3D扫描仪参数

3d扫描误差范围

3d扫描误差范围

3D扫描的误差范围会因扫描对象、扫描仪的精度、环境因素等多种因素而异。

手持式三维扫描仪实际扫描精度要看被测物体的尺寸,可以扫描小物件,扫描精度能控制在0.025mm内,如果是大物件,会存在累计误差,一般要配合摄影测量设备。

拍照式扫描仪一般用工业相机,通过拍照的方式,将被测物体的每一帧页面拼凑起来,形成一个三维模型图,点云数据比较均匀,且因为测量的物体都偏小,所以误差能控制在0.01mm,精度较高。

一米以内的工件,需要精度较高的情况下,可以考虑选择拍照式扫描仪。

此外,根据目前市场上常见3D扫描仪的性能,一般的抄数精度可以达到0.05mm至0.2mm之间,其中高端设备可以实现更高的精度。

如果需要更高的测量精度,可以采用多次扫描和数据融合等方法来提高精度。

此外,如果要实现更高的测量精度,还需要注意在扫描过程中避免因环境光、温度、振动等外界因素引入的误差。

以上信息仅供参考,如有需要,建议咨询专业技术人员。

三维扫描仪参数

文物数字化工具-非接触三维扫描仪在刚刚结束的第八界高新技术成果交易会上露面的艾美格受到广大业内人士的关注。

这款由深圳市好域安科技有限公司配合艾美格隆重推出地最新三维数字化仪在产品技术有很大的改进,加大了用户对设备的可选性,针对不同群体的客户推出不同精度和价格的机型,让每一用户能够完全和充分地利用该设备。

以下是设备的详细介绍:一、AMAGE 3-D SCANNER介绍艾美格三维扫描仪采用无接触测量技术,具有多分辨三维数字成像、高精度三维标定、多视点姿态估计及自标定和多视点深度像和纹理像自动匹配和融合等功能,其测量结果能直接与多种工业设计软件接口。

性能特点如下:◆面扫描采用照相式原理,在数秒内获得整个物体表面的三维数据,每次扫描一个面,效率很高,2秒内可得到130万点。

◆精度高利用独特的标定技术,不仅可获得非常高的z方向测量精度,同时也可获得x和y方向的高测量精度。

◆速度快单面扫描时间小于2秒。

◆无须贴标志点,全自动拼接与国内外其他公司的拼接技术不同,我们采用的全自动拼接技术不需要在物体表面贴标志点,或投射主动标记,因此给扫描工作带来了很多便利,同时也进一步提高了拼接精度、缩短了拼接时间。

◆可同时获得纹理像可利用同一个摄像机同时采集纹理信息,提供三维纹理像,以满足不同用户的需求。

◆非接触扫描适用于柔软、易变形的物体测量,适用范围非常广泛。

◆对环境条件不敏感环境光对该扫描仪的性能影响较小,相对其他光学式扫描仪系统而言,该系统不需要在暗室中操作,适用环境范围非常广泛,完全可以在露天环境进行扫描。

◆便携式设计可方便灵活地移动扫描仪对物体进行测量,适合对大型或重型物体的测量。

◆操作软件界面灵便、直观、友好高度集成和智能化的设计,使用户无需专业培训就可以在短时间内熟练掌握仪器的操作。

产品型号AMAGE-A5-ⅠAMAGE-A5-ⅡAMAGE-A3-ⅠAMAGE-A3-Ⅱ单面扫描范围(mm)400×300 200×150 300×200 150×100测量距离(mm)1200 800 1000 600景深(mm)400 200 300 150单面测量精度(mm)0.02 0.015 0.04 0.025x、y方向分辨率(mm)0.3 0.15 0.35 0.17图像分辨率(像素)1280×1024 720×576单面图的点数130万40万二、AMAGE 3-D Studio介绍点云噪声的处理◆完全自动剔除测量产生的噪声数据;◆鼠标手动剔除数据点;数据显示◆显示三维测量数据点云图/网格图/光滑渲染图/纹理图等;◆鼠标任意对测量数据进行旋转/平移/缩放等操作;数据匹配与融合◆与测量部分集成,测量的同时完成测量数据两两匹配;◆可手动选点匹配;◆可利用纹理信息辅助匹配;◆快速、准确地生成整个三维模型;模型优化◆模型空洞的填补/空洞边界的优化处理;◆对模型整体的网格优化;模型编辑◆保持模型特征的网格简化功能;◆利用简化算法构造多分辨率多细节模型;◆构造多种细分曲面;测量数据输出◆测量数据输出文件格式广泛:ASCII、DXF、STL、3DS、VRML等,可以直接与Imageware、Geomagic、CATIA、UG等主业设计软件交换数据。

三维激光扫描仪参数设置指南

三维激光扫描仪参数设置指南1. 前言嘿,朋友们!今天咱们来聊聊三维激光扫描仪,听起来高大上对吧?别担心,我们会把这个复杂的东西说得简单易懂。

就像喝水一样,轻轻松松就能搞定!那么,准备好了吗?咱们开始吧!2. 了解三维激光扫描仪2.1 什么是三维激光扫描仪?三维激光扫描仪就像你手里的“魔法相机”,它能瞬间把现实世界的三维数据记录下来。

你只需把它摆好,轻轻一按,咔嚓,整个场景都在它的“脑海”里了。

这就像你拍照一样,不过这个相机可不简单,能捕捉到更详细的深度信息,帮你生成超精准的三维模型。

2.2 用途有哪些?说到用途,那可是多得数不清!不管是建筑设计、文化遗产保护,还是工业测量,三维激光扫描仪都能派上大用场。

想象一下,在一个古老的寺庙里,扫描一下就能完美记录下所有细节,真是太酷了吧!而且,未来再复原的时候就方便多了,简直就是时间旅行者的必备良品!3. 参数设置的基本要领3.1 扫描模式的选择好啦,进入正题,咱们得开始调整参数了。

首先,要选择合适的扫描模式。

这里有几个常见的选择:快速模式、高清模式和室内/室外模式。

快速模式适合赶时间的朋友,反正结果也不要求太精细;高清模式呢,就像你的高清电视,细节满满,适合那些喜欢“看得仔细”的人。

室内和室外模式各有千秋,别搞混了哦!在室内扫描时,光线和反射会影响结果,得小心翼翼。

而室外就更要考虑天气情况,风一吹,数据可就飞了!3.2 分辨率与扫描范围接下来,咱们得聊聊分辨率和扫描范围。

这两个参数就像是给你的激光扫描仪穿衣服,得根据需求来选择。

分辨率越高,数据越细致,但扫描速度可能就会慢一些。

而扫描范围就像你拉开窗帘,看得越远,越能看到大千世界。

要是你只想扫描个小房间,范围就没必要设得太大,省电又省时间。

不过,记得适度哦,别像拿着放大镜看蚂蚁,哈哈!4. 实际操作小技巧4.1 数据存储与管理嘿,朋友们,数据存储也很重要!扫描完成后,数据会像一堆小星星,得好好管理。

建议你用外接硬盘,确保数据不丢失。

手持式3d扫描仪参数

三维扫描仪的种类和型号不计其数,不同的扫描仪特点有所差别,用于的领域也不同,目前在检测领域比较主流的有三坐标测量仪、拍照式三维扫描仪和手持式三维扫描仪等,并且型号和参数又是大家选购的时候比较关心的问题,下文将会针对国内外几款好用的三维扫描仪的型号和特点和参数给大家做一个简单的介绍。

一、适合工业用的高精度手持三维扫描仪(国外款)

二、适合工业用的高精度手持三维扫描仪(国内款)

近年来,在国家政策的扶持下,国内三维扫描行业的发展也非常迅猛,雨后春笋版出现了诸多的厂家。

经过了几年的发展和沉淀,一些对研发力量比较重视的企业就慢慢开始凸显起来了。

三、可以扫描彩色的手持三维扫描仪(国外款)

四、可以扫描彩色的手持三维扫描仪(国内款)

市面上的三维扫描仪型号参数不胜枚举,往往让刚接触到的人眼花缭乱。

但是按照功能来划分,其大类的划分还是很清晰的。

如此一来,在同类型产品中,选择一个稳定性更高、更符合自身需求的产品,选择起来就容易很多了。

上海沪敖信息科技有限公司是一家致力于三维数字化行业解决方案的技术型企业。

公司以行业应用为出发点,为客户提供三维数字化采集、三维数据处理等一系列服务。

沪敖拥有手持三维扫描仪、小空间三维扫描仪、地面三维激光扫描仪、无人机实景三维系统、3D 打印机等多种技术手段,是行业内知名设备的签约合作伙伴。

从几厘米到几十米的对象、或从几米到上千米的三维空间,沪敖均可提供涵盖软硬件产品和技术服务的完整解决方案。

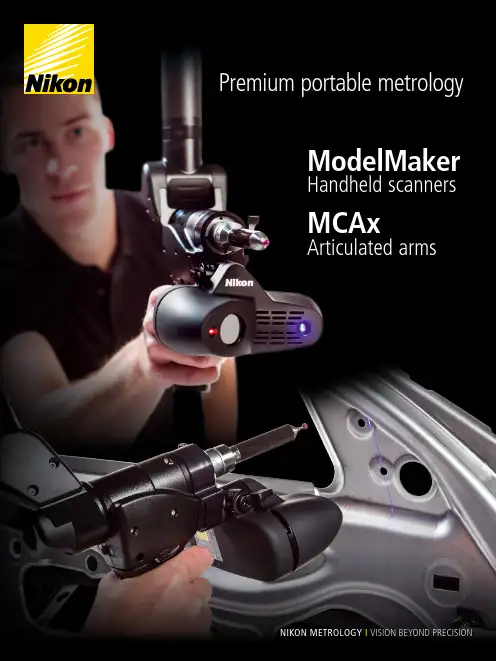

尼康3D扫描仪ModelMaker H120产品介绍说明书

Premium portable metrologyModelMakerHandheld scannersMCAxArticulated armsNIKON METROLOGY I VISION BEYOND PRECISIONUltra-fast high-definition3D scanning MODELMAKER H120More than two decades since theinception of the ModelMaker productline, the cutting-edge ModelMakerH120 firmly pushes the ever-exactingboundaries of handheld laser scanning.Incorporating blue laser technology,ultra-fast frame rate, speciallydeveloped Nikon optics and the abilityto measure the most challengingmaterials this represents the nextgeneration of portable laser scanning.The H120 makes no compromisesin addressing the market needsby efficiently deliveringthe most detailedand accurate datain a fraction of thetime of competingtechnologies.UNCOMPROMISING PERFORMANCEBy combining a frame rate of 450 Hz, a stripe width of 120 mm and a resolution of 35 μm, users benefit from high productivity and detailed measurements with a single sensor. Without relying on interpolation techniques to artificially boost data density, the ModelMaker H120guarantees fast data collection over a large area without compromising on small details – offering great flexibility in a single solution even when cycle time is critical, no matter the type of parts measured. Furthermore, the superior accuracy of the ModelMaker H120 ensures it stands far apart from similar technology, further pushing the traditionally accepted boundaries of handheld laser scanners.MEASURE THE MOST CHALLENGING MATERIALSThe 4th generation of Nikon’s patented Enhanced Sensor Performance (ESP4) provides faster-then-ever real-time dynamic adjustment of the laser intensity for every point. Users can confidently scan across parts with strong colour transitions and varying reflectivity from any direction with no loss in scanner speed and no need for prior part preparation. ModelMaker scanners also benefit from intelligent reflection control which allows users to measure very shiny or polished materials while unwanted reflections are filtered out.IMMEDIATE PRODUCTIVITYSimple system set-up, immediate boot-up and no need for scanner warm-up combined with the structural rigidity, thermal stability and absolute encoder technology of the MCAx arms allows users to switch on and start confidently collecting accurate data straightaway.EXTREMEL Y LOW NOISE DATABy combining specially-developed Nikon optics and low-speckle blue laser technology, the ModelMaker H120 achieves super low-noisemeasurements and can cleanly resolve details such as sharp edges and even surface scratches and abrasions which other scanners simply cannot.ENHANCED USER EXPERIENCEInnovative features such as thermal compensation, an integrated locking connector, contrasting full field of view projector, excellent touch probe clearance and a compact size give the user all the feedback and assurance he needs to concentrate purely on the measurement task.Integrated lockBest in class accuracyCompact and lightweightLow noise blue laserUp to 450,000 points per secondFull FOV indicatorMODELMAKER MMDxINTUITIVE SCANNING AND INSPECTION SOFTWAREScanning technology optimized for your applicationThe ModelMaker MMDx range of handheld laser scanners is ideally suited for portable 3D inspection and reverse engineering applications. With choices of scanner models for high detail, all-round scanning or high productivity, users can select the best hardware for their needs.MMDx incorporates 3rd generation Enhanced Sensor Performance (ESP3) to scan almost any sample materials and surface finishes without user interaction.The digital camera technology offers a measuring accuracy down to 7 microns and benefits from a true non-interpolated resolution of more than a thousand points per stripe, allowing freeform surfaces and features to be scanned accurately and efficiently.Featuring high frame rates and laser stripes up to 200 mm, the MMDx range provides the ultimate in scanning productivity. The scanner’s digital cameras benefit from a true (non-interpolated) resolution of over 1000 points per stripe, providing optimum resolution for scanning freeform surfaces and features efficiently.Weighing around 400 g and featuring an angled laser plane for comfort while scanning, MMDx scanners are optimized for ergonomic use. Set-up time and portability is optimized through the use of isolated thermal zones, temperature compensation and on-board processing – which means no external controller or extraneous cabling.ModelMaker scanners and MCAx arms seamlesslyinteract with Focus software for scan and tactile probe dataacquisition and inspection processing. It is a total solution that tightlyintegrates hardware and software to guarantee smooth and error-free operation.Focus software is specifically designed to easily control data flows with minimal user interaction.Users can complete handheld data acquisition and inspection jobs in Focus without compromising performance.Alternatively, through the Nikon Metrology API, the ModelMaker scanners and MCAx arms can be used directly in many 3rd party inspection and reverse engineering software applications, including PolyWorks ®, Metrolog ® and Geomagic ®.Scan rateProductivity Resolution Accuracy H120• • • • • •• • • • • • •• • • • •• • • • •MMDx50• •• •• • • •• • • •MMDx100• •• •• •• •MMDx200• •• • • •••APPLICATIONSThe combined solution of ModelMaker scanners and MCAx arms delivers high-productivity and precise non-contact and contact metrology. Used to optimise production workflow through rapid, reliable and accurate analysis of product dimensions – both freeform and geometric – it has proven to be an invaluable tool across many industries and workplaces from the shop floor to the metrology lab.Able to robustly measure almost any material and with the flexibility to inspect parts of sizes ranging from a few millimetres to several metres and more allows the solution to span many industries including Automotive, Aerospace, Power Generation and Consumer products, and well as Universities, Research Institutes and scanning service providers – especially for components such as tools and dies, body-in-white / sheet metal parts, castings, injection moulded, soft or fragile materials and additive manufactured parts.The ModelMaker handheld laser scanners paired with MCAx portable articulated co-ordinate measuring arms and Focus software allow you to reduce measurement times by rapidly diagnosing production issues in all areas of manufacture. This enables delivery of your products faster and with greater confidence by meeting the highest quality standards.Key benefits for your application• High accuracy and fast data throughput saves time and money • Optimized for hard-to-scan surfaces• Designed for use under all shop floor or field conditions• Extreme temperature stability and zero warm-up time• Quick and easy plug-and-play setup• Enhanced ergonomics for stress-free usage• Short learning curve• Seamless transition between scanning and touch-probing • Compatible with all major brands of point cloud software Uses within your process• Fast & accurate multi-sensor 3D inspection• Part-to-CAD inspection: First article inspection against CAD model • Inspection of geometric features• Gap-and-flush inspection• Reverse engineering: from concept studio clay to class A surfaces •Digitizing for additive manufacturingMCAxAccurate and portable multi-sensor measurement• Tactile probing performance from 0.023 mm and scanning system accuracy from 0.028 mm ensures the highest standard of measurement results • Available in six lengths between 2.0 m and 4.5 m to suit small to large measurement tasks• Absolute encoder technology means no referencing or warm-up period is required• Advanced carbon fiber construction for strength and thermally stability in all environments• Automatic probe recognition and repeatable probe and scanner mounting allows immediate switching between measurement tools• The ergonomic wrist features haptic feedback whilst the arm provides audio and visual notifications • Low friction handling positions for reduced user stress and fatigue• Counterbalance for effortless control infinite rotation of all principle axes for unrestricted use • Integrated lock secures the arm easily and safely • Quickly and easily attaches to a variety of stands / tripods or vacuum mount• Supports a wide variety of fixed and touch-trigger probes in many lengths and stylus configurations • MCAx++ and MCAx+ include a certified length standard for performance verification in the field • Certified performance according to ASME B89.4.22. VDI/VDE 2617-9 certification is also availableThe MCAx Manual Coordinate measuring Arm is a precise, reliable and easy-to-use portable 7-axis measuring arm. It is the perfect partner for the ModelMaker H120 and MMDx laser scanners and Focus Handheld scanning and inspection software due to its high precision, repeatability and stability. This total solution’s accuracy, capability and portability make it feel perfectly at home in the metrology lab, on the shop floor and in-the-field.The arm can be equipped with a wide range of probing systems aside from laser scanning, such as a large choice of probes for a variety of tasks including touch-trigger measurements and continuous scanning. Its flexibility makes this measurement arm the perfect solution for the widest range of measurement tasks. The MCAx range of 7-axis articulated arms is available in six different sizes and in three accuracy levels giving users the ability to specify thebest system for their needs.Infinite joint rotationRotating gripsAbsolute encodersCarbon constructionCounterbalanceIntegrated lockMagnetic mountSPECIFICATIONSComplies with 21 CFR 1040.10 and 1040.11, Laser Notice No. 50 dated June 24, 20071 Typical values are 30% better than published values.2 L aser scanner Accuracy is determined by scanning a plane from various directions, each time using the entire scanner field of view. The result is the maximum 1σ deviation of the scan data to fitted plane features.3T he Scanning performance test indicates the performance of the laser scanner combined with a MCAx arm. The test is performed by scanning a highly accurate reference plate in 5 different orientations of the articulated arm and laser scanner. The 5 resulting point clouds are merged together and a best-fit plane is constructed through this combined point cloud. For each of the points, the deviation distance to the best-fit plane is calculated. The result of the test is the 2σ value of all of the deviations.4T he Point repeatability test (or SPAT) is the reference test to determine measurement arm repeatability with a ball probe. The probe is placed in a conical socket and points are measured from multiple approach directions and is tested different zones of the arm measurement volume. The result is the maximum of the X, Y or Z range divided by two.5T he Volumetric accuracy test most accurately represents the reasonable expectations for probing performance in practical measuring applications since it involves measuring a certified length standard many times in several locations and orientations and compares the resulting measurements to the actual length. It is the most appropriate test for determining machine accuracy and repeatability. The result is the maximum deviation of the measuring distance less the theoretical length.Probing and scanning specifications are achieved under stable environmental conditions with the MCAx arm mounted on a base plate or magnetic base. A 15 mm diameter, 50 mm long, steel ball probe connected to both probeports is used for the probing performance tests. Probing specifications are based on a subset of ASME B89.4.22:2004. Probing certification to VDI/VDE 2617-9 is also available.Working temperature Storage temperature 0 – 50˚ C -30 – 70˚ CRelative humidity Operational elevation10 – 90% non-condensing 0 – 2000 m Universal worldwide voltage CE Compliance 110 – 240 V AC (50 – 60 Hz)YesH -120_E N _0118– C o p y r i g h t N i k o n M e t r o l o g y N V 2018. A l l r i g h t s r e s e r v e d . T h e m a t e r i a l s p r e s e n t e d h e r e a r e s u m m a r y i n n a t u r e , s u b j e c t t o c h a n g e a n d i n t e n d e d f o r g e n e r a l i n f o r m a t i o n o n l y.。

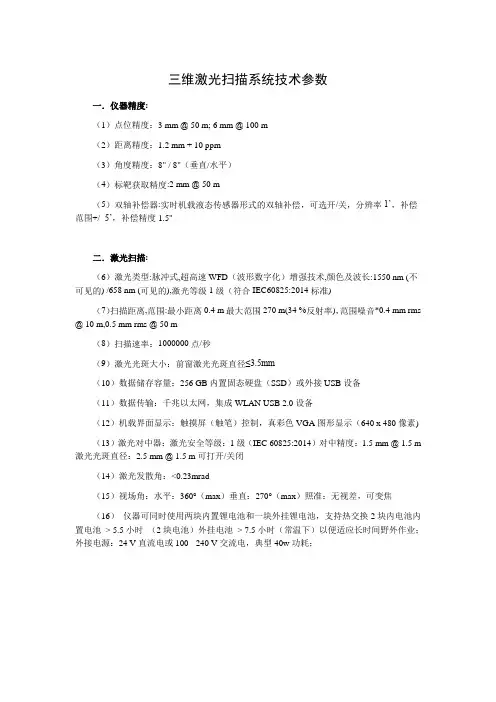

三维激光扫描系统技术参数

三维激光扫描系统技术参数一.仪器精度:(1)点位精度:3 mm @ 50 m; 6 mm @ 100 m(2)距离精度:1.2 mm + 10 ppm(3)角度精度:8" / 8"(垂直/水平)(4)标靶获取精度:2 mm @ 50 m(5)双轴补偿器:实时机载液态传感器形式的双轴补偿,可选开/关,分辨率1’,补偿范围+/- 5’,补偿精度1.5"二.激光扫描:(6)激光类型:脉冲式,超高速WFD(波形数字化)增强技术,颜色及波长:1550 nm (不可见的) /658 nm (可见的),激光等级1级(符合IEC60825:2014标准)(7)扫描距离,范围:最小距离0.4 m最大范围270 m(34 %反射率),范围噪音*0.4 mm rms @ 10 m,0.5 mm rms @ 50 m(8)扫描速率:1000000点/秒(9)激光光斑大小:前窗激光光斑直径≤3.5mm(10)数据储存容量:256 GB内置固态硬盘(SSD)或外接USB设备(11)数据传输:千兆以太网,集成WLAN USB 2.0设备(12)机载界面显示:触摸屏(触笔)控制,真彩色VGA图形显示(640 x 480像素)(13)激光对中器:激光安全等级:1级(IEC 60825:2014)对中精度:1.5 mm @ 1.5 m 激光光斑直径:2.5 mm @ 1.5 m可打开/关闭(14)激光发散角:<0.23mrad(15)视场角:水平:360°(max)垂直:270°(max)照准:无视差,可变焦(16)仪器可同时使用两块内置锂电池和一块外挂锂电池,支持热交换2块内电池内置电池> 5.5小时(2块电池)外挂电池> 7.5小时(常温下)以便适应长时间野外作业;外接电源:24 V直流电或100 - 240 V交流电,典型40w功耗;。

ESCAN-3三维扫描仪技术方案

ESCAN-3三维扫描仪技术方案1 公司介绍杭州思看科技有限公司是由海归博士、行业专家、青年科技骨干组成的高科技企业。

公司坐落在浙江杭州的未来科技城内,毗邻阿里巴巴淘宝城,主要从事手持式三维激光扫描仪、激光二维传感器等智能视觉检测设备的开发、研制和销售。

公司研发团队由美国海归博士领衔,依托浙江大学、浙江工业大学雄厚的科研实力,开发出一系列具有自主知识产权的、国内外领先的机电产品,包括手持式激光三维扫描仪、全局摄影测量系统和激光二维传感器等,公司产品已在国内许多大专院校、科研院所、汽车整车及零配件生产厂、大型机械加工企业和造型设计公司使用,深得用户的信赖和好评。

2产品介绍2.1概述ESCAN系列手持式激光三维激光扫描仪是杭州思看科技有限公司自主研发的产品,工作时采用多条线束激光来获取物体表面的三维点云,操作者可以将设备握在手上,可以实时调整仪器与被测物体之间的距离和角度,操作灵活方便简单易学。

在扫描大体积物体时,可以配合全局摄影测量系统,消除累计误差,提高全局扫描的精度。

该扫描仪可以方便携带到工业现场或者生产车间,并根据被扫描物体的大小、形状以及扫描的工况环境进行高效精确的扫描。

2.2 工作原理1)仪器上的两组相机可以分别获得投影到被扫描对象上的激光,该激光随对象形状发生变形,由于这两组相机事先经过准确标定,就可以通过计算获得激光线所投影的线状三维信息;2)仪器根据固定在被检测物体表面的视觉标记点来确定扫描仪在扫描过程中的空间位置,这些空间位置被用于空间位置转换;3)利用第1步获得的线状三维信息和第2步的扫描仪空间相对位置,当扫描仪移动时,不断获取激光所经过位置的三维信息,从而形成连续的三维数据。

2.3产品特点三束平行线激光扫描,扫描速度快;超高性价比,定价远低于市场上同类型手持式激光扫描仪,性能与高端扫描仪类似;被扫描物体可以移动,无需固定;目标点自动定位,不需要额外机械臂或其他跟踪设备;采用千兆网线连接,能支持远距离正常工作;两个高分辨率的图像采集单元及一套激光发射器,扫描更清晰精确;点云无分层,自动生成三维实体图形(三角网格面);手持任意扫描,随身携带,重量小于一公斤;可内、外扫描,也可在狭窄的空间扫描,如飞机驾驶舱,汽车内部仪表板等无局限。

HDI ADVANCE 三维扫描仪

在数秒内即可从实物获取数字化的 3D 扫描数据。

灵活的二合一 3D 扫描仪

小视野 用内相机插槽扫描小物体

大视野扫描仪靠简单的改变扫描仪的视野即可扫描不同形状和尺寸的物体。视野是系统能从一个特定的 距离获取 3D 数据的一个可见区域,它可以将相机放在不同的槽中来改变或者更换不同的相机镜头来完成 (相机镜头需要另外购买) 。

生成高分辨率的 3D 扫描结果

0.88

秒/每次扫描

分辨率:直到 2.6 万点(5.2 万个多边形) 精 度:直到±0.025 毫米

技术参数

相机 扫描软件 扫描速度 视野(对角) 空间距离 平均点分辨率 点距 精度 输出格式 接口 彩色贴图 外形尺寸 最低电脑配置 一对 2.8 万像素 USB3.0 接口彩色或单色相机,带 12 毫米镜头。 FlexScan3D 0.88 秒/次 可根据物体的不同尺寸和形状调整视野,预制 200 毫米,400 毫米,600 毫米对角长度视野 370 毫米-1040 毫米 2.6 万点/每次扫描 最高 0.075 毫米 最高±0.025 毫米 PLY,OBJ,STL,ASC,FBX,3D3 以太网 可升级为彩色扫描 276 毫米*74 毫米*49 毫米 Windows 7(64 位) ,双核 INTEL 2GHz 或更高,以太网接口,4GB 内存或更高,512MB 显卡,250GB 硬盘或更高。

手持式三维扫描仪

手持式三维激光扫描仪手持式三维扫描仪(3D scanner) 是一种科学仪器,用来侦测并分析现实世界中物体或环境的形状(几何构造)与外观数据(如颜色、表面反照率等性质)。

搜集到的数据常被用来进行三维重建计算,在虚拟世界中创建实际物体的数字模型。

这些模型具有相当广泛的用途,举凡工业设计、瑕疵检测、逆向工程、机器人导引、地貌测量、医学信息、生物信息、刑事鉴定、数字文物典藏、电影制片、游戏创作素材等等都可见其应用。

●参数配置○详细参数型号:EXAscan(高精度型)重量: 1.25(KG)分辨率:0.1毫米(0.004英寸)测量精度:最高0.040 mm外形尺寸:172 x 260 x 216mm十字线:双激光线300X300mm测量范围:无局限,内外均可测量速率:25,000 次测量/秒,约50000点/秒激光安全等级:二类(对视力无害)输出格式:.dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr用途:逆向工程、外观造型与设计、检测、FEA/CFD、原型法○标准配置(手提箱内)1、校准板2、人体工程学支架3、FireWire数据线4、PCMCIA连接卡5、电源6、定位目标点○兼容软件激光扫描仪与以下CAD/后处理软件配合使用,可产生极佳性能:CATIA V5:适用于CATIA V5的扫描模块Geomagic:激光扫描仪拥有与STUDIO及QUALIFY相兼容Polyworks:可与Innovmetric的IMEdit和IMlnspect模块相兼容的插件PRELUDE V5 Inspect:可从Formi订购的用于此软件的插件●优点- 高分辨率:检测每个细节并提供极高的分辨率。

- 极高精度:提供无可比拟的高精度,生成精密的3D物体图像。

- 真正自动多分辨率:新型批量三角化处理装置(Decimate Triangles slider)可在需要时保持更高分辨率,同时在平面上保持更大的三角网格,从而生成更小的STL文件格式。

三维激光扫描仪

三维激光扫描仪三维激光扫描仪参数1防尘/防水等级:≥IP54。

2扫描技术规格:扫描最远距离≥130m。

激光类别:I级安全激光。

*3激光发射频率:≥1500,000点/秒。

*4测量精度:距离精度:基础误差≤1.5mm,每增加1km误差增加≤10mm;角度精度:≤18″/18″(垂直/水平);噪音精度:≤0.5mm;点位精度:在10m距离扫描单点精度≤1.9mm。

5扫描视角:水平方向:360°;垂直方向:≥290°。

6相机系统:单个镜头像素≥1200万像素,能够生成全景影像,全景影像最高像素≥4.32亿像素。

任何光线条件下的HDR图像获取都可在2分钟之内完成。

7数据采集速度:一测站360°扫描和HDR全景照片的获取时间<2分钟。

*8实时拼接:可实现扫描仪实时全自动点云拼接。

9双倍扫描:可开关,实现自动去除视场内移动物体10视觉惯性系统:实时跟踪计算扫描测站相对于前一测站的实时相对位置。

11倾斜传感器:基于惯性导航系统,倾斜补偿精度≤3分12附加传感器:内置测高仪、指南针、卫星定位系统13移动设备操作:可远程控制扫描,2D和3D的数据查看、标注,扫描测站可自动配准。

14数据存储:工业级可插拔3.0闪存,单个闪存≥256G15电池:原装电池2块,支持热插拔,使用两块电池工作时间≥4小时。

备用电池2块。

16配套一台笔记本电脑和一个平板笔记本电脑参数:屏幕尺寸>15英寸、屏幕分辨率≥3840*2160、CPU≥Xeon E-2186M、显卡显存≥16GB、内存≥16GB硬盘:≥1T,预装正版Windows10专业版,三年全球联保(自出厂之日起);平板参数:系统:ios系统、硬盘:≥512G、尺寸:10.1英寸~12英寸二、配套三维点云后处理软件*17、三维后处理软件必须为一体的,不需要在另加第三方软件,且必须至少包含以下模块:A、点云处理模块,要求可同时处理点云数据≥10亿,软件调用数据流畅。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

江苏农林职业技术学院

机电工程学院

三维扫描仪技术参数

一、拍照式三维扫描仪

型号(项目)VTOP200B

二、手持式激光三维扫描仪

型号(项目)VTOP600H 生产企业天津微深科技有限公司品牌VTOP

型号600H

重量小于1kg

尺寸315*165*105毫米

光源形式三束交叉激光线以及一束可以单独工作的激光线,共计

7束激光线,高速扫描

激光发射位置所有激光由同一位置发出,最大限度避免多位置多角度发射激光而产生遮挡和相互干扰

白光补偿启动照度阀值35LX

切换单束激光扫描深孔及

死角

支持

扫描速率265,000次测量/秒

激光类别Ⅱ级(人眼安全)

分辨率0.05毫米

精度最高0.03毫米

体积精度1

(单独使用扫描仪)

0.02毫米+0.08毫米/米

基准距300毫米

景深250毫米

输出格式. ply、.xyz、.dae、.fbx、.ma、.obj、.asc、.stl等,可定制工作温度5~40℃

接口方式采用千兆网线连接,能支持远距离正常工作价格22.8万元

三、桌面SLA打印机

四、双喷头FDM印机。