In-plane and out-of-plane unified constraint-dependent creep crack growth rate of 316H steel

In-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate of 316H

steel

H.S.Ma,G.Z.Wang ?,S.Liu,S.T.Tu,F.Z.Xuan

Key Laboratory of Pressure Systems and Safety,Ministry of Education,East China University of Science and Technology,Shanghai 200237,China

a r t i c l e i n f o Article history:

Received 24June 2015

Received in revised form 19October 2015Accepted 13January 2016

Available online 28January 2016Keywords:

In-plane creep constraint

Out-of-plane creep constraint Creep crack growth rate Specimen geometry Equivalent creep strain

a b s t r a c t

The uni?ed characterization parameter A c of in-plane and out-of-plane creep constraints along three-dimensional crack front in different specimen geometries has been analyzed.Based on the parameter A c and the experimental creep crack growth rate data of different specimen geometries in the literature,the in-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate equation of 316H steel has been obtained.The predicted creep crack growth rate by using the equation for each specimen agrees well with the experimental data.Based on the two-parameter C ?àA c concept,the equation may be used in creep crack growth life assessments incorporating in-plane and out-of-plane constraint effects.

ó2016Elsevier Ltd.All rights reserved.

1.Introduction

Under creep conditions,a lot of experimental and theoretical evidences have shown that the crack-tip constraint can affect creep crack growth (CCG)rate [1–11].The constraint includes in-plane and out-of-plane constraints.The in-plane con-straint is directly affected by crack depth,length of the un-cracked ligament and loading con?guration of specimens,while the out-of-plane constraint is affected by the specimen thickness.To accurately predict creep life and achieve structural integrity assessments for high temperature components,it is important to quantify the creep crack-tip constraint levels.The creep crack-tip stress and strain rate ?elds are often described by the C ?àQ two-parameter under plane strain or plane stress conditions and the Q was used to quantify the constraint [12–14].The effect of in-plane constraint on CCG has been examined by using Q parameter [13].Combined the C ?àQ two-parameter concept with the NSW model,Nikbin [3]inves-tigated the effect of constraint on the CCG rate.Based on the C ?àQ two-parameter concept and ?nite element analysis,Bet-tinson et al.[14]examined the effect of specimen type and load level on the Q from short to long term creep conditions for elastic-creep materials.Recently,Zhao et al.[8]quanti?ed the constraint effect induced by specimen geometry on creep crack growth behavior in P92steel by using the parameter Q .The two-parameter C (t )àT Z and the three-parameter C (t )àT Z àQ descriptions for crack-tip ?elds were proposed by Xiang et al.[15]and Xiang and Guo [16]for small and exten-sive creeping,respectively.The T Z is an out-of-plane constraint factor,and the in-plane constraint is characterized by the parameter Q .In the de?nition of the Q parameter above,the HRR stress ?eld is usually taken as the reference ?eld.

In the previous work of authors [17],it has been suggested that the HRR stress ?eld may not be suitable to be used as a reference ?eld for de?ning the constraint parameter under creep condition due to larger crack-tip blunting and creep damage.Based on the reference ?eld of the standard C(T)specimen in plane strain with deep crack (a/W =0.5)and high https://www.360docs.net/doc/ce16335152.html,/10.1016/j.engfracmech.2016.01.0170013-7944/ó2016Elsevier Ltd.All rights reserved.

?Corresponding author.Tel./fax:+862164252681.

E-mail address:gzwang@https://www.360docs.net/doc/ce16335152.html, (G.Z.Wang).

constraint,a constraint parameter R was proposed to characterize the creep crack-tip constraint,and the constraint effects induced by the crack depths [17,18],specimen thicknesses [19]and loading con?gurations [20]have been investigated in detail.For the convenience of application,a load-independent creep constraint parameter R ?has been de?ned by modifying the parameter R [21].Based on the parameter R ?,the characterization and correlation of two-dimensional and three-dimensional creep constraint between axially cracked pipelines and test specimens were studied [22,23],and the constraint-dependent CCG rate equations were established for Cr–Mo–V steel [21].

The creep constraint parameters described above only can quantify the in-plane or out-of-plane constraint separately,and they may not characterize both of them and overall level of constraints.In actual high-temperature components,there exist both in-plane and out-of-plane constraints.In order to describe their interaction and the overall level of constraints,a uni?ed creep constraint parameter which can characterize both in-plane and out-of-plane creep constraint together is

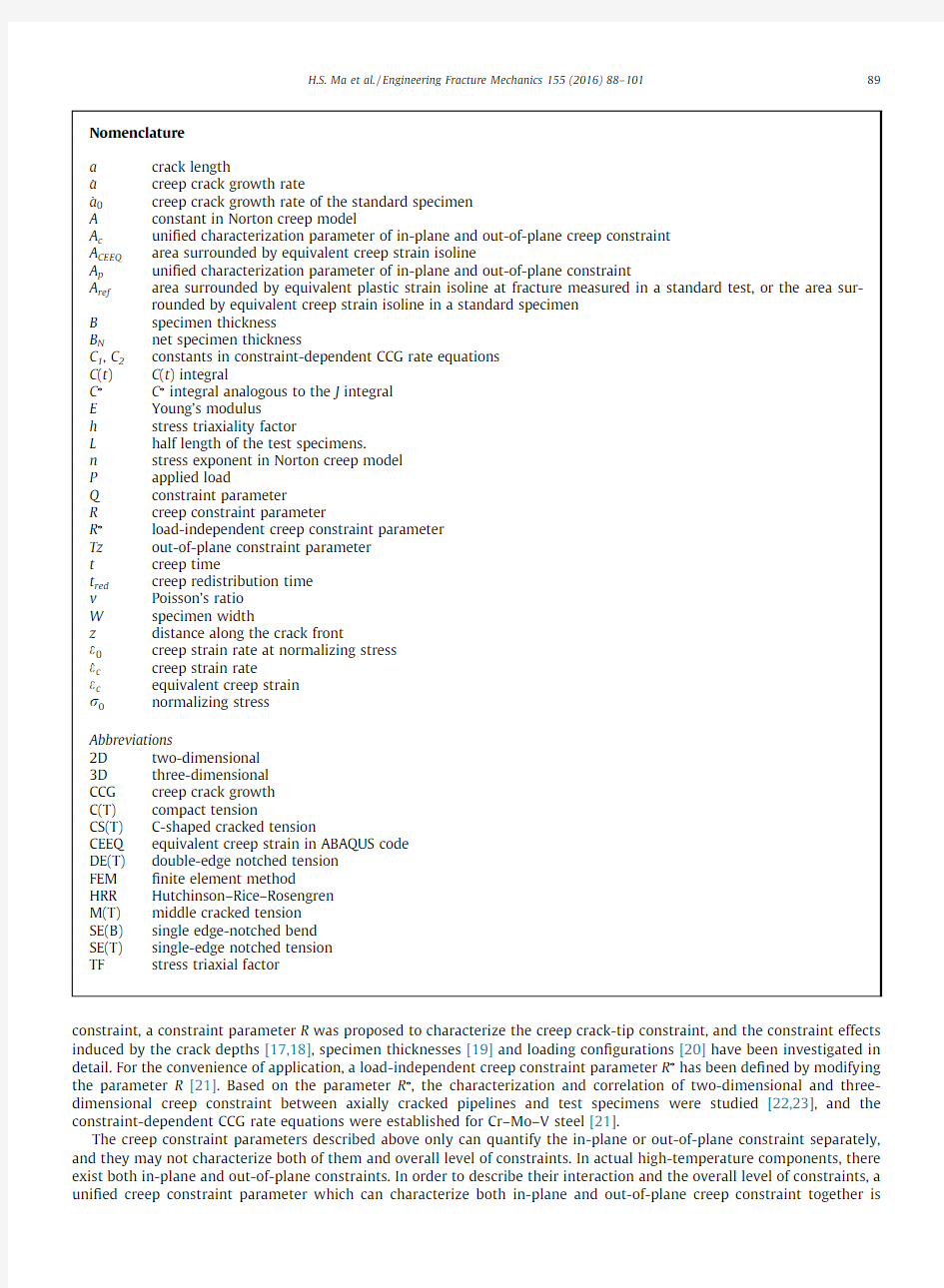

Nomenclature a crack length

_a creep crack growth rate

_a 0creep crack growth rate of the standard specimen A constant in Norton creep model

A c

uni?ed characterization parameter of in-plane and out-of-plane creep constraint A CEEQ area surrounded by equivalent creep strain isoline

A p uni?ed characterization parameter of in-plane and out-of-plane constraint

A ref area surrounded by equivalent plastic strain isoline at fracture measured in a standard test,or the area sur-rounded by equivalent creep strain isoline in a standard specimen

B specimen thickness B N

net specimen thickness

C 1,C 2constants in constraint-dependent CCG rate equations C (t )C (t )integral

C ?C ?integral analogous to the J integral E Young’s modulus

h stress triaxiality factor

L half length of the test specimens.

n stress exponent in Norton creep model P applied load

Q constraint parameter

R creep constraint parameter

R ?load-independent creep constraint parameter Tz out-of-plane constraint parameter t creep time

t red creep redistribution time v Poisson’s ratio W specimen width

z distance along the crack front

_e 0creep strain rate at normalizing stress _e

c creep strain rate

e c equivalent creep strain r 0

normalizing stress

Abbreviations 2D two-dimensional 3D three-dimensional CCG creep crack growth C(T)compact tension CS(T)C-shaped cracked tension CEEQ equivalent creep strain in ABAQUS code DE(T)double-edge notched tension FEM ?nite element method HRR Hutchinson–Rice–Rosengren M(T)middle cracked tension SE(B)single edge-notched bend SE(T)single-edge notched tension TF stress triaxial factor

H.S.Ma et al./Engineering Fracture Mechanics 155(2016)88–10189

90H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–101

required.In the case of steady-state creep,the power law creep is analogous to power law plasticity,and the equivalent plas-tic strain is analogous to equivalent creep strain.By analogy to the uni?ed constraint parameter A p based on the equivalent plastic strain[24–27],a uni?ed creep constraint parameter A c based on crack-tip equivalent creep strain was de?ned in the previous work of authors[28]:

A c?A CEEQ=A ref at t=t red?1e1Twhere A CEEQ is the area surrounded by the equivalent creep strain(e c)isoline ahead of a crack tip and A ref is the reference area surrounded by the e c in a standard reference specimen,t is creep time,and the t red is stress redistribution time.The A c rep-resents a ratio of the A CEEQ of a specimen to the reference area A ref at the same e c isoline,the same creep time t/t red=1and C?level.An increase in the parameter A c implies loss of constraint.The analysis results in C(T)specimens in the previous work [28]show that a monotonic correlation line between the CCG rate and the parameter A c can be formed regardless of the in-plane and out-of-plane constraints.This indicated that the parameter A c may be equally sensitive to both in-plane and out-of-plane constraints,and it is a uni?ed characterization parameter of in-plane and out-of-plane creep constraint.It also has been proved that the parameter A c is independent on the choice of e c isolines and load level C?,and for t/t red>0.7the A c essentially does not change with the creep time t/t red.These features of the parameter A c may bring convenience for its use.However,the parameter A c along three-dimensional(3-D)crack fronts in a wide range of specimen geometries with dif-ferent in-plane and out-of-plane constraints has not been fully analyzed,and its applicability for establishing a wide range of in-plane and out-of-plane uni?ed constraint-dependent CCG rate equations for different materials has not been widely investigated.

In this work,extensive three-dimensional?nite element analyses have been conducted for six types of test specimen geometries with different in-plane and out-of-plane constraints in the literature[29],and the uni?ed characterization parameter A c of in-plane and out-of-plane creep constraints was calculated and analyzed for these specimens.Based on the parameter A c and the experimental creep crack growth rate data in the different specimen geometries in the literature [29],the applicability of the parameter A c for establishing a wide range of in-plane and out-of-plane uni?ed constraint-dependent CCG rate equation for316H steel was investigated.

2.Finite element model and numerical procedures

2.1.Material

The material used in this work was the316H stainless steel which is the same as that used in the literature[29].An elastic–plastic-power law creep material model was used,and the creep strain rate_e is given by:

r n?_e0er=r0Tne2T_e

c?A

The creep and elastic–plastic material parameters of316H stainless steel at550°C in the literature[29]were used.The values of n and A are11.3and3.0?10à34MPaàn hà1,respectively.The Young’s Modulus E of the steel at550°C is140GPa, and the Poisson’s ratio v was taken to be0.3.The normalizing stress r0was taken as170MPa,and the corresponding _e0=4.80Eà9hà1.The true stress–strain curve of the316H stainless steel at550°C is shown in Fig.1[29].

2.2.Finite element model for test specimens

The six different types of cracked specimens with a wide range of geometries and sizes(including a wide range of in-plane and out-of-plane constraints)used in the literature[29]for measuring creep crack growth rate of the316H steel have been modeled using3-D FE analyses.The test specimens include compact tension(C(T))specimens of width W=50mm and

W=25mm(denoted as1T and1/2T specimens,respectively),C-shaped cracked tension(CS(T))specimen with X/W=0.5

H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–10191 and R i/R0=0.5,single-edge cracked bend(SE(B))specimen with2L=4W,single-edge cracked tension(SE(T))and middle cracked tension(M(T))specimens with2L=4W.Schematic illustrations of the specimens are shown in Fig.2.Detailed geometries of specimens and the information on creep crack growth tests in the literature[29]are listed in Table1.The rel-ative initial crack depth a/W is ranged from0.17to0.53.Some1T C(T)specimens had40%side-grooves and M(T)specimens had no side-groove.All other specimens had20%side-grooves[29].The B N in Table1is the thickness of specimens with side-

Fig.2.Schematic illustrations of specimens:(a)C(T),(b)CS(T),(c)SE(B),(d)SE(T),and(e)M(T).

the element size.Hence the minimum mesh size of 40l m around the crack tips was used in this study.The local mesh dis-tribution around the crack tip is shown in Fig.3(f).

The FE analyses were performed using large-displacement with the NLGEOM option ON,and the blunting of crack tip was taken into consideration.The contour integral C (t )and C ?were evaluated by using the in-built ABAQUS routines.Ten con-tours were set around the crack tips.The C ?is usually path-independent,and C (t )is not path-independent,but with increas-ing time the C (t )gradually becomes path-independent.The C (t )was de?ned as the value from the sixth contour near the crack tip for the different specimens with the same size of meshes and contours (The C (t )de?ned by other contours has sim-ilar value as the sixth contour).The areas surrounded by the equivalent creep strain e c isolines,C ?and constraint parameter A c ahead of crack tips were calculated.2.3.Calculation of creep constraint parameter A c

To establish in-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate for 316H steel at 550°C and at steady-state creep by using the constraint parameter A c ,the three-dimensional FEM calculations were conducted to obtain values of the parameter A c along crack fronts for the test specimens with a wide range of geometries and sizes (a wide range of in-plane and out-of-plane constraints)in Table 1.The parameter A c was calculated by using Eq.(1),and the area A CEEQ sur-rounded by the equivalent creep strain e c (The e c is denoted as CEEQ in ABAQUS code)isoline at creep time t/t red =1and a given C ?level is calculated by FEM for each specimen in Table 1.In order to calculate the A CEEQ accurately for characterizing crack-tip constraints,it must ensure that the e c isolines ahead of a crack-tip at t/t red =1and a given C ?level do not connect those in loading region near the surface of specimens [28].Fig.4gives typical equivalent creep strain e c isolines in the middle plane of the 1T CT1specimen at an applied load of 20kN and MT1specimen at an applied load of 27.5kN and creep time t/t red =1in Table 1.It can be seen that for e c P 0.015in the 1T CT1specimen and MT1specimen,the e c isolines at crack-tip region cannot connect to loading region near specimen surface.The area A CEEQ can characterize creep crack-tip constraint,and a larger A CEEQ indicates constraint loss [28].

In this work,the A CEEQ surrounded by e c =0.02isoline in Eq.(1)was calculated at the same creep time t/t red =1and the tested load levels for the various test specimens with different in-plane and out-of-plane constraints in Table 1.The speci-men with W =2B =50mm and a /W =0.5in plane strain was chosen as the standard specimen,and the reference area A ref surrounded by the e c =0.02in the standard specimen was calculated at t/t red =1and the C ?level which is the same as the C ?level for each specimen at the tested load in Table 1.It should be noted that the parameter A c is independent on the choice of e c isolines and load level C ?[28].

3.Distributions of constraint parameter A c along 3-D crack fronts

The constraint is generally regarded as the resistance of a structure against plastic or creep deformation.The locations with lower constraint along crack fronts may have larger creep deformation.Fig.5gives the distributions of equivalent creep strain (CEEQ)along crack fronts for two typical specimens of 1T CT2specimen at an applied load of 26.5kN and MT1spec-imen at an applied load of 27.5kN in Table 1.The sizes of three-dimensional creep deformation zone may re?ect the overall constraint level composed of in-plane and out-of-plane constraints in the specimens.The largest creep strain zone along crack fronts occurs at the locations near the free surfaces,which indicates the lower constraint there.This result is similar to that of the constraint parameter A p based on crack-tip equivalent plastic strain within elastic–plastic fracture mechanics in the literature [31].

Table 1

Detailed geometries of specimens and information on creep crack growth test [29].

Test name

P (kN)W (mm)B (mm)W/B B N /B a/W (mm)Test duration (h)1T C(T)

CT1205024.9 2.010.810.531221CT226.55025 2.000.600.45323CT3275025 2.000.600.453781/2T C(T)CT18.6726.213 2.020.800.46856CT28.5926.212.9 2.030.800.46933CS(T)CST 16.52525 1.000.800.233830M(T)

MT127.58.988.95 1.00 1.000.34772MT235.58.998.94 1.01 1.000.17678MT3148.99 4.5 2.00 1.000.33308MT4178.98 4.46 2.01 1.000.17655SE(B)SB192512.5 2.000.800.33641SB27.62512.5 2.000.800.336522SE(T)

ST1302512.5 2.000.800.38379ST2352512.5 2.000.800.31601ST3

32

25

12.5

2.00

0.80

0.35

525

92H.S.Ma et al./Engineering Fracture Mechanics 155(2016)88–101

Fig.6shows the distributions of the constraint parameter A c along 3-D crack fronts (specimen thickness)for all test spec-imens in Table 1.It shows that the A c in the center region (from z /B =0to about 0.3)of all specimens has uniform distribution and lower value,and that in the region near free surface (from z /B =0.33to 0.45)has protuberant distribution and higher value.The protuberant distribution is related to the larger creep deformation zone in Fig.5.These results imply that the cen-ter region of all specimens has high and uniform constraint,and the lower constraint occurs at the region near free surface.Fig.6also indicates that the specimen order in terms of crack-tip constraint from high to low is 1T C(T),1/2T C(T),CS(T),SE (B),SE(T)and M(T).For the same type of specimen,the constraint increases with increasing specimen thickness B (out-of-plane constraint)and crack depth a /W (in-plane constraint).The specimens with the same geometry and size have the same constraint.The results in Fig.6further show that the parameter A c is sensitive to both in-plane and out-of-plane creep con-straints,and is a uni?ed creep constraint

parameter.

3.Typical 3D FE meshes for specimens:(a)C(T),(b)M(T),(c)CS(T),(d)SE(B),(e)SE(T)and (f)local meshes around the crack

4.In-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate of 316H steel

Under creep conditions,a lot of experimental and theoretical evidences have shown that the geometry constraint of spec-imens can affect creep crack growth (CCG)rate [1–11].For a given C ?value (creep fracture mechanics parameter),the model predications showed that the CCG rates in plane strain are signi?cantly greater than those in plane stress [3].Some exper-imental results have shown that there is an effect of specimen thickness on the CCG rate [2,6],and the specimens with larger thickness exhibit higher CCG rate.It also has been found that at the same C ?value the creep crack growth rates measured in the middle tension (M(T))specimens are lower than those obtained from deep crack compact tension (C(T))specimens for the austenitic stainless steels [1]and ferritic steels [4].Yokobori et al.proposed a parameter Q ?for correlating creep crack growth rate [10,11,32–36],and their work showed that the creep crack growth rate for a thick specimen is higher than that of a thin specimen [10,34].This geometry constraint effect is related to multi-axial stress state around the creep crack-tip,and was de?ned as ‘structural brittleness’[11,34].The effect of the ‘structural brittleness’on CCG rate of materials could be analyzed by a stress triaxial factor TF [11,34,35].The creep ductility and constraint effects can be estimated by using the parameter Q ?[33,34].Because the geometry constraint of specimens can affect CCG rate,the use of the C(T)specimen with high constraint for testing and analysis is expected to provide a safe upper bound to the CCG rate of the material [37].Thus,a wider range of test geometries is needed in order to apply the results from experimental laboratory test specimens to the range of conditions experienced by engineering components with different constraint levels under service conditions [37].The geometry related g factor for determining experimental C ?parameter for a range of specimen geometries (C(T),SE(T),SE(B),DE(T),M(T)and CS(T))has been examined and presented [36,37].This will allow a user to determine values of C ?for a wide range of cracked geometries.However,to accurately predict the creep life and achieve structural integrity assessments for high temperature components with any constraint levels (it includes both in-plane and out-of-plane con-straints),it may be important to quantify the creep crack-tip constraint levels in specimens or cracked components by using appropriate constraint parameter and obtain constraint-dependent creep crack growth rate of materials,and to develop methodology of creep life assessments based on two-parameter creep fracture mechanics.

In the recent work by Kim et al.[29],the effects of specimen geometry and loading mode on CCG rate of 316H steel have been investigated.In present paper,the uni?ed characterization parameter A c of in-plane and out-of-plane creep constraints along three-dimensional crack front in different specimen geometries used in the work of Kim et al.[29]was analyzed.Based on the parameter A c and the experimental CCG rate data of the different specimen geometries,the in-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate equation of 316H steel was investigated.The relations between

the

isolines in the middle plane for 1T CT1specimen at an applied load of 20kN 1.

equivalent creep strain (CEEQ)along crack fronts for 1T CT2specimen at an applied load of 26.5kN in Table 1at creep time t/t red =1.

0.0

0.1

0.20.30.4

0.5

1.0

1.21.41.61.8

2.02.2A c

z/B (z/B n )

1T CT1 1T CT2 1T CT3 1/2T CT1 1/2T CT2 CST SB1 SB2 ST1 ST2 ST3 MT1 MT2 MT3 MT4

Fig.6.The distributions of the constraint parameter A c along thickness for all test specimens in Table

experimental creep crack growth rate da/dt and C?for all the specimens of the316H steel in Table1are shown in Fig.7[29]. The CCG rate is usually expressed in the form[38],

_a?D

0C?qe3T

Table2

The CCG rate correlation equations in the tested C?range for different specimens of316H steel.

Specimen CCG rate equation Tested C?range(MPa m hà1) 1T C(T)CT1_a?15:38C?0:84 4.78Eà66C?69.58Eà5

CT2,CT3_a?7:84C?0:9 1.27Eà46C?64.77Eà3?TC(T)CT1,CT2_a?7:17C?0:849.53Eà66C?61.26Eà3 CS(T)CST_a?9:47C?0:779.61Eà76C?62.90Eà5 M(T)MT1_a?7:27C?0:85 2.30Eà56C?61.00Eà3

MT2_a?18:8C?0:95 3.84Eà56C?61.57Eà3

MT3_a?5:82C?0:85 6.97Eà56C?67.39Eà4

MT4_a?9:53C?0:87 2.56Eà56C?64.91Eà4 SE(B)SB1_a?85:82C?1:12 1.11Eà56C?63.01Eà3

SB2_a?192:2C?0:98 5.76Eà76C?61.04Eà5 SE(T)ST1_a?5:22C?0:858.46Eà56C?68.79Eà4

ST2_a?25:09C?0:85 1.38Eà56C?61.65Eà2

ST3_a?14:64C?0:84 2.98Eà56C?62.63Eà4

Table3

The applied load P,C?and average constraint parameter A c along crack front for each specimen.

Specimens Applied load P(KN)C?(MPa m hà1)A c

1T C(T)CT1208.68?10à5 1.16 CT226.5 1.84?10à4 1.31

CT327 2.29?10à4 1.32

1/2T C(T)CT18.67 4.14?10à4 1.44 CT28.59 3.58?10à4 1.45

CS(T)CST16.5 3.62?10à5 1.49 M(T)MT127.5 6.42?10à5 1.81 MT235.5 4.61?10à5 1.86

MT314 3.14?10à5 1.83

MT417 2.41?10à5 1.91

SE(B)SB19 3.67?10à5 1.49 SB27.67.93?10à6 1.48

SE(T)ST130 2.48?10à5 1.69 ST235 1.09?10à5 1.56

ST332 1.48?10à5 1.51 96H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–101

where _a

is CCG rate and in mm h à1,and C ?is crack-tip fracture parameter and in MPa m h à1.The D 0and q are material con-stants which are usually measured experimentally.From the experimental results in Fig.7[29],the da/dt -C ?correlation equations in tested C ?range were ?tted for all specimens,as shown in Table 2.When the constraint effect is considered,the CCG rate can be expressed as a function of C ?and constraint parameter.In this study,the constraint parameter A c is used

and the constraint dependent CCG rate _a

can be described in the following form [13],_a

?_a 0f eA c Te4T

where _a

0is the CCG rate from the standard specimen with high constraint,and f eA c Tis a function of A c .

H.S.Ma et al./Engineering Fracture Mechanics 155(2016)88–10197

Fig.6shows that the constraint A c is not uniform along3-D crack front.In the3-D constraint analysis,in addition to the constraint parameter being evaluated at mid-thickness of a specimen,an average value of constraint parameter along the crack front also is usually determined to characterize the average constraint level[12,39].The average constraint may re?ect overall constraint level and incorporate both in-plane and out-of-plane constraint effects.Thus,the average value of the con-straint parameter A c along the crack front(specimen thickness)for each specimen in Table1was calculated and tabulated in Table3.The applied load and C?level for each specimen are also listed in Table3.

According to the previous studies[28],the f(A c)in Eq.(4)can be taken as the form of the C1eA cTC2,then the Eq.(4)can be written as:

_a?C

1eA cTC2_a

0e5T

The constants C1and C2can be determined by?tting the relation curve between the CCG rate ratio_a=_a0and A c on log–log scale.The constraint parameter A c was used to establish the constraint-dependent CCG rate equations.Because the geometry and crack depth of the1T CT1specimen meet the test standard,the high constraint1T CT1specimen was taken to be the stan-dard reference specimen and its CCG rate was taken to be_a0=15.38C?0.84(Table2).The CCG rate ratio_a=_a0can be calculated by the equations in Table2at different C?values(It can be typically taken to be1?10à5,1?10à4and1?10à3MPa m hà1) for different specimens,and the corresponding A c for the specimens can be calculated by Eq.(1).It should be noted that the constraint parameter A c is independent on the choice of e c isolines and load level C?[28].So the constraint parameter A c can be calculated at different C?.The relations calculated between the CCG rate ratio_a=_a0and A c on log–log scale for different spec-imens at three C?values are shown in Fig.8.The power law relation can be used to?t the curve and the Eq.(5)can be written as:

_a=_a

0?1:895eA cT

à2:667e6Twhere_a0=15.38C?0.84is for the reference specimen.It can be seen that a monotonic correlation line between the da/dt and A c on log–log scale is formed for the three C?levels for all specimens with different geometries and sizes,loading modes and crack sizes.This further suggests that the parameter A c is regardless of the in-plane and out-of-plane constraints and load levels,and is a uni?ed characterization parameter for a wide of specimen geometries with different in-plane and out-of-plane constraints.However,the results in the previous work of authors[28]have showed that compared with the parameter A c,the constraint parameters R?and stress triaxiality h based on crack-tip stress?elds cannot form a monotonic correlation

98H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–101

H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–10199 line with the CCG rates for the specimens with different in-plane and out-of-plane constraints due to a larger scatter in data. The reason for this is that the parameters R?and h based on crack-tip stress?elds can effectively incorporate the in-plane creep constraint effect,but they are inadequate for capturing the out-of-plane creep constraint[28].

In CCG tests and life assessments,the CCG data in different specimen geometries may be measured and used,and high-temperature components may have different degrees of in-plane and out-of-plane constraints.Thus,it is necessary to estab-lish in-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate for a material,and it may be used in accurate creep life assessments for specimens or cracked components with different in-plane and out-of-plane constraint levels.Because the parameter A c based on crack-tip equivalent creep strain can effectively capture in-plane and out-of-plane creep constraints[28],the Eq.(6)represents the relation between the CCG rate and the overall constraint level com-posed of in-plane and out-of-plane constraint for the316H steel.For a specimen or component with a certain geometry and loading mode,as long as the constraint parameter A c is calculated under an arbitrary loading level C?using FE analysis,the in-plane and out-of-plane uni?ed constraint-dependent-dependent CCG rate can be predicted at different C?levels using Eq.

(6).The applicability of the Eq.(6)for components with different in-plane and out-of-plane constraint levels needs to be fur-ther investigated.

https://www.360docs.net/doc/ce16335152.html,parison of predicted CCG rates with experimental data

For analyzing and validating the uni?ed constraint-dependent CCG rate equation in Eq.(6),the predicted CCG rates by Eq.

(6)can be compared with the experimental data of each test specimen in Table1.As long as the constraint parameter A c for each specimen and the normalized CCG rate(_a0?15:38C?0:84in Table2)for reference specimen are obtained,the CCG rate_a for each specimen in the Table1can be predicted at different C?levels by using Eq.(6)(_a?1:895eA cTà2:667_a0).The average A c value along crack front for each specimen in Table3was used in Eq.(6),and Figs.9–11show the predicted CCG rates and their comparisons with experimental data.Fig.9shows that the comparison of predicted CCG rates with experimental data for1T C(T)specimen(CT1,CT2and CT3)and1/2T C(T)specimen(CT1and CT2).It shows that the predicted da/dt-C?line for each specimen agrees well with the experimental data.Fig.10shows that the comparison of predicted CCG rates with exper-imental data for CS(T)specimen and SE(B)specimen(SB1and SB2).The predictions of CS(T)specimen and SB1specimen agree well with the experimental data.But the test data of the SB2specimen(Fig.10(b))are located above the predicted line. This may be caused by faster CCG rate during long term test.Table1shows that the test duration of the SB2specimen

100H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–101

(6522h)is the longest at lower load,and the corresponding CCG rate data are mainly located at lower C?region less than 1?10à5MPa m hà1(Fig.10(b)).It has been shown that at lower C?region,the creep fracture mechanism of the316H steel [40]and the Cr–Mo–V steel[6]is creep brittle fracture,and the corresponding CCG rate is higher than that at middle-high C?region.Fig.11shows that the comparison of predicted CCG rates with experimental data for SE(T)specimen(ST1,ST2and ST3)and M(T)specimen(MT1and MT2).It can be seen that the predicted CCG rates for most specimens also agree well with the experimental data.The experimental data of ST1specimen are below the predicted line.This may be caused by exper-imental error.Because the three specimens ST1,ST2and ST3have similar sizes,they should have similar constraint levels and CCG rates.

Figs.9–11indicate that the uni?ed constraint-dependent CCG rate equation in Eq.(6)based on the constraint parameter A c and C?can predict the CCG rates of specimens with different in-plane and out-of-plane constraints.It can be inferred that the Eq.(6)may also be used to predict the CCG rates of high-temperature components with different in-plane and out-of-plane constraints by using the two-parameter C?àA c concept.The use of the two-parameter concept C?àA c in the CCG life prediction and assessment of specimens or cracked components may signi?cantly improve accuracy and decrease the degree in conservatism or non-conservatism.The constraint parameter A c of the cracked components may be calculated by the method similar to specimens.The application methodology of the two-parameter C?àA c concept needs to be further investigated.

6.Conclusion

Extensive three-dimensional?nite element analyses have been conducted for six types of test specimen geometries(1TC (T),1/2C(T),CS(T),M(T),SE(B)and SE(T))with different in-plane and out-of-plane constraints in the literature[29],and the uni?ed characterization parameter A c of in-plane and out-of-plane creep constraints was calculated and analyzed for these specimens.Based on the parameter A c and the experimental creep crack growth rate data of the six types of specimen geometries for316H steel in the literature[29],the applicability of the parameter A c for establishing a wide range of in-plane and out-of-plane uni?ed constraint-dependent CCG rate equation for316H steel was investigated.The main results obtained are summarized as follows:

(1)The three-dimensional?nite element analyses show that the center regions of all specimen geometries have higher

and uniform constraint,and the lower constraint occurs at the regions near free surface.

(2)A monotonic correlation line between the CCG rate_a=_a0and the constraint parameter A c on log–log scale can be

formed for different specimen geometries and sizes.This further indicates that the parameter A c can effectively char-acterize both in-plane and out-of-plane creep constraints for a wide range of specimen geometries with different in-plane and out-of-plane constraint levels.

(3)Based on the parameter A c,the in-plane and out-of-plane uni?ed constraint-dependent creep crack growth rate equa-

tion of316H steel has been obtained.The predicted CCG rate by using the equation for each specimen agrees well with the experimental data.

(4)Based on the two-parameter C?àA c concept,the uni?ed constraint-dependent creep crack growth rate equation may

be used for accurate CCG life prediction and assessment incorporating in-plane and out-of-plane constraint effects. Acknowledgments

This work was?nancially supported by the Projects of the National Natural Science Foundation of China(51375165, 51575184,51325504).

References

[1]Bettinson AD,O’Dowd NP,Nikbin KM,Webster GA.Experimental investigation of constraint effects on creep crack growth.In:ASME2002pressure

vessels and piping conference,Vancouver,BC,Canada;2002.[PVP2002-1117].

[2]Tabuchi M,Kubo K,Yagi K.Effect of specimen size on creep crack growth rate using ultra-large CT specimens for1Cr–Mo–V steel.Engng Fract Mech

1991;40:311–21.

[3]Nikbin KM.Justi?cation for meso-scale modelling in quantifying constraint during creep crack growth.Mater Sci Engng A2004;365:107–13.

[4]Takahashi Y,Igari T,Kawashima F,Date S,Titoh NI,Noguchi Y,et al.High temperature crack growth behavior of high-chromium steels.In:18th

International conference on structural mechanics in reactor technology,Beijing,China,2005.p.1904–15.

[5]Budden PJ,Dean DW.Constraint effects on creep crack growth.Eighth international conference on creep and fatigue at elevated temperatures.San

Antonio(TX,USA):American Society of Mechanical Engineers;2007[CREEP2007-26104].

[6]Tan JP,Tu ST,Wang GZ,Xuan FZ.Effect and mechanism of out-of-plane constraint on creep crack growth behavior of a Cr–Mo–V steel.Engng Fract

Mech2013;99:324–34.

[7]Zhao L,Jing H,Xu L,Han Y,Xiu J.Evaluation of constraint effects on creep crack growth by experimental investigation and numerical simulation.Engng

Fract Mech2012;96:251–66.

[8]Zhao L,Jing H,Xiu J,Han Y,Xu L.Experimental investigation of specimen size effect on creep crack growth behavior in P92steel welded joint.Mater

Des2014;57:736–43.

[9]Zhao L,Xu LY,Han YD,Jing HY.Quantifying the constraint effect induced by specimen geometry on creep crack growth behavior in P92steel.Int J Mech

Sci2015;94–95:63–74.

H.S.Ma et al./Engineering Fracture Mechanics155(2016)88–101101

[10]Yokobori Jr AT,Yokobori T,Nishihara T,Yamaoka T.An alternative correlating parameter for creep crack growth rate and its application-derivation of

the parameter Q?.Mater High Temp1992;10:108–18.Errata:224.

[11]Yokobori Jr AT,Sugiura R,Tabuchi M,Fuji A,Adachi T,Yokobori T.The effect of multi-axial stress component on creep crack growth rate concerning

structural brittleness.In:Proc of ICF11in the content of high temperature and creep of CD Rom;2005.

[12]Shih CF,O’Dowd NP,Kirk MT.A framework for quantifying crack tip constraint.In:Constraint effects in fracture.Philadelphia:American Society for

Testing and Materials;1993.p.2–20.

[13]Budden PJ,Ainsworth RA.The effect of constraint on creep fracture assessments.Int J Fract1999;97:237–47.

[14]Bettinson AD,O’Dowd NP,Nikbin KM,Webster GA.Two parameter characterization of crack tip?elds under creep conditions,In:IUTAM Symposium

on creep in structures,Netherlands,2001.p.95–104.

[15]Xiang MJ,Yu ZB,Guo WL.Characterization of three-dimensional crack border?elds in creeping solids.Int J Solids Struct2011;48:2695–705.

[16]Xiang MJ,Guo WL.Formulation of the stress?elds in power law solids ahead of three-dimensional tensile cracks.Int J Solids Struct2013;50:3067–88.

[17]Wang GZ,Liu XL,Xuan FZ,Tu ST.Effect of constraint induced by crack depth on creep crack-tip stress?eld in CT specimens.Int J Solids Struct

2010;47:51–7.

[18]Sun PJ,Wang GZ,Xuan FZ,Tu ST,Wang ZD.Quantitative characterization of creep constraint induced by crack depths in compact tension specimens.

Engng Fract Mech2011;78:653–65.

[19]Sun PJ,Wang GZ,Xuan FZ,Tu ST,Wang ZD.Three-dimensional numerical analyses of out-of-plane creep crack-tip constraint in compact tension

specimens.Int J Pres Ves Pip2012;96–97:78–89.

[20]Wang GZ,Kui LB,Xuan FZ,Tu ST.Numerical investigation on the creep crack-tip constraint induced by loading con?guration of specimens.Engng Fract

Mech2012;79:353–62.

[21]Tan JP,Tu ST,Wang GZ,Tu ST.Load-independent creep constraint parameter and its application.Engng Fract Mech2014;116:41–57.

[22]Tan JP,Wang GZ,Xuan FZ,Tu ST.Correlation of creep crack-tip constraint between axially cracked pipelines and test specimens.Int J Pres Ves Pip

2012;98:16–25.

[23]Tan JP,Tu ST,Wang GZ,Xuan FZ.Characterization and correlation of3-D creep constraint between axially cracked pipelines and test specimens.Engng

Fract Mech2015;136:96–114.

[24]Yang J,Wang GZ,Xuan FZ,Tu ST.Uni?ed characterisation of in-plane and out-of-plane constraint based on crack-tip equivalent plastic strain.Fatigue

Fract Engng Mater Struct2013;36:504–14.

[25]Yang J,Wang GZ,Xuan FZ,Tu ST.Uni?ed correlation of in-plane and out-of-plane constraints with fracture toughness.Fatigue Fract Engng Mater Struct

2014;37:132–45.

[26]Yang J,Wang GZ,Xuan FZ,Tu ST.Uni?ed correlation of in-plane and out-of-plane constraint with fracture resistance of a dissimilar metal welded joint.

Engng Fract Mech2014;115:296–307.

[27]Mu MY,Wang GZ,Xuan FZ,Tu ST.Uni?ed parameter of in-plane and out-of-plane constraint effects and its correlation with brittle fracture toughness

of steel.Int J Fract2014;190:87–98.

[28]Ma HS,Wang GZ,Xuan FZ,Tu ST.Uni?ed characterization of in-plane and out-of-plane creep constraint based on crack-tip equivalent creep strain.

Engng Fract Mech2015;142:1–20.

[29]Kim NH,Oh CS,Kim YJ,Davies C,Nikbin K,Dean DW.Creep failure simulations of316H at550°C:Part II–Effects of specimen geometry and loading

mode.Engng Fract Mech2013;105:169–81.

[30]Hibbitt,Karlsson,Sorensen.ABAQUS user’s manual,version6.10;2011.

[31]Mu MY,Wang GZ,Xuan FZ,Tu ST.Three-dimensional analyses of in-plane and out-of-plane crack-tip constraint characterization for fracture

specimens.Fatigue Fract Engng Mater Struct2016.submitted for publication.

[32]Yokobori Jr AT,Yokobori T.New concept to crack growth at high temperature creep and creep-fatigue.Advances in fracture research.In:Salama K,

Ravi-chandar K,Taplin DMR,Rama Rao P,editors.Proc.of int.conf.on fracture(ICF7).Pergamon Press;1989.p.1723–35.

[33]Yokobori Jr AT,Yokobori T,Yamazaki K.A characterization of high temperature creep fracture life for ceramics.J Mater Sci Lett1996;15:2002–7.

[34]Yokobori Jr AT,Sugiura R.Effects of component size,geometry,microstructure and aging on the embrittling behavior of creep crack growth correlated

by the Q?parameter.Engng Fract Mech2007;74:898–911.

[35]Sugiura R,Yokobori AT,Sato K,Tabuchi M,Yatomi M,Kobayashi K,et al.Creep crack initiation and growth characteristics in weldment for P92based

on C?,d d/d t and Q?parameters.Strength Fract Complex2010;6:177–89.

[36]ASTM E1457-13.Standard test method for measurement of creep crack growth times and rates in metals.ASTM Standards;2013.

[37]Davies CM,Kourmpetis SM,O’Dowd NP,Nikbin KM.Experimental evaluation of the J or C?parameter for a range of cracked geometries.Journal of

ASTM international2006;3:Paper ID JAI13221.

[38]Webster GA,Ainsworth RA.High temperature component life assessment.London:Chapman and Hall;1994.

[39]Silva LAL,Cravero S,Ruggieri C.Correlation of fracture behavior in high pressure pipelines with axial?aws using constraint designed test specimens–

Part II:3-D effects on constraint.Engng Fract Mech2006;73:2123–38.

[40]Dean DW,Gladwin DN.Creep crack growth behaviour of Type316H steels and proposed modi?cations to standard testing and analysis methods.Int J

Pres Ves Pip2007;84:378–95.

LDAR(挥发性有机物泄漏检测与修复)

LDAR(挥发性有机物泄漏检测与修复) 中国科学院广州化学研究所分析测试中心 卿工---189—3394--6343 中科检测作为中国科学院独立的第三方检测技术服务机构,其中生态环境事业部专业从事“生态环境检测、鉴定和评估工作”,充分发挥技术领先与服务专业的优势,可为政府相关部门、企事业单位提供全流程技术服务,多年来,中科检测为生产、科研、贸易、政府管理、诉讼、技术引进、商务仲裁等活动提供了大量优质的分析测试技术和客观公正的评估鉴别服务,为企业科技创新提供了强有力的分析测试共性技术支撑。 服务内容: ●土壤环境调查、污染场地风险评估; ●污染场地治理与修复效果监测评估; ●重点企业隐患排查 ●LDAR(挥发性有机物泄漏检测与修复) ●环境风险评估 ●建设项目竣工环境保护验收 ●企业清洁生产审核验收 ●在产企业土壤与地下水监测 ●突发环境事件风险评估 ●LDAR(挥发性有机物泄漏检测与修复) ● VOCs减排及监测一站式解决方案 ●固体废物鉴定、管理与综合利用全过程解决方案 ●危险废物鉴定、管理与综合利用全过程解决方案 ●工业固废综合利用评价与鉴定 ●生态环境损害评估与鉴定 ●企业碳排放测算及评价 ●环境健康安全与评价 ●有机污染物及重金属监测分析

●环境有毒有害物质模型分析与评估 ●地球物理勘探 ●协助责任单位完成其他相关备案程序。 工作内容 企业“泄漏检测与维修”(LDAR)项目的评估应依照以下流程(图1)开展。 图1 LDAR项目评估流程

LDAR现场检测流程图 一、技术评估依据和过程 1.1. 评估依据 1.2. 评估过程 二、评估范围和内容 2.1. 评估范围 2.2. 评估内容 三、评估结论 3.1. LDAR项目建立 3.1.1 实施范围完整性 3.1.2组件标识及描述规范性 3.2. 检测与维修情况 3.2.1 仪器校准和示值漂移数据 3.2.2检测数据有效性 3.1.3检测数据准确性

安徽省挥发性有机物污染整治工作方案

安徽省挥发性有机物污染整治工作方案 治理挥发性有机物污染是大气污染防治的重点领域。为进一步贯彻落实《国务院关于印发大气污染防治行动计划的通知》(国发〔2013〕37号)(简称“大气十条”)有关精神,切实推进挥发性有机物污染治理,加快改善我省环境空气质量,保障广大人民群众身体健康,按照《安徽省大气污染防治行动计划实施方案》(皖政〔2013〕89号)(简称“实施方案”)的要求,结合我省实际情况,制定本方案。 一、总体要求 坚持以科学发展观为指导,以国家“大气十条”和省“实施方案”为要求,以石化、有机化工、表面涂装、包装印刷等为重点行业,以化工园区(集中区)为重点区域,以重点行业挥发性有机物(简称VOCs,下同)排放企业为重点整治对象,多措并举,有序推进,大力开展VOCs污染整治,按期完成整治任务,达到整治要求。健全长效工作机制,有效解决VOCs 环境污染问题,努力提升空气环境质量。 二、整治范围 我省主要VOCs污染行业全部纳入整治范围,确定石化、有机化工、表面涂装、包装印刷业为重点,同步开展合成革、纺织印染、橡胶塑料制品、化纤、木业、制鞋等行业污染整治。各市可根据实际,确定本地区VOCs污染整治的重点行业。

三、工作目标 优化产业布局,加强源头控制和污染治理,推广使用低挥发性有机物排放的有机溶剂。突出抓好重点行业、重点区域、重点企业污染整治,科学制定VOCs污染整治方案,综合治理挥发性有机物污染。推广应用重点行业最佳可行技术(BAT)和最佳环境实践(BEP),分阶段完成VOCs污染整治任务,做到VOCs高效净化,有效推进VOCs减排,确保有组织排放和厂界无组织监控浓度达标。建立健全VOCs污染监测预警与监管体系,努力改善区域空气质量。 四、主要任务 (一)开展VOCs排放现状调查。 各市根据省统一部署,组织开展辖区内石化、有机化工、表面涂装、包装印刷以及合成革、纺织印染、橡胶塑料制品、化纤、木业、制鞋等行业VOCs排放调查。做到底数清楚,重点明确,有的放矢,有效整治。 (二)建立VOCs污染治理台账。 各地在VOCs排放现状调查的基础上,组织开展VOCs 排放清单编制工作。采取“一区一策、一厂一策”,排出时限进度,确定整治要求,建好VOCs污染治理台账。 (三)开展工业企业VOCs污染治理。 自2014年起,各地要围绕VOCs污染整治的重点,突出开展石化、有机化工、表面涂装、包装印刷等行业VOCs专项整治和石化行业“泄漏检测与修复”技术改造,结合开展合

固定污染源废气挥发性有机物在线监测技术规范编制说明

固定污染源废气挥发性有机物在线监测技术规范(征求意见稿) 编制说明 标准编制组 2019年8月

目录 1 项目背景 (3) 2 标准编制的必要性 (5) 3 国内外VOCs 监测标准及在线监测技术应用状况研究 (7) 4 标准制订的编制原则和技术路线 (16) 5 标准制定的技术路线 (18) 6 标准主要技术内容及确定依据 (18) 7 性能指标验证 (29)

1 项目背景 1.1 项目来源 根据江苏省生态环境厅《关于下达2017年度省级环保科研课题项的通知》(苏环办[2018]25号),下达了江苏省《固定污染源废气挥发性有机物在线监测技术规范》制订任务,项目统一编号:2017016。由江苏省环境科学研究院承担本课题的制定任务,合作单位为苏州工业园环境执法大队。之后,2019年2月《固定污染源废气挥发性有机物在线监测技术规范》标准列入江苏省生态环境监测监控系统三年建设规划(2018-2020年)。 1.2 工作过程 2017年12月,江苏省环境科学研究院作为项目承担单位与合作单位成立了《固定污染源废气挥发性有机物在线监测技术规范》项目研究组,完成了项目任务书和合同的填报签订。研究组初步拟定了标准编制的工作目标、工作内容,讨论了在标准制订过程中可能遇到的问题,按照任务书的要求,制定了详细的标准编制计划与任务分工。 2018年1月,根据《江苏省环保科研课题项目管理办法》等有关文件要求,江苏省环境科学研究院组织有关单位及专家对承担的“江省固定污染源废气挥发性有机物在线监测技术规范”(编号:2017016)听取了课题组的汇报,经质询和认真讨论,通过开题论证,建议尽快启动实施。

精神分裂症的病因及发病机理

精神分裂症的病因及发病机理 精神分裂症病因:尚未明,近百年来的研究结果也仅发现一些可能的致病因素。(一)生物学因素1.遗传遗传因素是精神分裂症最可能的一种素质因素。国内家系调查资料表明:精神分裂症患者亲属中的患病率比一般居民高6.2倍,血缘关系愈近,患病率也愈高。双生子研究表明:遗传信息几乎相同的单卵双生子的同病率远较遗传信息不完全相同 的双卵双生子为高,综合近年来11项研究资料:单卵双生子同病率(56.7%),是双卵双生子同病率(12.7%)的4.5倍,是一般人口患难与共病率的35-60倍。说明遗传因素在本病发生中具有重要作用,寄养子研究也证明遗传因素是本症发病的主要因素,而环境因素的重要性较小。以往的研究证明疾病并不按类型进行遗传,目前认为多基因遗传方式的可能性最大,也有人认为是常染色体单基因遗传或多源性遗传。Shields发现病情愈轻,病因愈复杂,愈属多源性遗传。高发家系的前瞻性研究与分子遗传的研究相结合,可能阐明一些问题。国内有报道用人类原癌基因Ha-ras-1为探针,对精神病患者基因组进行限止性片段长度多态性的分析,结果提示11号染色体上可能存在着精神分裂症与双相情感性精神病有关的DNA序列。2.性格特征:约40%患者的病前性格具有孤僻、冷淡、敏感、多疑、富于幻想等特征,即内向

型性格。3.其它:精神分裂症发病与年龄有一定关系,多发生于青壮年,约1/2患者于20~30岁发病。发病年龄与临床类型有关,偏执型发病较晚,有资料提示偏执型平均发病年龄为35岁,其它型为23岁。80年代国内12地区调查资料:女性总患病率(7.07%。)与时点患病率(5.91%。)明显高于男性(4.33%。与3.68%。)。Kretschmer在描述性格与精神分裂症关系时指出:61%患者为瘦长型和运动家型,12.8%为肥胖型,11.3%发育不良型。在躯体疾病或分娩之后发生精神分裂症是很常见的现象,可能是心理性生理性应激的非特异性影响。部分患者在脑外伤后或感染性疾病后发病;有报告在精神分裂症患者的脑脊液中发现病毒性物质;月经期内病情加重等躯体因素都可能是诱发因素,但在精神分裂症发病机理中的价值有待进一步证实。(二)心理社会因素1.环境因素①家庭中父母的性格,言行、举止和教育方式(如放纵、溺爱、过严)等都会影响子女的心身健康或导致个性偏离常态。②家庭成员间的关系及其精神交流的紊乱。③生活不安定、居住拥挤、职业不固定、人际关系不良、噪音干扰、环境污染等均对发病有一定作用。农村精神分裂症发病率明显低于城市。2.心理因素一般认为生活事件可发诱发精神分裂症。诸如失学、失恋、学习紧张、家庭纠纷、夫妻不和、意处事故等均对发病有一定影响,但这些事件的性质均无特殊性。因此,心理因素也仅属诱发因

外阴疾病

外阴疾病 外阴:阴道口外边的外露部分肛门、阴道口及尿道邻近,经常受阴道分泌物及尿液的浸渍,容易发炎。 常见病症:外因瘙痒、外阴炎、外阴白色病变、外因溃疡、外阴癌 外阴疾病 外阴:阴道口外边的外露部分肛门、阴道口及尿道邻近,经常受阴道分泌物及尿液的浸渍,容易发炎。 常见病症:外因瘙痒、外阴炎、外阴白色病变、外因溃疡、外阴癌 外因瘙痒 外阴瘙痒是妇科疾病中很常见的一种症状,外阴是特别敏感的部位,妇科多种病变及外来刺激均可引起瘙痒,使人寝食难安、坐卧不宁。外阴瘙痒多发生于阴蒂、小阴唇,也可波及大阴唇、会阴和肛周 病因:1.慢性局部刺激,外阴、阴道、宫颈炎症的异常分泌物的刺激; 2.外阴不清洁及紧身化纤内裤、卫生巾等致通透不良; 3.外阴寄生虫病,如阴虱、蛲虫、疥疮等; 4.各种外阴皮肤病和外阴肿瘤等; 5.全身性疾病的外阴局部症状,如糖尿病、尿毒症、维生素缺乏等。 症状:外因皮肤瘙痒、烧灼感和疼痛瘙痒部位多生与阴帝、小阴唇、也可波及大阴、会阴、甚至肛周围 危害:(1)性外阴部瘙痒严重时,不但使人坐卧不宁,影响工作、学习、生活和睡眠。 (2)由于女性外阴瘙痒,会影响夫妻生活,所以极有导致夫妻感情不和,严重的 甚至造成感情破裂,婚姻走向终点。 (3)诱发生殖器感染,盆腔炎、肾周炎、性交痛等,日久不愈还可导致多种疾病 同时发生,疾病的危害严重的会危害女性健康,甚至还会造成女性不孕等严重后果。 (4)女性外阴瘙痒严重时,不易根治,易反复,引发早产、胎儿感染畸形等,造 成终身遗憾。 治疗1.外阴涂药

使用有止痒作用的洗剂、膏霜等,如炉甘石洗剂、苯海拉明软膏、皮质醇类软膏等。 2.局部封闭或穴位注药 如皮质醇激素、维生素B12、非那根等。 3.针对病因治疗。 4.预防1. 注意经期卫生,勤清洗。 2.不要冲洗阴道,因为阴道有自清的功能,如果刻意冲洗反而不利 3.忌乱用、烂用药物,忌抓搔及局部摩擦。 4.忌酒及辛辣食物,不吃海鲜等及易引起过敏的药物 6 .久治不愈者应作血糖检查。少吃糖类可避免常常感染霉菌,如少吃淀粉类、糖类以及刺激性的食物(例如酒、辛辣物、油炸类),多吃蔬菜水果类,水份要充足。 5、不穿紧身兜裆裤,内裤更须宽松、透气,并以棉制品为宜。 6.就医检查是否有霉菌或滴虫,如有应及时治疗,而不要自己应用“止痒水”治疗。 8.保持外阴清洁干燥,尤其在经期、孕期、产褥期,每天用女性护理液清洗外阴更换内裤。 9.不穿化纤内裤、紧身裤,着棉织内衣裤。局部坐浴时注意溶液浓度、温度及时间、注意事项。 10.外阴瘙痒者应勤剪指甲、勤洗手,不要搔抓皮肤,以防破溃感染从而继发细菌性感染。 11.上完厕所请记得由前往后擦,因为肛门可能会带来不少细菌,所以如厕后请不要由肛门擦到阴部,才能减少感染的机会。 12.内裤要和其他的衣物分开洗,最好暴晒,可以减少细菌的滋生。如果患有霉菌性阴道炎的话,最好内裤都有热水煮 外阴溃疡外阴溃疡是发生于外阴部的皮肤黏膜发炎、溃烂、缺损。病灶多发生于小阴唇和大阴唇内侧,其次为前庭黏膜及阴道口周围。病程有急性及慢性。 大小阴唇、阴道口周围、阴蒂等处(外阴疾病发展中出现的一个过程,不是一个独立的疾病,有急性和慢性)急性外阴溃疡:非特异性外阴炎病情较轻,多在搔抓之后出现一般比较表浅,但疼痛比较厉害 慢性外阴溃疡:持续时间较长,或者反复发作 癌症引起的溃疡,与结核性溃疡很难鉴别,需做确诊

石化行业挥发性有机物综合整治方案

石化行业挥发性有机物综合整治方案 环发【】号 为贯彻落实《大气污染防治行动计划》,大力推进石化行业挥发性有机物()污染治理,制定本方案。 一、工作思路和目标 全面开展石化行业综合整治,大幅减少石化行业排放,促进环境空气质量改善。严格控制工艺废气排放、生产设备密封点泄漏、储罐和装卸过程挥发损失、废水废液废渣系统逸散等环节及非正常工况排污。通过实施工艺改进、生产环节和废水废液废渣系统密闭性改造、设备泄漏检测与修复()、罐型和装卸方式改进等措施,从源头减少的泄漏排放;对具有回收价值的工艺废气、储罐呼吸气和装卸废气进行回收利用;对难以回收利用的废气按照相关要求处理。到年,全国石化行业基本完成综合整治工作,建成监测监控体系,排放总量较年削减以上。二、主要任务 本方案中的石化行业包括以原油、重油等为原料生产汽油馏分、柴油馏分、燃料油、石油蜡、石油沥青、润滑油和石油化工原料等的石油炼制工业生产性企业,以及以石油馏分、天然气为原料生产有机化学品、合成树脂原料、合成纤维原料、合成橡胶

原料等的石油化学工业生产性企业。有机液体储运、煤化工、其他化工等相关企业可参照本方案有关要求开展工作。 (一)开展污染源排查。地方各级环境保护主管部门应组织本行政区内的石化企业,开展污染源摸底排查工作,采用实测、物料衡算、模型计算、公式计算、排放系数等方法,重点对企业原辅材料和产品、主要生产工艺、排放环节、治理措施和效果、排放量和物质清单等开展排查,摸清企业的排放状况。排查结果按《环境信息公开办法(试行)》要求向社会公开,并作为排污收费、总量控制和危险化学品环境管理等的依据。 (二)严格建设项目环境准入。各级环境保护主管部门结合主体功能区划、环境功能区划、城市总体规划等要求,优化调整石化产业布局。加强产业政策的引导与约束,加快淘汰落后产品、技术和工艺装备。新、改、扩建石化项目应在设计和建设中选用先进的清洁生产和密闭化工艺,提高设计标准,实现设备、装置、管线、采样等密闭化,从源头减少泄漏环节,工艺、储存、装卸、废水废液废渣处理等环节应采取高效的有机废气回收与治理措施,满足国家及地方的达标排放和环境质量要求。 (三)完善监督管理体系。各级环境保护主管部门应对行政区内石化企业进行全面监管,以企业为单元,通过统一的信息管理平台做好统计、审核与监管工作,不定期对企业申报情况进行抽查和评估,逐级上报上一年企业排放清单及减排效果等。

挥发性有机物在线监测系统安装及联网验收技术指南试行.doc

寿光市环保局挥发性有机物在线监测系统安装、联网及验收技术指南 (试行)

目录 一、仪器要求 (4) (一)资质认证 (4) (二)技术要求 (4) (三)设备品牌及售后服务要求 (9) 二、安装指南 (9) (一)安装监测点选择 (9) 1、有组织排放安装监测点选择9 2、园区及厂界安装监测点选择10 (二)安装技术要求 (10) 1、有组织排放在线监测技术要求10 2、园区在线监测技术要求13 3、厂界在线监测技术要求16 4、数据采集和传输设备技术要求16 5、监测房技术要求17 三、联网技术要求 (18) 四、验收 (18)

前言 为贯彻《中华人民共和国环境保护法》、《中华人民共和国大气污染防治法》,规范挥发性有机物在线监测系统的安装、联网及验收,特制定本技术指南。 各企业(园区)按照本技术指南,制定挥发性有机物在 线监测系统建设实施方案,报寿光市环保局审核后,方可组 织监测设备采购及项目实施。“实施方案”中应包括:监测点选择、监测指标、监测系统组成、主要分析仪器技术参数 及资质证书、招标采购方案、售后运营维护方案、工作进度 计划等内容。寿光市环保局负责技术指导、技术服务和验收 的组织协调工作。 2017 年 4 月

一、仪器要求 (一)资质认证 1、具有中华人民共和国计量器具制造许可证(进口仪器具有国家质量技术监督部门的计量器具型式批准证书)。 2、具有中国环境保护产品认证书。 3、具有环境保护产品质量监督检验总站出具的产品适用性检测合格报告。 4、仪器的名称、型号必须与上述证书及检测报告相符合,且在有效期内。 (二)技术要求 1、监测指标 污染物排放类型自动监控点位置污染物监测项目 排放口企业特征污染物、企业有组织排放VOCs 厂区边界企业特征污染物 企业无组织排放厂区边界企业特征污染物、 VOCs 氨气、硫化氢 园区园区边界VOCs 特征污染物

挥发性有机物泄漏检测与修复(LDAR)管理规程

挥发性有机物泄漏检测与修复(LDAR)管理规程 一、目的 为贯彻落实江苏省泄漏检测与修复(LDAR)实施技术指南,深入推进公司挥发性有机物污染治理工作,有效控制挥发性有机物的无组织排放,结合本公司实际,特制定本规程。 二、适用范围 适用于××××公司挥发性有机物泄漏检测与修复(LDAR)管理的全过程。 三、责任 1.EHS部:负责联系第三方检测单位统计本公司监测点位数量并进行挥发性有机物泄漏 检测与修复(LDAR)。 2.各车间:负责配合第三方检测公司对各车间开展挥发性有机物泄漏检测与修复(LDAR) 工作。 四、术语 1.挥发性有机物volatile organic compounds(VOCs):参与大气光化学反应的有机化合 物,或者根据有关规定确定的有机化合物。在表征VOCs 总体排放情况时,根据行业特征和环境管理要求,可采用总挥发性有机物(以TVOC 表示)、非甲烷总烃(以NMHC 表示)作为污染物控制项目。 2.无组织排放fugitive emission :大气污染物不经过排气筒的无规则排放,包括开放式 作业场所逸散,以及通过缝隙、通风口、敞开门窗和类似开口(孔)的排放等。 3.泄漏检测与修复leak detection and repair:泄漏检测与修复是指对工业生产全过程挥发 性有机物物料逸散、泄漏进行控制的系统工程。该技术采用固定或移动检测仪器,定量检测易产生挥发性气体泄漏的场所和所有挥发性气体排放源,从而控制VOCs逸散、泄漏排放,减少对环境造成的污染。简称LDAR。

4.VOCs物料VOCs-containing materials:本标准是指VOCs质量占比大于等于10%的物 料,以及有机聚合物材料。 5.密封点:采用密封措施,阻止设备流体从相邻结合面间或开口处向外泄漏的点位。 6.泄漏控制浓度:指在相关排放标准或法规中规定的,在泄漏排放源表面测得的VOCs 浓度值,表示有VOCs泄漏存在,需采取措施进行控制。它是一个基于经校准气体校准的仪器的测定读数。 五、工作程序 1.LDAR项目建立 1.1检测对象确定 EHS部审核各车间的物料平衡表、工艺流程图、管道流程图、操作规程、装置平面布置图等内容。分析装置涉及的原料、中间产品、最终产品和各类助剂的组分和含量是否涉及VOCs,从而确定需要实施泄漏检测与修复装置。 1.2 设备与管线组件符合下列条件之一,可免予泄漏检测:

2018年重点地区环境空气挥发性有机物监测方案

2018年重点地区环境空气挥发性机物监测方案 环保部印发了《2018年重点地区环境空气挥发性有机物监测方案》。方案对于VOCs监测的城市、监测项目、时间频次及操作规程等做了详细规定。 一、监测城市 直辖市(4个):北京、天津、上海、重庆 省会城市及计划单列市(15个):石家庄、太原、沈阳、南京、杭州、济南、郑州、武汉、广州、成都、西安、大连、青岛、深圳、宁波 地级城市(59个):廊坊、保定、唐山、邯郫、衡水、邢台、沧州、新乡、鹤壁、安阳、集作、濮阳、开封、淄博、聊城、德州、滨州、济宁、菏泽、阳泉、长治、晋城(京津冀及周边22个);无锡、徐州、常州、苏州、南诵、连云港、淮安、盐城、扬州、镇江、泰州、宿迁、温州、嘉兴、湖州、绍兴、金华、衢州、舟山、台州、丽水(长三角21个);珠海、佛山、江门、肇庆、惠州、东莞、中山(珠三角7个);抚顺、锦州、营口、盘锦、铁岭、萌芦岛(辽宁中南部6个);鄂州、孝感、黄冈(武汉及同边城市3个)。 二、监测项目 监测项目包括光化学反应活性较强或可能影响人类健康的VOCs,包括烷烃、烯烃、芳香烃、含氧挥发性有机物(OVOCS)、卤代烃等。各级城市监测项目范围见表2。直辖市、省会城市及计划单列市监测117种物质(表3-表5),地级城市监测70种物质(表3、表4)。 三、进度安排 2018年1月-2018年3月:经费由相关地方自行筹措,组织硬件釆购,做好测试方法开发及自动站点联网等准备工作。2018年4月起:开展监测工作,按时上报监测结果,各省、直辖市每月将监测结果分析报告上报监测总站,监测总站每月5日前,形成上月综合分析报告并报送环境保护部环境监测司。详细文件见附件: 四、有机挥发物监测仪表的选型: 有机挥发物现行比较常用检测方法主要包括:

固定污染源废气挥发性有机物监测技术规范

ICS点击此处添加ICS号 点击此处添加中国标准文献分类号DB11 北京市地方标准 DB 11/ ****—2016 固定污染源废气挥发性有机物 监测技术规范 The Technical Specification for Monitoring of volatile organic compounds emitted from stationary source 点击此处添加与国际标准一致性程度的标识 (征求意见稿) (本稿完成日期:2016.07.01) 2016-XX-XX发布2016-XX-XX实施

目次 前言................................................................................ II 引言............................................................................... III 1 范围 (1) 2 规范性引用文件 (1) 3 术语和定义 (1) 4 测定项目的确定 (2) 5 监测方法的选择 (2) 6 采样技术要求 (3) 7 样品的运输和保存 (5) 8 结果与计算 (6) 9 质量保证与质量控制 (6) 附录A(规范性附录)固定污染源废气苯系物的测定气袋采样-气相色谱质谱法 (8) 附录B(资料性附录)固定污染源废气非甲烷总烃或总烃标准监测方法表 (14) 附录C(资料性附录)固定污染源废气特征项目标准监测方法表 (15) 附录D(资料性附录)固定污染源废气中挥发性有机物的检测流程 (16)

精神分裂症的发病原因是什么

精神分裂症的发病原因是什么 精神分裂症是一种精神病,对于我们的影响是很大的,如果不幸患上就要及时做好治疗,不然后果会很严重,无法进行正常的工作和生活,是一件很尴尬的事情。因此为了避免患上这样的疾病,我们就要做好预防,今天我们就请广州协佳的专家张可斌来介绍一下精神分裂症的发病原因。 精神分裂症是严重影响人们身体健康的一种疾病,这种疾病会让我们整体看起来不正常,会出现胡言乱语的情况,甚至还会出现幻想幻听,可见精神分裂症这种病的危害程度。 (1)精神刺激:人的心理与社会因素密切相关,个人与社会环境不相适应,就产生了精神刺激,精神刺激导致大脑功能紊乱,出现精神障碍。不管是令人愉快的良性刺激,还是使人痛苦的恶性刺激,超过一定的限度都会对人的心理造成影响。 (2)遗传因素:精神病中如精神分裂症、情感性精神障碍,家族中精神病的患病率明显高于一般普通人群,而且血缘关系愈近,发病机会愈高。此外,精神发育迟滞、癫痫性精神障碍的遗传性在发病因素中也占相当的比重。这也是精神病的病因之一。 (3)自身:在同样的环境中,承受同样的精神刺激,那些心理素质差、对精神刺激耐受力低的人易发病。通常情况下,性格内向、心胸狭窄、过分自尊的人,不与人交往、孤僻懒散的人受挫折后容易出现精神异常。 (4)躯体因素:感染、中毒、颅脑外伤、肿瘤、内分泌、代谢及营养障碍等均可导致精神障碍,。但应注意,精神障碍伴有的躯体因素,并不完全与精神症状直接相关,有些是由躯体因素直接引起的,有些则是以躯体因素只作为一种诱因而存在。 孕期感染。如果在怀孕期间,孕妇感染了某种病毒,病毒也传染给了胎儿的话,那么,胎儿出生长大后患上精神分裂症的可能性是极其的大。所以怀孕中的女性朋友要注意卫生,尽量不要接触病毒源。 上述就是关于精神分裂症的发病原因,想必大家都已经知道了吧。患上精神分裂症之后,大家也不必过于伤心,现在我国的医疗水平是足以让大家快速恢复过来的,所以说一定要保持良好的情绪。

挥发性有机物VOCs一厂一策提标改造方案

XXXXX单位/公司VOCs“一厂一策”提标改造 方案 企业名称: 编制单位: 编制时间:

目录

1企业现状 1.1企业概况 1.2生产现状 1.3生产工艺流程 1.4原辅材料使用情况 1.5生产设备情况 1.6有机液体储存情况 1.7设备动静密封点情况 1.8含挥发性有机物料的废水集输、储存、处理处置情况1.9有组织废气排放情况 2现状排查及排放量计算 2.1设备动静密封点泄漏 2.1.1现状排查 2.1.2排放量计算 2.2有机液体储存与调和挥发损失 2.2.1现状排查 2.2.2排放量计算 2.3 有机液体装载挥发损失 2.3.1现状排查 2.3.2排放量计算 2.4废水集输、储存、处理处置 2.4.1现状排查 2.4.2排放量计算 2.5工艺有组织排放 2.5.1现状排查 2.5.2排放量计算

2.6燃烧烟气排放 2.6.1现状排查 2.6.2排放量计算 2.7工艺无组织排放 2.7.1现状排查 2 2 2 2 2 2 2 2 2.7.2排放量计算 2.8采样过程排放 2.8.1现状排查 2.8.2排放量计算 2.9火炬排放 2.9.1现状排查 2.9.2排放量计算 2.10非正常工况(含开停工及维修)排放2.10.1现状排查 2.10.2排放量计算 2.11冷却塔、循环冷却系统释放 2.11.1现状排查 2.11.2排放量计算

2.12事故排放 2.12.1现状排查 2.12.2排放量计算 2.13 其他排查 2.14提标改造前VOCS排查分析2.14.1 排放量分析 2.14.2达标性分析 2.14.3 减排潜力分析 3提标改造方案 3.1方案选择确立 3.1.1方案选择 3.1.2方案比选 3.1.3方案确立 3.2 收集及转输方案 3.2.1收集及转输方式 3.2.2主要工程量 3.3 废气处理(处置)方案 3.3.1工艺流程设计及说明 3.3.2 工程总体布置 3.3.3工程设施配置 3.3.4工程设备选型 3.3.5二次污染防治 3.3.6资源化利用 3.3.7建筑工程 3.3.8电气工程 3.3.9自动化工程 3.4环境管理 3.4.1环境监测、申报及信息公开

精神分裂症的病因是什么

精神分裂症的病因是什么 精神分裂症是一种精神方面的疾病,青壮年发生的概率高,一般 在16~40岁间,没有正常器官的疾病出现,为一种功能性精神病。 精神分裂症大部分的患者是由于在日常的生活和工作当中受到的压力 过大,而患者没有一个良好的疏导的方式所导致。患者在出现该情况 不仅影响本人的正常社会生活,且对家庭和社会也造成很严重的影响。 精神分裂症常见的致病因素: 1、环境因素:工作环境比如经济水平低低收入人群、无职业的人群中,精神分裂症的患病率明显高于经济水平高的职业人群的患病率。还有实际的生活环境生活中的不如意不开心也会诱发该病。 2、心理因素:生活工作中的不开心不满意,导致情绪上的失控,心里长期受到压抑没有办法和没有正确的途径去发泄,如恋爱失败, 婚姻破裂,学习、工作中不愉快都会成为本病的原因。 3、遗传因素:家族中长辈或者亲属中曾经有过这样的病人,后代会出现精神分裂症的机会比正常人要高。 4、精神影响:人的心里与社会要各个方面都有着不可缺少的联系,对社会环境不适应,自己无法融入到社会中去,自己与社会环境不相

适应,精神和心情就会受到一定的影响,大脑控制着人的精神世界, 有可能促发精神分裂症。 5、身体方面:细菌感染、出现中毒情况、大脑外伤、肿瘤、身体的代谢及营养不良等均可能导致使精神分裂症,身体受到外界环境的 影响受到一定程度的伤害,心里受到打击,无法承受伤害造成的痛苦,可能会出现精神的问题。 对于精神分裂症一定要配合治疗,接受全面正确的治疗,最好的 疗法就是中医疗法加心理疗法。早发现并及时治疗并且科学合理的治疗,不要相信迷信,要去正规的医院接受合理的治疗,接受正确的治 疗按照医生的要求对症下药,配合医生和家人,给病人创造一个良好 的治疗环境,对于该病的康复和痊愈会起到意想不到的效果。

外阴白色病变的症状表现有哪些

外阴白色病变的症状表现有哪些 外阴白色病变是慢性外阴的营养不良。属于营养不良的一种。而这也有分为好几个类型,混合型、增生型和硬化苔藓型等等都是外阴白色病变的类型。 外阴奇痒为主要症状,搔痒时间从发病到治疗有2~3月之内,也有达20 年之久,搔痒剧烈程度不分季节与昼夜,如伴有滴虫性或霉菌性阴道炎,分泌物会更多,局部烧灼感,刺痛与搔痒所致的皮肤粘膜破损或感染有关,局部有不同程度的皮肤粘膜色素减退,常有水肿,皲裂及散在的表浅溃疡。 一、增生型营养不良 一般发生在30~60岁的妇女,主要症状为外阴奇痒难忍,抓伤后疼痛加剧,病变范围不一,主要波及大阴唇,阴唇间沟,阴蒂包皮和后联合处,多呈对称性,病变皮肤增厚似皮革,隆起有皱襞,或有鳞屑,湿疹样改变,表面颜色多暗红或粉红,夹杂有界限清晰的白色斑块,一般无萎缩或粘连。 二、硬化苔藓型营养不良 可见于任何年龄,多见于40岁左右妇女,主要症状为病变区发痒,但一般远较增生型病变为轻,晚期出现性交困难,病变累及外阴皮肤,粘膜和肛周围皮肤,除皮肤或粘膜变白,变薄,干燥易皲裂外,并失去弹性,阴蒂多萎缩,且与包皮粘连,小阴唇平坦消失,晚期皮肤菲薄皱缩似卷烟纸,阴道口挛缩狭窄,仅容指尖。 幼女患此病多在小便或大便后感外阴及肛周不适,外阴及肛周区出现锁孔状珠黄色花斑样或白色病损,一般至青春期时,病变多自行消失。 三、混合型营养不良 主要表现为菲薄的外阴发白区的邻近部位,或在其范围内伴有局灶性皮肤增厚或隆起。 四、增生型或混合型伴上皮非典型增生 一般认为在增生型及混合型病变中,仅5、10例可出现非典型增生,且此非典型增生仅限于增生的上皮细胞部分。非典型增生多无特殊临床表现,局部组织活体组织检查为唯一的诊断方法。但如外阴局部出现溃疡。或界限清楚的白色隆起时,在该处活检发现非典型增生,其癌变的可能性较大。

空气中挥发性有机物在线监测技术研究进展

CHEMICAL INDUSTRY AND ENGINEERING PROGRESS 2008年第27卷第5期 ·648· 化 工 进 展 空气中挥发性有机物在线监测技术研究进展 刘景允,孙宝盛,张海丰 (天津大学环境科学与工程学院,天津 300072) 摘 要:综述了近年来国内外在空气中挥发性有机物在线监测技术上的研究进展,对膜萃取气相色谱、质子转移反应质谱、飞行时间质谱、傅里叶变换红外光谱以及激光光谱等在线监测技术进行了介绍和对比,重点讨论了可调谐激光吸收光谱在线监测技术的优势和不足,并对其发展前景进行了展望。 关键词:挥发性有机物;在线监测;可调谐激光吸收光谱 中图分类号:X 831 文献标识码:A 文章编号:1000–6613(2008)05–0648–06 Progress in research on on-line monitoring techniques for volatile organic compounds in ambient air LIU Jingyun ,SUN Baosheng ,ZHANG Haifeng (School of Environmental Science and Technology ,Tianjin University ,Tianjin 300072,China ) Abstract :V olatile organic compounds (VOCs )in air do great harm to human health. This paper reviews the progress in research on the on-line monitoring techniques for volatile organic compounds (VOCs )in recent years at home and abroad. Some on-line monitoring techniques ,including membrane extraction gas chromatography ,proton-transfer-reaction mass spectroscopy ,time-of-flight mass spectrometry ,Fourier transform infrared spectroscopy and laser spectroscopy are introduced and compared. The advantages and shortages of tunable diode laser absorption spectrometry are discussed ,and the prospect of its application is also presented. Key words :volatile organic compounds (VOCs );on-line monitoring ;tunable diode laser absorption spectrometry 挥发性有机化合物(volatile organic compounds ,VOCs )是室内外空气中普遍存在且对环境影响最为严重的有机污染物,主要来源于石油化工生产、污水和垃圾处理厂、汽油发动机尾气以及制药、制鞋、喷漆等行业[1]。VOCs 组成复杂,含量甚微,其中许多物质有致癌、致畸、致突变性,具有遗传毒性及引起“雌性化”,对环境安全和人类生存繁衍构成严重威胁。目前世界各国都已在监测项目中增加了VOCs ,美国的光化学自动监测系统中有56种VOCs ,欧洲也有30多种VOCs 被列入。 目前,测量VOCs 的主要手段是气相色谱-质谱 (gas chromatography- mass spectrometry ,GC-MS ) [2]。该技术在精确测量VOCs 方面一直发挥着重要作用,但由于涉及色谱和电子轰击电离,该方法存在很大的局限性:分析监测具有明显的滞后性;复杂 的样品预处理耗时费力,需要消耗大量的样品和溶剂;在样品的取样、运输与储存的过程中发生的样品损失以及成分间的交叉污染都会使监测结果出现偏差;样品的采集、浓缩提取与分离提高了单个样品的监测费用,监测样品的数目也受到限制[3]。现代环境监测工作要求快速准确地得到所需要的分析结果和信息,以便及时采取相应控制措施,因此空气中VOCs 的在线监测技术研究与相关仪器的开发就显得迫在眉睫。近年来,人们一直致力于VOCs 在线监测方法的研究,出现了多种在线监测技术。 收稿日期:2007–11–05;修改稿日期:2007–12–20。 基金项目:国家高技术研究发展(863)计划项目(2006AA06Z410)。第一作者简介:刘景允(1985—),男,硕士研究生。联系人:孙宝盛,副教授,从事环境监测与废水处理方面研究。E –mail baosheng_sun@https://www.360docs.net/doc/ce16335152.html, 。

TVOC总挥发性有机物检测方法综述

1 前言 总挥发性有机物TVOC是由一种或多种碳原子组成,容易在室温和正常大气压下蒸发的化合物的总称,他们是存在于室内环境中的无色气体。室内环境中的TVOC可能从室外空气中进入,也可能从建筑材料、清洗剂、化妆品、蜡制品、地毯、家具、激光打印机、影印机、粘合剂以及室内的油漆中散发出来。一旦这些TVOC暂时的或持久的超出正常的背景水平,就会引起室内空气质量问题。若暴露在含高浓度VOCs工业环境中,会对人体的中枢神经系统、肝脏、肾脏及血液有毒害影响。长期暴露在诸如苯,致癌物等化合物中可能增加致癌的可能。[1]因为目前VOCs对人体的毒害及感官影响以及他们的成分的了解有限,所以防止过分暴露在VOCs中是十分必要的。TVOC是民用建筑工程室内环境污染控制指标中的一项重要检测指标,本文主要对目前国内外TVOC的检测方法以及TVOC检测过程中的影响因素进行综述。 2 TVOC采样及检测方法介绍 室内空气中TVOC的分析测试技术有很多种,既有非标准化的快速粗略现场检测法,又有比较成熟的标准检测方法;实践分为现场检测和实验室检测两种,其中现场检测精度稍低,可用于样品初筛或精准度要求不高的检测,而实验室检测对设备要求较高。采样技术只有两种:动力泵采样和自然扩散采样,目前应用较多的是动力泵采样。下面简单介绍现阶段用于检测TVOC的几种方法。[2] 2.1 比色管检测法 比色管检测是一种简单实用的检测技术,由一个充满显色物质的玻璃管和一个抽气采样泵构成。在检测时,将玻璃管的两头折断,通过采样泵将室内空气抽入检测管,吸入的气体和显色物质反应,气体浓度与显色长度成比例关系,从而可以直观地得到气体的大致浓度。该方法的不足之处是数据的代表性差,目前的检测范围不足以覆盖全部的TVOC成分。[3] 2.2 便携式TVOC仪检测法 便携式TVOC检测仪可以快速地测定待测环境中TVOC的大致浓度,发现超标再采用色谱或色质联用等方法加以确认,从而达到多快好省的检测目的。该检测仪可以检测绝大多数的VOCs;干扰少,只对有机化合物产生响应,大多数无

重点地区环境空气挥发性有机物监测方案

根据《环境保护部办公厅关于印发2018年重点地区环境空气挥发性有机物监测方案》(环办监测函【2017】2024号),我市与河南省内郑州、新乡、鹤壁、安阳、濮阳、开封市等同属于京津冀及周边地区,须开展环境空气VOCs监测。 为避免设备不同引起的监测结果差异,以满足上级部门开展的实验室间比对等质控措施检查,满足环境管理要求,该套设备须与京津冀及周边地区开展环境空气VOCs监测城市的监测设备的工作原理一致。 一、大气挥发性有机物采样与样品预处理系统主要指标 1.主要用途 主要用于环境空气、应急监测、室内环境气体样品和工业场所空气中VOC的定量采集及处理。并可作为气相色谱和色质联用系统的前处理装置。 2.工作原理 采样罐在实验室被清洗和抽成真空,带到现场后无需电源、动力及辅助设施,即可迅速采样。样品空气拿回实验室经过预浓缩仪进行多级浓缩处理,得到目标待测挥发性有机物,自动转移到气相色谱或气质联用仪中分析。在分析过程中,需要配气装置把高浓度的标准气体稀释为低浓度气体以绘制分析的标准曲线。 3.工作条件 3.1工作电源:AC 220V±10%,50Hz。 3.2工作温度:-5~50℃ 3.3相对湿度:≤90% 4. 技术性能与要求 4.1 为避免设备不同引起的监测结果差异,以满足上级部门开展的实验室间比对等质控措施检查,满足环境管理要求,该套设备须与京津冀及周边地区开展环境空气VOCs监测城市的监测设备的工作原理一致。 4.2该套设备能符合环境标准HJ759-2015以及EPA标准方法TO-14、TO-15中样品采集、分析前处理及标样配制等的要求,可以较好地应用于大气中挥发性有机化合物(包括甲醛、乙醛、丙烯醛、丙酮、丙醛、丁烯醛、甲基丙烯醛、2-丁酮、正丁醛、苯甲醛、戊醛、间甲基苯甲醛、己醛)的检测。

精神分裂症应该怎么治疗

精神分裂症应该怎么治疗 1、坚持服药治疗 服药治疗是最有效的预防复发措施临床大量统计资料表明,大多数精神分裂症的复发与自行停药有关。坚持维持量服药的病人复发率为40%。而没坚持维持量服药者复发率高达80%。因此,病人和家属要高度重视维持治疗。 2、及时发现复发的先兆,及时处理 精神分裂症的复发是有先兆的,只要及时发现,及时调整药物和剂量,一般都能防止复发,常见的复发先兆为:病人无原因出现睡眠不好、懒散、不愿起床、发呆发愣、情绪不稳、无故发脾气、烦躁易怒、胡思乱想、说话离谱,或病中的想法又露头等。这时就应该及时就医,调整治疗病情波动时的及时处理可免于疾病的复发。 3、坚持定期门诊复查 一定要坚持定期到门诊复查,使医生连续地、动态地了解病情,使病人经常处于精神科医生的医疗监护之下,及时根据病情变化调整药量。通过复查也可使端正人及时得到咨询和心理治疗解除病人在生活、工作和药物治疗中的各种困惑,这对预防精神分裂症的复发也起着重要作用。 4、减少诱发因素 家属及周围人要充分认识到精神分裂症病人病后精神状态的薄弱性,帮助安排好日常的生活、工作、学习。经常与病人谈心,帮助病人正确对待疾病,正确对待现实生活,帮助病人提高心理承受能力,学会对待应激事件的方法,鼓励病人增强信心,指导病人充实生活,使病人在没有心理压力和精神困扰的环境中生活。 首先是性格上的改变,塬本活泼开朗爱玩的人,突然变得沉默寡言,独自发呆,不与人交往,爱干净的人也变的不注意卫生、生活

懒散、纪律松弛、做事注意力不集中,总是和患病之前的性格完全 相悖。 再者就是语言表达异常,在谈话中说一些无关的谈话内容,使人无法理解。连最简单的话语都无法准确称述,与之谈话完全感觉不 到重心。 第三个就是行为的异常,行为怪异让人无法理解,喜欢独处、不适意的追逐异性,不知廉耻,自语自笑、生活懒散、时常发呆、蒙 头大睡、四处乱跑,夜不归宿等。 还有情感上的变化,失去了以往的热情,开始变的冷淡、对亲人不关心、和友人疏远,对周围事情不感兴趣,一点消失都可大动干戈。 最后就是敏感多疑,对任何事情比较敏感,精神分裂症患者,总认为有人针对自己。甚至有时认为有人要害自己,从而不吃不喝。 但是也有的会出现难以入眠、容易被惊醒或睡眠不深,整晚做恶梦或者长睡不醒的现象。这些都有可能是患上了精神分裂症。 1.加强心理护理 心理护理是家庭护理中的重要方面,由于社会上普遍存在对精神病人的歧视和偏见,给病人造成很大的精神压力,常表现为自卑、 抑郁、绝望等,有的病人会因无法承受压力而自杀。家属应多给予 些爱心和理解,满足其心理需求,尽力消除病人的悲观情绪。病人 生活在家庭中,与亲人朝夕相处,接触密切,家属便于对病人的情感、行为进行细致的观察,病人的思想活动也易于向家属暴露。家 属应掌握适当的心理护理方法,随时对病人进行启发与帮助,启发 病人对病态的认识,帮助他们树立自信,以积极的心态好地回归社会。 2.重视服药的依从性 精神分裂症病人家庭护理的关键就在于要让病人按时按量吃药维持治疗。如果不按时服药,精神病尤其是精神分裂症的复发率很高。精神病人在医院经过一系统的治疗痊愈后,一般需要维持2~3年的

精神分裂症患者在怎样的情况下会自杀

精神分裂症患者在怎样的情况下会自杀 精神分裂症是最常见的一种精神病。早期主要表现为性格改变,如不理采亲人、不讲卫生、对镜子独笑等。病情进一步发展,即表现为思维紊乱,病人的思考过程缺乏逻辑性和连贯性,言语零乱、词不达意。精神分裂症患者随时有可能出现危险行为,这主要是指伤人毁物、自伤自杀和忽然出走。这些危险行为是受特定的精神症状支配的.那么精神分裂症患者在什么情况下会自杀呢? 被害妄想:这是所有精神病人最常见的症状之一,多数病人采取忍耐、逃避的态度,少数病人也会“先下手为强”,对他的“假想敌”主动攻击。对此,最重要的是弄清病人的妄想对象,即:病人以为是谁要害他。假如病人的妄想对象是某个家里人,则应尽量让这位家属阔别病人,至少不要让他与病人单独在一起。 抑郁情绪:精神分裂症病人在疾病的不同时期,可能出现情绪低落,甚至悲观厌世。特别需要留意的是,有相当一部分自杀成功的病人,是在疾病的恢复期实施自杀行为的。病人在精神病症状消除以后,因自己的病背上了沉重的思想包袱,不能正确对待升学、就业、婚姻等现实问题,感到走投无路,因此选择了轻生。对此,家属一定要防患于未然,要尽早发现病人的心理困扰,及时疏导。 对已经明确表示出自杀观念的病人,家属既不要惊慌失措,也不要躲躲闪闪,要主动与病人讨论自杀的利弊,帮助病人全面、客观地评估现实中碰到的各种困难,找出切实可行的解决办法。 另外,这种病人在自杀之前,是经过周密考虑,并且做了充分预备的,例如写遗书、收拾旧物、向家人离别、选择自杀时间、预备自杀工具等。这类病人的自杀方式也是比较温顺的,多数是服药自杀。因此,他需要一定的时间来积攒足足数目的药物,这时就能看出由家属保管药品的重要性了。只要家属密切观察病人的情绪变化,是不难早期发现病人的自杀企图的。 药源性焦虑:抗精神病药的副作用之一是可能引起病人莫名的焦躁不安、手足无措,并伴有心慌、出汗、恐惧等。这些表现多是发作性的,多数发生在下午到傍晚时分,也有的病人在打长效针以后的2?3天内出现上述表现。这种时间上的规律性,有助于家属判定病人的焦虑情绪是否由于药物所致。病人急于摆脱这种强烈的痛苦,会出现冲动伤人或自伤,这些行为只是为了发泄和解脱,并不以死为终极目的。家属可以在病人发作时,给他服用小剂量的安定类药物,或者在医生的指导下,调整抗精神病药的剂量或品种,这样就可以有效地控制病人的焦虑发作。 极度兴奋:病人的精神症状表现为严重的思维紊乱、言语杂乱无章、行为缺乏目的性,这类病人也可能出现自伤或伤人毁物。由于病人的兴奋躁动是持续性的,家属有充分的思想预备,一般比较轻易防范。家属要保管好家里的刀、剪、火、煤气等危险物品,但最根本的办法,是使用大剂量的、具有强烈镇静作用的药物来控制病人的兴奋。假如在家里护理病人确有困难,则可以强制病人住院治