施耐德软启动器使用作业指导书

施耐德ATS48软启动器使用手册

Altistart 48软起动-软停止单元用户手册User's Manual中文23中文目录起动器设置步骤4出厂配置6初步建议7技术规格8操作建议9起动器-电机组合12尺寸18安装建议20壁挂式或落地式安装的壳体21电源端子22控制端子27连线/RUN-STOP 命令28应用接线图29热保护39显示组件及编程43远程操作盘选件46设定菜单 (Set)47保护菜单 (PrO)52高级设定菜单 (drC)56I/O 菜单 (IO)60第二电机参数菜单 (St2)64通讯菜单 (COP)68参数显示菜单 (SUP)70兼容性表73维护74故障、原因、处理方法75配置/设定值表80中文起动器设置步骤1、Altistart 48 的交货•检查印在标签上的起动器型号与定单相对应的提货单上标注的型号是否一致。

•打开Altistart 48的包装,确认在运输过程中没有发生损坏。

2、根据20页和21页上的指导安装 Altistart 483、按如下步骤连接 Altistart 48:•控制线路电源 (CL1 - CL2),确保电源断开•主电源 (1/L1 - 3/L2 - 5/L3),确保电源断开•电机 (2/T1 - 4/T2 - 6/T3),确保电机电压与电源电压匹配注意: 如果使用旁路接触器,应将其连接到电源端的 L1, L2, L3 和 Altistart 48 上的端子 A2, B2, C2 上。

见30 页图。

如果在电机三角形绕组中使用 ATS48•••Q,应遵循 10、11 页的说明以及 31 页的图示。

ATS48 电力部件框图进线电源2/T1 4/T2 6/T3电机A2 B2 C2起动器旁路45中文起动器设置步骤控制端子的出厂配置:连接RUN (运行) 和STOP (停止) 命令,如有必要还应连接其他输入/输出端子。

Stop 为 1 (通) 且RUN 为 1 (通): 起动命令。

Stop 为 0 (断) 且RUN 为 1 或0: 停机命令。

施耐德ATS22软启动器用户手册[1]

![施耐德ATS22软启动器用户手册[1]](https://uimg.taocdn.com/d3d26d772a160b4e767f5acfa1c7aa00b52a9d99.webp)

施耐德ATS22软启动器用户手册========================一、产品简介------------施耐德ATS22软启动器是一种用于控制三相异步电动机启动和停止的设备,它可以根据设定的参数,对电动机的电压进行平滑调节,从而实现电动机的柔和启动和停止,减少电网冲击和机械应力,提高设备的可靠性和寿命。

适用于额定功率为3至315千瓦的三相异步电动机。

内置了多种保护功能,如过载、过热、过流、短路、缺相、欠压、过压等。

支持多种控制方式,如本地控制、远程控制、串口通讯等。

支持多种工作模式,如标准模式、泵模式、扭矩控制模式等。

具有故障诊断功能,可以记录最近的四次故障信息,并提供故障代码和解决方法。

二、产品安装------------选择合适的安装位置,确保软启动器周围有足够的空间进行散热和维护。

按照软启动器的型号和电动机的额定电流,选择合适的电缆和接线方式。

按照软启动器上的接线图,将电源线、电动机线、控制线等正确地连接到软启动器上。

检查接线是否正确无误,无短路或接地故障。

通电后,检查软启动器上的显示屏是否正常工作,无故障提示。

三、产品参数------------ATS22软启动器有多种型号,其主要参数如下表所示:---型号 ---额定电流(A) ---额定功率(kW) ---尺寸(mm) -----------------------------------------------------------------ATS22D17S ---17 ---7.5 ---140x230x165 -------ATS22D32S ---32 ---15 ---140x230x165 -------ATS22D47S ---47 ---22 ---140x230x165 -------ATS22D62S ---62 ---30 ---140x230x165 -------ATS22D75S ---75 ---37 ---140x230x165 -------ATS22D88S ---88 ---45 ---140x230x165 -------ATS22C11S ---110 ---55 ---210x300x200 -------ATS22C14S ---140 ---75 ---210x300x200 -------ATS22C17S ---170 ---90 ---210x300x200 -------ATS22C21S ---210 ---110 ---210x300x200 -------ATS22C25S ---250 ---132 ---210x300x200 -------ATS22C32S ---320 ---160 ---210x300x200 -------ATS22C41S ---410 ---200 ---210x300x200 -------ATS22C48S ---480 ---250 ---210x300x200 -------ATS22C59S ---590 ---315 ---210x300x200 ----四、产品操作------------参数设置:通过液晶显示屏和按键,可以对软启动器的各种参数进行设置,如启动电压、启动时间、停止时间、工作模式、保护功能等。

Schneider ATS 01 软启动器 说明书

1 这些起动器的设计是针对以下简单应用场合: 2 b 传送

b 传送带 b泵 b 风机 3 b 压缩机 b 自动门 b 小型起重机 b 皮带驱动设备等。

ATS 01 结构紧凑,易于安装,可与其他单元水平并排安装,符合 IEC/EN 60947-42 标准。通过了 UL,CSA,C-Tick,CCC 和 GOST 认证,并具有 e 标志。 ATS 01 软起动器包括 3 个产品系列:

ATS 01 控制端

LI +

LI1

LI2

ATS 01 控制端

01

02

03

3 线控制的连线图

3 线控制的连线图

b 起动时间 控制起动时间意味着作用在电机上的电压斜坡时间可以调整,并且达到逐步起动时 间,该时间取决于电机负载。

b 通过逻辑输入实现的电压提升功能: 激活 BOOST 逻辑输入可使起动过转矩功能克服任何机械摩擦。 当此输入为 1 状态时,此功能有效 ( 输入连接至 + 24 V),且起动器会在起动前一段 受限时间内向电机提供一个固定的电压。

介绍 ( 续 )

异步电动机软起动器 2

ATS 01(从 0.37 到 75kW/3 到 85A)

U

100 % Un

50 % Un

电压斜坡

初始电压

200 ms 应用等于电机额定电压 100% 的电压 BOOST

说明 ( 续 )

触点型号的等效性表 功能 继电器输出

0 V 外部电源 停止命令 运行命令 提供控制电源 提升 起动结束 115 V 外部电源

额定运行电流 起动时间调整范围 减速时间调整范围 起动力矩

起动器类型 用法

I 起动时间

全电压状态或起动器 在静止状态

Schneider Electric ATS22C59Q 软启动器产品说明书

T h e i n f o r m a t i o n p r o v i d e d i n t h i s d o c u m e n t a t i o n c o n t a i n s g e n e r a l d e s c r i p t i o n s a n d /o r t e c h n i c a l c h a r a c t e r i s t i c s o f t h e p e r f o r m a n c e o f t h e p r o d u c t s c o n t a i n e d h e r e i n .T h i s d o c u m e n t a t i o n i s n o t i n t e n d e d a s a s u b s t i t u t e f o r a n d i s n o t t o b e u s e d f o r d e t e r m i n i n g s u i t a b i l i t y o r r e l i a b i l i t y o f t h e s e p r o d u c t s f o r s p e c i f i c u s e r a p p l i c a t i o n s .I t i s t h e d u t y o f a n y s u c h u s e r o r i n t e g r a t o r t o p e r f o r m t h e a p p r o p r i a t e a n d c o m p l e t e r i s k a n a l y s i s , e v a l u a t i o n a n d t e s t i n g o f t h e p r o d u c t s w i t h r e s p e c t t o t h e r e l e v a n t s p e c i f i c a p p l i c a t i o n o r u s e t h e r e o f .N e i t h e r S c h n e i d e r E l e c t r i c I n d u s t r i e s S A S n o r a n y o f i t s a f f i l i a t e s o r s u b s i d i a r i e s s h a l l b e r e s p o n s i b l e o r l i a b l e f o r m i s u s e o f t h e i n f o r m a t i o n c o n t a i n e d h e r e i n .Product data sheetCharacteristicsATS22C59Qsoft starter-ATS22-control 220V-power230V(160kW)/400V(315kW)/440V(355kW)MainRange of product Altistart 22Product or component typeSoft starterProduct destination Asynchronous motorsProduct specific appli-cationSevere and standard applications Component name ATS22Network number of phases3 phasesPower supply voltage 230...440 V (- 15...10 %)Motor power kW355 kW at 440 V 315 kW at 400 V 160 kW at 230 V Factory setting current 560 APower dissipation in W 251 W for standard applications Utilisation category AC-53AType of start Start with torque control (current limited to 3.5 In)Icl nominal current 590 A (connection in the motor supply line) for stan-dard applications IP degree of protectionIP00ComplementaryAssembly style With heat sink Function available Internal bypass Power supply voltage limits 195...484 VPower supply frequency 50...60 Hz (- 10...10 %)Network frequency 45...66 HzDevice connection In the motor supply lineTo the motor delta terminals Control circuit voltage 220...230 V -15...10 % at 50/60 Hz Control circuit consumption 20 W Discrete output number 2Discrete output type(R2)Relay outputs 230 V running, alarm, trip, stopped, not stopped, starting,ready, C/O(R1)Relay outputs 230 V running, alarm, trip, stopped, not stopped, starting,ready, C/OMinimum switching current Relay outputs 100 mA at 12 V, DCMaximum switching currentRelay outputs 2 A at 30 V, DC inductive load, L/R = 7 msRelay outputs 2 A at 250 V, AC inductive load, cos phi = 0.4, L/R = 20 ms Relay outputs 5 A at 30 V, DC resistive load, cos phi = 1Relay outputs 5 A at 250 V, AC resistive load, cos phi = 1Discrete input number 3Discrete input type (LI1, LI2, LI3)logic 5 mA 4.3 kOhm Discrete input voltage 24 V (<= 30 V)Discrete input logic (LI1, LI2, LI3)positive logic state 0 < 5 V and < 2 mA state 1 > 11 V and > 5 mA Output current 0.4...1 Icl adjustable PTC probe input750 Ohm Communication port protocol Modbus Connector type1 RJ45Communication data link SerialPhysical interfaceRS485 multidropTransmission rate4800, 9600 or 19200 bpsMax nodes number31Protection type Thermal protection on starterThermal protection on motorPhase failure on lineMarking CEType of cooling Forced convectionOperating position Vertical +/- 10 degreeHeight455 mmWidth304 mmDepth339.7 mmProduct weight50 kgEnvironmentElectromagnetic compatibility Voltage/Current impulse conforming to IEC 61000-4-5 level 3Immunity to radiated radio-electrical interference conforming to IEC 61000-4-3level 3Immunity to electrical transients conforming to IEC 61000-4-4 level 4Electrostatic discharge conforming to IEC 61000-4-2 level 3Damped oscillating waves conforming to IEC 61000-4-12 level 3Conducted and radiated emissions conforming to IEC 60947-4-2 level A Standards EN/IEC 60947-4-2Product certifications CCCCSAC-TickGOSTULVibration resistance 1.5 mm (f = 2...13 Hz) conforming to EN/IEC 60068-2-61 gn (f = 13...200 Hz) conforming to EN/IEC 60068-2-6Shock resistance15 gn for 11 ms conforming to EN/IEC 60068-2-27Noise level56 dBPollution degree Level 2 conforming to IEC 60664-1Relative humidity<= 95 % without condensation or dripping water conforming to EN/IEC 60068-2-3 Ambient air temperature for operation> 40...< 60 °C with current derating 2.2 % per °C-10...40 °C without deratingAmbient air temperature for storage-25...70 °COperating altitude> 1000...< 2000 m with current derating of 2.2 % per additional 100 m<= 1000 m without deratingOffer SustainabilitySustainable offer status Not Green Premium productRoHS Compliant - since 0939 -Schneider Electric declaration of conformity Product environmental profile Available Download Product EnvironmentalProduct end of life instructions Available Download End Of Life ManualDimensions DrawingsFrame Size E DimensionsMounting and ClearancePrecautionsStandardsThe Altistart 22 soft starter is compliant with pollution Degree 2 as defined in NEMA ICS1-1 or IEC 60664-1.DANGERAir CirculationLeave sufficient free space to help the air required for cooling purposes to circulate from the bottom to the top of the unit.OverheatingTo avoid the soft starter to overheat, respect the following recommendations:●Mount the Altistart 22 Soft Starter within ± 10° of vertical.●Do not locate the Altistart 22 Soft Starter near heat radiating elements.●Electrical current through the Altistart 22 Soft Starter will result in heat losses that must be dissipated into the ambient air immediatelysurrounding the soft starter. To help prevent a thermal fault, provide sufficient enclosure cooling and/or ventilation to limit the ambient temperature around the soft starter.●If several soft starters are installed in a control panel, arrange them in a row. Do not stack soft starters. Heat generated from the bottomsoft starter can adversely affect the ambient temperature around the top soft starter.Wall mounted or Floor-standing Enclosure with IP 23 Degree of protectionIntroductionTo help proper air circulation in the soft starter, grilles and forced ventilation can be installed.Ventilation GrillesForced Ventilation UnitProduct data sheetConnections and SchemaATS22C59QPower TerminalBar StylePower supply and output to motor Barb 40 mm (1.18 in)a5 mm (0.2 in)BoltM12 (0.47 in)Cable and protective cover Size 2X240 mm²Gauge2X500 MCM Protective cover LA9F703Tightening torque 57 N.m498.75 lb.inPower connections, minimum required wiring section230 Vac control, logic Inputs (LI) 24 Vdc, 3-wire control With Line Contactor, Freewheel or Controlled Stop230 Vac control, logic Inputs (LI) 24 Vdc, 2-wire control,freewheel stopConnection in the motor delta winding in series with each windingWiringATS22 soft starters connected to motors with the delta connections can be inserted in series in the motor windings.The following wiring requieres particular attention. It is documented in the Altistart 22 Soft start - soft stop unit user manual. Please contact Schneider Electric commercial organisation for further informations.ExampleA 400 V - 110 kW motor with a line current of 195 A (nominal current for the delta connection). The current in each winding is equal to 195/1.5 or 130 A. The rating is determined by selecting the soft starter with a permanent nominal current (ICL) just above this current.Product data sheetPerformance CurvesATS22C59QMotor Thermal Protection - Cold CurvesCurvesA Class 10B Class 20C Class 30Trip time for a Standard Application (Class 10)3.5 ln 32 sTrip time for a Severe Application (Class 20)3.5 ln 63 sTrip time for a Severe Application (Class 30)3.5 ln 95 sMotor Thermal Protection - Warm CurvesCurvesA Class 10B Class 20C Class 30Trip time for a Standard Application (Class 10)3.5 ln 16 sTrip time for a Severe Application (Class 20)3.5 ln 32 sTrip time for a Severe Application (Class 30)3.5 ln 48 s。

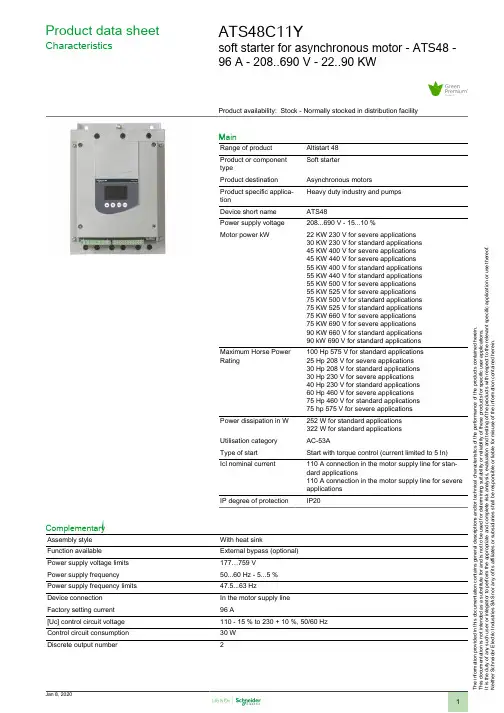

Schneider Electric ATS48C11Y软启动器用户指南说明书

T h e i n f o r m a t i o n p r o v i d e d i n t h i s d o c u m e n t a t i o n c o n t a i n s g e n e r a l d e s c r i p t i o n s a n d /o r t e c h n i c a l c h a r a c t e r i s t i c s o f t h e p e r f o r m a n c e o f t h e p r o d u c t s c o n t a i n e d h e r e i n .T h i s d o c u m e n t a t i o n i s n o t i n t e n d e d a s a s u b s t i t u t e f o r a n d i s n o t t o b e u s e d f o r d e t e r m i n i n g s u i t a b i l i t y o r r e l i a b i l i t y o f t h e s e p r o d u c t s f o r s p e c i f i c u s e r a p p l i c a t i o n s .I t i s t h e d u t y o f a n y s u c h u s e r o r i n t e g r a t o r t o p e r f o r m t h e a p p r o p r i a t e a n d c o m p l e t e r i s k a n a l y s i s , e v a l u a t i o n a n d t e s t i n g o f t h e p r o d u c t s w i t h r e s p e c t t o t h e r e l e v a n t s p e c i f i c a p p l i c a t i o n o r u s e t h e r e o f .N e i t h e r S c h n e i d e r E l e c t r i c I n d u s t r i e s S A S n o r a n y o f i t s a f f i l i a t e s o r s u b s i d i a r i e s s h a l l b e r e s p o n s i b l e o r l i a b l e f o r m i s u s e o f t h e i n f o r m a t i o n c o n t a i n e d h e r e i n .Product data sheetCharacteristicsATS48C11Ysoft starter for asynchronous motor - ATS48 -96 A - 208..690 V - 22..90 KWProduct availability: Stock - Normally stocked in distribution facilityMainRange of product Altistart 48Product or component typeSoft starterProduct destination Asynchronous motorsProduct specific applica-tionHeavy duty industry and pumps Device short name ATS48Power supply voltage 208...690 V - 15...10 %Motor power kW22 KW 230 V for severe applications 30 KW 230 V for standard applications 45 KW 400 V for severe applications 45 KW 440 V for severe applications 55 KW 400 V for standard applications 55 KW 440 V for standard applications 55 KW 500 V for severe applications 55 KW 525 V for severe applications 75 KW 500 V for standard applications 75 KW 525 V for standard applications 75 KW 660 V for severe applications 75 KW 690 V for severe applications 90 KW 660 V for standard applications 90 kW 690 V for standard applications Maximum Horse Power Rating100 Hp 575 V for standard applications 25 Hp 208 V for severe applications 30 Hp 208 V for standard applications 30 Hp 230 V for severe applications 40 Hp 230 V for standard applications 60 Hp 460 V for severe applications 75 Hp 460 V for standard applications 75 hp 575 V for severe applications Power dissipation in W 252 W for standard applications 322 W for standard applications Utilisation category AC-53AType of start Start with torque control (current limited to 5 In)Icl nominal current110 A connection in the motor supply line for stan-dard applications110 A connection in the motor supply line for severe applications IP degree of protectionIP20ComplementaryAssembly style With heat sinkFunction available External bypass (optional)Power supply voltage limits 177…759 V Power supply frequency 50...60 Hz - 5...5 %Power supply frequency limits 47.5...63 HzDevice connection In the motor supply line Factory setting current 96 A[Uc] control circuit voltage 110 - 15 % to 230 + 10 %, 50/60 Hz Control circuit consumption 30 W Discrete output number2Discrete output type LO1) logic output 0 V common configurableLO2) logic output 0 V common configurableR1) relay outputs fault relay NO(R2) relay outputs end of starting relay NOR3) relay outputs motor powered NOOutput absolute accuracy precision+/- 5 %Minimum switching current10 mA 6 V DC relay outputsMaximum switching current Logic output 0.2 A 30 V DCRelay outputs 1.8 A 230 V AC inductive, cos phi = 0.5 20 msRelay outputs 1.8 A 30 V DC inductive, cos phi = 0.5 20 msDiscrete input number5Discrete input type PTC, 750 Ohm 77 °F (25 °C)Stop, Run, LI3, LI4) logic, <= 8 mA 4300 OhmDiscrete input voltage24 V <= 30 VDiscrete input logic Positive logic Stop, Run, LI3, LI4 < 5 V <= 2 mA > 11 V, >= 5 mA Starting current0.4...1.3 Icl adjustableAnalogue output type Current output AO 0-20 mA or 4-20 mA 500 OhmCommunication port protocol ModbusConnector type 1 RJ45Communication data link SerialPhysical interface RS485 multidropTransmission rate4800, 9600 or 19200 bpsMax nodes number31Protection type Phase failure lineThermal protection motorThermal protection starterMarking CEType of cooling Forced convectionOperating position Vertical +/- 10 degreeHeight11.42 in (290 mm)Width7.48 in (190 mm)Depth9.25 in (235 mm)Net weight18.30 lb(US) (8.3 kg)Motor power range AC-315…25 KW 200…240 V 3 phase30…50 KW 200…240 V 3 phase55…100 KW 380…440 V 3 phase55…100 kW 480…500 V 3 phaseMotor starter type Soft starterEnvironmentElectromagnetic compatibility Conducted and radiated emissions level A IEC 60947-4-2Conducted and radiated emissions level B IEC 60947-4-2Damped oscillating waves level 3 IEC 61000-4-12Electrostatic discharge level 3 IEC 61000-4-2Immunity to electrical transients level 4 IEC 61000-4-4Immunity to radiated radio-electrical interference level 3 IEC 61000-4-3Voltage/current impulse level 3 IEC 61000-4-5Standards EN/IEC 60947-4-2Product certifications GOSTTCFCCCSEPRONOM 117C-TickCSAULDNVVibration resistance 1 gn 13…200 Hz)EN/IEC 60068-2-61.5 mm 2…13 Hz)EN/IEC 60068-2-6Shock resistance15 gn 11 ms EN/IEC 60068-2-27Noise level58 dBPollution degree Level 3 IEC 60664-1Relative humidity0…95 % without condensation or dripping water EN/IEC 60068-2-3Ambient air temperature for operation104…140 °F (40…60 °C) with current derating of 2 % per °C)14…104 °F (-10…40 °C) without)Ambient air temperature for storage-13…158 °F (-25…70 °C)Operating altitude<= 3280.84 ft (1000 m) without> 3280.84...6561.68 ft (> 1000...2000 m) with current derating of 2.2 % per addi-tional 100 mOrdering and shipping detailsCategory22579 - OPEN ATS48 ALTISTARTDiscount Schedule CP1GGTIN00785901982340Package weight(Lbs)9.76 kg (21.52 lb(US))Returnability YesCountry of origin IDOffer SustainabilitySustainable offer status Green Premium productREACh Regulation REACh DeclarationEU RoHS Directive Pro-active compliance (Product out of EU RoHS legal scope)EU RoHS Decla-rationMercury free YesRoHS exemption information YesChina RoHS Regulation China RoHS DeclarationEnvironmental Disclosure Product Environmental ProfileCircularity Profile End Of Life InformationWEEE The product must be disposed on European Union markets following specificwaste collection and never end up in rubbish bins.Contractual warrantyWarranty18 monthsDimensions DrawingsDimensions(1) Right View (2) Front ViewMounting and Clearance Clearance。

施耐德软启动器使用作业指导书

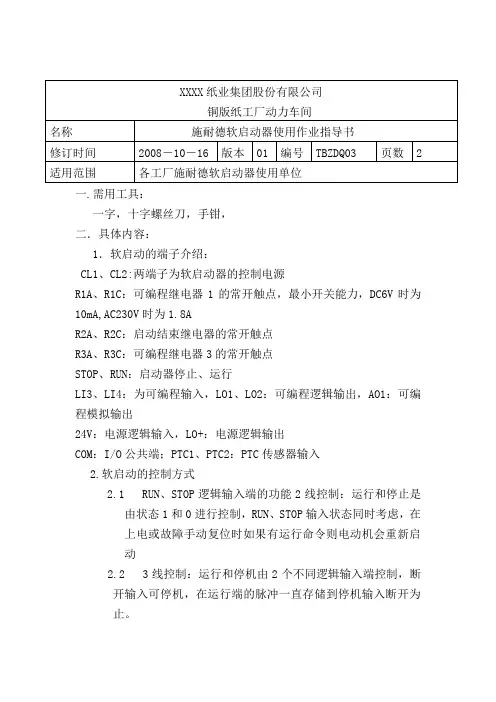

XXXX纸业集团股份有限公司铜版纸工厂动力车间名称施耐德软启动器使用作业指导书修订时间2008-10-16 版本 01 编号TBZDQ03 页数 2 适用范围各工厂施耐德软启动器使用单位一.需用工具:一字,十字螺丝刀,手钳,二.具体内容:1.软启动的端子介绍:CL1、CL2:两端子为软启动器的控制电源R1A、R1C:可编程继电器1的常开触点,最小开关能力,DC6V时为10mA,AC230V时为1.8AR2A、R2C:启动结束继电器的常开触点R3A、R3C:可编程继电器3的常开触点STOP、RUN:启动器停止、运行LI3、LI4:为可编程输入,LO1、LO2:可编程逻辑输出,AO1:可编程模拟输出24V:电源逻辑输入,LO+:电源逻辑输出COM:I/O公共端;PTC1、PTC2:PTC传感器输入2.软启动的控制方式2.1 RUN、STOP逻辑输入端的功能2线控制:运行和停止是由状态1和0进行控制,RUN、STOP输入状态同时考虑,在上电或故障手动复位时如果有运行命令则电动机会重新启动2.2 3线控制:运行和停机由2个不同逻辑输入端控制,断开输入可停机,在运行端的脉冲一直存储到停机输入断开为止。

2.3在上电或故障手动复位时或在一个停机命令之后,电机只能在运行输入端断开后跟着一个新脉冲时才能上电。

3.软启动的过温保护3.1启动器会根据受控制的额定电流和实际吸收的电流持续的计算电机的温升3.1.1温升可能由长时间或短时间的欠载或过载引起。

3.1.2启动器出厂设置为10级保护,可以使用PrO菜单修改保护等级3.2启动器显示的热保护对应于加热时间常数。

3.2.1如果电机超过了其额定温升阀值(电机热状态=110%),激活过载报警。

3.2.2如果超过了临界温升阀值(电机热状态=125%),热故障将使电动机停止3.2.3在出现启动延长时,即使显示的值低于脱扣值启动器也能由故障或热报警脱扣3.2.4如果没有禁止热保护,则热故障可以由继电器R1指示3.2.5软启动热控制系统可以防止在电动机温升过高的情况下重新启动电机三、注意事项及相关案例:铜版纸工厂空压机用一软启动器显示内部故障报警,且不能复位,确定软启动器坏。

Schneider Electric ATS01N212RT软启动器数据手册说明书

T h e i n f o r m a t i o n p r o v i d e d i n t h i s d o c u m e n t a t i o n c o n t a i n s g e n e r a l d e s c r i p t i o n s a n d /o r t e c h n i c a l c h a r a c t e r i s t i c s o f t h e p e r f o r m a n c e o f t h e p r o d u c t s c o n t a i n e d h e r e i n .T h i s d o c u m e n t a t i o n i s n o t i n t e n d e d a s a s u b s t i t u t e f o r a n d i s n o t t o b e u s e d f o r d e t e r m i n i n g s u i t a b i l i t y o r r e l i a b i l i t y o f t h e s e p r o d u c t s f o r s p e c i f i c u s e r a p p l i c a t i o n s .I t i s t h e d u t y o f a n y s u c h u s e r o r i n t e g r a t o r t o p e r f o r m t h e a p p r o p r i a t e a n d c o m p l e t e r i s k a n a l y s i s , e v a l u a t i o n a n d t e s t i n g o f t h e p r o d u c t s w i t h r e s p e c t t o t h e r e l e v a n t s p e c i f i c a p p l i c a t i o n o r u s e t h e r e o f .N e i t h e r S c h n e i d e r E l e c t r i c I n d u s t r i e s S A S n o r a n y o f i t s a f f i l i a t e s o r s u b s i d i a r i e s s h a l l b e r e s p o n s i b l e o r l i a b l e f o r m i s u s e o f t h e i n f o r m a t i o n c o n t a i n e d h e r e i n .Product data sheetCharacteristicsATS01N212RTsoft starter for asynchronous motor - ATS01 -12 A - 460..480 VProduct availability: Stock - Normally stocked in distribution facilityMainRange of product Altistart 01Product or component typeSoft starterProduct destination Asynchronous motors Product specific applica-tionSimple machine Device short name ATS01Phase3 phase[Us] rated supply volt-age460...480 V - 10...10 %Maximum Horse Power Rating7.5 hp, 3 phase 460...480 V IcL starter rating 12 AUtilisation category AC-53B EN/IEC 60947-4-2Current consumption 60 A at nominal load Type of startStart with voltage rampPower dissipation in W4 W at full load and at end of starting 124 W in transient stateComplementaryAssembly style With heat sink Function available Integrated bypass Supply voltage limits 414…528 V Supply frequency 50...60 Hz - 5...5 %Network frequency 47.5...63 HzOutput voltage<= power supply voltage [Uc] control circuit voltage Built into the starter Starting timeAdjustable from 1 to 10 s Deceleration time symb Adjustable from 1 to 10 sStarting torque 30...80 % of starting torque of motor connected directly on the line supply Discrete input type Logic LI1, LI2, BOOST) stop, run and boost on start-up functions <= 8 mA 27kOhm Discrete input voltage 24...40 VDiscrete input logic Positive LI1, LI2, BOOST < 5 V <= 0.2 mA > 13 V, >= 0.5 mA Discrete output current 2 A DC-133 A AC-15Discrete output type Open collector logic LO1 end of starting signal Relay outputs R1A, R1C NO Discrete output voltage 24 V 6...30 V) open collector logic Minimum switching current 10 mA 6 V DC relay outputsMaximum switching current Relay outputs 2 A 250 V AC cos phi = 0.5 20 ms inductive Relay outputs 2 A 30 V DC cos phi = 0.5 20 ms inductive Display type 1 LED green)starter powered up1 LED yellow)nominal voltage reached Tightening torque16.82…22.13 Lbf.In (1.9…2.5 N.m)4.43 lbf.in (0.5 N.m)Electrical connection 4 mm screw clamp terminal - rigid 1 1...10 mm² AWG 8 power circuitScrew connector - rigid 1 0.5...2.5 mm² AWG 14 control circuit4 mm screw clamp terminal - rigid 2 1...6 mm² AWG 10 power circuitScrew connector - rigid 2 0.5...1 mm² AWG 17 control circuitScrew connector - flexible with cable end 1 0.5...1.5 mm² AWG 16 control circuit4 mm screw clamp terminal - flexible without cable end 1 1.5...10 mm² AWG 8power circuitScrew connector - flexible without cable end 1 0.5...2.5 mm² AWG 14 control cir-cuit4 mm screw clamp terminal - flexible with cable end 2 1...6 mm² AWG 10 powercircuit4 mm screw clamp terminal - flexible without cable end 2 1.5...6 mm² AWG 10power circuitScrew connector - flexible without cable end 2 0.5...1.5 mm² AWG 16 control cir-cuitMarking CEOperating position Vertical +/- 10 degreeHeight 4.88 in (124 mm)Width 1.77 in (45 mm)Depth 5.16 in (131 mm)Net weight0.93 lb(US) (0.42 kg)Compatibility code ATS01N2EnvironmentElectromagnetic compatibility Conducted and radiated emissions level B CISPR 11Conducted and radiated emissions level B IEC 60947-4-2Damped oscillating waves level 3 IEC 61000-4-12Electrostatic discharge level 3 IEC 61000-4-2EMC immunity EN 50082-1EMC immunity EN 50082-2Harmonics IEC 1000-3-2Harmonics IEC 1000-3-4Immunity to conducted interference caused by radio-electrical fields level 3 IEC61000-4-6Immunity to electrical transients level 4 IEC 61000-4-4Immunity to radiated radio-electrical interference level 3 IEC 61000-4-3Micro-cuts and voltage fluctuation IEC 61000-4-11Voltage/current impulse level 3 IEC 61000-4-5Standards EN/IEC 60947-4-2Product certifications ULB44.1-96/ASME A17.5 for starter wired to the motor delta terminalCSACCCC-TickGOSTIP degree of protection IP20Pollution degree 2 EN/IEC 60947-4-2Vibration resistance 1 gn 13…150 Hz)EN/IEC 60068-2-61.5 mm peak to peak 3…13 Hz)EN/IEC 60068-2-6Shock resistance15 gn 11 ms EN/IEC 60068-2-27Relative humidity5…95 % without condensation or dripping water EN/IEC 60068-2-3Ambient air temperature for operation14…104 °F (-10…40 °C) without)104…122 °F (40…50 °C) with current derating of 2 % per °C)Ambient air temperature for storage-13…158 °F (-25…70 °C) EN/IEC 60947-4-2Operating altitude<= 3280.84 ft (1000 m) without> 3280.84 ft (1000 m) with current derating of 2.2 % per additional 100 m Ordering and shipping detailsCategory22392 - ATSU01/ATS01 LOW HP SOFT STARTERSDiscount Schedule I11GTIN00785901588337Package weight(Lbs)0.50 kg (1.11 lb(US))Returnability YesCountry of origin DEOffer SustainabilityREACh Regulation REACh DeclarationREACh free of SVHC YesEU RoHS Directive Pro-active compliance (Product out of EU RoHS legal scope)EU RoHS Decla-rationToxic heavy metal free YesMercury free YesRoHS exemption information YesChina RoHS Regulation China RoHS DeclarationCircularity Profile End Of Life InformationWEEE The product must be disposed on European Union markets following specificwaste collection and never end up in rubbish bins.Contractual warrantyWarranty18 monthsDimensions DrawingsDimensionsMounting on Symetrical (35 mm) RailScrew Fixing(1)Retractable fixingsConnections and Schema Example of Manual ControlA1 :Soft start/soft stop unit(1)For type 2 coordinationQ1 :Motor circuit-breakerF3 : 3 fast-acting fusesTechnical DescriptionFunction Diagram2-wire Control with DecelerationUs :Power supply voltageGreen LEDLED1 :LI2 :Logic inputR1 :Relay outputLO1 :Logic outputLEDYellow LED2 :3-wire Control with DecelerationUs :Power supply voltageGreen LEDLED1 :Logic inputsLI2,LI1 :R1 :Relay outputLO1 :Logic outputUm :Motor voltageLEDYellow LED2 :。

ATS22施耐德软启动操作流程

ATS22施耐德软启动操作流程引言:一、ATS22软启动器的组成与功能ATS22软启动器主要由主控模块、电源模块、保护模块等部分组成。

主控模块通过控制电路和触摸屏操作,实现对电机的启动、停止、设定转速等功能;电源模块为整个设备提供电能供给;保护模块用于监测电机的运行状态,一旦发生异常情况,如电压过高、电流过载等,保护模块会及时切断电源,从而保护电机的安全运行。

二、软启动器的操作流程1.准备工作:a.确保电源供应稳定,并连接好ATS22软启动器;b.检查起动电机的线路接线是否正确;c.检查软启动器的参数设置是否符合实际要求。

2.启动操作:a.打开ATS22软启动器的电源开关,主控模块开始运行;b.在触摸屏上选择启动模式,如手动、自动等;c.设置电机的额定电流、启动电流、启动时间等参数;d.通过触摸屏或外部控制信号启动电机;e.主控模块将依次开启软启动器的接触器,逐步使电机达到设定的启动电流和转速;f.一旦电机达到设定的转速,主控模块将维持设定状态,并进入运行模式。

3.运行操作:a.在转速控制模式下,主控模块可以通过触摸屏或外部控制信号改变电机的转速;b.在保护模式下,保护模块会实时监测电机的电压、电流等参数,一旦发生异常情况,如过载、过热等,保护模块会及时切断电源,避免损坏电机;c.在停机模式下,通过触摸屏或外部控制信号停止电机的运行。

4.停机操作:a.在通常情况下,可以通过触摸屏或外部控制信号停止电机的运行;b.在紧急情况下,如电源故障、电机过热等,软启动器会自动切断电源,停止电机运行。

5.维护操作:a.定期检查ATS22软启动器的运行状态,如触摸屏的响应速度、运行指示灯;b.定期检查软启动器的接线是否松动,紧固螺丝是否正常;c.定期清洁软启动器的外壳,并及时更换老化的部件,如保护模块。

三、易错点与应对措施1.启动电机时,发现软启动器没有反应:a.检查电源线路是否通电;b.检查软启动器的开关是否打开。

施耐德ATS22软启动器使用说明

决方案融合在一个统一的架构下 , 通过标准的界面为各行业客户提供一个开放

、 透明 、 节能 、 高效的

能效管理平台 ,为企业客户节省高达 30 % 的投资成本和运营成本 。

目录

重要信息 ___________________________________________________________________________________________________________________4 开始之前 ___________________________________________________________________________________________________________________5 文档结构 ___________________________________________________________________________________________________________________6

软起动器设置步骤 ( 另参见 “快速起动”指南 ) ____________________________________________________________________ 7

接收和搬运 _________________________________________________________________________________________________________________8 选型 _____________________________________________________________________________________________________________

施耐德ATS22软启动器用户手册

ATS22软起动-软停止单元用户手册施耐德电气在中国1987年,施耐德电气在天津成立第一家合资工厂梅兰日兰,将断路器技术带到中国,取代传统保险丝,使得中国用户用电安全性大为增强,并为断路器标准的建立作出了卓越的贡献。

90年代初,施耐德电气旗下品牌奇胜率先将开关面板带入中国,结束了中国使用灯绳开关的时代。

施耐德电气的高额投资有力地支持了中国的经济建设,并为中国客户提供了先进的产品支持和完善的技术服务,中低压电器、变频器、接触器等工业产品大量运用在中国国内的经济建设中,促进了中国工业化的进程。

目前,施耐德电气在中国共建立了77个办事处,26家工厂,6个物流中心,1个研修学院,3个研发中心,1个实验室,500家分销商和遍布全国的销售网络。

施耐德电气中国目前员工数近22,000人。

通过与合作伙伴以及大量经销商的合作,施耐德电气为中国创造了成千上万个就业机会。

施耐德电气 能效管理平台全球能效管理专家施耐德电气为世界100多个国家提供整体解决方案,其中在能源与基础设施、工业过程控制、楼宇自动化和数据中心与网络等市场处于世界领先地位,在住宅应用领域也拥有强大的市场能力。

致力于为客户提供安全、可靠、高效的能源,施耐德电气2009年的销售额为158亿欧元,拥有超过100,000名员工。

施耐德电气助您——善用其效,尽享其能!施耐德电气善用其效 尽享其能凭借其对五大市场的的深刻了解、对集团客户的悉心关爱,以及在能效管理领域的丰富经验,施耐德电气从一个优秀的产品和设备供应商逐步成长为整体解决方案提供商。

今年,施耐德电气首次集成其在建筑楼宇、IT 、安防、电力及工业过程和设备等五大领域的专业技术和经验,将其高质量的产品和解决方案融合在一个统一的架构下,通过标准的界面为各行业客户提供一个开放、透明、节能、高效的能效管理平台,为企业客户节省高达30%的投资成本和运营成本。

目录重要信息___________________________________________________________________________________________________________________ 4开始之前___________________________________________________________________________________________________________________ 5文档结构___________________________________________________________________________________________________________________ 6软起动器设置步骤(另参见“快速起动”指南)____________________________________________________________________ 7接收和搬运_________________________________________________________________________________________________________________ 8选型_______________________________________________________________________________________________________________________ 10尺寸和重量_________________________________________________________________________________________________________________ 14安装________________________________________________________________________________________________________________________ 17安装 - 风扇选件_____________________________________________________________________________________________________________ 20热保护____________________________________________________________________________________________________________________ 22连线_______________________________________________________________________________________________________________________ 26连线 - 动力端子_____________________________________________________________________________________________________________ 32连线 - 控制端子_____________________________________________________________________________________________________________ 35连线 - 标准连接 - 应用图_____________________________________________________________________________________________________ 38显示终端__________________________________________________________________________________________________________________ 42远程显示终端 - 选件_________________________________________________________________________________________________________ 44编程_______________________________________________________________________________________________________________________ 45参数列表__________________________________________________________________________________________________________________ 48参数设置__________________________________________________________________________________________________________________ 49配置菜单(ConF)___________________________________________________________________________________________________________ 50设定菜单(SEt)______________________________________________________________________________________________________________ 51高级调整菜单(AdJ)_________________________________________________________________________________________________________ 53高级设定菜单(SEt2)________________________________________________________________________________________________________ 55高级保护菜单(PrO)_________________________________________________________________________________________________________ 56高级输入/输出菜单(IO)____________________________________________________________________________________________________ 60高级通讯菜单(COP)________________________________________________________________________________________________________ 62高级监视菜单(SUP)________________________________________________________________________________________________________ 63实用菜单(UtIL)_____________________________________________________________________________________________________________ 64命令通道__________________________________________________________________________________________________________________ 65 Modbus功能_______________________________________________________________________________________________________________ 68与RS485总线的连接_______________________________________________________________________________________________________ 73维护_______________________________________________________________________________________________________________________ 74诊断/故障排查____________________________________________________________________________________________________________ 75参数索引和Modbus通讯地址________________________________________________________________________________________________ 77附录1:UL508图解________________________________________________________________________________________________________ 82附录2:短路额定值和支路保护______________________________________________________________________________________________ 8434重要信息注意在安装、操作或维护本设备之前,请仔细阅读这些说明,并熟悉本设备。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

XXXX纸业集团股份有限公司

铜版纸工厂动力车间

名称施耐德软启动器使用作业指导书

修订时间2008-10-16 版本 01 编号TBZDQ03 页数 2 适用范围各工厂施耐德软启动器使用单位

一.需用工具:

一字,十字螺丝刀,手钳,

二.具体内容:

1.软启动的端子介绍:

CL1、CL2:两端子为软启动器的控制电源

R1A、R1C:可编程继电器1的常开触点,最小开关能力,DC6V时为10mA,AC230V时为1.8A

R2A、R2C:启动结束继电器的常开触点

R3A、R3C:可编程继电器3的常开触点

STOP、RUN:启动器停止、运行

LI3、LI4:为可编程输入,LO1、LO2:可编程逻辑输出,AO1:可编程模拟输出

24V:电源逻辑输入,LO+:电源逻辑输出

COM:I/O公共端;PTC1、PTC2:PTC传感器输入

2.软启动的控制方式

2.1 RUN、STOP逻辑输入端的功能2线控制:运行和停止是

由状态1和0进行控制,RUN、STOP输入状态同时考虑,在

上电或故障手动复位时如果有运行命令则电动机会重新启

动

2.2 3线控制:运行和停机由2个不同逻辑输入端控制,断

开输入可停机,在运行端的脉冲一直存储到停机输入断开为

止。

2.3在上电或故障手动复位时或在一个停机命令之后,电机只

能在运行输入端断开后跟着一个新脉冲时才能上电。

3.软启动的过温保护

3.1启动器会根据受控制的额定电流和实际吸收的电流持续的

计算电机的温升

3.1.1温升可能由长时间或短时间的欠载或过载引起。

3.1.2启动器出厂设置为10级保护,可以使用PrO菜单修改保

护等级

3.2启动器显示的热保护对应于加热时间常数。

3.2.1如果电机超过了其额定温升阀值(电机热状态=110%),

激活过载报警。

3.2.2如果超过了临界温升阀值(电机热状态=125%),热故

障将使电动机停止

3.2.3在出现启动延长时,即使显示的值低于脱扣值启动器也

能由故障或热报警脱扣

3.2.4如果没有禁止热保护,则热故障可以由继电器R1指示

3.2.5软启动热控制系统可以防止在电动机温升过高的情况下

重新启动电机

三、注意事项及相关案例:

铜版纸工厂空压机用一软启动器显示内部故障报警,且不能复位,确定软启动器坏。

按照本作业指导书更换施耐德软启动器

四、补充修改内容:

修改内容修改原因修改人确认人时间。