飞秒激光器的应用

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

Industrial femtosecond lasers and material processing

01/22/2019

NORMAN HODGSON, MICHAEL LAHA, TONY S. LEE, ALBRECHT STEINKOPFF, and SEBASTIAN HEMING

Over the last five years, material processing with femtosecond pulses in the range of 300 to 900 fs has gained in popularity due to the small heat-affected zone (HAZ) and increased energy penetration depth resulting from the high laser pulse intensity. Industrial ultrashort-pulse (USP) diode-pumped solid-state and fiber lasers are now being used to cut foils for flat panel displays, to cut stents, and to drill fuel injector nozzles, as well as for wafer scribing and surface microstructuring.

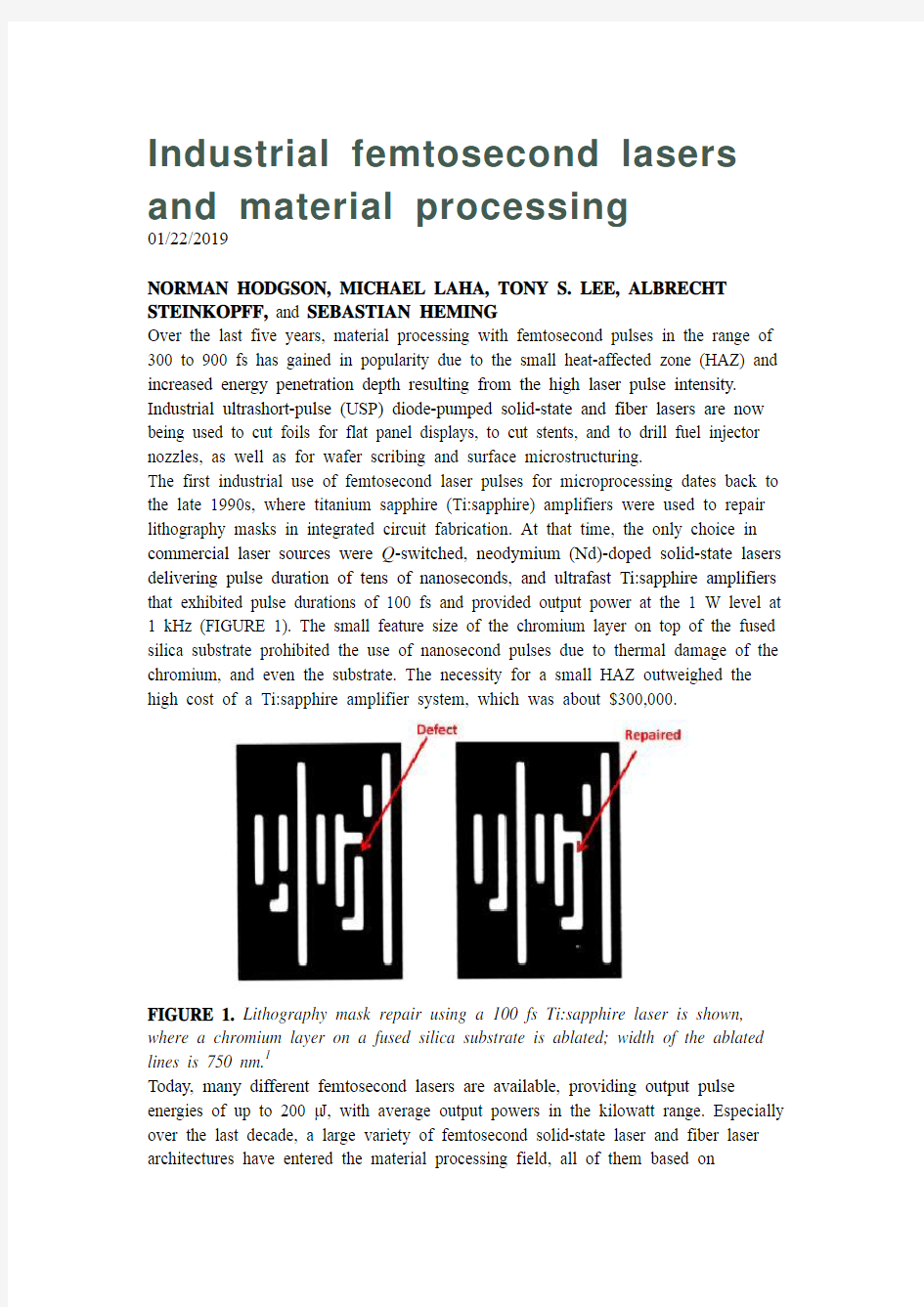

The first industrial use of femtosecond laser pulses for microprocessing dates back to the late 1990s, where titanium sapphire (Ti:sapphire) amplifiers were used to repair lithography masks in integrated circuit fabrication. At that time, the only choice in commercial laser sources were Q-switched, neodymium (Nd)-doped solid-state lasers delivering pulse duration of tens of nanoseconds, and ultrafast Ti:sapphire amplifiers that exhibited pulse durations of 100 fs and provided output power at the 1 W level at 1 kHz (FIGURE 1). The small feature size of the chromium layer on top of the fused silica substrate prohibited the use of nanosecond pulses due to thermal damage of the chromium, and even the substrate. The necessity for a small HAZ outweighed the high cost of a Ti:sapphire amplifier system, which was about $300,000.

FIGURE 1. Lithography mask repair using a 100 fs Ti:sapphire laser is shown, where a chromium layer on a fused silica substrate is ablated; width of the ablated lines is 750 nm.1

Today, many different femtosecond lasers are available, providing output pulse energies of up to 200 µJ, with average output powers in the kilowatt range. Especially over the last decade, a large variety of femtosecond solid-state laser and fiber laser architectures have entered the material processing field, all of them based on

ytterbium (Yb)-doped gain materials. Average output powers of up to 100 W are currently employed in industrial applications, with pulse durations between 300 and 900 fs and repetition rates of up to 2 MHz. Compared to the original Ti:sapphire amplifier systems, the output powers have increased by two orders of magnitude, while system cost has been considerably decreased at the same time.

A majority of the low-power lasers have been deployed in ophthalmic applications. In the 2000s, Nd:glass regenerative amplifiers were used to cut the corneal flap in LASIK surgery by generating a bubble plane inside the cornea. These Nd:glass systems were later replaced by Yb:fiber master-oscillator power-amplifiers (MOPAs), which allowed higher repetition rates at a lower cost (FIGURE 2). Typical pulse energies required for flap cutting are 2–4 µJ at repetition rates of 50 to 200 kHz and pulse durations of around 300 fs. A second, more recently emerging ophthalmic application is lens dissection as part of cataract surgery. In this case, the pulse energies employer are in the range of 20 to 40 µJ at repetition rates of 50 to 100 kHz, and pulse durations are preferably below 800 fs.

FIGURE 2.The evolution of the deployment of femtosecond lasers in microprocessing applications is shown; Ti:sapphire regenerative amplifiers for mask repair have been replaced by picosecond Nd:YVO4 lasers and Nd:glass regenerative amplifiers by femtosecond Yb fiber MOPAs.

According to a forecast by Strategies Unlimited in 2016, the total market in 2019 for femtosecond and picosecond lasers used for material processing (including ophthalmic applications) is projected to be $460 million (TABLE 1).2 Half of this revenue is generated by picosecond lasers, which have been widely used in microelectronic manufacturing. The other half is split between ophthalmic femtosecond lasers ($136 million) and femtosecond lasers for non-biological material processing ($98 million).