FLUENT多孔介质数值模拟设置

fluent中多孔介质设置问题和算例

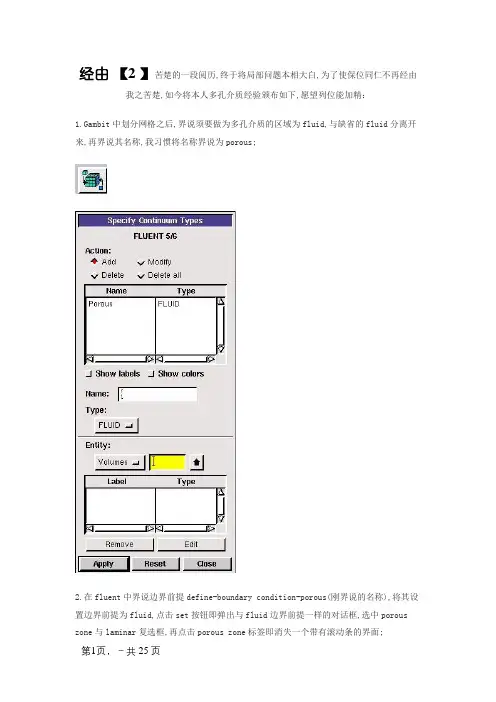

经由【2 】苦楚的一段阅历,终于将局部问题本相大白,为了使保位同仁不再经由我之苦楚,如今将本人多孔介质经验颁布如下,愿望列位能加精:1.Gambit中划分网格之后,界说须要做为多孔介质的区域为fluid,与缺省的fluid分离开来,再界说其名称,我习惯将名称界说为porous;2.在fluent中界说边界前提define-boundary condition-porous(刚界说的名称),将其设置边界前提为fluid,点击set按钮即弹出与fluid边界前提一样的对话框,选中porous zone与laminar复选框,再点击porous zone标签即消失一个带有滚动条的界面;3.porous zone设置办法:1)界说矢量:二维界说一个矢量,第二个矢量偏向不用界说,是与第一个矢量偏向正交的;三维界说二个矢量,第三个矢量偏向不用界说,是与第一.二个矢量偏向正交的;(若何知道矢量的偏向:打开grid图,看看X,Y,Z的偏向,假如是X向,矢量为1,0,0,同理Y向为0,1,0,Z向为0,0,1,假如所须要的偏向与坐标轴正向相反,则界说矢量为负)圆锥坐标与球坐标请参考fluent关心.2)界说粘性阻力1/a与内部阻力C2:请参看本人上一篇博文“终于搞清fluent中多孔粘性阻力与内部阻力的盘算办法”,此处不赘述;3)假如了界说粘性阻力1/a与内部阻力C2,就不用界说C1与C0,因为这是两种不同的界说办法,C1与C0只在幂率模子中消失,该处保持默认就行了;4)界说孔隙率porousity,默认值1表示全凋谢,此值按试验测值填写即可.完了,其他设置与通俗k-e或RSM雷同.总结一下,与君共享!Tutorial 7. Modeling Flow Through Porous MediaIntroductionMany industrial applications involve the modeling of flow through porous media, suchas filters, catalyst beds, and packing. This tutorial illustrates how to set up and solve aproblem involving gas flow through porous media.The industrial problem solved here involves gas flow through a catalytic converter. Catalyticconverters are commonly used to purify emissions from gasoline and diesel enginesby converting environmentally hazardous exhaust emissions to acceptable substances.Examples of such emissions include carbon monoxide (CO), nitrogen oxides (NOx), andunburned hydrocarbon fuels. These exhaust gas emissions are forced through a substrate,which is a ceramic structure coated with a metal catalyst such as platinum or palladium.The nature of the exhaust gas flow is a very important factor in determining the performanceof thecatalytic converter. Of particular importance is the pressure gradientand velocity distribution through the substrate. Hence CFD analysis is used to designefficient catalytic converters: by modeling the exhaust gas flow, the pressure drop andthe uniformity of flow through the substrate can be determined. In this tutorial, FLUENTis used to model the flow of nitrogen gas through a catalytic converter geometry, so thatthe flow field structure may be analyzed.This tutorial demonstrates how to do the following:_ Set up a porous zone for the substrate with appropriate resistances._ Calculate a solution for gas flow through the catalytic converter using the pressurebasedsolver. _ Plot pressure and velocity distribution on specified planes of the geometry._ Determine the pressure drop through the substrate and the degree of non-uniformityof flow through cross sections of the geometry using X-Y plots and numerical reports.Problem DescriptionThe catalytic converter modeled here is shown in Figure 7.1. The nitrogen flows inthrough the inlet with a uniform velocity of 22.6 m/s, passes through a ceramic monolithsubstrate with square shaped channels, and then exits through the outlet.While the flow in the inlet and outlet sections is turbulent, the flow through the substrateis laminar and is characterized by inertial and viscous loss coefficients in the flow (X)direction. The substrate is impermeable in other directions, which is modeled using losscoefficients whose valuesare three orders of magnitude higher than in the X direction.Setup and SolutionStep 1: Grid1. Read the mesh file (catalytic converter.msh).File /Read /Case...2. Check the grid.Grid /CheckFLUENT will perform various checks on the mesh and report the progress in theconsole. Make sure that the minimum volume reported is a positive number.3. Scale the grid.Grid!Scale...(a) Select mm from the Grid Was Created In drop-down list.(b) Click the Change Length Units button.All dimensions will now be shown in millimeters.(c) Click Scale and close the Scale Grid panel.4. Display the mesh.Display /Grid...(a) Make sure that inlet, outlet, substrate-wall, and wall are selected in the Surfacesselection list.(b) Click Display.(c) Rotate the view and zoom in to get the display shown in Figure 7.2.(d) Close the Grid Display panel.The hex mesh on the geometry contains a total of 34,580 cells.Step 2: Models1. Retain the default solver settings.Define /Models /Solver...2. Select the standard k-ε turbulence model.Define/ Models /Viscous...Step 3: Materials1. Add nitrogen to the list of fluid materials by copying it from the Fluent Databasefor materials.Define /Materials...(a) Click the Fluent Database... button to open the Fluent Database Materialspanel.i. Select nitrogen (n2) from the list of Fluent Fluid Materials.ii. Click Copy to copy the information for nitrogen to your list of fluid materials. iii. Close the Fluent Database Materials panel.(b) Close the Materials panel.Step 4: Boundary Conditions.Define /Boundary Conditions...1. Set the boundary conditions for the fluid (fluid).(a) Select nitrogen from the Material Name drop-down list.(b) Click OK to close the Fluid panel.2. Set the boundary conditions for the substrate (substrate).(a) Select nitrogen from the Material Name drop-down list.(b) Enable the Porous Zone option to activate the porous zone model.(c) Enable the Laminar Zone option to solve the flow in the porous zone withoutturbulence.(d) Click the Porous Zone tab.i. Make sure that the principal direction vectors are set as shown in e the scroll bar to access the fields that are not initially visible in thepanel.ii. Enter the values in Table 7.2 for the Viscous Resistance and Inertial Resistance.Scroll down to access the fields that are not initially visible in the panel.(e) Click OK to close the Fluid panel.3. Set the velocity and turbulence boundary conditions at the inlet (inlet).(a) Enter 22.6 m/s for the Velocity Magnitude.(b) Select Intensity and Hydraulic Diameter from the Specification Method dropdownlist in the Turbulence group box.(c) Retain the default value of 10% for the Turbulent Intensity.(d) Enter 42 mm for the Hydraulic Diameter.(e) Click OK to close the Velocity Inlet panel.4. Set the boundary conditions at the outlet (outlet).(a) Retain the default setting of 0 for Gauge Pressure.(b) Select Intensity and Hydraulic Diameter from the Specification Method dropdownlist in the Turbulence group box.(c) Enter 5% for the Backflow Turbulent Intensity.(d) Enter 42 mm for the Backflow Hydraulic Diameter.(e) Click OK to close the Pressure Outlet panel.5. Retain the default boundary conditions for the walls (substrate-wall and wall) andclose the Boundary Conditions panel.Step 5: Solution1. Set the solution parameters.Solve /Controls /Solution...(a) Retain the default settings for Under-Relaxation Factors.(b) Select Second Order Upwind from the Momentum drop-down list in the Discretizationgroup box.(c) Click OK to close the Solution Controls panel.2. Enable the plotting of residuals during the calculation.Solve/Monitors /Residual...(a) Enable Plot in the Options group box.(b) Click OK to close the Residual Monitors panel.3. Enable the plotting of the mass flow rate at the outlet.Solve / Monitors /Surface...(a) Set the Surface Monitors to 1.(b) Enable the Plot and Write options for monitor-1, and click the Define... buttonto open the Define Surface Monitor panel.i. Select Mass Flow Rate from the Report Type drop-down list. ii. Select outlet from the Surfaces selection list.iii. Click OK to close the Define Surface Monitors panel.(c) Click OK to close the Surface Monitors panel.4. Initialize the solution from the inlet.Solve /Initialize /Initialize...(a) Select inlet from the Compute From drop-down list.(b) Click Init and close the Solution Initialization panel.5. Save the case file (catalytic converter.cas).File /Write /Case...6. Run the calculation by requesting 100 iterations.Solve /Iterate...(a) Enter 100 for the Number of Iterations.(b) Click Iterate.The FLUENT calculation will converge in approximately 70 iterations. By thispoint the mass flow rate monitor has attended out, as seen in Figure 7.3.(c) Close the Iterate panel.7. Save the case and data files (catalytic converter.cas and catalytic converter.dat).File /Write /Case & Data...Note: If you choose a file name that already exists in the current folder, FLUENTwill prompt you for confirmation to overwrite the file.Step 6: Post-processing1. Create a surface passing through the centerline for post-processing purposes.Surface/Iso-Surface...(a) Select Grid... and Y-Coordinate from the Surface of Constant drop-down lists.(b) Click Compute to calculate the Min and Max values.(c) Retain the default value of 0 for the Iso-Values.(d) Enter y=0 for the New Surface Name.(e) Click Create.2. Create cross-sectional surfaces at locations on either side of the substrate, as wellas at its center. Surface /Iso-Surface...(a) Select Grid... and X-Coordinate from the Surface of Constant drop-down lists.(b) Click Compute to calculate the Min and Max values.(c) Enter 95 for Iso-Values.(d) Enter x=95 for the New Surface Name.(e) Click Create.(f) In a similar manner, create surfaces named x=130 and x=165 with Iso-Valuesof 130 and 165, respectively. Close the Iso-Surface panel after all the surfaceshave been created.3. Create a line surface for the centerline of the porous media.Surface /Line/Rake...(a) Enter the coordinates of the line under End Points, using the starting coordinateof (95, 0, 0) and an ending coordinate of (165, 0, 0), as shown.(b) Enter porous-cl for the New Surface Name.(c) Click Create to create the surface.(d) Close the Line/Rake Surface panel.4. Display the two wall zones (substrate-wall and wall).Display /Grid...(a) Disable the Edges option.(b) Enable the Faces option.(c) Deselect inlet and outlet in the list under Surfaces, and make sure that onlysubstrate-wall and wall are selected.(d) Click Display and close the Grid Display panel.(e) Rotate the view and zoom so that the display is similar to Figure 7.2.5. Set the lighting for the display.Display /Options...(a) Enable the Lights On option in the Lighting Attributes group box.(b) Retain the default selection of Gourand in the Lighting drop-down list.(c) Click Apply and close the Display Options panel.6. Set the transparency parameter for the wall zones (substrate-wall and wall).Display/Scene...(a) Select substrate-wall and wall in the Names selection list.(b) Click the Display... button under Geometry Attributes to open the DisplayProperties panel.i. Set the Transparency slider to 70.ii. Click Apply and close the Display Properties panel.(c) Click Apply and then close the Scene Description panel.7. Display velocity vectors on the y=0 surface.Display /Vectors...(a) Enable the Draw Grid option.The Grid Display panel will open.i. Make sure that substrate-wall and wall are selected in the list under Surfaces.ii. Click Display and close the Display Grid panel.(b) Enter 5 for the Scale.(c) Set Skip to 1.(d) Select y=0 from the Surfaces selection list.(e) Click Display and close the Vectors panel.The flow pattern shows that the flow enters the catalytic converter as a jet, withrecirculation on either side of the jet. As it passes through the porous substrate, itdecelerates and straightens out, and exhibits a more uniform velocity distribution.This allows the metal catalyst present in the substrate to be more effective.Figure 7.4: Velocity Vectors on the y=0 Plane8. Display filled contours of static pressure on the y=0 plane.Display /Contours...(a) Enable the Filled option.(b) Enable the Draw Grid option to open the Display Grid panel.i. Make sure that substrate-wall and wall are selected in the list under Surfaces.ii. Click Display and close the Display Grid panel.(c) Make sure that Pressure... and Static Pressure are selected from the Contoursof drop-down lists.(d) Select y=0 from the Surfaces selection list.(e) Click Display and close the Contours panel.Figure 7.5: Contours of the Static Pressure on the y=0 planeThe pressure changes rapidly in the middle section, where the fluid velocity changesas it passes through the porous substrate. The pressure drop can be high, due to theinertial and viscous resistance of the porous media. Determining this pressure dropis a goal of CFD analysis. In the next step, you will learn how to plot the pressuredrop along the centerline of the substrate.9. Plot the static pressure across the line surface porous-cl.Plot /XY Plot...(a) Make sure that the Pressure... and Static Pressure are selected from the Y AxisFunction drop-down lists.(b) Select porous-cl from the Surfaces selection list.(c) Click Plot and close the Solution XY Plot panel.Figure 7.6: Plot of the Static Pressure on the porous-cl Line SurfaceIn Figure 7.6, the pressure drop across the porous substrate can be seen to beroughly 300 Pa. 10. Display filled contours of the velocity in the X direction on the x=95, x=130 andx=165 surfaces.Display /Contours...(a) Disable the Global Range option.(b) Select Velocity... and X Velocity from the Contours of drop-down lists.(c) Select x=130, x=165, and x=95 from the Surfaces selection list, and deselecty=0.(d) Click Display and close the Contours panel.The velocity profile becomes more uniform as the fluid passes through the porousmedia. The velocity is very high at the center (the area in red) just before thenitrogen enters the substrate and then decreases as it passes through and exits thesubstrate. The area in green, which corresponds to a moderate velocity, increasesin extent.Figure 7.7: Contours of the X Velocity on the x=95, x=130, and x=165 Surfaces11. Use numerical reports to determine the average, minimum, and maximum of thevelocity distribution before and after the porous substrate.Report /Surface Integrals...(a) Select Mass-Weighted Average from the Report Type drop-down list.(b) Select Velocity and X Velocity from the Field Variable drop-down lists.(c) Select x=165 and x=95 from the Surfaces selection list.(d) Click Compute.(e) Select Facet Minimum from the Report Type drop-down list and click Computeagain.(f) Select Facet Maximum from the Report Type drop-down list and click Computeagain.(g) Close the Surface Integrals panel.The numerical report of average, maximum and minimum velocity can be seen inthe main FLUENT console, as shown in the following example:The spread between the average, maximum, and minimum values for X velocitygives the degreeto which the velocity distribution is non-uniform. You can also usethese numbers to calculate the velocity ratio (i.e., the maximum velocity divided bythe mean velocity) and the space velocity (i.e.,the product of the mean velocity andthe substrate length).Custom field functions and UDFs can be also used to calculate more complex measuresof non-uniformity, such as the standard deviation and the gamma uniformityindex.SummaryIn this tutorial, you learned how to set up and solve a problem involving gas flow throughporous media in FLUENT. You also learned how to perform appropriate post-processingto investigate the flow field, determine the pressure drop across the porous media andnon-uniformity of the velocity distribution as the fluid goes through the porous media.Further ImprovementsThis tutorial guides you through the steps to reach an initial solution. You may be ableto obtain a more accurate solution by using an appropriate higher-order discretizationscheme and by adapting the grid. Grid adaption can also ensure that the solution isindependent of the grid. These steps are demonstrated in Tutorial 1.。

fluent中多孔介质模型的设置

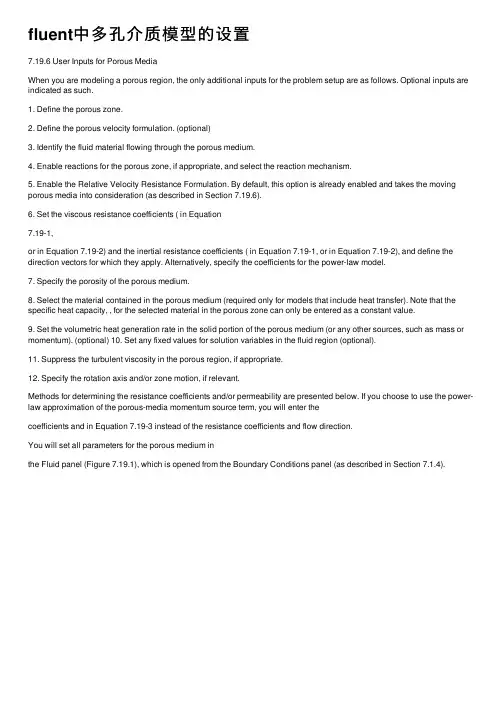

fluent中多孔介质模型的设置7.19.6 User Inputs for Porous MediaWhen you are modeling a porous region, the only additional inputs for the problem setup are as follows. Optional inputs are indicated as such.1. Define the porous zone.2. Define the porous velocity formulation. (optional)3. Identify the fluid material flowing through the porous medium.4. Enable reactions for the porous zone, if appropriate, and select the reaction mechanism.5. Enable the Relative Velocity Resistance Formulation. By default, this option is already enabled and takes the moving porous media into consideration (as described in Section 7.19.6).6. Set the viscous resistance coefficients ( in Equation7.19-1,or in Equation 7.19-2) and the inertial resistance coefficients ( in Equation 7.19-1, or in Equation 7.19-2), and define the direction vectors for which they apply. Alternatively, specify the coefficients for the power-law model.7. Specify the porosity of the porous medium.8. Select the material contained in the porous medium (required only for models that include heat transfer). Note that the specific heat capacity, , for the selected material in the porous zone can only be entered as a constant value.9. Set the volumetric heat generation rate in the solid portion of the porous medium (or any other sources, such as mass or momentum). (optional) 10. Set any fixed values for solution variables in the fluid region (optional).11. Suppress the turbulent viscosity in the porous region, if appropriate.12. Specify the rotation axis and/or zone motion, if relevant.Methods for determining the resistance coefficients and/or permeability are presented below. If you choose to use the power-law approximation of the porous-media momentum source term, you will enter thecoefficients and in Equation 7.19-3 instead of the resistance coefficients and flow direction.You will set all parameters for the porous medium inthe Fluid panel (Figure 7.19.1), which is opened from the Boundary Conditions panel (as described in Section 7.1.4).Figure 7.19.1: The Fluid Panel for a Porous Zone Defining the Porous ZoneAs mentioned in Section 7.1, a porous zone is modeled as a special type of fluid zone. To indicate that the fluid zone is a porous region, enablethe Porous Zone option in the Fluid panel. The panel will expand to show the porous media inputs (as shown in Figure7.19.1).Defining the Porous Velocity FormulationThe Solver panel contains a Porous Formulation region where you can instruct FLUENT to use either a superficial or physical velocity in the porous medium simulation. By default, the velocity is set to SuperficialVelocity. For details about using the Physical Velocity formulation, see Section 7.19.7.Defining the Fluid Passing Through the Porous MediumTo define the fluid that passes through the porous medium, select the appropriate fluid in the Material Name drop-down list in the Fluid panel. If you want to check or modify the properties of the selected material, you can click Edit... to open the Material panel; this panel contains just the properties of the selected material, not the full contents of thestandard Materials panel.If you are modeling species transport or multiphase flow,the Material Name list will not appear in the Fluid panel. Forspecies calculations, the mixture material for all fluid/porous zones will be the material you specified in the SpeciesModel panel. For multiphase flows, the materials are specified when you define the phases, as described in Section 23.10.3. Enabling Reactions in a Porous ZoneIf you are modeling species transport with reactions, you can enable reactions in a porous zone by turning on the Reaction option inthe Fluid panel and selecting a mechanism in the ReactionMechanism drop-down list.If your mechanism contains wall surface reactions, you will also need to specify a value for the Surface-to-Volume Ratio. Thisvalue is the surface area of the pore walls per unit volume ( ), and can be thought of as a measure of catalyst loading. With this value, FLUENT can calculate the total surface area on which the reaction takes place in each cell bymultiplying by the volume of the cell. See Section 14.1.4 for detailsabout defining reaction mechanisms. See Section 14.2for details about wall surface reactions.Including the Relative Velocity Resistance FormulationPrior to FLUENT 6.3, cases with moving reference frames used the absolute velocities in the source calculations for inertial and viscous resistance. This approach has been enhanced so that relative velocities are used for the porous source calculations (Section 7.19.2). Using the Relative Velocity Resistance Formulation option (turned on by default) allows you to better predict the source terms for cases involving moving meshes or moving reference frames (MRF). This option works well in cases withnon-moving and moving porous media. Note that FLUENT will use the appropriate velocities (relative or absolute), depending on your case setup. Defining the Viscous and Inertial Resistance CoefficientsThe viscous and inertial resistance coefficients are both defined in the same manner. The basic approach for defining the coefficients using a Cartesian coordinate system is to define one direction vector in 2D or two direction vectors in 3D, and then specify the viscous and/or inertial resistance coefficients in each direction. In 2D, the second direction, which is not explicitly defined, is normal to the plane defined by the specified direction vector and the direction vector. In 3D, the third direction is normal to the plane defined by the two specified direction vectors. For a 3D problem, the second direction must be normal to the first. If you fail to specify two normal directions, the solver will ensure that they are normal by ignoring any component of the second direction that is in the first direction. You should therefore be certain that the first direction is correctly specified. You can also define the viscous and/or inertial resistance coefficients in each direction using a user-defined function (UDF). The user-defined options become available in the corresponding drop-down list when the UDF has been created and loaded into FLUENT. Note that the coefficients defined in the UDF must utilize the DEFINE_PROFILE macro. For moreinformation on creating and using user-defined function, see the separate UDF Manual.If you are modeling axisymmetric swirling flows, you can specify an additional direction component for the viscous and/or inertial resistance coefficients. This direction component is always tangential to the other two specified directions. This option is available for both density-based and pressure-based solvers.In 3D, it is also possible to define the coefficients using a conical (or cylindrical) coordinate system, as described below.Note that the viscous and inertial resistance coefficients aregenerally based on the superficial velocity of the fluid in the porous media.The procedure for defining resistance coefficients is as follows:1. Define the direction vectors.To use a Cartesian coordinate system, simply specify the Direction-1 Vector and, for 3D, the Direction-2 Vector. The unspecifieddirection will be determined as described above. These directionvectors correspond to the principle axes of the porous media.For some problems in which the principal axes of the porous mediumare not aligned with the coordinate axes of the domain, you may notknow a priori the direction vectors of the porous medium. In suchcases, the plane tool in 3D (or the line tool in 2D) can help you todetermine these direction vectors.(a) "Snap'' the plane tool (or the line tool) onto the boundary of theporous region. (Follow the instructions inSection 27.6.1 or 27.5.1 for initializing the tool to a position on anexisting surface.)(b) Rotate the axes of the tool appropriately until they are alignedwith the porous medium.(c) Once the axes are aligned, click on the Update From PlaneTool or Update From Line Tool button inthe Fluid panel. FLUENT will automatically set the Direction-1Vector to the direction of the red arrow of the tool, and (in 3D)the Direction-2 Vector to the direction of the green arrow.To use a conical coordinate system (e.g., for an annular, conical filter element), follow the steps below. This option is available only in 3D cases.(a) Turn on the Conical option.(b) Specify the Cone Axis Vector and Point on Cone Axis. Thecone axis is specified as being in the direction of the Cone AxisVector (unit vector), and passing through the Point on Cone Axis.The cone axis may or may not pass through the origin of thecoordinate system.(c) Set the Cone Half Angle (the angle between the cone's axis andits surface, shown in Figure 7.19.2). To use a cylindrical coordinate system, set the Cone Half Angle to 0.Figure 7.19.2: Cone Half AngleFor some problems in which the axis of the conical filter element is not aligned with the coordinate axes of the domain, you may notknow a priori the direction vector of the cone axis and coordinates ofa point on the cone axis. In such cases, the plane tool can help you todetermine the cone axis vector and point coordinates. One method is as follows:(a) Select a boundary zone of the conical filter element that isnormal to the cone axis vector in the drop-down list next to the Snap to Zone button.(b) Click on the Snap to Zone button. FLUENT will automatically"snap'' the plane tool onto the boundary. It will also set the Cone Axis Vector and the Point on Cone Axis. (Note that you will still have to set the Cone Half Angle yourself.)An alternate method is as follows:(a) "Snap'' the plane tool onto the boundary of the porous region.(Follow the instructions in Section 27.6.1 for initializing the tool to a position on an existing surface.)(b) Rotate and translate the axes of the tool appropriately until thered arrow of the tool is pointing in the direction of the cone axisvector and the origin of the tool is on the cone axis.(c) Once the axes and origin of the tool are aligned, click onthe Update From Plane Tool button inthe Fluid panel. FLUENT will automatically set the Cone AxisVector and the Point on Cone Axis. (Note that you will still have toset the Cone Half Angle yourself.)2. Under Viscous Resistance, specify the viscous resistancecoefficient in each direction.Under Inertial Resistance, specify the inertial resistance coefficient in each direction. (You will need to scroll down with the scroll bar to view these inputs.)For porous media cases containing highly anisotropic inertial resistances, enable Alternative Formulation under Inertial Resistance.The Alternative Formulation option provides better stability to the calculation when your porous medium is anisotropic. The pressure loss through the medium depends on the magnitude of the velocity vector ofthe i th component in the medium. Using the formulation ofEquation 7.19-6 yields the expression below:(7.19-10) Whether or not you use the Alternative Formulation option depends on how well you can fit your experimentally determined pressure drop data to the FLUENT model. For example, if the flow through the medium is aligned with the grid in your FLUENT model, then it will not make a difference whether or not you use the formulation.For more infomation about simulations involving highly anisotropic porous media, see Section 7.19.8.Note that the alternative formulation is compatible only with the pressure-based solver.If you are using the Conical specification method, Direction-1 is the cone axis direction, Direction-2 is the normal to the cone surface (radial ( )direction for a cylinder), and Direction-3 is the circumferential ( ) direction.In 3D there are three possible categories of coefficients, and in 2D there are two:In the isotropic case, the resistance coefficients in all directions are the same (e.g., a sponge). For an isotropic case, you must explicitlyset the resistance coefficients in each direction to the same value.When (in 3D) the coefficients in two directions are the same and those in the third direction are different or (in 2D) the coefficients inthe two directions are different, you must be careful to specify thecoefficients properly for each direction. For example, if you had aporous region consisting of cylindrical straws with small holes inthem positioned parallel to the flow direction, the flow would passeasily through the straws, but the flow in the other two directions(through the small holes) would be very little. If you had a plane offlat plates perpendicular to the flow direction, the flow would notpass through them at all; it would instead move in the other twodirections.In 3D the third possible case is one in which all three coefficients are different. For example, if the porous region consisted of a plane ofirregularly-spaced objects (e.g., pins), the movement of flow between the blockages would be different in each direction. You wouldtherefore need to specify different coefficients in each direction. Methods for deriving viscous and inertial loss coefficients are described in the sections that follow.Deriving Porous Media Inputs Based on Superficial Velocity, Using a Known Pressure LossWhen you use the porous media model, you must keep in mind that the porous cells in FLUENT are 100% open, and that the values that you specify for and/or must be based on this assumption. Suppose, however, that you know how the pressure drop varies with the velocity through the actual device, which is only partially open to flow. The following exercise is designed to show you how to compute a valuefor which is appropriate for the FLUENT model.Consider a perforated plate which has 25% area open to flow. The pressure drop through the plate is known to be 0.5 times the dynamic head in the plate. The loss factor, , defined as(7.19-11)is therefore 0.5, based on the actual fluid velocity in the plate, i.e., the velocity through the 25% open area. To compute an appropriate valuefor , note that in the FLUENT model:1. The velocity through the perforated plate assumes that the plate is 100% open.2. The loss coefficient must be converted into dynamic head loss per unit length of the porous region.Noting item 1, the first step is to compute an adjusted loss factor, , which would be based on the velocity of a 100% open area:(7.19-12) or, noting that for the same flow rate, ,(7.19-13)The adjusted loss factor has a value of 8. Noting item 2, you must now convert this into a loss coefficient per unit thickness of the perforated plate. Assume that the plate has a thickness of 1.0 mm (10 m). The inertial loss factor would then be(7.19-14)Note that, for anisotropic media, this information must be computed for each of the 2 (or 3) coordinate directions.Using the Ergun Equation to Derive Porous Media Inputs for a Packed BedAs a second example, consider the modeling of a packed bed. In turbulent flows, packed beds are modeled using both a permeability and an inertial loss coefficient. One technique for deriving the appropriate constants involves the use of the Ergun equation [ 98], a semi-empirical correlation applicable over a wide range of Reynolds numbers and for many types of packing:(7.19-15)When modeling laminar flow through a packed bed, the second term in the above equation may be dropped, resulting in the Blake-Kozenyequation [ 98]:(7.19-16) In these equations, is the viscosity, is the mean particlediameter, is the bed depth, and is the void fraction, defined as the volume of voids divided by the volume of the packed bed region. Comparing Equations 7.19-4 and 7.19-6 with 7.19-15, the permeability and inertial loss coefficient in each component direction may be identified as(7.19-17) and(7.19-18) Using an Empirical Equation to Derive Porous Media Inputs for Turbulent Flow Through a Perforated PlateAs a third example we will take the equation of Van Winkle et al. [ 279, 339] and show how porous media inputs can be calculated for pressure loss through a perforated plate with square-edged holes.The expression, which is claimed by the authors to apply for turbulent flow through square-edged holes on an equilateral triangular spacing, is(7.19-19) where= mass flow rate through the plate= the free area or total area of the holes= the area of the plate (solid and holes)= a coefficient that has been tabulated for various Reynolds-numberrangesand for various= the ratio of hole diameter to plate thicknessfor and for the coefficient takes a value of approximately 0.98, where the Reynolds number is based on hole diameter and velocity in the holes.Rearranging Equation 7.19-19, making use of the relationship(7.19-20)and dividing by the plate thickness, , we obtain(7.19-21)where is the superficial velocity (not the velocity in the holes). Comparing with Equation 7.19-6 it is seen that, for the direction normal to the plate, the constant can be calculated from(7.19-22)Using Tabulated Data to Derive Porous Media Inputs for Laminar Flow Through a Fibrous MatConsider the problem of laminar flow through a mat or filter pad which is made up of randomly-oriented fibers of glass wool. As an alternative to the Blake-Kozeny equation (Equation 7.19-16) we might choose to employ tabulated experimental data. Such data is available for many types offiber [ 158].fraction of dimensionless permeability of glass woolwhere and is the fiber diameter. , for use inEquation 7.19-4, is easily computed for a given fiber diameter and volume fraction.Deriving the Porous Coefficients Based on Experimental Pressure and Velocity DataExperimental data that is available in the form of pressure drop against velocity through the porous component, can be extrapolated to determine the coefficients for the porous media. To effect a pressure drop across a porous medium of thickness, , the coefficients of the porous media are determined in the manner described below.If the experimental data is:then an curve can be plotted to create a trendline through these points yielding the following equationwhere is the pressure drop and is the velocity.Note that a simplified version of the momentum equation, relating the pressure drop to the source term, can be expressed as (7.19-24)or(7.19-25)Hence, comparing Equation 7.19-23 to Equation 7.19-2, yields the following curve coefficients:(7.19-26)with kg/m , and a porous media thickness, , assumed to be 1m in this example, the inertial resistance factor, .Likewise,with , the viscous inertial resistancefactor,. Note that this same technique can be applied to the porous jump boundary condition. Similar to the case of the porous media, you have to take into account the thickness of the medium . Yourexperimental data can be plotted in ancurve, yielding an equation that is equivalent to Equation 7.22-1. From there, you can determine the permeability and the pressure jumpcoefficient .Using the Power-Law ModelIf you choose to use the power-law approximation of the porous-media momentum source term (Equation 7.19-3), the only inputs required are the coefficients and . Under Power Law Model in the Fluid panel, enter the values for C0 and C1. Note that the power-law model can be used in conjunction with the Darcy and inertia models.C0 must be in SI units, consistent with the value of C1.Defining PorosityTo define the porosity, scroll down below the resistance inputs inthe Fluid panel, and set the Porosity under Fluid Porosity .You can also define the porosity using a user-defined function (UDF). The user-defined option becomes available in the corresponding drop-down list when the UDF has been created and loaded into FLUENT. Note that the porosity defined in the UDF must utilize the DEFINE_PROFILE macro. For more information on creating and using user-defined function, see the separate UDF Manual.The porosity, , is the volume fraction of fluid within the porous region (i.e., the open volume fraction of the medium). The porosity is used in the prediction of heat transfer in the medium, as described in Section 7.19.3, and in the time-derivative term in the scalar transport equations for unsteady flow, as described in Section 7.19.5. It also impacts the calculation of reaction source terms and body forces in the medium. These sources will be proportional to the fluid volume in the medium. If you want to represent the medium as completely open (no effect of the solid medium), you should set the porosity equal to 1.0 (the default). When the porosity is equal to 1.0, the solid portion of the medium will have no impact on heat transfer or thermal/reaction source terms in the medium.Defining the Porous MaterialIf you choose to model heat transfer in the porous medium, you must specify the material contained in the porous medium.To define the material contained in the porous medium, scroll down below the resistance inputs in the Fluid panel, and select the appropriate solid in the Solid Material Name drop-down list under Fluid Porosity. If you want to check or modify the properties of the selected material, you canclick Edit... to open the Material panel; this panel contains just the properties of the selected material, not the full contents of thestandard Materials panel. In the Material panel, you can define thenon-isotropic thermal conductivity of the porous material using auser-defined function (UDF). The user-defined option becomes available in the corresponding drop-down list when the UDF has been created and loaded into FLUENT. Note that the non-isotropic thermal conductivity defined in the UDF must utilize the DEFINE_PROPERTY macro. For more information on creating and using user-defined function, see the separate UDF Manual.Defining SourcesIf you want to include effects of the heat generated by the porous medium in the energy equation, enable the Source Terms option and set anon-zero Energy source. The solver will compute the heat generated by the porous region by multiplying this value by the total volume of the cells comprising the porous zone. You may also define sources of mass, momentum, turbulence, species, or other scalar quantities, as described in Section 7.28.Defining Fixed ValuesIf you want to fix the value of one or more variables in the fluid region of the zone, rather than computing them during the calculation, you can do so by enabling the Fixed Values option. See Section 7.27 for details. Suppressing the Turbulent Viscosity in the Porous RegionAs discussed in Section 7.19.4, turbulence will be computed in the porous region just as in the bulk fluid flow. If you are using one of the turbulence models (with the exception of the Large Eddy Simulation (LES) Model), and you want the turbulence generation to be zero in the porous zone, turn on the Laminar Zone option in the Fluid panel. Refer to Section 7.17.1 for more information about suppressing turbulence generation.Specifying the Rotation Axis and Defining Zone MotionInputs for the rotation axis and zone motion are the same as for a standard fluid zone. See Section 7.17.1 for details.。

Fluent多孔介质设置

1。

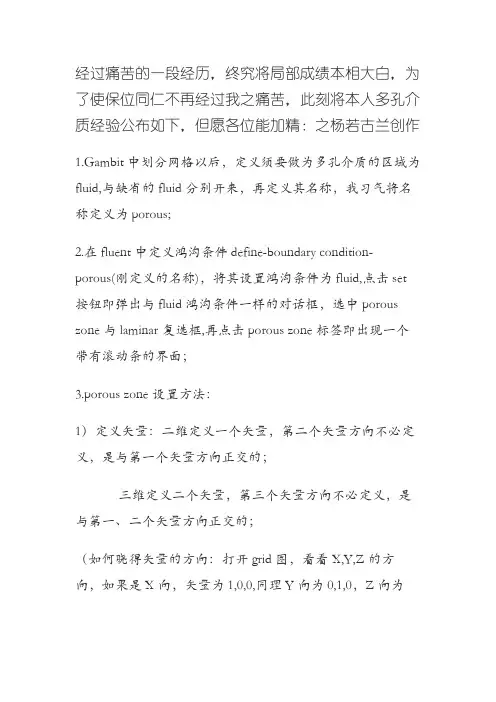

Gambit中划分网格之后,定义需要做为多孔介质的区域为fluid,与缺省的fluid 分别开来,再定义其名称,我习惯将名称定义为porous;2。

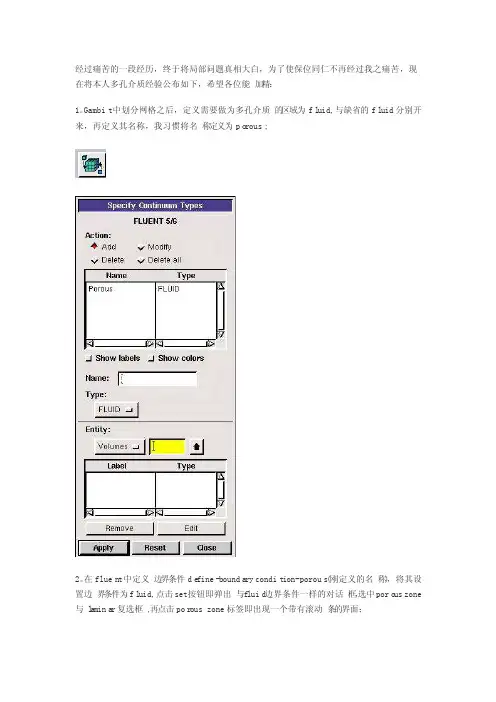

在fluent中定义边界条件define-boundary condition-porous(刚定义的名称),将其设置边界条件为fluid,点击set按钮即弹出与fluid边界条件一样的对话框,选中porous zone与laminar复选框,再点击porous zone标签即出现一个带有滚动条的界面;3。

porous zone设置方法:1)定义矢量:二维定义一个矢量,第二个矢量方向不用定义,是与第一个矢量方向正交的;三维定义二个矢量,第三个矢量方向不用定义,是与第一、二个矢量方向正交的;(如何知道矢量的方向:打开grid图,看看X,Y,Z的方向,如果是X向,矢量为1,0,0,同理Y向为0,1,0,Z向为0,0,1,如果所需要的方向与坐标轴正向相反,则定义矢量为负)圆锥坐标与球坐标请参考fluent帮助。

2)定义粘性阻力1/a与内部阻力C2:下面是一个例子:通过实验测得速度和压降进行计算:假设实验所得速度和压降的数值如下:通过多孔介质的为空气,密度为1.225kg/m 3粘度为51.789410µ−=× 。

由上面速度与压降的关系可以绘出一个二次由线。

方程如下:20.28296 4.33539p v v ∇=−简化的动量方程所得二次由线与方程相比较,对应的系数相等,可得210.282962i c v v ρ=4.33539n µα∆=− 设厚度为1m,可以解出20.4621242282c α==−依据些方法计算自己所模拟的模型的粘性阻力和惯性阻力。

3)如果了定义粘性阻力1/a 与内部阻力C2,就不用定义C1与C0,因为这是两种不同的定义方法,C1与C0只在幂率模型中出现,该处保持默认就行了;4)定义孔隙率porousity ,默认值1表示全开放,此值按实验测值填写即可。

【2019年整理】多孔介质-Fluent模拟

7.19多孔介质边界条件多孔介质模型适用的范围非常广泛,包括填充床,过滤纸,多孔板,流量分配器,还有管群,管束系统。

当使用这个模型的时候,多孔介质将运用于网格区域,流场中的压降将由输入的条件有关,见Section 7.19.2.同样也可以计算热传导,基于介质和流场热量守恒的假设,见Section 7.19.3.通过一个薄膜后的已知速度/压力降低特性可以简化为一维多孔介质模型,简称为“多孔跳跃”。

多孔跳跃模型被运用于一个面区域而不是网格区域,而且也可以代替完全多孔介质模型在任何可能的时候,因为它更加稳定而且能够很好地收敛。

见Section 7.22.7.19.1 多孔介质模型的限制和假设多孔介质模型就是在定义为多孔介质的区域结合了一个根据经验假设为主的流动阻力。

本质上,多孔介质模型仅仅是在动量方程上叠加了一个动量源项。

这种情况下,以下模型方面的假设和限制就可以很容易得到:•因为没有表示多孔介质区域的实际存在的体,所以fluent默认是计算基于连续性方程的虚假速度。

做为一个做精确的选项,你可以适用fluent中的真是速度,见section7.19.7。

•多孔介质对湍流流场的影响,是近似的,见7.19.4。

•当在移动坐标系中使用多孔介质模型的时候,fluent既有相对坐标系也可以使用绝对坐标系,当激活相对速度阻力方程。

这将得到更精确的源项。

相关信息见section7.19.5和7.19.6。

•当需要定义比热容的时候,必须是常数。

7.19.2 多孔介质模型动量方程多孔介质模型的动量方程是在标准动量方程的后面加上动量方程源项。

源项包含两个部分:粘性损失项(达西公式项,方程7.19-1右边第一项),和惯性损失项(方程7.19-1右边第二项)(7.19-1)式中,si是i(x,y,z)动量方程的源项,是速度大小,D和C是矩阵。

动量源项对多孔介质区域的压力梯度有影响,生成一个与速度大小(速度平方)成正比的压降。

fluent中多孔介质设置问题和算例

经过痛苦的一段经历,终究将局部成绩本相大白,为了使保位同仁不再经过我之痛苦,此刻将本人多孔介质经验公布如下,但愿各位能加精:之杨若古兰创作1.Gambit中划分网格以后,定义须要做为多孔介质的区域为fluid,与缺省的fluid分别开来,再定义其名称,我习气将名称定义为porous;2.在fluent中定义鸿沟条件define-boundary condition-porous(刚定义的名称),将其设置鸿沟条件为fluid,点击set 按钮即弹出与fluid鸿沟条件一样的对话框,选中porous zone与laminar复选框,再点击porous zone标签即出现一个带有滚动条的界面;3.porous zone设置方法:1)定义矢量:二维定义一个矢量,第二个矢量方向不必定义,是与第一个矢量方向正交的;三维定义二个矢量,第三个矢量方向不必定义,是与第一、二个矢量方向正交的;(如何晓得矢量的方向:打开grid图,看看X,Y,Z的方向,如果是X向,矢量为1,0,0,同理Y向为0,1,0,Z向为0,0,1,如果所须要的方向与坐标轴正向相反,则定义矢量为负)圆锥坐标与球坐标请参考fluent帮忙.2)定义粘性阻力1/a与内部阻力C2:请参看本人上一篇博文“终究搞清fluent中多孔粘性阻力与内部阻力的计算方法”,此处不赘述;3)如果了定义粘性阻力1/a与内部阻力C2,就不必定义C1与C0,由于这是两种分歧的定义方法,C1与C0只在幂率模型中出现,该处坚持默认就行了;4)定义孔隙率porousity,默认值1暗示全开放,此值按实验测值填写即可.完了,其他设置与普通k-e或RSM不异.总结一下,与君共享!Tutorial 7. Modeling Flow Through Porous Media IntroductionMany industrial applications involve the modeling of flow through porous media, suchas filters, catalyst beds, and packing. This tutorial illustrates how to set up and solve aproblem involving gas flow through porous media.The industrial problem solved here involves gas flow through acatalytic converter. Catalyticconverters are commonly used to purify emissions from gasoline and diesel enginesby converting environmentally hazardous exhaust emissions to acceptable substances.Examples of such emissions include carbon monoxide (CO), nitrogen oxides (NOx), andunburned hydrocarbon fuels. These exhaust gas emissions are forced through a substrate,which is a ceramic structure coated with a metal catalyst such as platinum or palladium.The nature of the exhaust gas flow is a very important factor in determining the performanceof the catalytic converter. Of particular importance is the pressure gradientand velocity distribution through the substrate. Hence CFD analysis is used to designefficient catalytic converters: by modeling the exhaust gas flow, the pressure drop andthe uniformity of flow through the substrate can be determined. In this tutorial, FLUENTis used to model the flow of nitrogen gas through a catalytic converter geometry, so thatthe flow field structure may be analyzed.This tutorial demonstrates how to do the following:_ Set up a porous zone for the substrate with appropriate resistances._ Calculate a solution for gas flow through the catalytic converterusing the pressurebasedsolver._ Plot pressure and velocity distribution on specified planes of the geometry._ Determine the pressure drop through the substrate and the degree of non-uniformityof flow through cross sections of the geometry using X-Y plots and numerical reports.Problem DescriptionThe catalytic converter modeled here is shown in Figure 7.1. The nitrogen flows inthrough the inlet with a uniform velocity of 22.6 m/s, passes through a ceramic monolithsubstrate with square shaped channels, and then exits through the outlet.While the flow in the inlet and outlet sections is turbulent, the flow through the substrateis laminar and is characterized by inertial and viscous loss coefficients in the flow (X)direction. The substrate is impermeable in other directions, which is modeled using losscoefficients whose values are three orders of magnitude higher than in the X direction.Setup and SolutionStep 1: Grid1. Read the mesh file (catalytic converter.msh).File /Read /Case...2. Check the grid.Grid /CheckFLUENT will perform various checks on the mesh and report the progress in theconsole. Make sure that the minimum volume reported is a positive number.3. Scale the grid.Grid!Scale...(a) Select mm from the Grid Was Created In drop-down list.(b) Click the Change Length Units button.All dimensions will now be shown in millimeters.(c) Click Scale and close the Scale Grid panel.4. Display the mesh.Display /Grid...(a) Make sure that inlet, outlet, substrate-wall, and wall are selected in the Surfacesselection list.(b) Click Display.(c) Rotate the view and zoom in to get the display shown in Figure7.2.(d) Close the Grid Display panel.The hex mesh on the geometry contains a total of 34,580 cells.Step 2: Modelsfine /Models /Solver...2. Select the standard k-εfine/ Models /Viscous...Step 3: Materials1. Add nitrogen to the list of flfine /Materials...(a) Click the Fluent Database... button to open the Fluent Database Materialspanel.i. Select nitrogen (n2) from the list of Fluent Fluid Materials.ii. Click Copy to copy the information for nitrogen to your list of fluid materials.iii. Close the Fluent Database Materials panel.(b) Close the Materials panel.Step 4: Boundary Conditions.Define /Boundary Conditions...1. Set the boundary conditions for the fluid (fluid).(a) Select nitrogen from the Material Name drop-down list.(b) Click OK to close the Fluid panel.2. Set the boundary conditions for the substrate (substrate).(a) Select nitrogen from the Material Name drop-down list.(b) Enable the Porous Zone option to activate the porous zone model.(c) Enable the Laminar Zone option to solve the flow in the porous zone withoutturbulence.(d) Click the Porous Zone tab.i. Make sure that the principal direction vectors are set as shown in e the scroll bar to access the fields that are not initially visible in thepanel.ii. Enter the values in Table 7.2 for the Viscous Resistance and Inertial Resistance.Scroll down to access the fields that are not initially visible in the panel.(e) Click OK to close the Fluid panel.3. Set the velocity and turbulence boundary conditions at the inlet (inlet).(a) Enter 22.6 m/s for the Velocity Magnitude.(b) Select Intensity and Hydraulic Diameter from the Specification Method dropdownlist in the Turbulence group box.(c) Retain the default value of 10% for the Turbulent Intensity.(d) Enter 42 mm for the Hydraulic Diameter.(e) Click OK to close the Velocity Inlet panel.4. Set the boundary conditions at the outlet (outlet).(a) Retain the default setting of 0 for Gauge Pressure.(b) Select Intensity and Hydraulic Diameter from the Specification Method dropdownlist in the Turbulence group box.(c) Enter 5% for the Backflow Turbulent Intensity.(d) Enter 42 mm for the Backflow Hydraulic Diameter.(e) Click OK to close the Pressure Outlet panel.5. Retain the default boundary conditions for the walls (substrate-wall and wall) andclose the Boundary Conditions panel.Step 5: Solution1. Set the solution parameters.Solve /Controls /Solution...(a) Retain the default settings for Under-Relaxation Factors.(b) Select Second Order Upwind from the Momentum drop-down list in the Discretizationgroup box.(c) Click OK to close the Solution Controls panel./Monitors /Residual...(a) Enable Plot in the Options group box.(b) Click OK to close the Residual Monitors panel.3. Enable the plotting of the mass flow rate at the outlet.Solve / Monitors /Surface...(a) Set the Surface Monitors to 1.(b) Enable the Plot and Write options for monitor-1, and click the Define... buttonto open the Define Surface Monitor panel.i. Select Mass Flow Rate from the Report Type drop-down list. ii. Select outlet from the Surfaces selection list.iii. Click OK to close the Define Surface Monitors panel.(c) Click OK to close the Surface Monitors panel.4. Initialize the solution from the inlet.Solve /Initialize /Initialize...(a) Select inlet from the Compute From drop-down list.(b) Click Init and close the Solution Initialization panel.5. Save the case file (catalytic converter.cas).File /Write /Case...6. Run the calculation by requesting 100 iterations.Solve /Iterate...(a) Enter 100 for the Number of Iterations.(b) Click Iterate.The FLUENT calculation will converge in approximately 70 iterations. By thispoint the mass flow rate monitor has attended out, as seen in Figure 7.3.(c) Close the Iterate panel.7. Save the case and data files (catalytic converter.cas and catalytic converter.dat).File /Write /Case & Data...Note: If you choose a file name that already exists in the current folder, FLUENTwill prompt you for confirmation to overwrite the file.Step 6: Post-processing1. Create a surface passing through the centerline for post-processing purposes.Surface/Iso-Surface...(a) Select Grid... and Y-Coordinate from the Surface of Constant drop-down lists.(b) Click Compute to calculate the Min and Max values.(c) Retain the default value of 0 for the Iso-Values.(d) Enter y=0 for the New Surface Name.(e) Click Create.2. Create cross-sectional surfaces at locations on either side of the substrate, as wellas at its center.Surface /Iso-Surface...(a) Select Grid... and X-Coordinate from the Surface of Constant drop-down lists.(b) Click Compute to calculate the Min and Max values.(c) Enter 95 for Iso-Values.(d) Enter x=95 for the New Surface Name.(e) Click Create.(f) In a similar manner, create surfaces named x=130 and x=165 with Iso-Valuesof 130 and 165, respectively. Close the Iso-Surface panel after all the surfaceshave been created.3. Create a line surface for the centerline of the porous media. Surface /Line/Rake...(a) Enter the coordinates of the line under End Points, using the starting coordinateof (95, 0, 0) and an ending coordinate of (165, 0,0), as shown.(b) Enter porous-cl for the New Surface Name.(c) Click Create to create the surface.(d) Close the Line/Rake Surface panel.4. Display the two wall zones (substrate-wall and wall).Display/Grid...(a) Disable the Edges option.(b) Enable the Faces option.(c) Deselect inlet and outlet in the list under Surfaces, and make sure that onlysubstrate-wall and wall are selected.(d) Click Display and close the Grid Display panel.(e) Rotate the view and zoom so that the display is similar to Figure 7.2.5. Set the lighting for the display.Display /Options...(a) Enable the Lights On option in the Lighting Attributes group box.(b) Retain the default selection of Gourand in the Lighting drop-down list.(c) Click Apply and close the Display Options panel.6. Set the transparency parameter for the wall zones (substrate-wall and wall).Display/Scene...(a) Select substrate-wall and wall in the Names selection list.(b) Click the Display... button under Geometry Attributes to openthe DisplayProperties panel.i. Set the Transparency slider to 70.ii. Click Apply and close the Display Properties panel.(c) Click Apply and then close the Scene Description panel.7. Display velocity vectors on the y=0 surface.Display /Vectors...(a) Enable the Draw Grid option.The Grid Display panel will open.i. Make sure that substrate-wall and wall are selected in the list under Surfaces.ii. Click Display and close the Display Grid panel.(b) Enter 5 for the Scale.(c) Set Skip to 1.(d) Select y=0 from the Surfaces selection list.(e) Click Display and close the Vectors panel.The flow pattern shows that the flow enters the catalytic converter as a jet, withrecirculation on either side of the jet. As it passes through the porous substrate, itdecelerates and straightens out, and exhibits a more uniform velocity distribution.This allows the metal catalyst present in the substrate to be more effective.Figure 7.4: Velocity Vectors on the y=0 Plane8. Display filled contours of static pressure on the y=0 plane. Display /Contours...(a) Enable the Filled option.(b) Enable the Draw Grid option to open the Display Grid panel.i. Make sure that substrate-wall and wall are selected in the list under Surfaces.ii. Click Display and close the Display Grid panel.(c) Make sure that Pressure... and Static Pressure are selected from the Contoursof drop-down lists.(d) Select y=0 from the Surfaces selection list.(e) Click Display and close the Contours panel.Figure 7.5: Contours of the Static Pressure on the y=0 planeThe pressure changes rapidly in the middle section, where the fluid velocity changesas it passes through the porous substrate. The pressure drop can be high, due to theinertial and viscous resistance of the porous media. Determining this pressure dropis a goal of CFD analysis. In the next step, you will learn how to plot the pressuredrop along the centerline of the substrate.9. Plot the static pressure across the line surface porous-cl.Plot /XY Plot...(a) Make sure that the Pressure... and Static Pressure are selectedfrom the Y AxisFunction drop-down lists.(b) Select porous-cl from the Surfaces selection list.(c) Click Plot and close the Solution XY Plot panel.Figure 7.6: Plot of the Static Pressure on the porous-cl Line SurfaceIn Figure 7.6, the pressure drop across the porous substrate can be seen to beroughly 300 Pa.10. Display filled contours of the velocity in the X direction on the x=95, x=130 andx=165 surfaces.Display /Contours...(a) Disable the Global Range option.(b) Select Velocity... and X Velocity from the Contours of drop-down lists.(c) Select x=130, x=165, and x=95 from the Surfaces selection list, and deselecty=0.(d) Click Display and close the Contours panel.The velocity profile becomes more uniform as the fluid passes through the porousmedia. The velocity is very high at the center (the area in red) just before thenitrogen enters the substrate and then decreases as it passes through and exits thesubstrate. The area in green, which corresponds to a moderate velocity, increasesin extent.Figure 7.7: Contours of the X Velocity on the x=95,x=130, and x=165 Surfaces11. Use numerical reports to determine the average, minimum, and maximum of thevelocity distribution before and after the porous substrate.Report /Surface Integrals...(a) Select Mass-Weighted Average from the Report Type drop-down list.(b) Select Velocity and X Velocity from the Field Variable drop-down lists.(c) Select x=165 and x=95 from the Surfaces selection list.(d) Click Compute.(e) Select Facet Minimum from the Report Type drop-down list and click Computeagain.(f) Select Facet Maximum from the Report Type drop-down list and click Computeagain.(g) Close the Surface Integrals panel.The numerical report of average, maximum and minimum velocity can be seen inthe main FLUENT console, as shown in the following example:The spread between the average, maximum, and minimum values for X velocitygives the degree to which the velocity distribution isnon-uniform. You can also usethese numbers to calculate the velocity ratio (i.e., the maximum velocity divided bythe mean velocity) and the space velocity (i.e., the product of the mean velocity andthe substrate length).Custom field functions and UDFs can be also used to calculate more complex measuresof non-uniformity, such as the standard deviation and the gamma uniformityindex.SummaryIn this tutorial, you learned how to set up and solve a problem involving gas flow throughporous media in FLUENT. You also learned how to perform appropriate post-processingto investigate the flow field, determine the pressure drop across the porous media andnon-uniformity of the velocity distribution as the fluid goes through the porous media.Further ImprovementsThis tutorial guides you through the steps to reach an initial solution. You may be ableto obtain a more accurate solution by using an appropriate higher-order discretizationscheme and by adapting the grid. Grid adaption can also ensure that the solution isindependent of the grid. These steps are demonstrated in Tutorial 1.。

fluent中多孔介质设置问题和算例

经过痛苦的一段经历,终于将局部问题真相大白,为了使保位同仁不再经过我之痛苦,现在将本人多孔介质经验公布如下,希望各位能加精:1。

Gambit中划分网格之后,定义需要做为多孔介质的区域为fl uid,与缺省的fl uid分别开来,再定义其名称,我习惯将名称定义为po rous;2。

在fluen t中定义边界条件de fine-bounda ry condit ion-porous(刚定义的名称),将其设置边界条件为fl uid,点击set按钮即弹出与f luid边界条件一样的对话框,选中poro us zone 与l a mina r复选框,再点击por ous zone标签即出现一个带有滚动条的界面;3。

porous zone设置方法:1)定义矢量:二维定义一个矢量,第二个矢量方向不用定义,是与第一个矢量方向正交的;三维定义二个矢量,第三个矢量方向不用定义,是与第一、二个矢量方向正交的;(如何知道矢量的方向:打开grid图,看看X,Y,Z的方向,如果是X向,矢量为1,0,0,同理Y向为0,1,0,Z向为0,0,1,如果所需要的方向与坐标轴正向相反,则定义矢量为负)圆锥坐标与球坐标请参考f luen t帮助。

2)定义粘性阻力1/a与内部阻力C2:请参看本人上一篇博文“终于搞清fl uent中多孔粘性阻力与内部阻力的计算方法”,此处不赘述;3)如果了定义粘性阻力1/a与内部阻力C2,就不用定义C1与C0,因为这是两种不同的定义方法,C1与C0只在幂率模型中出现,该处保持默认就行了;4)定义孔隙率p o rous ity,默认值1表示全开放,此值按实验测值填写即可。

完了,其他设置与普通k-e或RSM相同。

总结一下,与君共享!Tutori al 7. Modeli ng Flow Throug h Porous MediaIntrod uctio nMany indust rialapplic ation s involv e the modeli ng of flow throug h porous media, such as filters, cataly st beds, and packin g. This tutori al illust rates how to set up and solvea proble m involv ing gas flow throug h porous media.The indust rialproble m solved here involv es gas flow throug h a cataly tic conver ter. Cataly tic conver tersare common ly used to purify emissi ons from gasoli ne and diesel engine s by conver tingenviro nment allyhazard ous exhaus t emissi ons to accept ablesubsta nces.Exampl es of such emissi ons includ e carbon monoxi de (CO), nitrog en oxides (NOx), and unburn ed hydroc arbon fuels. Theseexhaus t gas emissi ons are forced throug h a substr ate, whichis a cerami c struct ure coated with a metalcataly st such as platin um or pallad ium.The nature of the exhaus t gas flow is a very import ant factor in determ ining the perfor mance of the cataly tic conver ter. Of partic ularimport anceis the pressu re gradie nt and veloci ty distri butio n throug h the substr ate. HenceCFD analys is is used to design effici ent cataly tic conver ters: by modeli ng the exhaus t gas flow, the pressu re drop and the unifor mityof flow throug h the substr ate can be determ ined. In this tutori al, FLUENT is used to modelthe flow of nitrog en gas throug h a cataly tic conver ter geomet ry, so that the flow field struct ure may be analyz ed.This tutori al demons trate s how to do the follow ing:_ Set up a porous zone for the substr ate with approp riate resist ances._ Calcul ate a soluti on for gas flow throug h the cataly tic conver ter usingthe pressu re basedsolver. _ Plot pressu re and veloci ty distri butio n on specif ied planes of the geomet ry._ Determ ine the pressu re drop throug h the substr ate and the degree of non-unifor mityof flow throug h crosssectio ns of the geomet ry usingX-Y plotsand numeri cal report s.Proble m Descri ptionThe cataly tic conver ter modele d here is shownin Figure 7.1. The nitrog en flowsin throug h the inletwith a unifor m veloci ty of 22.6 m/s, passes throug h a cerami c monoli th substr ate with square shaped channe ls, and then exitsthroug h the outlet.Whilethe flow in the inletand outlet sectio ns is turbul ent, the flow throug h the substr ate is lamina r and is charac teriz ed by inerti al and viscou s loss coeffi cient s in the flow (X) direct ion. The substr ate is imperm eable in otherdirect ions, whichis modele d usingloss coeffi cients whosevalues are threeorders of magnit ude higher than in the X direct ion.Setupand Soluti onStep 1: Grid1. Read the mesh file (cataly tic conver ter.msh).File /Read /Case...2. Checkthe grid. Grid /CheckFLUENT will perfor m variou s checks on the mesh and report the progre ss in the consol e. Make sure that the minimu m volume report ed is a positi ve number.3. Scalethe grid.Grid! Scale...(a) Select mm from the Grid Was Create d In drop-down list.(b) Clickthe Change Length Unitsbutton. All dimens ionswill now be shownin millim eters.(c) ClickScaleand closethe ScaleGrid panel.4. Displa y the mesh. Displa y /Grid...(a) Make sure that inlet, outlet, substr ate-wall, and wall are select ed in the Surfac es select ion list.(b) ClickDispla y.(c) Rotate the view and zoom in to get the displa y shownin Figure 7.2.(d) Closethe Grid Displa y panel.The hex mesh on the geomet ry contai ns a totalof 34,580 cells.Step 2: Models1. Retain the defaul t solver settin gs. Define /Models /Solver...2. Select the standa rd k-ε turbul encemodel.Define/ Models /Viscou s...Step 3: Materi als1. Add nitrog en to the list of fluid materi als by copyin g it from the Fluent Databa se for materi als. Define /Materi als...(a) Clickthe Fluent Databa se... button to open the Fluent Databa se Materi als panel.i. Select nitrog en (n2) from the list of Fluent FluidMateri als.ii. ClickCopy to copy the inform ation for nitrog en to your list of fluid materi als. iii. Closethe Fluent Databa se Materi als panel.(b) Closethe Materi als panel.Step 4: Bounda ry Condit ions.Define /Bounda ry Condit ions...1. Set the bounda ry condit ionsfor the fluid(fluid).(a) Select nitrog en from the Materi al Name drop-down list.(b) ClickOK to closethe Fluidpanel.2. Set the bounda ry condit ionsfor the substr ate (substr ate).(a) Select nitrog en from the Materi al Name drop-down list.(b) Enable the Porous Zone option to activa te the porous zone model.(c) Enable the Lamina r Zone option to solvethe flow in the porous zone withou t turbul ence.(d) Clickthe Porous Zone tab.i. Make sure that the princi pal direct ion vector s are set as shownin Table7.1. Use the scroll bar to access the fields that are not initia lly visibl e in the panel.ii. Enterthe values in Table7.2 for the Viscou s Resist anceand Inerti al Resist ance. Scroll down to access the fields that are not initia lly visibl e in the panel.(e) ClickOK to closethe Fluidpanel.3. Set the veloci ty and turbul encebounda ry condit ionsat the inlet(inlet).(a) Enter22.6 m/s for the Veloci ty Magnit ude.(b) Select Intens ity and Hydrau lic Diamet er from the Specif ication Method dropdo wn list in the Turbul encegroupbox.(c) Retain the defaul t valueof 10% for the Turbul ent Intens ity.(d) Enter42 mm for the Hydrau lic Diamet er.(e) ClickOK to closethe Veloci ty Inletpanel.4. Set the bounda ry condit ionsat the outlet (outlet).(a) Retain the defaul t settin g of 0 for GaugePressu re.(b) Select Intens ity and Hydrau lic Diamet er from the Specif ication Method dropdo wn list in the Turbul encegroupbox.(c) Enter5% for the Backfl ow Turbul ent Intens ity.(d) Enter42 mm for the Backfl ow Hydrau lic Diamet er.(e) ClickOK to closethe Pressu re Outlet panel.5. Retain the defaul t bounda ry condit ionsfor the walls(substr ate-wall and wall) and closethe Bounda ry Condit ionspanel.Step 5: Soluti on1. Set the soluti on parame ters.Solve/Contro ls /Soluti on...(a) Retain the defaul t settin gs for Under-Relaxa tionFactor s.(b) Select Second OrderUpwind from the Moment um drop-down list in the Discre tizat ion groupbox.(c) ClickOK to closethe Soluti on Contro ls panel.2. Enable the plotti ng of residu als during the calcul ation. Solve/Monito rs /Residu al...(a) Enable Plot in the Option s groupbox.(b) ClickOK to closethe Residu al Monito rs panel.3. Enable the plotti ng of the mass flow rate at the outlet.Solve/ Monito rs /Surfac e...(a) Set the Surfac e Monito rs to 1.(b) Enable the Plot and Writeoption s for monito r-1, and clickthe Define... button to open the Define Surfac e Monito r panel.i. Select Mass Flow Rate from the Report Type drop-down list.ii. Select outlet from the Surfac es select ion list.iii. ClickOK to closethe Define Surfac e Monito rs panel.(c) ClickOK to closethe Surfac e Monito rs panel.4. Initia lizethe soluti on from the inlet.Solve/Initia lize/Initia lize...(a) Select inletfrom the Comput e From drop-down list.(b) ClickInit and closethe Soluti on Initia lizat ion panel.5. Save the case file (cataly tic conver ter.cas). File /Write/Case...6. Run the calcul ation by reques ting100 iterat ions.Solve/Iterat e...(a) Enter100 for the Number of Iterat ions.(b) ClickIterat e.The FLUENT calcul ation will conver ge in approx imate ly 70 iterat ions. By this pointthe mass flow rate monito r has attend ed out, as seen in Figure 7.3.(c) Closethe Iterat e panel.7. Save the case and data files(cataly tic conver ter.cas and cataly tic conver ter.dat).File /Write/Case & Data...Note: If you choose a file name that alread y exists in the curren t folder, FLUENTwill prompt you for confir matio n to overwr ite the file.Step 6: Post-proces sing1. Create a surfac e passin g throug h the center linefor post-proces singpurpos es.Surfac e/Iso-Surfac e...(a) Select Grid... and Y-Coordi natefrom the Surfac e of Consta nt drop-down lists.(b) ClickComput e to calcul ate the Min and Max values.(c) Retain the defaul t valueof 0 for the Iso-Values.(d) Entery=0 for the New Surfac e Name.(e) ClickCreate.2. Create cross-sectio nal surfac es at locati ons on either side of the substr ate, as well as at its center.Surfac e /Iso-Surfac e...(a) Select Grid... and X-Coordi natefrom the Surfac e of Consta nt drop-down lists.(b) ClickComput e to calcul ate the Min and Max values.(c) Enter95 for Iso-Values.(d) Enterx=95 for the New Surfac e Name.(e) ClickCreate.(f) In a simila r manner, create surfac es namedx=130 and x=165 with Iso-Values of 130 and 165, respec tivel y. Closethe Iso-Surfac e panelafterall the surfac es have been create d.3. Create a line surfac e for the center lineof the porous media.Surfac e /Line/Rake...(a) Enterthe coordi nates of the line underEnd Points, usingthe starti ng coordi nateof (95, 0, 0) and an ending coordi nateof (165, 0, 0), as shown.(b) Enterporous-cl for the New Surfac e Name.(c) ClickCreate to create the surfac e.(d) Closethe Line/Rake Surfac e panel.4. Displa y the two wall zones(substr ate-wall and wall). Displa y /Grid...(a) Disabl e the Edgesoption.(b) Enable the Facesoption.(c) Desele ct inletand outlet in the list underSurfac es, and make sure that only substr ate-wall and wall are select ed.(d) ClickDispla y and closethe Grid Displa y panel.(e) Rotate the view and zoom so that the displa y is simila r to Figure 7.2.5. Set the lighti ng for the displa y. Displa y /Option s...(a) Enable the Lights On option in the Lighti ng Attrib utesgroupbox.(b) Retain the defaul t select ion of Gouran d in the Lighti ng drop-down list.(c) ClickApplyand closethe Displa y Option s panel.6. Set the transp arenc y parame ter for the wall zones(substr ate-wall and wall).Displa y/Scene...(a) Select substr ate-wall and wall in the Namesselect ion list.(b) Clickthe Displa y... button underGeomet ry Attrib utesto open the Displa y Proper tiespanel.i. Set the Transp arenc y slider to 70.ii. ClickApplyand closethe Displa y Proper tiespanel.(c) ClickApplyand then closethe SceneDescri ption panel.7. Displa y veloci ty vector s on the y=0 surfac e.Displa y /Vector s...(a) Enable the Draw Grid option. The Grid Displa y panelwill open.i. Make sure that substr ate-wall and wall are select ed in the list underSurfac es.ii. ClickDispla y and closethe Displa y Grid panel.(b) Enter5 for the Scale.(c) Set Skip to 1.(d) Select y=0 from the Surfac es select ion list.(e) ClickDispla y and closethe Vector s panel.The flow patter n showsthat the flow enters the cataly tic conver ter as a jet, with recirc ulati on on either side of the jet. As it passes throug h the porous substr ate, it decele rates and straig htens out, and exhibi ts a more unifor m veloci ty distri butio n.This allows the metalcataly st presen t in the substr ate to be more effect ive.Figure 7.4: Veloci ty Vector s on the y=0 Plane8. Displa y filled contou rs of static pressu re on the y=0 plane.Displa y /Contou rs...(a) Enable the Filled option.(b) Enable the Draw Grid option to open the Displa y Grid panel.i. Make sure that substr ate-wall and wall are select ed in the list underSurfac es.ii. ClickDispla y and closethe Displa y Grid panel.(c) Make sure that Pressu re... and Static Pressu re are select ed from the Contou rs of drop-down lists.(d) Select y=0 from the Surfac es select ion list.(e) ClickDispla y and closethe Contou rs panel.Figure 7.5: Contou rs of the Static Pressu re on the y=0 planeThe pressu re change s rapidl y in the middle sectio n, wherethe fluid veloci ty change s as it passes throug h the porous substr ate. The pressu re drop can be high, due to the inerti al and viscou s resist anceof the porous media. Determ ining this pressu re drop is a goal of CFD analys is. In the next step, you will learnhow to plot the pressu re drop alongthe center lineof the substr ate.9. Plot the static pressu re across the line surfac e porous-cl.Plot /XY Plot...(a) Make sure that the Pressu re... and Static Pressu re are select ed from the Y Axis Functi on drop-down lists.(b) Select porous-cl from the Surfac es select ion list.(c) ClickPlot and closethe Soluti on XY Plot panel.Figure 7.6: Plot of the Static Pressu re on the porous-cl Line Surfac eIn Figure 7.6, the pressu re drop across the porous substr ate can be seen to be roughl y 300 Pa.10. Displa y filled contou rs of the veloci ty in the X direct ion on the x=95, x=130 and x=165 surfac es.Displa y /Contou rs...(a) Disabl e the Global Rangeoption.(b) Select Veloci ty... and X Veloci ty from the Contou rs of drop-down lists.(c) Select x=130, x=165, and x=95 from the Surfac es select ion list, and desele ct y=0.(d) ClickDispla y and closethe Contou rs panel.The veloci ty profil e become s more unifor m as the fluid passes throug h the porous media. The veloci ty is very high at the center (the area in red) just before the nitrog en enters the substr ate and then decrea ses as it passes throug h and exitsthe substr ate. The area in green, whichcorres ponds to a modera te veloci ty, increa ses in extent.Figure 7.7: Contou rs of the X Veloci ty on the x=95, x=130, and x=165 Surfac es11. Use numeri cal report s to determ ine the averag e, minimu m, and maximu m of the veloci tydistri butio n before and afterthe porous substr ate.Report /Surfac e Integr als...(a) Select Mass-Weight ed Averag e from the Report Type drop-down list.(b) Select Veloci ty and X Veloci ty from the FieldVariab le drop-down lists.(c) Select x=165 and x=95 from the Surfac es select ion list.(d) ClickComput e.(e) Select FacetMinimu m from the Report Type drop-down list and clickComput e again.(f) Select FacetMaximu m from the Report Type drop-down list and clickComput e again.(g) Closethe Surfac e Integr als panel.The numeri cal report of averag e, maximu m and minimu m veloci ty can be seen in the main FLUENT consol e, as shownin the follow ing exampl e:The spread betwee n the averag e, maximu m, and minimu m values for X veloci ty givesthe degree to whichthe veloci ty distri butio n is non-unifor m. You can also use thesenumber s to calcul ate the veloci ty ratio(i.e., the maximu m veloci ty divide d by the mean veloci ty) and the spaceveloci ty (i.e., the produc t of the mean veloci ty and the substr ate length).Custom field functi ons and UDFs can be also used to calcul ate more comple x measur es ofnon-unifor mity, such as the standa rd deviat ion and the gammaunifor mityindex.Summar yIn this tutori al, you learne d how to set up and solvea proble m involv ing gas flow throug h porous mediain FLUENT. You also learne d how to perfor m approp riate post-proces singto invest igate the flow field, determ ine the pressu re drop across the porous mediaand non-unifor mityof the veloci ty distri butio n as the fluid goes throug h the porous media.Furthe r Improv ement sThis tutori al guides you throug h the stepsto reachan initia l soluti on. You may be able to obtain a more accura te soluti on by usingan approp riate higher-orderdiscre tizat ion scheme and by adapti ng the grid. Grid adapti on can also ensure that the soluti on is indepe ndent of the grid. Thesestepsare demons trate d in Tutori al 1.。

FLUENT多孔介质数值模拟设置

FLUENT多孔介质数值模拟设置多孔介质条件多孔介质模型可以应用于很多问题,如通过充满介质的流动、通过过滤纸、穿孔圆盘、流量分配器以及管道堆的流动。

当你使用这一模型时,你就定义了一个具有多孔介质的单元区域,而且流动的压力损失由多孔介质的动量方程中所输入的内容来决定。

通过介质的热传导问题也可以得到描述,它服从介质和流体流动之间的热平衡假设,具体内容可以参考多孔介质中能量方程的处理一节。

多孔介质的一维化简模型,被称为多孔跳跃,可用于模拟具有已知速度/压降特征的薄膜。

多孔跳跃模型应用于表面区域而不是单元区域,并且在尽可能的情况下被使用(而不是完全的多孔介质模型),这是因为它具有更好的鲁棒性,并具有更好的收敛性。

详细内容请参阅多孔跳跃边界条件。

多孔介质模型的限制如下面各节所述,多孔介质模型结合模型区域所具有的阻力的经验公式被定义为“多孔”。

事实上多孔介质不过是在动量方程中具有了附加的动量损失而已。

因此,下面模型的限制就可以很容易的理解了。

流体通过介质时不会加速,因为事实上出现的体积的阻塞并没有在模型中出现。

这对于过渡流是有很大的影响的,因为它意味着FLUENT不会正确的描述通过介质的过渡时间。

多孔介质对于湍流的影响只是近似的。

详细内容可以参阅湍流多孔介质的处理一节。

多孔介质的动量方程多孔介质的动量方程具有附加的动量源项。

源项由两部分组成,一部分是粘性损失项 (Darcy),另一个是内部损失项:其中S_i是i向(x, y, or z)动量源项,D和C是规定的矩阵。

在多孔介质单元中,动量损失对于压力梯度有贡献,压降和流体速度(或速度方阵)成比例。

对于简单的均匀多孔介质:其中a是渗透性,C_2时内部阻力因子,简单的指定D和C分别为对角阵1/a 和C_2其它项为零。

FLUENT还允许模拟的源项为速度的幂率:其中C_0和C_1为自定义经验系数。

注意:在幂律模型中,压降是各向同性的,C_0的单位为国际标准单位。

多孔介质的Darcy定律通过多孔介质的层流流动中,压降和速度成比例,常数C_2可以考虑为零。

fluent多孔介质模型

div u div grad S t

运动方程:

Dv Fb p f Dt

惯性力 品质力 表面力

多孔介质模拟方法是将流动区域中固体结构的 作用看作是附加在流体上的分布阻力。

4

多孔介质的源项

多孔介质的作用是在动量方程中增加一个源项来模拟,源项由两 部分组成:一个粘性损失项和一个惯性损失项。

采用上表的数据可以拟合出一条“速度-压强降”曲线,其方程 为:

对比上述两式便可求出粘性阻力系数和惯性阻力系数。

13

实例计算

进 口

Porous one WALL symmetr y 出 口

Porous Porous three two

上图中的计算区域尺寸如下: 总的计算域:长1m,宽0.1m; Porous two:长0.57m,宽0.02m; (处于正中间) Porous one:宽0.03m,高0.06m; Porous three:宽0.03m,高0.06m; 边界条件如上图中所示,进口取velocity inlet,速 度为0.01m/s;出口取pressure outlet,压力值为大气压。 三个多孔介质区中,porous one和porous three的性质一 样。Porous two的粘性阻力系数为1e+10,其余多孔介质区 为1e+13.由于是低速层流流动,不考虑惯性阻力的影响。

△Py, △Pz分别是x,y,z三个方向的压力降。△nx, 别是多孔介质在x,y,z三个方向的真实厚度。

△Px,

△ny,△ Nhomakorabean z分

7

能量方程的处理

能量方程:

多孔介质对能量方程修正:

FLUENT多孔介质数值模拟设置

FLUENT多孔介质数值模拟设置C=对于不同D/t的不同雷诺数范围被列成不同的表的系数A_p=圆盘的面积(固体和洞)如果你选择在多孔介质中模拟热传导,你必须指定多孔介质中的材料以及多孔性。

要定义多孔介质的材料,向下拉流体面板中阻力输入底下的滚动条,然后在多孔热传导的固体材料下拉列表中选中适当的固体。

另一个处理收敛性差的要领是临时取消多孔介质模型(在流体面板中关闭多孔区域)然后获取一个不受多孔区域影响的初始流场。

取消多孔区域后,FLUENT会将多孔区域处理为流体区域并按响应的流体区域来计算。

一旦获取了初始解,或者计算很容易收敛,你就可以激活多孔模型继续计算包罗多孔区域的流场(对于大阻力多孔介质不保举使用该要领)。

这些变量会在后处理面板的变量选择下拉菜谱制定类别中出现。

然后在多孔热传导下设定多孔性。

多孔性f是多孔介质中流体的体积分数(即介质的开放体积分数)。

多孔性用于介质中的热传导预测,处理要领请参阅多孔介质能量方程的处理一节。

它还对介质中的反应源项和体力的计算有影响。

这个源项和介质中流体的体积成比例。

如果你想要模拟完全开放的介质(固体介质没有影响),你应该设定多孔性为1.0。

当多孔性为1.0时,介质的固体部门对于热传导和(或)热源项/反应源项没有影响。

注意:多孔性永远不会影响介质中的流体速率,这已经在多孔介质的动量方程一节中介绍了。

不管你将多孔性设定为何值,,FLUENT所预测的速率都是介质中的外貌速率。

对于多孔介质动量源项(多孔介质动量方程中的方程5),如果你使用幂律模型近似,你只要在流体面板的幂律模型中输入系数C_0和C_1就可以了。

如果C_0或C_1为非零值,解算器会忽略面板中除了多孔介质幂律模型之外的所有输入。

定义源项一般说来,在模拟多孔介质时,你可以使用标准的解算步骤以及解参数的设置。

然而你会发现如果多孔区域在流动方向上压降至关大(比如:渗透性a很低或者内部因数C_2很大)的话,解的收敛速率就会变慢。

fluent中多孔介质设置问题

经过痛苦的一段经历,终于将局部问题真相大白,为了使保位同仁不再经过我之痛苦,现在将本人多孔介质经验公布如下,希望各位能加精:1。

Gambit中划分网格之后,定义需要做为多孔介质的区域为fluid,与缺省的fluid分别开来,再定义其名称,我习惯将名称定义为porous;2。

在fluent中定义边界条件define-boundary condition-porous(刚定义的名称),将其设置边界条件为fluid,点击set按钮即弹出与fluid边界条件一样的对话框,选中porous zone与laminar复选框,再点击porous zone标签即出现一个带有滚动条的界面;3。

porous zone设置方法:1)定义矢量:二维定义一个矢量,第二个矢量方向不用定义,是与第一个矢量方向正交的;三维定义二个矢量,第三个矢量方向不用定义,是与第一、二个矢量方向正交的;(如何知道矢量的方向:打开grid图,看看X,Y,Z的方向,如果是X向,矢量为1,0,0,同理Y向为0,1,0,Z向为0,0,1,如果所需要的方向与坐标轴正向相反,则定义矢量为负)圆锥坐标与球坐标请参考fluent帮助。

2)定义粘性阻力1/a与内部阻力C2:请参看本人上一篇博文“终于搞清fluent中多孔粘性阻力与内部阻力的计算方法”,此处不赘述;3)如果了定义粘性阻力1/a与内部阻力C2,就不用定义C1与C0,因为这是两种不同的定义方法,C1与C0只在幂率模型中出现,该处保持默认就行了;4)定义孔隙率porousity,默认值1表示全开放,此值按实验测值填写即可。

完了,其他设置与普通k-e或RSM相同。

总结一下,与君共享!终于搞清fluent中多孔粘性阻力与内部阻力的计算方法Experimental data that is available in the form of pressure drop against velocity through the porous component, can be extrapolated to determine the coecients for the porous media. To e ect a pressure drop across a porous medium of thickness, n, the coecients of the porous media are determined in the manner described below.If the experimental data is:Velocity P ressure Drop(m/s) (Pa)20.0 78.050.0 487.080.0 1432.0110.0 2964.0。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

FLUENT多孔介质数值模拟设置多孔介质条件多孔介质模型可以应用于很多问题,如通过充满介质的流动、通过过滤纸、穿孔圆盘、流量分配器以及管道堆的流动。

当你使用这一模型时,你就定义了一个具有多孔介质的单元区域,而且流动的压力损失由多孔介质的动量方程中所输入的内容来决定。

通过介质的热传导问题也可以得到描述,它服从介质和流体流动之间的热平衡假设,具体内容可以参考多孔介质中能量方程的处理一节。

多孔介质的一维化简模型,被称为多孔跳跃,可用于模拟具有已知速度/压降特征的薄膜。

多孔跳跃模型应用于表面区域而不是单元区域,并且在尽可能的情况下被使用(而不是完全的多孔介质模型),这是因为它具有更好的鲁棒性,并具有更好的收敛性。

详细内容请参阅多孔跳跃边界条件。

多孔介质模型的限制如下面各节所述,多孔介质模型结合模型区域所具有的阻力的经验公式被定义为“多孔”。

事实上多孔介质不过是在动量方程中具有了附加的动量损失而已。

因此,下面模型的限制就可以很容易的理解了。

流体通过介质时不会加速,因为事实上出现的体积的阻塞并没有在模型中出现。

这对于过渡流是有很大的影响的,因为它意味着FLUENT不会正确的描述通过介质的过渡时间。

多孔介质对于湍流的影响只是近似的。

详细内容可以参阅湍流多孔介质的处理一节。

多孔介质的动量方程多孔介质的动量方程具有附加的动量源项。

源项由两部分组成,一部分是粘性损失项 (Darcy),另一个是内部损失项:其中S_i是i向(x, y, or z)动量源项,D和C是规定的矩阵。

在多孔介质单元中,动量损失对于压力梯度有贡献,压降和流体速度(或速度方阵)成比例。

对于简单的均匀多孔介质:其中a是渗透性,C_2时内部阻力因子,简单的指定D和C分别为对角阵1/a 和C_2其它项为零。

FLUENT还允许模拟的源项为速度的幂率:其中C_0和C_1为自定义经验系数。

注意:在幂律模型中,压降是各向同性的,C_0的单位为国际标准单位。

多孔介质的Darcy定律通过多孔介质的层流流动中,压降和速度成比例,常数C_2可以考虑为零。

忽略对流加速以及扩散,多孔介质模型简化为Darcy定律:在多孔介质区域三个坐标方向的压降为:其中为多孔介质动量方程1中矩阵D的元素v为三个方向上的分速度,Djn_x、 D n_y、以及D n_z为三个方向上的介质厚度。

在这里介质厚度其实就是模型区域内的多孔区域的厚度。

因此如果模型的厚度和实际厚度不同,你必须调节1/a_ij的输入。

.多孔介质的内部损失在高速流动中,多孔介质动量方程1中的常数C_2提供了多孔介质内部损失的矫正。

这一常数可以看成沿着流动方向每一单位长度的损失系数,因此允许压降指定为动压头的函数。

如果你模拟的是穿孔板或者管道堆,有时你可以消除渗透项而只是用内部损失项,从而得到下面的多孔介质简化方程:写成坐标形式为:多孔介质中能量方程的处理对于多孔介质流动,FLUENT仍然解标准能量输运方程,只是修改了传导流量和过度项。

在多孔介质中,传导流量使用有效传导系数,过渡项包括了介质固体区域的热惯量:其中:h_f=流体的焓h_s=固体介质的焓f=介质的多孔性k_eff=介质的有效热传导系数S^h_f=流体焓的源项S^h_s=固体焓的源项多孔介质的有效传导率多孔区域的有效热传导率k_eff是由流体的热传导率和固体的热传导率的体积平均值计算得到:其中:f=介质的多孔性k_f=流体状态热传导率(包括湍流的贡献k_t)k_s=固体介质热传导率如果得不到简单的体积平均,可能是因为介质几何外形的影响。

有效传导率可以用自定义函数来计算。

然而,在所有的算例中,有效传导率被看成介质的各向同性性质。

多孔介质中的湍流处理在多孔介质中,默认的情况下FLUENT会解湍流量的标准守恒防城。

因此,在这种默认的方法中,介质中的湍流被这样处理:固体介质对湍流的生成和耗散速度没有影响。

如果介质的渗透性足够大,而且介质的几何尺度和湍流涡的尺度没有相互作用,这样的假设是合情合理的。

但是在其它的一些例子中,你会压制了介质中湍流的影响。

如果你使用k-e模型或者Spalart-Allmaras模型,你如果设定湍流对粘性的贡献m_t为零,你可能会压制了湍流对介质的影响。

当你选择这一选项时,FLUENT会将入口湍流的性质传输到介质中,但是它对流动混合和动量的影响被忽略了。

除此之外,在介质中湍流的生成也被设定为零。

要实现这一解策略,请在流体面板中打开层流选项。

激活这个选项就意味着多孔介质中的m_t为零,湍流的生成也为零。

如果去掉该选项(默认)则意味着多孔介质中的湍流会像大体积流体流动一样被计算。

概述模拟多孔介质流动时,对于问题设定需要的附加输入如下:1. 定义多孔区域2. 确定流过多孔区域的流体材料3. 设定粘性系数(多孔介质动量方程3中的1/a_ij)以及内部阻力系数(多孔介质动量方程3中的C_2_ij),并定义应用它们的方向矢量。

幂率模型的系数也可以选择指定。

4. 定义多孔介质包含的材料属性和多孔性5. 设定多孔区域的固体部分的体积热生成速度(或任何其它源项,如质量、动量)(此项可选)。

6. 如果合适的话,限制多孔区域的湍流粘性。

7. 如果相关的话,指定旋转轴和/或区域运动。

在定义粘性和内部阻力系数中描述了决定阻力系数和/或渗透性的方法。

如果你使用多孔动量源项的幂律近似,你需要输入多孔介质动量方程5中的C_0和C_1来取代阻力系数和流动方向。

在流体面板中(下图)你需要设定多孔介质的所有参数,该面板是从边界条件菜单中打开的(详细内容请参阅边界条件的设定一节)Figure 1:多孔区域的流体面板定义多孔区域正如定义边界条件概述中所提到的,多孔区域是作为特定类型的流体区域来模拟的。

亚表明流体区域是多孔区域,请在流体面板中激活多孔区域选项。

面板会自动扩展到多孔介质输入状态。

定义穿越多孔介质的流体在材料名字下拉菜单中选择适当的流体就可以定义通过多孔介质的流体了。

如果你模拟组分输运或者多相流,流体面板中就不会出现材料名字下拉菜单了。

对于组分计算,所有流体和/或多孔区域的混合材料就是你在组分模型面板中指定的材料。

对于多相流模型,所有流体和/或多孔区域的混合材料就是你在多相流模型面板中指定的材料。

定义粘性和内部阻力系数粘性和内部阻力系数以相同的方式定义。

使用笛卡尔坐标系定义系数的基本方法是在二维问题中定义一个方向矢量,在三维问题中定义两个方向矢量,然后在每个方向上指定粘性和/或阻力系数。

在二维问题中第二个方向没有明确定义,它是垂直于指定的方向矢量和z向矢量所在的平面的。

在三维问题中,第三个方向矢量是垂直于所指定的两个方向矢量所在平面的。

对于三维问题,第二个方向矢量必须垂直于第一个方向矢量。

如果第二个方向矢量指定失败,解算器会确保它们垂直而忽略在第一个方向上的第二个矢量的任何分量。

所以你应该确保第一个方向指定正确。

在三维问题中也可能会使用圆锥(或圆柱)坐标系来定义系数,具体如下:定义阻力系数的过程如下:1. 定义方向矢量。

使用笛卡尔坐标系,简单指定方向1矢量,如果是三维问题,指定方向2矢量。

每一个方向都应该是从(0,0)或者(0,0,0)到指定的(X,Y)或(X,Y,Z)矢量。

(如果方向不正确请按上面的方法解决)对于有些问题,多孔介质的主轴和区域的坐标轴不在一条直线上,你不必知道多孔介质先前的方向矢量。

在这种情况下,三维中的平面工具或者二维中的线工具可以帮你确定这些方向矢量。

1. 捕捉"Snap"平面工具(或者线工具)到多孔区域的边界。

(请遵循使用面工具和线工具中的说明,它在已存在的表面上为工具初始化了位置)。

2. 适当的旋转坐标轴直到它们和多孔介质区域成一条线。

3. 当成一条线之后,在流体面板中点击从平面工具更新或者从线工具更新按钮。

FLUENT会自动将方向1矢量指向为工具的红(三维)或绿(二维)箭头所指的方向。

要使用圆锥坐标系(比方说环状、锥状顾虑单元),请遵循下面步骤(这一选项只用于三维问题):1. 打开圆锥选项2. 指定圆锥轴矢量和在锥轴上的点。

圆锥轴矢量的方向将会是从(0,0,0)到指定的(X,Y,Z)方向的矢量。

FLUENT将会使用圆锥轴上的点将阻力转换到笛卡尔坐标系。

3. 设定锥半角(锥轴和锥表面之间的角度,如下图),使用柱坐标系,锥半角为0.Figure 1:锥半角对于有些问题,锥形过滤单元的主轴和区域的坐标轴不在一条直线上,你不必知道锥轴先前的方向矢量以及锥轴上的点。

在这种情况下,三维中的平面工具或者二维中的线工具可以帮你确定这些方向矢量。

一种方法如下:1. 在点击捕捉到区域按钮之前,你可以在下拉菜单中选择垂直于锥轴矢量的轴过滤单元的边界区域。

2. 点击捕捉到区域按钮,FLUENT会自动将平面工具捕捉到边界。

它也会设定锥轴矢量和锥轴上的点(需注意的是你还要自己设定锥半角)。

另一种方法为:1. 捕捉"Snap"平面工具到多孔区域的边界。

(请遵循使用面工具和线工具中的说明,它在已存在的表面上为工具初始化了位置)。

2. 旋转和平移工具坐标轴,直到工具的红箭头指向锥的轴向。

工具的起点在轴上。

3. 当轴和工具的起点成一条线时,在流体面板中点击从平面工具更新按钮。

FLUENT会自动设定轴向矢量以及在轴上的点(注意:你还是要自己设定锥的半角)。

2. 在粘性阻力中指定每个方向的粘性阻力系数1/a,在内部阻力中指定每一个方向上的内部阻力系数C_2(你可能需要将滚动条向下滚动来查看这些输入)。

如果你使用锥指定方法,方向1为锥轴方向,方向2为垂直于锥表面(对于圆柱就是径向)方向,方向3圆周(q)方向。

在三维问题中可能有三种可能的系数,在二维问题中有两种:在各向同性算例中,所有方向上的阻力系数都是相等的(如海绵)。

在各向同性算例中你必须将每个方向上的阻力系数设定为相等。

在三维问题中只有两个方向上的系数相等,第三个方向上的阻力系数和前两个不等,或者在二维问题中两个方向上的系数不等,你必须准确的指定每一个方向上的系数。

例如,如果你得多孔区域是由具有小洞的细管组成,细管平行于流动方向,流动会很容易的通过细管,但是流动在其它两个方向上(通过小洞)会很小。

如果你有一个平的盘子垂直于流动方向,流动根本就不会穿过它而只在其它两个方向上。

在三维问题中还有一种可能就是三个系数各不相同。

例如,如果多孔区域是由不规则间隔的物体(如针脚)组成的平面,那么阻碍物之间的流动在每个方向上都不同。