卡套管接头概述

相关主题

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

重复安装 Reassembly

所有的卡套接头都可以多次重装,但是保证零件无损坏且清洁。 Fitting can be used many times. To ensure this, part must be clean and free of defect. 1. 把管子插入接头体直至卡套贴紧接头体内锥面,用手拧紧螺母。

.

Stronger Hydraulic 苏强格·液压

-2-

钢管总成 Steel Pipe Assembly

6. 将预装配接头体拆下,检验卡套刃边的嵌入情况,可 见的突起带必须填满卡套端面的空间。卡套可以稍旋 转,但不能轴向推移。 Disassembly the pre-assembly fitting body, check penetration of cutting edge. A visible ring of material should fill the space in front of the cutting ring end face. Cutting ring may rotate on tube, but should not be axial displacement.

安装 Assembly

1. 锯下合适长度的无缝钢管,去除端口处毛刺。管子 端面要与轴线垂直,角度公差不大于 0.5°,如管子 需要折弯,则从管子端面至弯曲位部的直线段长度 不能少于三倍螺母长度。

Stronger Hydraulic 苏强格·液压

-1-

钢管总成 Steel Pipe Assembly

2. 把螺母和卡套套在无缝钢管上。 注意螺母和卡套的方 向,如右图所示,不要装反了。 Set a nut and cutting ring on the tube. Make sure the cutting ring and nuts are facing the fitting, as the picture shown at right side.

Stronger Hydraulic 苏强格·液压

-3-

钢管总成 Steel Pipe Assembly

钢管尺寸、公差以及最大工作压力 Tube Size, Tolerance and Max. Working Pressure

外径

O.D.

(mm)

6 6 8 8 8 10 10 10 12 12 12 14 14 14 14 15 15 15 16 16 16 16 18 18 18 20 20 20 20 22 22 22 22 25 25 25 25 28 28 28 30 30 30 30 30 35 35 35 35 38 38 38 38 38 42 42 42 50 50 50 50 50 60 60 60 60 60 60.3 60.3 60.3 60.3

钢管总成 Steel Pipe Assembly

卡套接头概述 Bite Type Fittings Instructions

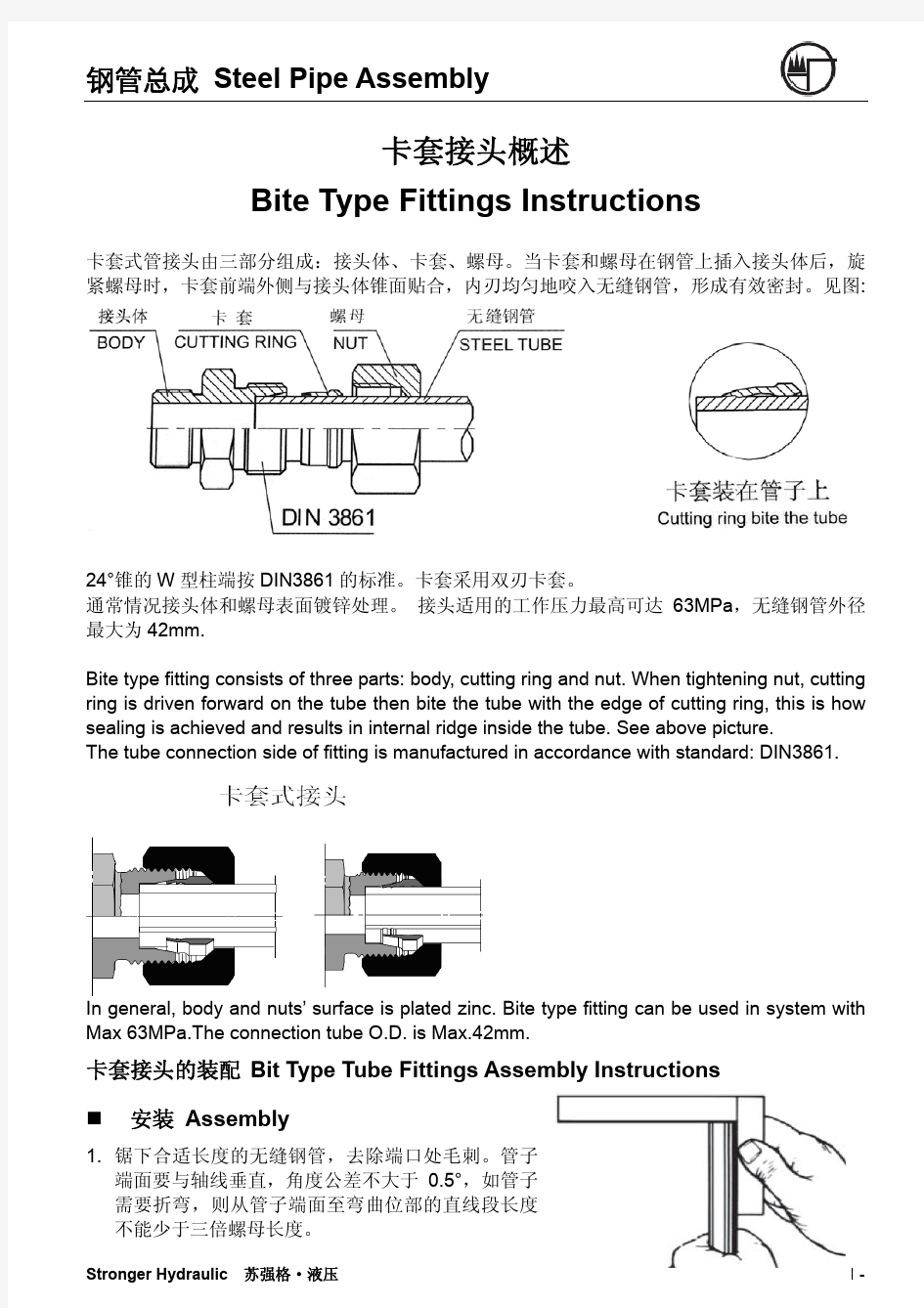

卡套式管接头由三部分组成:接头体、卡套、螺母。当卡套和螺母在钢管上插入接头体后,旋 紧螺母时,卡套前端外侧与接头体锥面贴合,内刃均匀地咬入无缝钢管,形成有效密封。见图:

24°锥的 W 型柱端按 DIN3861 的标准。卡套采用双刃卡套。 通常情况接头体和螺母表面镀锌处理。 接头适用的工作压力最高可达 63MPa,无缝钢管外径 最大为 42mm.

328

2.5

434

415

655

604

415

399

3.0

507

485

765

705

485

466

1.5

282

248

426

360

270

238

2.0

336

321

507

467

321

309

2.5

409

391

617

569

391

376

1.5

264

233

399

wk.baidu.com339

253

224

2.0

353

303

533

公差

Tolerance

(mm)

+0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.20 +0.20 +0.20 +0.20 +0.20 +0.20 +0.20 +0.20 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25

10 号碳素钢管 20 号碳素钢或 16Mn 钢管 不锈钢(SUS316)

壁厚 Carbon Steel C1010 or St37.4

Tube St52.4

Stainless steel

Thickness

最大工作压力

最大工作压力

最大工作压力

(mm)

Max. working Pressure Max. working Pressure Max. working Pressure 静压 Static 动压 Dynamic 静压 Static 动压 Dynamic 静压 Static 动压 Dynamic

4. 拧紧螺母直至卡套卡住管子,这个转折点可以通过拧 紧力矩的增加感受到(压力点) Tighten nut until ferrule grips tube which is felt by a noticeable increase in torque (Increase in force).

5. 达到压力点后,再将压紧螺母拧紧 1/2 圈。Tighten nut 1/2 of a turn after increase in force.

检查 Checking up the bite condition

可拆下管子检查装配是否合乎要求:卡套端面的管子 上应该有均匀的轻微凸起。卡套不能前后移动,但允 许有轻微转动。 All bite type fitting must be disassembled prior to service to check up if small ridge inside the tube is completely formed around front edge of cutting ring. Otherwise tighten slightly more to have it. Cutting ring may rotate on the tube but should not be axial displacement, that doesn’t mean wrong installation. The cutting ring shall be refitted once the nut is retightened.

泄漏原因 Leakage reason

1. 管子没有插到底。When the tube is not fully bottomed 2. 螺母没有拧紧。When the nut is not tightened enough. 3. 管子外表刮伤或管子不圆。When the tube is of scratches or oval. 4. 管子太硬。When the tube is extremely hard.

In general, body and nuts’ surface is plated zinc. Bite type fitting can be used in system with Max 63MPa.The connection tube O.D. is Max.42mm.

卡套接头的装配 Bit Type Tube Fittings Assembly Instructions

Bite type fitting consists of three parts: body, cutting ring and nut. When tightening nut, cutting ring is driven forward on the tube then bite the tube with the edge of cutting ring, this is how sealing is achieved and results in internal ridge inside the tube. See above picture. The tube connection side of fitting is manufactured in accordance with standard: DIN3861.

(Bar)

(Bar)

(Bar)

(Bar)

(Bar)

(Bar)

1.0

409

391

587

541

391

376

1.5

567

551

830

764

561

529

1.0

353

303

503

419

338

291

1.5

452

433

651

599

433

416

2..0

576

551

830

764

561

529

1.0

282

248

426

360

7. 最终安装,将实际安装的接头体的罗纹涂上润滑油、压紧螺母之配合拧至可感受到的拧紧力 增加为止,接着再拧紧 1/2 圈安装完毕。 Lubricate the fitting body to be subsequently installed nut until a noticeable increase in force is required. Tighten nut by1/2 of a turn beyond this point for final assembly.

3. 在预装配接头体螺纹和卡套上涂上润滑油,把管子插 入接头体,(管子一定要插到底)扳手旋转螺母。 Lubricate the pre-assembly fitting body threads and cutting ring. Insert tube end into fitting body until it is firmly seated on bottom (fitting shoulder) and tighten the nut by wrench.

Cut the tube at right angle and de_burr inside and outside of tube end. Minimum straight length of tube from the starting point of tube bend to the tube end may be not less 3 times height of the nut.

270

238

1.5

373

357

563

519

357

343

2.0

478

458

722

655

458

439

1.0

235

209

355

304

225

201

1.5

353

303

533

441

338

291

2.0

409

391

617

569

391

376

1.5

302

264

456

383

289

253

2.0

357

342

539

497

342

Insert the tube into fitting body until cutting ring seats firmly in the fitting and hand-tighten the nut. 2. 用扳手拧紧螺母,直至力矩急剧增大,再拧紧 1/4 至 1/2 圈即可。 Tighten the nut with a wrench by holding the fitting body with a back wrench until a sharp rise in torque is felt. Further tighten the nut 1/4 to 1/2 turn.

所有的卡套接头都可以多次重装,但是保证零件无损坏且清洁。 Fitting can be used many times. To ensure this, part must be clean and free of defect. 1. 把管子插入接头体直至卡套贴紧接头体内锥面,用手拧紧螺母。

.

Stronger Hydraulic 苏强格·液压

-2-

钢管总成 Steel Pipe Assembly

6. 将预装配接头体拆下,检验卡套刃边的嵌入情况,可 见的突起带必须填满卡套端面的空间。卡套可以稍旋 转,但不能轴向推移。 Disassembly the pre-assembly fitting body, check penetration of cutting edge. A visible ring of material should fill the space in front of the cutting ring end face. Cutting ring may rotate on tube, but should not be axial displacement.

安装 Assembly

1. 锯下合适长度的无缝钢管,去除端口处毛刺。管子 端面要与轴线垂直,角度公差不大于 0.5°,如管子 需要折弯,则从管子端面至弯曲位部的直线段长度 不能少于三倍螺母长度。

Stronger Hydraulic 苏强格·液压

-1-

钢管总成 Steel Pipe Assembly

2. 把螺母和卡套套在无缝钢管上。 注意螺母和卡套的方 向,如右图所示,不要装反了。 Set a nut and cutting ring on the tube. Make sure the cutting ring and nuts are facing the fitting, as the picture shown at right side.

Stronger Hydraulic 苏强格·液压

-3-

钢管总成 Steel Pipe Assembly

钢管尺寸、公差以及最大工作压力 Tube Size, Tolerance and Max. Working Pressure

外径

O.D.

(mm)

6 6 8 8 8 10 10 10 12 12 12 14 14 14 14 15 15 15 16 16 16 16 18 18 18 20 20 20 20 22 22 22 22 25 25 25 25 28 28 28 30 30 30 30 30 35 35 35 35 38 38 38 38 38 42 42 42 50 50 50 50 50 60 60 60 60 60 60.3 60.3 60.3 60.3

钢管总成 Steel Pipe Assembly

卡套接头概述 Bite Type Fittings Instructions

卡套式管接头由三部分组成:接头体、卡套、螺母。当卡套和螺母在钢管上插入接头体后,旋 紧螺母时,卡套前端外侧与接头体锥面贴合,内刃均匀地咬入无缝钢管,形成有效密封。见图:

24°锥的 W 型柱端按 DIN3861 的标准。卡套采用双刃卡套。 通常情况接头体和螺母表面镀锌处理。 接头适用的工作压力最高可达 63MPa,无缝钢管外径 最大为 42mm.

328

2.5

434

415

655

604

415

399

3.0

507

485

765

705

485

466

1.5

282

248

426

360

270

238

2.0

336

321

507

467

321

309

2.5

409

391

617

569

391

376

1.5

264

233

399

wk.baidu.com339

253

224

2.0

353

303

533

公差

Tolerance

(mm)

+0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.08 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.15 +0.20 +0.20 +0.20 +0.20 +0.20 +0.20 +0.20 +0.20 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25 +0.25

10 号碳素钢管 20 号碳素钢或 16Mn 钢管 不锈钢(SUS316)

壁厚 Carbon Steel C1010 or St37.4

Tube St52.4

Stainless steel

Thickness

最大工作压力

最大工作压力

最大工作压力

(mm)

Max. working Pressure Max. working Pressure Max. working Pressure 静压 Static 动压 Dynamic 静压 Static 动压 Dynamic 静压 Static 动压 Dynamic

4. 拧紧螺母直至卡套卡住管子,这个转折点可以通过拧 紧力矩的增加感受到(压力点) Tighten nut until ferrule grips tube which is felt by a noticeable increase in torque (Increase in force).

5. 达到压力点后,再将压紧螺母拧紧 1/2 圈。Tighten nut 1/2 of a turn after increase in force.

检查 Checking up the bite condition

可拆下管子检查装配是否合乎要求:卡套端面的管子 上应该有均匀的轻微凸起。卡套不能前后移动,但允 许有轻微转动。 All bite type fitting must be disassembled prior to service to check up if small ridge inside the tube is completely formed around front edge of cutting ring. Otherwise tighten slightly more to have it. Cutting ring may rotate on the tube but should not be axial displacement, that doesn’t mean wrong installation. The cutting ring shall be refitted once the nut is retightened.

泄漏原因 Leakage reason

1. 管子没有插到底。When the tube is not fully bottomed 2. 螺母没有拧紧。When the nut is not tightened enough. 3. 管子外表刮伤或管子不圆。When the tube is of scratches or oval. 4. 管子太硬。When the tube is extremely hard.

In general, body and nuts’ surface is plated zinc. Bite type fitting can be used in system with Max 63MPa.The connection tube O.D. is Max.42mm.

卡套接头的装配 Bit Type Tube Fittings Assembly Instructions

Bite type fitting consists of three parts: body, cutting ring and nut. When tightening nut, cutting ring is driven forward on the tube then bite the tube with the edge of cutting ring, this is how sealing is achieved and results in internal ridge inside the tube. See above picture. The tube connection side of fitting is manufactured in accordance with standard: DIN3861.

(Bar)

(Bar)

(Bar)

(Bar)

(Bar)

(Bar)

1.0

409

391

587

541

391

376

1.5

567

551

830

764

561

529

1.0

353

303

503

419

338

291

1.5

452

433

651

599

433

416

2..0

576

551

830

764

561

529

1.0

282

248

426

360

7. 最终安装,将实际安装的接头体的罗纹涂上润滑油、压紧螺母之配合拧至可感受到的拧紧力 增加为止,接着再拧紧 1/2 圈安装完毕。 Lubricate the fitting body to be subsequently installed nut until a noticeable increase in force is required. Tighten nut by1/2 of a turn beyond this point for final assembly.

3. 在预装配接头体螺纹和卡套上涂上润滑油,把管子插 入接头体,(管子一定要插到底)扳手旋转螺母。 Lubricate the pre-assembly fitting body threads and cutting ring. Insert tube end into fitting body until it is firmly seated on bottom (fitting shoulder) and tighten the nut by wrench.

Cut the tube at right angle and de_burr inside and outside of tube end. Minimum straight length of tube from the starting point of tube bend to the tube end may be not less 3 times height of the nut.

270

238

1.5

373

357

563

519

357

343

2.0

478

458

722

655

458

439

1.0

235

209

355

304

225

201

1.5

353

303

533

441

338

291

2.0

409

391

617

569

391

376

1.5

302

264

456

383

289

253

2.0

357

342

539

497

342

Insert the tube into fitting body until cutting ring seats firmly in the fitting and hand-tighten the nut. 2. 用扳手拧紧螺母,直至力矩急剧增大,再拧紧 1/4 至 1/2 圈即可。 Tighten the nut with a wrench by holding the fitting body with a back wrench until a sharp rise in torque is felt. Further tighten the nut 1/4 to 1/2 turn.