TS16949来料检验程序(中英文)

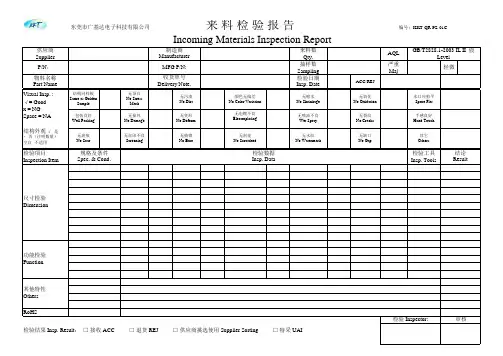

来料检验报告(中英版)

供应商Supplier 来料数Qty.AQL P/N :抽样数Sampling 严重Maj轻微物料名称Part Name 检验日期Insp. DateACC/REJ结构同样板Same as GoldenSample 无顶白No Stress Mark 无污渍No Dirt 颜色无偏差No Color Variation 无缩水No Shrinkage 无氧化No Oxidation 水口应剪平Sprue Flat 包装良好Well Packing 无损坏No Damage 无变形No Deform 无电镀不良Electroplating无喷油不良Wet Spray 无裂纹No Cracks 手感良好Hand Touch 无斑痕No Scar无丝印不良Screening无披锋No Burr无刮花No Scratched无水纹No Watermark无缺口No Gap其它Others检验项目Inspection Item 检验工具Insp. Tools RoHS尺寸检验Dimension功能检验Function其他特性Others 检验结果 Insp. Result : □ 接收 ACC □ 退货 REJ □ 供应商挑选使用 Supplier Sorting □ 特采 UAI检验 Inspector:审核规格及条件Spec. & Cond.检验数据Insp. Data 结论Result收货单号Delivery Note.MFG P/N:Visual Insp. :√= Good x = NG Space = NA 结构外观 √--是×--否(注明数量)空白--不适用东莞市广基达电子科技有限公司来 料 检 验 报 告编号:KKT-QR-PZ-01C制造商Manufacturer Incoming Materials Inspection ReportGB/T2828.1-2003 IL II 級Level。

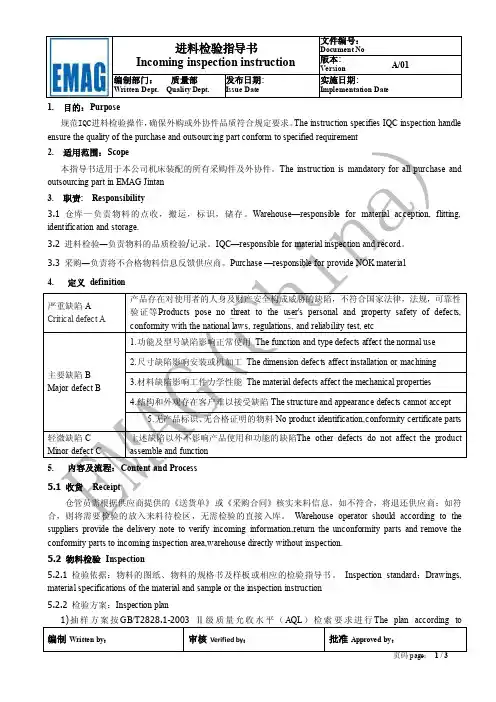

中英文进料检验指导书

编制部门:质量部Written Dept.Quality Dept. 发布日期:Issue Date实施日期:Implementation Date1. 目的:Purpose规范IQC进料检验操作,确保外购或外协件品质符合规定要求。

The instruction specifies IQC inspection handle ensure the quality of the purchase and outsourcing part conform to specified requirement2. 适用范围:Scope本指导书适用于本公司机床装配的所有采购件及外协件。

The instruction is mandatory for all purchase and outsourcing part in EMAG Jintan3. 职责: Responsibility3.1 仓库—负责物料的点收,搬运,标识,储存。

Warehouse—responsible for material acception, flitting, identification and storage.3.2 进料检验—负责物料的品质检验/记录。

IQC—responsible for material inspection and record。

3.3 采购—负责将不合格物料信息反馈供应商。

Purchase —responsible for provide NOK material4. 定义definition严重缺陷A Critical defect A 产品存在对使用者的人身及财产安全构成威胁的缺陷,不符合国家法律,法规,可靠性验证等Products pose no threat to the user's personal and property safety of defects, conformity with the national laws, regulations, and reliability test, etc主要缺陷B Major defect B 1.功能及型号缺陷影响正常使用The function and type defects affect the normal use2.尺寸缺陷影响安装或机加工The dimension defects affect installation or machining3.材料缺陷影响工件力学性能The material defects affect the mechanical properties4.结构和外观存在客户难以接受缺陷The structure and appearance defects cannot accept5.无产品标识、无合格证明的物料No product identification,conformity certificate parts轻微缺陷C Minor defect C 上述缺陷以外不影响产品使用和功能的缺陷The other defects do not affect the product assemble and function5. 内容及流程:Content and Process5.1 收货Receipt仓管员需根据供应商提供的《送货单》或《采购合同》核实来料信息,如不符合,将退还供应商;如符合,则将需要检验的放入来料待检区,无需检验的直接入库。

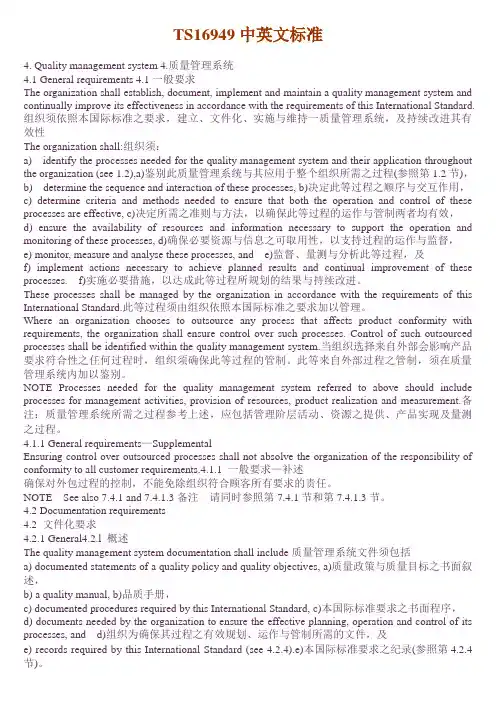

TS16949中英文标准

TS16949中英文标准4. Quality management system 4.质量管理系统4.1 General requirements 4.1一般要求The organization shall establish, document, implement and maintain a quality management system and continually improve its effectiveness in accordance with the requirements of this International Standard.组织须依照本国际标准之要求,建立、文件化、实施与维持一质量管理系统,及持续改进其有效性The organization shall:组织须:a)identify the processes needed for the quality management system and their application throughout the organization (see 1.2),a)鉴别此质量管理系统与其应用于整个组织所需之过程(参照第1.2节),b)determine the sequence and interaction of these processes, b)决定此等过程之顺序与交互作用,c) determine criteria and methods needed to ensure that both the operation and control of these processes are effective, c)决定所需之准则与方法,以确保此等过程的运作与管制两者均有效,d) ensure the availability of resources and information necessary to support the operation and monitoring of these processes, d)确保必要资源与信息之可取用性,以支持过程的运作与监督,e) monitor, measure and analyse these processes, and e)监督、量测与分析此等过程,及f) implement actions necessary to achieve planned results and continual improvement of these processes. f)实施必要措施,以达成此等过程所规划的结果与持续改进。

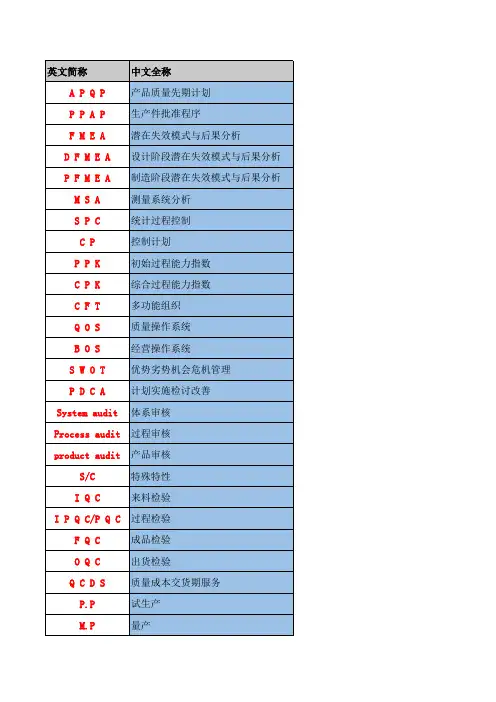

TS16949常用术语中英文对照

Mean time to failure Mean time between failure Industrial engineering On-time delivery Off-tool sample Customer oriented process Support process Management process Quality manual Quality procedure Work instruction Quality record Form Input quality control In process quality control Finall quality control Output quality control

英文简称 A P Q P P P A P F M E A D F M E A P F M E A M S A S P C C P P P K C P K C F T Q O S B O S S W O T P D C A System audit Process audit product audit S/C I Q C I P Q C/P Q C F Q C O Q C Q C D S P.P M.P

ቤተ መጻሕፍቲ ባይዱ

中文全称 产品质量先期计划 生产件批准程序 潜在失效模式与后果分析 设计阶段潜在失效模式与后果分析 制造阶段潜在失效模式与后果分析 测量系统分析 统计过程控制 控制计划 初始过程能力指数 综合过程能力指数 多功能组织 质量操作系统 经营操作系统 优势劣势机会危机管理 计划实施检讨改善 体系审核 过程审核 产品审核 特殊特性 来料检验 过程检验 成品检验 出货检验 质量成本交货期服务 试生产 量产

英文简称中文全称apqp产品质量先期计划ppap生产件批准程序fmea潜在失效模式与后果分析dfmea设计阶段潜在失效模式与后果分析pfmea制造阶段潜在失效模式与后果分析msa测量系统分析spc统计过程控制cp控制计划ppk初始过程能力指数cpk综合过程能力指数cft多功能组织qos质量操作系统bos经营操作系统swot优势劣势机会危机管理pdca计划实施检讨改善systemaudit体系审核processaudit过程审核productaudit产品审核sc特殊特性iqc来料检验ipqcpqc过程检验fqc成品检验oqc出货检验qcds质量成本交货期服务pp试生产mp量产mttf平均设备故障时间mtbf平均设备故障间隔时间ie工业工程otd准时交付率ots工装样件cop顾客导向过程sp支持过程mp管理过程qm质量手册qp程序文件wi作业指导书qr质量记录fm表格记录iqc进料检验ipqc过程检验fqc成品检验oqc出货检验英文全称advancedproductqualitypianningproductionpartapprovalprocesspotentialfailuremodeandeffectanalysisdesignfailuremodeandeffectanalysisprocessfailuremodeandeffectanalysismeasurementsystemanalysisstatisticalprocesscontrolcontrolplanpreprocessindexcapabilityprocessindexcrossfunctionteamqualityoperatingsystembusinessoperatingsystemstrengthweaknessopportunitythreatplandocheckactionsystemauditprocessauditproductauditspecialcharacteristicincomingqualitycontrolinprocessqualitycontrolfinalqualitycontrolongoingqualitycontrolqualitycostdeliveryservicepreproductionmassproductionmeantimetofailuremeantimebetween

汽车行业必须掌握的TS16949中英文术语

汽车行业必须掌握TS16949中英文术语TS16949中英文术语(一)CP控制计划,Control PlanSP支持过程,Support ProcessPPM百万分之,Parts Per MillionMP管理过程,Management ProcessCPK过程能力指数,Process CapabilityIndexSPC统计过程控制,Statistical ProcessControlCOP顾客导向过程,Customer OrientedProcessMSA测量系统分析,Measurement SystemsAnalysisPPAP生产件批准程序,Production PartApproval ProcessAPQP产品质量先期策划,Advanced ProductQuality Planning (二)FMEA潜在失效模式及后果分析,Failure Mode andEffects AnalysisDFMEA设计潜在失效模式及后果分析,DesignFailureMode and Effects AnalysisPFMEA过程潜在失效模式及后果分析,ProcessFailureMode and Effects AnalysisPPK初始过程能力指数或过程性能指数,PreliminaryProcess Index或Performance ProcessIndex高级统计方法advanced statisticalmethods可数型数据attributes data均值average认知awareness基本的统计方法basic statistical methods二项分布binomial distribution(三)因果图cause-effect diagram中心线central line普通原因common cause连续的consecutive控制control控制图control limit(charts)质量和生产率持续改进continualimprovement in quality and productivity累计和cesium探测detection分布distribution(四)单值individual位置location平均值mean中位数median移动极差moving range排列图praetor chart正态分布normal distribution可操作的定义operational definition 泊松分布Poisson distribution预防prevention(五)解决问题problem solving过程均值process average过程能力process capability过程控制process control过程性能process performance过程分布宽度process spread随机性randomness二次方程式quadratic随机抽样random sampling极差range链run(六)合理子组rational subgroup链图run chart样本sample形状shape特殊原因special cause规范specification稳定性stability统计值statistic稳定过程stable process标准差standard deviation(七)统计控制statistical control统计过程控制statistical processcontrol 子组subgroupI类错误type errorⅡ类错误type error变差variation区域分析zone analysis分配apportionment基准数据benchmark data材料清单bill of material(八)特性矩阵图characteristics matrix设计失效模式及后果分析design failuremode and effects analysis 可制造性和装配设计design formanufacturability and assembly 设计信息检查表design informationchecklist设计评审design reviews设计确认design validation设计验证design verification耐久性durability失效模式分析failure modes analysis可行性feasibility(九)改善kaizen有限元分析finite element analysis维修性maintainability包装packaging初始材料清单preliminary bill ofmaterial初始过程流程preliminary processflow chart过程失效模式及后果分析process failuremode and effects analysis 仿真simulation产品保证计划product assurance plan试生产production trial run(十)质量策划认定quality planningsign-off可靠性reliability特殊特性special characteristics可靠性分配reliabilityapportionment同步工程simultaneous engineering子系统subsystem系统system小组可行性承诺team feasibilitycommitment进度计划timing plan价值工程/价值分析value engineering / value analysis (十一)顾客的呼声voice of the customer过程的呼声voice of the process控制计划control plan设计意图design intent设计寿命design life实验设计DOE防错error /mistake proofing排列图pare to过程更改process change质量功能展开QFD(十二)根本原因root cause过程特殊特性special processcharacteristic 车辆召回vehiclecampaign认可的实验室accredited laboratory在用零件active part同意agreement外观项目appearance item批准approved批准的图样approved drawing批准的材料approved materials(十三)批准的货源清单approved source list计数型数据attributes散装材料bulk material数学数据math data散装材料要求检查表bulk materialrequirements checklist 校准calibration测绘图样checker print关键特性critical characteristic设计记录design record顾客产品批准部门customer productapproval activity (十四)环境environment设计预期的稳健范围design intendedrobust range完全批准full approval量具的重复性和再现性gage repeatabilityand reproducibility 首次样品initial sample初始过程研究initial process study临时批准interim sample主要设计特性key designcharacteristics标记过图样marked print主要过程特性key processcharacteristics(十五)主要产品特性key product characteristics实验室laboratory实验室范围laboratory scope易损工装perishable tools测量系统分析研究measurement systemanalysis studies生产件production part零件提交保证书part submissionwarrant过程流程图process flow diagram生产环境production environment生产材料production material(十六)线性linearity生产件批准提交production partapproval submission 质量指数quality indices常规生产工装regular production tooling拒收rejected外部场所remote location安全特性safety characteristics可销售产品salvable production现场site自我认证供方self-certifyingsupplier(十七)重要的生产过程significant production run 提交等级submission level工具tool工装维修tooling maintenance偏倚bias工装重新整修tooling refurbishment确认validation保证书warrant合同contract关键控制点critical control point(十八)关键限值critical limit流程图flow diagram危害hazard危害分析hazard analysis绩效performance初级生产primary production步骤step事故accident事件incident风险risk(十九)职业健康安全occupational health and safety 风险评价risk assessment可容许风险tolerable risk环境因素environmental环境影响environmental impact环境目标environmental objective环境表现environmental performance 环境指标environmental target污染预防prevention of pollution。

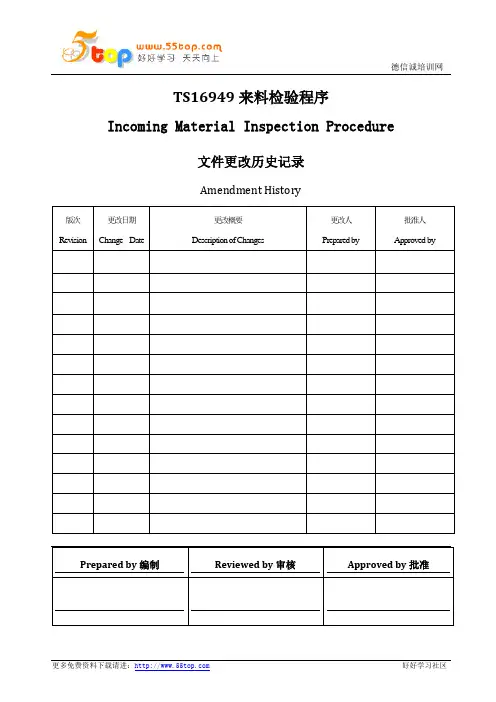

TS16949来料检验程序(中英文)

TS16949来料检验程序Incoming Material Inspection Procedure文件更改历史记录Amendment History版次Revision更改日期Change Date更改概要Description of Changes更改人Prepared by批准人Approved byPrepared by编制Reviewed by审核Approved by批准TS16949来料检验程序Incoming Material Inspection Procedure1.0目的Purpose:对所有外来生产用物料和外包商提供的产品进行来料检验,确保来料品质符合要求,及时发现来料不良问题,防止不良品流入。

Checking all incoming material including sub-contractor provide products to ensure the quality meet requirement and nonconformity is found in time so as to prevent released nonconformingincoming material.2.0范围Scope:本公司所有生产用来料(除制模来料及免检产品),包括客户提供物料和外包商提供的产品。

All incoming materials (Expect some material for mold making andship-to-stock material), including customer-supplied material andsub-contactor supplied products.3.0定义 Definition: N/A3.1RMT: 物料进仓单的英文简写。

RMT is the short form of Receiving Move Ticket.3.2MRB 仓库:指仓库中指定的摆放不良品的区域/位置。

TS16949进料检验作业程序(中英文)

TS16949进料检验作业程序Incoming inspection procedure 文件更改历史记录Amendment HistoryTS16949进料检验作业程序Incoming inspection procedure1.0 目的:本程序旨在建立适切之进料检验作业管制,以确保外购的生产性材料材质符合环境要求,质量符合本公司的设计要求.Attempt: The procedure is to establish unanimous incoming inspectoperations, in order to make sure those purchasing stuff canmanage environment requirement and the quality can come up todesign .2.0 范围:适用于本公司所有外购的生产性物料的进料检验.Range: Apply to all incoming inspection of purchasing stuff.3.0 定义: Definition3.1 IQC: 进料检验单位(Incoming Quality Control).3.2 SQE :供货商质量工程(Supplier Quality Engineer).3.3 客供配件:由客户提供,代为出货包装用之配件,并不参与成品组立、加工作业流程.(此种配件不纳入零件承认规范内,仅作资材面处理).Customer supplied parts: Customer supplied parts are used to delivery package parts, not participate in final-products、operation procedure.(the parts are not bring into parts recognition rules, only be regarded as stuff management)4.0 权责: Rights and responsibility4.1 品保部负责物料的检验、判定、检验后的标识及不合格品的改善追踪工作.QA Dep. manage stuff inspection、judgment、mark and rejects improving or tracking after inspection.4.2 资材部采购员负责与供货商联络,并协助来料质量异常的处理及改善追踪.Material purchaser manage and communicate with suppliers, then support dealing and tracking anomaly.5.0 作业内容: Contents5.1 检验规划:Inspection planning5.1.1 抽样计划:IQC依MIL-STD-105E(II)对进料实施抽样检验.Sampling scheme: IQC refer to MIL-STD-105E(II)to execute sampling action.5.1.2 正常检验:IQC依MIL-STD-105E(II)对进料实施抽样检验.Regular inspection: IQC refer to MIL-STD-105E(II)to execute sampling action.5.1.3 抽样时机:IQC依照MIL-STD-105E(II)对物料进行抽验检验,取样需平均抽样,在仓库平均取样后,在IQC室依照该物料之承认书与图纸执行检验。

TS16949产品审核操作指导书(中英文)

TS16949产品审核操作指导书QA Product audit work instruction1.Purpose 目的In this work instruction the types, frequency and inspection items of product audit are described.本操作指导描述了产品审核的类型、频次及检查项目。

2.Scope应用范围This work instruction applies to the activities of product audit.本操作指导书适用于工厂的产品审核等相关活动。

3.Definitions, Abbreviations定义,缩略语None. 无。

4.Task Description 任务描述To conduct product audit on assembly products, thereby ensuring that the products comply with the technical specifications and customer requirements. The product plans are as following:通过对总成产品实施产品审核,以确认产品是否符合技术规范及客户要求。

具体审核计划描述如下:Product audit type 产品审核类型Frequency频次Inspection items检查项目Responsible负责人Spot check 抽检1 piece Min. of all variantproducts per shift每班每种产品至少一件QM_013 2nd handcheck sheet检验员/产品审核员Inspector/productauditorQ data in PVS check 在PVS中核对质量数1 piece Min. of all variantproducts per day每天每种产Torque list inControl plan产品审核员product据品至少一件auditorFinal Check 终检1 piece Min. of all variantproducts per day每天每种产品至少一件QM_014 FinalInspection Record产品审核员productauditorDelivery audit 发货审核1 piece Min. of all variantproducts per week每周每种产品至少一件Sequence, loadingstatus, quantityetc.排序,装载状态,数量等产品审核员productauditorConduct product audit according to audit plan and keep record.根据产品审核计划进行审核,并保持记录。

TS16949标志和可追溯性程序(中英文)

TS16949产品标识和追溯程序Product Identification and Trace-ability文件更改历史记录Amendment HistoryTS16949产品标识和追溯程序Product Identification and Trace-ability1.0目的 Purpose:生产物料、产品施以明确的标记,以识别质量状态,产品种类,并反映某一箱或某一批产品的历史,以对质量问题及原因、责任等进行追溯,需要时追回不合格的产品。

Make clear identification to all incoming materials and product manufactured by DXC to identify their status of quality and specifications, to reflect the history of a certain carton or a certain batch of production so that trace the problem and its cause, responsibility and collect the rejected product if required.2.0范围Scope:所有生产的塑料产品于来料、生产过程、储存、检查和交付的各阶段,如果客户有特别的要求,则按客户的要求进行标识。

Apply to all injection molding plastics product, incoming material, product in process, storage, inspected and delivery stages. Make identification in accordance with customer if customer have special requirement.3.0定义Definitions:3.1DXC: 的简称。

TS16949内部审核程序(中英文)

TS16949内部审核程序Internal Quality System Audit1.0目的 Purpose:本程序规定了开展内部质量审核的策划,准备,实施,审核,报告,跟踪验证各阶段的控制要求和方法,以确定本公司的质量管理体系是否符合标准要求并得到有效地实施和保持。

This procedure give the methods and control requirements of internal quality audit planning, preparing, implementing, auditing, reporting and following-up, to ensure that the quality management system is in compliance with requirements and is implemented and maintained effectively.2.0范围Scope:适用于本公司内部质量管理体系审核及质量体系涉及的所有部门或个人。

FP internal audit and all departments and persons related to quality management system 3.0定义Definitions: N/A3.1IQAR:内部质量审核报告Internal Quality Audit Report3.2NC:不符项(不符合ISO要求的项目)Non-conformance (item against ISOrequirement.)a)Major严重不符合项: there are systematic problem, territorial problem,and the findings will cause the major result during the system run; 体系运行出现系统性失效,体系运行出现区域性失效,出现影响产品或体系运行的严重后果的不合格现象.b)Minor一般不合格项: aim at the systematic requirements, the finding isseparate, occasional and isolated minor problem; 对不满足质量体系过程或体系文件的要求而言,是个别的、偶然的、孤立的性质轻微的问题.3.3OBS观察项: 未构成不合格,但有变成不合格的趋势,或是证据暂时不足。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

TS16949来料检验程序

Incoming Material Inspection Procedure

文件更改历史记录

Amendment History

版次Revision

更改日期

Change Date

更改概要

Description of Changes

更改人

Prepared by

批准人

Approved by

Prepared by编制Reviewed by审核Approved by批准

TS16949来料检验程序

Incoming Material Inspection Procedure

1.0目的Purpose:

对所有外来生产用物料和外包商提供的产品进行来料检验,确保来料品质符合要求,及时发现来料不良问题,防止不良品流入。

Checking all incoming material including sub-contractor provide products to ensure the quality meet requirement and nonconformity is found in time so as to prevent released nonconforming

incoming material.

2.0范围Scope:

本公司所有生产用来料(除制模来料及免检产品),包括客户提供物料和外包商提供的产品。

All incoming materials (Expect some material for mold making and

ship-to-stock material), including customer-supplied material and

sub-contactor supplied products.

3.0定义 Definition: N/A

3.1RMT: 物料进仓单的英文简写。

RMT is the short form of Receiving Move Ticket.

3.2MRB 仓库:指仓库中指定的摆放不良品的区域/位置。

MRB Store means the

rejected area assigned by store.

4.0职责 Responsibility:

4.0IQC负责物料的检验与测试。

IQC is responsible for the inspection and test

of all in-coming material and parts.

4.1采购部负责将来料之不合格情况通报供应商或分包商并办理不合格物料的退货。

Purchasing is responsible for informing non-conforming material to vendors

/ sub-contractors.

5.0程序Procedure:。