化工英文文献翻译

化工学科英语作文模板

化工学科英语作文模板英文回答:Chemical Engineering: A Multidisciplinary Field with Wide-Ranging Applications。

Chemical engineering is a branch of engineering that deals with the application of science and mathematics to the design, construction, and operation of chemical plants and processes. The discipline encompasses a wide range of topics, including thermodynamics, fluid mechanics, heat and mass transfer, process control, and chemical reaction engineering.Chemical engineers work in a variety of settings, including chemical plants, pharmaceutical companies, food processing facilities, and environmental protection agencies. They are responsible for designing and operating processes that produce a wide range of products, including chemicals, pharmaceuticals, plastics, and fuels. They alsowork to develop and improve processes that are more efficient, less polluting, and safer.Chemical engineering is a rapidly growing field, as the demand for chemicals and other products continues to increase. In addition, the need for sustainable and environmentally friendly processes is driving the development of new technologies and processes in the field.Key Features of Chemical Engineering。

化工专业英语(可编辑)

化工专业英语Volatile:挥发性的 Semipermeable membrane:半透膜 immiscible:不相混的 Debit:把….记入借方 Credit:记入贷方Electrical potential:电势 Leaching:浸提 Extraction:萃取 Direct current:直流 Instantaneous:瞬间的 Successive:连续的 Collision:碰撞 Impeller:叶轮 Wavelet analysis:微元分析 Entrainment:夹带 Breakage:破坏Attrition:磨损 Indispensable:不可缺少的 Trajectory:轨道 Acrylic:丙烯酸 Baffle:挡板 Ruffle:滋扰 Discharge:释放 circulation flow:环流attrition:磨损 nucleation:成核 Catalytic:催化 frequency:频率shutter:快门 inertia:惯性 Pitched:倾斜的 histogram:柱状图breakdown:破坏 Unit 14 Distillation Dumped or ordered packings:乱堆或整齐堆放填料 Plate:板 Tray:塔盘 Hold-down and support plates:固定和支撑板 Fraction:馏分 Cascading:成瀑布落下,分多级进行 Reboiler:再沸器Overhead condenser: 塔顶冷凝器 Reflux:回流 Distillate:馏出物Countercurrent:逆流 Relative volatility:相对挥发度 Rectifying section:精馏段 Stripping section:提留段 Sidestream:侧线馏分 Circumvent:回避Hypothetical:假设的 Equilibrium-stage:平衡级(理论板) Tray efficiency:塔板效率 The number of hypothetical equilibrium stages required is then converted to a number actual trays by means of tray efficiencies, which describe the extent to which the performance of actual contact tray duplicates the performance of an equilibrium stage 然后理论塔板数通过塔板效率被转换成实际塔板数;塔板效率是实际塔板表现和理论塔板表现的比值。

化工英语文献

3 化工英语文献3.1化工英语文献的结构Title, (Author names, Affiliation),Abstract ,(Keywords),Introduction,Experimental,Results, Discussions (Results and discussions),Conclusions,Acknowledgements,References3.2 英语文献的检索Elsevier—science directSpringerlinkWiley interscience3.3 中英文摘要1、定义以提供文献内容梗概为目的,不加评论和补充解释,简明、准切地记叙文献重要内容的短文。

好的摘要对于增加论文的被检索和引用的机会、吸引读者、扩大影响起着不可忽视的作用。

2、摘要的类型和基本内容类型:根据内容的不同,摘要分为三大类:报道性摘要、指示性摘要和报道-指示性摘要。

1)报道性摘要(informative abstract)。

也称信息性摘要或资料性摘要。

其特点是全面、简要地概括论文的目的、方法、主要数据和结论。

通常,这种摘要可部分地取代阅读全文。

2)指示性摘要(indicative abstract)。

也称说明性摘要、描述性摘要(descriptive abstract)或论点摘要(topic abstract)。

一般只用二、三句话概括论文的主题,而不涉及论据和结论,多用于综述、会议报道等。

帮助读者决定是否需要阅读全文。

3)报道-指示性摘要(informative- indicative abstract)。

以报道性摘要的形式表述一次文献中信息总价值较高的部分,以指示性摘要的形式表述其余部分。

传统的摘要多为一般式,在内容上大致包括引言(introduction)、材料和方法(materials and methods)、结果(results)和讨论(discussion)。

即IMRAD3、EI对摘要的要求《EI》中国信息部要求信息性文摘(Information Abstract)应该用简洁、明确的语言(约300汉字,150 英文字)将论文的“目的(Purposes)”,主要的研究“过程(Procedures)”及所采用的“方法(Methods)”,由此得到的主要“结果(Results)”和得出的重要“结论(Conclusions)”表达清楚。

中英文文献以及翻译(化工类)

Foreign material:Chemical Industry1.Origins of the Chemical IndustryAlthough the use of chemicals dates back to the ancient civilizations, the evolution of what we know as the modern chemical industry started much more recently. It may be considered to have begun during the Industrial Revolution, about 1800, and developed to provide chemicals roe use by other industries. Examples are alkali for soapmaking, bleaching powder for cotton, and silica and sodium carbonate for glassmaking. It will be noted that these are all inorganic chemicals. The organic chemicals industry started in the 1860s with the exploitation of William Henry Perkin’s discovery if the first synthetic dyestuff—mauve. At the start of the twentieth century the emphasis on research on the applied aspects of chemistry in Germany had paid off handsomely, and by 1914 had resulted in the German chemical industry having 75% of the world market in chemicals. This was based on the discovery of new dyestuffs plus the development of both the contact process for sulphuric acid and the Haber process for ammonia. The later required a major technological breakthrough that of being able to carry out chemical reactions under conditions of very high pressure for the first time. The experience gained with this was to stand Germany in good stead, particularly with the rapidly increased demand for nitrogen-based compounds (ammonium salts for fertilizers and nitric acid for explosives manufacture) with the outbreak of world warⅠin 1914. This initiated profound changes which continued during the inter-war years (1918-1939).Since 1940 the chemical industry has grown at a remarkable rate, although this has slowed significantly in recent years. The lion’s share of this growth has been in the organic chemicals sector due to the development and growth of the petrochemicals area since 1950s. The explosives growth in petrochemicals in the 1960s and 1970s was largely due to the enormous increase in demand for synthetic polymers such as polyethylene, polypropylene, nylon, polyesters and epoxy resins.The chemical industry today is a very diverse sector of manufacturing industry, within which it plays a central role. It makes thousands of different chemicals whichthe general public only usually encounter as end or consumer products. These products are purchased because they have the required properties which make them suitable for some particular application, e.g. a non-stick coating for pans or a weedkiller. Thus chemicals are ultimately sold for the effects that they produce.2. Definition of the Chemical IndustryAt the turn of the century there would have been little difficulty in defining what constituted the chemical industry since only a very limited range of products was manufactured and these were clearly chemicals, e.g., alkali, sulphuric acid. At present, however, many intermediates to products produced, from raw materials like crude oil through (in some cases) many intermediates to products which may be used directly as consumer goods, or readily converted into them. The difficulty cones in deciding at which point in this sequence the particular operation ceases to be part of the chemical industry’s sphere of activities. To consider a specific example to illustrate this dilemma, emulsion paints may contain poly (vinyl chloride) / poly (vinyl acetate). Clearly, synthesis of vinyl chloride (or acetate) and its polymerization are chemical activities. However, if formulation and mixing of the paint, including the polymer, is carried out by a branch of the multinational chemical company which manufactured the ingredients, is this still part of the chemical industry of does it mow belong in the decorating industry?It is therefore apparent that, because of its diversity of operations and close links in many areas with other industries, there is no simple definition of the chemical industry. Instead each official body which collects and publishes statistics on manufacturing industry will have its definition as to which operations are classified as the chemical industry. It is important to bear this in mind when comparing statistical information which is derived from several sources.3. The Need for Chemical IndustryThe chemical industry is concerned with converting raw materials, such as crude oil, firstly into chemical intermediates and then into a tremendous variety of other chemicals. These are then used to produce consumer products, which make our livesmore comfortable or, in some cases such as pharmaceutical produces, help to maintain our well-being or even life itself. At each stage of these operations value is added to the produce and provided this added exceeds the raw material plus processing costs then a profit will be made on the operation. It is the aim of chemical industry to achieve this.It may seem strange in textbook this one to pose the question “do we need a chemical industry?” However trying to answer this question will provide(ⅰ) an indication of the range of the chemical industry’s activities, (ⅱ) its influence on our lives in everyday terms, and (ⅲ) how great is society’s need for a chemical industry. Our approach in answering the question will be to consider the industry’s co ntribution to meeting and satisfying our major needs. What are these? Clearly food (and drink) and health are paramount. Other which we shall consider in their turn are clothing and (briefly) shelter, leisure and transport.(1)Food. The chemical industry makes a major contribution to food production in at least three ways. Firstly, by making available large quantities of artificial fertilizers which are used to replace the elements (mainly nitrogen, phosphorus and potassium) which are removed as nutrients by the growing crops during modern intensive farming. Secondly, by manufacturing crop protection chemicals, i.e., pesticides, which markedly reduce the proportion of the crops consumed by pests. Thirdly, by producing veterinary products which protect livestock from disease or cure their infections.(2)Health. We are all aware of the major contribution which the pharmaceutical sector of the industry has made to help keep us all healthy, e.g. by curing bacterial infections with antibiotics, and even extending life itself, e.g. ß–blockers to lower blood pressure.(3)Clothing. The improvement in properties of modern synthetic fibers over the traditional clothing materials (e.g. cotton and wool) has been quite remarkable. Thus shirts, dresses and suits made from polyesters like Terylene and polyamides like Nylon are crease-resistant, machine-washable, and drip-dry or non-iron. They are also cheaper than natural materials.Parallel developments in the discovery of modern synthetic dyes and the technology to “bond” th em to the fiber has resulted in a tremendous increase in the variety of colors available to the fashion designer. Indeed they now span almost every color and hue of the visible spectrum. Indeed if a suitable shade is not available, structural modification of an existing dye to achieve this canreadily be carried out, provided there is a satisfactory market for the product.Other major advances in this sphere have been in color-fastness, i.e., resistance to the dye being washed out when the garment is cleaned.(4)Shelter, leisure and transport. In terms of shelter the contribution of modern synthetic polymers has been substantial. Plastics are tending to replace traditional building materials like wood because they are lighter, maintenance-free (i.e. they are resistant to weathering and do not need painting). Other polymers, e.g. urea-formaldehyde and polyurethanes, are important insulating materials f or reducing heat losses and hence reducing energy usage.Plastics and polymers have made a considerable impact on leisure activities with applications ranging from all-weather artificial surfaces for athletic tracks, football pitches and tennis courts to nylon strings for racquets and items like golf balls and footballs made entirely from synthetic materials.Like wise the chemical industry’s contribution to transport over the years has led to major improvements. Thus development of improved additives like anti-oxidants and viscosity index improves for engine oil has enabled routine servicing intervals to increase from 3000 to 6000 to 12000 miles. Research and development work has also resulted in improved lubricating oils and greases, and better brake fluids. Yet again the contribution of polymers and plastics has been very striking with the proportion of the total automobile derived from these materials—dashboard, steering wheel, seat padding and covering etc.—now exceeding 40%.So it is quite apparent even from a brief look at the chemical industry’s contribution to meeting our major needs that life in the world would be very different without the products of the industry. Indeed the level of a country’s development may be judged by the production level and sophistication of its chemical industry4. Research and Development (R&D) in Chemical IndustriesOne of the main reasons for the rapid growth of the chemical industry in the developed world has been its great commitment to, and investment in research and development (R&D). A typical figure is 5% of sales income, with this figure being almost doubled for the most research intensive sector, pharmaceuticals. It is important to emphasize that we are quoting percentages here not of profits but of sales income, i.e. the total money received, which has to pay for raw materials, overheads, staff salaries, etc. as well. In the past this tremendous investment has paid off well, leading to many useful and valuable products being introduced to the market. Examplesinclude synthetic polymers like nylons and polyesters, and drugs and pesticides. Although the number of new products introduced to the market has declined significantly in recent years, and in times of recession the research department is usually one of the first to suffer cutbacks, the commitment to R&D remains at a very high level.The chemical industry is a very high technology industry which takes full advantage of the latest advances in electronics and engineering. Computers are very widely used for all sorts of applications, from automatic control of chemical plants, to molecular modeling of structures of new compounds, to the control of analytical instruments in the laboratory.Individual manufacturing plants have capacities ranging from just a few tones per year in the fine chemicals area to the real giants in the fertilizer and petrochemical sectors which range up to 500,000 tonnes. The latter requires enormous capital investment, since a single plant of this size can now cost $520 million! This, coupled with the widespread use of automatic control equipment, helps to explain why the chemical industry is capital-rather than labor-intensive.The major chemical companies are truly multinational and operate their sales and marketing activities in most of the countries of the world, and they also have manufacturing units in a number of countries. This international outlook for operations, or globalization, is a growing trend within the chemical industry, with companies expanding their activities either by erecting manufacturing units in other countries or by taking over companies which are already operating there.化学工业1.化学工业的起源尽管化学品的使用可以追溯到古代文明时代,我们所谓的现代化学工业的发展却是非常近代(才开始的)。

英文文献中文翻译

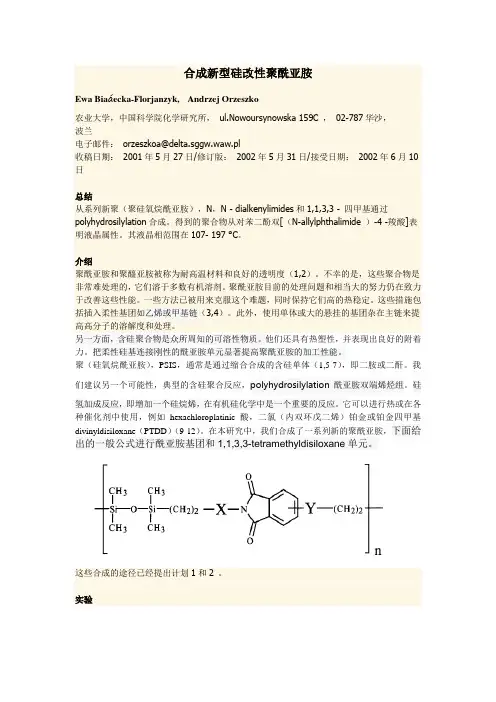

合成新型硅改性聚酰亚胺Ewa Biaáecka-Florjanzyk, Andrzej Orzeszko农业大学,中国科学院化学研究所,ul.Nowoursynowska 159C ,02-787华沙,波兰电子邮件:orzeszkoa@delta.sggw.waw.pl收稿日期:2001年5月27日/修订版:2002年5月31日/接受日期:2002年6月10日总结从系列新聚(聚硅氧烷酰亚胺),N,N - dialkenylimides和1,1,3,3 - 四甲基通过polyhydrosilylation合成。

得到的聚合物从对苯二酚双[(N-allylphthalimide )-4 -羧酸]表明液晶属性。

其液晶相范围在107- 197 °C。

介绍聚酰亚胺和聚醯亚胺被称为耐高温材料和良好的透明度(1,2)。

不幸的是,这些聚合物是非常难处理的,它们溶于多数有机溶剂。

聚酰亚胺目前的处理问题和相当大的努力仍在致力于改善这些性能。

一些方法已被用来克服这个难题,同时保持它们高的热稳定。

这些措施包括插入柔性基团如乙烯或甲基链(3,4)。

此外,使用单体或大的悬挂的基团杂在主链来提高高分子的溶解度和处理。

另一方面,含硅聚合物是众所周知的可溶性物质。

他们还具有热塑性,并表现出良好的附着力。

把柔性硅基连接刚性的酰亚胺单元显著提高聚酰亚胺的加工性能。

聚(硅氧烷酰亚胺),PSIS,通常是通过缩合合成的含硅单体(1,5-7),即二胺或二酐。

我们建议另一个可能性,典型的含硅聚合反应,polyhydrosilylation酰亚胺双端烯烃组。

硅氢加成反应,即增加一个硅烷烯,在有机硅化学中是一个重要的反应。

它可以进行热或在各种催化剂中使用,例如hexachloroplatinic酸,二氯(内双环戊二烯)铂金或铂金四甲基divinyldisiloxane(PTDD)(9-12)。

在本研究中,我们合成了一系列新的聚酰亚胺,下面给出的一般公式进行酰亚胺基团和1,1,3,3-tetramethyldisiloxane单元。

英文文献和中文翻译Probing the Relationship of Long-Range Order in Nanodomain

对利用三元添置中子衍射得到的纳米级FeCo合金远程有序关系的探究1.简介由于具有非常高的饱和磁化强度和居里温度,FeCo合金在工业上是一种重要的工程材料。

这些合金在软磁材料的应用中发挥了重要作用,例如发电机和电动机。

进一步应用的例子是变压器磁芯,磁驱动传动器,高场磁体的磁极以及电磁阀。

在工业的大部分应用当中,面临的挑战是在保持磁性能的同时,如何提高FeCo合金的拉伸强度和韧性。

曾经尝试过的方法有改变合金设计(比如加入一些镍,钒,铌,钽,铬,钼三元金属)、进行退火处理或是采用先进的变形处理。

然而,在现代应用中,要求有更好的力学、磁学性能。

近几年来,由于对现代发电机和配电设备需求的增加,科学家在FeCo合金方面的研究兴趣与日俱增。

特别是在极端环境下,对电气应用的要求非常严格。

另一方面,针对FeCo合金的结构和物理性能,尤其是针对它的纳米结构系统提出了有趣的问题。

得益于低钴FeCo合金(钴占到质量分数的17%到35%)的发展,在满足所需的磁性能的同时,合金的成本才得以降低。

此外,较低的Co含量能够提高合金的延展性和韧性。

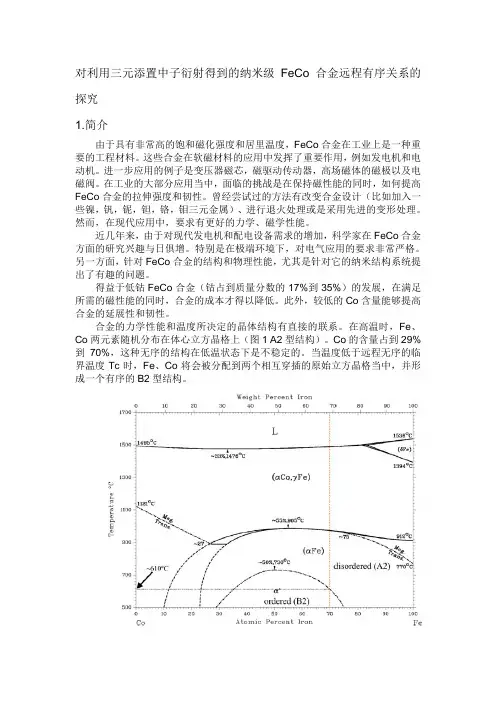

合金的力学性能和温度所决定的晶体结构有直接的联系。

在高温时,Fe、Co两元素随机分布在体心立方晶格上(图1 A2型结构)。

Co的含量占到29%到70%,这种无序的结构在低温状态下是不稳定的。

当温度低于远程无序的临界温度Tc时,Fe、Co将会被分配到两个相互穿插的原始立方晶格当中,并形成一个有序的B2型结构。

图1 二元合金FeCo的相图。

所讨论的三元合金的区域示意图。

B2型结构的合金有一些典型的特点。

比如说,“反结构”和“三点”机制产生的点缺陷能够导致晶格空位。

无序的B2型结构合金表现出波浪滑移,而局部无序型合金表现出平面滑移。

有序—无序之间的转变影响了FeCo合金的力学性能,比如合金韧性的改变、更脆的无序相、有序相等。

另外,磁性影响了结构的稳定性,造就了FeCo合金的有序性。

比如,在富铁FeCo合金中,磁有序稳定了体心立方结构,也稳定了来源于铁磁性B2相的有序性。

关于磷酸铁锂的英文文献(含中文翻译)

Preparation and characterization of carbon-coated LiFePO 4cathode materials for lithium-ion batteries with resorcinol –formaldehyde polymer as carbon precursorYachao Lan,Xiaodong Wang ⁎,Jingwei Zhang,Jiwei Zhang,Zhishen Wu,Zhijun Zhang ⁎Key Laboratory for Special Functional Materials,Henan University,Kaifeng 475004,Chinaa b s t r a c ta r t i c l e i n f o Article history:Received 8February 2011Received in revised form 26May 2011Accepted 3June 2011Available online 12June 2011Keywords:Lithium iron phosphateResorcinol –formaldehyde polymer Lithium-ion batteryLiFePO 4/C composites were synthesized by two methods using home-made amorphous nano-FePO 4as the iron precursor and soluble starch,sucrose,citric acid,and resorcinol –formaldehyde (RF)polymer as four carbon precursors,respectively.The crystalline structures,morphologies,compositions,electrochemical performances of the prepared powders were investigated with XRD,TEM,Raman,and cyclic voltammogram method.The results showed that employing soluble starch and sucrose as the carbon precursors resulted in a de ficient carbon coating on the surface of LiFePO 4particle,but employing citric acid and RF polymer as the carbon precursors realized a uniform carbon coating on the surface of LiFePO 4particle,and the corresponding thicknesses of the uniform carbon films are 2.5nm and 4.5nm,respectively.When RF polymer was used as the carbon precursor,the material showed the highest initial discharge capacity (138.4mAh g −1at 0.2C at room temperature)and the best rate performance among the four materials.©2011Elsevier B.V.All rights reserved.1.IntroductionLiFePO 4is an attractive cathode material for lithium-ion batteries because of its high theoretical capacity of 170mAh g −1,environ-mental benign,and high thermal stability.However,its poor electric conductivity of less than 10−13S cm −1limits its battery performance [1],such as the dramatic decrease in power at a high current density,which is the main drawback to commercial use.To overcome the low electric conductivity of LiFePO 4,many effective approaches have been introduced,including metal substitution [2–5],metal powder com-pounding [6],and conductive carbon coating [7–15].Among them,the preparation of LiFePO 4/carbon composite (LiFePO 4/C)is one of the attractive ways to improve the electric conductivity of the final product by forming a good conduction path.Furthermore,carbon can be also used as a reductant,which can reduce Fe 3+ions to Fe 2+ions.It should be noted that many studies involving the synthesis of nano-sized LiFePO 4employ Fe 2+salts as precursors [3,16–20],such as FeC 2O 4·2H 2O and (CH 3COO)2Fe,which are expensive.Therefore,it is necessary to use cheap materials and a convenient method.Here,we report the synthesis,characterization and electrochemical test of LiFePO 4/C composites prepared by two methods using home-made amorphous nano-FePO 4as the iron precursor and various organics as carbon precursors.The two methods using FePO 4as starting material are cheap and environmentally benign for the production of LiFePO 4material.Particularly,we present a novel method to synthesize a uniformcarbon film coated LiFePO 4cathode materials.This method involved an in situ reaction of resorcinol and formaldehyde on the surface of amorphous FePO 4.At room temperature,electrochemical tests showed that this material exhibited an initial discharge capacity of 138.4mAh g −1at 0.2C and a good cycling property at 0.5and 1.0C rate,respectively.2.Experimental2.1.Preparation of amorphous nano-FePO 4Amorphous nano-FePO 4was prepared by spontaneous precipita-tion from aqueous solutions.An equimolar solution of H 3PO 4was added to a solution of Fe(NO 3)3·9H 2O at 60°C under stirring and given amounts of PEG-400as surfactant.Then ammonia water (NH 3·H 2O)was slowly added to the mixed solution under vigorous stirring and a milk-white precipitate formed immediately.The pH of the solution was kept at 2.0.The precipitate was filtered and washed several times with distilled water.After drying in vacuum oven at 120°C for 12h,yellowish-white amorphous FePO 4was obtained.2.2.Preparation of LiFePO 4/CTwo methods were used to prepare the LiFePO 4/C composites in this study.2.2.1.Method oneA rheological phase method [21]was employed to synthesize LiFePO 4/C composite.Stoichiometric amount of amorphous FePO 4,LiOH·H 2O were used as the starting materials.The carbon precursorsPowder Technology 212(2011)327–331⁎Corresponding authors.Tel./fax:+863783881358.E-mail address:donguser@ (X.Wang).0032-5910/$–see front matter ©2011Elsevier B.V.All rights reserved.doi:10.1016/j.powtec.2011.06.005Contents lists available at ScienceDirectPowder Technologyj o u r n a l h o me p a g e :w w w.e l sev i e r.c o m /l oc a t e /pow t e care soluble starch(50.0g/1mol LiOH·H2O),sucrose(35.0g/1mol LiOH·H2O),citric acid monohydrate(21.0g/1mol LiOH·H2O),respec-tively.These carbon precursors were respectively solved in an appropri-ate amount of distilled water under stirring and heating.Then the amorphous FePO4and LiOH·H2O were added under vigorous stirring. Subsequently,the mixtures were respectively dried in an oven at120°C for6h,heated at350°C for1h in argonflow,treated at750°C for12h in argonflow,and ground.Finally,the LiFePO4/C composites were obtained and were denoted as sample A,sample B and sample C,respectively. 2.2.2.Method twoIn a typical synthesis,0.10g of CTAB was solved in30ml of distilled water solution under continuous stirring.Subsequently,1.52g FePO4·3H2O,0.055g resorcinol(R)and0.10ml formaldehyde(F)were successively added.When the temperature of water bath was up to85°C,LiOH·H2O was added.The mixture was kept stirred up in the dark for2h,dried in an oven at120°C for6h,heated at 350°C for1h in argonflow,treated at750°C for12h in argonflow, andfinally ground to obtain the LiFePO4/C composites(denoted as sample D).These four samples and their corresponding parameters are listed in Table1.The carbon contents of the samples were calculated by the loss on ignition of the four LiFePO4/C composites in air.2.3.CharacterizationThermogravimetric(TG)and differential thermal analysis(DTA) analyses were conducted with an EXSTAR6000thermal analysis system at a heating rate of10°C min−1.The powder X-ray diffraction (XRD,X'Pert Pro MPD,Philips)using Cu Ka radiation was employed to identify the crystalline phase of the prepared materials.Raman spectrum was recorded on a Renishaw RM-1000Microscopic Raman spectrometer with457.5nm excitation requiring a10mW power at room temperature.Low-magnification and high-magnification TEM images were taken on a JEM-2010transmission electron microscope (using an accelerating voltage of200kV).Electrodes were fabricated from a mixture of prepared carbon-coated LiFePO4powders(80wt.%),carbon black(12wt.%),and polyvinylidenefluoride in N-methylpyrrolidinon(8wt.%).The slurry was spread onto Al foil and dried in vacuum at120°C for12h.The carbon-coated LiFePO4loading was2mg cm−2in the experimental cells.The cells were assembled in an argon-atmosphere-filled glove box.The electrolyte was1M LiPF6in a mixture of ethylene carbonate (EC)and dimethyl carbonate(DMC)(1:1volume).The cells were galvanostatically charged and discharged at a voltage range of2.5–4.2V with LAND battery testing system at room temperature.Cyclic voltammograms were run on an IM6impedance and electrochemicalmeasurement system(Zahner,Germany)at a scan rate of0.1mV s−1 between2.5and4.0V.3.Results and discussionThe TEM images of the amorphous nano-FePO4were shown in Fig.1.The morphology of the as-prepared FePO4is an irregular particle with an average diameter of30nm.Most of the particles connected to each other because of their high surface energy which results from their small sizes.Fig.2a shows the TG/DTA curves of the FePO4·3H2O powder with a heating rate of10°C/min from room temperature to850°C in air.On the DTA curve near150°C,there is a very strong endothermic peak, associating with the sharp weight loss on the TG curve,which is related to the quick dehydration of FePO4·3H2O.During150–550°C, 26.3%weight loss on the TG curve indicates the slow elimination of residual H2O in FePO4·3H2O,exactly corresponding to the loss of crystalline water of FePO4·3H2O.And one exothermic peak is displayed at a higher temperature of590°C,which is not accompa-nied by appreciable weight loss in the TG curve,indicating the transformation of the amorphous FePO4to hexagonal FePO4crystal. The XRD patterns of FePO4·3H2O before and after calcination have been investigated in Fig.2b.As illustrated in pattern A,it can be seen that there is no evidence of diffraction peaks before calcination, indicating the synthesized FePO4·3H2O is just amorphous.While for the calcinated FePO4·3H2O at600°C for6h in air,it exhibits strong and narrow peaks revealing a well-crystallized material in pattern B. All of the diffraction peaks of the prepared FePO4are indexed to a single-phase hexagonal structure with a P3121space group and without any impurities,which is in good agreement with the standard card(JCPDS card no:72–2124).Table1Carbon precursors and residual carbon content of samples A,B,C and D.Samples A B C DCarbon precursor Starch Sucrose Citric acid RF polymer Final carbon content(wt.%) 5.48.5 4.35.1Fig.1.TEM images of the prepared amorphous nano-FePO4.n et al./Powder Technology212(2011)327–331The XRD diffraction patterns of LiFePO 4/C powders prepared with different carbon precursors were shown in Fig.3.All peaks can be indexed as a single phase with an ordered olivine structure indexed to the orthorhombic space group,Pnmb (JCPDS card no.83–2092).The obtained lattice parameters are sample A:a=10.2956Å,b=6.0367Å,and c =4.7001Å,sample B:a =10.1992Å,b =6.0483Å,andc=4.6971Å,sample C:a=10.2472Å,b=6.0208Å,and c=4.6882Åand sample D:a=10.3372Å,b=5.9993Å,and c=4.6932Å,respec-tively.There is no evidence of diffraction peaks for carbon,though some amorphous masses and films attached to the LiFePO 4particles were observed from TEM images (see Fig.4).This indicates the carbon contents are very low.Morphologies of these LiFePO 4/C composites were shown in Fig.4.It is obvious that the samples show different carbon distribution on LiFePO 4particle surface.From Fig.4a,c,e and g,we observed that the samples were composed of agglomerated particles whose sizes range from 50to 300nm.From Fig.4b and d,there is not enough carbon coating to spread throughout the substrate particles.In contrast to sample A and sample B,there are uniform carbon thin films on the grain surfaces of sample C and sample D,and the thickness of the carbon films are about 2.5nm (Fig.4f)and 4.5nm (Fig.4h),respectively.The reason may lie in that different carbon precursors have different adsorbabilities on the surface of FePO 4·3H 2O particles,resulting in different carbon distribution on the surface of LiFePO 4particle after the post treatment.Soluble starch and sucrose possess plentiful hydroxyl groups,by which soluble starch and sucrose molecules could probably weakly adsorb on the surface of FePO 4·3-H 2O particles in the hydrogen bonding.In the post treatment process,part of soluble starch and sucrose molecules desorbed from the surface of FePO 4·3H 2O particles,resulting in the de ficient carbon coating.But citric acid possesses carboxyl groups,which may be partially esteri fied by hydroxyl groups on the FePO 4·3H 2O particles,forming a tight connection.This results in more complete carbon coating after the post treatment.For sample D,we suppose that,in the present synthetic system,the surfactant CTAB may con fine the resorcinol –formaldehyde (RF)polymer molecules and FePO 4·3H 2O particles in plenty of tiny spaces,so the RF polymer molecules were tightly attached to FePO 4·3H 2O particles.After the post treatment,the RF polymer was transformed into the carbon film which tightly stuck on the surface of LiFePO 4particle.In addition,from the HRTEM image of sample D (shown in Fig.4h),the d-spacing of 0.294nm corresponds to the (211)plane of LiFePO 4.As an important aid investigating the structure of the carbon,the Raman measurement was adopted,and the results were shown in Fig.5.Every Raman spectrum consists of a small band at 940cm −1,which corresponds to the symmetric PO 4stretching vibration in LiFePO 4.The intense broad bands at 1350and 1590cm −1can be attributed to the characteristic Raman spectra of carbon.The bands at 1590cm −1mainly correspond to graphitized structured carbon of G band,while that at 1350cm −1corresponds to disordered structured carbon of D band [22,23].The graphitized carbon contains sp 2hybrid bonding,which is positively correlated with the electronic conduc-tivity of carbon,and the disordered carbon mainly corresponds to sp 3hybrid bonding.As shown in Fig.5,the integrated intensity ratios of sp 2/sp 3of the LiFePO 4/C composites synthesized with different carbon precursors are 0.865(curve A),0.857(curve B),0.856(curve C)and 0.860(curve D),respectively.So the similar sp 2/sp 3ratios of the four samples give us few clues to explain the difference in their electrochemical performances.Fig.6shows the cycling performance curves of all the samples at different rates.As shown in Fig.6,the initial discharge capacities of sample A,sample B,sample C and sample D at room temperature at 0.2C rate are 110.4,118.8,137.7and 138.4mAh g −1,respectively.The capacity of sample D gradually increases in the initial cycles.This may be due to the incomplete dispersion of the electrolyte into the electrode material at the beginning.Moreover,the capacity of sample D is highest among the four samples at 0.5C and 1.0C,indicating that method two is better than method one.The lower capacities of sample A and sample B must be due to the incomplete carbon coating on the LiFePO 4particles.The higher capacity of sample D than that of sample C may be attributed to the thicker carbon film of sample D keeping the crystal structure of LiFePO 4morestable.Fig.2.(a)TG/DTA curves of the FePO 4·3H 2O.(b)XRD patterns of the FePO 4samples before (A)and after (B)calcination inair.Fig. 3.XRD patterns of LiFePO 4/C composites synthesized with different carbon precursors.329n et al./Powder Technology 212(2011)327–331In order to further understand the electrochemical properties of the four samples,the cyclic voltammogram (CV)curves were performed at a scan rate of 0.1mV s −1at room temperature (as shown in Fig.7).Each of the CV curves consists of an oxidation peak and a reduction peak,corresponding to the charge reaction and discharge reaction of the Fe 2+/Fe 3+redox couple.In the CV pro files of the LiFePO 4cathode material,the smaller voltage difference between the charge and discharge plateaus and the higher peak current means better electrode reaction kinetics,and consequently better rate performance.Sample A and sample B electrodes have broad peaks in CV curves.In contrast,sample C and sample D electrodes demonstrate sharp redox peaks,which indicate an improvement in the kinetics of the lithium intercalation/de-intercalation at the electrode/electrolyte interface.The voltage difference of sample D is smaller than that of sample C,so sample D demonstrates a better rate performance.4.ConclusionsLiFePO 4/C composites were synthesized by two methods using home-made amorphous nano-FePO 4as the iron precursor and various organics as carbon precursors.It was found that employing soluble starch and sucrose as the carbon precursors resulted in a de ficient carbon coating on the surface of LiFePO 4particle,but employing citric acid and RF polymer as the carbon precursors realized a uniform carbon coating on the surface of LiFePO 4particle.Particularly,when RF polymer was used as the carbon precursor,the carbon film is thicker,and the material showed the highest initial discharge capacity (138.4mAh g −1at 0.2C at room temperature)and the best rate performance among the four materials.The intensities of redox peak and the voltage differences in the CV curves of the four samples are consistent with their rateperformance.Fig.4.TEM images of synthesized LiFePO 4/C composite synthesized with different carbon precursors.(a)and (b)sample A,(c)and (d)sample B,(e)and (f)sample C,(g)and (h)sampleD.Fig. 5.Raman shift of LiFePO 4/C composites synthesized with different carbonprecursors.Fig.6.The cycling performance curves of the samples with different carbon precursors at various discharge rates.n et al./Powder Technology 212(2011)327–331References[1] A.K.Padhi,K.S.Nanjundaswamy,J.B.Goodenough,Phospho-olivines as positive-electrode materials for rechargeable lithium batteries,J.Electrochem.Soc.144(1997)1188–1194.[2]T.Nakamura,Y.Miwa,M.Tabuchi,Y.Yamada,Structural and surfacemodi fications of LiFePO 4olivine particles and their electrochemical properties,J.Electrochem.Soc.153(2006)A1108–A1114.[3]S.-Y.Chung,J.T.Bloking,Y.-M.Chiang,Electronically conductive phospho-olivinesas lithium storage electrodes,Nat.Mater.1(2002)123–128.[4]P.S.Herle,B.Ellis,N.Coombs,L.F.Nazar,Nano-network electronic conduction iniron and nickel olivine phosphates,Nat.Mater.3(2004)147–152.[5]G.X.Wang,S.Bewlay,S.A.Needham,H.K.Liu,R.S.Liu,V.A.Drozd,J.-F.Lee,J.M.Chend,Synthesis and characterization of LiFePO 4and LiTi 0.01Fe 0.99PO 4cathode materials,J.Electrochem.Soc.153(2006)A25–A31.[6] F.Croce,A.D'Epifanio,J.Hasson,A.Duptula,T.Olczac,B.Scrosati,A novel conceptfor the synthesis of an improved LiFePO 4lithium battery cathode,Electrochem.Solid-State Lett.5(2002)A47–A50.[7]H.Huang,S.C.Yin,L.F.Nazar,Approaching theoretical capacity of LiFePO 4at roomtemperature at high rates,Electrochem.Solid-State Lett.4(2001)A170–A172.[8]M.Herstedt,M.Stjerndahl,A.Nyten,T.Gustafsson,H.Rensmo,H.Siegbahn,N.Ravert,M.Armand,J.O.Thomas,K.Edstroem,Surface chemistry of carbon-treated LiFePO 4particles for Li-ion battery cathodes studied by PES,Electrochem.Solid-State Lett.6(2003)A202–A206.[9]M.M.Doeff,Y.Hu,F.McLarnon,R.Kostecki,Effect of surface carbon structure onthe electrochemical performance of LiFePO 4,Electrochem.Solid-State Lett.6(2003)A207–A209.[10]Y.Hu,M.M.Doeff,R.Kostecki,R.Finones,Electrochemical performance of sol –gelsynthesized LiFePO 4in lithium batteries,J.Electrochem.Soc.151(2004)A1279–A1285.[11]X.Z.Liao,Z.Ma,L.Wang,X.Zhang,Y.Jiang,Y.He,A novel synthesis route forLiFePO 4/C cathode materials for lithium-ion batteries,Electrochem.Solid-State Lett.7(2004)A522–A525.[12] C.H.Mi,X.B.Zhao,G.S.Cao,J.P.Tu,In situ synthesis and properties of carbon-coated LiFePO 4as Li-ion battery cathodes,J.Electrochem.Soc.152(2005)A483–A487.[13]R.Dominko,M.Bele,M.Gaberscek,M.Remskar,D.Hanzel,S.Pejovnik,J.Jamnik,Impact of the carbon coating thickness on the electrochemical performance of LiFePO 4/C composites,J.Electrochem.Soc.152(2005)A607-A607.[14]K.Zaghib,J.Shim,A.Guer fi,P.Charest,K.A.Striebel,Effect of carbon source asadditives in LiFePO 4as positive electrode for lithium-ion batteries,Electrochem.Solid-State Lett.8(2005)A207–A210.[15]K.S.Park,J.T.Son,H.T.Chung,S.J.Kim,C.H.Lee,K.T.Kang,H.G.Kim,Surfacemodi fication by silver coating for improving electrochemical properties of LiFePO 4,Solid State Commun.129(2004)311–314.[16] A.Yamada,S.C.Chung,K.Hinokuma,Optimized LiFePO 4for lithium batterycathodes,J.Electrochem.Soc.148(2001)A224–A229.[17]N.Meethong,H.-Y.Shadow Huang,W.C.Carter,Y.-M.Chiang,Size-dependentlithium miscibility gap in nanoscale Li 1−x FePO 4,Electrochem.Solid-State Lett.10(2007)A134–A138.[18] C.Delacourt,P.Poizot,S.Levasseur,C.Masquelier,Size effects on carbon-freeLiFePO 4powders,Electrochem.Solid-State Lett.9(2006)A352–A355.[19] D.Choi,P.N.Kumta,Surfactant based sol –gel approach to nanostructured LiFePO 4for high rate Li-ion batteries,J.Power Sources 163(2007)1064–1069.[20]K.Zaghib,A.Mauger,F.Gendron,C.M.Julien,Surface effects on the physical andelectrochemical properties of thin LiFePO 4particles,Chem.Mater.20(2008)462–469.[21]Y.H.Huang,H.B.Ren,S.Y.Yin,Y.H.Wang,Z.H.Peng,Y.H.Zhou,Synthesis ofLiFePO 4/C composite with high-rate performance by starch sol assisted rheolog-ical phase method,J.Power Sources 195(2010)610–613.[22]M.M.Doeff,J.D.Wilcox,R.Kostecki,u,Optimization of carbon coatings onLiFePO 4,J.Power Sources 163(2006)180–184.[23]G.L.Yang,A.F.Jalbout,Y.Xu,H.Y.Yu,X.G.He,H.M.Xie,R.S.Wang,Effect ofpolyacenic semiconductors on the performance of olivine LiFePO 4,Electrochem.Solid-State Lett.11(2008)A125–A128.Fig.7.The CV pro files of the different samples at the scan rate of 0.1mV s −1.331n et al./Powder Technology 212(2011)327–331。

介绍化工专业的认识英文作文

介绍化工专业的认识英文作文English: Chemical engineering is a specialized field of study that combines principles of chemistry, physics, biology, and mathematics to design and operate industrial processes that convert raw materials into useful products. Students studying chemical engineering gain a deep understanding of chemical reactions, process design, thermodynamics, and fluid mechanics, among other technical subjects. The field of chemical engineering is incredibly diverse, with applications in industries such as pharmaceuticals, petroleum refining, food and beverage, environmental protection, and materials manufacturing. Working in chemical engineering requires problem-solving skills, attention to detail, creativity, and the ability to work collaboratively in multidisciplinary teams to tackle complex challenges. Graduates with a degree in chemical engineering have a wide range of career opportunities available to them, including roles in research and development, process engineering, production management, quality control, and environmental engineering.中文翻译: 化工工程是一门专业研究领域,结合了化学、物理、生物学和数学原理,用于设计和运行将原材料转化为有用产品的工业过程。

什么是化工 英文作文

什么是化工英文作文英文:Chemical engineering is a branch of engineering that deals with the design, development, and operation of chemical processes and equipment. It involves the use of chemistry, physics, mathematics, and economics to solve problems related to the production and use of chemicals, fuels, drugs, food, and other products. Chemical engineers work in a wide range of industries, including oil and gas, pharmaceuticals, food and beverage, plastics, and environmental engineering.As a chemical engineer, I have been involved in the development of new processes for producing chemicals and materials. For example, I worked on a project to develop a new method for synthesizing a polymer that is used in medical devices. This involved designing and building a new reactor system, optimizing reaction conditions, and testing the product to ensure that it met the requiredspecifications.Another aspect of chemical engineering is process optimization. This involves analyzing existing processes to identify inefficiencies and areas for improvement. For example, I worked on a project to optimize a production process for a specialty chemical. We were able to reducethe cycle time, increase yield, and improve product quality, which resulted in significant cost savings for the company.中文:化学工程是一种工程学科,涉及化学过程和设备的设计、开发和操作。

英文文献翻译

The utilization of carbon dioxide as raw material for chemical industry is paid increased attraction [1]. Aliphatic polycarbonates can be synthesized via the direct copolymerization of CO 2 with epoxides, which were used as drug delivery carrier and implant materials, due to their excellent biocompatibility, low toxicity and biodegradability [2]. To fulfill the diverse requirements in surgery and medicine, aliphatic polycarbonates can be modified by functional groups, such as carboxyl [3], ester [4–7] to improve their thermal properties and degradability. Poly(e-caprolactone) (PCL) is a semicrystalline linear resorbable aliphatic polyester, has been extensively investigated for use as implantable or injectable biodegradable carriers for the controlled release of active agents [8,9]. PCL is biodegradable and of commercial interest because of its remarkable compatibility with a number of polymers [10]. However, applications of PCL might be limited for its hydrophobic character, high crystallinity and poor mechanical properties [11]. e-Caprolactone copolymerized with other monomers, such as poly(ethylene glycol) [12], their biodegradability and mechanical properties can be improved. The modified aliphatic polycarbonates from CO 2, epoxides and e-caprolactone have also been reported by researchers [6,7,13,14]. In the present work, we designed a new aliphatic polycarbonate (PBCL) by terpolymerization of carbon dioxide, 1,2-butylene oxide (BO) and e-caprolactone (CL). The introduction of the hydrolytic ester units in CL, resulted in a enhancement of the degradability and thermal properties of the polycarbonates. The preparations of the PBCL and poly(butylene carbonate) (PBC), were carried out in a 300 ml stainless steel autoclave equipped with a magnetic stirrer. Both reactions are shown in Scheme 1.

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

Heavy Oil Development Technology of Liaohe Oilfield Han Yun(Scientific Research Information Department Exploration&Development Research Institute,Liaohe Oilfield Company)Liaohe Oilfield,the largest heavy oil production base in China,features in various reservoir types,deep burial,and wide range of crude oil viscosity.For many years,a series of technologies have been developed for different oil products and reservoir types of the oilfield,of which water flooding,foam slug drive,steam stimulation,steam drive,and SAGD are the main technologies. After continuous improvement,they have been further developed and played an important role in the development of heavy oil in the oilfield.Liaohe Oilfield is abundant in heavy oil resources,46%of the total proved reserves of Liaohe Oilfield Company. Horizontally the resources concentrates in the West Depression and the southern plunging belt of the Central Uplift in Liaohe Rift. Vertically,it is mainly distributed in Paleocene Shahejie Formation(ES). The distinctive geological feature of Liaohe 0ilfield is manifested in three aspects:first,the heavy oil reservoirs are deeply buried and 80%of them are buried more than 900m deep;second,the heavy oil viscosity ranges widely.For most of the reservoirs.the dead oil viscosity ranges in 100~100000mPa·s with the maximum 650000mPa·s.Third the reservoir types are various with complicated oil—water relationship,most of the reservoirs are edge water and bosom water reservoirs and there are also edge water reservoirs,top water reservoirs and bosom water reservoirs.For more than 20 years of development,Liaohe Oilfield has developed series of heavy oil development technologies for different oil products and different types of reservoirs,such as water flooding, foam slug drive,steam stimulation steam drive and SAGD.The most difficult issues have been overcome in the development of the superheavy oil in deeper formation.which has maintained the annual heavy oil output at 8 million tons for many years in Liaohe Oilfield.Water flooding development technology for conventional heavy oil-type 1Based on heavy oil classification,the conventional heavy oil.type I refers to the heavy oil with viscosity ranging in 50~100mPa·s,taking up about 20%of the proved oil reserves of the oilfield.The heavy oil reservoirs of this type are buried ranging from 1 500m to 2400m deep and are capable of flowing.Therefore,natural energy is utilized for conventional development and then water flooding technology is used.For example,the reservoir of $32 oil unit of Block Leng-43 is buried 1 650~l 940m deep with the average oil zone 87.7m thick and the oil viscosity in situ 58mPa·s.In 1992,the 141 m spacing square well pattern was adopted to develop the kind of reservoirs by utilizing natural energy and two sets of oil production zones.In 2004,water flooding technology was applied. Currently,the degree of reserve recovery reaches 14%.the annual oil recovery rate is 1%,and the ultimate recovery ratio is predicted to be as high as 22%.Technology of foam slug and for conventional heavy oil-type steam flooding for conventional heavy oil-type 2 The upper limit of viscosity for the conventional heavy oil—type II is l 0000mPa·s(the dead oil viscosity in situ).This kind of heavy oil is the dominant type of heavy oil in Liaohe Oilfield,accounting for 60%of total proved reserves.The reservoir of such heavy oil is buffed 800-1 600m deep in genera1. At initial development stage, steam stimulation was carried out to develop this kind of reservoirs.In the higher cycles of steam flooding,the reservoirs with the heavy oil viscosity close to the lower limit of this kind of heavy oil are conversed into the steam drive development.Pilot tests of foam slug and steam flooding have conducted inBlock Jin-90 and Block Qi-40 successfully,and they will be applied to the whole blocks in near future.The recovery factor is forecast to be up to 50%~60%.Steam stimulation technology for special heavy oilThe special heavy oil refers to the heavy oil with the viscosity ranging in 10000~50000mPa·s in situ,which takes up 10% of proved oil reserves of the oilfield. The reservoir of the kind of oil is buried ranging from 1400m to 1800m. Steam simulation technology is often applied to develop such reservoirs. However, technology of steam drive or SAGD are also under research and experiments for reservoirs of good quality.SAGD technology for super heavy oilThe super heavy oil reservoir refers to the heavy oil with dead oil viscosity in situ over 50000mPa·s, which accounts for 10% of proved reserves of the oilfield. Due to its extremely high viscosity, it is just developed for few years. For the massive super heavy oil reservoirs, SAGD can be applied in the late stage of steam stimulation. At present, good intermediate results have been obtained in SAGD pilot test in Block Du-84 of Guantao Formation, showing good prospect for application. They have been applied in the whole block and the ultimate recovery factor is predicted to achieve 55%.ConclusionVarious technology should be applied to develop different types of heavy oil reservoirs. Besides the technologies mentioned above, the technologies of combustion in situ, flue gas drive, and steam foam drive are also under research currently. Therefore, various development technologies will be increasingly improved with the heavy oil development of Liaohe Oilfield.References[1] Wang Xu. 2006. Heavy Oil Development Technologies and Discussion on the ResearchOrientation in the Next Step. Petroleum Exploration and Development [J],33(4):484~490[2] Liu Junrong. The Paper Collection of Liaohe Oilfield Development Seminar [C]:Beijing, Petroleum Industry Press, 2002[3] Zeng Yuqiang. 2006. Heavy Oil steam Stimulation Review. Special Oil&Gas Reservoir[J], 13(6):5~9辽河油田的重油开发技术韩云(科研信息部门勘探和开发研究所、辽河油田公司)辽河油田,在中国最大的重油生产基地,在不同的储层类型,具有埋藏深,与原油粘度范围宽。