HHIR-85B型红外热像仪说明书

雷泰红外说明书

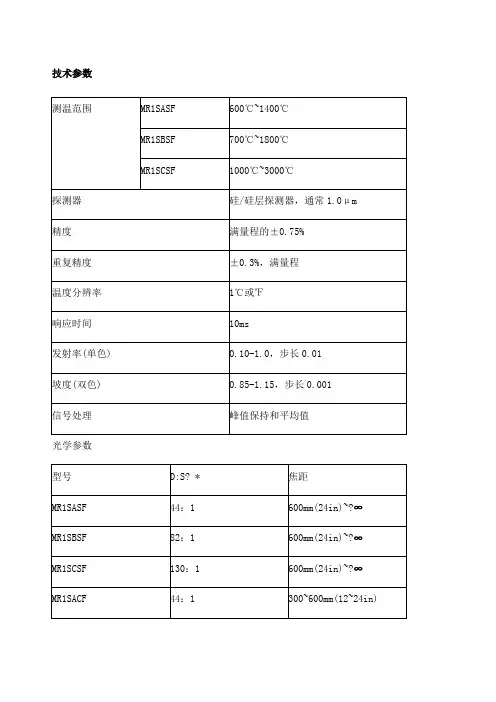

技术参数光学参数*?? 95%能量时,CF=近焦,SF=标准焦距??? 最小焦距时的最小光点尺寸*? 最小的光点尺寸直径=最小焦距/最小的D:S 一般参数电气参数仪器特点Marathon FA?红外测温仪技术参数:1、温度测量范围: 250℃到 3000℃(482°F to 5432°F)2、光学分辨率最高可达 100:13、特别适用于现场安装空间狭小的安装条件4、精度高,测量值的± 0.3%5、更快速响应时间 10 毫秒,可选到10秒6、提供模拟量和数字量输出技术参数Marathon FA 红外测温仪介绍雷泰马拉松 FA 系列红外测温仪使用光纤技术可克服测量过程中各种极端的环境条件。

FA 系列红外测温仪由电子盒和光纤探头、光缆组成,探测器和信号处理部分集成在一电子盒中,此电子盒可远距离放置,光纤探头和光缆可安装在强电磁场中的环境中,并且可耐的最高环温达200℃。

雷泰马拉松 FA 系列光纤测温仪的测温范围为250℃到3000℃(482°F to 5432°F) ,FA 光纤探头由耐用光缆将光学探头连接到电路盒上,电路盒包括:探测器、电子线路、内置用户接口、LED 显示及连接电缆的接线端子。

FA1 和FA2 系列尤其适用于目标不能接近的、恶劣的工业环境,安装空间狭小的现场测温应用。

雷泰 FA 系列单色光纤式测温仪的固定焦距的光学探头包括一个小的不锈钢圆柱形外壳和透镜,其可承受的环境温度高达200℃,并且符合NEMA-4的标准。

雷泰 FA 系列的光纤探头可装一空气吹扫器以防止透镜被污染,光缆由金属套保护,并由VITON 保护套所密封,以防止水和油的流入,这种装配可使光缆以很小的半径弯曲以便其方便地穿过狭小的空间。

雷泰 FA 系列单色光纤式测温仪还提供可在PC 上使用的WINDOWS下的马拉松软件,以实现远程进行参数设置、数据读取、数据的图形显示及RS485的多点网络配置。

福禄克红外热像仪使用说明书

全优方案 全力以赴从精密到简便,从主管到基层,皆有所选!福禄克红外热像仪什么是红外热像仪?红外热像仪的优势典型应用被动接收被测目标发出的红外辐射(热量),并将这种热量转化为带有温度数据的可视化图像(所有高于绝对零度(的物体都会发出红外辐射)。

可见光图红外热图安全快速无遗漏非接触式检测,适应各种工作环境。

面测量无需逐点扫描,毫秒级反应速度,提高工作效率。

可视化图像显示整体温度分布,实时发现问题点。

工业、机械、过程设备、耐节能审核、建电气设备、负修复、水渍以建筑问题、缺坚固耐用易于操作●独有的IR-Fusion®红外-可见光点对点融合技术,完美展示画面细节。

●AutoBlend™优组合模式,实现0%-100%红外融合度轻松调节。

●集成了领先的热灵敏度和空间分辨率,呈现业内最清晰的图像。

●设计可承受2米跌落●IP54防护等级全红外画中画红外/可见报警全可见.5 m1 m1.5 m 5 ft3.25 ft1.6 ft2 m 6.5 ft1. 对准2. 聚焦3. 拍摄对包装产品:8个角、6个面、 12个边跌落试验以10升/分钟、100 kN/m2压力进行防水试验3个垂直轴方向进行30分钟的振动试验湿度95% @ 40℃工作环境下测试电磁场和射频辐射试验模拟海拔12,000米工作环境下测试对未包装产品:2米跌落试验,每一面进行6次-10℃至50℃工作环境下测试12345678冠名福禄克之前,需经过8项耐损试验Ti400Ti300Ti200 1.31mRad 1.75mRad 2.09mRadTi25Ti10Ti92.5mRad 2.5mRad 2.5mRadTi29Ti27Ti125Ti110Ti105Ti100 1.43mRad 1.67mRad 3.39mRad 3.39mRad 3.39mRad 3.39mRadTi95Ti90VT02 5.6mRad 5.6mRad对焦不准确的热图传统自动对焦:聚焦于最近的物体,即画面中的铁丝网。

在线式红外测温仪说明书

使用说明书

POWER CONTRO,LSI.NC

一、概述

图1:仪器

一切温度高于绝对零度的物体时时刻刻都在不停的辐射红外能量,物体辐射的

红外能量的多少与物体的表面温度存在一定的函数关系。通过探测器接收物体辐射

能量再经过计算获得物体表面温度的方法称为红外测温。红外测温具有响应速度快、

1000℃~3000℃(MTX300)

2.2测量精度:±1%FS

2.3重复精度:±0.5%

2.4响应时间:300ms

2.5分 辨 率:1℃

2.6辐 射 率:0.10~1.00可调 步长0.01

2.7距离系数:120:1

2.8工作波段:2.1um~2.4um

2.9测温方式:最大值、平均值、实时值测量,峰值保持

2.10时间间隔:1~99秒 步长1秒

2.11信号输出:4~20mA和RS485

2.12工作环境温度:-10℃~60℃

带水冷:可到150℃

2.13储存温度:- 40℃~85℃

2.14尺寸:L:186mmФ:62mm

2.15重量:0.60Kg,带水冷套吹尘器重量为1.6Kg

2.16电源:24V DC±10%,100mA

灵敏度高、准确度高和测温范围广的优点,尤其是其非接触测量的特点,使红外测

温在测量运动物体和难以接近的物体的温度方面得到了很好的应用。

红外测温仪一般由光学系统、红外探测器、电信号处理线路、温度指示和输出

部分组成。

二、技术参数

2.1测温范围:600℃~1400℃(MTX140)

800℃~2000℃(MTX200)

以上参数若有个别改变恕不通知。

三、使用说明

3.1显示与按键

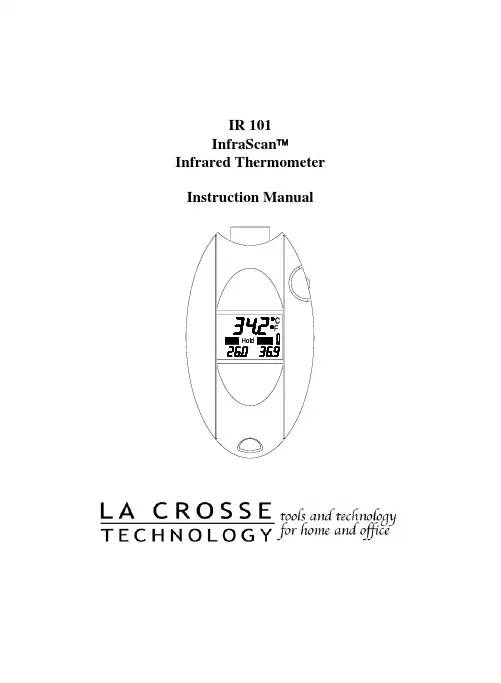

InfraScan 红外温度计说明书

IR 101InfraScan™Infrared ThermometerTABLE OF CONTENTSPage GeneralQuick instructions 3Equipment Supplied 3Description of Measuring Principle 3OperationDisplay and Operator Controls 4Making a Measurement 45Minimum and Maximum TemperatureIndicationChanging the Temperature Units 5Back Light 5Measurement Inaccuracies 5-6Trouble Shooting 6MaintenanceChanging the Batteries 7Cleaning 7 Fastening the Infrared Thermometer 7Technical Information8-9Warranty Information 10General1.Quick InstructionsPress and hold the operating button for more than 1.5 seconds. Thetemperature of the surface the lens is aimed at will read on the top of thedisplay. The minimum and maximum temperatures of the currentmeasurement are shown on the bottom of the display. When the operatingbutton is released “Hold” will be displayed between “min” and “max”indicating the measurement is completed. After 4 seconds the backlightwill turn off. The unit will switch off after 8 seconds. Press and hold theoperating button again to begin a new measurement. To switch between °Fand °C simply “double click” the operating button.2.Equipment Supplieda.Infrared Thermometer base unitb. 4 button cell batteries (already in unit)c.Neck strapd.Soft sided case3.Description of measuring principleWhen making a temperature measurement, the surface radiation of theobject to be measured is evaluated using the principle of radiationthermometry. This is a purely passive process, i.e. no radiation istransmitted, but instead, use is only made of the natural electromagneticradiation energy (heat radiation) that every body above a temperature ofabsolute zero (-273 °C) has. The temperature can be determined veryaccurately from this radiation energy if the emission factor of the objectbeing measured is known.Operation1.Display and operator controlsAll of the functions of the measuring unit are controlled and monitored usingb.Hold indicatorc.d.Temperature display - maximum valuee.Battery symbol – low battery indicatorf.Temperature units – °F or °Cg.Operating Buttonh.Lens2.Making a measurementThe object being measured should be a minimum of twice the size of theinfrared thermometer’s lens. The ideal measuring distance is 3 to 12 inches, which will yield a measurement area of ½ inch to 2 inches. As the infraredthermometer is moved away from the object being measured the area beingmeasured increases (6:1 ratio).The infrared thermometer is switched on by holding the operating button down for 1.5 seconds or more. By continuously holding down the operating button the measured value will be updated as long as the operating button is pressed.Releasing the operating button will finish the measurement. The “Hold”indication signals that measuring has stopped. The backlight will shut off 4seconds after the operating button is released. The infrared thermometer will automatically switch off 8 seconds after the last measurement. Holding down the operating button again will clear the minimum and maximum memory and begin a new measurement.3.Minimum and maximum temperature indicationThe minimum and maximum value memories are cleared at the start of ameasurement by pressing the operating button. The temperature will bemeasured and the minimum and maximum temperatures will be determined for as long as the button is pressed. The minimum temperature is shown in thelower left-hand part of the display and the maximum temperature can be seen in the lower right hand part. These values each apply to the current measuring cycle and are cleared as soon as the button is pressed again.4.Changing the temperature units ( °F/°C )The units for the temperature display can be switched between degrees Celsius (°C) and degrees Fahrenheit (°F) by pressing the button briefly twice (double click).5.Back lightThe LCD back light is constantly switched ON while the operating button ispressed. When the operating button is released, the backlight will be ON for approximately 4 seconds before automatically switching off 8 seconds after the last measurement.6.Measurement inaccuraciesThe following points should be observed in order to avoid measurement errors:a.It must be ensured that the object to be measured completely fills theInfrared Thermometer monitoring area. Errors can occur whenmeasuring small objects, as the unit also monitors the temperature ofthe surroundings as well as the object to be measured.b.The principle of measurement requires the ambient temperature to bedetermined. This takes place at one-minute intervals or each time theunit is switched on. Changes in the ambient temperature, which canoccur when the user holds the unit in their hand, are not monitoredwithin this time period and therefore neither of them is taken intoaccount when determining the indicated temperature. A gradualwarming of the unit (the lens) between ambient temperaturemeasurements can, for example, lead to the indicated temperatureslowly falling.c.If the emission factor for the object does not correspond to the presetvalue of 0.95, the temperature will not be calculated correctly. Mostsurfaces have an emission factor in the range of 0.8 to 0.98. In general,the darker and more matte the surface is, the larger their emissionsfactor. If the factor is greater the 0.95, the temperature indicated willbe greater than the actual temperature of the object being measured. Ifthe factor is less then 0.9, the temperature indicated will be less thanthe surface temperature. Polished metals have a very low emissionfactor and are therefore not suitable for measuring with an infraredthermometer. On the other hand, affixing adhesive tape to or paintingthe surface will increase the emission factor and reduce the inaccuracyof the measurement.d.It is not possible to take measurements through transparent materials(glass, plexiglas, etc.).e.It is not possible to measure air temperatures.f.Measurement errors can occur due to air contaminated with dust,steam, smoke, etc.7.TROUBLESHOOTINGProblem: Display shows -.-Solution: The operating button has not been pressed for long enough. This must be pressed for at least the duration of one measurement, i.e. for at least 1.5seconds.Problem: Display shows Err 1Solution: The ambient temperature is outside the permitted rangeProblem: Display shows 1Solution: The measured value is outside the permitted range.Problem: Battery symbol illuminatesSolution: The batteries are dead.NOTE: For problems not solved, please contact La Crosse Technology. Maintenance1.Changing the batteriesIf the battery symbol appears in the display, the batteries must be changed. The four button cells are accessible after opening the battery compartment at the rear of the unit. The used batteries must be removed from the battery holders and replaced by new button cells of the same type. Only LR44 type batteries may be used. Care must be taken to ensure that the polarity is correct when inserting.The plus terminal of all four batteries should point upwards. The batteries must be checked to see that they are properly seated before closing the batterycompartment.2.CleaningClean the unit using only a dry cloth. If the unit is very dirty, the cloth may be slightly dampened. Do not use cleaners containing solvents. Make sure that no moisture enters the interior of the unit. When cleaning the lens, loose particles must be removed using compressed air. Any remaining dirt can then beremoved with a soft brush or with a cotton swab moistened with water. CAUTION Do not use cleaners containing solvents.Fastening the Infrared ThermometerA soft-sided pouch with a belt loop and a quick release neck strap are included with the infrared thermometer. To attach the infrared thermometer to the neck strap simply insert the clip of the neck strap into the buckle end of the thermometer until it clicks. To release, press both sides of the clip on the neck strap and pull the buckle end until it is free.Technical Information1.Accuracy: The larger of the two values given is applicable in each case.2.Distance to measuring spot size: The parameter D : S characterizes the sizeof the measuring spot in proportion to the distance between the object to bemeasured and the Infrared Thermometer. For example, with a ratio of 6 : 1: °F or °CUnitDistance to measuring spot size D:S : 6:1Ambient temperature range : 32°F to 104°F: 0.95factorEmissionLR44: 4xsupplyPowerbutton cellbatteriesBattery life (approx.) : 2000 measurements(depending on theusage)Dimensions (L”xW”xH”) : 2.25” x 1” x 4”3.Emissions factor: The physical quantity known as the emission factordescribes to what extent the infrared heat radiation that is emitted from anobject is determined by its own temperature. Accordingly, a value of 1 tellsus that the infrared heat radiation from the object is based only on its owntemperature. A value of less than 1 means that the radiation emitted fromthe object is not only determined by its own temperature but also byreflections from neighboring bodies or due to the transmission, i.e. thediathermancy, of the object. The emission factor thus has an effect on theresult of the measurement. The Infrared Thermometer works with anemission factor of 0.95, i.e. the measuring unit assumes that the objectbeing monitored has a factor of 0.95. If this is not the case, there will beinaccuracies in the measurement (see Section 2.6 “MeasurementInaccuracies”).WARRANTY INFORMATIONLa Crosse Technology provides a 1-year warranty on this infrared thermometer. Contact La Crosse Technology immediately upon discovery of any defects covered by this warranty.Before sending the infrared thermometer in for repairs, contact La Crosse Technology. The infrared thermometer will be repaired or replaced with the same or similar model.This warranty does not cover any defects resulting from improper use, unauthorized repairs or faulty batteries.LA CROSSE TECHNOLOGY WILL NOT ASSUME LIABILITY FOR INCIDENTAL, CONSEQUENTIAL, PUNITIVE, OR OTHER SIMILAR DAMAGES ASSOCIATED WITH THE OPERATION OR MALFUNCTION OF THIS INFRARED THERMOMETER. THIS PRODUCT IS NOT TO BE USED FOR MEDICAL PURPOSES OR FOR PUBLIC INFORMATION. THIS PRODUCT IS NOT A TOY. KEEP OUT OF CHILDRENS’ REACH.This warranty gives you specific legal rights. You may also have other rights specific to your State. Some States do no allow the exclusion of consequential or incidental damages therefore the above exclusion of limitation may not apply to you. For warranty work, technical support, or information contact:La Crosse Technology2809 Losey Blvd. S.La Crosse, WI 54601Phone: 608.782.1610Fax: 608.796.1020e-mail:******************************(warranty work)****************************(information on other products)web:。

红外热像仪操作说明书

红外热像仪操作说明书一、简介红外热像仪是一种用于检测、显示和记录目标表面温度分布的仪器设备。

本操作说明书旨在帮助用户了解该设备的基本功能和操作方法,以便正确、有效地使用。

二、设备外观及功能1. 外观红外热像仪外观紧凑,采用人体工程学设计,便于携带和操作。

设备主体由显示屏、镜头、控制按钮和电池仓组成。

2. 功能红外热像仪具备以下功能:- 温度测量:能够测量目标物体表面的温度,并以数字形式显示在屏幕上。

- 热像显示:将温度信息以热像形式显示在屏幕上,通过不同颜色的图像表达温度分布。

- 图像记录:支持将热像图像保存在内部存储器或可拓展的存储介质中,以供后续分析和比较。

- 视频记录:能够录制目标表面的温度变化过程,以便用户进行详细分析。

三、操作步骤1. 开机与关机- 开机:按下电源按钮并保持几秒钟直到设备启动。

- 关机:按下电源按钮并在菜单中选择“关机”选项。

2. 温度测量- 瞄准目标物体:通过查看屏幕,将设备对准需要测量温度的目标物体。

- 按下“测温”按钮:在设备上方的控制按钮中找到“测温”按钮,轻按一次进行测量。

- 查看温度结果:屏幕上将显示目标物体的表面温度。

3. 热像显示- 瞄准目标物体:与温度测量相同,将设备对准目标物体。

- 按下“热像”按钮:在控制按钮中找到“热像”按钮,轻按一次启动热像显示。

- 查看热像图像:屏幕将显示目标物体的热像图像,不同颜色代表不同温度区域。

4. 图像和视频记录- 图像记录:在热像显示模式下,按下“图像记录”按钮进行图像保存。

屏幕将提示保存成功。

- 视频记录:在热像显示模式下,按住“视频记录”按钮进行视频录制。

再次按下停止录制。

5. 其他功能本红外热像仪还具备一些其他功能,如温度单位切换、锁定测量、亮度调节等。

用户可根据实际需求,在菜单中选择相应选项进行设置和操作。

四、注意事项1. 确保设备电量:在使用前,请确保红外热像仪电池电量充足,以免影响操作效果。

2. 避免遮挡镜头:在使用过程中,请确保镜头没有被任何物体遮挡,以保证测量的准确性。

红外测温枪说明书 AS852B

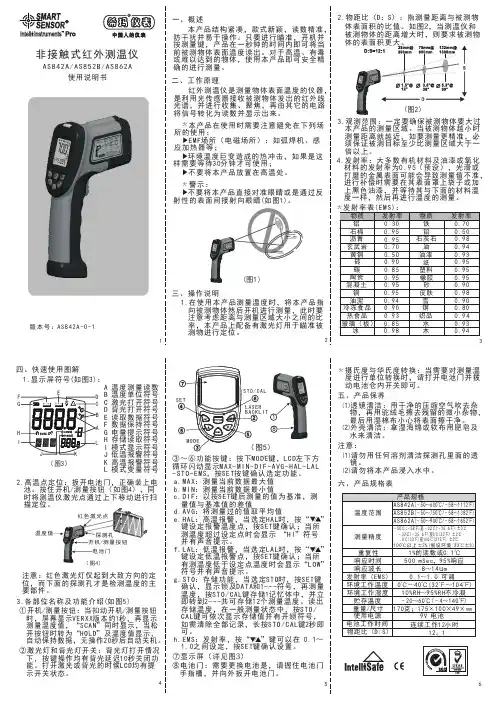

(图2 )

﹡本 产 品 在 使 用 时 需 要 注 意 避 免 在 下 列 场

所的使用: ▶E M F场 所 ( 电 磁 场 所 ) : 如 弧 焊 机 、 感

应加热器等; ▶环 境 温 度 巨 变 造 成 的 热 冲 击 , 如 果 是 这

样 需 要 等 待3 0分 钟 才 可 使 用 ; ▶不 要 将 本 产 品 放 置 在 高 温 处 。

②激光灯和背光灯开关:背光灯打开情况 下 , 按 键 操 作 均 有 背 光 延 迟1 0秒 关 闭 功 能 。 打 开 激 光 或 背 光 的 时 候L C D均 有 提 示开关状态。

4

STO/CAL

SET LASER BACKLIT 1

8

MODE

( 图5)

③ ~ ⑥ 功 能 按 键 : 按 下M O D E键 ,L C D左 下 方 循 环 闪 动 显 示M A X - M I N - D I F - A V G - H A L - L A L - S T O - E M S, 按S E T按 键 确 认 选 定 功 能 。 a . M A X: 测 量 当 前 数 据 最 大 值 b . M I N: 测 量 当 前 数 据 最 小 值 c . D I F: 以 按S E T键 后 测 量 的 值 为 基 准 , 测

﹡警示: ▶不 要 将 本 产 品 直 接 对 准 眼 睛 或 是 通 过 反

射 性 的 表 面 间 接 射 向 眼 睛(如 图1 )。

进行补偿时需要在其表面罩上袋子或加 上黑色油漆,并等待其与下面的材料温 度一样,然后再进行温度的测量。

﹡发 射 率 表( E M S ):

(图1 )

三、操作说明

1 .在 使 用 本 产 品 测 量 温 度 时 , 将 本 产 品 指

flir红外热像仪使用说明

flir红外热像仪使用说明一、引言FLIR红外热像仪是一种高科技的测温工具,可以通过红外线来检测物体表面的温度分布情况,广泛应用于建筑、电力、化工、医疗等领域。

本文将详细介绍FLIR红外热像仪的使用方法。

二、准备工作1. 充电:首先需要将FLIR红外热像仪充满电,以确保其能够正常工作。

2. 校准:在使用前需要对FLIR红外热像仪进行校准,以确保其测量结果的准确性。

3. 选择测量模式:根据实际需求选择不同的测量模式,例如表面温度模式、最大/最小值模式等。

三、操作步骤1. 打开FLIR红外热像仪:按下电源键即可打开设备。

2. 调整焦距:根据实际需求调节镜头焦距,以便更好地观察被测物体。

3. 调节亮度和对比度:根据环境光线调节屏幕亮度和对比度,以便更清晰地观察图像。

4. 测量温度:将FLIR红外热像仪对准被测物体,观察屏幕上的图像,并记录温度数据。

5. 存储数据:按下存储键即可将测量数据保存到设备内部存储器中。

6. 分析结果:通过软件分析保存的数据,可以得出更为详细的温度分布情况,并进行进一步分析和处理。

四、注意事项1. 避免使用在高温或低温环境下,以免影响设备的正常工作。

2. 避免长时间暴露在阳光下,以免损坏设备。

3. 使用前需要对设备进行校准,以确保测量结果的准确性。

4. 使用时需要注意安全,避免触电、烫伤等意外发生。

5. 使用后需要及时清洁设备,并放置在干燥通风处存放。

五、总结FLIR红外热像仪是一种高科技测温工具,在建筑、电力、化工、医疗等领域广泛应用。

使用时需要注意安全,并遵循正确的操作步骤。

通过对测量结果进行分析和处理,可以得出更为详细的温度分布情况,并为后续工作提供参考依据。

米克罗恩非常红外测量、热成像与校准标准的产品说明书

& Calibration Standards Visit T H E I N F R A R E D P R O SMaterials Temperature Mikron Model*3Infrared Technology4Infrared Temperature MeasurementThe non-contact temperature measurement or pyrometry is an optical measurement based on the property of all materials to send out elec-tromagnetic radiation (infrared radiation). The infrared thermometer (pyrometer) uses this radiation to determine the temperature. The pyrometer aims with the optics at a certain spot of the object and determines the temperature of this spot. Today typically spectral responses of pyrometers are in the near, middle and distant infrared.Electromagnetic SpectrumX-RayUV-LightVisible InfraredRadiolightVisible Near Middle Distant Extreme lightInfraredInfraredInfraredInfrared0,40,736151000 µmWavelengthSelection of the Correct Mikron PyrometerTo choose the correct pyrometer for a certain application different properties of the measuring object have to be taken into considera-tion, such as temperature, material and size.0°C1000°C 2000°C3000°CNon MetalsGlassMetalsMeasuring temperatureThe Temperature RangeMIKRON pyrometers measure temperatures from -100 to 4000°C. The selection of the temperature range depends on the application.The Spectral RangeThe material of the measured object demands the correct selection of the optimum spectral range of the pyrometer for a certain application.Therefore the correct spectral range is one of the most important features. Typical spectral ranges are:0.8-1.1 µm:Measurement of molten glass, metals, ceramics (∆600°C)1.45-1.8 µm:Measurement of metals, ceramics (∆250°C)2.0-2.8 µm:Measurement of metals (∆75°C)5.14 µm:Measurement of glass surfaces (∆100°C)8-14 µm:Measurement of non-metal surfaces and coated metals (∆-40°C)The Spot SizeThe spot size of a pyrometer is determined by the dimensions of the measured object. At least it has to be as big as the measured object. The spot sizes (M) depends on the pyrometer type and the measuring distance (a). For M and a please see data sheets.If a distance ratio is mentioned instead of “M“ and “a“ the following calculation for the spot size has to be done: Distance ratio = distance /spot size (10 : 1 e.g. means: at a distance 500mm the spot size is 50mm).Example:SightingFor easy alignment of the pyrometers to the measuring object, different sighting systems are available:- LED aiming - Laser aiming- Through-the-lens-sighting - TV cameraThe DesignThe pyrometers are available in different designs:- Compact pyrometer with integrated lens - Fiber optic pyrometers (LO); benefit of this design: fiber optic and optical head can be used in high ambient temperatures without cooling.OutputDifferent pyrometers provide different outputs. Analog outputs and digital interfaces are available. Some pyrometers have various switchable outputs, others can be offered with different outputs, the required output has to be selected when ordering. The required digital interface always has to be chosen.- Analog output 4-20mA or 0-20mA - Analog output 10 mV/°C - Analog output 0-5 V- Analog output thermocouple type J or K - Digital interface RS232 or RS4855Mikron portable infrared thermometers are lightweight, hand-held and are the ideal general purpose instruments for non-contact temperature measurement. They are used most often in the areas of preventative maintenance, quality assurance and short term process monitoring.6Mikron has a wide selection of industrial fixed mount non-contact temperature sensors to fill any need. Select from low cost, compact models, highly advanced fiber optic and 2/color instruments, flexible single color non-contact pyrometers,and high speed ultra precision digital units with multi-channels.7891011Implementing a systems approach for thermal process applications requires full knowledge of the customer’s applications,available thermal imagers and thermal scanners, customer’s existing controls platform, and software requirements, etc.Mikron’s staff of engineering and software specialists are available for the design and development of comprehensive turn-key systems for all customer applications.12The highly accurate, high resolution M9104 is a multi-range unit for laboratory use and the M9103 to the ideal process instrument.Mikron offers the widest selection of blackbody calibration sources providing high emissivity, fast slew rates andunparalleled accuracies. They are essential for checking accuracy of infrared temperature sensors, spectral radiometers,infrared thermal imaging equipment, optical pyrometers, emissivity/reflectivity determination, heat flux meters, etc.1415Mikron offers a variety of highly sophisticated thermal imaging systems for a wide range of applications which allow the user to see the temperature gradient of an entire surface rather than a single point. Four MiKroScan instruments are lightweight, hand-held IR cameras which offer capabilities normally found in models costing much more.For Temperatures from -20°to 3000°C. Traceable to NISTMikron offers state-of-the-art calibration services for all makes of Infrared Thermometers,Radiometers, Optical Pyrometers, Thermal Imaging Systems.The proliferation of high accuracy, infrared temperature measurement instrumentation and its growing application in critical industries, such as steel, glass, ceramics, semiconductor, aerospace, environ-mental sciences, etc., has created the need for qualified primary calibration facilities independent of NIST.To meet this need, Mikron has established a fully equipped and expertly staffed laboratory to perform calibration services to national standards on all makes of infrared and optical pyrometric temperature measurement and imaging equipment. Normal calibration time is less than 2 weeks from receipt of the instrument.Mikron’s calibration laboratory equipment uses primary standard blackbody sources similar to NIST (freezing point of metal). Calibration procedures and specifications meet NIST and ANSI standards.Mikron Infrared, Inc., Headquarters 16 Thornton RoadOakland, NJ 07436 USA Tel: 201-405-0900Tel: (USA only) 800-631-0176Fax: 201-405-0090E-mail:************************West Coast Office:Mikron4475 Dupont Court #9Ventura, CA 93003Tel: 805-644-9544Fax: 805-644-9584E-mail:*************Visit our websites:Catalog Cond. Rev. D 080310Printed in USAISO 9001Mikron has been an innovative leader in the field of non-contact temperature measurement since 1969. The company provides industrial customers and R&D laboratories with accurate instrumentation ranging from convenient portable units to fixed mount instruments, complete thermal imaging systems,and line scanners. In addition Mikron manufactures the world’s largest selection of Black Body Calibration Sources.Mikron specializes in providing customized products to solve the most difficult non-contact temperature sensing problems across a broad range of industries. The company also offers Value Imageering, a turnkey package consisting of complete engineering, design and installation services to meet the most severe and difficult thermal imaging system requirements.Mikron also provides Calibration Standards Laboratory Service. This fullyequipped and expertly staffed laboratory provides prompt re-calibration of infrared thermometers, radiometers and thermal imaging equipment to assure their accuracy traceable to NIST standards.。

红外热像使用说明

红外热像使⽤说明观测式红外热成像机芯组件使⽤说明书烟台艾睿光电科技有限公司/doc/5f4487acdd3383c4bb4cd22c.html⽬录1概述 (2)1.1简介 (2)1.2结构⽰意图 (3)2特点及功能 (4)2.1特点 (4)2.2功能 (4)3接⼝ (5)3.1接⼝⽰意图及接⼝定义 (5)3.1.1通⽤功能接⼝J6 (5)3.1.2数字视频接⼝J3 (6)3.1.3外同步接⼝J1 (7)3.2接⼝时序 (7)3.2.1数字视频接⼝时序 (7)3.2.2外同步接⼝时序 (8)4通讯协议 (9)4.1通讯串⼝设置 (9)4.2信息格式 (9)4.3数据协议 (10)4.3.1接收命令 (10)4.3.2返回状态信息 (11)4.4控制流程 (12)4.4.1信息应答 (12)4.4.2出错控制 (13)5使⽤注意事项 (14)6软件操作说明 (15)7常见故障排除 (16)8维护与保养 (17)1概述1.1简介该机芯组件的结构系统、图像处理采集外围系统由本公司独⽴研发,采⽤了320×240⾮制冷焦平⾯阵列,具有极⾼的灵敏度,极好的均匀性,⼩巧轻便,堪称世界上⾮制冷热成像核⼼组件顶级低功耗产品。

该机芯组件具有技术成熟、功耗低、计算机接⼝标准灵活等特点,是⼀款功能强⼤、性能稳定、全天候⼯作、⽆须补偿、电磁兼容性好、环境温度适应性强的产品。

⽬前已⼴泛应⽤于我国航天、航空、军⼯、安全、监控等⾏业领域。

1.2结构⽰意图2特点及功能2.1特点1)320×240⾮制冷氧化钒(VOx)焦平⾯阵列;2)体积⼩,重量轻,功耗⼩;3)具有极⾼的灵敏度及均匀性;4)25Hz/30Hz图像输出;5)RS232串⼝控制功能(RS422/RS485可选);6)各种红外镜头可选;7)供电范围直流9VDC~18VDC;8)⼯作环境温度范围-40℃~+60℃,满⾜国军标要求。

2.2功能1)⼿动/⾃动调节亮度及对⽐度;2)中⼼⼗字线加载及消隐;3)⿊⽩极性切换;4)快门校正及背景校正;5)2倍图像放⼤;6)伪彩/⿊⽩图像模式切换;7)14bit(原始图像)/8bit(图像增强)数字视频切换;8)⾃动快门开关使能;9)控制接⼝形式有:RS232/RS422/RS485;10)模拟输出格式PAL制/NTSC制可选;11)外同步功能。

红外热成像仪使用说明书

红外热成像仪使用说明书仪器概述:DM160A红外热成像仪是现场沮度检测、预防性维护等应用场合的不二选择1.测温范围-20℃至+300℃(可扩展至1500℃)2.先进的UFPA非制冷焦平面红外探测器和高质量的光学镜头3.六种调色板、手动聚焦、8V-11V直流输出、领先水平的人体工学结构设计一:概述DM160A红外热成像仪,以先进的UFPA非制冷焦平面红外探测器和高质量的光学镜头为核心,结合方便快捷的操作系统、领先水平的人体工学结构设计、功能完善的拓展配件,为适用用户打造了一款“成像清晰、测量准确、操作简单、携带轻便”的理想测温工具,是现场沮度检测、预防性维护等应用场合的不二选择。

可广泛应用于电力、电子及咧造、建筑、能源、冶炼、石化、铁路、汽车等行业。

测量原理:红外辐射:在自然界中,任何温度高于绝对零度(-273℃)的物体都会向外界辐射红外线,物体的辐肘能量的大小。

和物体表面的温度高低相关。

红外探测A:能把被测物体红外辐射量的变化变成电量变化的装置,也即将光信号转换成电信号。

红外热像仪利用光学器件将被测目标辐射的红外能量聚热在红外探测器上。

将探测器上每个像素点接收的红外数据进行处理后,对比预先标定好的温度数据。

转换成标准的视频格式并显示出来。

从而实现了将被测物的热分布转换为红外热图的过程。

这种红外热图与被测物体表面的热分布相对应。

热图像上面的不同颜色代表被测物体的不同温度。

二:产品结构1.正面部分2.按键部分3.多功能底座(选配)图3.1图3.2图3.3 三:技术指标1.技术参数红外热像仪成像属性分辨率160×120像素热敏度0.08 ℃@ 30℃测量准确度±0.2%±2个字(满量程)空间分辨率 2.2mrad聚焦方式手动聚焦调色板六种(铁红/反铁红/彩红/羽红/白热/黑热)工作波段8-14um测温范围-20℃至+300℃(可扩展至1500℃)测温精度±2%或者2℃(两者取最大值)工作环境温度-15℃至+50℃存储环境温度-40℃至+70℃湿度-95%RH(非凝露)电源适配器8V-11V直流输出整机重量<500克(含电池)产品尺寸170×160×80mm3电池可充电锂电池(可连续工作3小时)工作模式双模式(标准模式、节能模式可选)机身颜色红色+灰色整机重量<500克(含电池)2.产品配件四:使用操作1.场作入门1)为电池充电当液晶显示器显示电池电量低的时候,请按照下面的步骤对电池进行充电。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

1 概述1.1 用途HHIR-85B型红外热像仪(以下简称红外热像仪)用于单兵夜间观察、发现目标,实现夜间侦察作战能力。

它可以与多种瞄准、射击、观察类装备联合使用,具有较强的穿透烟雾、识别伪装、全天时(昼/夜)工作的能力;可在夜间单独使用,用于单兵夜间侦察,监控。

1.2 特点a)可应用于单兵手持;b)具备完整的人机工程设计;c)可昼夜工作。

1.3 主要性能1.3.1观察距离(能见度>15km,温度15℃∼30℃,湿度<40%条件下):a) 喷气式飞机探测距离(15m × 5m):≥5000m。

(探测是指可以发现飞行中的喷气式飞机,成像最少两像素。

)b) 探测站立人员(高170cm × 宽40cm)目标:≥2000m。

(探测是指可以发现直立走动的人员,成像最少两像素。

)--------------------------------------------------------------------------------12-1--------------------------------------------------------------------------------12-2c) 识别站立人员(高170cm × 宽40cm )目标:≥1000m 。

(识别是指可以分辨直立走动的人员外形轮廓,成像最少五像素。

)1.3.2 技术指标探测器类型: 非制冷焦平面探测器: 384pixel × 288pixel ,面元25μm 噪声等效温差(NETD):≤100mk@30°C工作波段: 8μm ~12μm场频: 50Hz电子放大倍率: 2×空间分辨率MRTD : ≤0.4℃(在特征频率下) 视场: 6.5°×4.8°红外物镜参数: 物镜直径=85mm ,F 数=1.0,物镜焦距f=85mm 。

物镜类型: 电动调焦镜头调焦范围: 10m~∞启动工作时间: <30s电池工作时间: 3h (常温)功耗: ≤6W (常温)颜色: 主体制做成黑色三角架接口类型: 1/4inch主体外形尺寸(mm): (280±15)长×(130±5)宽--------------------------------------------------------------------------------12-3×(130±5)高(不含眼罩)重量(含电池组): 1.9 kg±0.2kg (不含电池,含镜头盖)视频输出: PAL接口类型: 视频接口(BNC );12V 电源接口,预留接口一个操作控制功能: 电源开/关电动镜头调焦手动均匀性校正图像电子放大图像极性切换图像对比度调节自动均匀性校正开关图像增益调节液晶亮度调节液晶对比度调节电池低电压报警1.3.3 环境适应性工作温度: -40°C ~ +50°C储存温度: -40°C ~ +70°C--------------------------------------------------------------------------------12-41.4 产品清单图1为产品装箱图示。

图1 红外热像仪装箱图包装箱 1只红外热像仪 1套镜头盖 1个电池 1组电池充电器 1套外部线缆 2根镜头布 1块电源线缆 1根--------------------------------------------------------------------------------12-5电源适配器 1个使用维护说明书(中文) 1册分拆组装示意图(英文和中文) 1份装箱单 1张质量保证书 1份2 操作说明2.1控制按钮及功能图2 2.1.1控制按钮 (位置如图2所示)按键1(shift ):切换菜单功能;按键2、3:功能调节。

刚开机时2、3按键都处于第4--------------------------------------------------------------------------------12-6 “0”状态,任何时候,如果10s 内没有对按键进行任何操作,那么显示的按键相关信息就会自动消失。

当菜单显示时,只要按下按键1,按键2、3的模式就会上升一位。

常规状态下,按键2、3的模式在0至7间循环变换。

按键的状态切换见表1。

开关4:红外热像仪电源开关 。

旋钮5:电池盖旋钮。

表1 按键功能对照表 按键1状态按键2 按键3 0电动调焦+(向远目标方向) 电动调焦-(向近目标方向) 1基于快门的手动均匀性校正 基于背景的手动均匀性校正 2图像电子放大开关 图像极性切换 3图像对比度调节+(对比度增加) 图像对比度调节-(对比度减小) 4自动均匀性校正开关显示模式切换 5视频增益+ 视频增益- 6液晶亮度+ 液晶亮度- 7液晶对比度+ 液晶对比度-2.1.2功能描述(1) 电源开关:按下电源开关按钮接通电源,红外热像仪即开始工作;再次按下电源开关,则关闭电源。

--------------------------------------------------------------------------------12-7(2) 功能模式切换:操作按键1,切换不同工作模式。

(3) 调焦控制(状态0):调焦控制调节红外热像仪调焦镜片对不同距离的物体成像;按动按键1,当屏幕显示为“调焦: 远 近 ”时,按动按键2则向远目标方向调焦,按动按键3则向近目标方向调焦。

(4) 基于快门的均匀性校正(状态1):快门校正是利用传感器前的快门挡板进行校正。

当机器工作较长时间后,图像效果将有可能变差,此时可以采用快门校正。

按动按键1,当屏幕显示为“快门校正 背景校正”时,按动按键2则进行基于快门的手动均匀性校正。

(5) 基于背景的均匀性校正(状态1):利用均匀的背景目标作为背景对图像进行均匀性校正;当用红外热像仪观看远处天空时,图像四周出现发白的状态,此时需要进行背景校正。

背景校正所用的背景可选用无云均匀的天空,干净均匀的墙面或者是平整均匀的桌面。

按动按键1,当屏幕显示为“快门校正 背景校正”时,按动按键3则进行基于背景的手动均匀性校正。

(6) 图像电子放大(状态2):可以将需要仔细观察的图像放大;按动按键1,当屏幕显示为“电子放大 极性”时,按动按键2一次,图像放大2倍;按动按键2两次,图像放大4倍;再按动一次恢复正常图像。

(7) 图像极性(状态2):图像分为白热和黑热两种极--------------------------------------------------------------------------------12-8性,可任意切换这两种图像状态;当切换为白热状态时,温度高的物体亮度较高;当切换为黑热状态时,温度高的物体亮度较低。

按动按键1,当屏幕显示为“电子放大 极性”时,每按动一次按键3,可改变一次图像的极性。

(8) 图像对比度调节(状态3):可调节图像对比度以改变视觉效果;当图像整体偏黑或偏亮的时候,通过图像对比度的调节可以使图像达到一个较好的效果。

当图像偏黑实将对比度往小调节,当图像偏亮时将对比度往大调节。

按动按键1,当屏幕显示为“对比度:x.xxx ”时,按动按键2则对比度增加,按动按键3则对比度减小。

推荐值为1.000。

(9) 自动均匀性校正开关(状态4):仪器根据使用环境温度的变化和图像的变化自动校正图像。

按动按键1,当屏幕显示为“自动校正:开(或关)”时,按动按键3,自动校正功能开启,再次按动按键3,则关闭该功能;无论自动校正功能处于何种状态,“手动均匀性校正”功能都会起作用。

(10) 增益调节(状态5):可调节图像增益值,通过调节增益值,可以使图像的视频信号放大或者缩小以改变图像对比度。

按动按键1,当屏幕显示为“增益:xxx ”时,按动按键2则增益值增加,按动按键3则增益值减小,当图像整体层次感不强或者过强时可调节此参数。

推荐值为--------------------------------------------------------------------------------12-9128。

(11) 液晶亮度(状态6):可调节液晶的亮度差。

按动按键1,当屏幕显示为“液晶亮度:xxx ”时,按动按键2则左目亮度增加,按动按键3则左目亮度减小,当感觉两个液晶之间存在亮度差异可调节此参数。

一般不需要调节此参数。

推荐值为20。

(12) 液晶对比度(状态7):可调节和改变液晶对比度。

按动按键1,当屏幕显示为“对比度:xxx ”时,按动按键2则对比度增加,按动按键3则对比度减小,当液晶图像显示的层次感很弱或者太强时需要进行此项调节。

一般不需要调节此参数。

推荐值为127。

(13) 电池低电压报警:当锂离子电池连续或累计工作3h 以上时,电池电量减少,电压降低,这时屏幕左下方位出现图标“”,提示用户及时更换电池。

2.2 红外热像仪的操作使用2.2.1 打开红外热像仪的镜头盖;2.2.2 启动红外热像仪电源开关,等待大约30s ,监视器屏幕上将出现红外热图像的画面(当视场中有目标时),仪器将自动进行均匀性校正,经过几次均匀性校正后,图像逐渐稳定;2.2.3 将光学镜头对准目标,启动调焦功能进行调焦,直到--------------------------------------------------------------------------------12-10 目标清晰为止;2.2.4 使用过程中的调整:当工作一定时间,或者用户对图像均匀性不满意时,可按动手动校正改善图像质量;也可以启动自动校正功能,将图像均匀性修正转换成自动校正状态。

2.2.5 根据被观察目标、背景和环境的不同,通过调整图像增益、对比度,极性控制,电子放大,焦距等功能,可以得到理想的观察效果;具体操作见4.1条。

2.2.6 使用完毕后,首先关闭红外热像仪电源开关;当电池电量不足时,应使用电池充电器及时充电。

长时间不使用时将电池取出。

2.2.7 盖上红外热像仪镜头盖。

2.3 充电器的操作使用充电器使用220V/50Hz 交流供电。

充电器面板上有两个状态指示灯,分别指示电源通断和充电状态。

充电时间≤4h 。

使用过程:a) 接入电源,当电源输入时,需打开电源开关,电源指示灯亮;b) 当电池未接入时充电指示灯不亮;c) 电池载入后充电器将自动侦测电池,开始对电池进--------------------------------------------------------------------------------12-11行自动充电,此时充电指示为恒流或恒压,当电池充电完成后充电指示灯熄灭。