Supplier Equipment Cost Breakdown - Contractual

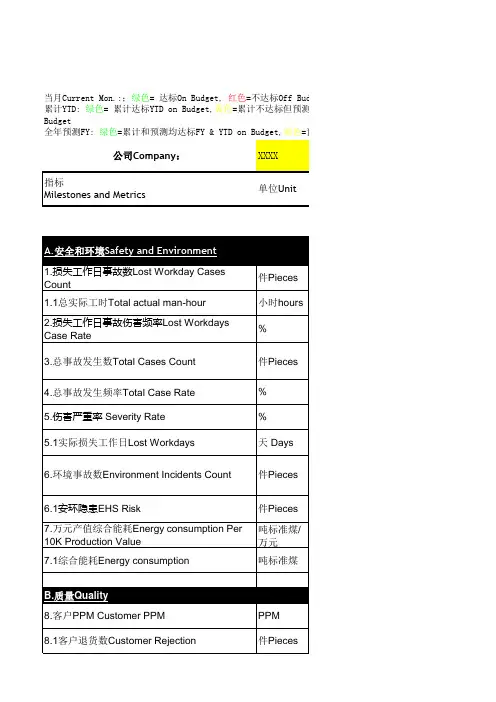

BSC工厂运营绩效评估(平衡积分卡)-上传

XXX

1月

指标解释Explanation

Jan 预算&目标

指员工受伤后需要歇工8小时及以上的工伤事故数 Number of cases that injured employee need to rest at least 8 work hours 指所有在册员工实际工作工时之和 Actual work hours in current month* Employee number 损失工作日事故数*200000/总工时 Lost workday cases number * 200000/ Total man hour 总事故包括损工事故、治疗事故 Total cases, include lost workday cases, therapy cases and attempt cases with high danger 总事故发生数*200000/总工时 Total Cases Count * 200000/ Total man hour 实际损失工作日天数*200000/总工时 Lost workdays* 200000/ Total man hour 受伤失能天数-期间周六、周日天数-法定节假日天数 weekdays of injured staff had to be out of work 1.受到环境行政部门处罚的事件;2.严重违反环境法规可能导致行政处罚的事 件 1.Punished by administration; 2.Disobey the rule of law and might be p日u常nis巡he查d中by发a现dm的in不is符tra合tio安n.环标准或操作规程的事件 EHS risk exposed by daily inspection 当月折算成吨标准煤的综合能耗/当月万元产值 Energy consumption converted into Ton Standard Coal / 10 k RMB 当月折算成吨标准煤的综合能耗 Energy consumption converted into Ton Standard Coal

供应链降本的方法英文版

供应链降本的方法英文版1、Supplier negotiation: negotiate with suppliers to reduce prices, improve quality, and reduce delivery time.2、Streamlining logistics: optimize logistics operations to reduce transportation costs and inventory carrying costs.3、Inventory management: optimize inventory levels to reduce carrying costs and improve responsiveness to demand changes.4、Process automation: use technology to automate processes and reduce labor costs.5、Cost reduction: identify and eliminate unnecessary costs throughout the supply chain.6、Sourcing strategies: evaluate sourcing options to reduce costs and risks.7、Contracting: negotiate better contracts with suppliers to reduce costs and risks.8、Improving demand forecasting: improve demand forecasting accuracy to reduce overstocking and understocking.9、Cross-functional collaboration: improve collaboration between different functions within the organization to reduce costs and improve efficiency.10、Benchmarking: compare performance with industry standards to identify areas for improvement and cost reduction.1、供应商谈判:与供应商协商以降低价格、提高质量和缩短交货时间。

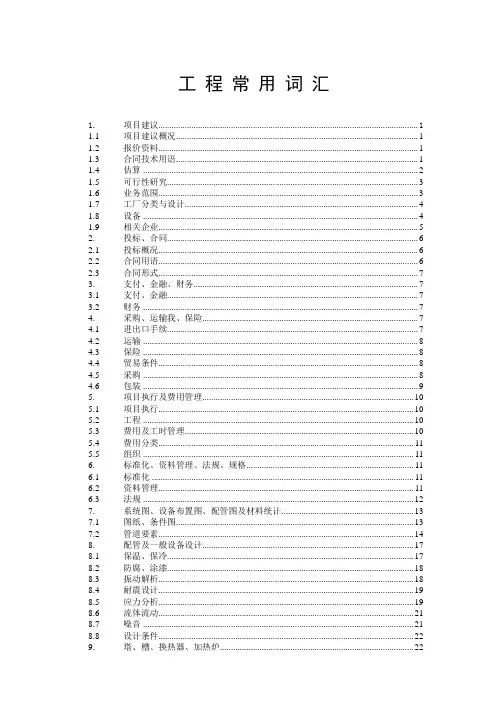

工程常用词汇中英对照

工程常用词汇1.项目建议 (1)1.1 项目建议概况 (1)1.2 报价资料 (1)1.3 合同技术用语 (1)1.4 估算 (2)1.5 可行性研究 (3)1.6 业务范围 (3)1.7 工厂分类与设计 (4)1.8 设备 (4)1.9 相关企业 (5)2. 投标、合同 (6)2.1 投标概况 (6)2.2 合同用语 (6)2.3 合同形式 (7)3. 支付、金融、财务 (7)3.1 支付、金融 (7)3.2 财务 (7)4. 采购、运输我、保险 (7)4.1 进出口手续 (7)4.2 运输 (8)4.3 保险 (8)4.4 贸易条件 (8)4.5 采购 (8)4.6 包装 (9)5. 项目执行及费用管理 (10)5.1 项目执行 (10)5.2 工程 (10)5.3 费用及工时管理 (10)5.4 费用分类 (11)5.5 组织 (11)6. 标准化、资料管理、法规、规格 (11)6.1 标准化 (11)6.2 资料管理 (11)6.3 法规 (12)7. 系统图、设备布置图、配管图及材料统计 (13)7.1 图纸、条件图 (13)7.2 管道要素 (14)8. 配管及一般设备设计 (17)8.1 保温、保冷 (17)8.2 防腐、涂漆 (18)8.3 振动解析 (18)8.4 耐震设计 (19)8.5 应力分析 (19)8.6 流体流动 (21)8.7 噪音 (21)8.8 设计条件 (22)9. 塔、槽、换热器、加热炉 (22)9.3 内件 (23)9.4 主要附属品 (23)9.5 换热器 (24)9.6 加热炉 (25)10. 转动机械 (26)10.1 转动机械 (26)10.2 转动机械性能 (27)10.3 泵 (27)10.4 压缩机、风机等 (28)10.5 透平 (28)10.6 冷冻机 (28)11. 其它机器 (29)11.1 搬运 (29)11.2 粉碎 (29)11.3 化学机械 (30)12. 公用工程 (31)12.1 锅炉、蒸汽及给水系统 (31)12.2 蒸汽轮机 (32)12.3 燃气轮机 (32)12.4 电厂 (33)12.5 水处理 (33)12.6 水质 (34)13. 化工操作及工厂装置名称 (34)13.1 反应 (34)13.2 吸收、吸附、分离 (35)13.3 热交换 (35)13.4 其它 (36)14. 流体名称及流体的性质 (36)14.1 流体名 (36)14.2 流体的性质 (37)14.3 粉体特性 (38)15. 操作 (39)15.1 操作、维护 (39)15.2 操作状态 (40)16. 防火和环保 (40)16.1 消防设备 (40)16.2 火灾报警设备 (41)16.3 其它防火设备 (41)16.4 电气防爆 (42)16.5 危险场所、火灾、爆炸 (42)16.6 化学设备、危险物、有害物 (43)16.7 安全 (43)16.8 公害 (43)17. 原子能 (44)17.1 一般 (44)17.2 反应堆与核燃料 (44)17.3 原子能发电 (45)17.4 放射性管理 (46)17.5 原子能单位 (47)18. 电气(含通信) (47)18.1 图面 (47)18.4 电气设备 (52)18.5 控制、运行 (54)18.6 接地 (55)18.7 照明 (56)18.8 通信 (56)18.9 配线材料 (58)18.10 电气加工 (59)18.11 测定、试验 (59)19. 仪表 (61)19.1 图面 (61)19.2 仪表控制 (61)19.3 测试仪器 (62)19.4 控制阀和安全阀 (63)19.5 其它 (63)20. 土建 (64)20.1 图面、计算、规定 (64)20.2 调查 (65)20.3 建筑设计 (65)20.4 土木设计 (67)20.5 建筑设备设计 (68)20.6 工程 (69)21. 施工 (70)21.1 一般工程 (70)21.2 土木机械 (70)21.3 起吊、搬运 (71)21.4 试验、检查工具 (71)21.5 通用工程器材 (72)21.6 作业机械 (72)21.7 木工机械 (73)21.8 制罐、扳金机械 (73)21.9 各种工程用工具 (73)21.10 测量工具 (75)22. 检验 (75)22.1 检验及处理 (75)22.2 压力试验 (76)22.3 焊接、材料试验 (76)23. 焊接、切割 (77)23.1 焊接方式和种类 (77)23.2 焊接设计 (78)24. 材料及其损伤 (80)24.1 金属材料 (80)24.2 表面处理 (81)24.3 材料性质 (82)24.4 金相及加工 (82)24.5 热处理 (83)24.6 材料组织及缺陷 (83)24.7 腐蚀及其它材料损伤 (84)24.8 有机材料 (84)24.9 无机材料 (85)1.项目建议1.1项目建议概况资格qualification预备资格prequalification商务条款与条件commercial terms and condition 商务commercial技术technical技术说明technical specification建议书proposal book资料费information price估价estimated price报价quoted price报价书quotation1.2报价资料工艺说明process description工艺特点process feature经验记载experience record工艺性能process peroformance设备表equipment list说明、规定、规格specification简要说明short specification条件图sketch drawing流程图flow diagram平衡图balance diagram方框图block diagramP&L图P&L diagram单线图single line diagram布置图layout平面布置图plot plan总图general plot plan附件appendix资料、文件documentation1.3合同技术用语保证guarantee性能保证performance时间保证time gaarantee交货保证delivery guarantee建造保证workmanship guarantee生产能力capacity质量quality消耗量consumption原材料feedstock辅助原料sub-raw material产品product付产品by-product中间产品intermediate公用工程utility燃料fuel化学品chemical界区battery limits(界区)进料incoming(界区)出料outgoing界区条件battery limits condition (配管图)分界线match line工厂、装置plant设备equipment关键设备 critical equipment专利设备proprietary equipment有位号设备itemized equipment无位号设备non-itemized equipment散装材料bulk material施工材料material of construction 仪表instrument备品备件spare parts建筑工具constrution aid(现场)居住设施accommmodation现场派遣espatriate运转率oin stream factor运转天数stream day系列train日历日calender day日历月calender month机械(试车)完工mechanical completion试车trial operation初次试车initial oeration开车start up注油oil in投料feed in首次出料first drop保证试运转guarantee test run装置验收plant acceptance移交turnover议定书protocol1.4估算估算estimate概算budgetary estimate推算slide幂指数power term(费用)分类、分项价格breakdown外汇foreign currency当地货币local currency可兑换货币convertible currency专利费license fee专利权税royalty变动专利权税running royalty专有技术费knowhow fee基础设计费basic engineering fee代理费agent fee手续费commission不可预见费contingency外汇风险exchange risk易货补偿compensation直接费用direct cost间接费用indirect cost项目管理费protect expense现场管理费field expense一般管理费overhead利润profit生活费living expense出勤津贴daily allowance(出差)准备费outfit allowance劳务费labour cost基本工资base wage补偿费payroll burden福利费fringe beneft1.5可行性研究可行性feasibility现场选定site selection(现场)位置location市场marketing可获利润率profitability生产成本production cost经营费operation cost可变成本variable cost不变成本fixed cost总投资total investment cost折旧费depreciation现金流量cash flow折现现金流量discount cash flow工况研究case study产权资本、自有资金equity建设资本利息interest during construction 1.6业务范围现场勘测site survey工艺设计process design基础设计basic engineering基础设计包basie design package详细设计detail engineering采购procurement海运ocean transportation陆运inland transportation 安装erection work土建工作civil work施工construction work临时工作temporary work投料试车commissioning培训training(现场)指导supervisory servive顾问advisory servive初步设计preliminary project最终设计final project基础设施infrastruture上部结构superstructure软件software硬件hardware1.7工厂分类与设计处女地工厂grass root plant总厂integral plant分厂single plant成套装置package plant翻版(设计)厂copy plant生产厂commercial plant中试工厂pilot plant试验室规模装置bench scale unit石化总厂petrochemical complex 下游(厂) downstream(工业)放大scale-up扩建expansion改建、更改modification镜象布置mirror image设计余量overdesign降负荷运转turndown消除瓶颈debottlenecking工厂模型plant model1.8设备工艺装置process plant装置区内on site装置区外off site界区内inside battery limit界区外outside battery limit 公用工程设施utility facility贮存设施storage facility辅助设施auxiliary facility衔接interconnection主变电所main substation发电设施power generation facility事故发电设施emergerncy power generation facility 水处理装置water treatment facility冷却塔cooling tower抽水设备water intakefacility海水淡化装置desallination facility仪表空气发生装置instrument air generation facility惰性气发生装置inert gas generation facility空分装置air separation facility罐区tank yard散装贮存设备bulk storage facility包装机械bag making facility制袋设备bag making facility装瓶设备bottling facility装货设施loading facility卸货设施unloading facility铁路侧线railway siding栈桥jetty行政办公室administration building维修车间maintenance shop中央化验室central laboratory内部通信设施intercommunication facility广播系统public address system询呼设施paging facility消防设施fire fighting facility安全器具safety equipment生活设施colony公用设施townshop娱乐设施recreation facility1.9相关企业承包商contractor主承包商prime contractor分包商subcontractor直接雇用direct hire专利商licenser转专利者sub-licenser专利使用者licensee专利拥有者patent owner竞争者competitor国际财团consortium合作者collaborator买方(1) buyer(2) purchaser卖方seller厂商vendor制造商(1) maker(2) manufacturer业主owner顾问consultant技术顾问technical adviser用户user最终用户end user客户(1) customer(2) client代理商agent挂名人dummy2.投标、合同2.1投标概况询价inquiry报价估价书quitation、estimation投标、投标书bid 、tender投标资料bid documents预审pre-qualification意向书letter of intent2.2合同用语协议agreement合同、契约contract注消cancellation约定consideration合同转让assignment of contract不可抗力force majeure仲裁arbitrarion基本法governing law秘密条款(1) secrect ckayse(2) non-disclosure clause预定损坏赔偿费liquidated damages总赔偿额度total liability连带(债务) joint and several优先债权lien免除waiver保证guaranty担保warranty赔偿indemnity定义definition增额escalation罚款penalty支付条款penalty税金tax and duties侵犯专利patent infringement最高现额ceiling委任书power保证金bond2.3合同形式招标合同competitive bid contract议付合同negotiating contractFOB合同FOB-type contract成套承包合同(1)turnkey contract(交钥匙工程)(2)chef montage contract总付合同lump sum pri ce contract单价契约unit price contract正价加附加费合同cost plus fee contract预投标协议pre-bid agreement产品抵债products互购交易counterpurchase transaction 3.支付、金融、财务3.1支付、金融支付条款、支付条件 payment terms延期付款deferred payment留存款项、保留资金 retention money定期付款schedule payment施工分期付款progressive payment付款交单D/P documents against payment承兑交单调D/A document against acceptaned 信贷、信用credit卖方信贷、供应商信贷sup plier’s credit买方信贷buyer’s credit银行信贷bank loan财政、金融finance借款、借贷loan偿还reimburse,reimbursement保证书letter of guarantee信用证、信贷书letter of credit外汇兑换率exchange rate兑换单、汇票单据documentary vill of exchange 汇款,汇兑基金remittance3.2财务自然增长基数accrual basis资产负债表,决算表balance sheet损益报表P&L protit and loss statement 4.采购、运输我、保险4.1进出口手续出口手续export license出口许可证变更E/L amendCOCOM coordinating committee标准结算方法standard payment非标准结算方法non-standard paymentDBC draw-back cargo [DBC]出口申报银行expoet declaration custom出口申报单export declaration custom进口许可证import license进口申报单omport declaration保税区域bonded area关税import duty原产地证明书certificate of origin发票invoice4.2运输装箱单packing list提单bill of lading [B/L]指示提单order B/L直接提单straight B/L装运提单shipped B/L,on-board B/L备运提单received B/L船上收货单clean B/L装货通知单shipping order [S/O]交货单delivery order [D/O]空运货单airway bill海上运费同盟ocean freight目的地付费freight payable at destination 出港前付费freight prepaid码头工人搬运费stevedorage空载运费dead freight船到港预定时间expected time of arrival[ETA]船离港预定时间expected time of departure[ETD] 海关快速发货custom quidk dispatch [ODC]滞船费demurrage码头搬运商stevedore超尺寸运输over-dimension cargo [ODC]4.3保险海上保险marine cargo insurance现场指导失误保险supervisor’s risk insurance4.4贸易条件出厂价(1) EX works(2) EX factory(3) EX mill海上交货FOB-named port of含保险海上交货4.5采购采购procurement厂家vendor厂家一览表vendor list市场价market price黑市价dark price现价up-to-date price level报价quotation偏差表deviation list到货时间rime of delivery支付方式(1) terms of payment(2) payment conditions(3) payment terms延缓支付deferred payment现金支付cash on delivery分期支付instalment payment预先支付down payment发货前支付advance payment到货后支付progress payment计划支付scheduled payment购买条件terms and conditions of purchase 折价discount谈判、交涉negotiation澄清clarification购买意向intent to purchase比较表tabulation评标evaluation价格分析value analysis订购单purchase order支付方式method of payment现金cash支票check期票promissory note催货expediting跟踪系统follow-up system4.6包装包装packing防锈包装rust-proof packing防潮湿包装moisure-proof packing防水包装moisture-proof packing软包装shrink packing木箱wooden box板条箱crate框架箱framed box滑橇底座skid base码垛盘pallet侧板side plate吊具sling fitting花蓝螺丝turnbuckle钢带steel strapping角保护带adge protecter closure plate防护角corner protecter板board合板pluwood缓冲材料cushioning material通气孔盖ventilation cover超载superimposed load开包unpacking船上标志shopping mark注意标志care mark5.项目执行及费用管理5.1项目执行总图会议kick-off meeting项目研究会议project study meeting开工会议launching meeting项目报告project reporting审查会议screening meeting进展报告progress report协调过程coordination procedure变更指示change order认可approval复阅review5.2工程项目完工报告job close-out report项目执行报告job performance report完工汇编close-out book反馈系统feed back system项目设计条件project design information会签inter-department check工程设计engineering review工艺条件确认engineering checking工艺条件校核engineering checking项目完成指标审核表project performance check sheet施工版approved for construction (AFC)设计变更error report技术文件technical data book管道材料工艺条件process data for piping mateial荷载条件loading data关键路径法critical path method关键路径进度表critical path schedulingPERT program evaluation and review technique 5.3费用及工时管理工程预算project control budget工时man-hour (M/H)工日man-day (M/D)人月man-month(M/M)考勤表time sheet工作号work number项目号job number前期项目号proposal number改进工作improvement work闲滞idle工时报告man-hour report项目工时汇总job man-hour report5.4费用分类费用分类code主账major account分账sub-account设备位号item number5.5组织指定assign借调on-loan项目成员project member项目经理project manager (PM)项目经理助理assistant project manager (APM) 施工经理construction manger (CM)开车经理operation manager (OM)现场指挥field manger项目前期经理proposal manager估算员estimator原始购销员originator协调员coordinator项目设计协调员project design coordinator (PDC) 6.标准化、资料管理、法规、规格6.1标准化标准化standardization标准、规格standard工程规定engineer specification项目特殊要求specific job requirement工程手册engineering specification标准图standard drawing工程用表格engineering form法规law and regulation法律law6.2资料管理情报管理information and documentation信息中心information center调研(追述)retrospective searching信息选择服务selective dissemination of information 情报跟踪current awareness检索效率retrieval efficiency资料documents原文献primary sources文献摘抄secondary sources连载刊物serials定期刊物periodieals(学会)纪要memoirs会报transactions会议论文conference paper会议记录proceedings索引期刊index journal文摘期刊abstract journal情报摘要informative abstracts提示文稿indicative abstracts图书目录book catalog标题目录standar总目录union catalog标准目录standard cutalog关键词keyword省略词stopwordKWIC索引keyword-in-context indexKWOC索引keyword-out-of context index顺序索引permuted index相关索引coordinate index主题分析subjecft analysis统计分类statistical classification国际十进分类法Universal decimal classification借阅卡片visible card书卡book card档案系统filing system微缩复制microcopy微缩系统micro-system维缩片夹aperture card维缩卡片fiche film6.3法规高压气体取缔法high pressure gas control law消防法fire service law劳动安全卫生法industrial safety and health law建筑基本法building standard law单位制system of units国际单位制international system of units7.系统图、设备布置图、配管图及材料统计7.1图纸、条件图工艺流程图process flow diagram (PFD)管道仪表流程图process piping & instrument公用流程图utility flow diagram框图block flow diagram公用工程介质平衡图utility balance diagram (UBD) 平面布置图plot plan立面布置图general arrangement总图general plot plan规划图planning drawing管道研究图piping study drawing管道布置图(配管图)piping arrangement drawing分区图key plan管道走向研究图piping routing study drawing 地下管道图underground piping drawing管道特殊管件图piping special parts drawing 管架详图piping hanging drawing预制图prefabrication drawing参考图reference drawing通用图typical drawing制造厂图vendor’s drawing管道轴测图isometric piping drawing竣工图as-built drawing模型model管线表line schedule计算书calculation sheet图纸目录drawing schedule发图阶段issue stage版次revision number编号体系numbering system比例scale工厂北向plant north海平面标高over-sea mean level [OSL]标高elevation [EL]已有结构existing structure装货区loading area公用工程站utility station柱号column number净空headroom通道access way小通道cat way钢结构顶部标高top of structure elevation管底标高bottom of piping elevation主管口径run size顶平偏心异径管eccentric reducer elevation中心到面的距离center to face工作点标高working point elevation 管架标注hanging marking冷拉cold spring管线记号line symbol管线接口line connection物流号stream NO.管线等级号(1) class designation(2) spec designation阀门号valve No.等级分界specification break重要管道critical piping总管header pipe仪表管道instrument piping排放管道blowdown piping火炬气管道flare piping输送管线transfer line入口管线suction line排水管effluent line旁通管bypass line吹扫系统purge system放空接口vent connection软管接口hose connection双切断阀及排放阀double and bleeder污水沟sewer ditch冷凝液池condensate pit积水坑sump box漏斗drip funnel管段spool piece垫环spacer ring限流孔板restriction orifice流量喷咀flow nozzle液体混合用三通mixing tee喷头spray nozzle粗滤器strainer临时粗滤器temporary strainer疏水阀steam trap爆破膜rupture disk蒸汽伴热管道steam-traced piping夹套管道jacketed piping地下管道underground piping7.2管道要素钢管steel pipe螺纹端管threaded pipe法兰端管flanged pipe锻制swage光滑弯管smooth bendU型弯管U-bend弯管bending pipe波纹管膨胀节expansinon bellows柔性管flexible pipe管件接头pipe fitting joint机械连接mechanical joint活套连接lapped joint环形垫连接ring type joint扩口接头flare type joint非扩口连接flareless type joint承插连接bell and spigotvictaulic接头victaulic joint弯头elbow异径管reducer管接头coupling活接头union短管nipple法兰flange配对法兰companion flange法兰盖blind flange异径法兰reducing flange8字盲板(1) spectactle blind(2) reversible blind平板式法兰plate flange带颈法兰hubbed flange对焊法兰welding neck flange松套法兰loose flange管端突缘stub end法兰面flange face垫片沟槽gasket groove满平面full face突面raised face大准槽面large tongue and groove face 双凹凸面double male & female face 大凹凸面large male &female face金属垫片metallic gasket非金属垫片non-metallic gasket半金属垫片semi-metallie gasketO型环O-ring透镜垫lens ring对焊butt weld承插焊接socket weld滑套焊接slip-on weld焊接支管台weldolet插入环insert ring管帽cap材料表bill of material材料统计take-off管段表line bill of material估算汇总表estimation summary sheet备品备件表spare parts list报价单quotation sheet订货表purchase order schedule材料汇总表bill of material summary状态报告status report分布报告distribution report价格、重量一览表cost & weight summary价格、重量汇总表cost & weight total定货管理表order control管道材料管理表piping material control sheet 元件代码item code标记号tag number标准形态standard shape轴测图isometric drawing管线号line reference批号batch reference管子下料表piping cutting list制做件表fabrication parts list组装件表erection part list固定架anchor滑动架resting support导向架guide限位架direction stop减振架dampener支架support管托shoe保冷管托cradle鞍座saddle耳轴turnnion吊架hanger刚性吊架rigid hanger弹簧吊架spring hanger恒力吊架constant hanger阀门valve截止阀globe valve闸阀gate valve针形阀needle valve球阀ball valve止回阀check valve隔膜阀diaphragm valve三通阀three-way valve角阀angle valve碟阀butterfly valve旋塞阀cock伸长杆操作extension stem-operation链操作chain-operated齿轮操作gear-operated扳手操作wrench-operated电动操作motor-operated阀芯trim阀盖bonnet焊接支管weld branch偏置offset焊缝根部间隙weld root gap现场调整后再下料和焊接cut and weld after adjusting坡度slope工作点working point管架说明notes for piping hanging部门间校核版interdepartmental check print平端plain end坡口端beveled end管道联接图piping hook-up drawing管道图说明notes for piping drawing标题栏title block询价单piping requisition sheet8.配管及一般设备设计8.1保温、保冷绝热insulation设备绝热表equipment insulation schedule绝热符号insulation code保温设计design of cold insulation正常操作所用的保温insulation for stable operating 人身防护personnel protection防火层fire-proofing防结露anti-sweat防冻winterizing防音sound protection保温材料hot insulation material保冷材料cold insulation material石棉asbesttos硅藻土diatomaceous earth岩棉rock wool玻璃棉glass wool碳酸镁magnesium carbonate硅酸铝calcium silicate珍珠岩perlite软木板cork boards毛毡hair felt泡沫聚氨酯foam polystyrene硬泡沫氨基甲酸乙酯rigid foam urethane硬泡沫橡胶rigid foam rubber玛碲脂mastic耐磨损材料anti-abrasion coating material管壳lagging cloth铁丝网hexagonal wire netting填缝材料caulking material保护层(1) jacketing sheet(2) cover sheet波纹铝板corrugated galvanized sheet有色镀锌钢板precoated galvanized sheet搭板butt strapZ型接头Z-joint8.2防腐、涂漆色标colour-code孟塞尔色系Munsell notation管道识别色identification of piping system 防腐层external coating油漆paint清漆varnish防腐漆(1) anti-corrosive paint(2) rush-proof paint含铝漆aluminum paint底漆primer耐酸漆acid-proof paint耐碱漆acid-proof paint耐热漆alkali-proof paint测温漆thermo-paint表面处理surface preparation涂漆painting阴级保护cathodic protection8.3振动解析机械振动mechanical vibration自由振动free vibration强制振动forced vibration自励振动self-excited vibration固有频率natural frequency固有周期natural period波谷loop波峰node正弦振动sinusoidal oscillation非线性振动non-linear oscillation阻尼振动damped vibration监界阻尼critical damping衰减系数(1) attenuation constant(2) decay coefficinent(3) decay factor共振resonance扭曲振动torsional vibration挠性振动flexural vibration极限速度critical speed固有值characteristic value临界条件boundary condition弹簧系数spring constant惯性矩moment of inertia回转半径radius of gyration振动吸收装置dynamic vibration absorber液压减振器hydraulic damper弹簧减振器(1) spring dampener(2) spring damper油压锁定oil lock8.4耐震设计固有振动方式natural frequency mode卓越周期predominant period横波transverse wave纵波longitudinal wave相对位移relative displacement质量比mass ratio静解析法static method修正静解析法corrected static method动解析法modal analysis时历响应解析法time history response analysis设计响应谱design response spectrum加速响应光谱acceleration response spectrum地板响应光谱floor response spectrum标准响应光谱standard response spectrum加速响应增幅比acceleration response amplitude ratio 刚性结构rigid structure柔性结构flexible structure长周期结构long-period structure刚性框架Rahmen rigid frame地震波earthquake accelerogram位移量记录displaecment record设计地震design seismic coefficient设计地震design seismic coefficient地震earthquake震源距离distance to centrum震中距离distance to epicenter震吸magnitude地震波显示仪seismoscope地震仪seismograph耐震等级seismic class基岩base rock8.5应力分析外力cxternal force内力internal force反作用力reaction force力偶 couple of force弯矩bending moment扭矩twisting moment应力stress弯曲应力bending stress扭曲应力torsional stress圆周应力hoop stress峰值应力peak stress一次应力primary stress二次应力secondary stress轴向应力axial stress重复应力repeated stress脉动应力pulsating stress交变应力alternating stress主应力理论principal stress theory最大剪切应力理论maximum shearing stress theory残余应力residual stress热应力thermal stress热破坏thermal shock疲劳fatifue疲劳曲线S-N diagram疲劳极限(1) fatigue limit(2) endurance limit腐蚀疲劳corrosion fatigue蠕变creep蠕变疲劳creep fatigue尺寸效应size effect应力集中系数coefficient of stress concentration 形状系数shape coefficient缺口系数notch factor应力强度系数stress intensity factor几何惯性矩geometrical moment of inertia断面极惯性矩polar moment of inertie of area杨氏模量young’s modulus横向弹性系数modulus of transverse elasticity体积弹性系数modulus of volumetric elasticity泊松比poissor’s ratio弹性极限elastic limit屈服点yielf point拉伸强度tensile strength伸长elongation永久变形permanent set弹性flexibility弹性分析elsastic analysis弹性屈服elastic buckling塑性plasticity塑变滞后plasticity hysteresis极限分析limit anslysis弹塑性分析elastic-plastic analysis疲劳分析fatigye analysis有限元法finite element method静荷载dead load8.6流体流动水锤water hammer急关rapid closure缓关slow closure冲击波shock液压振动acoustic vibration of liquid flow 脉动pulsation flow两相流rwo-phase flow气压振动acoustic vibration卡门涡街karman eddies颤动fluttering气蚀cavitation8.7噪音噪音(1) noise(2) undersired sound听力范围auditory sensation area掩蔽masking背景噪音background noise声强sound intensity声压sound pressure声压值sound pressure level噪声值(1) noise level(2) sound level噪声计sound level meter听觉校正回路weighting network音平loundness level音能sound power音能值sound power level总体值overall level90%范围90% range中间值medianNR数noise rating number频率分析器frequency analyzer倍频带octave band1/3的倍频带1/3 ocatave band波段值band level音场sound field方向性directivity方向系数directivity factor衍射diffraction声源sound source房间常数room constant吸音率sound absorption coefficient 穿透损失transmission loss质量原理mass law8.8设计条件操作压力operating pressure最高操作压力maximum operating pressure操作温度operating temperature最高操作温度maximum operation temperature 温度基准base temperature腐蚀裕度corrosion allowance许容应力allowavle stress安全系数safety factor地理条件geolgical conditions9.塔、槽、换热器、加热炉9.1图画用语设备表vessel schedule工程图engineering drawing管口表(1) nozzle chart(2) nozzle schedule管口方位nozzle orientation予焊件图clip schedule切线tangent line (TL)焊缝线weld line (WL)参照线working line (WL)基准线base line (BL)9.2容器容器vessel塔tower自支承塔self-supported tower板式塔tray tower填料塔packed tower喷淋塔spray tower槽、罐drum贮罐tank球罐(1) spherical tank(2) ball tank浮顶罐floating roof tank锥顶罐cone roof tank拱顶罐dome roof tank双壁罐double wall tank湿式气柜wet gas holder干式气柜dry gas holder料仓(1) silo(2) bin料斗9.3内件内件internal塔盘tray泡罩塔盘bubble cap tray筛板塔盘perforated tray浮阀塔盘valve tray单流向式塔盘uni-flux tray波纹塔盘ripple tray塔盘板deck溢流堰weir降液管downcomer密封槽seal pot取液槽draw-off pot密封盘seal pan塔盘支承环tray support ring鲍尔环pall ring泪孔weep hole填料packing拉希环Rasching ring矩鞍形填料intalox saddle分布器distributor除沫器demister进料挡板feed deflector防涡流挡板vortex breaker内筒cartridge9.4主要附属品壳体shell变颈段reducing section封头head椭圆形封头ellipsoidal head蝶形封头(1) dished head(2) torispherical head半球形封头hemispherical head锥形封头conical head平封头flat head加强圈reinforcing ring夹套jacket入孔manhole手孔hand hole检查孔inspection hole接管nozzle凸缘pad nozzle锻制接管forged nozzle补强板reinforcing pad信号孔tell-tale hole容器支座vessel support裙座skirt支腿leg支耳support lug底座base block基础环base ring筋板gusset plate压环compression ring鞍座saddle模板template通道access opening套管pipe sleeve连接板lug予焊件clip接地板earth lug吊耳lifting lug平台platform梯子ladder保温支承insulation support吊柱davit入孔绞链manhole hinge放空口vent nozzle呼吸阀breather valve计量口gauge hatch9.5换热器换热器heat exchanger换热面积heat transfer area总传热系数overall heat transfer coefficient境膜传热系数film coefficient对数平均温差logarithmic mean temperature difference (LMD) 平均温差mean temperature difference (MTD)污垢系数fouling factor布管图tube arrangement三角形排列triangular arrange转角三角形排列rotated triangular arrangement正方形排列square arrangement转角正方形排列rotated square arrangement最大布管图outside tube limited管壳式换热器sheet and tube heat exchanger固定管板换热器fixed tube sheet heat exchanger浮头式换热器floating head type heat exchangerU形管换热器U-tube type heat exchanger釜式换热器kettle type heat exchanger套管式换热器double tube type heat exchanger冲洗式冷却器irrigation cooler蛇管式换热器coil type heat exchanger插管式换热器bayonet type heat exchanger 板式换热器plate type heat exchanger螺旋板式换热器spiral heat exchanger夹套式换热器jacket type heat exchanger 石墨换热器graphite heat exchanger空冷式换热器air-cooled heat exchanger换热管tube折流板baffle plate管箱channel分程隔板pass partition plate浮头floating head防冲挡板impingement baffle管束tube bundle管板tube sheet管子与管板的连接tube-to-tube sheet joint管接头ferrule9.6加热炉加热炉direct-fired heater热负荷(1) heat duty(2) heat release热损失heat loss加热炉效率efficient of heater热流率heat flux管壁温度tube skin temperature体积热负荷volumetric heat release辐射段radiant section对流段convection section屏蔽段shield section坝墙bridge wall暴露墙exposed wall屏蔽墙shield section管支承tube support炉管(1) heater tube(2) furnace tube扩大表面管extended surface tube联箱(1) header(2) header box回弯头return bend管群间连接管crossover通风draft烟道flue烟道挡板damper烟囱stack烧嘴burner过量空气excess air风箱wind box观察孔(1) observation door(2) peep door检修孔access door防爆门explosion door吹灰器soot blower油漆清车导轨painter trolley陶瓷纤维ceramic fiber耐火砖fire brick保温耐火砖insulation fire brick 保温板insulation board可铸耐火材料castable衬里支撑lining anchor炉臂横梁lintel膨胀节expansion joint10.转动机械10.1转动机械轴shaft轴承bearing轴承箱bearing housing联轴节shaft coupling滑轮pulleyV形皮带(三角皮带)V-belt转动设备turning equipment润滑lubricating润滑油(1) lubricating oil(2) lube oil密封seal轴封shaft seal填料packing填料箱stuffing box油膜密封oil film seal油封seal oil机械密封mechanical seal齿轮gear曲轴crankshaft连杆connecting rod十字头crosshead气缸cylinder缸套cylinder liner汽缸阀cylinder valve活塞piston金属填料metallic packing予埋板soleplate基座baseplate柱塞plunger箱体(壳体)casing。

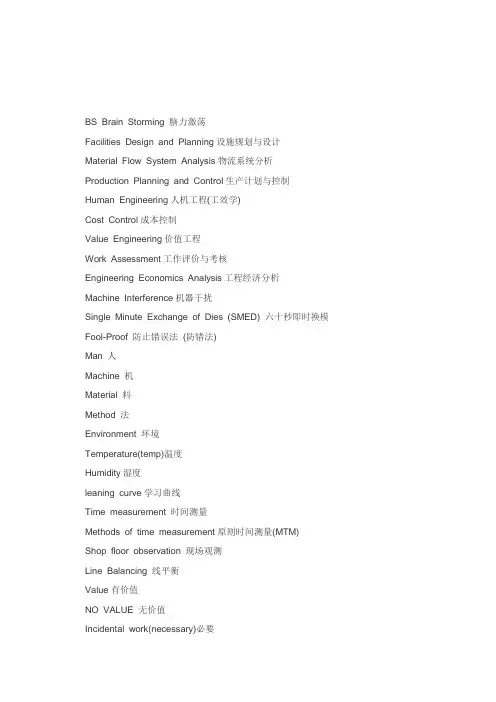

生产品质工程用到的IE专业英语对照词汇

BS Brain Storming 脑力激荡Facilities Design and Planning设施规划与设计Material Flow System Analysis物流系统分析Production Planning and Control生产计划与控制Human Engineering人机工程(工效学)Cost Control成本控制Value Engineering价值工程Work Assessment工作评价与考核Engineering Economics Analysis工程经济分析Machine Interference机器干扰Single Minute Exchange of Dies (SMED) 六十秒即时换模Fool-Proof 防止错误法(防错法)Man 人Machine 机Material 料Method 法Environment 环境Temperature(temp)温度Humidity湿度leaning curve学习曲线Time measurement 时间测量Methods of time measurement原则时间测量(MTM)Shop floor observation 现场观测Line Balancing 线平衡Value有价值NO VALUE 无价值Incidental work(necessary)必要Waste挥霍Takt Time生产节拍Transport Empty 伸手Grasp 握取Move 移物Disassemble 折卸Use 应用Assemble 装配Release Load 放手Inspect 检查Search 寻找Select 选择Play 计划Pre-Position预定位Position 定位Hold 持住Rest 休息Unavoidable Delay 迟延Avoidable Delay 故延E: Elimination剔除C :Combination合并R: Re-arrangement重排S :Simplification简化PRA-Probabilistic Risk风险率评估Risk Priority Number (RPN) 风险关键指数What 完毕了什么where 何处做When 何时做who 由谁做Why 为何这样做how 何时做delay等待operation操作inspection检查transportation搬运storage储存Color management 颜色管理Quality Control Circle 品管圈(QCC)Activity-Base Management作业制成本管理(ABM)In-Process Quality Control制程质量管理(IPQC)Incoming Quality Control进料质量管理(IQC)International Organization for Standardization国际原则组织(ISO) Predetermined Motion Time Standard 简称PTS 预定动作时间原则法Methods-time-measurement 措施时间衡量Work factor system 工作原因法(WF)Modolar arrangement of pre-determind time standard MOD法Leveling 平准化= westing 西屋法objective rating 客观评比synthetic leveling 合成评比Work Sampling 工作抽样Motion time analysis 动作时间分析Business Process Reengineering (BPR)企业流程再造Enterprise Resource Planning ERP企业资源规划Economic Order Quantity (EOQ)基本经济订购量Flexible Manufacture System 弹性制造系统(FMS)Finish or Final Quality Control成品质量管理(FQC)In-Process Quality Control制程质量管理(IPQC)Incoming Quality Control进料质量管理(IQC)Just In Time实时管理(JIT)Manufacturing Execution System制造执行系统(MES) Master Production Scheduling主生产排程(MPS) Master Production Planning主生产计划Material Requirement Planning物料需求规划(MRP) Manufacturing Resource Planning制造资源计划(MRPII) Operation Scheduling作业计划Flow shop流水车间Optimized Production Technology最佳生产技术Supply Chain Management供应链管理(SCM)Statistic Process Control记录制程管制(SPC)Total Production Management全面生产管理(TPM) Total Quality Management全面质量管理(TQM)Zero Defect Quality Control零缺陷质量管理:PDCA Cycle PDCA循环:continue Improvement持续改善:Project项目Project Manager项目经理Project Management项目管理Project Plan项目计划Process Improvement现场改善WORK IN PROCESS 半成品Visual management 目视管理bottleneck 瓶颈Layout 布置图quality engineering 质量工程人员(QE)first article inspection 新品首件检查(FAI)first article assurance首件确认(FAA)capability index能力指数(CP)Quality Improvement Team 质量改善小组(QIT)Classification整顿(sorting, organization)-seiriRegulation整顿(arrangement, tidiness)-seitonCleanliness打扫(sweeping, purity)-seisoConservation清洁(cleaning, cleanliness)-seiktsuCulture教养(discipline)-shitsukeSave 节省Safety安全Make-to-stock备货型生产(MTS)Make-to-order订货型生产(MTO)Assemble-to-order按订单装配(ATO)Flexible manufacturing system柔性制造系统Group technology成组技术(GT)Concurrent engineering并行工程(CE)Time compression technology时间压缩技术(TCT)Business process reengineering业务过程重组(BPR)Agile manufacturing敏捷制造(AM)Leap production精细生产(LP)Intelligent manufacturing 智能制造(IM)Computer-aided-manufacturing计算机辅助制造(CAM) Computer-aided-design计算机辅助设计(CAD)Computer-aided-engineering计算机辅助工程(CAE)Computer-aided-process planning计算机辅助工艺编制( CAPP) overall cost leadership成本优先differentiation独具一格Market focus集中一点cost efficiency成本效率quality质量Dependability可靠性Flexibility柔性product date management产品数据管理(PDM)Facility location设施选址Fixed position layout固定式布置process layout工艺过程布置layout based on group technology成组制造单元布置Job design工作设计work measurement工作测量Time study时间研究Basic motion study基本动作世界研究法(BMS)Modolar arrangement of predetermind time standard模特法Human factor engineering人因工程business plan经营计划Fixed capacity固定能力Adjustable capacity可?#123;整能力production rate生产率Inventory库存Job-shop production单间小批生产Bill of materials (BOM)物料清单文献Lead time提前期modular bill of materials模块物料清单Maximum part-period gain最大周期收益(MPG) distribution requirements planning分派需求计划scheduling编制作业计划sequencing排序Dispatching派工controlling控制expediting赶工supply chain供应链Purchasing Management采购管理Quick Response迅速顾客反应JIT Purchasing准时采购physical distribution物流Materials handling物料搬运project项目critical path method关键路线法optimistic time最乐观时间Most likely time最也许时间pessimistic time最消极时间Mean time between failure平均故障期(MTBF) Mean time to repair平均维修期(MTTR)plan 计划do 执行check 检查action 处理level production生产平准化optimized production technology最优生产技术(OPT) Overall Equipment Effectiveness整体设备效能Operation Research运筹学Service Sector服务业Operation Management运作管理Operation System运作系统World Class Manufacturing世界级制造Time-based Competition基于时间旳竞争Operation Flexibility运作战略Product Development产品开发Dependent Demand独立需求Economic Order Lot 经济订货批量:Safety Stock安全库存Shortage Costs缺货成本ABC Classing Method A BC分类法Reorder Point订货点Holding Costs存储成本Productivity Improvement Team生产力提高小组(PIT) Productivity Improvement Center生产力提高中心(PIC) Break PAD 折PADBreak PIN 折脚Paste Base 沾BASEapproved by: 核准Apr.(April) 四月assembly(ass’y)组合Aug.(August) 八月Base 底座bifilar 双线并绕Bobbin(BBN)绕线管bottom 底部Brush Epoxy On Core 铁芯刷胶Brush Epoxy On Loop 线圈刷胶checked by: 审核Choke电感clip耳夹close winding密绕component 组件condition条件condition条件copper铜箔立式core铁芯Curing烘烤current 电流CUT WIRE 裁线Dec.(December) 十二月defective product box不良品箱deficient manufacturing procedure制程不良description: 阐明Design Failure Mode and Effect Analysis DFMEA设计Desk Topdip 浸入Direction 方向ECN Engineering Change Notice工程变更告知Electronic Magnetic In EMI 抗电磁干扰Enameled copper wire 漆包线Engineering Change Request 工程变更规定epoxy胶equipment/instrument设备Failure Mode and Effect Analysis FMEA失效模式与效应分析Feb.(February) 二月fixture治具flow chart 流程窗体flux助焊剂FN: Factory Notice 工厂告知FN: Immediated change 立即变更Function test 测试gap 间隙,缝隙HI-POT安规测试IE﹕Industrial Engineering 工业工程impregnation浸泡inductance 电感ink油墨inspection(INSP)检查Insulating Tape绝缘胶布issued date: 发行日期item发料Jan.(January) 一月Joint Quality Engineering (JQE)Jul.(July) 七月Jun.(June) 六月Kapton Tape高温胶布layer 层line线Magnetic Components 磁性组件magnetic 磁性旳Mar.(March) 三月Margin Tape安胶marking印章materials物料May五月ME: Mechanical Engineering 机械工程measurement测试mechanical dimension 外观尺寸MFG: manufacturing制造Mini-TowerModel: 机种Not Deviate Measure 量平整度Nov.(November) 十一月O/I Operation Instruction 作业指导书Oct.(October) 十月OEM:委托代工(Original Equipment Manufacture)oven 烤箱P/n: part number 品名P/R Pilot-Run试作验证pad 垫片PE Production/Process Engineering 制造工程/制程工程pin adjustment对脚PIN BENDING& WIRE TRIMMING 折弯钢片pin 脚plastic 塑料,塑料poor processing 制程不良Pre-soldering 预焊primary(pri)初级process 流程production capacity生产力卧式production control (PC)生管purchasing采购QCC:品管圈(Quality Control Circle)QE:质量工程(Quality Engineering)remark: 备注Reported by: 草拟Revision(REV﹒): 版本sample样品schematic 构造图second(sec)次级Sept.(September) 九月solder bar锡棒solder iron 烙铁solder wire锡丝soldering焊锡solvent 稀释剂space winding疏绕Specification (Spec)生产规格stand-off 凸点station 站别step步序straighten 弄直,使变直tape 胶带TE: Test Engineering 测试工程terminal 脚,端子Time (时间)timer定期器top顶部,上层transformer 变压器trifler三线并绕tube 套管turn ratio圈数比turn圈数twist绞线vacuum抽真空varnish dipping泡凡立水varnish凡立水warehouse仓库winding direction 绕线方向winding绕线wire trimming理线。

Die Casting Manufacturing Process Cost Breakdown

Die casting is a casting method in which a molten alloy liquid is poured into a pressure chamber, where a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting. The main features of die casting that distinguish it from other casting methodsare high pressure and high speed.The production of die casting products needs to be completed by using die-casting equipment. The technical level of die-casting equipment determines the quality and level of products.In this article, we will talk about the cost of each procedure of the die casting manufacturing process, in order to save your working time, reduce production costs and improve efficiency.You should focus on the 3 key factors that influence the cost of die casting manufacturing process as follows and we will give you some tips to save these costs:•Material cost•Production cost, and•Mold costDie Casting Factory in Taiwan.Image Source.1. What you should know about material cost?The material cost depends on the weight of material required and the unit price of the material. The weight of the material is clearly the result of part volume and material density; but, the maximum wall thickness of parts can also work.The weight of the material that is required includes material that fills the channel of the die. Thinner walls parts require a larger channel system to ensure that the entire part fills quickly and evenly, thus increasing the amount of material required.However, such additional materials are typically less than materials saved from partial volume reduction due to the thinner walls. Therefore, despite the larger channels, the use of thinner walls will lower the material cost.2. What you should know about production cost?The production cost is mainly calculated on the hourly rate and cycle time. The hourly rate is proportional to the size of the die casting machine, so it is important to understand how the design of the part affects the machine selection. Die casting machines are usually referred to by the tonnage of the clamping force they provide.Therefore, larger components will require a larger clamping force and require a more expensive machine. Moreover, certain materials that require high injection pressures may require higher tonnage machines. The size of the part must also conform to other machine specifications.In addition to the size of the machine, the type of machine (hot chamber and cold chamber) also affects the cost. The use of materials with highmelting temperatures, such as aluminum, would require a more expensive cold chamber machine.The cycle time can be broken down into injection time, cooling time and resetting time. By reducing these times, production cost will be reduced. The injection time can be decreased by reducing the maximum wall thickness of the part.The use of a hot chamber machine can save a lot of time because in a cold chamber machine process, molten metal must be ladled into the machine, significantly increasing producing time. The thermodynamic properties of the material also affect the cooling time.3. What you should know about mold cost? In the die casting industry,optimization of mold design and reuse of existing molds is one of the most effective and practical ways to reduce the cost of die casting.3.1 Mold flow analysis reduces costsIn the past, mold design and producing relied on the experience of engineers. The mold development and design method required repeated trials, and then the mold was continually modified according to the resultsof the test. Each trial increased the cost and increased the product development cycle.With the development of CAD/CAE technology, through simulation analysis, engineers can see the true flow and solidification of the molten metal inside the mold during die casting, and find the location of defects in advance, thereby optimizing mold design and process and reducing costs.3.2 Use core to reduce mold costsMany products are designed with similarities and can be used on other models with partial modifications. For this kind of product, we can consider making different parts into a core, and a pair of molds to make a variety of products. For example, our common natural gas meters have many different types of natural gas joints at both ends, and one type of joint is a product.We can make the joints into different cores, and several products share a set of molds, which can reduce the cost of several pairs of molds. If the core adopts a quick-change structure, it is possible to directly produce another product in a shorter period of time without producing another mold.3.3 Reuse old molds to reduce mold costsAfter many molds reach the end of their service life, a replica mold process is necessary, which will increase the cost of a set of molds. For the old mold with good mold frame, we can reuse it. We only need to re-do a set of cores and use the new mold core with the old mold frame, so that the cost of a set of mold frames can be saved.That’s all you need to know about the price issue of die casting. We hope it’d be helpful! Feel free to contact us if you have any questions!。

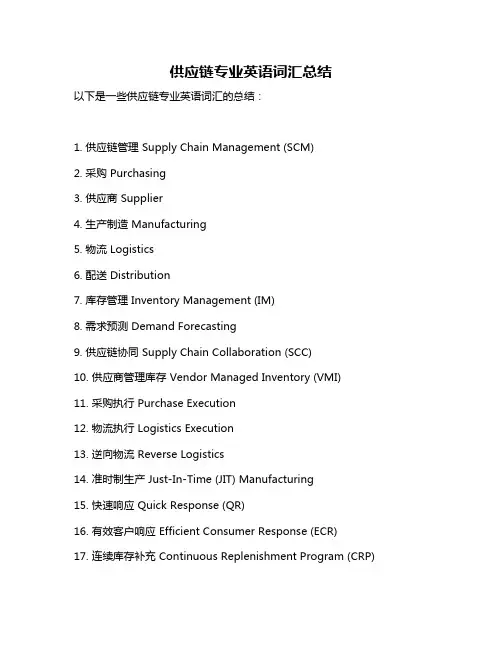

供应链专业英语词汇总结

供应链专业英语词汇总结以下是一些供应链专业英语词汇的总结:1. 供应链管理 Supply Chain Management (SCM)2. 采购 Purchasing3. 供应商 Supplier4. 生产制造 Manufacturing5. 物流 Logistics6. 配送 Distribution7. 库存管理 Inventory Management (IM)8. 需求预测 Demand Forecasting9. 供应链协同 Supply Chain Collaboration (SCC)10. 供应商管理库存 Vendor Managed Inventory (VMI)11. 采购执行 Purchase Execution12. 物流执行 Logistics Execution13. 逆向物流 Reverse Logistics14. 准时制生产 Just-In-Time (JIT) Manufacturing15. 快速响应 Quick Response (QR)16. 有效客户响应 Efficient Consumer Response (ECR)17. 连续库存补充 Continuous Replenishment Program (CRP)18. 电子数据交换 Electronic Data Interchange (EDI)19. 全球定位系统 Global Positioning System (GPS)20. 射频识别技术 Radio Frequency Identification (RFID)21. 自动化仓库 Automated Warehouse22. 高级计划与排程 Advanced Planning and Scheduling (APS)23. 企业资源规划 Enterprise Resource Planning (ERP)24. 客户关系管理 Customer Relationship Management (CRM)25. 电子采购 e-Procurement26. 供应链风险管理 Supply Chain Risk Management (SCRM)27. 精益供应链管理 Lean Supply Chain Management (LSCM)28. 环境可持续供应链管理 Environmentally Sustainable Supply Chain Management (ESSCM)29. 社会可持续供应链管理 Socially Sustainable Supply Chain Management (SSSCM)30. 可持续供应链管理 Sustainable Supply Chain Management (SSCM)31. 供应商评价 Supplier Evaluation32. 采购谈判 Purchasing Negotiation33. 供应链绩效评估 Supply Chain Performance Evaluation (SCPE)34. 总成本分析 Total Cost Analysis (TCA)35. 总持有成本 Total Cost of Ownership (TCO)36. 经济订货量模型 Economic Order Quantity Model (EOQ)37. 安全库存 Safety Stock38. 采购周期 Purchasing Cycle39. 供应链网络 Supply Chain Network40. 多供应商 Multi-supplier41. 多配送中心 Multi-distribution Center42. 库存周转率 Inventory Turnover Rate43. 在途库存 In-transit Inventory44. 在途货物 In-transit Cargo45. 在途车辆 In-transit Vehicle46. 在途订单 In-transit Order47. 在途发票 In-transit Invoice。

采购英语专业名词

采购英语专业名词custom made:需指定制造的first priority:最高的优先级别PPR( Premium price request):高于标准价格采购请求RFQ(request for quote):报价请求,询盘ESI(Early supplier involvement):供应商早期介入cost modeling:成本模型STD price:标准价格Stock-out cost:缺货成本awarded supplier:指定供应商escalate to higher level:提交上级处理cut hard order:手动下订单customer demand pull-in:客户需求提前或增加distributor:分销商;Manufacturing:厂商; Broker:经纪商。

(紧急情况下启用,价格较高。

)EAU (Estimated annual usage):预估每年需求量line down:停产R&D (research and DESign) 研发APS (automated purchasing system) 自动采购系统CAD (computer automated design) 机辅助设计ERP (enterprise resource planning) 企业资源计划ANX (automotive network exchange) 自动网络交换CPO (chief procurement officers) 采购总监CPE (collaborative planning and execution) 合作计划和执行TCA (total cost of acquisition) 总获取成本 或 TCO OwnershipCPFR(collaborative,planning,forecasting,rEPLenishment) 合作,计划,预测,补充SCM (supply chain management) 供应链管理VMI (vendor managed inventory) 卖方管理库存VMR (vendor managed replenishment) 卖方管理补货SCOR (supply chain operations reference) 供应链管理指南LEW (least ex works) 最小离岸价MOM (markup over COAt model) 成本变动3PL (third party logistics) 第三方后勤服务MRP (material requirements planning) 物料需求计划CIO (computer information officers) 信息主管PDCA (plan-do-check action CYcle) 计划-实施-检查循环。

76个供应链常用英文术语

76个供应链常用英文术语以下是一份包含76个供应链常用英文术语的列表,涵盖多个领域和流程:1. Activity-based costing (ABC) - 基于活动的成本计算2. SKU (Stock Keeping Unit) - 库存单位3. BPA (Blanket Purchase Agreement) - 大宗采购协议4. Purchase Order (PO) - 采购订单5. Standard Purchase Order (SPO) - 标准采购订单6. Material Requirements Planning (MRP) - 物料需求计划7. Net prices - 净价8. Quick Response (QR) - 快速响应9. Reverse Logistics - 逆向物流10. Supply Chain Integration - 供应链一体化11. Transit Stock - 在途库存12. Just-in-Time (JIT) - 准时制生产13. Demand Forecasting - 需求预测14. Economic Order Quantity (EOQ) - 经济订货量15. Lead Time - 订购周期16. Bill of Materials (BOM) - 物料清单17. Inventory Management - 库存管理18. Vendor Managed Inventory (VMI) - 供应商管理库存19. Distribution Center (DC) - 分销中心20. Transportation Management System (TMS) - 运输管理系统21. Enterprise Resource Planning (ERP) - 企业资源规划22. Third-Party Logistics (3PL) - 第三方物流23. Fourth-Party Logistics (4PL) - 第四方物流24. Finished Goods Inventory - 成品库存25. Work in Process (WIP) - 在制品26. Cycle Counting - 循环盘点27. Cost of Goods Sold (COGS) - 销售成本28. Freight Forwarder - 货运代理29. Incoterms - 国际贸易术语解释通则30. Dock Scheduling - 码头调度31. Drop Shipping - 直接配送32. Pick and Pack - 拣选包装33. Cross-Docking - 越库作业34. Sales & Operations Planning (S&OP) - 销售与运营计划35. Customer Relationship Management (CRM) - 客户关系管理36. Total Quality Management (TQM) - 全面质量管理37. Supplier Relationship Management (SRM) - 供应商关系管理38. Return Merchandise Authorization (RMA) - 商品退货授权39. Barcode / QR Code - 条形码/二维码40. Hazardous Materials (HazMat) Handling - 危险品处理41. Cold Chain - 冷链物流42. Lean Manufacturing - 精益生产43. Six Sigma - 六西格玛44. KPIs (Key Performance Indicators) - 关键绩效指标45. Port of Origin - 起运港46. Port of Destination - 目的港47. Customs Clearance - 海关清关48. Free On Board (FOB) - 船上交货49. Cost, Insurance, and Freight (CIF) - 成本、保险费加运费50. Delivered Duty Paid (DDP) - 完税后交货51. Ex Works (EXW) - 工厂交货价52. Inbound Logistics - 入库物流53. Outbound Logistics - 出库物流54. Order-to-Cash (OTC) - 订单到收款55. Procure-to-Pay (P2P) - 采购到付款56. Global Trade Management (GTM) - 全球贸易管理57. EDI (Electronic Data Interchange) - 电子数据交换58. Takt Time - 节拍时间59. Kanban - 看板管理60. FIFO (First In, First Out) - 先进先出61. LIFO (Last In, First Out) - 后进先出62. Safety Stock - 安全库存63. Lot Size - 批量大小64. Containerization - 集装箱化65. MRP II (Manufacturing Resource Planning) - 制造资源计划66. DRP (Distribution Resource Planning) - 分销资源计划67. Drop Trailer Program - 拖车卸货计划68. Consolidation - 集拼69. Deconsolidation - 拆箱分拨70. Value-Added Services (VAS) - 增值服务71. Trade Compliance - 贸易合规72. Shipment Tracking - 运输追踪73. Carrier Selection - 承运商选择74. Multi-modal Transport - 多式联运75. Green Supply Chain - 绿色供应链76. Blockchain Technology - 区块链技术(在供应链中的应用)请注意,这并非一个详尽无遗的列表,但涵盖了供应链管理中广泛使用的许多关键术语。

20131023-Cost-Breakdown-Sheet

DATE:SUPPLIER NAME:VOLUME QUOTED:PART #:PLANT LOCATION:TOOLING CAPACITY:PART NAME:MFG DUNS CODE:@ HRS/DAY:DWG LEVEL:LOCAL CURRENCY:@ DAYS/WEEK:RFQ #:EXCHANGE RATE:PREPARED BY:RAW MATERIAL AND PURCHASED COMPONENTS:NET UNITGROSS UNIT % MAT'L AMOUNTAMOUNTUOMUTILIZATIONPCTOTAL MATERIAL:PERCENTAGE OF SALES PRICE:0%LABOR & BURDEN:---------------------------LABOR DETAIL ---------------------------------------MACHINE DATA ------------------------------------BURDEN DETAIL -----------------------------TOTAL LABOR:- PERCENTAGE OF SALES PRICE:0%(TOT FIXED)PERCENTAGE OF SALES PRICE:0%% SALES TOTAL MANUFACTURING COST (MATERIAL + LABOR + BURDEN):0%SELLING, GENERAL & ADMINISTRATIVE EXPENSE:0%PROFIT:0%PACKAGING:SELLING PRICE:TRANSPORTATION & FREIGHTTOTAL TRANSPORTATION COST:PIECE PRICE AND TOOLING COST BREAKDOWN FORMMATERIAL COST- ITEM DESCRIPTIONITEM I.D.COST/ UNITSCRAP RECLAIM TOTAL (COST/#, YD, SQ FT, ETC.)COST/UNIT- - - - - - -Op #OPERATION /DESCRIPTIONLABOR RATETHROUGHPUT (PCS/HR)# OPERLABOR COSTMACHINE SIZEMACHINE TYPEVAR COSTFIXED COSTTOTAL BURDENCOSTBURDEN COST / HRTOTAL ANNUALCOST-0.00- - - TOTAL ANNUAL- 0.00-TAXFREIGHT DUTY ITEM DESCRIPTIONTOTALCOSTThis transportation & freight cost should be the estimate of the cost to deliver the goods to the Nexteer dock from the Named Place, if applicable. If a cost should be captured for delivering the goods from your facility to the Named Place, please include that in the Burden Detail listed above.Note: This "Total Transportation Cost" will NOT be included in your selling price.PRODUCTION TOOLING DETAILS:PRE-PRODUCTION PROTOTYPE INVESTMENT DETAILS:TOTAL PRE-PRODUCTION TOOLS COST:PRE-PRODUCTION PROTOTYPE INVESTMENT COSTS:PRE-PRODUCTION PIECE COSTS:-。

设备报价单

供应商名称Supplier Name SOR NUMBER:

TOOLING/EQUIPMENT BREAKDOWN QUOTATION SHEET

报 价 Date:

工装或设备名称/ Tooling or Equimpment Name

热熔胶复合设备

பைடு நூலகம்

成本构成 Cost Structure

小时单价 Labor cost/Hour

#REF! 小计 Sub-Total

0 0 0 0

备注/Comment

合计 Total

-

管理费合计 Administration Fee

设计/材料/加工+装配+调试费 Total ( Design,Material,Manufacture+Assebmly+Debug)

材料费

非标零件/ Customized Component

Material Fee

加工/装配/调试费 /项目管 理

类型

机械加工/Manufacturing 装配/Assembly 调试/Debug 项目管理/Project Management

Type

合计/Total 合计/Total

工时 Labor Hours

币种/Currency RMB

设计费用 Design Fee

小时(Hours) 15

工时费/小时(Labor Cost/Hour) 400

合计 Total

名称/Component Name

材料/Material

单价/Unit Price

数量/

小计

Quantity Sub-Total

备注/Comment

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

VALEO EQUIPMENT NEGOTIATED COST BREAKDOWN SUPPLIER : SUPPLIER

Site DESCRIPTION Electrical Material Hydraulics Robot Standard Componants Mechanical Components Pneumatic Measure & control unit Other Total material selling price Metal working Mechanical design Electrical design Mechanical assembly Pneumatic Hydraulics Electrical wiring Electrical cabinet wiring Software PLC & robots Assembly of the shields Setting and tests Packing and consignement Installation and preproduction Quality / PFMEA Documentation Total net activity price of the fonction Total selling price of the activity Total selling price of the fonction €

Mark up on purchased materials Fonction 1- 0- - Fonction 2- 0- - Fonction 3- 0- - Fonction 4- 0- -

- 0- -

Fonction n - 0- - Total Selling price of materials - - - - - - - - -

- - - - - - - - - - - - - -

- Currency used : EUR

“SUPPLIER WORK RATE”

The rates listed below are valid until new rates are agreed.

Supplier supply qualified personnel at following rates:

Mechanical and electrical technician EUR /h

Team leader EUR /h

Engineer EUR /h

Total agreed lodging cost per day 0EUR /day

Including Meal EUR /day

Diner EUR /day

Night at Hotel EUR /day

Travel time to and from VALEO’s facilities % of hourly rate

Travel costs by car EUR /km

Transport costs (based on evidences) % supported by VALEO

% additional cost

% additional cost

ADDED VALUE TOTAL

MATERIAL Total hours Total selling price of the equipment Margin

EUR HOURS

Cost (/h)

For services carried out by the Supplier after warranty period expiration or on specific demand from VALEO,cost shall be paid by VALEO after completion of work by the Supplier (confirmed by writen by VALEO).

SUPPLIER’s personnel have to fill out a work log which will be signed by VALEO for all billing.

Works carried out outside of the normal work time (06:00 am to 7:00 pm) will be billed with Work carried out during weekends and bank holidays will be billed with VALEO Confidentiel 22/06/2012Supplier Equipment Cost Breakdown - Contractual.xls。