进外企业必读-企业常用缩写(中英文对照)

企业常用缩写-中英文对照

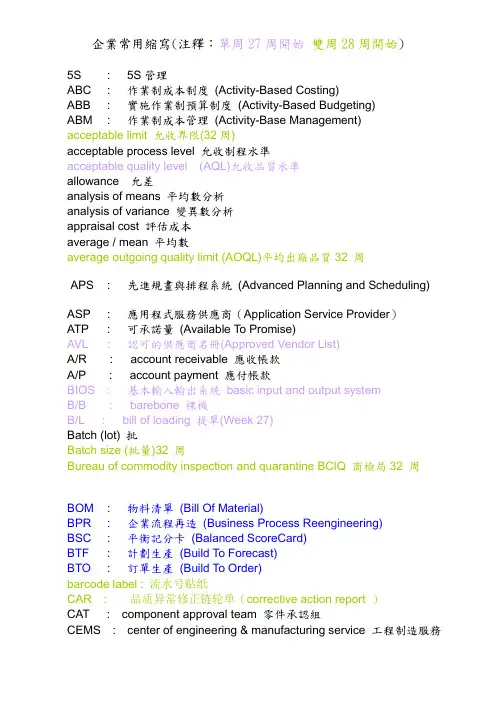

企業常用縮寫(注釋:單周27周開始雙周28周開始)5S : 5S管理ABC : 作業制成本制度(Activity-Based Costing)ABB : 實施作業制預算制度(Activity-Based Budgeting)ABM : 作業制成本管理(Activity-Base Management)acceptable limit 允收界限(32周)acceptable process level 允收制程水準acceptable quality level (AQL)允收品質水準allowance 允差analysis of means 平均數分析analysis of variance 變異數分析appraisal cost 評估成本average / mean 平均數average outgoing quality limit (AOQL)平均出廠品質32 周APS : 先進規畫與排程系統(Advanced Planning and Scheduling)ASP : 應用程式服務供應商(Application Service Provider)ATP : 可承諾量(Available To Promise)AVL : 認可的供應商名冊(Approved Vendor List)A/R : account receivable 應收帳款A/P : account payment 應付帳款BIOS : 基本輸入輸出系統basic input and output systemB/B : barebone 裸機B/L : bill of loading 提單(Week 27)Batch (lot) 批Batch size (批量)32 周Bureau of commodity inspection and quarantine BCIQ 商檢局32 周BOM : 物料清單(Bill Of Material)BPR : 企業流程再造(Business Process Reengineering)BSC : 平衡記分卡(Balanced ScoreCard)BTF : 計劃生產(Build To Forecast)BTO : 訂單生產(Build To Order)barcode label : 流水号贴纸CAR : 品质异常修正链轮单(corrective action report )CAT : component approval team 零件承認組CEMS : center of engineering & manufacturing service 工程制造服務中心CLCA : close loop correction action 循環改善措施CPM : 要徑法(Critical Path Method)CPM : 每一百萬個使用者會有幾次抱怨(Complaint per Million) CPSR : customer product standard request 客戶產品規格標準要求CQA : 客验(customer quality assurance)CRM : 客戶關係管理(Customer Relationship Management)CRP : 產能需求規劃(Capacity Requirements Planning)CSD customer service department 客户服务部门CTO : 客製化生產(Configuration To Order)DBR : 限制驅導式排程法(Drum-Buffer-Rope)DCC : 文件資料管制中心(document control center )Defect rate : 不良率DMT : 成熟度驗證(Design Maturing Testing)DVT : 設計驗證(Design Verification Testing)DRP : 運銷資源計劃(Distribution Resource Planning)DSS : 決策支援系統(Decision Support System)deduct AP: 扣除應付帳款EC : 設計變更/工程變更(Engineer Change)ECN : 工程變更通知(engineering change notice )EC : 電子商務(Electronic Commerce)ECRN : 原件規格更改通知(Engineer Change Request Notice)EDI : 電子資料交換(Electronic Data Interchange)EIS : 主管決策系統(Executive Information System)已經用EMC : 電磁相容(Electric Magnetic Compatibility)EMI : 電磁幹擾(electro-magnetic interference)EOQ : 基本經濟訂購量(Economic Order Quantity)EOL : end of line 產品壽命終止ERP: 企業資源規劃(Enterprise Resource Planning)ETD : expected time of departure 預定開航時間ETA : expected time of arrival 預定到達時間(week 29)FAE: 終端應用工程部門(Final Application Engineer)FCST : 預估(Forecast)FG : finished goods 制成品(week 30)FMS : 彈性製造系統(Flexible Manufacture System)FQC : 成品品質管制(Finish or Final Quality Control) 已經用FQA : 成品品質管制(final quality assurance)IE : 工業工程(Industrial engineering )IEC : 國際電工委員會(international electro-technical commission)IPQC : 製程品質管制(In-Process Quality Control)IQC : 進料品質管制(Incoming Quality Control)ISO : 國際標準組織(International Organization for Standardization) ISAR : 首批樣品認可(Initial Sample Approval Request)JIT : 即時管理(Just In Time)KPI : key part index 關鍵指標KM :知識管理(Knowledge Management)L4L : 逐批訂購法(Lot-for-Lot)LTC : 最小總成本法(Least Total Cost)LTQ : leadership through quality 品質領導機制LUC : 最小單位成本(Least Unit Cost)MES : 製造執行系統(Manufacturing Execution System)MC :Material control 物控MO : 製令(Manufacture Order)M/P : 量產mass productionMPS : 主生產排程(Master Production Schedule)MRO : 請修(購)單(Maintenance Repair Operation)MRP : 物料需求規劃(Material Requirement Planning)MRPII : 製造資源計劃(Manufacturing Resource Planning) MVB: mass verification boardNFCF : 更改預估量的通知Notice for Changing ForecastNCMR : 不合格物料審核(non-conformity material report )OEM : 委託代工(Original Equipment Manufacture)ORT : on-going reliability test 生產過程中的可靠度測試ODM : 委託設計與製造(Original Design & Manufacture)OLAP : 線上分析處理(On-Line Analytical Processing)OLTP : 線上交易處理(On-Line Transaction Processing)OM : order management 訂單管理OPT : 最佳生產技術(Optimized Production T echnology) Purchasing data 採購資料(32周)OOB : out of box 開箱檢查OQC : 出貨品質管制(Out-going Quality Control)OPT : optimized production technology 最佳生產技術OQA : 出貨品質保証(Out-going quality assurance)(33周) QE : 品質工程(Quality engineering)QVL : 合格廠商名冊(qualified vendor list )P/C : power cable電源線PC : Production control 生管PE : 生計(34)PDCA : PDCA管理循環(Plan-Do-Check-Action)PCB : 印刷電路板printed circuit boardPCA : printed circuit assembly 印刷電路插件39周PDM : 產品資料管理系統(Product Data Management)PERT : 計畫評核術(Program Evaluation and Review Technique) PIC : person in charge 負責人P L : project leader 左客戶大訂單的全面管理P/L : packing list 裝箱單PO : 訂單(Purchase Order)POH : 預估在手量(Product on Hand)P/n : part number 料號PMC : production and material control 生管及物控管理PM : production management 生產管理PMP : project management plan專案管理計劃書P/R : 試產pilot run(34 周)PVT : project verification testPR : 採購申請Purchase RequestQA : 品質保證(Quality Assurance) 35周QC : 品質管制(Quality Control)QCC : 品管圈(Quality Control Circle)QE : 品質工程(Quality Engineering)QIT : 品質提高小組(quality improvement team)QIP : quality improvement plan 品質改善計劃RCCP : 粗略產能規劃(Rough Cut Capacity Planning)RMA : 退貨驗收Returned Material ApprovalRCN : 設計變更通知(RD change notice)36周ROP : 再訂購點(Re-Order Point)已經用R&D : 研究與開發research and development(36周)S/A : shipping advice 出貨通知38 周S/I : shipping invoice 發貨單SCM : 供應鏈管理(Supply Chain Management)SCAR : 供應商品質異常修正聯絡單(supplier corrective action report)SFC : 現場控制(Shop Floor Control)SIP : 作業指導書standard inspection processSIS : 策略資訊系統(Strategic Information System)SO : 訂單(Sales Order)S/O : shipping order 裝貨通知單37周SOP : 作業指導書standard operation processSOR : 特殊訂單需求(Special Order Request)SPC : 統計製程管制(Statistic Process Control)SQC : 統計品管(statistic quality control )TOC : 限制理論(Theory of Constraints)TOP : 測試作業指導書(test operation process)TPM : 全面生產管理Total Production ManagementTQA : 全面品質保証(total quality assurance )TQC : 全面品質管制(Total Quality Control)TQM : 全面品質管理(Total Quality Management)UCL : up control line 上管制線VAT : value add tax 增值稅WIP : 在製品(Work In Process)Make/send/give/cable quotation for報價:In duplicate一式兩份/ duplicate copy副本triplicate一式三份Expire到期EC: electronic commence電子商務SO/PO: sales order/ purchase order訂單Parcel一批貨batch一次生產量一批5S管理5S是由日本企業研究出來的一種環境塑造方案,其目的在藉由整理(SEIRI)、整頓(SEITON)、清掃(SEISO)、清潔(SEIKETSU)及身美(SHITSUKE)五種行為來創造清潔、明朗、活潑化之環境,以提高效率、品質及顧客滿意度。

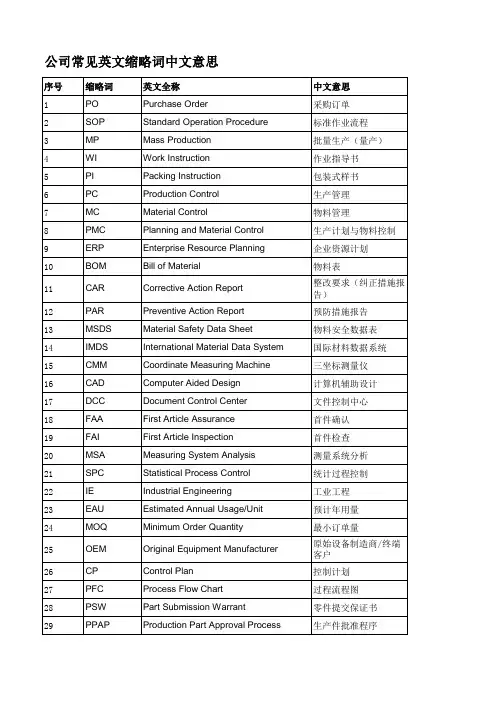

公司常见英文缩略词中文意思

序号 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 缩略词 PO SOP MP WI PI PC MC PMC ERP BOM CAR PAR MSDS IMDS CMM CAD DCC FAA FAI MSA SPC IE EAU MOQ OEM CP PFC PSW PPAP 英文全称 Purchase Order Standard Operation Procedure Mass Production Work Instruction Packing Instruction Production Control Material Control Planning and Material Control Enterprise Resource Planning Bill of Material Corrective Action Report Preventive Action Report Material Safety Data Sheet International Material Data System Coordinate Measuring Machine Computer Aided Design Document Control Center First Article Assurance First Article Inspection Measuring System Analysis Statistical Process Control Industrial Engineering Estimated Annual Usage/Unit Minimum Order Quantity Original Equipment Manufacturer Control Plan Process Flow Chart Part Submission Warrant Production Part Approval Process 中文意思 采购订单 标准作业流程 批量生产(量产) 作业指导书 包装式样书 生产管理 物料管理 生产计划与物料控制 企业资源计划 物料表 整改要求(纠正措施报 告) 预防措施报告 物料安全数据表 国际材料数据系统 三坐标测量仪 计算机辅助设计 文件控制中心 首件确认 首件检查 测量系统分析 统计过程控制 工业工程 预计年用量 最小订单量 原始设备制造商/终端 客户 控制计划 过程流程图 零件提交保证书 生产件批准程序

企业常用英文及缩写

Burn 51,

企业常用英文及缩写(五) 54, SOP standard operation procedure作业指导书/标准书 55, ESD electrical static discharge 静电释放 56, MP mass production 量产 57, EMC Electro Magnetic Compatibility, 电磁兼容性 58, EMI Electro Magnetic Interference, 电磁干扰 59, SIR Surface Impedance Resistance 表面阻抗测试 60, Engineer工程 61, PE Products Engineer; 产品工程Process engineer制程工程 63, TE Test Engineer测试工程 64, ME Manufacturing Engineer;制造工程 65, Mechanical Engineer机械工程 66, IE Industrial Engineer工业工程 67, DCC Document Control Center文管中心 68, BOM Bill Of Material材料清单

企业常用英文及缩写(十)

122, ERP : 企业资源规划 (Enterprise Resource Planning) 123, FAE : 应用工程师(Field Application Engineer) 124, FCST : 预估(Forecast) 125, FMS : 弹性制造系统 (Flexible Manufacture System) 126, SCM : 供应链管理 (Supply Chain Management) 127, BPR企业流程再造 (Business Process Reengineering) 128, GB : Green Belt 绿带 129, NPCR : New Product Configuration Release 130, PUH : Pick Up Head 131, OPU : Optical Product unit/ Optical Pick Up

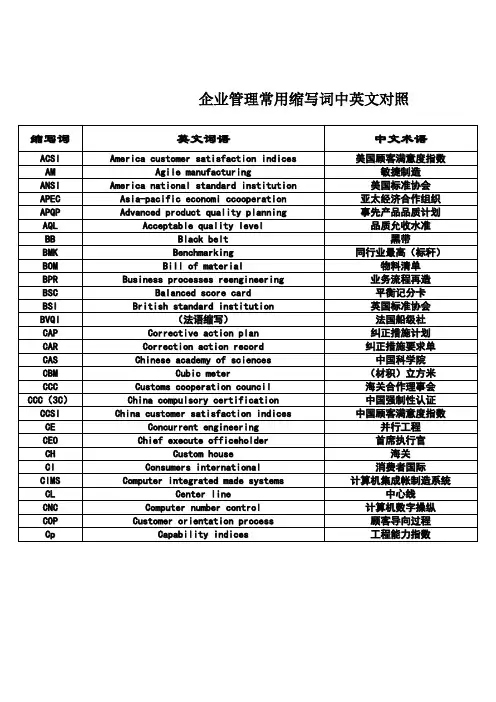

企业管理常用缩写词中英文对照

缩写词

英文词语

中文术语

ACSI

Americacustomer satisfaction indices

美国顾客满意度指数

AM

Agile manufacturing

敏捷制造

ANSI

Americanational standard institution

美国标准协会

APEC

Asia-pacific economi ccooperation

亚太经济合作组织

APQP

Advanced product quality planning

事先产品品质计划

AQL

Acceptable quality level

品质允收水准

BB

Black belt

黑带

BMK

Benchmarking

同行业最高(标秆)

BOM

Bill of material

物料清单

BPR

日本质量体系认可机构

JIS

Japanindustry standard

日本工业标准

JIT

Just in time

务必时间

KAB

Koreanaccreditation board

韩国认可委员会

KFQ

Koreanfoundation for quality

韩国质量财团

L/C

Letter of credit

办公自动化

OEM

Origin epuipment munfactory

原设计制造商

OFF-JT

Off job for training

原设备制造商

OJT

On job for training

企业常用英文缩写

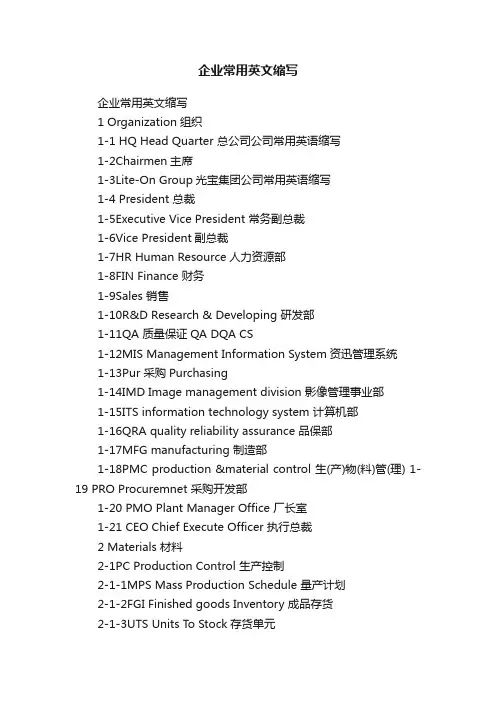

企业常用英文缩写企业常用英文缩写1 Organization组织1-1 HQ Head Quarter 总公司公司常用英语缩写1-2Chairmen主席1-3Lite-On Group光宝集团公司常用英语缩写1-4 President 总裁1-5Executive Vice President 常务副总裁1-6Vice President副总裁1-7HR Human Resource人力资源部1-8FIN Finance 财务1-9Sales 销售1-10R&D Research & Developing 研发部1-11QA 质量保证QA DQA CS1-12MIS Management Information System资迅管理系统1-13Pur 采购Purchasing1-14IMD Image management division 影像管理事业部1-15ITS information technology system 计算机部1-16QRA quality reliability assurance 品保部1-17MFG manufacturing 制造部1-18PMC production &material control 生(产)物(料)管(理) 1-19 PRO Procuremnet 采购开发部1-20 PMO Plant Manager Office 厂长室1-21 CEO Chief Execute Officer 执行总裁2 Materials 材料2-1PC Production Control 生产控制2-1-1MPS Mass Production Schedule 量产计划2-1-2FGI Finished goods Inventory 成品存货2-1-3UTS Units To Stock存货单元2-1-4WIP Working In Process Inventory在制品2-1-5C/T Cycle Time 循环时间,瓶颈2-1-6WD Working Days 工作天2-1-7MTD Month To Days 月初到今日(例如总表整理)2-1-8YTD Year To Days 年初到今日2-1-9 SO Sales Order 销售单2-1-10MO Manufacture Order 制造单2-1-11 BTO Build T o Order 订单生产2-1-12 P/N part number 料号2-1-13 FCST Forecast 预测计划2-1-14 W/O Working Order 工单2-1-15 P/O Purchasing Order 采购单2-1-16 VDS Vendor Delivery Schedule 厂商送货进度表2-1-17 D/C Delivery Order 交货单2-2 MC Material Control材料控制2-2-1 MRP Material Requisition plan 材料申请计划2-2-2 INV Inventory 存货清单; Invoice 本人2-2-3 Inv Turn Over Days=INV$/NSB X WD 库存周转天数2-2-4 PSI Production Shipping Inventory 预备待出货2-2-5 JIT Just In Time 实时2-2-6 Safety Inventory 安全存量2-2-7 CKD Completed Kits Delivery全件组装出货2-2-8 SKD Semi Kits Delivery半件(小件)组装出货2-3 W/H Warehouse 仓库2-3-1 Rec Receiving Center 接收中心2-3-2 Raw MTL 原物料2-3-3 F/G finish goods 成品2-3-4 GRN Goods Receive Note 货物接收单2-4 Import/Export进出口2-4-1 SI Shipping Instruction发货指令2-4-2 PL Packing List包装清单2-4-3 Inv Shipping Invoice出货本人2-4-4 ETD Estimate Departure 预估离开时间2-4-5 ETA Estimate Arrive 预估到达时间2-4-6 BL Bill of Landing 提货单(海运)2-4-7 AWB Air Way Bill 提货单(空运)2-4-8 MAWA Master Air Way Bill主提货单2-4-9 HAWB House Air Way Bill副提货单2-4-10 TEU Twenty foot Equipment Unit(Contain)二十英尺货柜2-4-11 FEU Forty foot Equipment Unit(Contain)四十英尺货柜2-4-12 CY Container Yard货柜场2-4-13 THC Terminal Handing Charge 码头费2-4-14 ORC Original Receiving Charge码头费2-5 PUR Purchasing采购2-5-1 FOB Free on Board货运至甲板2-5-2 CIF Cost Insurance Freight2-5-3 OA Open Account 开户2-5-4 TT Telegram Transfer电汇2-5-5 COD Cash On Delivery 现金支付2-5-6 CRP Cost Reduction Program降低成本方案2-5-7 PR Purchasing Requisition采购申请2-5-8 PO Purchasing Order采购单2-5-9 LT Lead Time 交期2-5-10 LLT Long Lead Time 长时间交期2-5-11 Payment term 付款条件2-5-12 Debit note 扣款2-5-13 CRP Cost Reduction Program 降价计划2-5-14 Quotation 报价3 MFG Manufacturing Production制造控制3-1 DL Director Labor直接人工3-2 IDL Indirect Labor间接人工3-3 DLH Direct Labor Hours直接工时3-4 Productivity=UTS/DLH3-5 PPH Pieces Per Hour每小时件数3-6 Efficiency=Actual/Target(%)3-7 DT Machine Down Time停机时间3-8 AI Auto Insertion自动插入3-9 MI Manual Insertion人工插入3-10 SMD Su**ce Mount Device表面粘着零件SMT Su**ce mount technology 表面粘着技术3-11 B/I Burn In (for how many hours at how many degree)烧机3-12 Equipment Utilization3-13 WI work instruction 工作说明3-14 SOP standard operation procedure作业指导书3-15 R/I run in 运转机器3-16 ESD electrical static discharge 静电释放3-17 MP mass production 量产3-18 EMC Electro Magnetic Compatibility, 电磁兼容性3-19 EMI Electro Magnetic Interference, 电磁干扰3-19 SIR Su**ce Impedance Resistance 表面阻抗测试4 Engineer工程4-1 PE Products Engineer; 产品工程Process engineer制程工程4-2 TE Test Engineer测试工程4-3 ME Manufacturing Engineer;制造工程Mechanical Engineer机械工程4-4 IE Industrial Engineer工业工程4-5 DCC Document Control Center文管中心4-6 BOM Bill Of Material材料清单4-7 ECN Engineering Change Notice工程变动公告4-8 TECN Temporary Engineering Change Notice工程临时变动公告4-9 ATY Assembly Test Yield Total Yield直通率4-10 TPM Total Productivity Maintenance全面生产维护4-11 PM product manager ;project manager 产品经理;项目经理4-12 ECR engineering change request 工程变更申请4-13 ECO engineering change order 工程变更指令4-14 EN engineering notice 工程通告4-15 WPS work procedure sheet 作业说明书4-16 ICT in circuit test 电路测试4-17 P/R pilot run ;C/R control run; T/R trial run试做4-18 EVT engineer verification test工程验证测试4-19 DVT design verification test 设计验证测试4-20 MVT multi-verification test 多项验证测试4-21 ORT on going reliability test 出货信赖性测试4-22 S/W software 软件4-23 H/W hardware 硬件4-24 EAR Engineering Aanlysis Request 工程分析需求4-25 ECE Engineering Change Estimation 工程变更评估4-26 ECC Engineering Change Cancellation 工程变更取消4-27 IEM Internal Engineering Meno 内部工程备忘录4-28 PAS Part Approval Sheet 零件承认书4-29 DAB Daily Action Boaed 日常工作广告牌4-30 TMR Tooling Modify Report 修模协议书4-31 CRT Control Run Testing 试产测试4-32 DCD Design Change Description 设计变更通知4-33 ESR Engineering Study Report 工程研究报告4-34 EI Engineering Information 工程讯息4-35 PMP Process Management Plan 制程管制计划4-36 MBO Management By Object 目标管理4-37 KPI Key Performance Indicator 重点绩效指标4-38 PIP Part Inspection Plan 零件检验标准4-39 CTF Criticle T o Function 功能重点尺寸4-40 CTA Criticle T o Assembly 组装重点尺寸4-41 R&D Research and Development 研究与开发4-42 GR&R Gauge Repeatability and Reproducibility 治具重复性及重现性验证4-43 Cpk 制程能力指标4-44 FAI First Article Inspection 首件检查表5 QA Quality Assurance质量保证QRA Quality & Reliability Assurance质量与可靠性保证5-1 MQA Manufacturing Quality Assurance制造质量保证5-2 DQA Design Quality Assurance设计质量保证5-3 QC Quality Control质量控制5-4 IQC Incoming Quality Control进货质量控制5-5 VQC Vendor Quality Control售货质量控制5-6 IPQC In Process Quality Control制程质量控制5-7 OQA Out going Quality Control 出货质量控制5-8 QE Quality Engineer质量工程5-9 AQL Acceptable Quality Level可接受的质量水平5-10 **M Defective Pieces Per Million units百万件中有损件数5-11 PPM Pieces Per million百万分之一5-12 CS Custom Service顾客服务5-13 MRB Material Review Board 材料审核委员会5-14 DMR Defective Material Report材料缺陷报告5-15 RMA Return Material Administration材料回收处理5-16 Life Test 寿命测试5-17 T/C Temperature Cycle温度循环5-18 H/T High Temperature Test高温测试5-19 L/T Low Temperature Test低温测试5-20 ISO International Standard Organization国际标准化组识5-21 SPC Statistic process control统计过程控制5-22 "5S" 整理.整顿.清理.清扫.素养5-23 VMI visual mechanical inspection 外观机构检验5-24 MIL-STD military standard 美军标准5-25 SPEC specification 规格5-26 A VL approval vendor list 合格厂商名单5-27 QVL qualified vendor list 合格厂商名单5-28 FQC final quality control 最终质量控制5-29 OBA open box audit 成品检验5-30 EAR engineering analysis request 工程分析需求5-31 FAI first aide inspection 首件检验5-32 VQM vendor quality management 厂商质量管理5-33 CAR corrective action request 改进对策要求5-34 4M man; machine; material; method 人、机、材、方法5-35 M man;machine;material;method;measurement 人、机、材、方法测量5-36 MTBF mean time between failure平均寿命5-37 TTL total 总量5-38 MRT Markeing Relability Testing 信赖性测试5-39 8 D 8 Disciplines5-40 Q7 Method (Stratification: Histogram; Pareto; Scatter; (Cause & effect diagram) Fish Bone; (Check sheets); (Graphs & Control Chart)5-41 6 Sigma5-42 3 W What, Who, When5-43 2 Q Quality and Quantity5-44 1 G 1 Goal 一个目标6 FIN Finance &Accounting财务与帐目6-1 P&L Profit &Lose6-2 PV Performance Variance现象差异6-3 3 Element of Cost=M,L,O6-4 M Material材料6-5 L Labor人力6-6 O Overhead管理费用6-7 Fix OH Fix Overhead固定管理费用6-8 Var OH Variable Overhead不定管理费用6-9 COGS Cost Of Goods Sold工厂制造成本6-10 AR Account Receivable应收6-11 AP Account Payable应支7 MIS Management Information System资迅管理系统7-1 IS Information System资迅系统7-2 IT Information Technology 系统技术7-3 MRP Material Requisition Plan材料需求计划7-4 I2 Information Integration System资迅整合系统7-5 SAP System Application Programming系统申请项目7-6 ERP Enterprise Resource Programming企业资源项目8 HR Human Resource人力资源8-1 PR Public relation公共关系8-2 T/O Turn Over Rate =Monthly T/O Total People*12 8-3 GR General Affair总务。

外资企业的英文缩写

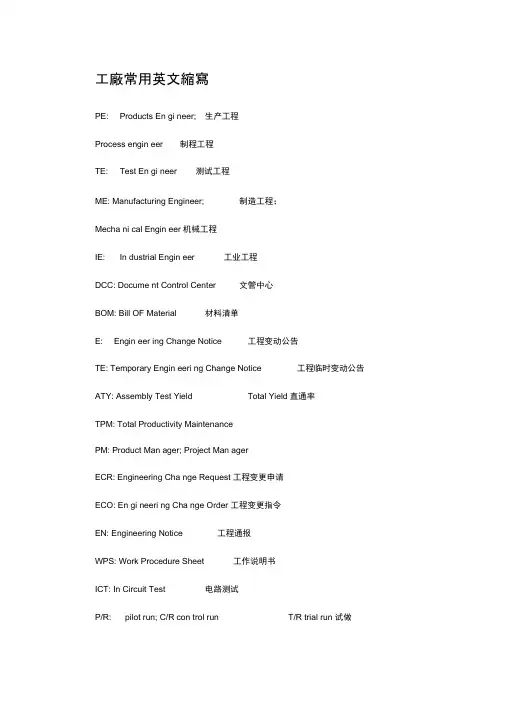

工廠常用英文縮寫PE: Products En gi neer; 生产工程Process engin eer 制程工程TE: Test En gi neer 测试工程ME: Manufacturing Engineer; 制造工程;Mecha ni cal Engin eer 机械工程IE: In dustrial Engin eer 工业工程DCC: Docume nt Control Center 文管中心BOM: Bill OF Material 材料清单E: Engin eer ing Change Notice 工程变动公告TE: Temporary Engin eeri ng Change Notice 工程临时变动公告ATY: Assembly Test Yield Total Yield 直通率TPM: Total Productivity MaintenancePM: Product Man ager; Project Man agerECR: Engineering Cha nge Request 工程变更申请ECO: En gi neeri ng Cha nge Order 工程变更指令EN: Engineering Notice 工程通报WPS: Work Procedure Sheet 工作说明书ICT: In Circuit Test 电路测试P/R: pilot run; C/R con trol run T/R trial run 试做EVT: En gi neer Verification Test 工程验证测试DVT: Desig n Verificatio n Test 设计验证测试MVT: Mass Verification Test 多项验证测试ORT: On Goi ng Reliability Test 出货信赖性测试S/W:software 软件H/W: hardware 硬件D: Design Cha nge Notice 设计变更通知PVT: Productio n Verificati on Test 生产验证测试MTF: Modulation Tran sfer Fun ction 调整转换功能CAT: Carriage Alig nment Tool 载器调整具ID: Industrial Design 工业设计(外观设计)PCBA: Prin ted Circuit Board Assembly 电路板组装F/T: Fun ction Test 功能测试CCD: Charge Coupled Device 扫描仪之读器ERS: External Refere nee Spec 外部规格PMP: Production Ma nageme nt Pla n 工程管理计划SOP: Stan dar Operati on Procedure 作业标准书QRA: Quality reliability Assura nee 品保部ESD: Electrical Static Discharge 静电释放或静电防护OAY: Output Accept Yeild 直通率VMI: Visual mecha ni cal in specti on 外观检杳PK: Packi ng 包装FQA: Fi nal quality assura nee 质量追踪EE: Electro nic engineer电子工程师工程验证测试在制品质量与CE: ponen t e ngineer 材料工程师EVT: Engineer verification testWIP: Worki ng in process inven toryQA Quality Assura nee 质量保证QRA :Quality & Reliability Assura neeMQA :Manu facturi ng Quality Assura nee 制造质量保证DQA: Desig n Quality Assura nee 设计质量保证QC: Quality Con trol 质量控制IQC: I ning Quality Con trol 进货质量控制VQC: Ven dor Quality Co ntrol 售货质量控制IPQC: In Process Quality Con trol 制程质量控制OQA: Out goi ng Quality Co ntrol 出货质量控制QE: Quality En gi neer 质量工程AQL: Acceptable Quality Level 可承受的质量水平DPPM: Defective Pieces Per Millio n un its 百万件中有损件数PPM: Pieces Per Millio n 百万分之一CS: Custom Service 顾客服务MRB: Marerial Review Board 材料审核委员会DMR Defective Material Report 材料缺陷报告RMA: Retur n Marerial Admi nistratio n 材料回收处理wordLife Test 寿命测试T/C: Temperature Cycle 温度循环H/T: High Temperature Test 高温测试L/T: Low Temperature Test 低温测试ISO: I nternatio nal Sta ndard Orga ni zatio n 国际标准化组织SPC: Statistic process con trol 统计过程控制5S: Seiri Seito Seiso Seiketsu ShitsukeVMI: Visual Mecha nical In spectio n 外观机构检验MIL-STD: Military Sta ndard 美军标准SPEC: Specificati on 规格AVL: Approval Vendor List 合格丿商QVL: Qualified Ven dor List 合格丿商FQC: Fi nal Quality Co ntrol 最终质量控制OBA: Ope n Box Audit 成品检验EAR: Engin eeri ng An alysis Request 工程分析需求FAI: First Article In specti on 首件检验VQM: Ven dor Quality Man ageme nt 厂商质量管理CAR: Corrective Actio n Request 改良对策要求4M: Man; Machine; Material; Method 人,机,材,方法5M: Man; Machine; Material; Method; Measurement 人,机,材,方法,测量MTBF: Mea n Time Betwee n Failure 平均寿命TTL: TotalFIN Finan ce&Accou nting 财务与账目P&L: Profit & LosePV : Performa nee Varia nee 现象差异3 Element of Cost = M,L,OM: Material 材料L: Labor 人力O: Overhead管理费用Fix OH Fix Overhead 固定管理费用Var OH Variable Overhead 不定管理费用COGS Cost Of Goods Sold 工厂制造本钱AR: Account Receivable 应收AP: Accou nt Payable 应支MIS Ma nageme nt In formation System 资迅管理系统IS: I nformation System 资迅系统IT: In formati on Tech no logy 系统技术MRP: Material Requisition Pla n 材料需求计划I2:I nformation In tegratio n System 资迅整合系统SAP: System Applicatio n Programmi ng 系统申请项目ERP: En terprise Resource Programmi ng 企业资源项目HR Human Resource 人力资源PR: Public relation 公共关系T/O: Turn Over Rate=Mo nthly T/O Total People*12 GR: General Affair 总务Orga ni zati on 组织HQ Head Quarter 总公司Chairme n 主席Preside nt 总裁Executive Vice Preside nt 常务副总裁Vice Preside nt 副总裁HR Human Resource人力资源部FIN Finance 财务Sales销售R&D: Research & Developi ng 研发部QA:质量保证QA DQA CSMIS: Ma nageme nt In formation System 资迅管理系统PUR 采购Purchas ingIMD: Image Man ageme nt Divisio n 影像管理事业部ITS: In formati on Tech no logy System 计算机咅B QRA: Quality Reliability Assura nee 品保部MFG: Manu facturi ng 制造部PMC: Production & Material Control 生(产)物(料)管(理)Materials 材料PC: Production Co ntrol 生产控制MPS: Mass Production Schedule 量产计划FGI: Fini shed goods Inven tory 成品存货UTS: Units To Stock 存货单元WIP: Worki ng In Process In ve ntory 在制品C/T: Cycle Time 循环时间,瓶颈WD: Working Days 工作天MTD: Mo nth To Days月初到今日(例如总表整理)YTD: Year To Days 年初到今日SO: Sales Order 销售清单MO: Manu facture Order 制造清单BTO: Build To Order 订单生产P/N: Part Number 料号MC: Material Co ntrol 材料控制MRP: Material Requisition Pla n 材料需求计划INV: I nve ntory 存货清单Inv Turn Over Days=INVS/NSB X WD 库存周转天数PSI: Production Shippi ng In ve ntory 预备待出货JIT: Just In Time 实时Safety In ve ntory 安全存量CKD: pleted Kits Delivery 全件组装出货SKD: Semi Kits Delivery 半件(小件)组装出货W/H: Warehouse 仓库Rec: Receivi ng Center 接收中心Raw MTL原物料F/G: finish goods 成品Import/Export 进出口SI: Shippi ng In structio n 发货指令PL: Packi ng List 包装清单Inv: Shippi ng In voice 出货发票ETA: Estimate Arrive 预估到达时间ETD: Estimate departure 预估离开时间BL: Bill of Lan di ng 提货单(海运)AWB: Air Way Bill 提货单(空运)MAWB: Master Air Way Bill 主提货单HAWB: House Air Way Bill 副提货单TEU: Twenty foot Equipme nt Un it(Co ntai n)二十英尺货柜FEU: Forty foot Equipme nt Uni t(Co nta in)四十英尺货柜CY: Container Yard 货柜场THC: Termi nal Handing Charge 码头费ORC: Origi nal Receivi ng Charge 码头费PUR: Purchasi ng 采购FOB: Free on Board 货运至甲板(离岸价)CIF: Cost In sura nee Freight 本钱+ 运费+ 保险OA: Ope n Accou nt 开户TT: Telegram Transfer 电汇COD: Cash On DeliveryCRP: Cost Reduction Program 降低本钱方案PR: Purchas ing Requisitio n 采购申请PO: Purchasi ng Order 采购单MFG Manufacturing Production 制造生产DL: Director Labor 直接人工IDL: I ndirect Labor 间接人工DLH: Direct Labor Hours 直接工时Productivity=UTS/DLHPPH: Pieces Per Hour 每小时件数Efficie ncy=Actual/Target(%)DT: Machi ne Dow n Time 停机时间烧机 AI: Auto In sertion自动插入 MI: Manual In sertion 人工插入SMD: Surface Mou nt Device 外表粘着零件SMT: Surface mou nt tech nology 外表粘着技术 B/l: Bur n In (for how many hours at how many degree) WI: Work In structio n 工作说明SOP: Sta ndard Operatio n Procedure 作业指导书 R/I: Run In 运转机器ESD: Electrical Static Discharge 静电释放 MP: Mass Production 量产。

企业常用英文缩写解释

三.部份材料英文名稱

11.警告標簽 Warning label 12.主機外殼 Housing 13.主機板 Main board 14.設備 Device&Equipment 15.治具Fixture&Instrument 16.夾具 Jig 17.機器 Machine 18.工具 Tool 19.紙箱 Carton 20.紙箱標簽 Carton label

20.縮水 Sink marks 21.拖痕 Dragging 22.黏模part sticking 23.龜裂裂痕 Cracking 24. 結合線 融合線 Weld lines 25.噴射痕Jetting 26.黑.光澤不良 Cloudy

17

三.部份材料英文名稱

21.ABS 丙烯晴-丁二烯-苯己烯塑膠 Acrylonitrible-butadiene styrene plastic 22.AS 苯己烯-丙烯晴共聚物 (SAN) Acrylonitrile styrene plastics 23.HIPS 耐衝擊聚苯己烯 24.PC 聚碳酸酯 Polycarbonate 25.PS 聚苯己烯 Polystyrene 26.PU 聚胺基甲酸己酯 Polyurethane 27.PPO 聚氧化苯 Polypropylene oxide 28.PMMA 聚甲基丙烯酸甲酯 Poly (methyl a-chloroacrylate)

10

一.企業常用英文縮寫

52. SOP作業程序標準Standard Operation Procedure 53. SPC統計制程品管 Statistical Process Control 54. SQC供應商品質檢驗 Subcontractor Quality Control 55. TE測試工程Test Engineering 56. TQC全面品質管制Total Quality Control 55. WIP 正存放在生產線上的制品 Working in process

企业常用缩写中英文对照

企业常用缩写5S : 5S管理ABC : 作业制成本制度 (Activity-Based Costing)ABB : 实施作业制预算制度 (Activity-Based Budgeting)ABM : 作业制成本管理 (Activity-Base Management)APS : 先进规画与排程系统 (Advanced Planning and Scheduling)ASP : 应用程序服务供货商(Application Service Provider)ATP : 可承诺量 (Available To Promise)AVL : 认可的供货商清单(Approved Vendor List)BOM : 物料清单 (Bill Of Material)BPR : 企业流程再造 (Business Process Reengineering)BSC : 平衡记分卡 (Balanced ScoreCard)BTF : 计划生产 (Build To Forecast)BTO : 订单生产 (Build To Order)CPM : 要径法 (Critical Path Method)CPM : 每一百万个使用者会有几次抱怨(Complaint per Million)CRM : 客户关系管理 (Customer Relationship Management)CRP : 产能需求规划 (Capacity Requirements Planning)CTO : 客制化生产 (Configuration To Order)DBR : 限制驱导式排程法 (Drum-Buffer-Rope)DMT : 成熟度验证(Design Maturing Testing)DVT : 设计验证(Design Verification Testing)DRP : 运销资源计划 (Distribution Resource Planning)DSS : 决策支持系统 (Decision Support System)EC : 设计变更/工程变更 (Engineer Change)EC : 电子商务 (Electronic Commerce)ECRN : 原件规格更改通知(Engineer Change Request Notice)EDI : 电子资料交换 (Electronic Data Interchange)EIS : 主管决策系统 (Executive Information System)EMC : 电磁兼容(Electric Magnetic Capability)EOQ : 基本经济订购量 (Economic Order Quantity) ERP : 企业资源规划 (Enterprise Resource Planning)FAE : 应用工程师(Field Application Engineer)FCST : 预估(Forecast)FMS : 弹性制造系统 (Flexible Manufacture System)FQC : 成品品质管制 (Finish or Final Quality Control)IPQC : 制程品质管制 (In-Process Quality Control)IQC : 进料品质管制 (Incoming Quality Control)ISO : 国际标准组织 (International Organization for Standardization)ISAR : 首批样品认可(Initial Sample Approval Request) JIT : 实时管理 (Just In Time)KM :知识管理 (Knowledge Management)L4L : 逐批订购法 (Lot-for-Lot)LTC : 最小总成本法 (Least Total Cost)LUC : 最小单位成本 (Least Unit Cost)MES : 制造执行系统 (Manufacturing Execution System) MO : 制令(Manufacture Order)MPS : 主生产排程 (Master Production Schedule) MRO : 请修(购)单(Maintenance Repair Operation)MRP : 物料需求规划 (Material Requirement Planning)MRPII : 制造资源计划 (Manufacturing Resource Planning) NFCF : 更改预估量的通知Notice for Changing ForecastOEM : 委托代工 (Original Equipment Manufacture)ODM : 委托设计与制造 (Original Design & Manufacture)OLAP : 线上分析处理 (On-Line Analytical Processing)OLTP : 线上交易处理 (On-Line Transaction Processing)OPT : 最佳生产技术 (Optimized Production Technology)OQC : 出货品质管制 (Out-going Quality Control)PDCA : PDCA管理循环 (Plan-Do-Check-Action)PDM : 产品数据管理系统 (Product Data Management)PERT : 计画评核术 (Program Evaluation and Review Technique) PO : 订单(Purchase Order)POH : 预估在手量 (Product on Hand)PR : 采购申请Purchase RequestQA : 品质保证(Quality Assurance)QC : 品质管制(Quality Control)QCC : 品管圈 (Quality Control Circle)QE : 品质工程(Quality Engineering)RCCP : 粗略产能规划 (Rough Cut Capacity Planning) RMA : 退货验收Returned Material ApprovalROP : 再订购点 (Re-Order Point)SCM : 供应链管理 (Supply Chain Management) SFC : 现场控制 (Shop Floor Control)SIS : 策略信息系统 (Strategic Information System) SO : 订单(Sales Order)SOR : 特殊订单需求(Special Order Request)SPC : 统计制程管制 (Statistic Process Control)TOC : 限制理论 (Theory of Constraints)TPM : 全面生产管理Total Production ManagementTQC : 全面品质管制 (Total Quality Control)TQM : 全面品质管理 (Total Quality Management)WIP : 在制品 (Work In Process)5S管理5S是由日本企业研究出来的一种环境塑造方案,其目的在藉由整理(SEIRI)、整顿(SEITON)、清扫(SEISO)、清洁(SEIKETSU)及身美(SHITSUKE)五种行为来创造清洁、明朗、活泼化之环境,以提高效率、品质及顾客满意度。

企业管理常用缩写术语中英文对照(大全五篇)

企业管理常用缩写术语中英文对照(大全五篇)第一篇:企业管理常用缩写术语中英文对照企业管理常用缩写术语中英文对照A ABC: 作业制成本制度(Activity-Based Costing)ABB: 实施作业制预算制度(Activity-Based Budgeting)ABM: 作业制成本管理(Activity-Base Management)APS: 先进规画与排程系统(Advanced Planning and Scheduling)ASP: 应用程序服务供货商(Application Service Provider)ATP: 可承诺量(Available To Promise)AVL: 认可的供货商清单(Approved Vendor List)BBOM: 物料清单(Bill Of Material)BPR: 企业流程再造(Business Process Reengineering)BSC:平衡记分卡(Balanced ScoreCard) BTF: 计划生产(Build To Forecast)BTO: 订单生产(Build To Order)CCPM: 要径法(Critical Path Method)CPM: 每一百万个使用者会有几次抱怨(Complaint per Million)CRM: 客户关系管理(Customer Relationship Management)CRP: 产能需求规划(Capacity Requirements Planning)CTO: 客制化生产(Configuration To Order)DDBR: 限制驱导式排程法(Drum-Buffer-Rope)DMT:成熟度验证(Design Maturing T esting)DVT: 设计验证(Design Verification Testing)DRP: 运销资源计划(Distribution Resource Planning)DSS: 决策支持系统(Decision Support System)EEC:设计变更/工程变更(Engineer Change)EC:电子商务(Electronic Commerce)ECRN: 原件规格更改通知(Engineer Change RequestNotice)EDI: 电子数据交换(Electronic Data Interchange) EIS: 主管决策系统(Executive Information System)EMC: 电磁相容(Electric Magnetic Capability)EOQ: 基本经济订购量(Economic Order Quantity)ERP: 企业资源规划(Enterprise Resource Planning)F FAE: 应用工程师(Field Application Engineer)FCST: 预估(Forecast)FMS: 弹性制造系统(Flexible Manufacture System)FQC: 成品质量管理(Finish or Final Quality Control)IIPQC: 制程质量管理(In-Process Quality Control)IQC:进料质量管理(Incoming Quality Control)ISO:国际标准组织(International Organization for Standardization)ISAR: 首批样品认可(Initial Sample Approval Request)JJIT:实时管理(Just In Time)KKM:知识管理(Knowledge Management)LL4L:逐批订购法(Lot-for-Lot)LTC:最小总成本法(Least Total Cost)LUC:最小单位成本(Least Unit Cost)MMES:制造执行系统(Manufacturing Execution System)MO:制令(Manufacture Order)MPS:主生产排程(Master Production Schedule)MRO:请修(购)单(Maintenance Repair Operation)MRP:物料需求规划(Material Requirement Planning)MRPII: 制造资源计划(Manufacturing Resource Planning)NNFCF: 更改预估量的通知(Notice for Changing Forecast)OOEM:委托代工(Original Equipment Manufacture)ODM:委托设计与制造(Original Design & Manufacture)OLAP: 在线分析处理(On-Line Analytical Processing)OLTP: 在线交易处理(On-Line Transaction Processing)OPT:最佳生产技术(Optimized Production Technology)OQC:出货质量管理(Out-goingQuality Control)PPDCA: PDCA管理循环(Plan-Do-Check-Action)PDM:产品数据管理系统(Product Data Management)PERT: 计划评核术(Program Evaluation and Review Technique)PO:订单(Purchase Order) POH:预估在手量(Product on Hand)PR:采购申请(Purchase Request)QQA:质量保证(Quality Assurance)QC:质量管理(Quality Control)QCC:品管圈(Quality Control Circle)QE:质量工程(Quality Engineering)RRCCP: 粗略产能规划(Rough Cut Capacity Planning)RMA:退货验收Returned Material ApprovalROP:再订购点(Re-Order Point)SSCM:供应链管理(Supply Chain Management)SFC:现场控制(Shop Floor Control)SIS:策略信息系统(Strategic Information System)SO:订单(Sales Order)SOR:特殊订单需求(Special Order Request)SPC:统计制程管制(Statistic Process Control)TTOC:限制理论(Theory of Constraints)TPM:全面生产管理Total Production ManagementTQC:全面质量控制(Total Quality Control)TQM:全面质量管理(Total Quality Management)WWIP:在制品(Work In Process)第二篇:Roger-企业管理常用缩写术语中英文对照(定稿)Roger-咨询顾问工具包:管理理论企业管理常用缩写术语中英文对照•• : 5S管理6σ:六西格玛管理A•••••••: 作业制成本制度(Activity-Based Costing)ABB: 实施作业制预算制度(Activity-Based Budgeting): 作业制成本管理(Activity-Base Management)APS: 先进规画与排程系统(Advanced Planning and Scheduling):()ATP: 可承诺量(Available To Promise)AVL: 认可的供货商清单(Approved Vendor List)[编辑]B••••• : : : BTF: BTO: 物料清单(Bill Of Material)企业流程再造(Business Process Reengineering)平衡记分卡(Balanced ScoreCard)计划生产(Build To Forecast)订单生产(Build To Order)[编辑]C••••• : CPM: : CRP: CTO: 要径法(Critical Path Method)每一百万个使用者会有几次抱怨(Complaint per Million)客户关系管理(Customer Relationship Management)产能需求规划(Capacity Requirements Planning)客制化生产(Configuration To Order) [编辑]D•DBR: 限制驱导式排程法(Drum-Buffer-Rope)DMT:成熟度验证(Design Maturing T esting)•DVT: 设计验证(Design Verification Testing)•: 运销资源计划(Distribution Resource Planning)•DSS:(Decision Support System)•[编辑]E•••••••• EC:设计变更/工程变更(Engineer Change):()ECRN: 原件规格更改通知(Engineer Change Request Notice)EDI: 电子数据交换(Electronic Data Interchange)EIS: 主管决策系统(Executive Information System)EMC: 电磁相容(Electric Magnetic Capability): 基本经济订购量(Economic Order Quantity): 企业资源规划(Enterprise Resource Planning)[编辑]FFAE: 应用工程师(Field Application Engineer)• FCST: 预估(Forecast)• FMS: 弹性制造系统(Flexible Manufacture System)• FQC: 成品质量管理(Finish or Final Quality Control)•[编辑]IIPQC: 制程质量管理(In-Process Quality Control)• IQC:进料质量管理(Incoming Quality Control)•:国际标准组织(International Organization forStandardization)• ISAR: 首批样品认可(Initial Sample Approval Request)•[编辑]J• JIT:实时管理(Just In Time)[编辑]K•:()[编辑]LL4L:逐批订购法(Lot-for-Lot)• LTC:最小总成本法(Least Total Cost)• LUC:最小单位成本(Least Unit Cost)•[编辑]M••••••:()MO:制令(Manufacture Order):()MRO:请修(购)单(Maintenance Repair Operation):(Material Requirement Planning)MRPII:(Manufacturing Resource Planning)[编辑]N• NFCF: 更改预估量的通知(Notice for Changing Forecast)[编辑]O:(Original Equipment Manufacture)•:(Original Design & Manufacture)• OLAP:(On-Line Analytical Processing)• OLTP: 在线交易处理(On-Line Transaction Processing)•OPT:最佳生产技术(Optimized Production Technology)• OQC:出货质量管理(Out-going Quality Control)•[编辑]P•••••• PDCA: PDCA管理循环(Plan-Do-Check-Action):产品数据管理系统(Product Data Management): 计划评核术(Program Evaluation and Review Technique)PO:订单(Purchase Order)POH:预估在手量(Product on Hand)PR:采购申请(Purchase Request)[编辑]Q:质量保证(Quality Assurance)• QC:质量管理(Quality Control)• :(Quality Control Circle)• QE:质量工程(Quality Engineering)• [编辑]RRCCP: 粗略产能规划(Rough Cut Capacity Planning)• RMA:退货验收Returned Material Approval• :再订购点(Re-Order Point)•[编辑]S••••••:供应链管理(Supply Chain Management)SFC:(Shop Floor Control):策略信息系统(Strategic Information System)SO:订单(Sales Order)SOR:特殊订单需求(Special Order Request):统计制程管制(Statistic Process Control)• SQE:供应商质量工程师(Supplier Quality Engineer)[编辑]T:• TPM:• : •限制理论()全面生产管理Total Production Management全面质量控制(Total Quality Control)• :[编辑]W• :全面质量管理(Total Quality Management)在制品(Work In Process)第三篇:常用术语中英文对照十、常用术语中英文对照人生规划Life planning自我介绍Self-introduction 目标Target孔子Confucius《论语》The Analects of Confucius 修身养性cultivate one's moral character 儒家思想Confucianism诗歌Poem赏析Appreciation阅读理解Reading comprehension 意境Artistic conception意象Imagery情感Emotion朗诵Recite策划Consultant情景模拟Scenario simulation 记忆Memory贝多芬Beethoven命运交响曲Symphony of Destiny 古典音乐Classical music 莫扎特Mozart费加罗的婚礼The Marriage of Figaro 萧伯纳George Bernard Shaw 戏剧Drama理想主义Idealism人道精神Humanity反抗性Resistance辩论Debate演讲Speech主题Theme财富Wealth品格Character《红楼梦》Dream in Red Mansions 叶芝Yeats当你老了 when you are old 情景Scene道家Taoism无为而治Taoist Actionless Governance 消极避世Indifference 散文Prose小说Novel文学性Literary语言Language修辞Rhetoric敬畏生命Reverence for Life 抉择Choice普通话Mandarin个人简历Resume招聘求职Recruitment 求职信Cover letter自荐书Written submissions 岗位Post市场营销Marketing物流Logistics食品检测Food testing 高分子Macromolecule就业形势Employment situation 毕业论文Thesis摘要Abstract关键词Keyword答辩defense第四篇:会计相关术语中英文对照会计术语表►AICPA: American Institute of Certified Public Accountants 美国注册会计师协会►APB: Accounting Principles Board会计原则委员会►ASB: Auditing Standards Board(AICPA)(美国注册会计师协会)审计准则委员会►ARSC: Accounting and Review Services Committee(AICPA)(美国注册会计师协会)会计与复核服务委员会►ASC: Accounting Standards Codification会计准则汇编►ASU: Accounting Standards Update会计准则更新►CA: Chartered Accountant特许会计师►CAQ: Center for Audit Quality审计质量中心►CICA: Canadian Institute of Chartered Accountants加拿大特许会计师协会►CSEC: Consulting Services Executive Committee(AICPA)(美国注册会计师协会)咨询服务执行委员会►EITF: Emerging Issues Task Force(FASB)(美国财务会计准则委员会)紧急事务委员会►FAF: Financial Accounting Foundation财务会计基金会►FASB: Financial Accounting Standards Board美国财务会计准则委员会►FCA: Fellow of the Institute of Chartered Accountants特许会计师公众成员►FinREC: Financial Reporting Executive Committee财务报告执行委员会►FSP: FASB Staff Position(FASB)(美国财务会计准则委员会)工作人员立场公告►GAAP(US): Generally Accepted Accounting Principles(美国)一般公认会计原则►GAAS: Generally Accepted Auditing Standards一般公认审计准则►IAASB: International Auditing and Assurance Standards Board(IFAC)国际审计与可信性保证准则理事会(国际会计师联合会) ►IAESB: International Accounting Education Standards Board(IFAC)(国际会计师联合会)国际会计教育准则理事会►IASB: International Accounting Standards Board国际会计准则委员会►IAS: International Accounting Standards国际会计准则►IESBA: International Ethics Standards Board for Accountants(IFAC)(国际会计师联合会)国际会计师职业道德准则理事会►IFAC: International Federation of Accountants国际会计师联合会►IFRIC: International Financial Reporting Interpretations Committee(IASB)(国际会计准则委员会)国际财务报告解释委员会►IOSCO: International Organization of Securities Commissions国际公共部门会计准则►IPSAS: International Public Sector Accounting Standards国际公共部门会计准则►IPSASB: International Public Sector Accounting Standards Board(IFAC)(国际会计师联合会)国际公共部门会计准则理事会►PCAOB: Public Company Accounting Oversight Board公众公司会计监督委员会►PPEC: Public Practice Executive Committee(CAQ)(审计质量中心)公共实践执行委员会►SAB: Staff Accounting Bulletins(SEC)(美国证监会)首会办会计公告►SEC(US): Securities and Exchange Commission美国证监会►SEC Regulations Committee(SEC)(美国证监会)监管委员会►SFAS: Statement of Financial Accounting Standards财务会计准则公告►SIC: Standing Interpretations Committee(IASB)(国际会计准则委员会)常设解释委员会►SOP: Statements of Position(AICPA)(美国注册会计师协会)立场公告►SME: Small and Medium Sized Entities(IASB)(国际会计准则委员会)中小企业►TPA: Technical Practice Aids(AICPA)(美国注册会计师协会)技术实务支持体系/技术实务指引►VRG(US): Valuation Resource Group(FASB)(美国财务会计准则委员会)估值资源小组第五篇:篮球术语中英文对照A: Agent 经纪人。

企业常用术语缩写全称及释义

企业常用术语缩写全称及释义MTO――按订单生产(Make to Order)ETO――按订单设计MTS――库存生产(Make-to-Stock)PAPC――生产和流程控制(Production and Process Control)DHR――器械历史文件(Device History Record)NCR――不合格(Non-conformance)CAPA――纠正和预防措施(Corrective And Preventive Activity)NPV――净现值(Net Present Value)IRR――内部收益率(Internal Rate of Return)PP――回收期(Payback Period)SPC――统计过程控制(Statistic process control)B OM――物料清单(Bill of Material)OBOM――订单BOMMBOM――生产制造物料清单EBOM――工程设计BOMPBOM――工艺规划BOMSBOM――销售BOMPLM――产品生命周期管理(Product Lifecycle Management)PDM――产品数据管理(Product Data Management)CAD――计算机辅助设计(Computer Added Design)CAPP――计算机辅助工艺设计(Computer Aided Process Planning)KPI――关键绩效指标(Key Performance Index)SOA――面向服务架构(Service Oriented Architecture)WAN――广域网(Wide Area Network)LAN――局域网(Local Area Network)MAN――城域网(Metropolitan Area Network)TCP――传输控制协议(Transfer Control Protocol)IP――网际协议(Internet Protocol)ASN――预先发货通知(Advanced Shipment Notice)MHE――物料处理设备(Material Handling Equipment)EMEA―― 欧洲、中东和非洲CRM――客户关系管理(Customer Relationship Management)SCM――供应链管理(Supply Chain Management)BI――商业智能(Business Intelligence)LDAP――轻量级目录访问协议(Lightweight Directory Access Protocol)MRP――生产资源规划(Manufacturing Resource Planning)SFA――自动销售(Sales Force Automation)SCV――供应链可见性(Supply Chain Visibility)MDM――制造数据管理(Manafacturing Data Management)APS――高级计划系统(Advanced Planning System)CMMS――电脑化维修管理系统(computerized maintenance management system)HMI――人机界面(Human Machine Interface)OEM――原始设备制造商(Original Equipment Manafacturer)MES――制造执行系统(Manufacturing Execution System)CPG――消费包装产品(Customer Packaged Goods)Time to Market――即时上市/及时切入生产Time to Volume――即时量产/及时大量生产Time to Money――即时变现/及时大量交货AIT――自动验证技术(Automated IDentification Technologies)TAV――全部资产可视化(Total Assets Visualization)SCADA――数据采集和监视控制(Supervisory Control and Data Acquisition)OPC――用于过程控制的对象链接和嵌入(OLE for Process Control)ASRS――自动存贮与检索系统(Automatic Storage and Retrieval System )BTO――订单生产(Build-to-Order)CTO――(Configuration-to-Order)VMI――供货商免费存放(Vendor Managed Inventory)MCT――制造周期时间(Manufacturing Cycle Time)ABC――作业制成本制度(Activity-Based Costing)ABB――实施作业制预算制度(Activity-Based Budgeting)ABM――作业制成本管理(Activity-Base Management)APS――先进规画与排程系统(Advanced Planning and Scheduling)ASP――应用程序服务供货商(Application Service Provider)ATP――可承诺量(Available To Promise)AVL――认可的供货商清单(Approved Vendor List)BPR――企业流程再造(Business Process Reengineering)BSC――平衡记分卡(Balanced ScoreCard)BTF――计划生产(Build To Forecast)CPM――要径法(Critical Path Method)CPM――每一百万个使用者会有几次抱怨(Complaint per Million)CRM――客户关系管理(Customer Relationship Management)CRP――产能需求规划(Capacity Requirements Planning)CTO――客制化生产(Configuration To Order)DBR――限制驱导式排程法(Drum-Buffer-Rope)DMT――成熟度验证(Design Maturing Testing)DVT――设计验证(Design Verification Testing)DRP――运销资源计划(Distribution Resource Planning)DSS――决策支持系统(Decision Support System)EC――设计变更/工程变更(Engineer Change)EC――电子商务(Electronic Commerce)ECRN――原件规格更改通知(Engineer Change Request Notice)EDI――电子数据交换(Electronic Data Interchange)EIS――主管决策系统(Executive Information System)EMC――电磁相容(Electric Magnetic Capability)EOQ ――基本经济订购量(Economic Order Quantity)ERP――企业资源规划(Enterprise Resource Planning)FAE――应用工程师(Field Application Engineer)FCST――预估(Forecast)FMS――弹性制造系统(Flexible Manufacture System)FQC――成品质量管理(Finish or Final Quality Control)IPQC――制程质量管理(In-Process Quality Control)IQC――进料质量管理(Incoming Quality Control)ISO――国际标准组织(International Organization for Standardization) ISAR――首批样品认可(Initial Sample Approval Request)JIT――实时管理(Just In Time)KM ―― 知识管理(Knowledge Management)L4L――逐批订购法(Lot-for-Lot)LTC――最小总成本法(Least Total Cost)LUC――最小单位成本(Least Unit Cost)MES――制造执行系统(Manufacturing Execution System)MO――制令(Manufacture Order)MPS――主生产排程(Master Production Schedule)MRO――请修(购)单(Maintenance Repair Operation)MRP――物料需求规划(Material Requirement Planning)MRPII――制造资源计划(Manufacturing Resource Planning) NFCF――更改预估量的通知Notice for Changing ForecastOEM――委托代工(Original Equipment Manufacture)ODM――委托设计与制造(Original Design & Manufacture) OLAP――在线分析处理(On-Line Analytical Processing)OLTP――在线交易处理(On-Line Transaction Processing)OPT――最佳生产技术(Optimized Production Technology)OQC――出货质量管理(Out-going Quality Control)PDCA――PDCA管理循环(Plan-Do-Check-Action)PDM――产品数据管理系统(Product Data Management) PERT――计划评核术(Program Evaluation and Review Technique) PO――订单(Purchase Order)POH――预估在手量(Product on Hand)PR――采购申请Purchase RequestQA――品质保证(Quality Assurance)QC――质量管理(Quality Control)QCC――品管圈(Quality Control Circle)QE――品质工程(Quality Engineering)RCCP――粗略产能规划(Rough Cut Capacity Planning)RMA――退货验收Returned Material ApprovalROP――再订购点(Re-Order Point)SCM――供应链管理(Supply Chain Management)SFC――现场控制(Shop Floor Control)SIS――策略信息系统(Strategic Information System)SO―― 订单(Sales Order)SOR――特殊订单需求(Special Order Request)SPC――统计制程管制(Statistic Process Control)TOC――限制理论(Theory of Constraints)TPM――全面生产管理Total Production Management TQC――全面质量管理(Total Quality Control)TQM――全面品质管理(Total Quality Management)WIP――在制品(Work In Process)企业管理常用缩写术语之中英文对照表(含解释)5S:5S管理ABC:作业制成本制度(Activity-BasedCosting)ABB:实施作业制预算制度(Activity-BasedBudgeting)ABM:作业制成本管理(Activity-BaseManagement)APS:先进规画与排程系统(AdvancedPlanningandScheduling) ASP:应用程序服务供货商(ApplicationServiceProvider)ATP:可承诺量(AvailableToPromise)AVL:认可的供货商清单(ApprovedVendorList)BOM:物料清单(BillOfMaterial)BPR:企业流程再造(BusinessProcessReengineering)BSC:平衡记分卡(BalancedScoreCard)BTF:计划生产(BuildToForecast)BTO:订单生产(BuildToOrder)CPM:要径法(CriticalPathMethod)CPM:每一百万个使用者会有几次抱怨(ComplaintperMillion) CRM:客户关系管理(CustomerRelationshipManagement)CRP:产能需求规划(CapacityRequirementsPlanning)CTO:客制化生产(ConfigurationToOrder)DBR:限制驱导式排程法(Drum-Buffer-Rope)DMT:成熟度验证(DesignMaturingTesting)DVT:设计验证(DesignVerificationTesting)DRP:运销资源计划(DistributionResourcePlanning)DSS:决策支持系统(DecisionSupportSystem)EC:设计变更/工程变更(EngineerChange)EC:电子商务(ElectronicCommerce)ECRN:原件规格更改通知(EngineerChangeRequestNotice) EDI:电子数据交换(ElectronicDataInterchange)EIS:主管决策系统(ExecutiveInformationSystem)EMC:电磁相容(ElectricMagneticCapability)EOQ:基本经济订购量(EconomicOrderQuantity)ERP:企业资源规划(EnterpriseResourcePlanning)FAE:应用工程师(FieldApplicationEngineer)FCST:预估(Forecast)FMS:弹性制造系统(FlexibleManufactureSystem)FQC:成品质量管理(FinishorFinalQualityControl)IPQC:制程质量管理(In-ProcessQualityControl)IQC:进料质量管理(IncomingQualityControl)ISO:国际标准组织(InternationalOrganizationforStandardization)ISAR:首批样品认可(InitialSampleApprovalRequest)JIT:实时管理(JustInTime)KM:知识管理(KnowledgeManagement)L4L:逐批订购法(Lot-for-Lot)LTC:最小总成本法(LeastTotalCost)LUC:最小单位成本(LeastUnitCost)MES:制造执行系统(ManufacturingExecutionSystem) MO:制令(ManufactureOrder)MPS:主生产排程(MasterProductionSchedule)MRO:请修(购)单(MaintenanceRepairOperation)MRP:物料需求规划(MaterialRequirementPlanning) MRPII:制造资源计划(ManufacturingResourcePlanning) NFCF:更改预估量的通知NoticeforChangingForecast OEM:委托代工(OriginalEquipmentManufacture)ODM:委托设计与制造(OriginalDesign&Manufacture) OLAP:在线分析处理(On-LineAnalyticalProcessing) OLTP:在线交易处理(On-LineTransactionProcessing) OPT:最佳生产技术(OptimizedProductionTechnology) OQC:出货质量管理(Out-goingQualityControl)PDCA:PDCA管理循环(Plan-Do-Check-Action)PDM:产品数据管理系统(ProductDataManagement) PERT:计划评核术(ProgramEvaluationandReviewTechnique)PO:订单(PurchaseOrder)POH:预估在手量(ProductonHand)PR:采购申请PurchaseRequestQA:质量保证(QualityAssurance)QC:质量管理(QualityControl)QCC:品管圈(QualityControlCircle)QE:质量工程(QualityEngineering)RCCP:粗略产能规划(RoughCutCapacityPlanning) RMA:退货验收ReturnedMaterialApproval ROP:再订购点(Re-OrderPoint)SCM:供应链管理(SupplyChainManagement) SFC:现场控制(ShopFloorControl)SIS:策略信息系统(StrategicInformationSystem) SO:订单(SalesOrder)SOR:特殊订单需求(SpecialOrderRequest) SPC:统计制程管制(StatisticProcessControl) TOC:限制理论(TheoryofConstraints)TPM:全面生产管理TotalProductionManagement TQC:全面质量管理(TotalQualityControl)TQM:全面质量管理(TotalQualityManagement) WIP:在制品(WorkInProcess)------5S管理------5S是由日本企业研究出来的一种环境塑造方案,其目的在藉由整理(SEIRI)、整顿(SEITON)、清扫(SEISO)、清洁(SEIKETSU)及身美(SHITSUKE)五种行为来创造清洁、明朗、活泼化之环境,以提高效率、质量及顾客满意度。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

企业常用缩写5S : 5S管理ABC : 作业制成本制度(Activity-Based Costing)ABB : 实施作业制预算制度(Activity-Based Budgeting)ABM : 作业制成本管理(Activity-Base Management)APS : 先进规画与排程系统(Advanced Planning and Scheduling)ASP : 应用程序服务供货商(Application Service Provider) ATP : 可承诺量(Available To Promise)AVL : 认可的供货商清单(Approved Vendor List)BOM : 物料清单(Bill Of Material)BPR : 企业流程再造(Business Process Reengineering)BSC : 平衡记分卡(Balanced ScoreCard)BTF : 计划生产(Build To Forecast)BTO : 订单生产(Build To Order)CPM : 要径法(Critical Path Method)CPM : 每一百万个使用者会有几次抱怨(Complaint per Million)CRM : 客户关系管理(Customer Relationship Management) CRP : 产能需求规划(Capacity Requirements Planning)CTO : 客制化生产(Configuration To Order)DBR : 限制驱导式排程法(Drum-Buffer-Rope)DMT : 成熟度验证(Design Maturing Testing)DVT : 设计验证(Design Verification Testing)DRP : 运销资源计划(Distribution Resource Planning)DSS : 决策支持系统(Decision Support System)EC : 设计变更/工程变更(Engineer Change)EC : 电子商务(Electronic Commerce)ECRN : 原件规格更改通知(Engineer Change Request Notice)EDI : 电子资料交换(Electronic Data Interchange)EIS : 主管决策系统(Executive Information System)EMC : 电磁兼容(Electric Magnetic Capability)EOQ : 基本经济订购量(Economic Order Quantity)ERP: 企业资源规划(Enterprise Resource Planning)FAE: 应用工程师(Field Application Engineer)FCST : 预估(Forecast)FMS : 弹性制造系统(Flexible Manufacture System)FQC : 成品品质管制(Finish or Final Quality Control)IPQC : 制程品质管制(In-Process Quality Control)IQC : 进料品质管制(Incoming Quality Control)ISO : 国际标准组织(International Organization for Standardization)ISAR : 首批样品认可(Initial Sample Approval Request)JIT : 实时管理(Just In Time)KM :知识管理(Knowledge Management)L4L : 逐批订购法(Lot-for-Lot)LTC : 最小总成本法(Least Total Cost)LUC : 最小单位成本(Least Unit Cost)MES : 制造执行系统(Manufacturing Execution System)MO : 制令(Manufacture Order)MPS : 主生产排程(Master Production Schedule) MRO : 请修(购)单(Maintenance Repair Operation)MRP : 物料需求规划(Material Requirement Planning)MRPII : 制造资源计划(Manufacturing Resource Planning)NFCF : 更改预估量的通知Notice for Changing ForecastOEM : 委托代工(Original Equipment Manufacture)ODM : 委托设计与制造(Original Design & Manufacture)OLAP : 线上分析处理(On-Line Analytical Processing)OLTP : 线上交易处理(On-Line Transaction Processing)OPT : 最佳生产技术(Optimized Production T echnology)OQC : 出货品质管制(Out-going Quality Control)PDCA :PDCA管理循环(Plan-Do-Check-Action)PDM : 产品数据管理系统(Product Data Management)PERT : 计画评核术(Program Evaluation and ReviewTechnique)PO : 订单(Purchase Order)POH : 预估在手量(Product on Hand)PR : 采购申请Purchase RequestQA : 品质保证(Quality Assurance)QC : 品质管制(Quality Control)QCC : 品管圈(Quality Control Circle)QE : 品质工程(Quality Engineering)RCCP : 粗略产能规划(Rough Cut Capacity Planning)RMA : 退货验收Returned Material ApprovalROP : 再订购点(Re-Order Point)SCM : 供应链管理(Supply Chain Management)SFC : 现场控制(Shop Floor Control)SIS : 策略信息系统(Strategic Information System)SO : 订单(Sales Order)SOR : 特殊订单需求(Special Order Request)SPC : 统计制程管制(Statistic Process Control)TOC : 限制理论(Theory of Constraints)TPM : 全面生产管理Total Production ManagementTQC : 全面品质管制(Total Quality Control)TQM : 全面品质管理(Total Quality Management)WIP : 在制品(Work In Process)5S管理5S是由日本企业研究出来的一种环境塑造方案,其目的在藉由整理(SEIRI)、整顿(SEITON)、清扫(SEISO)、清洁(SEIKETSU)及身美(SHITSUKE)五种行为来创造清洁、明朗、活泼化之环境,以提高效率、品质及顾客满意度。

在原文中(日文),这五项皆是以"S"为其发音开头故称此种方案为「5S」。

5S活动的对象原本是针对现场的环境,它对生产现场环境全局进行综合考虑,并制订切实可行的计划与措施,从而达到规范化管理,有许多公司扩展到办公室的管理以增进办公效率,常见的手法为红牌作战,看板及衍生的目视管理。

ABC作业制成本制度(Activity-Based Costing)ABC及ABM(Activity-Base Management)作业制成本管理,以作业别作为分摊成本的基础,在企业管理上可运用在定价决策、生产及产能决策、产品管理、顾客管理及企业策略上,同时具有提供决策者实时且有效、精确信息的特性,对企业在创造竞争优势上,是具有相当大的功能,其做法常为最古老的簿记再加上计算机分类系统,由于会计资料数量庞大,在计算机尚未普及前必须采行种种简化如订定分摊比例,但简化可能会导致失真。

ASP应用程序服务供货商(Application Service Provider)对企业提供IT业务应用服务和管理服务,主要透过软件与硬件租用或租赁形式来实施,服务商的收入和利润来自客户的租金。

AVL 认可的供货商(Approved Vendor List)对提供企业产品或服务的众多供货商中,某些符合公司的策略、对产品服务的要求,而成为合格或认可的供货商。

BOM物料清单(Bill Of Material)一般亦可称为产品结构表或用料结构表,它乃用来表示一产品﹝成品或半成品﹞是由那些零组件或素材原料所结合而成之组成元素明细,其该元素构成单一产品所需之数量称之为基量,BOM是所有MRP系统的基础,如果BOM表有误,则所有物料需求都会不正确。

天瀚定义90阶为PCBA95阶为Driver或Bundle的程序97阶为Engine 或组合好的主机98阶为连包装盒的产品(不连外箱)BPR企业流程再造(Business Process Reengineering)关心客户的需求,对现有的经营过程进行思考和再设计,利用新的制造、信息技术及现代化的管理手段,打破传统的职能型组织结构(Function-Organization),建立全新的过程型组织结构(Process-Oriented Organization)。

以作业流程为中心,打破金字塔状的组织结构,使企业能适应新经济的高效率和快节奏,让企业员工参与企业管理,实现企业内部上下左右的有效沟通,具有较强的应变能力和较大的灵活性。

BPR的主要原则有三:1.以顾客为中心:全体员工建立以顾客服务中心的原则。

顾客可以是外部的,如在零售商业企业,柜台营业员直接面对的是真正的顾客;也可以是内部的,如商场内的理货员,他的顾客是卖场的柜台小组。

每个人的工作质量由他的「顾客」作出评价,而不是主管。

2. 企业的业务以「流程」为中心,而不以一个专业职能部门为中心进行。

一个流程是一系列相关职能部门配合完成的,体现于为顾客创造有益的服务。

对流程运行不利的障碍将被铲除,职能部门的意义将被减弱,多余的部门及重叠的流程将被合并。

3.「流程」改进需具有显效性。

改进后的流程提高效率、消除浪费,提高顾客满意度和公司竞争力,降低整个流程成本。