上纬底涂树脂资料--SW CP-95 MSDS 中文

上纬树脂资料chempulseMSDS中文

地址:上海市松江工业区松胜路 118 号

电话:86-21-57746183 传真:86-21-57746177

二、 成分辨识资料

中英文名称:乙烯基酯树脂(CHEMPULSE 901) 同义名称:

危害物质成份 树脂聚合体(polymer)

苯乙稀(styrene) *NA:一般状况下无害

含量(%) 52~65 35~48

手部防护:防渗手套。使用 8 小时以上,建议用 4H 或 Barricade(商品名);使用 4 小时以上,则可用聚乙稀醇、铁氟龙、氟化弹性体材 质。

眼睛防护:1.防溅之化学安全护目镜或护面罩。2.洗眼设备。 皮肤及身体防护:上述橡胶材质之连身式防护衣、围裙及工作靴。

卫生措施:1.工作后尽速脱掉污染之衣物,洗净后才可再穿戴或丢弃,且须告知洗衣人员污染物之危害性。 2.工作场所严禁抽烟或饮食。3.处理此物后,须彻底洗手。4.维持作业场所清洁。

版本:第 01 版 页码:2/5

修订日期: 2005.11.21

品质至上‧诚信为纬‧创新致胜‧勤俭兴利

Quality Products with In Time Service and Innovation

上 纬(上 海)精 细 化 工 有 限 公 司

SWANCOR(SHANGHAI) FINE CHEMICAL CO., LTD.

IARC 将之列为 Group 2B:可能人体致癌。

版本:第 01 版 页码:4/5

修订日期: 2005.11.21

品质至上‧诚信为纬‧创新致胜‧勤俭兴利

前先设法止漏,否则其泄漏的蒸气仍可能再度引燃。但是如不可行且周遭区域不致造成危害,则让火燃烧。 特殊灭火程序:1.隔离火场外的物质,并用水雾冷却暴露于火场中的储槽或容器,在不危及人员安全情况下,将容器移离火场。2.因其闪火

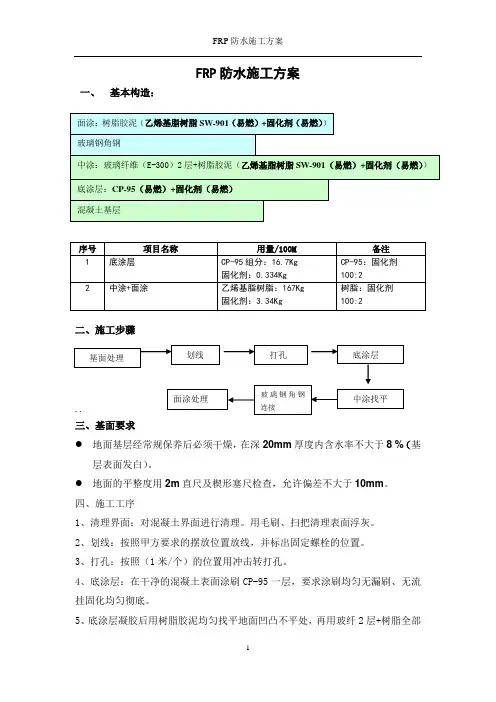

FRP防水施工方案

FRP防水施工方案一、基本构造:二、施工步骤三、基面要求●地面基层经常规保养后必须干燥,在深20mm厚度内含水率不大于8 %(基层表面发白)。

●地面的平整度用2m直尺及楔形塞尺检查,允许偏差不大于10mm。

四、施工工序1、清理界面:对混凝土界面进行清理。

用毛刷、扫把清理表面浮灰。

2、划线:按照甲方要求的摆放位置放线,并标出固定螺栓的位置。

3、打孔:按照(1米/个)的位置用冲击转打孔。

4、底涂层:在干净的混凝土表面涂刷CP-95一层,要求涂刷均匀无漏刷、无流挂固化均匀彻底。

5、底涂层凝胶后用树脂胶泥均匀找平地面凹凸不平处,再用玻纤2层+树脂全部浸透压实。

6、把角钢按照预先画的线放置压实,然后用自攻丝固定(1个/米)7、完全固化后用胶泥填充内折角处圆滑过渡,玻纤3层+树脂糊制内接缝和角钢的连接处。

8、处理完毕后处理毛刺涂刷面料。

CP-95组分成分表理化特性乙烯基脂树脂SW-901成分表理化特性固化剂成分表理化特性危险源辨识及管控序号危险源可能引起事故管控措施备注1CP-95、乙烯基脂树脂SW-901、固化剂易燃火灾环氧自流平施工区域需要拉警示带;施工人员进场禁止携带打火机等易燃物品;材料现在临时存放处实施隔离,张贴危险标示,并配备2台CO2灭火器,未经允许,任何人员不得进入材料存放区3 皮肤接触伤害人体健康施工人员需要穿戴防护手套,一旦接触皮肤脱去被污染的衣着,用肥皂水和清水彻底冲洗。

4 眼睛接触伤害人体健康施工人员需要配备防护眼镜,一旦进入人眼提起眼睑,用流动清水或生理盐水冲洗,就医。

5 食入伤害人体健康饮足量温水,催吐,就医6 吸入伤害人体健康施工人员全程佩戴口罩(防有机)做到每日更换一个材料运输与暂存取用施工过程中所用材料实行工人不间断运输至现场,现场不存放多余物料,堆放位置为吊装口附近,设置隔离区,配置专人看管,固化剂根据现场实际用量,随时提供至现场,固化剂现场不存留。

在吊装口临时存放区域先用警示带围起来,设置隔离区,未经批准不得进入贮存区域,并排专职人员监管,所有施工人员严禁携带打火机等易燃物品进入施工区域及临时存放区,同时临时存放区需要放置2台CO2灭火器,并悬挂“危险标示”如下:禁止在本物质的处理、储存和加工区域饮食和吸烟,工作人员应在饮食和吸烟前洗手,现场临时存储区域进行隔离存储,存储温度为2-40℃,防止直接光照,至于干燥凉爽和通风良好的区域,移除所有点火源(火花或火焰),与氧化性的物质分离。

UPR(树脂)-MSDS.doc

UPR MSDSMATERIAL SAFETY DATA SHEETUnsaturated Polyester ResinSECTION 1: PRODUCT AND COMPANY IDENTIFICATIONProduct Name: Unsaturated Polyester ResinManufacturer: King Way CorporationAddress: No. 40 Guizhou Road, QingdaoPostcode: 266001E-mail: resinschina@Fax: 0+86-532-8267-1533National emergency telephone:0+86-532-8388-9090;0+86-532-8388-9191SECTION 2: COMPOSITION AND INFORMATION ON INGREDIENTS Monomer □Mixture■(不饱和聚酯/苯乙烯)Product Name: Unsaturated Polyester ResinHarmful substance Content CAS NO.Styrene 35-55% 100-42-5SECTION 3: HAZARDS IDENTIFICATIONRisky category: 3.3rd kind, high flash point flammable liquid.Routes of Entry: Inhalation, Swallowing, Skin ContactHealth effects: The risk mainly is decided by the styrene which is additive, the styrene has the fetid odor which makes one laughs, may stimulate skin and the respiratory tract. Eating at nonventilated room may stimulate the mucosa.Environment effects: This matter has harm to environment, Pay attention specially to water body pollution.Explosion hazard: Flammable, its steam and air may form explosive gas. In presence of open flames or high heat, it has a danger of burning or explodes.SECTION 4: FIRST AID MEASURESSkin Contact: remove contaminated clothing and shoes. Flush skin with soap and water.Eye Contact: Check for and remove any contact lenses. In case of contact, immediately flush eyes with plenty of water for at least 15 minutes. Get medical attention immediately.Inhalation: If inhaled, remove to fresh air. If not breathing, give artificial respiration and heart massage technique immediately. Get medical attention immediately, to avoid epinephrine. Ingestion: Drink enough hot water, force to vomit, Get medical attention immediately.SECTION 5: FIRE FIGHTING PROCEDURESFlammability of Product: Flammable in presence of open flames, heat and oxidant. Risks of making container blasted in presence of polymerizing.Harmful burning gas: COFire Fighting Media and Instructions: Use dry chemical, carbon dioxide, appropriate foam, or sand .The water is prohibited use.SECTION 6: ACCIDENTAL RELEASE MEASURESEmergency measures: Keep away from sources of ignition. Rapid evacuation personnel which divulged in the pollution area to the safety zone, and carries on the isolation, strictly limits thein/out. Advised the personnel who emergency processing should be wear self-sufficient respirator, put on anti-poison clothing, shuts off as far as possible the divulged source.Large Spill and Leak: Dike if needed. Use water spray curtain to divert vapor drift. Use water spray to reduce vapors. Protection filed personnel .With explosion-proof Pumps shift to the tank car or the special-purpose collector, then recycling or transports to waste scene processing.SECTION 7 : HANDLING AND STORAGEHandling: The operator must pass through the specialized training, strictly observes the working instruction. Suggestion operator wears mouthpiece or self-absorption filter gas mask, wear chemistry security safekeeping eyeglasses, put on anti-poison seepage work clothes, wear rubber resistant oil glove. Keep away from heat, sparks and flame, prohibiting smoking in the work area. Use defending explosion-proof ventilation system and equipment. Prevent the steam divulges to the operational site air. Avoid contact with the oxidant. Should pay attention to the speed of flow (not to surpass 5m/s) when canned, and have grounding equipment, prevent the static electricity accumulation. When transporting must lightly unload and light packs, prevents package or vessel damage, and provides the variety corresponding fire-fighting equipment and handling emergency divulged. The vessel Dumped possibly remains harmfully.Storage: Keep container in a cool, well ventilated area. Keep away from heat, sparks and flame. The warehouse temperature do not surpass 30℃, keep the vessel seal. Should separate with the oxidant, food chemical, prohibit stores together. The illumination and ventilates equipment should be explosion-proof. Prohibited using easily produces the spark mechanical device and the tool. The store area should to have divulges emergency and appropriate accepts the material.SECTION 8: EXPOSURE CONTROLS PERSONAL PROTECTIONHigh the admissable concentration: 40mg/m3 (in air)Moniting method: GCEngineering Controls: Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their respective occupational exposure limits.Personal Protection:Eyes: Safety glasses and gloves.Body: Full suit.Hands: Rubber and oil-resistant gloves.Other protection: prohibiting smoking, eating and drinking in the work area. Before the work avoids with alcohol drink, after the work, please bath and changes clothes, carries on physical examination before the employment and the regular.SECTION 9: PHYSICAL AND CHEMICAL PROPERTIESPhysical State and Appearance: viscous fluid with various colors.Melting point(℃):-30.63Specific Gravity (Water=1):1:120.02Boiling Point(℃):145.2Auto-temperature(℃):490Saturated Vapor Pressure(KPa):1.33/30.8℃※Combustion Heat(kj/mol):4242.78Critical Temperature(℃)369.0※Critical pressure (mpa):3.81※Flash points (℃):23-61upper Explosion limits %(v/v):7:1lower Explosion limits %(v/v):6.5Solubility: Insoluble in water, soluble in acetone and acther.Main use: used extensively in thermoset composite material and reinforcing material. Note: refer to physical and chemical properties of styrene.SECTION 10: STABILITY AND REACTIVITYStability: unstable and may polymerice uponexposure to sunlight, heat or peroxide.Incompatibility with Various Substances: Reactive with oxidant.Conditions to avoid: naked flames, high temperature and heating.Hazardous Polymerization: Release large heat when polymerization.Decomposition Products: CO, CO2SECTION 11: TOXICOLOGICAL INFORMATION(On account of unsaturated polyester resin’s molecular weight of number average is over 1,500 and it has lower solubility. It can’t be absorbed through skin absorption and permeate organism cell. So it cann’t display toxicity. Because of unsaturated polyester resin’s low fluidity, it has litter damage to the environment. According to American FDA and EPA research, Australian EPA think non-ionic polymer which average molecular weight is over 1,000 concerns degree should be lower. But unsaturated polyer resin’s diluent is styrene, its toxictity and Ec ological information is relevant to styrene.)Acute toxicity: Acute oral toxicity (LD50) 265mg/kg [Mouse]Acute toxicity of the vapor (LC50) 12mg/m3/4h [Mouse]Acute Poisoning: In case of high concentration contact, may lead to eye and upper respiratory tract irritant. May cause ophthalmalgia, lacrimation, rhinorrhea, sneezing, pharyngodynia and cough. Continues the headache, dizziness,nausea, vomits, the whole body feels weak and so on; Serious may have the dizziness, staggering gait. When the eye is polluted by styrene, it may send burns.Chronic Poisoning: At times the symptoms of tiredness,response slowing and memory decreasing emerged in long-term exposure in the surrounding of 100ppm.Red and white blood cell population varied,as well as peripheral nerve and sense organ.Other changes of liver was caused by nutritional marasmus and the marasmus induced by total metabolism changing,other biocatalysts also varied.Irritancy: Draize test (rabbit) 100mg/24h moderateOpen draize test (rabbit) 500mg open slightMutagenicity Effects: DNA suppresses Gymphocyte cell 100umol/L.The sister chromosomes exchange Gymphocyte cell 100umol/L.Carcinogenicity: The research indicated,to the long-term contact crowd the mortality rate has not increased, cancer mortality rate has not increased, cancer formation rate has not increased. SECTION 12: ECOLOGICAL INFORMATIONEcology toxicology toxicity : 56.7mg/L 124-hr(de-ionized water),Pimophales Pronolas TL m53.6kg/L 148hr(de-ionized water),Pimophalespronolas TL m25.1kg/L 196hr (20mg/Lca CO3),Pimophalws pronolas LC20 9.1mg/L 196hr Cyprinido varieyatus LC50 26mg/L 124hr Cyprinido varieyatusBiodegradation: It has 2.3 –4.3% to degeneration in the earth’s surface of each week, and has2.8-12.0% to degeneration in the soil, Styrene has a 93% to be possible to degrade in 16 weeks and degradation product is carbon dioxide and waterNon- biodegradation: Styrene can very quickly react with the OH free radical and O3 in the air, the reaction half-life is 5h, the soil migration ratio is slightly, KOC is 270-550.The biology concentrates the nature: BCF, 13.5 goldfishes, because of relative highwater-solubility, it can not accumulate in the biological tissue.SECTION 13: DISPOSAL CONSIDERATIONSWaste material group: Dangerous waste.Waste disposal method: Incinerate in a furnace where permitted under nation and local regulations.SECTION 14: TRANSPORT INFORMATIONDangerous goods number: 33645UN Number: UN1866Packaging labeling: Flammable liquid.Packaging Group: ШPackaging method: Pails or drums.Notes: Store in cool and well ventilated warehouse. Far away from kindling material, heat source and direct sunlight. The illumination and ventilates equipment in the warehouse must be explosion-proof. The switch is located in the outside the warehouse. According to standard request dispose corresponding fire-fighting equipment. Prohibited using easily produces the spark mechanical device and the tool. When transporting should lightly put and unloads and away from direct sunlight, when transporting please abide by routing run.SECTION 15: REGULATORY INFORMATIONChemistry dangerous goods safety control rule(On January 9, 2002 the State Council issued), In view of chemistry dangerous material safety in production, use, storage, transportation, loading and unloading has made the corresponding stipulation.《General Dangerous Chemical Classification And Symbol》(GB 13690-1992), divide it into the 3.3rd kind of high flash point flammable liquid.SECTION 16: OTHER INFORMATIONReferences1、Heitmuller,R I,et al Bull.environ.Contam.Toxicol.1981,27,596-604。

混凝土内衬FRP施工方案

混凝土内衬FRP施工方案概述本施工方案根据用户的技术条件,对工程的选材、施工、检验作出了明确要求。

选材及说明底涂树脂:选用CP95#乙烯基树脂(台湾上纬精细化工有限公司生产)。

材质说明:CP95#乙烯基树脂为混凝土,内衬FRP专用底涂过渡树脂,与混凝土粘接性强,取得了以前的环氧树脂过渡。

防腐蚀层:选用MFE-2#乙烯基树脂(上海理工大学)面涂树脂,选用乙烯基MFE-2#+空气硬化剂。

材质说明:MFE-2#为乙烯基酯树脂。

耐腐蚀性能:耐盐酸(31%)、氢氧化钠(30%)、次氯酸钠(有效氯17%),耐温60℃以下。

纤维选用:无碱短切毡450克,玻璃表面毡30克(金牛集团玻纤分公司生产)。

施工标准现场施工及检验执行GB50212-2002《建筑防腐工程及验收规范》。

施工工艺搭设脚手架,铺好踏板并固定。

检查内表面:清除内表面的混凝土残渣。

内壁处理:用电动工具打磨光洁的内壁去掉凸出物,清扫表面浮土,保证内表面干净。

作底涂层:在干净的混凝土表面均匀涂刷一层CP95#树脂,凝固后施工下一道工序。

修补层:对于内表面的凹坑,用树脂腻子填充,防止在作FRP积层时出现空洞气泡。

作防腐蚀层:采用一层无碱短切毡+一层玻璃表面毡,要求纤维全部浸透,并将FRP的气泡排出,轧实使表面平整光滑。

作面涂层:防腐层固化后,用抛光机打磨去掉毛刺,均匀的涂刷一层面料树脂,树脂中加3%的空气硬化剂。

检验标准及验收提供原材料合格证及检验报告。

内壁处理按GB50212-2002中混凝土基层处理检验。

内表层检验:内表层应平整光洁、无杂质、无纤维外露、无目测可见的裂纹及分层。

铁罐衬里施工方案金属表面预处理:(1)用电动砂轮、钢丝刷、砂布等工具将罐体及锥封底打磨、除锈、如果遇到罐体锈迹严重或有油污,则采用喷砂除锈。

(2)酸洗或喷砂(石英砂)打底刮腻子:涂刷环氧树脂底漆。

增强层铺层:待底漆干后采用手糊法铺层,玻璃布须剪边,玻璃布应浸透、压实,接缝错开不小于50mm,1层环氧树脂04玻璃布+2层结构树脂短切毡与2层结构树脂04布交替铺层。

聚氨酯树脂的MSDS详解

聚氨酯树脂的MSDS详解概述聚氨酯树脂是一种常见的合成材料,广泛应用于涂料、粘合剂和填充剂等领域。

本文将详细解释聚氨酯树脂的材料安全数据表(Material Safety Data Sheet,简称MSDS),以帮助用户更好地了解该材料的性质和安全使用方法。

物理性质- 外观:聚氨酯树脂呈无色或浅黄色液体/固体。

- 气味:具有特殊气味。

- 密度:常温下的平均密度为X g/cm³。

- 熔点/沸点:聚氨酯树脂具有较高的熔点和沸点,分别为X℃和Y℃。

- 溶解性:聚氨酯树脂可溶于X溶剂,不溶于Y溶剂。

健康与安全信息吸入- 聚氨酯树脂的蒸气可能对呼吸系统产生刺激作用。

在操作时应保证通风良好,避免吸入蒸气。

如出现呼吸不畅或不适,应立即就医。

眼睛接触- 聚氨酯树脂进入眼睛可能引起刺激和不适。

如不慎接触到眼睛,应立即用清水冲洗眼睛,并寻求医疗帮助。

皮肤接触- 聚氨酯树脂可能对皮肤产生刺激作用。

接触后应立即用肥皂和清水彻底清洗皮肤。

如出现红肿、瘙痒或其他不适,应就医诊治。

摄入- 聚氨酯树脂不宜摄入或咀嚼。

如不慎误食,应立即漱口,并咨询医生建议。

防护措施- 操作时应佩戴适当的个人防护装备,包括防护眼镜、手套和防护面罩。

- 操作区域应保持通风良好,避免蒸气积聚。

- 避免与聚氨酯树脂长时间接触,尤其是对皮肤的长时间暴露。

废弃处理- 废弃的聚氨酯树脂应按照当地法规进行处理。

请咨询相关机构了解正确的废弃处理方法。

以上是关于聚氨酯树脂的MSDS详解。

请在使用该材料时遵循相关安全操作指南,并确保防护措施得当。

如有任何疑问或意外情况,请及时就医。

纸张凹印油墨MSDS安全数据表( 合成树脂 乙醇 异丙醇 乙酸丙脂 乙酯)

油墨MSDS安全数据表纸张凹印油墨版本:编制:编制日期:地址:电话号码:传真号码:1.0产品溶剂组成及性状具有气味的液体混合物,用于凹版印刷。

化学名称重量分数% 化学式CAS NO 颜料0-20 有合成树脂20-40 有乙醇10-15 C2H5OH 64-17-5异丙醇10-15 (CH3)2CHOH 67-63-0乙酸丙脂20-30 CH3COOC3H7109-60-11乙酯20-30 CH3C00C2H5148-78-6其它<5 有2.0危险有害性分类分类名称易燃性液体(化学危险性分类:易燃液体类第3.1类低闪点液体)急性毒性物质危险性●兴奋、催眠、麻醉、窒息四阶段,可导致意识丧失、瞳孔扩大、呼吸不规律、休克、心力循环衰竭及呼吸停止。

●长期接触时引起鼻、眼、粘膜刺激症状,以及头痛、头晕、疲乏、易激动、震颤、恶心等,皮肤接触可引起燥、脱屑、皲裂和皮炎。

●遇明火高温高压有爆炸危险。

●高温可分解出对眼睛、呼吸道和粘膜有刺激的气体。

●具腐蚀性。

有害性物质产生高浓度蒸汽对眼、鼻、喉有刺激,对中枢神经有影响,直接接触该物质对表皮有刺激。

稳定性稳定(避免接触条件:受热、光照、远离火源。

)3.0防护措施4.0急救措施皮肤接触擦去表面粘污物后,用大量肥皂水和流动清水冲洗皮肤。

溅入眼睛立即用清水冲洗眼并及时就医。

不慎吸入及时转移到空气流通好的场所,呼吸新鲜空气,并及时就医。

危险9.0溶剂在空气中的容许浓度注:TWA为时间加权平均容许浓度(8小时);STEL为短时间接触容许浓度(15分钟)。

(注:以上数据均为本公司内部数据,限于测定条件可能有所不同,如需引用,请充分验证。

)。

上纬树脂耐腐蚀性能

上纬树脂耐腐蚀性能上纬(上海)精细化工有限公司SWANCOR(SHANGHAI) FINE CHEMICAL CO., LTD.环氧乙烯基酯树脂耐化性简表(文件编号:055S007)环氧乙烯基酯树脂耐化性简表品质至上‧诚信为纬‧创新致胜‧勤俭兴利上纬(上海)精细化工有限公司SWANCOR(SHANGHAI) FINE CHEMICAL CO., LTD.环氧乙烯基酯树脂耐化性简表(文件编号:055S007)撰写:赵雪梅校订:赵雪梅核准:简伯然修订记录版本 00页数日期 35 08.06.12 内容摘要制定程序版本:第 00 版页码:2/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品 Aα-甲基苯乙烯桉树油胺盐胺:盐酸氨基磺酸氨基酸氨水氨气氨气(湿) 安息香酸安息酸钠 B保险粉苯胺苯果酸苯甲酚()苯甲酚(烟)苯甲醛苯苯酚苯酚(烟)苯酚磺酸苯酰氯苄基三甲基氯化铵苯磺酸苯磺酸:硫酸:水苯:乙苯苯:盐酸(湿) 苯(蒸汽) 苯(蒸气):水蒸汽浓度(重量百分比)100 100 ALL 2.9:1.1 1-10 11-15 16-25 ALL 1-5 5-20 100 40 饱和 All ALL 100 10 100 100 100 100 2 5 10 15 85 100 ALL 饱和 100 60 >0.5 88:7:5 33.5:65.5 901耐溫℃ 25 90 - 93 99 78 65 40 82 65 38 38 99 82 80 NR - NR - NR NR 27 NR - NR NR NR NR NR NR NR 38 65 60 - - - -907耐溫℃ 50 90 - 93 99 78 65 40 65 38 38 38 99 82 80 21 - NR - 18 38 48 48 48 32 18 NR NR NR NR 27 38 65 60 - - - -905耐溫℃ 25 90 - 93 99 78 65 40 82 65 38 38 99 82 80 NR - NR - NR NR 27 NR - NR NR NR NR NR NR NR 38 65 60 - - - -997耐溫℃ - - 29 93 - 60 - - NR NR 32 NR 99 80 - NR 35 NR 27 NR 32 82 82 38 27 NR NR - - 43 - - 93 60 38 32 32 79版本:第 00 版页码:3/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品 (含微量盐酸)苯酰苯甲酸苯甲醇苯甲酸苯甲酸铵苯甲酸钠苯甲酸丁酯苯二甲酸苯酐苯醌苯乙烯苯磺酸三癸酯蓖麻油吡啶变压器油(酯类) 变压器油(硅氧烷和矿物油类) 冰醋酸丙醇(1-) 丙酮丙酮:甲苯丙烯醇丙烯醛丙烯酰胺丙烯酸丙烯酸(2-乙基)己酯丙烯酸丁酯丙烯酸乳胶丙烯腈丙酸浓度(重量百分比)100 20 100 10 饱和 ALL ALL 100 100 饱和 100 100 ALL 100 20 100 100 100 100 10 100 50:20 100 20 100 50 10 25 100 100 100 ALL 20 100 1 20901耐溫℃ 99 38 NR - 99 80 80 NR 99 99 65 NR 99 90 38 NR 50 100 NR 49 - NR NR NR 40 NR 38 38 38 - 25 NR 78 38 NR 82 82907耐溫℃ 99 50 38 - 99 80 80 25 99 104 80 49 99 99 38 NR 65 120 40 49 80 NR NR 23 40 NR 38 38 38 38 25 25 78 38 NR 82 82905耐溫℃ 99 38 NR - 99 80 80 NR 99 99 65 NR 99 90 38 NR 65 100 NR 49 - NR NR NR 40 NR 38 38 38 - 25 NR 78 38 NR 82 82997耐溫℃ - - 38 35 - - - - - 38 - NR - - - NR NR - 27 - - NR - - - - 27 38 38 NR - - - NR NR 27 27版本:第 00 版页码:4/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品丙酸丙二醇丙烯酸乙酯丙酰胺薄荷油 C草酸草酸铵草酸钾草酸钠柴油橙油臭氧(干气)除草剂(LASSO)3)浓度(重量百分比)50 100 100 100 50 100 20 饱和 ALL ALL 饱和 100 100 2 mg/L饱和 10 20 100 50 50 0~18 18~21 >21 ALL ALL 20 ALL ALL ALL 100 饱和饱和 1 100 100 100901耐溫℃ 82 NR 99 NR - 90 90 90 40 63 99 82 80 38 NR 71 - 82 65 25 38 32 80 40 - 60 80 NR 27 90 99 NR 82 71 NR NR NR NR907耐溫℃ 82 38 99 NR 35 90 99 99 40 63 99 99 80 38 49 82 - 82 65 25 38 32 50 - - 38 38 38 27 99 108 38 82 82 21 21 NR 25905耐溫℃ 82 NR 99 NR - 90 90 90 40 63 99 82 80 38 NR 71 - 82 65 25 38 32 80 40 - 60 80 NR 27 90 99 NR 82 71 NR NR NR NR997耐溫℃ - - 82 NR - - - - - - - 80 - - 49 49 27 41 32 - - 46 52 49 - - - - - - - 38 82 - NR NR NR -次氯酸钙瓷土(泥浆) 次氯酸次磷酸次亚磷酸次氯酸钠次氯酸锂次氯酸镁醋酸乙烯醋酸铵醋酸钠醋酸铅醋酸酐醋酸钡醋酸铜醋酸乙酯醋酸乙酯单甲醚醋酸异丁酯版本:第 00 版页码:5/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品醋酸特丁酯醋酸正丁酯醋酸正戊酯醋酸铁醋醋酸D大豆油丹宁酸大豆油;硫酸单氟磷酸钠第二丁醇碘(结晶)碘(蒸气)碘(气): 碘化氢(气) 碘化钾淀粉丁胺(特-) 丁胺(特-) 丁胺(异-) 丁胺(异-) 丁胺(正-) 丁胺(正-) 丁醇丁醚丁二醇丁基纤溶剂丁酸浓度(重量百分比)100 100 ALL 饱和 10 15 26~50 75 100 100 ALL 90:10 饱和 10 100 100 20 ALL 40 100 40 100 40 100 100 100 100 100 1 25 50 70 100901耐溫℃ NR NR 25 82 99 99 99 82 65 NR 99 99 - 99 65 65 65 - 60 - NR NR NR NR NR NR 49 40 71 38 82 82 71 71 25907耐溫℃ 25 25 49 82 99 99 99 82 65 38 99 99 - 99 65 65 82 - 65 25 NR 25 NR 25 NR 67 40 82 38 82 82 71 71 49905耐溫℃ NR NR 25 82 99 99 99 82 65 NR 99 99 - 99 65 65 65 - 60 - NR NR NR NR NR NR 49 40 71 38 82 82 71 71 25997耐溫℃ - - - - 99 99 99 80 65 - - - 149 - 38 - 79 65 - 82 - - - - - - 38 40 71 32 82 82 - 32 32版本:第 00 版页码:6/35化学品丁基乙二醇对甲苯基磺酸丁二酸丁醛丁氧基二甘醇丁氧基乙醇(2-) 丁氧基乙氧基乙醇(2,2-)镀铝液(硫酸,重铬酸钠)镀黄铜液 3%氰化铜 6%氰化钠 1%氰化锌 3%碳酸钠镀铬液(含氟硅酸钠和硫酸钠之19%铬酸1)镀铜溶液10.5%铜 14%氰化钠 6%罗谢尔盐镀铜液 45%氟硼酸铜19%硫酸铜8%硫酸镀金液23%氰化钾铁 0.2%氰化金 0.8%氰化钠镀铁45%氯化铁 15%氯化钙 20%硫酸铁 11%硫酸铵镀铅液8%铅浓度(重量百分比)100 ALL ALL 100 100 100 100901耐溫℃ 38 99 80 NR 35 35 35 -907耐溫℃ 38 99 80 38 49 35 49 -905耐溫℃ 38 99 80 NR 35 35 35 -997耐溫℃ - - - - - -- 71- - - 8249 65 49 93- - - 8282 82 82 8299 99 99 9382 121 82 8282 82 82 NR版本:第 00 版页码:7/35化学品 0.8%氟硼酸0.4%硼酸镀镍液11%硫酸镍 2%氯化镍 1%硼酸镀镍液8% 镍0.8%氟硼酸 0.4%硼酸镀镍液44%硫酸镍 4%氯化铵 4%硼酸镀银液4%氰化银 7%氰化钾 5%氰化钠 2%碳酸钾镀锡液1) 18%氟硼亚锡7%锡9%氟硼酸 2%硼酸镀锌液9%氰化锌 4%氰化钠 9%氢氧化钠镀锌液49%氟硼酸锌5%氯化铵 6%氟硼酸铵多价螯合剂多聚磷酸(115%)多硫化铵对氨基磺酸多元醇浓度(重量百分比)901耐溫℃ 907耐溫℃ 905耐溫℃ 997耐溫℃82 82 82 9382 82 82 9382 82 82 -99 99 99 NR93 93 93 9382 82 82 NR93 93 93 -115 ALL ALL ALL修订日期: 2008.06.12- 90 45 80 80 - 99 65 99 80 - 90 45 80 80 52 - - - -版本:第 00 版页码:8/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品 E二氟化铵二铵四乙酸 2,4,6-三硝基苯酚2-丁氧基-1-乙醇2-氯乙醇 2-萘胺-1-磺酸二丁基卡必醇二甘醇二甘醇-丁醚二甘醇-丁醚二乙二醇二硫化碳(蒸气)二硫化碳二氯苯二甲基噻唑烷二甲苯二氧化碳(Gas) 二氯苯酚二氯丙酸二氯化硫(干燥,湿润)二硫化钠二氧化氯二氧化氯(烟)二异丙醇胺二异丁基甲酮二异丁烯二硫化碳(烟囟气)二溴酚二乙醚二丁醚二苯醚二氯苯二氯乙烷二氯乙烯浓度(重量百分比)ALL ALL 10 100 100 100 100 100 100 100 100 100 1 100 ALL 100 100 ALL 15 5 15 100 100 100 100 10 100 100 1 100 100 100901耐溫℃ 40 82 NR 38 38 99 25 82 25 NR 38 NR NR 65 NR 99 NR NR 99 99 93 60 NR 50 NR 38 38 NR NR 82 27 NR NR NR NR907耐溫℃ 65 82 40 38 38 99 40 99 40 25 65 NR 40 82 49 171 NR 38 121 99 93 82 82 65 50 38 38 38 NR 99 49 49 49 27 NR905耐溫℃ 40 82 NR 38 38 99 25 82 25 NR 38 NR NR 65 NR 99 NR NR - 99 93 60 NR 50 NR 38 38 NR NR 82 27 NR NR NR NR997耐溫℃ - -- - - - - - - - - NR - - - 121 - - - - - 49 32 - - - - NR NR 27 - NR NR NR NR 版本:第 00 版页码:9/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品二氯丙烷二氯甲苯二氯甲烷二氯丙烯二氯酚二氯丙酸二乙二醇单丁醚二乙醇胺二乙苯二乙酮二乙胺二乙二醇二异丁基酞二异丁基酮二异丁烯二异丙醇胺二甲基甲酰胺二甲基乙酰胺二甲基四氢对氧杂连氮3) 二甲基酞二甲基硫二甲基吗碄(2,6-)二甲胺二甲亚砜二甲苯胺二丁胺二辛基酞二丙二醇二缩三丙二醇二乙烯苯二氯化铁二氯化硫二氯化锡二溴乙烷浓度(重量百分比)100 100 0.2 100 100 1 100 100 100 30 100 100 100 100 100 100 100 100 100 100 70 100 100 100 100 4 20 20 100 100 100 100 100 100 100 饱和 ALL ALL 100901耐溫℃ NR NR 25 NR NR NR NR NR 27 49 49 38 NR NR 99 65 NR 38 49 NR - NR 65 NR 25 - 38 NR NR 25 NR 65 82 90 NR 99 NR 90 NR907耐溫℃ 38 45 25 NR 38 - - NR 38 65 65 65 NR NR 99 65 45 38 65 NR - 49 82 20 45 - 38 20 NR 40 NR 65 99 99 49 99 NR 99 -905耐溫℃ NR NR 25 NR NR NR NR NR 27 49 49 38 NR NR 99 65 NR 38 49 NR - NR 65 NR 25 - 38 NR NR 25 NR 65 82 90 NR 99 NR 90 NR997耐溫℃ NR - - NR NR NR NR - 29 43 43 49 - NR 121 32 38 - 65- - - - 54 - - - - NR - 99 - 32 104 NR - NR版本:第 00 版页码:10/35化学品二溴乙烯二溴丙醇二溴苯酚二硫化钼二甲苯磺酸钠二氧化硫(干或湿) 二乙胺四钠四乙酸酯1)二异氰酸酯甲苯二甲苯二甲苯:乙酸戊酯二甲苯:68%氯化崁烯二甲苯:煤油:85%磷酸二亚乙基三胺二正丙基胺F 发烟硫酸肥料8-8-8 肥料(尿素) 废水处理肥皂溶液酚醛树脂呋喃甲醛氟化铝氟硅化钾氟硅化镁氟化铵氟化铜氟化铵:氢氧化铵:硝酸铵(克/升) 氟氯烃类氟里昂11 氟化氢(气)氟化氢(湿)浓度(重量百分比)100 100 100 100 40 100 100 饱和 100 70:30 10:90 33:33:35100 50 ALL ALL 5 10 100 100 ALL ALL 10 100 ALL 62:165:2100 100 12901耐溫℃ NR NR NR 93 71 99 49 27 27 - - - NR 25 NR 49 49 - 99 40 49 38 NR 27 38 82 65 38 99 NR - 38 78 82907耐溫℃ NR NR 35 93 71 121 49 27 49 49 - - NR 25 NR 49 49 - 99 49 65 49 NR 27 38 82 65 38 99 - - 38 78 93905耐溫℃ NR NR NR 93 71 99 49 27 27 - - - NR 25 NR 49 49 - 99 40 49 38 NR 27 38 - 65 38 99 NR - 38 78 82997耐溫℃ NR NR - - 65 121- 65 38 49 49 38 - - - 35 35 32 32 - 32 - - 32 - - - 65 - 27 71 - 35 71版本:第 00 版页码:11/35化学品氟化钾氟化钠氟化氢钠氟气(湿,干)氟硼酸氟硼酸锌氟硅酸钾氟硅酸镁氟硅酸钠 G甘醇二甲醚甘油橄榄油钢铁清洗液 9%盐酸 23%硫酸高氯酸高硫酸铵高锰酸钾铬酸过硫酸胺铬酸:氢氟酸:磷酸铬酸:硝酸:氢氟酸铬酸:磷酸:氢氟酸铬酸:硫酸铬酸(气) 铬酸钾铬酸钠庚烷(正)浓度(重量百分比)100 ALL 100 ALL 2 ALL 50 ALL 37.5 ALL 100 100 10 30 饱和 ALL 1 5 10 20 30 40 ALL 9:11:8 6:2:1.5 7:40:2 12.5:16 20 ALL 50 饱和 100901耐溫℃ 38 78 82 49 78 99 99 25 40 40 NR 99 99 82 65 38 82 90 65 65 65 49 - NR 82 - - - - 38 90 99 99 99907耐溫℃ 38 78 82 49 99 99 99 35 60 49 NR 99 121 99 65 38 82 99 65 65 65 65 - NR 82 - - - - 65 99 99 104 99905耐溫℃ 38 78 82 49 78 99 99 25 40 40 NR 99 99 82 65 38 82 90 65 65 65 49 - NR 82 - - - - 38 90 99 99 99997耐溫℃ - 65 - - - - - - - - NR 93 60- - - 65 - 93 82 82 65 49 - - 38 27 38 107 82 - 82 82 93版本:第 00 版页码:12/35化学品汞硅酸乙酯硅氟酸硅油:盐酸硅酸钠(PH=12)硅酸钠硅氟酸钠硅油己酸甲醛硅脂过氧化氢过氧化氢(气)果糖酸过氯酸过锰酸钾过硫酸钾过硫酸钠过磷酸76%P2O5 H海水黑液(PH>7) 黑液(烟囟气) 花生油环己烷环己烷(气) 环己酮环己基胺环戊烷环烷酸浓度(重量百分比)100 100 1 10 25 35 发烟 - ALL 100 100 100 ALL 100 5 30 35 50 50 饱和 5 10 30 70 100 100 20 105 100 100 100 100 100 100 ALL901耐溫℃ 99 - 82 82 40 40 80 - 99 - 49 90 25 50 90 65 38 41 - - 99 - 65 38 - 99 99 54 99 94 82 163 82 49 82 49 25 40 90 907耐溫℃ 104 - 82 82 40 40 80 - 99 - 49 90 50 65 90 65 38 - - - 110 - 65 38 - 99 99 54 99 93 82 204 - 65 82 65 25 49 99 905耐溫℃ 99 - 82 82 40 40 80 - 99 - 49 90 25 50 90 65 38 41 - - 99 - 65 38 - 99 99 54 99 94 82 163 82 49 82 49 25 40 90 997耐溫℃ 121 38 82 82 82 71 65 91 93 71 - - - - - 99 - 41 38 60 - 29 29 29 29 65 32 - 121 82 - 116 - 60 82 _- - - -版本:第 00 版页码:13/35化学品环氧氯丙烷环氧大豆油环氧化蓖麻油环氧化菜籽油环氧树脂-EPIKOTE 828磺胺酸磺酸苯酚磺酰氯活性碳床层(水处理) J己二酸己二腈己二醇己烷己烯(2-) 季铵盐机油甲醇甲基异丁醇甲苯甲苯胺(1,2) 甲苯胺(1,3) 甲苯胺(1,4)甲醛甲酸甲酸(气) 镓酸甲基丙烯酸甲基丙烯酰胺甲醇:水浓度(重量百分比)100 100 100 100 100 100 ALL 100 23 ALL 100 100 25 100 10 100 10 100 100 100 100 25 37 44 ALL 1 10 25 50 90 100 10 饱和 40 48 80:20901耐溫℃ NR 65 40 90 45 99 25 NR - 82 49 65 71 60 80 99 49 NR 65 25 - - - - - - 50 82 82 49 49 - - - - 25 - NR907耐溫℃ 27 65 - 90 45 99 25 NR - 82 49 65 71 70 80 121 49 38 65 49 40 40 40 - - - 65 82 82 67 49 38 38 - - 25 - 38905耐溫℃ NR 65 40 90 45 99 25 NR - 82 49 65 71 60 80 99 49 NR 65 25 - - - - - - 50 82 82 49 49 - - - - 25 - NR997耐溫℃ - 52 - -- - - - 93 - - - 49 - - 99 38 38 - 32 - - - 93 65 65 65 93 93 60 38 38 38 91 27 32 32 38版本:第 00 版页码:14/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品甲乙酮焦磷酸钾焦磷酸四钾盐聚丙烯酸钠聚丙烯酸酰胺聚醋酸乙烯酯乳液聚氯乙烯乳胶聚乙烯亚胺甲基异丁基酮 3) 甲基异丁基卡必醇3)浓度(重量百分比)100 100 5 60 ALL ALL ALL ALL ALL 100 100 100 25 100 3 100 100 100 100 10 50 ALL 50:50 100 100 50 100 ALL 60 50 100901耐溫℃ NR 55 100 50 82 82 48 48 82 NR NR NR 27 - 90 40 NR 25 25 49 NR - 78 NR - 25 90 - 90 - NR NR 99907耐溫℃ 21 65 100 65 82 82 48 48 82 40 NR NR 49 - 90 60 NR 25 25 49 NR - 99 NR - 40 99 - 99 - 25 NR 99905耐溫℃ NR 55 - 50 82 82 48 48 82 NR NR NR 27 - 90 40 NR 25 25 49 NR - 90 NR - 25 90 - 90 - NR NR 99997耐溫℃ NR - - - - - - -- NR - - NR 82 - - - - - - - 38 NR NR 93 - - 38 - 52 - - -甲基丙烯酸甲酯甲基苯乙烯甲基丙烯酸钠(PH=10-10.5)甲基2,4-戊二醇甲基-2-砒硌烷酮(N-)甲基-2-砒硌烷酮(N-)甲基-4-氯苯氧基丙酸(2-)甲基-4-氯苯氧基乙酸(2-) 甲基二乙醇胺甲基异丁(甲)酮甲苯磺酸甲苯:丙酮甲苯(气) 甲酰胺碱式氯化铝焦磷酸钾焦磷酸钠焦磷酸四钾肼浸渍酸版本:第 00 版页码:15/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品酒石酸聚乙二醇聚乙烯醇聚乙烯醇:磷酸聚酯树脂聚偏二氯乙烯乳胶 (含35%DOP)抗静电剂(ELECTRSOL) K糠醇卡必醇矿物油糠醛苦味酸矿物油矿物精癸酸癸醇癸烷癸烯癸二酸二丁酯癸二酸 L联氨磷酸二氢铵磷苯二酸二甲酯磷酸氢钠硫酸亚铁六甲撑四胺氯化吡啶磷酸二氢钾氯化镉氯化钴磷酸二氢钠磷酸氢铵浓度(重量百分比)饱和 100 10 100 92:8 100 100 5 100 100 100 5 20 100 10 100 100 饱和 100 100 100 100 ALL 10 70 饱和饱和 ALL ALL 40 100 ALL ALL ALL ALL 65901耐溫℃ 99 65 82 38 - NR 49 65 - 38 99 70 45 NR NR 99 104 82 49 80 80 99 99 - NR 99 60 99 99 38 27 90 82 99 90 99907耐溫℃ 99 82 82 49 - 45 49 65 - 38 121 70 45 NR 38 121 104 82 82 80 90 99 99 - NR 99 60 99 99 50 50 99 82 99 99 99905耐溫℃ 99 65 82 38 - NR 49 65 - 38 99 70 45 NR NR 99 104 82 49 80 80 99 99 - NR 99 60 99 99 38 27 90 82 99 90 99997耐溫℃ 121 - - 27 32 -- - 38 - - - - - 38 104 138 - - - - - 32 38 NR 65 - - - - - - - - - 32版本:第 00 版页码:16/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品磷酸铵-D邻苯二甲酸丁苄酯邻苯二甲酸二烯丙酯磷酸铵邻苯二甲酸二丙烯邻苯二甲酸二丁酯磷酸二乙基己基酯(在煤油中)磷酸磷酸(气) 磷酸:氯化钙磷酸:铬酸:氢氟酸磷酸:盐酸磷酸:硝酸磷酸:硫酸磷酸(85%):硫酸(93%) 磷酸(气) :硝酸(气) 磷酸铵钠磷酸三苯酯磷酸三丁酯磷酸三甲苯酯磷酸三甲酚酯磷酸二丁酯:芳香烃溶剂磷酸三钾磷酸三钠磷酸锌硫磺硫酸钾铝硫酸铝硫酸铵硫酸铵:硫酸铁硫酸铵: 硫酸锰 (含微量二氧化浓度(重量百分比)ALL 100 100 65 100 100 20 100 10:25 40:7:2 15:9 80:4 20:10 50:50 95:5 100 100 100 ALL 35:65 0.03 ALL 25 饱和 ALL 100 100 饱和 10.5:20 125:12 901耐溫℃ 99 82 82 99 82 65 82 99 99 - - - - - - - - 60 - 60 60 - 80 65 99 99 - 82 99 99 99 - -907耐溫℃ 99 99 99 99 99 93 82 99 104 - - - - - - - - 60 65 70 60 - 80 65 - 121 - 82 121 121 121 - -905耐溫℃ 99 82 82 99 82 65 82 99 99 - - - - - - - - 60 - 60 60 - 80 65 99 99 - 82 99 99 99 - -997耐溫℃ 65 93- 32 - 32 - 121 121 38 38 104 93 71 71 93 93 - - - - 32 - - 65 32 93 - 99 121 104 82 38版本:第 00 版页码:17/35化学品硫)(克/升)硫化铵硫化钡硫化氢(干)硫化钠硫氰酸铵硫代硫酸铵硫代硫酸钠硫酸苯胺硫酸钡硫酸钙硫酸铬硫酸铜硫酸铜:硫酸硫酸二甲酯硫酸二乙酯硫酸乙酯硫酸铁硫酸铁:硫酸铵硫酸亚铁硫酸锂硫酸镁硫酸锰硫酸锰:硫酸硫酸镍硫酸钾铝硫酸钾硫酸氢钠硫酸钠:硫酸硫酸十二烷基醚酯硫氰化钠硫代硫酸钠硫酸盐清洁剂硫酸浓度(重量百分比)158:13 饱和饱和 100 10 饱和 20 60 ALL 饱和 100 饱和 100 饱和 5:18 100 100 100 饱和 20:10.5 饱和 100 饱和饱和 90:10 饱和饱和 100 100 23:35 ALL 57 100 ALL 1 5 25 50901耐溫℃ 52 49 82 99 99 99 99 38 90 99 99 99 82 99 49 25 40 27 99 - 99 99 99 99 - 99 99 99 99 - 60 82 99 99 99 99 99 99907耐溫℃ 52 49 82 99 104 99 99 38 90 99 121 121 82 121 49 25 49 38 99 - 99 99 121 104 - 99 121 99 99 - 60 82 99 99 104 104 104 99905耐溫℃ 52 49 82 99 99 99 99 38 90 99 99 99 82 99 49 25 40 27 99 - 99 99 99 99 - 99 99 99 99 - 60 82 99 99 99 99 99 99997耐溫℃ 52 49 - 121 60 NR 93 82 - 93 82 121 65 121 65 - - 38 93 82 104 93 93 - 38 104 99 104 93 82 - - - - 104 104 104 93版本:第 00 版页码:18/35化学品硫酸(气)硫酸:苯磺酸:水硫酸:氧化铬硫酸:硫酸铜硫酸:十二苯磺酸:水硫酸:盐酸硫酸:盐酸:硝酸硫酸:硝酸硫酸:烷基苯有机物硫酸:磷酸硫酸:氯化钠硫酸:氯化钠:硝酸钠硫酸:硫酸钠硫酸:大豆油 70%硫酸:70%硝酸93%硫酸:85%磷酸硫二甘酸硫酸锌:硫酸:硫酸钠硫酸锌硫化氢钠六亚甲基四胺六氯环戊二烯六氯乙烷六偏磷酸钠乳酸乳胶乳胶(PVAC) 氯丙烯浓度(重量百分比)70 75 80 93 10 20 50 80 7:88:5 80:2 18:5 10:85:4 45:14 20:30:12 20:5 15:15 75:2 10:20 12:8 20:8:8 35:23 10:90 51:10.5 50:50 10 8:10:20 3:5:5 100 65 28 100 100 ALL 100 100 100901耐溫℃ 82 38 NR - 99 82 60 - 60 - 49 - 38 - 67 - - 82 - - - - 27 - 27 35 96 99 - - - NR 80 99 49 99 27907耐溫℃ 82 49 NR - 104 82 60 - 60 - 49 - 49 - 78 - - 82 - - - - 27 - 38 - 96 121 - - 45 40 80 99 49 99 27905耐溫℃ 82 38 NR - 99 82 60 - 60 - 49 - 38 - 67 - - 82 - - - - 27 - 27 35 96 99 - - - NR 80 99 49 99 27997耐溫℃ 88 79 65 - 121 104 60 60 60 74 65 65 60 32 99 82 71 71 99 82 82 149 27 71 - - - 121 71 27 - - - 93 38 38 27版本:第 00 版页码:19/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品氯化铝氯化铵氯化钡氯化苄叉氯化苯氯化钙氯化锌氯桥酸酐氯化亚麻油氯化石蜡氯气(干) 氯气(湿) 氯水氯乙酸氯乙醇氯乙烯氯苯氯仿氯化磺酸氯甲苯氯化铜氯化铜:硝酸银氯化铜铵氯化铁氯化铁:盐酸氯化氢(干气)氯化氢(湿气)氯化樟酸氯化铅氯化亚麻仁油氯化锂浓度(重量百分比)100 饱和 100 100 100 饱和 70 66 100 100 100 PH<2.5 PH>9 PH 2.5-91 25 50 70 80 85 100 100 100 100 100 100 100 饱和 15:33 ALL 饱和 29:18.5 100 100 100 饱和 45 饱和901耐溫℃ 99 99 99 NR NR 99 - - - 82 99 99 80 80 - 49 49 38 25 25 25 NR 38 NR NR NR NR - 99 - 80 99 82 99 99 38 99 - 99 99 907耐溫℃ 121 99 99 NR 27 121 - - - 82 121 121 95 65 - 49 49 38 30 25 25 NR 38 NR 38 NR NR - 121 - 80 99 - 177 104 49 99 - 104 104 905耐溫℃ 99 99 99 - NR 99 - - - 82 99 99 80 80 - 49 49 38 25 25 25 NR 38 NR NR NR NR - 99 - 80 99 82 99 99 38 99 - 99 99 997耐溫℃ 121 93 93 - NR 121 121 79 32 - 149 104 - - 32 32 32 - - - - 93 - NR NR NR NR 121 32 - 121 82 177 110 99 104 32 121 71版本:第 00 版页码:20/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品氯化镁氯化汞氯化亚汞氯化戊烷氯甲烷氯化镍氯化钾氯化锡氯化亚锡 3氯1-溴丙烷氯酸锌氯酸钙氯酸钾氯酸钠氯化钠氯化钠(PH=3) 氯化钠(PH=3.5) 氯化钠:硝酸钠:硫酸氯化钠:硫酸M 没食子酸钼酸铵马达油马来酸马来酸酐马来酸残渣马来酸二乙酯煤油煤油:二甲苯:85%磷酸蜜胺树脂棉子油明矾木质磺酸木质素磺酸铵木质素磺酸钠盐浓度(重量百分比)饱和饱和 ALL ALL 100 饱和 100 100 100 100 ALL 饱和饱和 ALL 饱和饱和饱和饱和 8:8:20 8:12 ALL ALL 100 5 饱和 100 100 100 33:33:33100 饱和 50 ALL901耐溫℃ 99 99 99 NR NR 99 99 99 99 NR 99 99 99 90 99 99 99 -- - 60 65 90 99 99 65 - NR 82 - - 99 99 - - 80907耐溫℃ 121 99 99 49 NR 99 99 99 99 NR 99 99 121 99 99 99 99 -- - 60 - 120 104 110 65 - NR 82 - - 99 121 - 80 80905耐溫℃ 99 99 99 NR NR 99 99 99 99 NR 99 99 99 90 99 99 99 -- - 60 - 90 99 99 65 - NR 82 - - 99 99 - - 80997耐溫℃ 104 99 99 - - 104 121 82 121 - - 129 121 - 93 121 99 74 82 99 - - - - 93 - 85 - 82 38 27 38 121 32 - -版本:第 00 版页码:21/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品木质素硫酸酯3-7N奈烷萘萘胺-2-磺酸(1-) 尿甲醛数脂,PH<7尿素尿素:氯化铵:硝酸铵尿素:硝酸铵:水脲醛树脂柠檬酸铝柠檬酸钴柠檬酸铵柠檬酸牛奶和奶制品P喷射机油(普通硼氢化钠水溶液)硼砂硼酸硼酸钠硼酸三甲酯:甲醇啤酒蓖麻油偏铝酸钠偏己磷酸钠漂白剂次氯酸钙漂白剂二氧化氯漂白剂次氯酸钠漂白剂,次氯酸盐漂白剂,氯水漂白剂,亚硫酸氢盐漂白液葡萄糖酸浓度(重量百分比)ALL ALL 100 ALL ALL 50 38:2.5:20 35:44:21100 饱和 ALL 饱和饱和 ALL100 饱和 ALL 饱和 98:2 100 100 饱和 10 饱和饱和 0-5 5-15 10 饱和 50901耐溫℃ 80 60 99 - 25 65 - - - 93 80 65 99 70 82 99 90 - - 49 71 49 49 82 82 65 82 65 60 82 99 82907耐溫℃ 80 60 99 99 25 65 - - - 93 80 65 99 70 82 99 99 - - - 71 49 49 38 93 49 49 65 80 82 99 82905耐溫℃ 80 60 99 - 25 65 - - - 93 80 65 99 70 82 99 90 - - 49 71 49 49 82 93 65 82 65 60 82 99 82997耐溫℃- - - 32 - - 71 32 49 27 - - 65 93 - 38 82 - 77 65 NR 99 NR 65 49 - - - - - 52 版本:第 00 版页码:22/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品葡萄糖 Q漆树油氰化金钾汽油去离子水槭糖浆汽油(车用) 汽油(航空) 羟甲基纤维素羟乙基硫酸钠羟基乙酸氢氯化苯胺氢氧化铝氢氧化铵氢氧化钡氰化镉电镀液3%氧化镉10%氰化钠1.2%氢氧化钠清洁剂(有机)清洁剂(磺化)氢氧化钙氢氧化钙(泥浆)氰化铜氢氟硼酸氢溴酸氢溴酸(烟)浓度(重量百分比)100 100 12 100 ALL 10 100 35 70 100 100 1 5 10 20 29 10 饱和901耐溫℃ 99 80 99 82 82 80 82 82 65 - 60 25 82 82 82 82 65 65 38 65 65 907耐溫℃ 121 90 99 82 82 80 82 82 65 - 60 40 82 93 65 65 38 38 38 71 65 905耐溫℃ 99 80 99 82 82 80 82 82 65 - 60 25 82 82 82 82 65 65 38 65 65 997耐溫℃ 82 - - - - - - - - 49 - - 65 NR NR NR NR NR NR - -82 82 82 NR100 100 100 0.5-25 饱和饱和 1 18 25 48 62 100修订日期: 2008.06.1238 99 82 80 99 99 82 82 82 65 38 - 38 104 82 40 99 99 82 82 82 65 38 - 38 99 82 80 99 99 82 82 82 65 38 - 38 - 79 - 93 82 93 93 93 93 - 143版本:第 00 版页码:23/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品氢氰酸氢氟酸氢氟酸(气) 氢氟酸:盐酸:硝酸1)浓度(重量百分比)饱和 1 5 10 15 20 22 40 35 13:77:10901耐溫℃ 99 65 65 65 38 38 27 NR -- - - 38 - - 82 65 - 65 99 - 65 65 65 82 82 82 82 82 82 99 99 99 99 65 65 - 80 90907耐溫℃ 99 65 65 65 38 38 32 NR -- - - 38 - - 82 65 - 65 110 - 25 25 25 38 38 38 38 38 38 99 99 99 99 65 65 35 80 99905耐溫℃ 99 65 65 65 38 38 27 NR -- - - 38 - - 82 65 - 65 99 - 65 65 65 82 82 82 82 82 82 99 99 99 99 65 65 - 80 90997耐溫℃ 93 65 65 49 38 32 32 32 49 38 74 57 38 74 93 82 82 38 NR NR 38 NR NR NR NR NR NR NR NR NR - 43 60 65 - - - - -氢氟酸:硝酸2.5:7.53:20 3.5:20 5:15氢氟酸(气):硝酸5:35(气) 1)氢氟硅酸硅氟10酸 35 氢:臭氧氢氧化锂饱和氢氧化镁饱和氢: 臭氧氢氧化钾 1025 45 氢氧化钠 ALLALL ALL ALL ALL ALL 氰化银饱和氰化钠 10 50 饱和氰化钡 ALL 氰化钾 ALL 氰化金钾 12 氰化锌 ALL 氰酸铜 ALL版本:第 00 版页码:24/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品 R染料厂废水处理(PH=2-3)燃油热烟气壬烷壬烯壬基酚人造纤维浸渍液肉豆蒄酸肉豆蒄酸异丙酯鞣酸乳酸乳胶乳白胶(PVAC)软化水 S三氯化铝三氯化锑三氯甲苯三氯化磷三聚磷酸钠三氧化硫(干) 三氧化硫(湿) 三氯乙酸三氯苯三氯乙烷三氯乙烯三氯乙醛砷酸十六酸异丙酯十四烷酸异丙酯顺丁烯二酸羧乙基纤维素四氯化钛碳酸二乙酯三氯单氟甲烷三丙基胺-N浓度(重量百分比)100 100 100 100 100 100 饱和 10 80 100 100 100 40 饱和 100 100 饱和 100 50 100 100 100 100 ALL 100 100 ALL 10 ALL 100 100 100901耐溫℃- 82 171 80 80 - - 99 90 99 80 25 99 49 99 80 82 93 NR NR 99 99 - 99 NR 38 NR NR 82 99 99 99 65 65 - 27 25907耐溫℃- 99 204 80 99 - 60 121 99 99 80 25 99 49 99 80 99 104 - NR 99 149 - 99 - 49 NR NR 82 110 110 110 65 80 38 38 25905耐溫℃- 82 171 80 80 - - 99 90 99 80 25 99 49 99 80 82 93 NR NR 99 99 - 99 NR 38 NR NR 82 99 - 99 65 - 27 25997耐溫℃ 82 77 171 - - 43 82 - - 121 - - 93 38 38 - 99 93 - NR - 32 32 93 NR NR NR - - - - - - - - -版本:第 00 版页码:25/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品三丁胺-N三甘醇三甲胺三乙醇胺三乙胺三甲基甲醇三氯酚三苯基磷酸酯三聚磷酸钠三聚氰胺树脂三磷酸钠三磷酸五钠山梨醇溶液刹车油石灰泥浆石油精十二烷十二烷醇十二烯十二碳烯十二苯磺酸十二碳硫醇十二醇硫酸钠十二烷基苯磺酸钠(PH=8) 十二烷基硫醇十二醇十二烷基硫酸钠十三烷基硫酸钠石蜡双环戊二烯双氧水漂白剂2%过氧化钠96%5%硅油钠0(42Be)4%硫酸0(65Be)0.025%Epsom盐浓度(重量百分比)ALL 100 100 100 100 100 100 100 ALL ALL ALL 10 ALL 100 饱和 100 100 100 100 100 100 100 100 40 ALL 100 ALL ALL 100 100901耐溫℃ 25 90 25 49 65 - NR - 90 25 90 90 90 NR 77 82 27 80 65 80 80 - 71 - 90 65 60 90 90 -907耐溫℃ 25 99 25 49 65 - NR - 99 25 99 99 90 49 77 99 49 99 80 99 100 - 71 - 90 82 70 90 90 -905耐溫℃ 25 90 25 49 65 - NR - 90 25 90 90 90 NR 77 82 27 80 65 80 80 - 71 - 90 65 60 90 90 -997耐溫℃ - - - - - 38 - 49 - - - - - - 82 93 - - 32 - - 49 38 49 - 38 - - - 3882 - 82 -版本:第 00 版页码:26/35化学品浓度(重量百分比)双氧水漂白水水合肼 16 水合氯化铝 50 水力流体,中性 100 水力流体,碱性 100水杨酸饱和水处理(染料厂,PH=2-3) 水处理(软化和凝结) 水:丙酮 90:10 水:硝酸铵:尿素 21:44:35 水:苯磺酸:硫酸 5:88:7 水:苯:二甲基酰50:40:5胺水:盐酸:硫酸:40:30:20:10硝酸水:甲醇 20:80 水:硫酸:十二苯4:10:85 磺酸(含1%油类) 水(冷却塔) 水(去离子水) 100 水(高纯度去离子水1001.5umho/cm) 水(去矿物) 100 水(蒸馏水) 100 水(地表水水(蒸气冷凝) 100 水(气):盐酸(气):5:2:93甲醇(气) 四氯化碳 100 四氯化碳(气) 四氯吡啶 100 四氯乙烯100 四硼酸钠饱和四氯苯酚钠 13 四氯乙烷 100 四氧化二氮 100 松节油 100901耐溫℃ 82 30 99 90 25 60- - - - 60 NR - - 65 49 82 82 82 82 - 82 - 65 80 - 27 82 - NR NR 65907耐溫℃ 82 30 99 90 25 71- - 82 - 60 NR - - 65 49 82 82 82 82 - 82 - 82 95 - 49 82 - - NR 99905耐溫℃ 82 30 99 90 25 60- - - - 60 NR - - 65 49 82 82 82 82 - 82 - 65 80 - 27 82 - NR NR 65997耐溫℃ - - 74 - - 65 82 32 - 49 60 NR 32 38 65 49 82 - 99 99 43 99 65 52 52 49 38 82 32 - - 38版本:第 00 版页码:27/35化学品松木油松香胶料顺丁烯二酸羧乙基纤维素四氯化钛T 碳酸铵碳酸钡碳酸钙碳床(水处理)碳酸碳酸乙酯碳酸锂碳酸镁碳酸氢钾碳酸钾碳酸钠碳酸二乙酯糖浆天然气铁氰化钾铁氰化钠铜锍电解液30%氯化铁19%盐酸铜酸洗液10%硫酸铁10%硫酸桐油浓度(重量百分比)100 ALL 10 ALL 10 30 饱和 100 饱和饱和 100 饱和饱和 10 饱和 10 25 饱和 2 10 25 32 饱和 100 100 饱和饱和901耐溫℃ 90 90 99 65 65 38 38 65 99 82 - 65 NR 65 82 80 71 82 82 65 82 82 71 71 71 - 80 99 99 99 82907耐溫℃ 90 90 110 65 80 38 38 65 121 82 - 65 38 65 82 80 71 82 82 65 82 82 71 71 71 38 80 99 99 99 93905耐溫℃ 90 90 99 - 65 38 38 65 99 82 - 65 NR 65 82 80 71 82 82 65 82 82 71 71 71 - 80 99 99 99 82997耐溫℃ - - - - - NR - - 93 93 93 71 - 82 71 32 - 43 43 43 71 71 32 - 32 - - - 121 121-修订日期: 2008.06.1293 9393 10493 93104 93版本:第 00 版页码:28/35化学品 W戊二酸威士忌五倍子酸烷基苯铵盐烷基苯磺酸烷基苯磺酸钠烷基芳基磺酸钠(PH=8)烷基芳基磺酸盐烷基酚聚乙二醇醚烷基酚聚乙二醇醚硫酸酯及盐烷基磺酸及磺酸盐烷基磺酸酯烷基萘磺酸烷基萘聚乙二醇醚王水王水(烟) 乌洛托品戊醇五氯化锑戊二酸戊二醛戊烯二酸戊烷戊硼酸铵五氧化二磷 X烯丙醇硒酸洗涤剂(RENEX) 洗涤剂, 磺酸盐洗涤剂, 硫酸盐酰胺型表面活性剂硝酸铝硝酸铵硝酸铵:尿素:水浓度(重量百分比)50 饱和 ALL 92 100 40 ALL ALL ALL ALL ALL ALL ALL 60 100 100 50 50 ALL 100 ALL 0-54 100 ALL ALL 100 ALL 100 饱和饱和 10:40:50 44:35:21901耐溫℃ 50 30 82 80 - - 82 60 35 60 60 60 60 60 NR - 40 49 32 49 25 60 35 40 99 NR 99 - 90 60 - 82 99 49 -907耐溫℃ 50 - 82 80 82 - 82 60 35 60 60 60 60 60 NR - 45 93 32 49 49 80 35 40 99 25 99 65 99 60 - 82 121 - -905耐溫℃ 50 - 82 80 - - 82 60 35 60 60 60 60 60 NR - 40 49 32 49 25 60 35 40 99 NR 99 - 90 60 - 82 99 49 -997耐溫℃ - - - - 38 38 49 - - - - - - - 54 32 - 93 32 - - - - - - - - - - - 49 88 93 - 49版本:第 00 版页码:29/35化学品硝酸钙硝酸铈硝酸钴硝酸铜硝酸铁硝酸亚铁硝酸铅硝酸镁硝酸镍硝酸硝酸硝酸:盐酸硝酸:盐酸:氢氟酸硝酸:盐酸:硫酸硝酸:氢氟酸硝酸:磷酸硝酸:硫酸硝酸(气)硝基苯硝酸钾浓度(重量百分比)30:20:50 饱和饱和饱和饱和饱和饱和饱和饱和饱和 1 5 10 20 28 35 40 50 52.4 10:10 5:20 10:77:13 12:30:20 7.5:2.5 20:3 20:3.5 15:5 4:80 5:5 5:20 15:15 20:20 10 20 24 35 48 60 100 100901耐溫℃ 49 99 32 60 99 99 99 99 71 99 65 65 65 49 38 25 NR NR NR 82 -- - - - 38 - - 65 - - 38 71 - - 71 - 71 NR 99907耐溫℃ - 99 32 60 99 99 99 99 71 99 82 82 65 65 52 39 39 NR NR 82 -- - - - 49 - - 82 - - 49 82 - - 82 - 82 38 99905耐溫℃ 49 99 32 60 99 99 99 99 71 99 65 65 65 49 38 25 NR NR NR 82 -- - - - 38 - - 82 - - 38 71 - - 71 - 71 NR 99997耐溫℃ - 99 32 60 60 121 104 104 - 104 - 99 93 60 - - 49 43 43 93 99 38 32 74 57 38 74 93 - 99 82 - 79 - - 93 - - - 104版本:第 00 版页码:30/35环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品硝酸银硝酸银:氯化铜硝酸钠硝酸钠;氯化钠: 硫酸硝酸锌辛胺(2-) 辛胺(叔-) 辛胺(正-) 辛酸辛醇辛烷辛烯新戊二醇溴化铝溴化铵溴水溴代甲烷(气) 溴气(干) 溴气(湿) 溴化氢(干气) 溴化氢(湿气)溴化钡溴化锂溴化钾溴化钠溴酸铵溴酸钠溴酸钾溴化钠: 溴酸钠溴乙烷鳕鱼肝油Y亚甲基丁二酸亚甲基蓝,PH=2-5.5 亚硫酸铵浓度(重量百分比)ALL 33:15 饱和 8:8:20 饱和 100 100 100 饱和 ALL 100 100 90 100 饱和 0.5-43 5 100 10 100 100 100 100 ALL 100 饱和 100 ALL 5 ALL ALL 20:20 100 100 25 ALL ALL 901耐溫℃ 99 - 99- 99 - - - 82 60 90 90 - 80 71 70 82 NR NR 32 32 82 82 90 99 38 99 90 60 90 90 90 NR 90 - 60 65907耐溫℃ 99 - 99- 99 45 45 45 99 99 99 99 - 80 71 70 93 NR NR 38 32 82 82 99 121 49 99 99 65 99 99 99 NR 99 - 60 65905耐溫℃ 99 - 99- 99 - - - 82 60 90 90 - 80 71 70 82 NR NR 32 32 82 82 90 99 38 99 90 60 90 90 90 NR 90 - 60 65997耐溫℃ 104 32 121 82 82 - - - 60 - - - 65 - - - - - - 60 32 93 82 - 82 99 121 - - - - - - - 35 - -版本:第 00 版页码:31/35化学品亚砷酸亚硫酸钙亚硫酸氢钠亚麻仁油亚麻酸亚麻子油亚油酸亚硝酸亚磷酸亚磷酸:盐酸亚铁氰化钾亚硫酸氢钠亚硫酸氢钠:亚硫酸钠亚砷酸钠亚硝酸钠亚硝酸钾亚硫酸钠亚硫酸亚硫酰氯(气) 亚硫酸氢锌亚硫酸锌亚铁氰化钠亚氯酸钠厌氧污水烟酸盐水烟道气盐酸浓度(重量百分比)19Be ALL ALL 100 100 100 100 10 70 70:2 饱和饱和 50:50 50 饱和 ALL 100 10 饱和 100 饱和饱和饱和 2 15 25 50 饱和 ALL 饱和 1 5 10 15 20 25 32901耐溫℃ 82 82 99 99 90 90 90 - 80 - 99 99- - 99 90 99 49 38 NR - 82 99 - 65 - 38 - 29 45 99 163 82 82 82 82 82 65 65 907耐溫℃ 82 82 99 110 99 99 99 - 80 - 99 99- - 99 99 99 49 38 NR - 82 99 - 65 - 49 - 29 45 104 204 104 104 104 104 104 99 82905耐溫℃ 82 82 99 99 90- 90- 90- - 80 - 99 99- - 99 90 99 49 38 NR - 82 99 - 65 - 38 - 29 45 99 163 99 99 99 99 99 82 65 997耐溫℃ 82 82 93 93 - - - 32 - 82 93 93 65 54 82 - 104 65 65 65 71 - 82 99 79 79 - 65 29 - 104 177 110 110 110 110 110 82 82版本:第 00 版页码:32/35化学品盐酸:乙酸盐酸:胺盐酸:氯化铁盐酸:硝酸盐酸:硝酸:硫酸盐酸:磷酸盐酸:亚磷酸盐酸:硅油盐酸:硫酸盐酸(烟)(酸洗槽)盐酸(气) 盐酸(气):甲醇(气): 水蒸气盐酸苯胺盐酸含有机物盐酸三甲胺氧化钙(石灰泥浆) 氧化铬:硫酸氧化性气体液氯椰子油椰子油脂肪酸液压油乙醛乙酸:盐酸乙酸:过氧化氢乙酸:重铬酸钠乙腈(氰甲烷) 乙酰苯(苯乙酮) 乙酰丙酮乙酰丙酸乙醇浓度(重量百分比)36 37 20:50 18.5:50 1.1:2.9 18.5:29 10:10 20:5 30:12:20 9:15 2:70 21:79 14:45 9:23 30 32 2:93:5 ALL 饱和饱和 2:80 100 100 100 100 100 50:20 50:18.5 95:1.5 70:30 100 100 20 100 ALL 1 10901耐溫℃ 52 38 - - 93 82 93 - - - 82 - - 93 - 99- 80 NR 25 77 - - NR 82 90 82 NR - - - - NR NR 40 NR 90 65 65907耐溫℃ 62 48 - - 93 - 93 - - - 82 - - 93 - -- 80 49 25 77 - - NR 99 90 82 - - - - - NR NR 50 NR 99 65 65905耐溫℃ 52 38 - - 93 82 93 - - - 82 - - 93 - 99- 80 NR 25 77 - - NR 82 90 82 NR - - - - NR NR 40 NR 90 65 65997耐溫℃ 65 38 32 29 93 82 93 99 32 104 82 91 60 82 102 107 65 - - - 65 74 32 NR 99 - 82 NR 32 29 32 71 NR 32 - - - - 65版本:第 00 版页码:33/35化学品乙酸铵乙酸戊酯乙酸戊酯:二甲苯乙酸丁酯乙醇胺乙二胺四乙酸乙二胺四乙酸钠乙二胺四乙酸四钠乙苯乙苯:苯乙基溴乙基氯乙基氰乙醚乙二醇乙二醇单丁醚乙二醇二丁醚乙二醇醚乙醇酸乙二醛乙二酸乙酸钠乙酸铅乙基环己醇乙烯甲苯异丁基甲醇异戊醇异癸醇异丙醇异丁醇异辛醇异丙胺浓度(重量百分比) 15 50 95 100 50 65 100 30:70 100 100 ALL ALL ALL 100 65.5:33.5100 100 ALL 100 100 100 100 ALL 10 70 40 100 100 100 100 100 100 100 100 10 100 100 100 100901耐溫℃ 65 38 27 NR 43 27 NR - NR NR 60 60 60 27 - NR NR NR NR - 99 38 NR 25 82 38 38 99 99 99 60 27 50 38 82 65 27 49 60 49 907耐溫℃ 65 65 38 38 43 27 49 49 27 32 60 60 60 49 - NR 27 NR NR - 99 38 49 25 93 38 38 99 99 110 99 49 99 49 82 65 38 60 99 49 905耐溫℃ 65 38 27 NR 43 27 NR - NR NR 60 60 60 27 - NR NR NR NR - 99 38 NR 25 82 38 38 99 99 99 60 27 50 38 82 65 27 49 60 49 997耐溫℃ - 65 - 38 - - 32 NR 32 32 - - - NR 38 NR 32 - NR 121 121 32 - - 65 38 - 104 93 71 - 27 - - 65 71 32 - - 32版本:第 00 版页码:34/35化学品衣康酸一氯化碳一氯苯一乙醇胺一氧化碳阴离子型表面活性剂硬脂酸硬脂酸丁酯 (在矿物油中含5%) 油酸铀萃取物玉米油玉米淀粉玉米糖原油月桂醇月桂基硫酸铵月桂酰氯亚砒酸亚硒酸衣康酸油酸原油重铬酸钾一氯乙酸 Z 樟酸蔗糖液庶糖正磷酸铵正丙胺正癸醇正己二醇正己烷正己烯浓度(重量百分比)25 100 100 100 58 100 100 100 100 100 100 ALL ALL ALL 19Be ALL 25 ALL 100 ALL 25 50 80 饱和 ALL 100 40 100 100 ALL 100 100901耐溫℃ 49 NR NR NR 99- 99 25 93 99 - 82 99 99 99 90 60 49 82 98 49 99 99 99 49 38 25 99 82 82 - NR NR 80 80 60 60907耐溫℃ 49 NR 38 NR 171- 99 25 93 99 - 99 - - 121 90 60 49 82 98 49 99 121 68 49 38 25 99 82 82 - 25 NR 99 80 70 70905耐溫℃ 49 NR NR NR 99- 99 25 93 99 - 82 99 99 99 90 60 49 82 98 49 99 99 99 49 38 25 99 82 82 - NR NR 80 80 60 60997耐溫℃ 35 NR NR 27 121 49 121 - - 93 32 99 99 99 99 - - - - - - - - - - - - - - - 93 - - - - - -版本:第 00 版页码:35/35上纬(上海)精细化工有限公司环氧乙烯基酯树脂耐化性简表(文件编号:055S007)化学品脂肪酸酯脂肪酸脂肪烃石脑油重肪烃石脑油重碳酸铵重亚硫酸铵液(黑液) 重亚硫化钙重亚硫酸钙重碳酸镁重亚硫酸镁重铬酸钾重碳酸钠重铬酸钠重铬酸钠:乙酸重磷酸钠纸浆厂废水纸浆(漂白) 纸浆厂白液浓度(重量百分比)100 饱和 100 100 10 15 20 饱和饱和饱和饱和 100 100 10 饱和饱和 30:70 饱和 100 100 100 100 ALL901耐溫℃ 82 99 90 45 71 71 71 65 65 - 82 82 82 99 82 82 99 - 99 82 - 82 82 99 99 90 49907耐溫℃ 82 121 90 49 71 71 71 65 65 - 82 82 82 99 82 82 99 - 99 82 - 82 82 110 121 99 49905耐溫℃ 82 99 90 45 71 71 71 65 65 - 82 82 82 99 82 82 99 - 99 82 - 82 82 99 99 90 49997耐溫℃ 49 121 - - - 54 - -- - - 82 82 93 60 60 - 71 82 54 88 - - - - - -自来水棕榈酸异丙酯棕榈酸棕榈油棕榈酰氯“-” 表示暂时没有相关试验数据。

重防腐乙烯基FRP施工

重防腐乙烯基FRP(三布)涂层施工材料及施工工艺乙烯基酯重防腐地坪性能特点:1 乙烯基酯树脂具有环氧树脂优越之物理性能且兼具不饱和聚酯之快速硬化,简易便捷之加工成型性;2 耐化学性能优异,在100℃以下能抵抗绝大部分盐、酸、碱化学试剂的侵蚀;3 特别适用于重防腐要求的作业面和工作场所,如强酸、碱池排污沟槽等作业环境;4 优异的机械特性、韧性及耐疲劳性能。

乙烯基酯重防腐地坪适用范围:电镀厂、电池厂、化工厂;化学储区或桶漕,大型水漕,电解池等;污、废水处理漕,酸碱中和池。

使用年限:5mm厚度下一般使用年限为5-15年。

重防腐乙烯基FRP(三布)涂层示意图:一、涂层对基础的要求混凝项目检测及处理办法1、养生期:新混凝土结构体,要经28天养生,如养生期不足,则强度低,容易反碱,造成涂层剥离基体层。

达到养生期进行施工2、强度:新混凝土结构体抗压强度大於3000PSI。

无明显起砂、脱壳及起层现象,必要情况下做混凝土回弹试验确定。

如遇局部强度低下问题时,可采用低粘度渗透型环氧树脂双组料进行完全渗透处理,恢复基层强度六、重防腐乙烯基FRP自流平涂层系统设备机台底座施工七、重防腐乙烯基FRP自流平涂层系统施工方案1、素地处理;首先用批刀除去地面的颗粒及杂物,然后用扫把清扫干净,再用打磨机全面打磨,使水泥地面干净、粗糙、然后清扫干净,用吸尘器吸净灰尘,有油污应先用清洗剂洗掉,潮湿处需先烘干,有裂缝处需用树脂腻子补平,(素地处理是树脂地板最为关键的一步,基础处理达标是树脂地板是否可达标的关键);2.乙烯基酯防腐底涂:将采用渗透性及附着力特强的乙烯基酯树脂底漆与固化剂按比例混合,搅拌均匀,用滚筒均匀地滚涂一道,使底涂完全渗透,在水泥地表面形成一道全树脂封闭层.3.铺玻纤一布:待底涂完全固化后,将玻纤布放置平整,用调配好的乙烯基树脂中涂料将玻织布粘附地面,并用批刀将乙烯基中涂与玻纤布渗透批平,加强地坪的耐腐蚀性能。

4.铺玻纤二布:玻纤一布完全固化后,将玻纤布放置平整,用调配好的乙稀基树脂中涂料将玻织布粘附地面,并用批刀将乙稀基树脂中涂与玻纤布渗透批平,增强地面坚韧性与耐防腐性能;5.铺玻纤三布:玻纤二布完全固化后,将玻纤毡放置平整,用调配好的乙稀基树脂中涂料将玻纤布粘附地面,并用批刀将乙稀基树脂中涂与玻纤布毡渗透批平,使其增强地面坚韧性以及达到附罩整个地板的效果与高耐防腐性能;6.打磨:用打磨机进行全面打磨,将玻纤布的接头磨平,清扫干净。

聚氨酯树脂:材料安全数据表(MSDS)

聚氨酯树脂:材料安全数据表(MSDS)概述聚氨酯树脂是一种常用的材料,广泛应用于建筑、汽车制造和家具等领域。

本文档提供了聚氨酯树脂的材料安全数据表(MSDS),以便用户了解其安全性和使用注意事项。

物理性质- 外观:聚氨酯树脂呈液体/固体状态,具有不同的颜色和质地。

- 溶解性:可溶于有机溶剂,如醇类和酮类。

- 熔点:根据具体类型和配方的不同而有所变化。

健康和安全信息- 吸入风险:长时间吸入聚氨酯树脂的蒸气可能对呼吸系统产生刺激作用。

建议在使用时保持通风良好。

- 皮肤接触:聚氨酯树脂可能对皮肤产生刺激作用。

接触后,应立即用肥皂和水清洗受影响的区域。

- 眼睛接触:避免聚氨酯树脂进入眼睛。

如不慎接触,应立即用清水冲洗眼睛并就医。

- 摄入风险:不应摄入聚氨酯树脂。

灭火措施- 聚氨酯树脂在火灾中可能产生有毒气体。

如发生火灾,应使用干粉灭火器或二氧化碳灭火器进行灭火。

- 避免使用水进行灭火,以免加剧火势。

泄漏处置- 对于小规模的泄漏,可用吸收剂将聚氨酯树脂收集起来,并置于合适的中。

- 对于大规模的泄漏,应采取专业的泄漏处置措施,并遵循当地法规。

个人防护措施- 在使用聚氨酯树脂时,应佩戴适当的防护手套、眼镜和防护服。

- 避免吸入蒸气,确保工作区域通风良好。

废弃物处理- 废弃的聚氨酯树脂应按照当地法规进行处理。

不得将废弃物倾倒在环境中。

请注意,以上信息仅为参考,具体的聚氨酯树脂产品可能有所不同。

在使用聚氨酯树脂之前,请务必阅读并遵守该产品的具体材料安全数据表(MSDS)以及供应商提供的安全指南。

上纬901树脂资料-chempulse 901MSDS 中文

地址:上海市松江工业区松胜路 118 号

电话:86-21-57746183 传真:86-21-57746177

二、 成分辨识资料

中英文名称:乙烯基酯树脂(CHEMPULSE 901) 同义名称:

危害物质成份 树脂聚合体(polymer)

苯乙稀(styrene) *NA:一般状况下无害

含量(%) 52~65 35~48

IARC 将之列为 Group 2B:可能人体致癌。

版本:第 01 版 页码:4/5

修订日期: 2005.11.21

品质至上‧诚信为纬‧创新致胜‧勤俭兴利

版本:第 01 版 页码:2/5

修订日期: 2005.11.21

品质至上‧诚信为纬‧创新致胜‧勤俭兴利

Quality Products with In Time Service and Innovation

上 纬(上 海)精 细 化 工 有 限 公 司

SWANCOR(SHANGHAI) FINE CHEMICAL CO., LTD.

物质安全资料表

自燃温度:490℃ 蒸气压:4.3 mmHg@20oC 比重:1.04±0.02 (水=1)

爆炸界限:1.1%~7.0% 蒸气密度:3.6 溶解度:几乎不溶(300mg/l)(水)

十、 安定性及反应性

安定性:不安定 特殊状况下可能之危害反应:1.金属盐、过氧化物、氧化剂或强酸皆可能引发其聚合。2.氧、氧化剂:增加火灾爆炸的危害,形成爆炸性过

六、 泄漏处理方法

个人应注意事项:1.在外泄区尚未完全清理干净前,限制进入泄漏区。2.由受过训练之人员负责清理工作。3.配戴合适的个人防护装备。 环境注意事项:1.维持泄漏区之通风良好。2.扑灭或除去所有发火源。3.报告政府安全卫生与环保相关单位。 清理方法:1.勿碰触泄漏物。2.在安全状况许可下,设法阻止或减少泄漏。3.并避免其排入下水道、水沟或封闭的空间。4.用不会和外泄物

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

MATERIAL SAFETY DATA SHEETSWANCOR IND. CO., LTD.NO. 9 INDUSTRY SOUTH 6 ROAD,NAN-KANG INDUSTRIAL PARK,NAN-TOU CITY, TAIWAN 54066 R.O.C.TEL: 886-49-2255420FAX: 886-49-2251534E-MAIL: swancor@MSDS NO.: NT27-222-EISSUE DATE: 03/10/2006PREPARED BY: MARK HUANGSECTION I - IDENTITY INFORMATIONPRODUCT NAME: SWANCOR CP-95PRODUCT TYPE: Vinyl Ester ResinUN/NA NUMBER: UN1866HAZARD RATING: Health 2 / Flammability 3 / Reactivity 2SECTION II - COMPOSITION ON INGREDIENTSIngredient Percent CAS Index No.Vinyl Ester Resin 50~55 036425-16-8Styrene 45~50 000100-42-5SECTION III - HAZARDS IDENTIFICATIONEMERGENCY OVERVIEW:Straw-yellow viscous liquid. Pungent styrene odor. Flammable. Reactive. Causes eye irritation. Highly toxic to fish and/or other aquatic organismsPOTENTIAL HEALTH EFFECTS:Refer to Section XI for toxicological data, Effects of Overexposure: for styreneEYE CONTACT:May cause moderate eye irritation. May cause slight corneal injury. Vapors may irritate eyes. Vapors may cause lacrimation (tears). SKIN CONTACT:Prolonged or repeated exposure may cause skin irritation. Material may stick to skin causing irritation upon removal. A single prolonged exposure is not likely to result in the material being absorbed through skin in harmful amounts.INGESTION:Single dose oral toxicity is considered to be low. If aspirated (liquid enters the lung), may be rapidly absorbed through the lungs and result in injury to other body systems.INHALATION:Excessive vapor concentrations are attainable and could be hazardous on single exposure. Signs and symptoms of excessive exposure may be anesthetic or narcotic effects and result in injury to other body systems.SYSTEMIC (OTHER TARGET ORGAN) EFFECTS:Contains styrene, which, in animals, has been reported to cause effects on the following organs; central nervous system, kidney, liver and reparatory tract. Lung effects have been observed in mice following repeated exposure to styrene. Styrene is reported to have caused hearing loss in laboratory animals upon exposure to high concentrations (>600 ppm); however, the relevance of this to humans is unknown. Some studies in humans allege that repeated exposure to styrene may result in minor subclinical decreases in the ability to discriminate between colors.CANCER INFORMATION:This mixture contains a component (s) which are listed as potential carcinogens for hazard communication purposes under OSHA Standard 29 CFR 1910.1200. Component(s) listed by IARC; styrene. An increased incidence of lung tumors was observed in mice from a recent inhalation study on styrene. The relevance of this finding to humans is uncertain since data from other long-term animal studies and from epidemiology studies of workers exposed to styrene do not provide a basis to conclude that styrene is carcinogenic. TERATOLOGY:In laboratory animals, styrene did not produce birth defects or any other effects on the fetus even at exposure concentrations having an adverse effect on the mother.REPRODUCTIVE EFFECTS:Contains component(s) which did not interfere with reproduction in animal studies. The component(s) is/are: styrene.SECTION IV - FIRST AIDS PROCEDURESSKIN CONTACT:Thoroughly wash exposed area with soap and water immediately. Remove contaminated clothing. Launder contaminated clothing before re-use.EYE CONTACT:Flush with large amount of water immediately and continuously for 20 minutes, lifting upper and lower lids occasionally. Get medical attention.INGESTION:Do not induce vomiting. Keep person warm, quiet and get medical attention. Aspiration of material into the lungs can cause chemical pneumonitis which can be fatal.INHALATION:If affected, remove individual to fresh air. If breathing is difficult, administer oxygen. If breathing has stopped, give artificial respiration. Keep person warm, quiet, and get medical attentionNOTE TO PHYSICIAN:Because rapid absorption may occur through lungs if aspirated and cause systemic effects, the decision of whether to induce vomitingor not should be made by an attending physician. If lavage is performed, suggest endotracheal and/or exophageal control. Danger from lung aspiration must be weighed against toxicity when considering emptying the stomach. No Specific antidote. Supportive care. Treatment based on judgment of the physician in response to reactions of the patient.SECTION V - FIRE FIGHTING MEASURESFlash Point 88o F (31o C) for StyreneFlammable Limits Lower : 1.1% (For Styrene)Upper : 6.1% (For Styrene)HAZARDOUS DECOMPOSITION PRODUCT:May form toxic materials: carbon dioxide and carbon monoxide, various hydrocarbons.OTHER FLAMMABILITY INFORMATION:Dense smoke is produced when product burns. Violent steam generation or eruption may occur upon application of direct water stream. Vapors are heavier than air and may travel a long distance and accumulate in low areas. Ignition and/or flash back may occur. Flammable mixtures may exist within the vapor space of containers at room temperature. Flammable concentrations of vapor can accumulate at temperatures above 74o F. Spills of these organic liquids on hot fibrous insulations may lead to lowering of the auto-ignition temperatures possibly resulting in spontaneous combustion.EXTINUISHING MEDIA:Water fog or fine spray, carbon dioxide, dry chemical, foam. Water fog, applied gently may be used as a blanket for fire extinguishments. General purpose synthetic foams (including AFFF type) or protein foams are preferred if available. Alcohol resistant foams (ATC type) may function. Do not use direct water stream, straight or direct water. Stream may not be effective to extinguish fire.MEDIA TO BE AVOIDED:Do not use direct water stream.FIRE FIGHTING INSTRUCTIONS:Keep people away. Isolate fire area and deny unnecessary entry. Burning liquids may be moved by flushing with water to protect personnel and minimize property damage. Water fog, applied gently may be used as a blanket for fire extinguishments. Eliminate ignition sources. Stay upwind. Keep out of low areas where gases (fumes) can accumulate. Do not use direct water stream. May spread fire. Water may not be effective in extinguishing fire. Move container from fire area if this is possible without hazard.PROTECTIVE EQUIPMENT FOR FIRE FIGHTERS:Wear positive-pressure self-contained breathing apparatus (SCBA) and protective fire fighting clothing (includes fire fighting helmet, coat, pants, boots, and gloves). If protective equipment is not available or not used, fight fire from a protected location or safe distance.SECTION VI - ACCIDENTAL RELEASE MEASURESPROTECT PEOPLE:Do not breathe vapors. Vapor explosion hazard, keep out of sewers. Eliminate all sources of ignition in vicinity of spill or released vapor to avoid fire or explosion. For large spills, warn public of downwind explosion hazard. Check area with explosion meter before reentering area. Ground and bond all containers and handling equipment.PROTECT THE ENVIRONMENT:For large spills, evacuate upwind of spills and contain with dike.CLEANUP:Pump with explosion-proof equipment. If available use foam to smother and suppress. Remove residual with hot soapy water. Residual can be removed with solvent. Solvents are not recommended for cleanup unless the recommended exposure guide-lines and safehandling practices for the specific solvent are followed. Consult appropriate solvent MSDS for handling information and exposure guidelines.STEP TO BE TAKEN IN CASE MATERIAL IS RELEASED OR SPILLED:Small Spill : Absorb liquid on paper, vermiculite, floor absorbent, or other absorbent material and transfer to hood.Large Spill : Eliminate all ignition sources (flares, flames, including pilot lights electrical sparks). Persons not wearing protective equipment should be exclude from area of spill until clean-up has been completed. Stop spill at source, dike area ofspill to prevent spreading, pump liquid to salvage tank. Remaining liquid may be taken up on sand, clay, earth, floorabsorbent or other absorbent material and shoveled into containers.WASTE DISPOSAL METHOD:Small Spill : Allow volatile portion to evaporate in hood. Allow sufficient time for vapor to completely clear hood duct work.Dispose of remaining material in accordance with applicable regulations.Large Spill : Destroy by liquid incineration in accordance with applicable regulation.Contaminated absorbent should be disposed of in accordance with government regulations.SECTION VII - HANDLING AND STORAGEHANDLING INFORMATION:Avoid inhalation and contact with eyes, skin, and clothing. Wash hands thoroughly after handling and before eating or drinking. Remove and wash contaminated clothing before reuse. Use with adequate ventilation. Ground and bond containers when transferring the material to prevent static electricity sparks which could ignite the vapor. Use spark-proof tools and explosion-proof equipment. Consult your supplier or promoters and catalysts for additional instructions on proper mixing and usage.Empty containers may retain product residue (liquid and/or vapor). Do not pressurize, cut, weld, braze, solder, drill, grind, or expose these containers to heat, flame, sparks, static electricity, or other sources of ignition as the container may explode and may cause injury or death. Empty drums should be completely drained and properly bunged. Empty drums should be promptly returned to a drum re-conditioner or properly disposed.STORAGE INFORMATION:Keep away from ignition sources; flames, pilot lights, electrical sparks, and sparking tools. NO SMOKING. Do not store in direct sunlight. Store separate from oxidizing materials, peroxides, and metal salts. Keep container closed when not in use. To ensure maximum stability and maintain optimum resin properties, resins should be stored in closed containers at temperatures below 75 degrees F (25 degrees C). Copper or copper containing alloys should be avoided as containers.SECTION VIII - EXPOSURE CONTROLS/PERSONAL PROTECTIONRESPIRATORY PROTECTION:If TLV of the product or any component is exceeded, a NIOSH/MSHA jointly approved air supplied respirator is advised in absence of proper environmental control. OSHA regulation also permit other NIOSH/MSHA respirators under specified conditions. (See your safety equipment supplier). Engineering or administrative controls should be implemented to reduce exposure. When respiratory protection is required, use an approved air purifying or positive-pressure supplied-air respirator depending on the potential airborne concentration.VENTILATION:Provide sufficient mechanical (general and/or local exhaust) ventilation to maintain exposure below TLV(s).PROTECTIVE GLOVES:Wear resistant gloves such as: neoprene, nitrite rubber.EYE PROTECTION:Chemical splash goggles in compliance with OSHA regulations are advised; however, OSHA regulations also permit other type safety glasses (consult your safety equipment supplier).OTHER PROTECTIVE EQUIPMENT:Normal work clothing covering arms and legs.EXPOSURE GUIDELINE(S):Styrene, monomer: ACGIH TLV is 20ppm TWA, 40 ppm STEL, skin. ACGIH classifies as A4. OSHA PEL is 50 ppm TWA, 100 ppm STEL. The styrene PEL and STEL are in accordance with the OSHA-industry agreement dated March, 1996.SECTION IX - PHYSICAL AND CHEMICAL PROPERTIESProperties MeasurementInitial Boiling Point For Styrene 293.4o F/@ 760.0 mmHgVapor Pressure For Styrene 4.3 mmHg / 25o CVapor Density Air=1 3.6Specific Gravity 1.04 +/- 0.02 / 25o CPercent Non-volatile 55 +/- 2Evaporation Rate Slow than EtherSECTION X - STABILITY AND REACTIVITYHAZARDOUS POLYMERIZATION:May occur.STABILITY:Stable at room temperature.INCOMPATIBILITY:Strong alkalis, strong mineral acids and oxidizing agents.CONDITIONS TO AVOID:Exposure to excessive heat or direct sunshine or open flame; storage in open containers; storage above 38o C (100o F). Contamination with oxidizing agents.HAZARDOUS DECOMPOSITION PRODUCTS:Carbon Monoxide, Carbon Dioxide, Low Molecular Weight Hydrocarbon, Organic Acids.SECTION XI - TOXICOLOGICAL INFORMATION(See Section III for Potential Health Effects)SKIN CONTACT:The LD50 for skin absorption in rabbits is >2,000 mg/kg.INGESTION:The oral LD50 for rats is >4,000 mg/kgThe oral LC50 for rats is >5,000 ppm/4HMUTAGENICITY (EFFECTS ON GENETIC MATERIAL):For styrene: In vitro mutagenicity studies were inconclusive. Animal mutagenicity studies were inconclusive.SECTION XII - ECOLOGICAL INFORMATIONENVIRONMENTAL FATEMOVEMENT & PARTITIONING:Based on information for styrene. Bio-concentration potential is low (BCF less than 100 or Log Pow less than 3). Potential for mobility in soil is low (Koc between 500 and 2,000).DEGRADATION & PERSISTENCE: Based on information for styrene. Material is readily biodegradable. Passes OECD test(s) for ready biodegradability. Material is ultimately biodegradable. Reaches more than 70% mineralization in OECD test(s) for inherent biodegradability.ECOTOXICITY:Based on information for styrene. Material is highly toxic to aquatic organisms on an acute basis (LC50/EC50 between 0.1 and 1 mg/L in most sensitive species).SECTION XIII - DISPOSAL CONSIDERATIONS(See Section XV for Regulatory Information)DISPOSAL:DO NOT DUMP INTO ANY SEWERS, ON THE GROUND, OR INTO ANY BODY OF WATER. All disposal methods must be in compliance with all Federal, State/Provincial and local laws and regulations. Regulations may vary in different locations. Waste characterizations and compliance with applicable laws are the responsibility solely of the waste generator.SECTION XIV - TRANSPORT INFORMATIOND.O.T.: Bulk; ITAT: Non BulkProper Sipping Name: Resin SolutionHazard Class: 3ID: UN1866PG: IIIPlacard: FlammableEM Guidebook: 127SECTION XV - REGULATORY INFORMATION(Not meant to be all-inclusive--selected regulations represented)OSHA STATUS:This material is classified as a hazardous chemical under the criteria of the US Occupational Safety and Health Administration (OSHA) Hazard Communication Standard, 29 CFR 1910.1200.TSCA EXPORT NOTIFICATION:This material does not contain any components that are subject to the US Toxic Substances Control Act (TSCA) Section 12(b) Export Notification requirements.TSCA INVENTORY STATUS:All components of this material are listed on the US the Toxic Substances Control Act (TSCA) inventory.EUROPEAN/INTERNATIONAL REGULATIONS:European Labeling in Accordance with EC DirectivesHazard Symbols: XNRisk Phrases:FlammableR10:R 36/38: Irritating to eyes and skin.R 20: Harmful by inhalation.Safety Phrases:S 23: Do not inhale gas/fumes/vapor/spray.CALIFORNIA PROPOSITION 65:WARNING: This product contains a chemical(s) known to the State of California to cause cancer. Styrene Oxide.CAA:Styrene (100-42-5) is listed as a Hazardous Air Pollutant (HAP) under Section 112 of the Clean Air Act.CWA:Styrene (100-42-5) is listed under Section 311 as a Hazardous Substance.CANADA WHMIS:This material is classified by the Canadian Workplace Hazardous Material Information System as: B2 (flammable liquid) D2A (materials causing other toxic effects, very toxic material) D2B (materials causing other toxic effects, toxic material)CANADA CEPA:All components of this material are listed on the Canadian Domestic Substances List (DSL).ADDITIONAL CANADIAN REGULATORY INFORMATION:Under the Transportation of Dangerous Goods regulations, the following Chemicals have been assigned Regulated Limits (RL): Styrene Monomer (CAS # 100-42-5): RL=50 KG.The following chemicals are listed on the WHMIS Ingredient Disclosure List:Styrene Monomer (CAS # 100-42-5)The following chemical (s) are listed on the Canadian National Pollutant Release Inventory (NPRI):Styrene Monomer (CAS # 100-42-5)This material safety data sheet and the information it contains is offered to customers in good faith as accurate. We have reviewed any information contained in this data sheet which we received from sources outside our company. We believe that information to be correct but cannot guarantee its accuracy or completeness. Health and safety precautions in this data sheet may not be adequate for all individuals and/or situations. It is the user's obligation to evaluate and use this product safety and to comply with all applicable laws and regulations. No statement made in this data sheet shall be construed as a permission or recommendation for the use of any product in a manner that might infringe existing patents. No warranty is made, either express or implied.。