常见金属 热膨胀系数 精华版

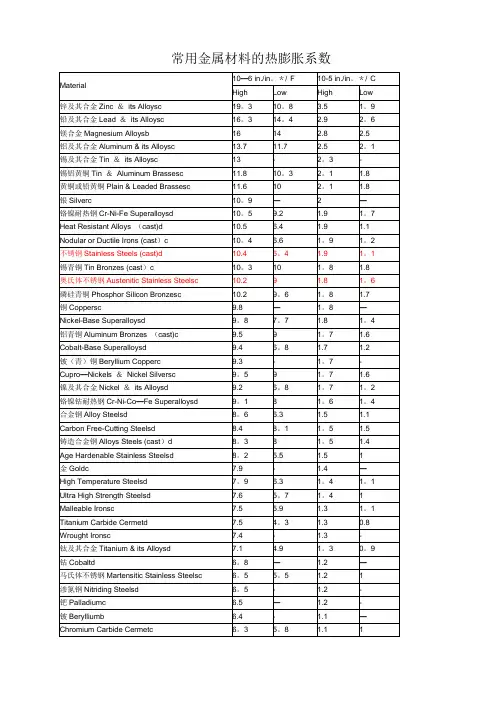

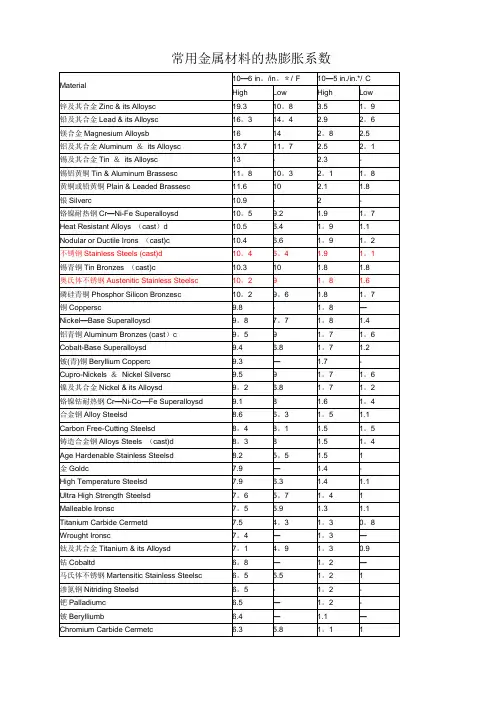

常用金属材料的热膨胀系数详细列表

0。9

-

Alumina Cermetsd

5.2

4。7

0。9

0。8

Molybdenum Disilicidec

5.1

—

0.9

—

Rutheniumb

5。1

-

0.9

—

Platinumc

4。9

—

0。9

-

Vanadiumb

4。8

—

0。9

-

Rhodiumb

4.6

-

0.8

-

Tantalum Carbided

4。6

10

2。1

1.8

银Silverc

10。9

—

2

—

铬镍耐热钢Cr-Ni-Fe Superalloysd

10。5

9.2

1.9

1。7

Heat Resistant Alloys(cast)d

10.5

6.4

1.9

1.1

Nodular or Ductile Irons (cast)c

10。4

6.6

1。9

1。2

不锈钢Stainless Steels (cast)d

—

马氏体不锈钢Martensitic Stainless Steelsc

6。5

5。5

1.2

1

渗氮钢Nitriding Steelsd

6。5

-

1.2

-

钯Palladiumc

6.5

—

1.2

-

铍Berylliumb

6.4

-

1.1

—

Chromium Carbide Cermetc

金属的热膨胀系数

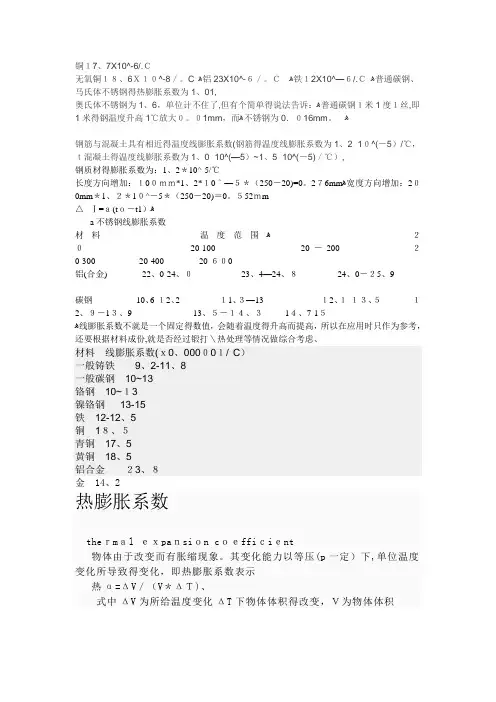

铜17、7X10^-6/.C无氧铜18、6X10^-8/。

C ﻫ铝23X10^-6/。

Cﻫ铁12X10^—6/.Cﻫ普通碳钢、马氏体不锈钢得热膨胀系数为1、01,奥氏体不锈钢为1、6,单位计不住了,但有个简单得说法告诉:ﻫ普通碳钢1米1度1丝,即1米得钢温度升高1℃放大0。

01mm,而ﻫ不锈钢为0.016mm。

ﻫ钢筋与混凝土具有相近得温度线膨胀系数(钢筋得温度线膨胀系数为1、2×10^(-5)/℃,t混凝土得温度线膨胀系数为1、0×10^(—5)~1、5×10^(-5)/℃),钢质材得膨胀系数为:1、2*10^-5/℃长度方向增加:100mm*1、2*10^—5*(250-20)=0。

276mmﻫ宽度方向增加:200mm*1、2*10^-5*(250-20)=0。

552mm△Ⅰ=a(to-t1)ﻫa不锈钢线膨胀系数材料温度范围ﻫ20 20-100 20-200 20-300 20-400 20-600铝(合金) 22、0-24、0 23、4—24、8 24、0-25、9碳钢 10、6-12、2 11、3—13 12、1-13、512、9-13、9 13、5-14、3 14、7-15ﻫ线膨胀系数不就是一个固定得数值,会随着温度得升高而提高,所以在应用时只作为参考,还要根据材料成份,就是否经过锻打\热处理等情况做综合考虑、材料线膨胀系数(x0、000001/°C)一般铸铁9、2-11、8一般碳钢10~13铬钢10~13镍铬钢13-15铁12-12、5铜18、5青铜17、5黄铜18、5铝合金23、8金 14、2热膨胀系数thermal expansion coefficient物体由于改变而有胀缩现象。

其变化能力以等压(p一定)下,单位温度变化所导致得变化,即热膨胀系数表示热α=ΔV/(V*ΔT)、式中ΔV为所给温度变化ΔT下物体体积得改变,V为物体体积物质、能量与信息就是构成自然社会得基本要素。

常见金属-热膨胀系数-精华版

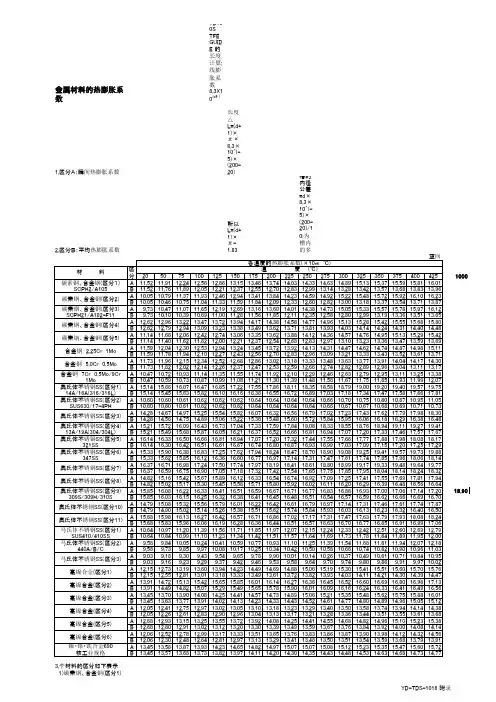

金属材料的热膨胀系数YD10 0S TFE GUID E 的长度计算:线膨胀系数8.3X1 0(-5 )1.区分A:瞬间热膨胀系数长度△L=(d+ 1)×π×8.3×10^(-5)×(200-20)2.区分B:平均热膨胀系数所以L=(d+1)×π-1.83槽的内径公差=d×8.3×10^(-5)×(200-20)/10;为槽内的多100018.90 3.个材料的区分如下表示 1)碳素钢、合金钢(区分1) ・碳素钢 ・ 3/4Ni-1/2Mo-Cr-V ・3/4Ni-1Mo-3/4Cr ・碳・钼钢 ・3/4Ni-1/2Mo-1/3Cr-V ・1Ni-1/2Cr-1/2Mo・ 1/2Ni-1/2Mo-V ・3/4Ni-1/2Cr-Mo-V 2)碳素钢、合金钢(区分2)・碳・硅钢 ・ 1/2Cr-1/2Mo ・1Cr-1/5Mo-Si ・1/2Mo ・1Cr-1/5Mo-V ・1Cr-1/2Mo・1Cr-1Mn-1/4Mo ・1Cr-1/5Mo ・1・3/4Cr-1/2Mo-Cu0.15145.15 3)碳素钢、合金钢(区分3) 2.382712.4 ・碳・钼钢 ・ 1・1/4Ni-1/2Mo ・2Cr-1/2Mo ・1/2Cr-1/4Mo-Si ・1・1/4Cr-1/2Mo-Si ・3Cr-1Mo ・1Cr-1/2Mo-V 4)碳素钢、合金钢(区分4) ・Mn-1/2Mo ・Mn-1/2Mo-1/2Ni ・Mn-1/2Mo-1/4Ni ・Mn-1/2Mo-3/4Ni 水泥在1000度以上的热膨胀系数为5.8 5)碳素钢、合金钢(区分5)310S 在800度时热膨胀系数为18.5・1.1/4Ni-1Cr-1/2Mo ・2Ni-3/4Cr-1/4Mo ・3.1/2Ni ・1.3/4Ni-3/4Cr-1/4Mo ・2Ni-3/4Cr-1/2Mo 310S 在1000度时热膨胀系数为19.5・3.1/2Ni-1.3/4Cr-1/2Mo-V ・2Ni-1Cu ・2.1/2Ni ・1Cr-1/2Mo-V6)奥氏体不锈钢SS(区分1) 7)奥氏体不锈钢SS(区分2)8)奥氏体不锈钢SS(区分3)・18Cr-13Ni-3Mo ・18Cr-12Ni-2Mo ・17Cr-4Ni-Cu・18Cr-5Ni-3Mo9)奥氏体不锈钢SS(区分4) 10)奥氏体不锈钢SS(区分5)11)奥氏体不锈钢SS(区分6)・18Cr-8Ni ・18Cr-11Ni ・18Cr-10Ni-Ti・18Cr-10Ni-Cb0.45912)奥氏体不锈钢SS(区分7) 13)奥氏体不锈钢SS(区分8)14)奥氏体不锈钢SS(区分9)0.505・18Cr-9Ni-Mo-W ・22Cr-13Ni-5Mn・25Cr-12Ni・23Cr-12Ni・25Cr-20Ni15)奥氏体不锈钢SS(区分10) 16)奥氏体不锈钢SS(区分11)・(660)26Ni-15Cr-2Ti ・28Ni-19Cr-Cu-Mo17)马氏体不锈钢SS(区分 ・12Cr ・12Cr-1Al ・13Cr ・13Cr-4Ni18)马氏体不锈钢SS(区分2) 19)马氏体不锈钢SS(区分3)・17Cr ・27Cr20)高镍合金(区分1) 21)高镍合金(区分2)22)高镍合金(区分3)・Ni-Cr-Fe(NCF600) ・Ni-Fe-Cr(NCF800,NCF800H)・Ni-Fe-Cr-Mo-Cu(NCF825,GNCF2種及び323)高镍合金(区分4) 24)高镍合金(区分5)25)高镍合金(区分6)・Ni-Cr-Mo-Cb(NCF625,GNCF1種) ・Ni-Fe-Cr-Mo-Cb(NCF718)・Ni-Cr(NCF750)。

常用金属材料的热膨胀系数详细列表

-

0.3

—

Carbon and Graphitec

1.5

1.3

0.3

0。2

—

马氏体不锈钢Martensitic Stainless Steelsc

6。5

5.5

1。2

1

渗氮钢Nitriding Steelsd

6。5

-

1。2

-

钯Palladiumc

6.5

—

1。2

-

铍Berylliumb

6.4

—

1.1

—

Chromium Carbide Cermetc

6.3

5.8

1。1

1

钍Thoriumb

9.5

9

1。7

1。6

镍及其合金Nickel & its Alloysd

9。2

6.8

1。7

1。2

铬镍钴耐热钢Cr—Ni-Co—Fe Superalloysd

9.1

8

1.6

1。4

合金钢Alloy Steelsd

8.6

6。3

1。5

1.1

Carbon Free-Cutting Steelsd

8。4

8。1

1.5

3。8

-

0.7

—

Alumina Ceramicsc

3.7

3.1

0.7

0.6

Zirconium Carbided

3.7

-

0.7

-

Osmium and Tantalumb

3.6

-

0.6

—

锆及其合金Zirconium & its Alloysb

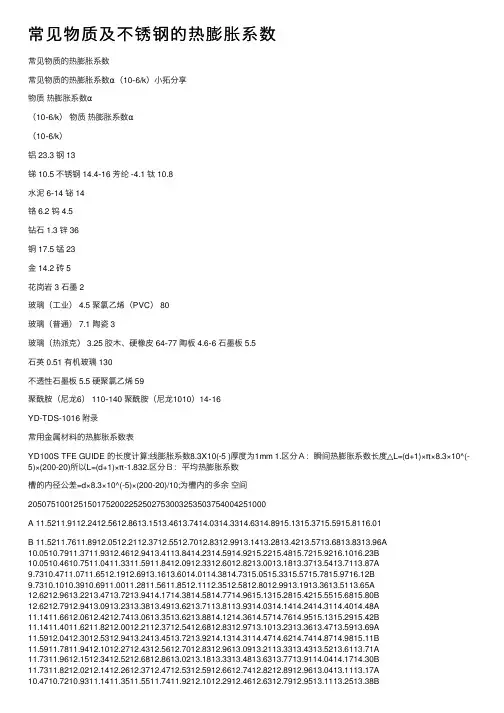

常见物质及不锈钢的热膨胀系数

常见物质及不锈钢的热膨胀系数常见物质的热膨胀系数常见物质的热膨胀系数α(10‐6/k)⼩拓分享物质热膨胀系数α(10‐6/k)物质热膨胀系数α(10‐6/k)铝 23.3 钢 13锑 10.5 不锈钢 14.4‐16 芳纶‐4.1 钛 10.8⽔泥 6‐14 铋 14铬 6.2 钨 4.5钻⽯ 1.3 锌 36铜 17.5 锰 23⾦ 14.2 砖 5花岗岩 3 ⽯墨 2玻璃(⼯业) 4.5 聚氯⼄烯(PVC) 80玻璃(普通) 7.1 陶瓷 3玻璃(热派克) 3.25 胶⽊、硬橡⽪ 64‐77 陶板 4.6‐6 ⽯墨板 5.5⽯英 0.51 有机玻璃 130不透性⽯墨板 5.5 硬聚氯⼄烯 59聚酰胺(尼龙6) 110‐140 聚酰胺(尼龙1010)14‐16YD-TDS-1016 附录常⽤⾦属材料的热膨胀系数表YD100S TFE GUIDE 的长度计算:线膨胀系数8.3X10(-5 )厚度为1mm 1.区分A:瞬间热膨胀系数长度△L=(d+1)×π×8.3×10^(-5)×(200-20)所以L=(d+1)×π-1.832.区分B:平均热膨胀系数槽的内径公差=d×8.3×10^(-5)×(200-20)/10;为槽内的多余空间2050751001251501752002252502753003253503754004251000A 11.5211.9112.2412.5612.8613.1513.4613.7414.0314.3314.6314.8915.1315.3715.5915.8116.01B 11.5211.7611.8912.0512.2112.3712.5512.7012.8312.9913.1413.2813.4213.5713.6813.8313.96A10.0510.7911.3711.9312.4612.9413.4113.8414.2314.5914.9215.2215.4815.7215.9216.1016.23B10.0510.4610.7511.0411.3311.5911.8412.0912.3312.6012.8213.0013.1813.3713.5413.7113.87A9.7310.4711.0711.6512.1912.6913.1613.6014.0114.3814.7315.0515.3315.5715.7815.9716.12B9.7310.1010.3910.6911.0011.2811.5611.8512.1112.3512.5812.8012.9913.1913.3613.5113.65A12.6212.9613.2213.4713.7213.9414.1714.3814.5814.7714.9615.1315.2815.4215.5515.6815.80B12.6212.7912.9413.0913.2313.3813.4913.6213.7113.8113.9314.0314.1414.2414.3114.4014.48A11.1411.6612.0612.4212.7413.0613.3513.6213.8814.1214.3614.5714.7614.9515.1315.2915.42B11.1411.4011.6211.8212.0012.2112.3712.5412.6812.8312.9713.1013.2313.3613.4713.5913.69A11.5912.0412.3012.5312.9413.2413.4513.7213.9214.1314.3114.4714.6214.7414.8714.9815.11B11.5911.7811.9412.1012.2712.4312.5612.7012.8312.9613.0913.2113.3313.4313.5213.6113.71A11.7311.9612.1512.3412.5212.6812.8613.0213.1813.3313.4813.6313.7713.9114.0414.1714.30B11.7311.8212.0212.1412.2612.3712.4712.5312.5912.6612.7412.8212.8912.9613.0413.1113.17A10.4710.7210.9311.1411.3511.5511.7411.9212.1012.2912.4612.6312.7912.9513.1113.2513.38B10.4710.5910.7310.8710.9911.0811.2111.3011.3911.4811.5811.6711.7511.8511.9311.9912.07A15.1415.6616.0716.4716.8517.2217.5517.8618.1118.3518.5818.7919.0019.2019.4019.5719.75B15.1415.4515.6315.8216.1016.1616.3816.5516.7216.8917.0317.1817.3417.4717.5817.6617.81A10.6010.6010.6110.6210.6210.6210.6410.6410.6410.6410.6610.7010.7510.8010.8710.9511.05B10.6010.6010.6110.6210.6210.6210.6410.6410.6410.6410.6610.6710.6710.6810.6910.7110.73A14.2814.6714.9715.2515.5415.8216.0716.3216.5616.7917.0217.2317.4317.6217.7917.9818.30B14.2814.5614.7514.8915.0615.2215.3615.4815.6015.7215.8415.9516.0616.1816.2916.3816.48A15.2115.7216.0916.4316.7317.0417.3317.5917.8418.0818.3318.5518.7618.9419.1119.2719.41B15.2115.4915.6815.8716.0516.2116.3716.5216.6616.8116.9417.0717.2017.3317.4617.5717.67A16.1416.3316.5016.6616.8116.9417.0717.2017.3217.4417.5517.6617.7717.8817.9818.0818.17B16.1416.3016.4216.5116.6116.6716.7416.8016.8716.9316.9917.0317.0917.1517.2017.2517.29A15.3315.9016.3816.8317.2517.6217.9418.2418.4718.7018.9019.0819.2519.4119.5719.7319.88B15.3315.6215.8516.1216.3616.6016.7716.9717.1417.3117.4717.6117.7417.8517.9618.0618.14A16.3716.7116.9817.2417.5017.7417.9718.1918.4118.6118.8018.9919.1719.3319.4819.6419.77B16.3716.5916.7516.9017.0517.1817.3217.4217.5417.6517.7517.8517.9518.0418.1418.2418.32A14.8215.1615.4215.6715.8916.1216.3316.5416.7416.9217.0917.2517.4117.5517.6917.8117.94B14.8215.0215.1715.3015.4515.5815.7115.8015.9216.0216.1116.2016.2916.3916.4816.5616.64A15.8516.0816.2216.3316.4116.5116.5916.6716.7116.7716.8316.8816.9317.0017.0617.1417.2018.90B 15.8516.0316.1516.2516.3216.3816.4116.4516.4816.5116.5416.5716.5916.6216.6616.6916.70A14.7915.0815.3215.5615.7916.0116.2216.4216.6116.7916.9717.1417.3117.4617.6117.7417.87B14.7914.9015.0215.1415.2615.3815.5115.6215.7415.8415.9316.0316.1316.2316.3216.4016.50A15.6815.9816.1316.2716.4216.5716.7116.8617.0217.1717.3117.4717.6317.7917.9318.0818.24B15.6815.8315.9616.0616.1916.2816.3616.4416.5116.5716.6316.7016.7716.8516.9116.9917.06A10.6410.9711.2011.3911.5611.7111.8511.9712.0712.1512.2412.3312.4212.5112.6012.6912.79B10.6410.8410.9911.1011.2311.3411.4211.5111.5711.6411.6911.7311.7811.8411.8911.9512.00A9.589.8410.0510.2410.4110.5910.7710.9311.1011.2511.3911.5411.6811.8111.9412.0712.18B9.589.739.859.9710.0810.1710.2510.3410.4210.5010.5810.6610.7410.8210.9010.9611.03A9.039.189.309.439.549.659.789.9010.0110.1410.2610.3710.4910.6110.7110.8410.95B9.039.169.239.299.379.429.469.539.589.649.709.749.809.869.919.9710.02A12.1512.7313.1913.6013.9414.2314.4914.6914.8815.0615.1915.3015.4115.5115.6015.7015.76B12.1512.5512.8113.0113.1813.3313.4913.6113.7213.8213.9314.0314.1114.2114.3014.3914.47A13.9114.7215.1315.4215.6515.8516.0116.1416.2716.3816.4516.5216.6016.6916.8016.9617.13B13.9114.4914.8215.0715.2915.4915.6515.7815.9016.0116.0916.1616.2416.3316.4116.4916.56A13.4513.7013.9014.0814.2514.4114.5714.7314.8915.0615.2115.3515.4815.6215.7515.8816.01B13.4513.6313.7713.9114.0214.1314.2314.3314.4314.5214.6114.7714.8014.8914.9615.0515.12A12.0512.4112.7512.9713.0213.0513.1013.1813.2313.2913.4013.5013.5813.7413.9414.1414.38B12.0512.2612.6112.8312.9012.9613.0413.1313.1713.2113.2813.3613.4413.5113.5513.6113.68A12.6812.9313.1513.2513.5513.7213.9214.0814.2514.4114.5514.6814.8214.9615.1015.2315.38B12.6812.8012.9113.0213.1213.2013.3013.3913.4913.5913.6713.7613.8413.9214.0014.0814.14A12.0612.5212.7812.9913.1713.3313.5113.6513.7613.8313.8613.8713.9013.9814.1214.3214.56B12.0612.3012.4812.6412.8112.9713.1313.2913.4113.4813.5013.5113.5413.5913.6813.7913.91A13.4513.5813.8713.9314.2314.6514.8214.9715.0715.0715.0815.1215.2315.3515.4715.6015.72B13.4513.5713.6813.7313.8213.9714.1114.2014.3014.3514.4314.4814.5314.6314.6814.7314.773.个材料的区分如下表⽰ 1)碳素钢、合⾦钢(区分1)碳素钢 ? 3/4Ni-1/2Mo-Cr-V ?3/4Ni-1Mo-3/4Cr ?碳?钼钢 ? 3/4Ni-1/2Mo-1/3Cr-V ?1Ni-1/2Cr-1/2Mo ? 1/2Ni-1/2Mo-V ?3/4Ni-1/2Cr-Mo-V 2)碳素钢、合⾦钢(区分2)碳?硅钢 ? 1/2Cr-1/2Mo ?1Cr-1/5Mo-Si ?1/2Mo ?1Cr-1/5Mo-V ?1Cr-1/2Mo ?1Cr-1Mn-1/4Mo ?1Cr-1/5Mo ?1?3/4Cr-1/2Mo-Cu 0.15145.15 3)碳素钢、合⾦钢(区分3) 2.382712.4 ?碳?钼钢 ? 1?1/4Ni-1/2Mo ?2Cr-1/2Mo ?1/2Cr-1/4Mo-Si ?1?1/4Cr-1/2Mo-Si ?3Cr-1Mo ?1Cr-1/2Mo-V 4)碳素钢、合⾦钢(区分4)Mn-1/2Mo Mn-1/2Mo-1/2Ni Mn-1/2Mo-1/4Ni Mn-1/2Mo-3/4Ni ⽔泥在1000度以上的热膨胀系数为5.8 5)碳素钢、合⾦钢(区分5)310S在800度时热膨胀系数为18.5 ?1.1/4Ni-1Cr-1/2Mo ?2Ni-3/4Cr-1/4Mo ?3.1/2Ni ?1.3/4Ni-3/4Cr-1/4Mo ?2Ni-3/4Cr-1/2Mo 310S在1000度时热膨胀系数为19.5 ?3.1/2Ni-1.3/4Cr-1/2Mo-V ?2Ni-1Cu ?2.1/2Ni ?1Cr-1/2Mo-V 6)奥⽒体不锈钢SS(区分1)7)奥⽒体不锈钢SS(区分2) 8)奥⽒体不锈钢SS(区分3) ?18Cr-13Ni-3Mo ?18Cr-12Ni-2Mo ?17Cr-4Ni-Cu18Cr-5Ni-3Mo9)奥⽒体不锈钢SS(区分4) 10)奥⽒体不锈钢SS(区分5) 11)奥⽒体不锈钢SS(区分6) ?18Cr-8Ni ?18Cr-11Ni ?18Cr-10Ni-Ti18Cr-10Ni-Cb 0.459 12)奥⽒体不锈钢SS(区分7) 13)奥⽒体不锈钢SS(区分8) 14)奥⽒体不锈钢SS(区分9)0.505 ?18Cr-9Ni-Mo-W22Cr-13Ni-5Mn25Cr-12Ni 23Cr-12Ni 25Cr-20Ni15)奥⽒体不锈钢SS(区分10) 16)奥⽒体不锈钢SS(区分11) ?(660)26Ni-15Cr-2Ti28Ni-19Cr-Cu-Mo17)马⽒体不锈钢SS(区分1)12Cr 12Cr-1Al 13Cr 13Cr-4Ni 18)马⽒体不锈钢SS(区分2) 19)马⽒体不锈钢SS(区分3) ?17Cr27Cr20)⾼镍合⾦(区分1) 21)⾼镍合⾦(区分2)22)⾼镍合⾦(区分3)Ni-Cr-Fe(NCF600) Ni-Fe-Cr(NCF800,NCF800H) Ni-Fe-Cr-Mo-Cu(NCF825,GNCF2種及び3種) 23)⾼镍合⾦(区分4)24)⾼镍合⾦(区分5)25)⾼镍合⾦(区分6) ?Ni-Cr-Mo-Cb(NCF625,GNCF1種)Ni-Fe-Cr-Mo-Cb(NCF718)Ni-Cr(NCF750)各温度的热膨胀系数(×10-6 ℃)温度 (℃)材料碳素钢、合⾦钢(区分1)SCPH2/A105碳素钢、合⾦钢(区分2)碳素钢、合⾦钢(区分3)SCPH21/A182-F11奥⽒体不锈钢SS(区分7)碳素钢、合⾦钢(区分4)碳素钢、合⾦钢(区分5)合⾦钢 2.25Cr 1Mo 合⾦钢 5.0Cr 0.5Mo 合⾦钢 7Cr 0.5Mo/9Cr1Mo奥⽒体不锈钢SS(区分1)14A/16A(316/316L)奥⽒体不锈钢SS(区分9)309S/309H/310S 奥⽒体不锈钢SS(区分10)奥⽒体不锈钢SS(区分11)马⽒体不锈钢SS(区分1)SUS410/410SS 马⽒体不锈钢SS(区分2)440A/B/C 奥⽒体不锈钢SS(区分2)SUS630/17-4PH 奥⽒体不锈钢SS(区分3)奥⽒体不锈钢SS(区分4)13A/19A(304/304L)奥⽒体不锈钢SS(区分5)321SS奥⽒体不锈钢SS(区分6)347SS ⾼镍合⾦(区分6)镍?铬?铁合⾦690核⼯业规格区分马⽒体不锈钢SS(区分3)⾼镍合⾦(区分1)⾼镍合⾦(区分2)⾼镍合⾦(区分3)⾼镍合⾦(区分4)⾼镍合⾦(区分5)奥⽒体不锈钢SS(区分8)。

常用金属材料的热膨胀系数

常用金属材料的热膨胀系数Material 10-6 in./in.*/°F10-5 in./in.*/°C High Low High Low锌及其合金Zinc & its Alloysc19.310.8 3.5 1.9铅及其合金Lead & its Alloysc16.314.4 2.9 2.6镁合金Magnesium Alloysb1614 2.8 2.5铝及其合金Aluminum & itsAlloysc13.711.7 2.5 2.1锡及其合金Tin & its Alloysc13- 2.3-锡铝黄铜Tin & AluminumBrassesc11.810.3 2.1 1.8黄铜或铅黄铜Plain & LeadedBrassesc11.610 2.1 1.8银Silverc10.9-2-铬镍耐热钢Cr-Ni-FeSuperalloysd10.59.2 1.9 1.7 Heat Resistant Alloys (cast)d10.5 6.4 1.9 1.1 Nodular or Ductile Irons(cast)c10.4 6.6 1.9 1.2不锈钢Stainless Steels (cast)d10.4 6.4 1.9 1.1锡青铜Tin Bronzes (cast)c10.310 1.8 1.8奥氏体不锈钢AusteniticStainless Steelsc10.29 1.8 1.6磷硅青铜Phosphor SiliconBronzesc10.29.6 1.8 1.7铜Coppersc9.8- 1.8-Nickel-Base Superalloysd9.87.7 1.8 1.4铝青铜Aluminum Bronzes9.59 1.7 1.6 (cast)cCobalt-Base Superalloysd9.4 6.8 1.7 1.2铍(青)铜Beryllium Copperc9.3- 1.7-Cupro-Nickels & Nickel9.59 1.7 1.6 Silversc镍及其合金Nickel & its Alloysd9.2 6.8 1.7 1.2铬镍钴耐热钢Cr-Ni-Co-Fe9.18 1.6 1.4 Superalloysd合金钢Alloy Steelsd8.6 6.3 1.5 1.1Carbon Free-Cutting Steelsd8.48.1 1.5 1.5铸造合金钢Alloys Steels8.38 1.5 1.4 (cast)dAge Hardenable Stainless8.2 5.5 1.51 Steelsd金Goldc7.9- 1.4-High Temperature Steelsd7.9 6.3 1.4 1.1Ultra High Strength Steelsd7.6 5.7 1.41Malleable Ironsc7.5 5.9 1.3 1.1Titanium Carbide Cermetd7.5 4.3 1.30.8Wrought Ironsc7.4- 1.3-钛及其合金Titanium & its7.1 4.9 1.30.9 Alloysd钴Cobaltd 6.8- 1.2-马氏体不锈钢Martensitic6.5 5.5 1.21 Stainless Steelsc渗氮钢Nitriding Steelsd 6.5- 1.2-钯Palladiumc 6.5- 1.2-铍Berylliumb 6.4- 1.1-Chromium Carbide Cermetc 6.3 5.8 1.11钍Thoriumb 6.2- 1.1-铁素体不锈钢Ferritic Stainless6 5.8 1.11 SteelscGray Irons (cast)c6- 1.1-Beryllium Carbided 5.8-1-Low Expansion Nickel Alloysc5.5 1.510.3Beryllia & Thoriae 5.3-0.9-Alumina Cermetsd 5.2 4.70.90.8Molybdenum Disilicidec 5.1-0.9-Rutheniumb 5.1-0.9-Platinumc 4.9-0.9-Vanadiumb 4.8-0.9-Rhodiumb 4.6-0.8-Tantalum Carbided 4.6-0.8-Boron Nitrided 4.3-0.8-铌及其合金Columbium & its4.1 3.80.70.68 AlloysTitanium Carbided 4.1-0.7-Steatitec4 3.30.70.6Tungsten Carbide Cermetc 3.9 2.50.70.4铱Iridiumb 3.8-0.7-Alumina Ceramicsc 3.7 3.10.70.6Zirconium Carbided 3.7-0.7-Osmium and Tantalumb 3.6-0.6-锆及其合金Zirconium & its3.6 3.10.60.55 AlloysbHafniumb 3.4-0.6-Zirconiae 3.1-0.6-钼及其合金Molybdenum & its3.1 2.70.60.5 AlloysSilicon Carbidee 2.4 2.20.40.39钨Tungstenb 2.2-0.4-Electrical Ceramicsc2-0.4-Zirconc 1.8 1.30.30.2 Boron Carbidee 1.7-0.3-Carbon and Graphitec 1.5 1.30.30.2。

常用金属材料的热膨胀系数

常用金属材料的热膨胀系数Material 10-6 in./in.*/°F10-5 in./in.*/°C High Low High Low锌及其合金Zinc & its Alloysc19.310.8 3.5 1.9铅及其合金Lead & its Alloysc16.314.4 2.9 2.6镁合金Magnesium Alloysb1614 2.8 2.5铝及其合金Aluminum & itsAlloysc13.711.7 2.5 2.1锡及其合金Tin & its Alloysc13- 2.3-锡铝黄铜Tin & AluminumBrassesc11.810.3 2.1 1.8黄铜或铅黄铜Plain & LeadedBrassesc11.610 2.1 1.8银Silverc10.9-2-铬镍耐热钢Cr-Ni-FeSuperalloysd10.59.2 1.9 1.7 Heat Resistant Alloys (cast)d10.5 6.4 1.9 1.1 Nodular or Ductile Irons(cast)c10.4 6.6 1.9 1.2不锈钢Stainless Steels (cast)d10.4 6.4 1.9 1.1锡青铜Tin Bronzes (cast)c10.310 1.8 1.8奥氏体不锈钢AusteniticStainless Steelsc10.29 1.8 1.6磷硅青铜Phosphor SiliconBronzesc10.29.6 1.8 1.7铜Coppersc9.8- 1.8-Nickel-Base Superalloysd9.87.7 1.8 1.4铝青铜Aluminum Bronzes9.59 1.7 1.6 (cast)cCobalt-Base Superalloysd9.4 6.8 1.7 1.2铍(青)铜Beryllium Copperc9.3- 1.7-Cupro-Nickels & Nickel9.59 1.7 1.6 Silversc镍及其合金Nickel & its Alloysd9.2 6.8 1.7 1.2铬镍钴耐热钢Cr-Ni-Co-Fe9.18 1.6 1.4 Superalloysd合金钢Alloy Steelsd8.6 6.3 1.5 1.1Carbon Free-Cutting Steelsd8.48.1 1.5 1.5铸造合金钢Alloys Steels8.38 1.5 1.4 (cast)dAge Hardenable Stainless8.2 5.5 1.51 Steelsd金Goldc7.9- 1.4-High Temperature Steelsd7.9 6.3 1.4 1.1Ultra High Strength Steelsd7.6 5.7 1.41Malleable Ironsc7.5 5.9 1.3 1.1Titanium Carbide Cermetd7.5 4.3 1.30.8Wrought Ironsc7.4- 1.3-钛及其合金Titanium & its7.1 4.9 1.30.9 Alloysd钴Cobaltd 6.8- 1.2-马氏体不锈钢Martensitic6.5 5.5 1.21 Stainless Steelsc渗氮钢Nitriding Steelsd 6.5- 1.2-钯Palladiumc 6.5- 1.2-铍Berylliumb 6.4- 1.1-Chromium Carbide Cermetc 6.3 5.8 1.11钍Thoriumb 6.2- 1.1-铁素体不锈钢Ferritic Stainless6 5.8 1.11 SteelscGray Irons (cast)c6- 1.1-Beryllium Carbided 5.8-1-Low Expansion Nickel Alloysc5.5 1.510.3Beryllia & Thoriae 5.3-0.9-Alumina Cermetsd 5.2 4.70.90.8Molybdenum Disilicidec 5.1-0.9-Rutheniumb 5.1-0.9-Platinumc 4.9-0.9-Vanadiumb 4.8-0.9-Rhodiumb 4.6-0.8-Tantalum Carbided 4.6-0.8-Boron Nitrided 4.3-0.8-铌及其合金Columbium & its4.1 3.80.70.68 AlloysTitanium Carbided 4.1-0.7-Steatitec4 3.30.70.6Tungsten Carbide Cermetc 3.9 2.50.70.4铱Iridiumb 3.8-0.7-Alumina Ceramicsc 3.7 3.10.70.6Zirconium Carbided 3.7-0.7-Osmium and Tantalumb 3.6-0.6-锆及其合金Zirconium & its3.6 3.10.60.55 AlloysbHafniumb 3.4-0.6-Zirconiae 3.1-0.6-钼及其合金Molybdenum & its3.1 2.70.60.5 AlloysSilicon Carbidee 2.4 2.20.40.39钨Tungstenb 2.2-0.4-Electrical Ceramicsc2-0.4-Zirconc 1.8 1.30.30.2 Boron Carbidee 1.7-0.3-Carbon and Graphitec 1.5 1.30.30.2。

常用金属材料的热膨胀系数详细列表

5.8

1.1

1

钍Thoriumb

6.2

-

1.1

-

铁素体不锈钢Ferritic Stainless Steelsc

6

5.8

1.1

1

Gray Irons (cast)c

6

-

1.1

-

Beryllium Carbided

5.8

-

1

-

Low Expansion Nickel Alloysc

5.5

1.5

1

1.8

1.3

0.3

0.2

Boron Carbidee

1.7

-

0.3

-

Carbon and Graphitec

1.5

1.3

0.3

0.2

温馨提示:最好仔细阅读后才下载使用,万分感谢!

0.3

Beryllia & Thoriae

5.3

-

0.9

-

Alumina Cermetsd

5.2

4.7

0.9

0.8

Molybdenum Disilicidec

5.1

-

0.9

-

Rutheniumb

5.1

-

0.9

-

Platinumc

4.9

-

0.9

-

Vanadiumb

4.8

-

0.9

-

Rhodiumb

4.6

16

14

2.8

2.5

铝及其合金Aluminum & its Alloysc

13.7

11.7

2.5

2.1

[精品]各种材料的膨胀系数

[精品]各种材料的膨胀系数各种材料的膨胀系数:1.不锈钢:0.00001032.碳素钢 0.00001173.铜 0.000015964.青铜0.000018 5.铸铁 0.000011 6.聚氯乙烯0.00007 8.聚乙烯 0.0001 9.玻璃0.000005 10.PPR 0.15各种材料的熔点:1.铁 15302.钢1300---14003.铜10834.铝6605.锡23250米管材,50度温差时的膨胀量:PEX交联聚乙管 500mmPP聚乙烯管 400mmPB聚丁烯管 375mmPVC聚氯乙烯管 200mmPE-AL-PE铝管 59.50mm铜管 41.25mm镀锌钢管 28.50mm不锈钢管 27.50mm不同管材的线膨涨系数(摘自《化工管工工艺学》成都科技大学出版社87.12第一版) 管道材质线膨涨系数α值管道材质线膨涨系数α值米/米)度毫米/米)度米/米)度毫米/米)度 -6 -6碳素钢 12*100.012 紫铜16.4*10 0.0164 -6-6铸钢 11.4*10 0.0114 黄铜 18.4*10 0.0184 -6-6中铬钢11.4*10 0.0114 铝 24*10 0.024 -6-6不锈钢 10.3*10 0.0103 聚氯乙烯 80*10 0.08 -6-6镍钢 13.1*10 0.0131 氯乙烯 10*10 0.01 -6-6奥氏体钢 17*10 0.017 玻璃 5*10 0.005管道总热膨胀量=管材线膨涨系数*管段总长*(工作温度-安装时温度)附:饱和水蒸汽物理参数绝对压力饱和温蒸汽比容蒸汽重度含热量J/kg 汽化热332度? m/kg kg/ mJ/kg MPa kgf/cm 水蒸汽 0.00981 0.1 45.45 14.95 0.0669 0.01961 0.2 59.67 7.795 0.1283 0.02942 0.3 68.68 5.328 0.1877 0.03923 0.4 75.42 4.0690.2458 0.04903 0.5 80.86 3.301 0.3029 0.09807 1 99.09 1.725 0.57970.14710 1.5 110.79 1.180 0.8472 0.19613 2.0 119.62 0.9016 1.109 0.245172.5 126.79 0.7318 1.367 0.294203.0 132.88 0.6166 1.622 2164.2 0.343233.5 138.19 0.5338 1.873 581.55 2731.5 2149.9 0.392274.0 142.92 0.4706 2.125 601.22 2735.7 2134.4 0.44130 4.5 147.20 0.4213 2.373 619.65 2741.1 2121.5 0.49033 5.0 151.11 0.3816 2.621 636.81 2745.7 2108.90.55840 6.0 158.08 0.3213 3.112 666.95 2754.1 2087.1 0.68647 7.0 164.17 0.2778 3.600 693.33 2760.8 2067.4 0.78453 8.0 169.61 0.2448 4.085 717.20 2766.6 2049.4 0.88260 9.0 174.53 0.2189 4.568 738.55 2771.7 2033.1 0.98067 10.0 179.04 0.1981 5.049 758.64 2775.8 2017.2 1.07872 11.0 183.20 0.1808 5.530 777.07 2779.6 2002.5 1.17680 12.0 187.08 0.1664 6.010 794.24 2783.0 1988.7 1.27486 13.0 190.71 0.1541 6.488 810.15 2785.9 1975.8 1.37293 14.0 194.13 0.1435 6.967 825.22 2788.4 1963.21.47100 15.0 197.36 0.1343 7.446 839.87 2790.9 1951.0刍议实际利率法在债券筹资业务核算中的运用【摘要】按各期应付债券总账余额和实际利率确定应承担的债券利息费用按票面利率确定各期应付债券总面值的应付利息各期承担债券的利息费用与应付利息的差额形成了应摊销的债券溢折价额【关键词】确定实际利率,债券利息费,摊销溢折价,账务处理企业在发行长期债券筹资业务中产生的溢折价应当在到期前的各期间内按照实际利率分摊实际利率法核算应付债券的利息费用要求企业按照各期应付债券的负债总额和债券实际利率确定各期承担的债券利息费用采用实际利率确定各期承担的利息费用能更合理体现各期应付债券的负债资金应承担利息费用的配比性要求2006年财政部发布的《会计准则第22号,金融工具确认和计量》第十四条3规定企业应当采用实际利率法确认各期应负担金融负债的利息费用从而分摊债券的溢折价笔者认为宜从以下方面把握实际利率法在核算长期债券筹资业务中的运用方法即长期债券筹资业务核算的初始计量、确认各期应承担债券利息费用的后续计量以及在应付债券转换处置业务中的运用一、实际利率法在长期债券筹资业务初始计量中的运用企业发行的长期债券也可以从多个角度分类比如按照付息方式可分为到期一次性还本付息和分期付息的债券,按照是否承诺未来转化为股票分为可转换债券和不可转换为股票的还本付息债券,按照发行价格方式可以划分为溢价、折价或平价方式发行的债券,按照计息方式分为单利法计息和复利法计息的债券等无论属于哪支类型的债券采用实际利率法核算债券的筹资业务都需要在“应付债券”总账下专设“面值”、“应计利息”、“利息调整”明细账对于按期付息的债券应当专设“应付利息”总账核算结算形成的未付利息额发行债券取得了筹资额的会计处4理为借银行存款,实收总额,贷应付债券,面值,利息调整举例说明如下假设光明公司在2007年1月1日经批准委托代理商在证券市场发行了5年期面值100元/张票面年利率9%到期一次性还本付息的债券100000张即总面值1000万元发行当日起开始按照单利法计息确定的发行价格为102元/张发行取得资金用于增补生产经营资金发行期间7天冻结全部申购资金所取得利息收入10万元承担的发行费用4万元已经签发了支票支付给代理商发行后直接在市场上市交易光明公司在发行期已经全部销售了债券并取得了筹资款发行债券手续费从发行债券取得资金和冻结申购资金取得利息的存款账户中支付在2007年初发行债券取得资金的会计处理为借银行存款10260000贷应付债券-面值100000005-利息调整260000二、实际利率法在核算各期应承担债券利息费用中的运用实际利率法在核算企业长期债券筹资业务中运用的核心内容是对债券利息费用的核算笔者认为应特别重视把握以下要点第一确定应付债券筹资额的实际利率发行债券的筹资额应当等价于未来支付债券利息和偿还债券本金的总现值从而计算确定其中的折现率即通过下列关系式解方程确定实际利率债券的发行价,未来各期支付债券利息额的总折现值,到期偿还债券本金额的折现值第二按照实际利率和应付债券结余额确定各期承6担的债券利息费用某年应确认的债券利息费用,应付债券额×实际年利率第三确定各期应付债券利息与承担债券利息费用额之间的差额企业需按持有债券的面值及票面利率确定应付的债券利息,这反映了债券发行企业与债券购买者之间的利息结算关系,按应付债券额及实际利率水平确定当期应承担的债券利息这反映了企业形成的利息费用额,各期应付债券利息与债券利息费用额之间的差额形成为债券溢价或折价的摊销额第四编制相应业务的会计分录借财务费用或在建工程(应付债券余额×实际利率)应付债券,利息调整,差额,贷应付债券,应计利息,面值×票面利率,注对于符合资本化条件的借款费用应当形成在建7工程,对于分期付息的债券应当计入到“应付利息”总账中在上述举例条件中,光明公司各期应承担债券利息费用的会计处理方法如下一是计算光明公司在2007年1月1日发行该债券筹资的实际年利率i注如果债券发行的费用大于债券发行期间冻结申购资金的利息收入额规定该差额形成财务费用或在建工程等账户在计算实际利率时不需要考虑,但本题中的债券发行费用小于债券发行期间冻结申购资金得到的利息该差额作为债券发行的溢价并入应付债券账户核算二是确定各期应承担的利息和应支付的利息、转回的债券数额、债券总账余额等项目额2007年末结计当年形成的应付债券利息=债券总面值×票面年利率=10000000×9%=90000082007年末确认当年应承担的债券利息费用额=该年初应付债券总账余额×实际利率=10260000×7.163%=734923.802007年应摊销转回债券溢价=应付利息-承担的债券利息费=900000-734923.8=165076.2元2007年末应付债券总账余额=年初总账余额+当年应付利息-当年摊销溢价转回的债券数额=10260000+900000-165076.2=10994923.8依次类推计算2008年后各年应付债券的利息下表反映各项目数额的计算过程和结果三是承担债券利息费用的会计处理2007年末结计利息和摊销债券溢价业务的会计分录借财务费用734923.80=10260000×7.163%9应付债券-利息调整165076.2=900000-734923.8贷应付债券-应计利息900000=10000000×9%2008年末结计利息和摊销债券溢价业务的会计分录借财务费用787566.39=10994923.8×7.163%应付债券-利息调整112433.61=900000-787566.39贷应付债券-应计利息900000=10000000×9%2009年末结计利息和摊销债券溢价业务的会计分录借财务费用843979.77=11782490.19×7.163%应付债券-利息调整56020.23=900000-843979.77贷应付债券-应计利息900000=10000000×9%102010年末结计利息和摊销债券溢价业务的会计分录借财务费用904434.04=12626469.96×7.163%贷应付债券-应计利息900000=10000000×9%应付债券-利息调整4434.04=900000-904434.04,表示形成财务费用的利息大于应付利息,2011年末结计利息和摊销债券溢价业务的会计分录借财务费用969096=14500000×7.163%贷应付债券-应计利息900000=10000000×9%应付债券-利息调整69096=900000-969096,表示形成财务费用的利息大于应付利息,2011年末利息调整明细账余额=260000-165076.211-112433.61-56020.23+4434.04+69096=02011年末应计利息明细账余额=900000×5=4500000元2011年末应付债券总账余额=1000万元+450万元+0=1450万元2011年末应付债券到期还本付息业务的会计处理借应付债券-面值10000000-应计利息4500000贷银行存款14500000三、实际利率法在可转换债券业务核算中的运用12笔者认为应用实际利率法核算可转换债券业务应着重把握两个要点一是需要计算发行债券的实际收款额与债券按照发行当时市场利率确定现值的差额,该差额形成资本公积,再计算债券面值与债券现值,即公允价,之间的差额该差额形成利息调整,二是在条件具备时将可转换债券转换为股票从而解除债务但一般债券是在到期日偿还债券本息后解除了债务在转换股票之前各期间的账务处理方法与一般债券相同见下列核算案例假设前进公司在2007年1月1日经过批准发行了总面值1000万元票面年利率6%5年期按年付息每年12月31日付息发行时的市场年利率9%扣除发行费用后实际收到发行价款900万元发行2年后可以转换股票按照每10元债券转换1股股票股票面值为1元/股设在可转换股票日可转换债券的持有者都行权办理了转换股票手续第一2007年初发行可转换债券需计算有关项目数额和编制的会计分录方法为13___?_____________________?__________________?_债券面值1000万元债券现值,公允价,883.4万元发行价900万可转换债券的现值,即公允价,=到期前未来各年利息额的现值+到期债还本金的现值=1000万×6%×5年及9%年利率的年金现值系数+1000万×5年及9%的复利现值系数=60万×3.89+1000万×0.65=233.4+650=883.4万元发行可转换债券形成的折价,利息调整账户额,=面值-现值,公允价,=1000-883.4=116.6发行债券实际收款与债券现值,公允价,之间的差额=900-883.4=16.6万元借银行存款9000000应付债券-可转换债券,利息调整,1166000贷应付债券-可转换债券,面值,1000000014资本公积-其他资本公积166000注?以发行可转换债券当时的市场利率作为计算债券现值的实际利率,?实际收取可转换债券的发行价总额与计算的债券现值之间的差额形成资本公积构成净资产,?如果不是发行可转换债券发行债券取得价款与债券面值之间的差额全都在“应付债券-利息调整”账户核算不必分离出形成资本公积的差额和形成“利息调整”明细账户的差额第二2007年12月31日确认本期间应承担的债券利息费用借财务费用795060=,1000-116.6,万元×9%=883.4万元×9%贷应付债券-可转换债券,应计利息,600000=1000万元×6%-可转换债券,利息调整,195060=79.506万元-60万元15第三2008年12月31日确认本期间应承担的债券利息费用借财务费用866615.4=,1000-116.6+60+19.506,万元×9%贷应付债券-可转换债券,应计利息,600000=1000万元×6%-可转换债券,利息调整,266615.4=86.66154万元-60万元第四2009年1月1日债券转换为股票的业务核算方法转换股票前账面结余的利息调整额,116.6-19.506-26.66154,70.43246万元转换股票前形成的应计利息结余额,60,60,120万元16债券转换的股份数=该债券的总账余额/10=(1000+120-70.43246)/10=104.956754万股=1049567.54股(不足1股的部分付现金结算,0.54股的债券额5.4元)借应付债券-可转换债券(面值)10000000-可转换债券(应计利息)1200000资本公积-其他资本公积166000贷应付债券-可转换债券(利息调整)704324.6股本1049567=104.9567万股×1元/股资本公积-资本溢价9612103库存现金5.40可转换债券转换成为股票之后企业在该债券上的偿债义务和风险才解除企业将按照接受股权投资的实收资本业务对其进行后续核算17【参考文献】1财政部会计资格评价中心编写.中级会计实务.经济科学出版社2007年1月.2《企业会计准则第22号,金融工具确认和计量》2006年2月15日财政部颁布.2007年1月1日起施行.3《企业会计准则,应用指南,2006,》2006年10月30日财政部颁布.自2007年1月1日起施行.1819。

常用金属材料的热膨胀系数详细列表

2。1

1.8

银Silverc

10。9

—

2

—

铬镍耐热钢Cr—Ni—Fe Superalloysd

10。5

9.2

1。9

1.7

Heat Resistant Alloys(cast)d

10.5

6.4

1。9

1。1

Nodular or Ductile Irons(cast)c

10。4

6。6

1。9

1。2

不锈钢Stainless Steels (cast)d

3。8

-

0。7

-

Alumina Ceramicsc

3。7

3.1

0。7

0.6

Zirconium Carbided

3.7

—

0。7

—

Osmium and Tantalumb

3。6

-

0。6

—

锆及其合金Zirconium & its Alloysb

3。6

3.1

0.6

0.55

Hafniumb

3。4

—

0.6

-

Zirconiae

7。6

5。7

1。4

1

Malleable Ironsc

7.5

5。9

1.3

1。1

Titanium Carbide Cermetd

7。5

4。3

1.3

0.8

Wrought Ironsc

7.4

—

1.3

—

钛及其合金Titanium & its Alloysd

7。1

4.9

1.3

0.9

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

金属材料的热膨胀系数YD10 0S TFE GUID E 的长度计算:线膨胀系数8.3X1 0(-5 )

1.区分A:瞬间热膨胀系数长度△

L=(d+ 1)×π×8.3×10^(-5)×(200-20)

2.区分B:平均热膨胀系数所以

L=(d+

1)×

π-

1.83

槽的

内径

公差

=d×

8.3×

10^(-

5)×

(200-

20)/1

0;为

槽内

的多

1000

18.90 3.个材料的区分如下表示

1)碳素钢、合金钢(区分1)

・碳素钢 ・ 3/4Ni-

1/2Mo-Cr-V ・3/4Ni-1Mo-

3/4Cr ・碳・钼钢 ・

3/4Ni-1/2Mo-1/3Cr-V ・

1Ni-1/2Cr-1/2Mo

・ 1/2Ni-1/2Mo-V ・

3/4Ni-1/2Cr-Mo-V

2)碳素钢、合金钢(区分2)

・碳・硅钢 ・ 1/2Cr-

1/2Mo ・1Cr-1/5Mo-Si ・

1/2Mo ・1Cr-1/5Mo-V ・

1Cr-1/2Mo

・1Cr-1Mn-1/4Mo ・

1Cr-1/5Mo ・1・3/4Cr-

1/2Mo-Cu0.15145.15 3)碳素钢、合金钢(区分3) 2.382712.4 ・碳・钼钢 ・ 1・1/4Ni-

1/2Mo ・2Cr-1/2Mo ・

1/2Cr-1/4Mo-Si ・1・

1/4Cr-1/2Mo-Si ・3Cr-

1Mo ・1Cr-1/2Mo-V

4)碳素钢、合金钢(区分4) ・Mn-1/2Mo ・Mn-

1/2Mo-1/2Ni ・Mn-

1/2Mo-1/4Ni ・Mn-

1/2Mo-3/4Ni 水泥在1000度以上的热膨胀系数为5.8

5)碳素钢、合金钢(区分5)310S 在800度时热膨胀系数为18.5

・1.1/4Ni-1Cr-1/2Mo ・2Ni-3/4Cr-1/4Mo ・

3.1/2Ni ・1.3/4Ni-3/4Cr-1/4Mo ・2Ni-3/4Cr-1/2Mo 310S 在1000度时热膨胀系数为19.5

・3.1/2Ni-1.3/4Cr-

1/2Mo-V ・2Ni-1Cu ・2.1/2Ni ・1Cr-1/2Mo-V

6)奥氏体不锈钢SS(区分1) 7)奥

氏体

不锈

钢

SS(区

分2)

8)奥

氏体

不锈

钢

SS(区

分3)

・18Cr-13Ni-3Mo ・18Cr-12Ni-2Mo ・

17Cr-

4Ni-

Cu

・

18Cr-

5Ni-

3Mo

9)奥氏体不锈钢SS(区分4) 10)

奥氏

体不

锈钢

SS(区

分5)

11)

奥氏

体不

锈钢

SS(区

分6)

・18Cr-8Ni ・18Cr-11Ni ・

18Cr-

10Ni-

Ti

・

18Cr-

10Ni-

Cb0.459

12)奥氏体不锈钢SS(区分7) 13)

奥氏

体不

锈钢

SS(区

分8)

14)

奥氏

体不

锈钢

SS(区

分9)0.505

・18Cr-9Ni-Mo-W ・

22Cr-

13Ni-

5Mn

・

25Cr-

12Ni

・

23Cr-

12Ni

・

25Cr-

20Ni

15)奥氏体不锈钢SS(区分10) 16)奥氏体不锈钢SS(区分11)

・(660)26Ni-15Cr-2Ti ・28Ni-19Cr-Cu-Mo

17)马氏体不锈钢SS(区分 ・12Cr ・12Cr-1Al ・13Cr ・13Cr-4Ni

18)马氏体不锈钢SS(区分2) 19)马氏体不锈钢SS(区分3)

・17Cr ・27Cr

20)高镍合金(区分1) 21)

高镍

合金

(区分

2)

22)

高镍

合金

(区分

3)

・Ni-Cr-Fe(NCF600) ・

Ni-

Fe-

Cr(NC

F800,

NCF8

00H)

・

Ni-

Fe-

Cr-

Mo-

Cu(N

CF82

5,GN

CF2

種及

び3

23)高镍合金(区分4) 24)

高镍

合金

(区分

5)

25)

高镍

合金

(区分

6)

・Ni-Cr-Mo-

Cb(NCF625,GNCF1種) ・

Ni-

Fe-

Cr-

Mo-

Cb(N

CF71

8)

・

Ni-

Cr(NC

F750)。