.1 总则6.1.1 电梯驱动主机及其附属设备和滑轮应设置在一个专用房间内,该房间应有实体的墙壁,房顶,门和(或)活板门,只有经过批准的人员(维修,检查和营救人员)才能接近。

机房或滑轮间不应用于电梯以外的其他用途,也不应设置非电梯用的线槽,电缆或装置。

但这些房间可设置:A)杂物电梯或自动扶梯的驱动主机;B)该房间的空调或采暖设备,但不包括以蒸汽和高压水加热的采暖设备;C)火灾探测器和灭火器。

具有高的动作温度,适用于电气设备,有一定的稳定期且有防意外碰撞的合适的保护。

解说:与井道相似,机房也不可以使用以蒸汽和高压水加热的采暖设备,同样是放置泄漏时损坏设备并危及在机房内工作的人员的人身安全。

灭火器的设置则强调了应“适用于电气设备”,很明显水是不可以作为灭火器的。

同时,由于上述空调或采暖设备设置在机房内,而机房只允许“经过批准的人员”接近,因此空调和采暖设备的维护必须从机房外进行。

如果需要在机房内维护,只有负责电梯维修的人员进行或他们到场时才可以进行。

2014_33_EU-欧盟电梯新指令

2014/33/EU-欧盟电梯新指令指令更新简介欧盟在2014年发布了电梯新指令2014/33/EU,以及新版电梯标准EN 81-20以及电梯制造与安装安全规范 EN 81-50,指令与标准将于2016年4月20日起执行,并与2017年9月起强制实施。

Lifts provide an essential means of comfortable and safe access to modern buildings. The provision of lifts in new buildings and the installation of lifts in many existing buildings have an increasingly important role to play in an ageing society giving growing priority to the social integration of people with special needs.The Lifts Directive 95/16/EC has the double aim of permitting the free circulation of lifts and its safety components within the internal EU market and ensuring a high level of safety for lift users and maintenance staff.While the harmonised European legislation governing the design, manufacturer and installation of lifts is mainly addressed to lift installers and components manufacturers, it also has important implications for the owners and users of lifts.The new Lifts Directive 2014/33/EU of the European Parliament and of the Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to lifts and safety components for lifts (recast) (all languages), aligned to the New Legislative Framework, will be applicable from 20 April 2016.新指令培训与认证沃证是欧盟知名电梯认证机构EURUCERT(公告号1128)在中国区的唯一办事处,可提供新电梯指令的完整培训、认证和指导计划,帮助电梯整梯与部件制造商顺利完成新指令的转换工作。

卡洛·加簇自动化有限公司Certus多功能安全模块数据表说明书

Certus MultifunctionSafety modulesDescriptionCertus offers a range of safety modules, compliantwith international standards, designed to providethe most comprehensive protection for equipmentand personnel. They enable safety functionsaccepting different types of input. This means costsaving and fewer product codes.Benefits• Flexible solution. Certus modules can be connectedwith different types of input: E-stop, E-gate, limit switch,non-contact switch, safety light curtains (ESPE Type 4,Type2), safety light beam (single beam), safety mat, liftlevelling.• Cost saving.Same module, different applications.Safety solutions for basic machines, equipment andproduction lines.• 4 different devices. The main model CM22D0A includes2 instantaneous digital outputs and 2 delayed digitaloutputs (both OSSDs). The delay can be easily selectedvia a hex-switch on the front panel.• Compact dimensions. 1 DIN, smaller than a standardsafety housing! W x H x D: 18 x 90 x 63 mm.• Standards compliance. Cat. 4 PL e in accordance withISO 13849-1, SIL 3 in accordance with IEC 62061, SILcl3 in accordance with IEC 61508.• Lift Directive pliant with standardsEN81-20 EN81-50 for CL20D2A model only• Approval by TÜV.ApplicationsThis safety module is able to monitor multiple safety functions of industrial machinery, protecting operators from dangerous moving parts of the machine.The CERTUS module provides a safety-related interruption of a safety circuit.The safety modules, compliant with the requirements of safety standards, can be used in applications with: E-stop, E-gate, limit switch, non-contact switch, safety light curtains (ESPE Type 4, Type2), safety light beam (single beam), safety mat, lift levelling.Main functions• 4 OSSD safety outputs. Certus provides up to 4 Output Signal Switching Devices. The correct opening and closing of the safety function OSSDs is tested automatically.• Selectable delay time. Can be easily set-up through the hex-switch, selected from a choice of 15 pre-set configurations, from 0 to 30 sec. The main model CM22D0A can include 2 delayed digital outputs.• 2 auxiliary outputs. All the modules provide at least 1 auxiliary output. 2 auxiliary outputs for CL20D2A.• Manual or automatic start selectable.CM22D0ASafety Module with configurable outputs using hex-switchThis module provides a safety-related interruption of a safety circuit. It is used in applications with: E-stop, E-gate, limit switch, non contact switch, safety light curtains (ESPE Type 4, Type 2), safety light beam (single beam), safety mat.The Certus CM22D0A safety module, compliant with international standards, is designed to provide the most comprehensive protection for equipment and personnel. It enables safety functions, accepting different types of input. This means cost saving and fewer product codes.This safety module is able to monitor multiple safety functions of industrial machinery, protecting operators from dangerous moving parts of the machine.Main features• Flexible Solution. Certus modules can be connected with different types of input: E-Stop, E-gate, limit Switch, non contact switch, safety light curtains (ESPE Type 4, Type2), safey light beam (single beam), safety mat.• Cost saving. Same module different applications. Safety solutions for basic machines, equipment and production lines.• Selectable delay time.• Compact dimensions. 1 DIN, smaller than a standard safety housing! W x H x D: 18 x 90 x 63 mm.• Standards compliance. Cat. 4, PL e in accordance with ISO 13849-1, SIL 3 in accordance with IEC 62061 and SILcl 3 in accordance with IEC 61508.• Status indicator. 4 LEDs on the front panel indicate the status and any errors during operation.• Approval by TÜV.Main functions• 4 OSSD safety outputs. Certus CM22D0A provides up to 4 Output Signal Switching Devices. The correct opening and closing of the safety function OSSDs is tested automatically.• Configurable Outputs. Configurable pre-set delayed safety outputs, set via the hex-switch.• Manual or automatic start selectable.StructureAB CD FEFeaturesGeneral90m m [3,543”]45m m [1,771”]18mm[0,708”]44mm [1,732”]49mm [1,929”]63mm[2,48”]Power SupplyThe external power supply fulfills the voltage supply requirements of EN 61496-1.Inputs* Depends on the delay of one light curtain (type 2). The maximum response time of the test trigger must not exceed 10ms.OutputsSafety parametersCompatibility and conformityEnvironmentalHex-switchInformation:• The Hex-switch must only be rotated clockwise.• Any counter clockwise movement leads to the module switching to safe condition.• Factory setting "0" (3NO + 1NC).• While power is OFF you can rotate in either direction with no adverse effect.• Full rotations can also be made several times if you have not immediately arrived at the correct position.ReferencesOrder codeCARLO GAVAZZI compatible componentsFurther readingQRCM40D0A, CM30D1ASafety modulesThese modules are the easiest and cheapest solution for safety related components.They include up to 4 OSSD outputs with no settable delays.These modules provide safety-related interruption of a safety circuit. They are used in applications with: E-stop, E-gate, limit switch, non contact switch, safety light curtains (ESPE Type 4, Type 2), safety light beam (single beam), safety pliant with international standards, they are designed to provide the most comprehensive protection for equipment and personnel. They enable safety functions, accepting different types of input. This means cost saving and fewer product codes.These modules are able to monitor multiple safety functions of industrial machinery, protecting operators from dangerous moving parts of the machine.Main features• Flexible Solution. Certus modules can be connected with different types of input: E-Stop, E-gate, limit Switch, non contact switch, safety light curtains (ESPE Type 4, Type2), safey light beam (single beam), safety mat.• Cost saving. 2 modules, different applications. Safety solutions for basic machines, equipment and production lines.• Compact dimensions. 1 DIN, smaller than a standard safety housing! W x H x D: 18 x 90 x 63 mm.• Status indicator. 4 LEDs on the front panel indicate the status and any errors during operation.• Standards compliance. Cat. 4 PL e in accordance with ISO 13849-1, SIL 3 in accordance with IEC 62061, SILcl 3 in accordance with IEC 61508.• Approval by TÜV.Main functions• Up to 4 OSSD safety outputs. The correct opening and closing of the safety function OSSD is tested automatically.• Certus CM40D0A has 4 Output Signal Switching Devices, not delayed.• Certus CM30D1A has 3 Output Signal Switching Devices, not delayed.• 1 auxiliary output. The CM30D1A includes 1 auxiliary output.• Manual or automatic start selectable.• Redundant circuit.StructureABCDEFeaturesGeneral90m m [3,543”]45m m [1,771”]18mm[0,708”]44mm [1,732”]49mm [1,929”]63mm[2,48”]Power SupplyThe external power supply fulfills the voltage supply requirements of the EN 61496-1.Inputs* Depends on the delay of one light curtain (type 2). The maximum response time of the test trigger must not exceed 10ms.CM40D0A, CM30D1A OutputsSafety parametersCompatibility and conformityEnvironmentalConnection Diagramsstartstart (start button not monitored)Fig. 3 E-Gate 4 wires, 2 channels with automatic start (external contactor monitored)Fig. 4 E-Stop / E-Gate 4 wires, 2 channels with manual start (start button monitored)Fig. 5 E-Stop / E-Gate 3 wires, 2 channels with manual start (start button monitored)Fig. 6 E-Stop / E-Gate 2 wires, 1 channel with manual start (start button monitored)Fig. 7 ESPE devices type 4 / type 2, 2 channels NO,with manual start (start button monitored)Fig. 8ESPE devices type 4 / type 2, 2 channels NO, with manual start and feedback from externalcontactorFig. 9 Testable ESPE devices type 2, 1 channel NO,2 wires, with manual startFig. 10 Safety mat, 4 wiresCM40D0A, CM30D1A ReferencesOrder codeFurther readingCL20D2ALift levelling safety moduleThe CM20D2A is for lift applications. There are 2 semiconductor safety outputs (OSSDs) and 2 auxiliary outputs (1 NC and 1 NO). These outputs are not delayed.In 2014 the European Committee for Standardization released two safety standards for the construction of lifts and for the testing of lift components.These standards apply to both passenger and goods lifts.EN 81-20 specifies the technical requirements for the construction of lifts.EN 81-50 specifies design rules, calculations and the testing of lift components.The Certus CL20D2A module is compliant with these Standards.Main features• Cost saving. Lift application solutions for escalators, public or private lifts.• Status indicator. 4 LEDs on the front panel indicate the status and any errors during operation.• Compact dimensions. 1 DIN, smaller than a standard safety housing! W x H x D: 18 x 90 x 63 mm.• Lift Directive Compliance. Compliant with standards EN81-20 EN81-50.• Standards compliance. Cat. 4 PL e in accordance with ISO 13849-1, SIL 3 in accordance with IEC 62061, SILcl 3 in accordance with IEC 61508.• Approval by TÜV.Main functions• The CL20D2A safety module is designed to be used in lift installations for floor levelling and re-levelling of the cabin. It is connected to the lift plant and to the lift controller board.• When the cabin arrives at the floor level, the landing circuit slows it down while the cabin doors circuit allows the cabin to be re-levelled to the floor, also the detection of any faults.StructureABCDEFeaturesGeneral90m m [3,543”]45m m [1,771”]18mm[0,708”]44mm [1,732”]49mm [1,929”]63mm[2,48”]Power SupplyThe external power supply fulfills the voltage supply requirements of the EN 61496-1.InputsOutputsSafety parametersLift directive complianceCompatibility and conformityEnvironmentalConnection Diagrams24Vbypass enablelift controller21Carlo Gavazzi Automation S.p.A.CL20D2ACertus Multifunction DS ENG 13/04/2018References Order codeFurther readingCOPYRIGHT ©2018Content subject to change. Download the PDF: 。