建筑施工混凝土裂缝的主要种类外文翻译、中英对照、英汉互译

建筑施工混凝土裂缝处理中英文对照外文翻译文献

中英文对照外文翻译(文档含英文原文和中文翻译)Building construction concrete crack ofprevention and processingAbstractThe crack problem of concrete is a widespread existence but again difficult in solve of engineering actual problem, this text carried on a study analysis to a little bit familiar crack problem in the concrete engineering, and aim at concrete the circumstance put forward some prevention, processing measure.Keyword:Concrete crack prevention processingForewordConcrete's ising 1 kind is anticipate by the freestone bone, cement, water and other mixture but formation of the in addition material of quality brittleness not and all material.Because the concrete construction transform with oneself, control etc. a series problem, harden model of in the concrete existence numerous tiny hole, spirit cave and tiny crack, is exactly because these beginning start blemish of existence just make the concrete present one some not and all the characteristic of quality.The tiny crack is a kind of harmless crack and accept concrete heavy, defend Shen and a little bit other use function not a creation to endanger.But after the concrete be subjected to lotus carry, difference in temperature etc. function, tiny crack would continuously of expand with connect, end formation we can see without the aid of instruments of macro view the crack be also the crack that the concrete often say in the engineering.Concrete building and Gou piece usually all take sewer to make of, because of crack of existence and development usually make inner part of reinforcing bar etc. material creation decay, lower reinforced concrete material of loading ability, durable and anti- Shen ability, influence building of external appearance, service life, severity will threat arrive people's life and property safety.A lot of all of crash of engineerings is because of the unsteady development of the crack withthe result that.Modern age science research with a great deal of of the concrete engineering practice certificate, in the concrete engineering crack problem is ineluctable, also acceptable in certainly of the scope just need to adopt valid of measure will it endanger degree control at certain of scope inside.The reinforced concrete norm is also explicit provision:Some structure at place of dissimilarity under the condition allow existence certain the crack of width.But at under construction should as far as possible adopt a valid measure control crack creation, make the structure don't appear crack possibly or as far as possible decrease crack of amount and width, particularly want to as far as possible avoid harmful crack of emergence, insure engineering quality thus.Concrete crack creation of the reason be a lot of and have already transformed to cause of crack:Such as temperature variety, constringency, inflation, the asymmetry sink to sink etc. reason cause of crack;Have outside carry the crack that the function cause;Protected environment not appropriate the crack etc. caused with chemical effect.Want differentiation to treat in the actual engineering, work°out a problem according to the actual circumstance.In the concrete engineering the familiar crack and the prevention1.Stem Suo crack and preventionStem the Suo crack much appear after the concrete protect beover of a period of time or concrete sprinkle to build to complete behind of around a week.In the cement syrup humidity of evaporate would creation stem Suo, and this kind of constringency is can't negative.Stem Suo crack of the creation be main is because of concrete inside outside humidity evaporate degree dissimilarity but cause to transform dissimilarity of result:The concrete is subjected to exterior condition of influence, surface humidity loss lead quick, transform bigger, inner part degree of humidity variety smaller transform smaller, bigger surface stem the Suo transform to be subjected to concrete inner part control, creation more big pull should dint but creation crack.The relative humidity is more low, cement syrup body stem Suo more big, stem the Suo crack be more easy creation.Stem the Suo crack is much surface parallel lines form or the net shallow thin crack, width many between 0.05-0.2 mm, the flat surface part much see in the big physical volume concrete and follow it more in thinner beam plank short to distribute.Stem Suo crack usually the anti- Shen of influence concrete, cause the durable of the rust eclipse influence concrete of reinforcing bar, under the function of the water pressure dint would creation the water power split crack influence concrete of loading dint etc..Concrete stem the Suo be main with water ash of the concrete ratio, the dosage of the composition, cement of cement, gather to anticipate of the dosage of the property and dosage, in addition etc. relevant.Main prevention measure:While being to choose to use the constringency quantity smaller cement, general low hot water mire and powder ash from stove cement in the adoption, lower the dosage of cement.Two is a concrete of stem the Suo be subjected to water ash ratio of influence more big, water ash ratio more big, stem Suo more big, so in the concrete match the ratio the design should as far as possible control good water ash ratio of choose to use, the Chan add in the meantime accommodation of reduce water.Three is strict control concrete mix blend with under construction of match ratio, use of concrete water quantity absolute can't big in match ratio design give settle of use water quantity.Four is the earlier period which strengthen concrete to protect, and appropriate extension protect of concrete time.Winter construction want to be appropriate extension concrete heat preservation to overlay time, and Tu2 Shua protect to protect.Five is a constitution the accommodation is in the concrete structure of the constringency sew.2.The Su constringency crack and preventionSu constringency is the concrete is before condense, surface because of lose water quicker but creation of constringency.The Su constringency crack is general at dry heat or strong wind the weather appear, crack's much presenting in the center breadth, both ends be in the centerthin and the length be different, with each other not coherentappearance.Shorter crack general long 20-30 cm, the longer crack can reach to a 2-3 m, breadth 1-5 mm.It creation of main reason is:The concrete is eventually almost having no strength or strength before the Ning very small, perhaps concrete just eventually Ning but strength very hour, be subjected to heat or compare strong wind dint of influence, the concrete surface lose water to lead quick, result in in the capillary creation bigger negative press but make a concrete physical volume sharply constringency, but at this time the strength of concrete again can't resist its constringency, therefore creation cracked.The influence concrete Su constringency open the main factor of crack to have water ash ratio, concrete of condense time, environment temperature, wind velocity, relative humidity...etc..Main prevention measure:One is choose to use stem the Suo value smaller higher Huo sour salt of the earlier period strength or common the Huo sour brine mire.Two is strict the control water ash ratio, the Chan add to efficiently reduce water to increment the collapse of concrete fall a degree and with easy, decrease cement and water of dosage.Three is to sprinkle before building concrete, water basic level and template even to soak through.Four is in time to overlay the perhaps damp grass mat of the plastics thin film, hemp slice etc., keep concrete eventually before the Ning surface is moist, perhaps spray to protect etc. to carry on protect in the concrete surface.Five is in the heatand strong wind the weather to want to establish to hide sun and block breeze facilities, protect in time.3.Sink to sink crack and preventionThe creation which sink to sink crack is because of the structure foundation soil quality not and evenly, loose soft or return to fill soil dishonest or soak in water but result in the asymmetry sink to decline with the result that;Perhaps because of template just degree shortage, the template propped up to once be apart from big or prop up bottom loose move etc. to cause, especially at winter, the template prop up at jelly soil up, jelly the soil turn jelly empress creation asymmetry to sink to decline and cause concrete structure creation crack.This kind crack many is deep enter or pierce through sex crack, it alignment have something to do with sinking to sink a circumstance, general follow with ground perpendicular or present 30 °s-45 ° Cape direction development, bigger sink to sink crack, usually have certain of wrong, crack width usually with sink to decline quantity direct proportion relation.Crack width under the influence of temperature variety smaller.The foundation after transform stability sink to sink crack also basic tend in stability.Main prevention measure:One is rightness loose soft soil, return to fill soil foundation a construction at the upper part structure front should carry on necessity of Hang solid with reinforce.Two is thestrength that assurance template is enough and just degree, and prop up firm, and make the foundation be subjected to dint even.Three is keep concrete from sprinkle infusing the foundation in the process is soak by water.Four is time that template tore down to can't be too early, and want to notice to dismantle a mold order of sequence.Five is at jelly soil top take to establish template to notice to adopt certain of prevention measure.4.Temperature crack and preventionTemperature crack much the occurrence is in big surface or difference in temperature variety of the physical volume concrete compare the earth area of the concrete structure.Concrete after sprinkling to build, in the hardening the process, cement water turn a creation a great deal of of water turn hot, .(be the cement dosage is in the 350-550 kg/m 3, each sign square the rice concrete will release a calories of 17500-27500 kJ and make concrete internal thus the temperature rise to reach to 70 ℃or so even higher)Because the physical volume of concrete be more big, a great deal of of water turn hot accumulate at the concrete inner part but not easy send forth, cause inner part the temperature hoick, but the concrete surface spread hot more quick, so formation inside outside of bigger difference in temperature, the bigger difference in temperature result in inner part and exterior hot the degree of the bulge cold Suo dissimilarity, makeconcrete surface creation certain of pull should dint.When pull should dint exceed the anti- of concrete pull strength extreme limit, concrete surface meeting creation crack, this kind of crack much occurrence after the concrete under construction period.In the concrete of under construction be difference in temperature variety more big, perhaps is a concrete to be subjected to assault of cold wave etc., will cause concrete surface the temperature sharply descend, but creation constringency, surface constringency of the concrete be subjected to inner part concrete of control, creation very big of pull should dint but creation crack, this kind of crack usually just in more shallow scope of the concrete surface creation.The alignment of the temperature crack usually none settle regulation, big area structure the crack often maneuver interleave;The size bigger structure of the beam plank length, the crack run parallel with short side more;Thorough with pierce through sex of temperature crack general and short side direction parallelism or close parallelism, crack along long side cent the segment appear, in the center more airtight.Crack width the size be different, be subjected to temperature variety influence more obvious, winter compare breadth, summer more narrow.The concrete temperature crack that the heat inflation cause is usually in the center the thick both ends be thin, but cold Suo crack of thick thin variety not too obvious.The emergence of the this kind crackwill cause the rust eclipse of reinforcing bar, the carbonization of concrete, the anti- jelly which lower concrete melt, anti- tired and anti- Shen ability etc..Main prevention measure:One is as far as possible choose to use low hot or medium hot water mire, like mineral residue cement, powder ash from stove cement...etc..Two is a decrease cement dosage, cement dosage as far as possible the control is in the 450 kg/m 3 following.Three is to lower water ash ratio, water ash of the general concrete ratio control below 0.6.Four is improvement the bone anticipate class to go together with, the Chan add powder ash from stove or efficiently reduce water etc. to come to reduce cement dosage and lower water to turn hot.Five is an improvement concrete of mix blend to process a craft, lower sprinkle of concrete to build temperature.Six is the in addition that the Chan add a have of fixed amount to reduce water and increase Su, slow Ning etc. function in the concrete, improvement the concrete mix to match a thing of mobility, protect water, lower water to turn hot, postpone hot Feng of emergence time.Seven is the heat season sprinkle to build can the adoption take to establish to hide sun plank etc. assistance measure control concrete of Wen Sheng, lower to sprinkle temperature of build the concrete.Eight is the temperature of big physical volume concrete should the dint relate to structure size, concrete structure size more big, temperature should dint more big, sowant reasonable arrangement construction work preface, layering, cent the piece sprinkle to build, for the convenience of in spread hot, let up control.Nine is at great inner part constitution of the physical volume concrete cool off piping, cold water perhaps cold air cool off, let up concrete of inside outside difference in temperature.Ten is the supervision which strengthen concrete temperature, adopt to cool off in time, protection measure.11 is to reserve temperature constringency to sew.12 is to let up to control, sprinkle proper before building concrete in the Ji rock and old concrete top build a 5 mm or so sand mat a layer or usage asphalt etc. material Tu2 Shua.13 is to strengthen concrete to protect, the concrete after sprinkle build use moist grass Lian in time, hemp slice's etc. overlay, and attention sprinkle water to protect, appropriate extension protect time, assurance the concrete surface be slow-moving cool off.At the cold season, concrete surface should constitution heat preservation measure, in order to prevent cold wave assault.14 is the allocation be a little amount in the concrete of reinforcing bar perhaps add fiber material concrete of temperature crack control at certain of scope inside.5.Crack and prevention that the chemical reaction causeAlkali bone's anticipating the crack that reaction crack and reinforcing bar rust eclipse cause is the most familiar in the reinforced concrete structure of because of chemical reaction but cause of crack.The concrete blend a future reunion creation some alkalescence ion, these ion with some activity the bone anticipate creation chemical reaction and absorb surroundings environment in of water but the physical volume enlarge, make concrete crisp loose, inflation open crack.In this kind of crack general emergence concrete structure usage period, once appear very difficult remediable, so should at under construction adopt valid the measure carry on prevention.Main of prevention measure:While being to choose to anticipate with the alkali activity small freestone bone.Two is the in addition which choose to use low lye mire with low alkali or have no alkali.Three is the Chan which choose to use accommodation with anticipate to repress an alkali bone to anticipate reaction.Because the concrete sprinkle to build, flap Dao bad perhaps is a reinforcing bar protection layer thinner, the harmful material get into concrete to make reinforcing bar creation rust eclipse, the reinforcing bar physical volume of the rust eclipse inflation, cause concrete bulge crack, the crack of this kind type much is a crack lengthways, follow the position of reinforcing bar ually of prevent measure from have:One is assurance reinforcing bar protection the thickness of the layer.Two is a concrete class to go together with to want good.Three is a concrete to sprinkle to note and flap Dao airtight solid.Four is a reinforcing bar surface layer Tu2 Shua antisepsis coating.Crack processingThe emergence of the crack not only would influence structure of whole with just degree, return will cause the rust eclipse of reinforcing bar, acceleration concrete of carbonization, lower durable and anti- of concrete tired, anti- Shen ability.Therefore according to the property of crack and concrete circumstance we want differentiation to treat, in time processing, with assurance building of safety usage.The repair measure of the concrete crack is main to have the following some method:Surface repair method, infuse syrup, the Qian sew method, the structure reinforce a method, concrete displacement method, electricity chemistry protection method and imitate to living from heal method.Surface repair the method be a kind of simple, familiar of repair method, it main be applicable to stability and to structure loading the ability don't have the surface crack of influence and deep enter crack of processing.The processing measure that is usually is a surface in crack daubery cement syrup, the wreath oxygen gum mire or at concrete surface Tu2 Shua paint, asphalt etc. antisepsis material, at protection of in the meantime for keeping concrete from continue under the influence of various function to open crack, usually can adoption the surface in crack glue to stick glass fiber cloth etc. measure.1, infuse syrup, the Qian sew methodInfuse a syrup method main the concrete crack been applicable to have influence or have already defend Shen request to the structure whole of repair, it is make use of pressure equipments gum knot the material press into the crack of concrete, gum knot the material harden behind and concrete formation one be whole, thus reinforce of purpose.The in common use gum knot material has the cement the syrup, epoxy, A Ji C Xi sour ester and gather ammonia ester to equalize to learn material.The Qian sew a method is that the crack be a kind of most in common use method in, it usually is follow the crack dig slot, the Qian fill Su in the slot or rigid water material with attain closing crack of purpose.The in common use Su material has PVC gum mire, plastics ointment, the D Ji rubber etc.;In common use rigid water material is the polymer cement sand syrup.2, the structure reinforce a methodWhen the crack influence arrive concrete structure of function, will consideration adopt to reinforce a method to carry on processing to the concrete structure.The structure reinforce medium in common use main have the following a few method:The piece of enlargement concrete structure in every aspect accumulate, outside the Cape department of the Gou piece pack type steel, adoption prepare should the dint method reinforce, glue to stick steel plate to reinforce, increaseto establish fulcrum to reinforce and jet the concrete compensation reinforce.3, concrete displacement methodConcrete displacement method is processing severity damage concrete of a kind of valid method, this method be first will damage of the concrete pick and get rid of, then again displacement go into new of concrete or other material.The in common use displacement material have:Common concrete or the cement sand syrup, polymer or change sex polymer concrete or sand syrup.4, the electricity chemistry protection methodThe electricity chemistry antisepsis is to make use of infliction electric field in lie the quality of electricity chemical effect, change concrete or reinforced concrete the environment appearance of the place, the bluntness turn reinforcing bar to attain the purpose of antisepsis.Cathode protection method, chlorine salt's withdrawing a method, alkalescence to recover a method is a chemistry protection method in three kinds of in common use but valid method.The advantage of this kind of method is a protection method under the influence of environment factor smaller, apply reinforcing bar, concrete of long-term antisepsis, since can used for crack structure already can also used for new set up structure.5, imitate to living from legal moreImitate to living from heal the method be a kind of new crack treatment, its mimicry living creature organization secrete a certain material towards suffering wound part auto, but make the wound part heal of function, join some and special composition(such as contain to glue knot of the liquid Xin fiber or capsule) in the concrete of the tradition the composition, at concrete inner part formation the intelligence type imitate to living from heal nerve network system, be the concrete appear crack secrete a parts of liquid Xin fiber can make the crack re- heal.ConclusionThe crack is widespread in the concrete structure existence of a kind of phenomenon, it of emergence not only will lower the anti- Shen of building ability, influence building of usage function, and will cause the rust eclipse of reinforcing bar, the carbonization of concrete, lower the durable of material, influence building of loading ability, so want to carry on to the concrete crack earnest research, differentiation treat, adoption reasonable of the method carry on processing, and at under construction adopt various valid of prevention measure to prevention crack of emergence and development, assurance building and Gou piece safety, stability work.建筑施工混凝土裂缝的预防与处理混凝土的裂缝问题是一个普遍存在而又难于解决的工程实际问题,本文对混凝土工程中常见的一些裂缝问题进行了探讨分析,并针对具体情况提出了一些预防、处理措施。

建筑专业土木工程词汇及术语 中英文对照

建筑专业笔记整理大全-结构工程常用词汇-土木工程常用英语术语结构工程常用词汇混凝土:concrete钢筋:reinforcing steel bar钢筋混凝土:reinforced concrete(RC)钢筋混凝土结构:reinforced concrete structure板式楼梯:cranked slab stairs刚度:rigidity徐变:creep水泥:cement钢筋保护层:cover to reinforcement梁:beam柱:column板:slab剪力墙:shear wall基础:foundation剪力:shear剪切变形:shear deformation剪切模量:shear modulus拉力:tension压力:pressure延伸率:percentage of elongation位移:displacement应力:stress应变:strain应力集中:concentration of stresses应力松弛:stress relaxation应力图:stress diagram应力应变曲线:stress—strain curve应力状态:state of stress钢丝:steel wire箍筋:hoop reinforcement箍筋间距:stirrup spacing加载:loading抗压强度:compressive strength抗弯强度:bending strength抗扭强度:torsional strength抗拉强度:tensile strength裂缝:crack屈服:yield屈服点:yield point屈服荷载:yield load屈服极限:limit of yielding屈服强度:yield strength屈服强度下限:lower limit of yield荷载:load横截面:cross section承载力:bearing capacity承重结构:bearing structure弹性模量:elastic modulus预应力钢筋混凝土:prestressed reinforced concrete预应力钢筋:prestressed reinforcement预应力损失:loss of prestress预制板:precast slab现浇钢筋混凝土结构:cast—in—place reinforced concrete 双向配筋:two—way reinforcement主梁:main beam次梁:secondary beam弯矩:moment悬臂梁:cantilever beam延性:ductileity受弯构件:member in bending受拉区:tensile region受压区:compressive region塑性:plasticity轴向压力:axial pressure轴向拉力:axial tension吊车梁:crane beam可靠性:reliability粘结力:cohesive force外力:external force弯起钢筋:bent-up bar弯曲破坏:bending failure屋架:roof truss素混凝土:non-reinforced concrete无梁楼盖:flat slab配筋率:reinforcement ratio配箍率:stirrup ratio泊松比:Poisson’s ratio偏心受拉:eccentric tension偏心受压:eccentric compression偏心距:eccentric distance疲劳强度:fatigue strength偏心荷载:eccentric load跨度:span跨高比:span—to-depth ratio跨中荷载:midspan load框架结构:frame structure集中荷载:concentrated load分布荷载:distribution load分布钢筋:distribution steel挠度:deflection设计荷载:design load设计强度:design strength构造:construction简支梁:simple beam截面面积:area of section浇注:pouring浇注混凝土:concreting钢筋搭接:bar splicing刚架:rigid frame脆性:brittleness脆性破坏:brittle failure土木工程常用英语术语第一节一般术语1. 工程结构building and civil engineering structures房屋建筑和土木工程的建筑物、构筑物及其相关组成部分的总称。

常见路面病害中英文对照

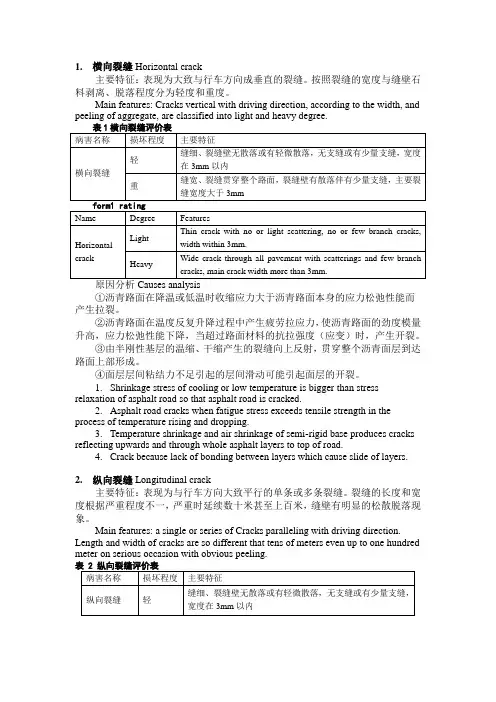

1.横向裂缝Horizontal crack主要特征:表现为大致与行车方向成垂直的裂缝。

按照裂缝的宽度与缝壁石料剥离、脱落程度分为轻度和重度。

Main features: Cracks vertical with driving direction, according to the width, and peeling of aggregate, are classified into light and heavy degree.①沥青路面在降温或低温时收缩应力大于沥青路面本身的应力松弛性能而产生拉裂。

②沥青路面在温度反复升降过程中产生疲劳拉应力,使沥青路面的劲度模量升高,应力松弛性能下降,当超过路面材料的抗拉强度(应变)时,产生开裂。

③由半刚性基层的温缩、干缩产生的裂缝向上反射,贯穿整个沥青面层到达路面上部形成。

④面层层间粘结力不足引起的层间滑动可能引起面层的开裂。

1.Shrinkage stress of cooling or low temperature is bigger than stress relaxation of asphalt road so that asphalt road is cracked.2.Asphalt road cracks when fatigue stress exceeds tensile strength in the process of temperature rising and dropping.3.Temperature shrinkage and air shrinkage of semi-rigid base produces cracks reflecting upwards and through whole asphalt layers to top of road.4.Crack because lack of bonding between layers which cause slide of layers. 2.纵向裂缝Longitudinal crack主要特征:表现为与行车方向大致平行的单条或多条裂缝。

混凝土相关词语中英文对照

混凝土相关词语中英文对照Al AbramsAbrams cone—Abrams圆筒(坍落度筒)Abrams law—Abrams定则l Admixture—外加剂→化学外加剂l Aggregate—骨料Absorption of water—吸水率Alkali-carbonate reaction—碱-碳酸盐反应Chloride—氯化物Clay—黏土combination of—结合criteria of acceptance—接受准则frost resistance—抗冻性grading—级配Los Angeles test—洛杉矶实验Maximum size and water requirement—最大粒径和需水量Mechanical properties—力学性能Moisture—含水率organic substance—有机杂质porosity—孔隙率sieve analysis—筛分分析S.S.D.—饱和面干sulphate—硫酸盐water requirement—需水量l Aggressive CO2—侵蚀介质CO2l Alite—阿利特l Ammonium salts—铵盐l Amorphous silica—无定形二氧化硅l ASR Alkali-silica-reaction in aggregate—骨料中的碱-硅反应: Bl Belite—贝利特l Blast furnace cement—矿渣水泥l Bleeding—泌水concrete in floor—地板混凝土grout—水泥浆influence of steel bond—钢筋粘结的影响influence of transition zone—过渡区的影响mortar—砂浆l BolomeyCl Capillary porosity—毛细管孔隙率l Capillary pressure—毛细管压力l Carbonation—碳化l Characteristic strength—特征强度l Chemical admixtures一化学外加剂Air entraining agents(AEA)—引气剂use in shotcrete—在喷射混凝土中的应用ASR inhibitor—碱-硅反应抑制剂Corrosion inhibitors—防腐剂Classification—分类Hardening accelerators—促硬剂Hydrophobic admixtures—防水剂High-range water reducers superplasticizers—高效减水剂(超塑化剂)Retarders—缓凝剂Setting accelerators—促凝剂Use in shotcrete—用于喷射混凝土中Silanes—硅烷Shrinkage-reducing admixtures—减缩剂SRA→Shrinkage-reducing admixturesSuperplasticizers—高效减水剂(超塑化剂)Mechanism of action of—作用机理Slump loss/retention—坍落度损失/保持Multifunctional—多功能的Use in shotcrete—用于喷射混凝土中Use to increase strength/durability—用于提高强度/耐久性Use to reduce cement—用于减少水泥Use to increase workability—用于提高工作性Viscosity modifying agents—黏度调节剂VMA→Viscosity modifying agentsWater-reducers—减水剂l Cement—水泥Norms—标准Set regulator—调凝剂Setting—凝结Strength—强度l Chloride—氯化物Diffusion—扩散l Compactability—密实性l Compacting factor—密实系数l Composite cement—复合水泥l Composite Portland cement—复合硅酸盐水泥l Concrete—混凝土Deterioration—劣化Manufacture—生产Placing—浇筑Prestressed—预应力Reinforced—增强l Corrosion of reinforcement—钢筋的腐蚀Promoted by carbonation—碳化引起Promoted by chloride—氯化物引起l Cracking—开裂l Creep—徐变Basic—基本Drying—干燥Influence of creep on drying shrinkage—徐变对干缩的影响Prediction of creep in concrete structures—混凝土结构的徐变预测l Cored concrete—混凝土芯样l Curing—养护Influence of curing on durability—养护对耐久性的影响Influence of curing on concrete strength—养护对混凝土强度的影响Membrane—薄膜Wet curing—湿养l C3A—铝酸三钙l C4AF—铁铝酸四钙l C3S—硅酸三钙l C2S—硅酸二钙l C-S-H—水化硅酸钙Dl Damage→deterioration—损伤→劣化l DEF—延迟钙矾石形成l Degree of compaction—密实度In shotcrete—喷射混凝土l Degree of consolidation—密实度l Degree of hydration—水化程度l Depassivation—去钝化l Deterioration—劣化l Drying shrinkage→shrinkage—干缩→收缩l DSP一致密小颗粒混凝土l Durability—耐久性Capillary porosity—毛细管孔隙率Concrete cover—混凝土保护层Exposure classes—暴露等级Long term durability—长期耐久性El Entrained air一引气Influence on freezing—对抗冻性的影响Influence on strength—对强度的影响l Entrapped air—夹杂气体l Ettringite—钙矾石Primary—一次Secondary—二次l Expansive agents→Shrinkage compensating concrete—膨胀剂→收缩补偿混凝土Fl Fibre-inforced concrete ( FRC )—纤维增强混凝土Application of FRC一纤维增强混凝土的应用Crack-free concrete一无裂缝混凝土Toughness of concrete—混凝土的韧性Impact strength—冲击强度In shotcrete—喷射混凝土Metallic fibre—金属纤维Polymer mini-fibre—聚合物微纤维Polymer macro-fibre—聚合物大纤维Polymer structure PVA fibres—聚合物结构聚乙烯醇纤维l Fictitious thickness一虚拟厚度l Fire endurance of concrete一混凝土的耐火性Behavior of concrete during fire一混凝土在火中的行为Behavior of high-strength concrete during fire—高强混凝土在火中的行为Influence of the aggregate—骨料的影响Influence of the concrete cover—混凝土保护层的影响Influence of the metallic fibres一金属纤维的影响Influence of the loading in service一服役荷载的影响Influence of the polymeric fibres—聚合物纤维的影响l Fly ash—粉煤灰Beneficiation—选矿l Freezing and thawing一冻融l Füllerl Füller&Thompson→FüllerGl GGBFS→slag—磨细粒化高炉矿渣→矿渣l Gluconate—葡萄糖酸盐l Glucose—葡萄糖l Grout—浆体l Gypsum—石膏Hl Heat—热Cracking due to thermal gradients—温度梯度诱发开裂Of hydration—水化热l Hydration—水化Of aluminates—铝酸盐的水化Of silicates—硅酸盐的水化l High-Performance Concrete—高性能混凝土l High Strength Concrete—高强混凝土l Hooke law—Hooke定律Kl Kiln一烧窑Ll Leaching—析浆l Lightweight concrete—轻混凝土Glassification—分类Expanded clay—陶粒Lightweight aggregate—轻骨料In the Rome Pantheon—罗马万神殿Natural lightweight aggregate(pumice)—天然轻骨料(浮石) Shrinkage—收缩Structural—结构的Precast L. C—预制轻混凝土SCC L. C—自密实轻混凝土Structural L. C for ready-mixed concrete—预拌结构轻混凝土l Lignosulphonate—木素磺酸盐l Lime—石灰l Limestone—石灰石Blended cement一混合水泥l Lyse rule—Lyse准则Ml Magnesium salts—镁盐l Mass concrete—大体积混凝土l Mix design—配合比设计l Modulus—模数Of elasticity—弹性模量Of fineness一细度模数l Mill一磨机l Municipal Solid Waste Incinerator一市政固体废物焚烧炉Pl Passivation—钝化l Permeability—渗透性l Pop-out一凸起l Porosity—孔隙率Capillary—毛细管孔隙Capillary porosity and strength—毛细管孔隙率与强度Capillary porosity and elastic modulus—毛细管孔隙率与弹性模量Capillary porosity and permeability—毛细管孔隙率与渗透性Capillary porosity and durability—毛细管孔隙率与耐久性Gel—凝胶Macroporosity—大孔孔隙率l Portland cement—硅酸盐水泥Blended cements一混合水泥European norm—欧洲标准Ferric一铁相Manufacture—生产White—白色l Powers—能源l Pozzolan一火山灰Activity—活性Industrial—工业的l Pozzolanic cement一火山灰水泥l Precast concrete—预制混凝土Steam curing—蒸养l Prescriptions on concrete structures—混凝土结构的质量要求Concrete composition prescriptions—混凝土组成的质量要求Concrete performance prescriptions—混凝土性能的质量要求Contractor prescriptions一对承包商的要求Rl Reactive Powder Concrete一活性粉末混凝土l Recycled concrete一再生混凝土Process of manufacturing recycled aggregate (RA)一再生骨料的加工工艺Properties of RA一再生骨料的性能Contaminant products—污染物Density of RA一再生骨料的密度Water absorption—吸水率Properties of concrete with RA—含有再生骨料混凝土的性能l Relaxation—松弛l Retempering—重拌合Sl Segregation—离析l SCC→Self-Compacting Concrete—自密实混凝土l Self-Compacting Concrete—自密实混凝土Architectural一装饰High strength—高强Mass concrete—大体积混凝土Lightweight concrete—轻混凝土Shrinkage-compensating—收缩补偿l Setting—凝结l Shrinkage—收缩Drying shrinkage—干缩Influence of aggregate on drying shrinkage一骨料对干缩的影响Influence of high range water reducers on drying shrinkage—高效减水剂对干缩的影响Influence of workability on drying shrinkage一工作性对干缩的影响Prediction of drying shrinkage in concrete structures—混凝土结构干缩的预测Plastic shrinkage—塑性收缩Standard shrinkage—标准收缩l Shrinkage-compensating concrete—收缩补偿混凝土Expansive agents—膨胀剂Combined use of SRA and expansive agents—减缩剂和膨胀剂的结合应用Lime-based expansive agents—石灰基膨胀剂Sulphoaluminate-based expansive agents—硫铝酸盐基膨胀剂Application of shrinkage compensating concrete—补偿收缩混凝土的应用Joint-free architectural buildings—无缝装饰建筑Joint-free industrial floor一无缝工业地板Repair of damaged concrete structures—损坏混凝土结构的修补Expansion of specimen vs. that of structure—试件的膨胀与结构的膨胀Restrained expansion—约束膨胀SCC shrinkage-compensating concrete—自密实收缩补偿混凝土l Shotcrete—喷射混凝土ACI recommendations—ACI建议Bond of shotcrete. to substrate—喷射混凝土与基层的粘结Chemical admixtures in—喷射混凝土的化学外加剂Alkali-free accelerators—无碱促进剂Sodium silicate accelerators—硅酸钠促进剂Composition of一喷射混凝土组成Fibres in—喷射混凝土的纤维High performance—高性能喷射混凝土Influence of steel bars on—配筋的影响Mineral additions in—矿物掺合料Nozzelman喷枪操作工Rebound—回弹l Sieve analysis—筛分l Silica fume—硅灰Silica fume in high strength concrete—高强混凝土中的硅灰l Slag—矿渣Cement—矿渣水泥l Slump—坍落度Slump loss—坍落度损失l SRA→Shrinkage Reducing Admixture in Chemical Admixtures-一化学外加剂中的减缩剂l Standard deviation一标准差l Steam curing—蒸养l Steel-concrete bond—钢筋-混凝土的粘结l Strength—强度Characteristic一特征强度Class of cement—水泥的强度等级Class of concrete一混凝土的强度等级Compressive—抗压强度DSP concrete—细颗粒密实混凝土Flexural—抗折强度High-strength concrete—高强混凝土Influence of compaction on一密实性对强度的影响Influence of cement on concrete一水泥对混凝土强度的影响Influence of temperature on concrete—温度对混凝土强度的影响Influence of transition zone on—过渡区对强度的影响Of cement paste—水泥浆的强度Of cored samples一芯样的强度Of specimens—试件的强度Standard deviation—标准差Tensile—抗拉强度l Stress—应力Compressive—压应力Flexural—弯曲应力Tensile一拉应力l Sulphate attack—硫酸盐侵蚀l Superplsticizer→Chemical. admixtures—超塑化剂(高效减水剂)→化学外加剂Tl Temperature—温度Influence of temperature on concrete strength—温度对强度的影响Influence of temperature on site organization—温度对现场浇筑的影响Placing in summer time一夏季浇筑Placing in winter time一冬季浇筑l Thaumasite—硅灰石膏l Thermal gradients—温度梯度l Transition zone—过渡区Vl Vebe—维勃l Vibration—振动Wl Water—水And workability—水与工作性And strength.一水与强度Addition on job site一水的现场添加l Water-cement ratio—水灰比l Workability—工作性And consolidation—工作性与密实性。

论混凝土的施工温度与结构裂缝外文翻译17页word

论混凝土的施工温度与结构裂缝外文翻译On the construction of concrete temperature and cracks1. the causes of the cracksCracks in concrete are a variety of reasons, mainly temperature and humidity changes, brittle and uneven concrete, as well as the structure is irrational, failure of raw materials (such as alkali-aggregate reaction), template deformation, and so on the basis of differential settlement.The concrete to harden off a large number of cement during the hydration heat, the internal temperature rising on the surface caused by tensile stress. Late in the cooling process, due to coagulation on the basis of or be bound by the old, will emerge in the concrete tensile stress. Lower temperatures in the concrete surface will be a lot of tensile stress. When the tensile stress beyond the capacity of concrete crack, the cracks will appear. A number of concrete changes in the internal humidity or changes very little slow, but possible changes in surface humidity or more dramatic changes. Such as conservation, failed to keep dry when wet, surface shrinkage deformation of concrete subject to internal constraints, but also often leads to cracks. Short-term loading at the time of ultimate tensile deformation only (0.6 ~ 1.0) × 104, the limit of long-term loading spaces when the only stretch deformation (1.2 ~ 2.0) × 104. Unevenly as a result of raw materials, water-cement ratio of instability, and transportation and pouring in the process of segregation phenomena, in the same piece of concrete in the tensile strength is uneven,there are many low tensile capacity, easy to fracture in a weak position. In reinforced concrete, the tensile stress is mainly borne by the steel, concrete is subject to compressive stress. In plain concrete or reinforced coagulation on the edge of the site if the structure of the tensile stress appears to be relying on its own concrete共12 页commitment.2. thermal stress analysisAccording to the formation of thermal stress can be divided into the following three stages:(1)early: Since the beginning of pouring concrete to cement the end of exothermic basic general about 30 days. Two characteristics of this stage, first, to release a large number of cement hydration heat, and the other is the elastic modulus of coagulation dramatic changes. Modulus of elasticity as a result of changes within this period in the formation of residual stress in the concrete.(2) medium-term: from the basic role of cement heat until the end of the stable temperature of the concrete cooling time, during this period, the temperature stress was mainly due to cooling and the outside concrete caused by temperature changes, stress and early formation of these residual stress superposition phase, during which the coagulation of the elastic modulus changed little.(3) late: concrete completely cooling period after the operation. Thermal stress is mainly caused by external temperature changes, the stress and the first two-phase superposition of residual stress.Under the thermal stress caused by the reasons can be divided into two categories:(1) self-stress: there is no constraint on the border or completely static structure, if the internal temperature distribution is nonlinear, due to structural constraints arising from their co-temperature stress. For example, the conversion layer of its relatively larger size, concrete cooling surface temperature low, the internal temperatures are high, the surface tensile stress, compressive stress appears in the middle.(2) bound by stress: the structure of all or part of the boundary bound by the outside world can not be free-form deformation caused by stress. Roof box,共12 页such as concrete and concrete barrier.Both the temperature and the concrete stress is often caused by shrinkage of the combined effect of stress.Known to be in accordance with an accurate analysis of the temperature of the thermal stress distribution, size is a more complex task. In most cases, the need to rely on model test or numerical calculation. Creep of concrete so that the temperature there is considerable stress relaxation, thermal stresscalculation, we must consider the effects of creep, is no longer calculated in detail here.3. temperature control and measures to prevent the cracksIn order to prevent cracking, reduce the thermal stress can control the conditions of temperature and to improve the binding of two aspects.Temperature control measures are as follows:(1) used to improve the aggregate gradation, dry hard concrete, mixed mixture, add air-entraining agent or plasticizer, etc. measures to reduce the amount of cement concrete;(2) mixing concrete by adding water or cooling water will be gravel and pouring concrete to reduce the temperature;(3) pouring hot days to reduce the pouring of concrete thickness, the use of pouring heat levels;(4) laid in concrete water pipes, access to cold water to cool;(5) the provisions of reasonable time, the temperature drop when the surface insulation, concrete surface in order to avoid a sharp temperature gradient;(6) Construction of long-term exposure to block the surface of the concrete pouring, or thin-walled structures, thermal insulation in the cold season to take measures;Measures to improve the constraints are:共12 页(1) a reasonable sub-block joints;(2) basis to avoid too much ups and downs;(3) reasonable arrangements for the construction process, to avoid excessive side elevation and long-term exposure;In addition, to improve the performance of concrete to improve theanti-cracking ability, to strengthen the conservation, to prevent surface drying, in particular, is to ensure the quality of concrete is very important to prevent cracks, should pay special attention to avoid cross-cracks appears to restore the integrity of its structure it is very difficult, so the construction should be to prevent the occurrence of cross-cutting the main crack.In concrete construction, in order to increase the turnover rate of the template, often require new pouring concrete as soon as possible. When the concrete temperature is higher than the temperature should be appropriate to consider time, so as to avoid the early cracks in the concrete surface. New pouring early, a lot of the surface tensile stress, a "temperature shock" phenomenon. Concrete pouring in the early heat of hydration as a result of the dissemination of the surface caused by a large tensile stress, when the surface temperature is higher than the temperature at this time to remove the template, a sharp fall in surface temperature is bound to lead to temperature gradient, so an additional one on the surface tensile stress, thermal stress superposition and hydration, coupled with the shrinkage of concrete, Tensile stress to reach the surface of great value, there is the danger oflead to cracks, but if in a timely manner after the removal of the template on the surface coverage of a light insulating material, such as foam sponge and so on, have a concrete surface to prevent excessive tensile stress, with significant results.Reinforced concrete on the large volume of thermal stress has little effect because the large volume of concrete reinforced with a very low rate. Only on 共12 页the general impact of reinforced concrete. Not too high in temperature and stress below the yield limit under the condition of the properties of steel is stable, and with the stress, time and temperature has nothing to do. Linear expansion coefficient of steel and concrete linear expansion coefficient difference between the small changes in temperature between the two with only a very small stress. Since the modulus of elasticity of steel to concrete elastic modulus of 7 ~ 15-fold, when the stress reached the tensile strength of concrete and cracking, the steel stress will not exceed 100 ~ 200kg/cm2 .. So , Want to use in reinforced concrete to prevent the emergence of small cracks is difficult. However, after the reinforced structure of the number of cracks in general has become more than a small distance, a smaller width and depth. And if the diameter of steel thin and close spacing, the crack resistance of concrete to enhance the effect of better. Concrete and reinforced concrete structure of the surface often occur cracks in thin and shallow, most of them belonging to shrinkage cracks. While this is generally shallow cracks, but itsstrength and durability of the structure is still a certain impact.In order to ensure the quality of concrete to prevent cracking and improve the durability of concrete, the proper use of admixtures is also one of the measures to reduce cracking. Such as the use of anti-cracking agent and water, in practice, its major role in concluding as follows:(1) the existence of a large number of pores in the concrete that, after evaporation of water generated by capillary capillary tension, deformation of the concrete shrinkage. Pores increased capillary diameter can reduce the surface tension, but would reduce the strength of concrete.(2) the impact of water-cement ratio is an important factor for concrete shrinkage, the use of anti-cracking agent can reduce water consumption reduced by 25% concrete.(3) the amount of cement concrete is also an important factor in shrinkage,共12 页water addition and subtraction mixed concrete cracking agent in maintaining the strength of concrete under the condition of 15 percent can reduce the amount of cement, aggregate size, by increasing the amount to supplement.(4) anti-cracking agent and water can improve the consistency of cement slurry to reduce the bleeding of concrete, reduce shrinkage deformation Shen.(5) to improve and cement bonded aggregate, and enhance theanti-cracking performance of concrete.(6) concrete bound in the contraction produced by tensile stress, when the tensile stress is greater than the tensile strength of concrete will be produced when the cracks. Water-reducing agent can be an effectiveanti-cracking of the concrete tensile strength to increase, a substantial increase in anti-cracking performance of concrete.(7) mixing-compacting concrete admixtures can, and can effectively improve the carbonation resistance of concrete to reduce the carbonation shrinkage.(8)-doped water-reducing agent after the concrete cracking retardation time due, in the effective prevention of the rapid hydration heat of cement based on cement to avoid long-term result of non-condensable increase plastic shrinkage.(9)-doped workability of concrete admixtures, and easy to find flat surfaces to form a micro-membrane to reduce evaporation and reduce drying shrinkage.Many have a retarding admixture to increase the workability and improve the function of plasticity, we in engineering practice in this area should be more contrast and research experiments than simply relying on external conditions to improve may be even more simple and economic.4. early concrete conservationPractice has proved that the common concrete cracks, the majority ofsurface cracks at different depths, mainly because of the temperature gradient caused by the cold temperature region is also vulnerable to a sharp fall in the formation共12 页of cracks. Insulation so that the concrete surface to prevent early cracking is particularly important.Thermal stress from the point of view, the insulation should meet the following requirements:(1) to prevent the concrete inside and outside the concrete surface temperature difference and gradient, to prevent surface cracks.(2) to prevent the concrete super-cold, it should be possible to make concrete the construction period of not less than the minimum temperature of concrete used for the stability of the temperature.(3) to prevent cold-old concrete in order to reduce the concrete between the old and new constraints.Early concrete conservation, the main objective is to maintain the appropriate temperature and humidity conditions in order to achieve the effect of two aspects, on the one hand, the concrete from adverse temperature and humidity deformation invasion to prevent the harmful and drying shrinkage. On the one hand, to enable the smooth progress of cement hydration, with a view to meet the design capacity of the strength and crack resistance.Appropriate conditions of temperature and humidity are interrelated. Coagulation on the insulation often has the effect of moisture.Theoretical analysis of fresh concrete contained in the water fully meets the requirements of cement hydration and more than. However, due to evaporation and other factors often cause water loss, thereby delay or prevent the hydration of cement, concrete surface and most likely to be directly affected by such a negative impact. Concrete pouring, therefore the first few days after the critical period of conservation in the construction should pay attention to.5. concluding remarksAbove the temperature of concrete and cracks in the construction of the 共12 页relation between theory and practice of the preliminary study, although the academic community about the causes of cracks in concrete and calculation methods are different theories, but specific measures to prevent and improve the opinion it is quite uniform At the same time, the application in practice is also a relatively good effect, concrete construction and more depends on our observation, and more, when compared to multi-issue analysis, and more sum up, combined with a wide range of prevention measures, the cracks in the concrete is completely avoided.论混凝土的施工温度与结构裂缝1.裂缝的原因混凝土中产生裂缝有多种原因,主要是温度和湿度的变化,混凝土的脆性和不均匀性,以及结构不合理,原材料不合格(如碱骨料反应),模板变形,基础不均匀沉降等。

混凝土工程中英文(个人整理)

混凝土工程concrete works一、材料袋装水泥bagged cement散装水泥bulk cement砂sand骨料aggregate商品混凝土commercial concrete现浇混凝土concrete-in-situ预制混凝土precast concrete预埋件embedment(fit 安装)外加剂admixtures抗渗混凝土waterproofing concrete 石场aggregate quarry垫块spacer二、施工机械及工具搅拌机mixer振动器vibrator电动振动器electrical vibrator 振动棒vibrator bar抹子(steel wood)trowel磨光机glasser混凝土泵送机concrete pump 橡胶圈rubber ring夹子clip混凝土运输车mixer truck自动搅拌站auto-batching plant 输送机conveyor塔吊tower crane汽车式吊车motor crane铲子shovel水枪jetting water橡胶轮胎rubber tires布袋cloth-bags塑料水管plastic tubes喷水雾spray water fog三、构件及其他专业名称截面尺寸section size(section dimension)混凝土梁concrete girder简支梁simple supported beam挑梁cantilever beam悬挑板cantilevered slab檐板eaves board封口梁joint girder翻梁upstand beam楼板floor slab空调板AC board飘窗bay window(suspending window)振捣vibration串筒 a chain of funnels混凝土施工缝concrete joint水灰比ratio of water and cement砂率sand ratio大体积混凝土large quantity of pouring混凝土配合比concrete mixture rate混凝土硬化hardening of concrete(in a hardening process 硬化中)规定时间regulated period质保文件quality assurance program设计强度design strength永久工程permanent works临时工程temporary works四、质量控制及检测不符合规格的non-standard有机物organic matters粘土clay含水率moisture content(water content)中心线central line安定性soundness (good soundness 优良的安定性)坍落度slump (the concrete with 18mm±20mm slump)混凝土养护concrete curing标养混凝土试件standard curing concrete test sample 同条件混凝土试件field-cure specimen收缩shrinkage初凝时间initial setting time终凝时间final setting time成品保护finished product protection混凝土试件concrete cube偏心受压eccentric pressing保护层concrete cover孔洞hole裂缝crack蜂窝honeycomb五、句子1,Usually we control the cement within 2% 我们将水泥的误差控制在2%2,Are there any pipe clogging happened during the concreting?浇筑混凝土中有堵管现象吗?3,Will the pipe be worn out very fast?管道磨损很快吗?4,T his embedment is fixed at 1500mm from the floor and 350mm from the left edge of the column. Would you measure the dimension by this meter?预埋件的位置在地面上1500mm,离柱边350mm。

毕业论文外文翻译-建筑施工混凝土开裂预防加工

毕业论文外文翻译-建筑施工混凝土开裂预防加工Prevention and Treatment of Concrete Cracks in Building ConstructionAbstract:Concrete is widely used in building construction because of its advantages such as durability, strength and low maintenance cost. However, concrete cracks can not only affect the aesthetic appearance of buildings, but also have negative impact on structural integrity and durability. This paper focuses on the prevention and treatment of concrete cracks in building construction. Firstly, the causes of concrete cracking are analyzed, including shrinkage, thermal stress, structural design, material quality and construction quality. Then, preventive measures in design and construction are proposed, such as proper reinforcement arrangement, control of concrete mix proportions, proper curing and protection after pouring, etc. Treatment measures for existing concrete cracks include surface treatment, filling and injection, and reinforcement. Finally, some new techniques are briefly introduced, such as fiber-reinforced concrete, self-healing concrete and material testing technology. This paper provides a comprehensive understanding of the prevention and treatment of concrete cracks in building construction, and proposes practical solutions to improve the quality of concrete structures.Key words: concrete cracks; building construction; prevention; treatmentIntroduction:Concrete is a popular building material due to its properties such as durability, strength and low maintenance cost. However, concrete cracking is a common problem in building construction, which can not only affect the aesthetic appearance of buildings, but also have negative impact on structural integrity and durability. Therefore, preventing and treating concrete cracks are crucial to ensure the long-term performance of buildings. This paper analyzes the causes of concrete cracking in building construction, and proposes preventive and treatment measures based on practical experience and research.1. Causes of Concrete Cracking:1.1 ShrinkageShrinkage is the most common cause of concrete cracking, which is due to the decrease in volume of concrete as it dries and hardens. Shrinkage can be classified into autogenous shrinkage, plastic shrinkage and drying shrinkage.Autogenous shrinkage is caused by the chemical reaction between water and cement, and it can lead to micro-cracks. Plastic shrinkage is caused by the evaporation of water from the surface of fresh concrete, which can cause cracks in the surface layer. Drying shrinkage is caused by the loss of moisture from the hardened concrete, which can lead to cracks in the bulk of the structure.1.2 Thermal StressThermal stress is another cause of concrete cracking, which is due to the temperature difference between the interior and exterior of concrete. When the temperature change is rapid or large, thermal stress can exceed the tensile strength of concrete and cause cracking.1.3 Structural DesignPoor structural design can also cause concrete cracking. For example, inadequate reinforcement or improper placement of reinforcement can lead to excessive stress concentration and cracking. In addition, insufficient structural support or improper joint design can also cause concrete cracking.1.4 Material QualityThe quality of concrete materials such as cement, aggregates and water can also affect concrete cracking. Poor quality materials can result in uneven shrinkage, low strength, and high water permeability, which can cause cracking.1.5 Construction QualityConstruction quality is an important factor in the prevention of concrete cracking. Improper placement, compaction and curing of concrete can lead to poor quality, which can cause cracking. In addition, inadequate protection measures such as insufficient cover or damage to the surface layer can also cause cracking.2. Prevention of Concrete Cracking:2.1 Reinforcement ArrangementProper reinforcement arrangement is essential to prevent concrete cracking. The size, spacing and distribution of reinforcement should be designed according to the structural requirements and the characteristics of concrete. In addition, the use of fiber reinforcement can improve the crack resistance of concrete.2.2 Control of Concrete Mix ProportionsThe control of concrete mix proportions is critical to the prevention of concrete cracking. The ratio of water to cement, the type and quality of aggregates, and the use of admixtures should be carefully considered to ensure proper workability and strength of concrete.2.3 Proper Curing and ProtectionProper curing and protection measures can effectively prevent concrete cracking. Adequate moist curing can reduce evaporation and shrinkage, and increase strength and durability. In addition, proper protection measures such as sufficient cover and protective coatings can protect the surface layer of concrete from damage.3. Treatment of Concrete Cracks:3.1 Surface TreatmentSurface treatment is a common method to repair concrete cracks. The damaged concrete is removed, and the surface is cleaned and roughened. Then, a bonding agent is applied and a new layer of concrete is poured to fill the crack.3.2 Filling and InjectionFilling and injection is another effective method to repair concrete cracks. The crack is filled with cementitious material, such as epoxy or polymer, to restore theintegrity of the structure. Injection is also used to repair cracks in reinforced concrete structures, where the material is injected under pressure to fill the voids and cracks.3.3 ReinforcementReinforcement is used when the crack is severe and structural integrity is compromised. Steel bars or plates are installed into the crack and bonded to the surrounding concrete to restore the strength and load-carrying capacity of the structure.4. New Techniques:4.1 Fiber-Reinforced ConcreteFiber-reinforced concrete is a new type of concrete that contains short fibers, such as glass, steel or synthetic fibers, which can improve the crack resistance and toughness of concrete.4.2 Self-Healing ConcreteSelf-healing concrete is a novel material that can repair micro-cracks by itself through the chemical reaction between water and the embedded capsules.4.3 Material Testing TechnologyMaterial testing technology such as acoustic emission and electrical resistance can effectively detect and monitor the formation and propagation of cracks in concrete structures, and provide early warning for potential failures.Conclusion:Concrete cracking is a common problem in building construction, which can affect the aesthetic appearance, structural integrity and durability of buildings. This paper analyzes the causes of concrete cracking, and proposes practical preventive and treatment measures to improve the quality of concrete structures. In addition, some new techniques such as fiber-reinforced concrete, self-healing concrete andmaterial testing technology are briefly introduced. With proper design, construction and maintenance, the occurrence and impact of concrete cracking can be effectively reduced, and the long-term performance of concrete structures can be ensured.。

外文翻译混凝土裂缝的成因预防及处理

The causes, prevention and treatment of cracks in concrete Abstract:In the building construction concrete cracks a quality common problem, the causes of cracks in concrete, prior prevention, as well as after the repair process is a more common phenomenon in the process of building production, should be taken seriously enough. The concrete is a brittle material of a gravel aggregate, cement, water and other additional material formed by mixing a non-homogeneous. Concrete construction and deformation constraints and a series of problems, there are a large number of micro-porosity, cavitation and micro-cracks in the concrete hardening molding. The author combines his engineering work experience, summed up the cracks in concrete causes and prevention measures.Keywords: causes of cracks in concrete preventive treatmentIn building construction, concrete cracks is a widespread problem, cracks solution is a more difficult problem. Cracks in concrete reasons are manifold, deformation: such as contraction, expansion, settlement and other causes cracks; external load caused by: improper maintenance of concrete; cracks caused by the external additive problems.Concrete cracks, if not prevention measures to solve, extending its further development will lead to the internal reinforcement corrosive, reducing the carrying capacity of the reinforced concrete structure, impermeability, durability useful life, and even affect people's lives and property safety . Crack is impossible to completely eliminate the engineering specification expressly provides some structure in which the different conditions, allowing the existence of a certain width and depth of the crack. But in the construction process should be as far as possible to take effective preventive and technical safeguards to effectively control the cracks, as little as possible or minimize crack width, depth, and in particular to avoid in key positions or harmful cracks.1.Causes and types of concrete cracksThe concrete is a brittle material of a gravel aggregate, cement, water and other additional material formed by mixing a non-homogeneous. Hardening molding concrete concrete construction and deformation constraints there are a large number of micro-porosity, cavitation and micro-cracks, precisely because of the existence of these initial defects before the concrete showing some heterogeneity characteristics . Micro-cracks is usually a harmless cracks on concrete load-bearing, seepage and use the function does not cause harm. But in the concrete under load, temperature effects, the micro-cracks will continue to expand and connectivity, and ultimately the formation of visible macro cracks, the cracks is often said that the concrete works.Many cracks in concrete cracks caused by deformation: such as temperature change, shrinkage, expansion, uneven subsidence caused cracks; external load induced cracks; cracks caused by improper conservation of the environment and chemical action, etc. .Common cracks in the concrete are the following: (1) shrinkage cracks; ②plastic shrinkage cracking; (3) settlement cracks; ④temperature cracks; ⑤chemical reaction caused by cracks.2.Concrete cracks and prevention2.1 Shrinkage cracks and prevention ofShrinkage cracks appear in a week or so after the end of the concrete curing period of time or after concrete pouring. The evaporation of the water in the slurry will produce shrinkage, and the shrinkage is irreversible. Drying shrinkage cracks are mainly caused due to the different degree of evaporation of the moisture inside and outside the concrete result of deformation of the type: concrete affected by the influence of external conditions, excessive surface moisture loss, large deformation, internal humidity changes smaller deformation smaller, the larger the surface shrinkage deformation by concrete internal constraints, have a greater tensile stress cracks. The lower the relative humidity, the greater the shrinkage of cement paste shrinkage cracks are easy to produce. Shrinkage cracks parallel to the surface of the linear or reticular light fine cracks, width of more than 0.05 to 0.2 mm between the flat parts more common in mass concrete, thin flat-slab along the short to distribution. Shrinkage cracks usually affect the impermeability of concrete, causing corrosion of steel affect the durability of concrete, water pressure will produce hydraulic fracturing affecting concrete bearing capacity. The concrete shrinkage main and to the water-cement ratio of the concrete, cement component, the amount of cement used, thenature and amount of aggregate, the amount of admixture.The main preventive measures:(1)Selection of a smaller amount of shrinkage cement, commonly used in low heat cement and fly ash cement, reduce the amount of cement.(2)Concrete shrinkage by water-cement ratio, the greater the water-cement ratio, the greater the shrinkage in the concrete mix design should try to control the selection of a good water-cement ratio, while mixing the water-reducing agent .(3)Strict control than with concrete mixing and construction, concrete water consumption must not be greater than the amount of water given by the mixture ratio design.(4)To strengthen the early curing of concrete and appropriate to extend the concrete curing time. Appropriate to extend the winter construction concrete insulation cover, and brushing curing agent curing.(5) Set the appropriate contraction joints in concrete structures2.2 Plastic shrinkage cracks and preventionThe plastic shrinkage refers to the before condensation, the concrete surface due to rapid dehydration resulting contraction. Plastic shrinkage cracking is generally hot and dry or windy weather, the cracks mostly wide in the middle, both ends of the thin and vary in length, non-coherentstate. Short cracks as long as 20 to 30cm the longer cracks of up to 2 to 3 m, width of 1 to 5 mm. Main causes: the concrete before the final setting almost no strength or intensity is very small or just the final setting concrete small strength, high temperature or a larger wind, the concrete surface excessive water loss, resulting in capillary have a greater negative pressure of the concrete volume of a sharp contraction, but this time the strength of the concrete can not resist its own contraction, resulting in cracking. The main factors affecting the plastic shrinkage cracking water-cement ratio, the setting time of the concrete, the ambient temperature, wind speed, relative humidity, and so on.The main preventive measures:(1) Selection of shrinkage values smaller high early strength Portland cement or ordinary Portland cement.(2) Strict control of water-cement ratio, to increase the slump and workability of the concrete, to reduce the amount of cement and water mixed with superplasticizer.(3) Pouring concrete before watering the grass roots and templates evenly soaked.(4) Timely covered by plastic film or wet straw, hemp sheet to maintain final setting of concrete the moist front surface or the surface of the concrete spraying curing agent for conservation.To set the sun and wind facilities .(5) At high temperatures and windy weather, timely conservation.2.3 subsidence cracks and preventionSubsidence cracks caused by structural foundation soil is uneven, soft, or backfill or flooding due to uneven settlement; template stiffness, the template support spacing is too large or the bottom of the support as a result of loose, especially in the template support winter on the frozen ground, permafrost thaw uneven settlement, resulting in the concrete structure cracks. Such cracks are deep into or through the cracks, toward subsidence, generally along the perpendicular to the ground or in the form of an angle of 30 °to 45 °direction, subsidence cracks tend to have a certain amount of dislocation, crack width is often and is proportional to the amount of the settlement. Crack width was less affected by temperature changes. Ground deformation stability, subsidence cracks basically stabilized.The main preventive measures:(1)on the soft soil, filling foundation should be carried out prior to the construction of the superstructure necessary compaction and reinforcement.(2)to ensure that the template has a sufficient strength and stiffness, and firmly support the foundation uniform force.(3) prevent the process of concreting the foundation is immersed inwater.(4) template removal time can not be too early, and pay attention to the order form removal.(5) in the erection of the template on the permafrost to take certain precautions.2.4 Temperature cracks and preventionTemperature cracks occurred in mass concrete surface or larger changes in temperature regions in concrete structures. Concrete pouring, in the hardening process of cement hydration reaction to produce large amounts of heat of hydration (when the amount of cement per cubic meter of concrete will release 17,500 27500kJ heat at 350 to 550 kg/m3, so that the internal temperature of the concrete SITA about 70 °C or higher). Cause the internal temperature to rise sharply due to the larger volume of concrete, the accumulation of a large amount of heat of hydration within the concrete and easy to distribute, and rapid cooling of the surface of the concrete, thus forming a larger temperature difference inside and outside, the larger the temperature difference caused by the internal and external different degrees of thermal expansion and contraction of the concrete surface tensile stress (Practice has proved that when the temperature difference between inside and outside of the concrete itself is 25 ° C to 26 °C, will produce roughly about10MPa concrete tensile stress). When the tensile stress exceeds the ultimate tensile strength of the concrete, the concrete surface cracks, cracks occurred in the concrete construction in the late. Concrete construction when the temperature changes, or concrete attacked by the cold wave will lead to concrete surface temperature sharp decline, and contraction, contraction of the concrete surface bound by internal concrete, will produce large tensile stress. cracks, such cracks are generated in the the shallow concrete surface within the range of usually only.The trend of temperature cracks usually certain rules, often criss-cross a large area of structural cracks; the length of the beam and plate size larger structures, cracks parallel to the short side; deep and penetrating temperature cracks are generally parallel or nearly parallel to the direction of the short side , cracks along the longest edge segments appear more dense middle. Crack width sizes, affected by temperature changes more obvious, summer, winter wide narrow. The high temperature expansion caused by the concrete temperature is usually middle coarse fine at both ends, while the the shrink cracks thickness less obvious changes. The emergence of such cracks can cause corrosion of steel, concrete carbonation, reduce freeze-thaw resistance of concrete, anti-fatigue and impermeability.The main preventive measures:(1) try to use low heat or moderate heat cement, slag cement, fly ash cement.(2) reduce the amount of cement to try to control the amount of cement 450kg/m3.(3) reduce the water-cement ratio, generally water-cement ratio of concrete is controlled below 0.6.(4) improve the aggregate gradation, fly ash or superplasticizer to reduce the amount of cement, lower heat of hydration.(5) improve the concrete mixing process, "secondary air" traditional "cold" on the basis of new technology, reduce the temperature of concrete pouring.(6)a certain amount of concrete admixture having less water, plasticizers, retarding admixture role to improve the fluidity of the concrete mixture, water retention, reduce the heat of hydration, delaying the time of occurrence of the thermal peak.(7)hot season puts up visor and other auxiliary measures to control the temperature rise of the concrete pouring, to reduce pouring concrete temperature.(8)mass concrete temperature stress associated with the structure size, the larger the size of the concrete structure, the greater the temperature stress, so reasonable arrangements for the construction process, hierarchical, block pouring, to facilitate cooling, reducingconstraints.2.5 chemical reaction caused cracks and preventionAlkali-aggregate reaction cracks and steel corrosion cracks caused by the most common due to the chemical reaction caused by cracks in the reinforced concrete structure. Concrete mixing will produce some of the alkaline ions, these ions produce a chemical reaction with certain reactive aggregate and absorbs water in the surrounding environment and the volume increases, resulting in concrete crisp, expansion cracking. Such cracks usually appear in the concrete structure during use, in the event difficult to remedy, should take effective measures to prevent it in the construction. Concrete pouring poor vibrators or reinforced protective layer is thin, harmful substances into the concrete reinforcing bars from corrosion, the corroded reinforcement volume expansion, leading to concrete Splitting the cracks of this type of longitudinal cracks along the location of reinforcement .The main preventive measures:(1) selection of the alkali reactivity of small sand and gravel aggregate.(2) selection of low-alkali cement and admixtures of low-alkali or alkali.(3) selection of a suitable admixture AAR with.3 crack treatmentCracks in concrete remedial measures mainly the following methods: surface repair method, grouting, caulking closure method, structural reinforcement, concrete replacement method, electrochemical protection and legal bionic self-healing.3.1 Surface repair methodSurface repair method is a simple, common repair method, the action is in the cracks in the surface of the painting grout, epoxy mortar or concrete surface coating paint, anti-corrosion materials such as asphalt, concrete protection at the same time in order to prevent various The Effect of cracking, usually can paste in cracks in the surface of the glass fiber cloth and other measures.3.2 grouting, caulking closure methodThe grouting method is the use of pressure equipment cementing material is pressed into the cracks in the concrete, the cementing material hardened concrete to form a whole, and thus play the purpose of plugging consolidation. Top cementing material grout, epoxy, methacrylate, polyurethane and other chemical materials. The filleting gouges along the cracks in the tank filled, the plastic or rigid sealing material, in order to achieve the purpose of closed cracks. Commonly used plastic materialsare PVC, clay, plastic ointment, butyl rubber, etc.; rigid sealing material is a polymer cement mortar.3.3 Structural reinforcement methodWhen the the cracks impact on the performance of concrete structures, to take structural reinforcement concrete structure. Commonly used in the following ways: structural reinforcement to increase the cross-sectional area of the concrete structure, corner in the component outsourcing steel, prestressed Reinforcing paste the steel reinforcement, additional the fulcrum reinforcement and shotcrete reinforcement.3.4 Concrete replacement methodThe concrete substitution method is an effective method for dealing with serious damage to the concrete, this method is deteriorated concrete is removed first, and then replaced into the new concrete or other materials. Top replacement materials: of Ordinary concrete or cement mortar, polymer or polymer modified concrete or mortar.3.5 electrochemical Protection ActCathodic protection, chloride extraction, alkaline recovery method, the use of the electrochemical action of the applied electric field in the medium, to change concrete or reinforced concrete in which the state of the environment, passivated steel, in order to achieve the purpose ofanti-corrosion.3.6 biomimetic self-healing legalBionic self-healing legitimate the traditional components of the concrete in some special components such as liquid-core fibers or capsules containing binder, formed within the concrete the intelligent bionic self-healing neural network system, when the concrete cracks secreted part of the liquid core fiber cracks can heal again. Conclusion:Cracks is a common phenomenon in the concrete structure, its appearance will not only reduce the impermeability of the building, affect the use of the building, and would lead to corrosion of steel, concrete carbonation, reduce the durability of the materials, the impact the carrying capacity of the building, so to carefully study the concrete cracks, be treated differently, using a reasonable method for processing to take effective preventive measures to prevent the emergence and development of cracks in the construction, to ensure the safety of buildings and structures and stable work.混凝土裂缝的成因、预防及处理摘要:在建筑工程施工中混凝土裂缝的产生是一项质量通病,因此对混凝土裂缝的成因分析、事先预防,以及产生后的修补处理是建筑生产过程中较为普遍的现象,应引起足够的重视。

建筑施工混凝土裂缝的预防与处理外文翻译、中英对照、英汉互译