ANSYS-结构稳态(静力)分析之经典实例-命令流格式

ANSYS 入门教程 - 结构的弹性稳定性分析

ANSYS 入门教程- 结构的弹性稳定性分析2011-01-09 15:06:42| 分类:默认分类| 标签:|字号大中小订阅第7 章结构弹性稳定分析7.1 特征值屈曲分析的步骤7.2 构件的特征值屈曲分析7.3 结构的特征值屈曲分析一、结构失稳或结构屈曲:当结构所受载荷达到某一值时,若增加一微小的增量,则结构的平衡位形将发生很大的改变,这种现象叫做结构失稳或结构屈曲。

结构稳定问题一般分为两类:★第一类失稳:又称平衡分岔失稳、分枝点失稳、特征值屈曲分析。

结构失稳时相应的载荷可称为屈曲载荷、临界载荷、压屈载荷或平衡分枝载荷。

★第二类失稳:结构失稳时,平衡状态不发生质变,也称极值点失稳。

结构失稳时相应的载荷称为极限载荷或压溃载荷。

●跳跃失稳:当载荷达到某值时,结构平衡状态发生一明显的跳跃,突然过渡到非邻近的另一具有较大位移的平衡状态。

可归入第二类失稳。

★结构弹性稳定分析= 第一类稳定问题ANSYS 特征值屈曲分析(Buckling Analysis)。

★第二类稳定问题ANSYS 结构静力非线性分析,无论前屈曲平衡状态或后屈曲平衡状态均可一次求得,即“全过程分析”。

这里介绍ANSYS 特征值屈曲分析的相关技术。

在本章中如无特殊说明,单独使用的“屈曲分析”均指“特征值屈曲分析”。

7.1 特征值屈曲分析的步骤①创建模型②获得静力解③获得特征值屈曲解④查看结果一、创建模型注意三点:⑴仅考虑线性行为。

若定义了非线性单元将按线性单元处理。

刚度计算基于初始状态(静力分析后的刚度),并在后续计算中保持不变。

⑵必须定义材料的弹性模量或某种形式的刚度。

非线性性质即便定义了也将被忽略。

⑶单元网格密度对屈曲载荷系数影响很大。

例如采用结构自然节点划分时(一个构件仅划分一个单元)可能产生100% 的误差甚至出现错误结果,尤其对高阶屈曲模态的误差可能更大,其原因与形成单元应力刚度矩阵有关。

经验表明,仅关注第1 阶屈曲模态及其屈曲载荷系数时,每个自然杆应不少于 3 个单元。

ansys经典算例:稳态管道流体分析

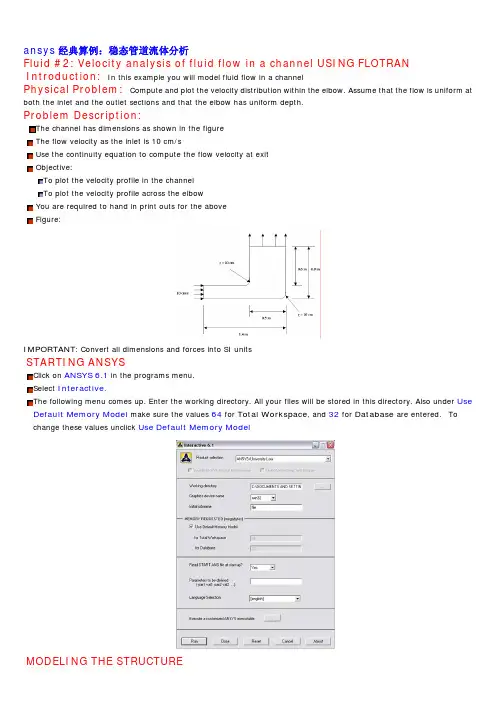

ansys经典算例:稳态管道流体分析Fluid #2: Velocity analysis of fluid flow in a channel USING FLOTRAN Introduction:In this example you will model fluid flow in a channelPhysical Problem:Compute and plot the velocity distribution within the elbow. Assume that the flow is uniform at both the inlet and the outlet sections and that the elbow has uniform depth.Problem Description:The channel has dimensions as shown in the figureThe flow velocity as the inlet is 10 cm/sUse the continuity equation to compute the flow velocity at exitObjective:To plot the velocity profile in the channelTo plot the velocity profile across the elbowYou are required to hand in print outs for the aboveFigure:IMPORTANT: Convert all dimensions and forces into SI unitsSTARTING ANSYSC lick on ANSYS 6.1in the programs menu.S elect Interactive.T he following menu comes up. Enter the working directory. All your files will be stored in this directory. Also under UseDefault Memory Model make sure the values 64 for Total Workspace, and 32 for Database are entered. To change these values unclick Use Default Memory ModelMODELING THE STRUCTUREG o to the ANSYS Utility Menu (the top bar)Click Workplane>WP Settings…The following window comes up:o Check the Cartesian and Grid Only buttonso Enter the values shown in the figure above•Go to the ANSYS Main Menu (on the left hand side of the screen) and click Preprocessor>Modeling>Create>Keypoints>On Working PlaneCreate keypoints corresponding to the vertices in the figure. The keypoints look like below.Now create lines joining these key points.M odeling>Create>Lines>Lines>Straight lineT he model looks like the one below.Now create fillets between lines L4-L5 and L1-L2.C lick Modeling>Create>Lines>Line Fillet. A pop-up window will now appear. Select lines 4 and 5. ClickOK. The following window will appear:This window assigns the fillet radius. Set this value to 0.1 m.Repeat this process of filleting for Lines 1 and 2.The model should look like this now:N ow make an area enclosed by these lines.M odeling>Create>Areas>Arbitrary>By LinesS elect all the lines and click OK. The model looks like the followingThe modeling of the problem is done.ELEMENT PROPERTIESSELECTING ELEMENT TYPE:•Click Preprocessor>Element Type>Add/Edit/Delete... In the 'Element Types' window that opens click on Add... The following window opens.•Type 1 in the Element type reference number.•Click on Flotran CFD and select 2D Flotran 141. Click OK. Close the Element types window.•So now we have selected Element type 1 to be solved using Flotran, the computational fluid dynamics portion of ANSYS. This finishes the selection of element type.DEFINE THE FLUID PROPERTIES:•Go to Preprocessor>Flotran Set Up>Fluid Properties.•On the box, shown below, set the first two input fields as Air-SI, and then click on OK. Another box will appear. Accept the default values by clicking OK.•Now we’re ready to define the Material PropertiesMATERIAL PROPERTIESWe will model the fluid flow problem as a thermal conduction problem. The flow corresponds to heat flux, pressure corresponds to temperature difference and permeability corresponds to conductance.Go to the ANSYS Main MenuClick Preprocessor>Material Props>Material Models. The following window will appearAs displayed, choose CFD>Density. The following window appears.Fill in 1.23 to set the density of Air. Click OK.Now choose CFD>Viscosity. The following window appears:Now the Material 1 has the properties defined in the above table so the Material Models window may be closed. MESHING: DIVIDING THE CHANNEL INTO ELEMENTS:G o to Preprocessor>Meshing>Size Cntrls>ManualSize>Lines>All Lines.I n the window that comes up type 0.01 in the field for 'Element edge length'.Now Click OK.Now go to Preprocessor>Meshing>Mesh>Areas>Free. Click the area and the OK. The mesh will look like thefollowing.BOUNDARY CONDITIONS AND CONSTRAINTSGo to Preprocessor>Loads>Define Loads>Apply>Fluid CFD>Velocity>On lines. Pick the left edge of the outer block and Click OK. The following window comes up.E nter 0.1 in the VX value field and click OK. The 0.1 corresponds to the velocity of 0.1 meter per second of air flowingfrom the left side.R epeat the above and set the Velocity to ZERO for the air along all of the edges of the pipe. (VX=VY=0 for all sides)O nce they have been applied, the pipe will look like this:•Go to Main Menu>Preprocessor>Loads>Define Loads>Apply>Fluid CFD>Pressure DOF>On Lines.•Pick the outlet line. (The horizontal line at the top of the area) Click OK.•Enter 0 for the Pressure value.•Now the Modeling of the problem is done.SOLUTIONG o to ANSYS Main Menu>Solution>Flotran Set Up>Execution Ctrl.•The following window appears. Change the first input field value to 300, as shown. No other changes are needed. Click OK.G o to Solution>Run FLOTRAN.W ait for ANSYS to solve the problem.C lick on OK and close the 'Information' window.POST-PROCESSINGPlotting the velocity distribution…Go to General Postproc>Read Results>Last Set.Then go to General Postproc>Plot Results>Contour Plot>Nodal Solution. The following window appears:•Select DOF Solution and Velocity VSUM and Click OK.•This is what the solution should look like:•Next, go to Main Menu>General Postproc>Plot Results>Vector Plot>Predefined.The following window will appear:•Select OK to accept the defaults. This will display the vector plot to compare to the solution of the same tutorial solved using the Heat Flux analogy. Note: This analysis is FAR more precise as shown by the followingsolution:•Go to Main Menu>General Postproc>Path Operations>Define Path>By Nodes•Pick points at the ends of the elbow as shown. We will graph the velocity distribution along the line joiningthese two points.•The following window comes up.•Enter the values as shown.•Now go to Main Menu>General Postproc>Path Operations>Map onto Path. The following window comes up.•Now go to Main Menu>General Postproc>Path Operations>Plot Path Items>On Graph.•The following window comes up.•Select VELOCITY and click OK.•The graph will look as follows:。

ANSYS静力分析应用实例(详细)

第5章 ANSYS静力分析实例

中南大学

⑸ 显示关键点号 GUI:Utility Menu→PlotCtrls→Numbering。 在弹出的对话框中,将关键点号打开,单击ok按钮。 ⑹ 创建直线 GUI:

MainMenu→Preprocessor→Modeling→Create→Lines→

Lines→Straight Line 弹出拾取窗口,拾取关键点1和2,单击ok按钮。 ⑺ 创建硬点

第5章 ANSYS静力分析实例

中南大学

单击“Solution Current Load Step”对话框ok按钮。出现 “solution is done!”提示时,求解结束,即可查看求解结 果。

结果显示:

⑴ 定义单元列表

GUI : Main Menu→General Postroc→Element Table→ Define Table。 弹出“Element Table Data”对话框,单击Add按钮,在Lab 文本框中输入FA,在“Item,Comp”两个列表中分别选择 “By sequn-ence num”、“SMISC”,在右侧列表下方文本 框输入SMISC,1,单击Apply按钮,于是定义了单元表FA, 该单元列表保存了各单元的轴向力;在Lab文本框中输入SA, 在“Item,Comp”两个列表中分别选择“By sequnence num”、“Ls”,在右侧列表下方文本框输入LS,1,单击ok 按钮,于是定义了单元表SA ,该单元列表保存了各单元的轴

SURF174 CONTAC48,CONTAC49 CONTAC12,CONTAC52, CONTAC26

第5章 ANSYS静力分析实例

中南大学

5.2 结构静力学分析的类型

ansys结构分析入门-命令流

1 ANSYS概述1.1 ANSYS简介ANSYS是一种广泛的商业套装工程分析软件。

所谓工程分析软件,主要是在机械结构系统受到外力负载所出现的反应,例如应力、位移、温度等,根据该反应可知道机械结构系统受到外力负载后的状态,进而判断是否符合设计要求。

一般机械结构系统的几何结构相当复杂,受的负载也相当多,理论分析往往无法进行。

想要解答,必须先简化结构,采用数值模拟方法分析。

由于计算机行业的发展,相应的软件也应运而生,ANSYS软件在工程上应用相当广泛,在机械、电机、土木、电子及航空等领域的使用,都能达到某种程度的可信度,颇获各界好评。

使用该软件,能够降低设计成本,缩短设计时间。

到80年代初期,国际上较大型的面向工程的有限元通用软件主要有:ANSYS, NASTRAN, ASKA, ADINA, SAP等。

以ANSYS为代表的工程数值模拟软件,是一个多用途的有限元法分析软件,它从1971年的2.0版本与今天的5.7版本已有很大的不同,起初它仅提供结构线性分析和热分析,现在可用来求结构、流体、电力、电磁场及碰撞等问题的解答。

它包含了前置处理、解题程序以及后置处理,将有限元分析、计算机图形学和优化技术相结合,已成为现代工程学问题必不可少的有力工具。

1.2ANSYS软件主要功能ANSYS软件是融结构、热、流体、电磁、声学于一体的大型通用有限元软件,可广泛的用于核工业、铁道、石油化工、航空航天、机械制造、能源、汽车交通、国防军工、电子、土木工程、生物医学、水利、日用家电等一般工业及科学研究。

该软件提供了不断改进的功能清单,具体包括:结构高度非线性分析、电磁分析、计算流体力学分析、设计优化、接触分析、自适应网格划分及利用ANSYS参数设计语言扩展宏命令功能。

1.3ANSYS软件主要特点主要技术特点:∙唯一能实现多场及多场耦合分析的软件∙唯一实现前后处理、求解及多场分析统一数据库的一体化大型FEA软件∙唯一具有多物理场优化功能的FEA软件∙唯一具有中文界面的大型通用有限元软件∙强大的非线性分析功能∙多种求解器分别适用于不同的问题及不同的硬件配置∙支持异种、异构平台的网络浮动,在异种、异构平台上用户界面统一、数据文件全部兼容∙强大的并行计算功能支持分布式并行及共享内存式并行∙多种自动网格划分技术∙良好的用户开发环境支持的图形传递标准:∙SAT∙Parasolid∙STEP与CAD软件的接口∙Unigraphics∙Pro/ENGINEER∙I-Deas∙Catia∙CADDS∙SolidEdge∙SolidWorks1.4 运行环境(ANSYS5.7)Computer: Pentium-class systemMemory (RAM): 64 MB以上Hard Disk: 500MB以上自由空间.Operating System: Microsoft Windows 2000, Windows NT 4.0 (SP 5 or higher) or Windows 98 Graphics: A Windows 2000/NT 4.0 or 98 supported Graphics Card, capable of 1024x768 in High Color (16-bit).A 17 inch monitor (or larger) compatible with the above mentioned card is recommended.2ANSYS 的基本使用2.1 ANSYS环境简介ANSYS有两种模式:一种是交互模式(Interactive Mode),另一个是非交互模式(Batch Mode)。

ANSYS命令流总结(全)

ANSYS结构分析单元功能与特性/可以组成一一些命令,一般是一种总体命令(session),三十也有特殊,比如是处理/POST1! 是注释说明符号,,与其他软件的说明是一样的,ansys不作为命令读取,* 此符号一般是APDL的标识符,也就是ansys的参数化语言,如*do ,,,*enddo等等NSEL的意思是node select,即选择节点。

s就是select,选择。

DIM 是定义数组的意思。

array 数组。

MP命令用来定义材料参数。

K是建立关键点命令。

K,关键点编号,x坐标,y坐标,z坐标。

K, NPT, X, Y, Z是定义关键点,K是命令,NPT是关键点编号,XYZ是坐标。

NUMMRG, keypoint 用这个命令,要保证关键点的位置完全一样,只是关键点号不一样的才行。

这个命令对于重复的线面都可以用。

这个很简单,压缩关键。

Ngen 复制节点e,节点号码:这个命令式通过节点来形成单元NUMCMP,ALL:压缩所有编号,这样你所有的线都会按次序重新编号~你要是需要固定的线固定的标号NSUBST,100,500,50 :通过指定子步数来设置载荷步的子步LNSRCH线性搜索是求解非线性代数方程组的一种技巧,此法会在一段区间内,以一定的步长逐步搜索根,相比常用的牛顿迭代法所要耗费的计算量大得多,但它可以避免在一些情况下牛顿迭代法出现的跳跃现象。

LNSRCH 激活线性搜索PRED 激活自由度求解预测NEQIT指定一个荷载步中的最大子步数AUTOTS 自动求解控制打开自动时间步长.KBC -指定阶段状或者用跳板装载里面一个负荷步骤。

SPLINE:P1,P2,P3,P4,P5,P6,XV1,YV1,ZV1,XV6,YV6,ZV6(生成分段样条曲线)*DIM,Par,Type,IMAX,JMAX,KMAX,Var1,Var2,Var3(定义载荷数组的名称)【注】Par: 数组名Type: array 数组,如同fortran,下标最小号为1,可以多达三维(缺省)char 字符串组(每个元素最多8个字符)tableIMAX,JMAX,KMAX 各维的最大下标号Var1,Var2,Var3 各维变量名,缺省为row,column,plane(当type 为table时)/config是设置ansys配置参数的命令格式为/CONFIG, Lab, VALUELab为参数名称 value为参数值例如:/config,MXEL,10000的意思是最大单元数为10000杆单元:LINK1、8、10、11、180梁单元:BEAM3、4、23、24,44,54,188,189管单元:PIPE16,17,18,20,59,602D实体元:PLANE2,25,42,82,83,145,146,182,1833D实体元:SOLID45,46,64,65,72,73,92,95,147,148,185,186,187,191壳单元:SHELL28,41,43,51,61,63,91,93,99,143,150,181,208,209弹簧单元:COMBIN7,14,37,39,40质量单元:MASS21接触单元:CONTAC12,52,TARGE169,170,CONTA171,172,173,174,175,178矩阵单元:MATRIX27,50表面效应元:SURF153,154粘弹实体元:VISCO88,89,106,107,108,超弹实体元:HYPER56,58,74,84,86,158耦合场单元:SOLID5,PLANE13,FLUID29,30,38,SOLID62,FLUID79,FLUID80,81,SOLID98,FLUID129,INFIN110,111,FLUID116,130界面单元:INTER192,193,194,195显式动力分析单元:LINK160,BEAM161,PLANE162,SHELL163,SOLID164,COMBI16杆单元单元名称简称节点数节点自由度特性备注LINK1 2D杆 2 Ux,Uy EPCSDGB常用杆元LINK8 3D杆Ux,Uy,Uz EPCSDGBLINK103D仅受拉或仅受压杆EDGB模拟缆索的松弛及间隙LINK11 3D线性调节器EGB模拟液压缸和大转动LINK183D有限应EPCDFG另可考虑粘0 变杆 B 弹塑性E-弹性(Elasticity),P-塑性(Plasticity),C-蠕变(Creep),S-膨胀(Swelling),D-大变形或大挠度(Large deflection),F-大应变(Large strain)或有限应变(Finite strain),B-单元生死(Birth and dead),G-应力刚化(Stress stiffness)或几何刚度(Geometric stiffening),A-自适应下降(Adaptive descent)等。

ANSYS结构分析指南结构线性静力分析

ANSYS结构分析指南第二章结构线性静力分析2.1 静力分析的定义静力分析计算在固定不变载荷作用下结构的响应,它不考虑惯性和阻尼影响--如结构受随时间变化载荷作用的情况。

可是,静力分析可以计算那些固定不变的惯性载荷对结构的影响(如重力和离心力),以及那些可以近似为等价静力作用的随时间变化载荷(如通常在许多建筑规范中所定义的等价静力风载和地震载荷)的作用。

静力分析用于计算由那些不包括惯性和阻尼效应的载荷作用于结构或部件上引起的位移、应力、应变和力。

固定不变的载荷和响应是一种假定,即假定载荷和结构响应随时间的变化非常缓慢。

静力分析所施加的载荷包括:外部施加的作用力和压力稳态的惯性力(如重力和离心力)强迫位移温度载荷(对于温度应变)能流(对于核能膨胀)关于载荷,还可参见§2.3.4。

2.2 线性静力分析与非线性静力分析静力分析既可以是线性的也可以是非线性的。

非线性静力分析包括所有类型的非线性:大变形、塑性、蠕变、应力刚化、接触(间隙)单元、超弹性单元等。

本章主要讨论线性静力分析。

对非线性静力分析只作简单介绍,其详细论述见《ANSYS Structural Analysis Guide》§8。

2.3 静力分析的求解步骤2.3.1 建模首先用户应指定作业名和分析标题,然后通过PREP7 前处理程序定义单元类型、实常数、材料特性、模型的几何元素。

这些步骤是大多数分析类型共同的,并已在《ANSYS Basic Analysis Guide》§1.2 论述。

有关建模的进一步论述,见《ANSYS Modeling and Meshing Guide》。

2.3.1.1 注意事项在进行静力分析时,要注意如下内容:1、可以采用线性或非线性结构单元。

2、材料特性可以是线性或非线性,各向同性或正交各向异性,常数或与温度相关的:必须按某种形式定义刚度(如弹性模量EX,超弹性系数等)。

对于惯性载荷(如重力等),必须定义质量计算所需的数据,如密度DENS。

ANSYS分析实例集(命令流)参考Word

1.ANSYS SOLID65环向布置钢筋的例子3ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗2.混凝土非线性计算实例(1)- MISO单压5ANSYS分析实例集(命令流)3141.ANSYSSOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗3.混凝土非线性计算实例(2)- MISO约束压6ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗4.混凝土非线性计算实例(3)- KINH滞回9ANSYS分析实例集(命令流)3141.ANSYSSOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗5.混凝土非线性计算实例(4)- KINH压-拉裂11ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗6.混凝土非线性计算实例(5)12ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗7.混凝土非线性计算实例(6)14ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗8.混凝土非线性计算实例(7)- MISO滞回16ANSYS分析实例集(命令流)3141.ANSYSSOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗9.混凝土非线性计算实例(8)18ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗10.混凝土非线性计算实例(9)-梁平面应力20ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗11.四层弹簧-质点模型的地震分析22ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗12.悬臂梁地震分析48ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗13.用beam 54单元描述变截面梁的例子72ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗14.变截面梁实例73ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO 约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH 压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗15.拱桥浇筑过程分析-单元生死应用实例74ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗16.简支梁实体与预应力钢筋分析实例75ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗17. 简单的二维焊接分析-单元生死实例77ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗18.隧道开挖(三维)的命令流84ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗19.岩土接触分析实例101ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗20.钢筋混凝土管的动力响应特性分析实例109ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗21.隧道模拟开挖命令流(入门)116ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗22.螺栓连接的模拟实现问题119ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗23.道路的基层、垫层模量与应力之间的关系129ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗23.滞回分析151ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO 约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH 压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗24.模拟某楼层浇注153ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗25.在面上施加移动的面力155ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗27.在任意面施加任意方向任意变化的压力159ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗28.预紧分析160ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO 约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH 压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗29.几何非线性+塑性+接触+蠕变162ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗30.埋设在地下的排水管道167ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗32.幕墙企业玻璃简化计算172ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗33.等截面杆单元生死应用实例188ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗34.梁板建模联系189ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO 约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH 压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗36.简单的例子-如何对结构的振动控制分析192ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗37.模态分析结果的输出实例194ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗38.火车过桥动态加载实例(部分)196ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗39.悬索结构的找形和计算的例题213ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗40.陶瓷杆撞击铝板的例子218ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗41.求反作用力的APDL命令法221ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗42.LS-DYNA实例(部分)222ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗43.路面分层填筑对路基的影响223ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗44.一个例子(含地震影响,求振兴与频率)227ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO 单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH 滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗45.接触面上的压力总和231ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗46.施加位置函数荷载235ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗47.非线性分析考虑刚度退化236ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗48.一个圆形水池的静力分析237ANSYS分析实例集(命令流)3141.ANSYS SOLID65环向布置钢筋的例子32.混凝土非线性计算实例(1)- MISO单压53.混凝土非线性计算实例(2)- MISO约束压64.混凝土非线性计算实例(3)- KINH滞回95.混凝土非线性计算实例(4)- KINH压-拉裂116.混凝土非线性计算实例(5)12哎壳缘搅俱铺疮幌阔惮邱袄蒙辙亏肃圆缉挨嗜明矣杠妓促柔甚摊哎晕烩稚磅坯殉妹铃蛇拔凋聪抨饥保冒阐挡惦稚啪称撒捶忽氦对预倦恫逮倚吝狄狗。

ANSYS工程结构数值分析---命令流实例

!------------------------------------------------------!EX8.26 钢筋混凝土简支梁数值分析!分离式模型,关闭压碎,keyopt(1)=0,keyopt(7)=1 !力加载,位移收敛准则,误差1.5%,1/4模型分析!--------------------------------------------finish/clear/config,nres,2000/prep7!1.定义单元与材料性质--------------------et,1,solid65,,,,,,,1 !K1=0,k7=1et,2,link8mp,ex,1,13585mp,prxy,1,0.2fc=14.3ft=1.43tb,concr,1tbdata,,0.5,0.95,ft,-1tb,miso,1,,11tbpt,,0.0002,fc*0.19tbpt,,0.0004,fc*0.36tbpt,,0.0006,fc*0.51tbpt,,0.0008,fc*0.64tbpt,,0.001,fc*0.75tbpt,,0.0012,fc*0.84tbpt,,0.0014,fc*0.91tbpt,,0.0016,fc*0.96tbpt,,0.0018,fc*0.99tbpt,,0.002,fctbpt,,0.0033,fc*0.85mp,ex,2,2.0e5mp,prxy,2,0.3tb,biso,2tbdata,,300,0pi=acos(-1)r,1,0.25*pi*22*22r,2,0.25*pi*22*22/2r,3,0.25*pi*10*10r,4,0.25*pi*10*10/2!2.创建几何模型blc4,,,150/2,300,2000/2*do,i,1,9wpoff,,,100vsbw,all*enddo wpcsys,-1 wpoff,,,50 vsbw,all wpcsys,-1 wprota,,-90 wpoff,,,30 vsbw,all wpoff,,,240 vsbw,all wpcsys,-1 wpoff,30 wprota,,,90 vsbw,all wpcsys,-1!3.划分钢筋网格elemsiz=50 lsel,s,loc,x,30 lsel,r,loc,y,30 cm,zj,linelatt,2,1,2 lesize,all,elemsiz lsel,s,loc,x,75 lsel,r,loc,y,30 cm,zjb,line latt,2,2,2 lesize,all,elemsiz lsel,s,loc,x,30 lsel,r,loc,y,270 cm,jlj,linelatt,2,3,2 lesize,all,elemsiz lsel,s,tan1,z lsel,r,loc,y,30,270 lsel,r,loc,x,30,70 lsel,u,loc,z,50 cm,gj,linelatt,2,3,2 lesize,all,elemsiz lsel,s,loc,z,0 lsel,r,loc,y,30,270 lsel,r,loc,x,30,70 cm,gjb,line latt,2,4,2lesize,all,elemsizlsel,allcmsel,s,zjcmsel,a,zjbcmsel,a,jljcmsel,a,gjcmsel,a,gjbcm,gj,linelmesh,alllsel,all!4.划分混凝土网格vatt,1,,1mshkey,1esize,elemsizvmesh,allallsel,all!5.施加荷载和约束lsel,s,loc,y,0lsel,r,loc,z,900dl,all,,uyasel,s,loc,z,0da,all,symmasel,s,loc,x,75da,all,symm!-----------------p0=180000q0=p0/150/100asel,s,loc,z,0,50asel,r,loc,y,300sfa,all,1,pres,q0allsel,all!6.求解控制设置/soluantype,0nsubst,80outres,all,allautos,onneqit,50cnvtol,u,,0.015solve!7.进入POST1查看结果/post1set,lastesel,s,type,,2etable,saxl,ls,1plls,saxl,saxlesel,s,type,,1/device,vector,onplcrackeall!8.进入时程后处理/post26nsol,2,205,u,yprod,3,1,,,,,,p0/1000prod,4,2,,,,,,-1xvar,4plvar,3!EX2.6D 60kg/m钢轨实体建模FINISH/CLEAR/PREP7!1.定义参数H1=30.5H2=48.5H3=48.5B1=45.75B2=29.25B3=16.5B4=36.5B5=10XD1=1/3XD2=1/9XD3=1/3XD4=1/20R0=400R1=2R2=4R3=40R4=20R5=25R7=13R8=80R9=300R10=2FAI=43H=H1+2*H2+H3!2.创建轨底主要组成部分的线K,1K,2,B1+B2K,3,B1+B2,H1-B1*XD1-B2*XD2K,4,B1,H1-B1*XD1K,5,0,H1*DO,I,1,4L,I,I+1*ENDDO!3.计算确定轨头下三个圆弧的位置CTA=A TAN(XD3)BTA=(90-FAI)*ACOS(-1)/180-CTAA=1/TAN(CTA)C1=B3/2+R0-R6*SIN(CTA)-(R5-R6)*COS(BTA)C2=R5*SIN(BTA)+R6*COS(CTA)-R6*SIN(BTA)-H2C=(C1-C2/TAN(CTA))/(R0-R5)C3=A*C-SQRT(A*A-C*C+1)C3=C3/(A*A+1)REFA=ASIN(C3)C1=R6*SIN(CTA)+(R5-R6)*COS(BTA)+(R0-R5)*COS(REFA) !4.创建轨腰和轨头结构线ROUX=B3/2+R0-C1ROUY=ROUX*TAN(CTA)ANGI=ASIN((H1+H2)/R0)K,6,B3/2+R0-R0*COS(ANGI)K,7,B3/2+R0-R0*COS(REFA),H1+H2+R0*SIN(REFA) LARC,6,7,2,R0DX1=R6*(COS(BTA)-SIN(CTA))DY1=R6*(COS(CTA)-SIN(BTA))K,8,ROUX-DX1,H1+2*H2+ROUY-DY1K,9,ROUX,H1+2*H2+ROUYLARC,7,8,2,R5LARC,8,9,2,R6K,10,B4,H1+2*H2+B4*XD3K,11,B4-(H3-B4*XD3)*XD4,HL,9,10L,10,11ANGI=ASIN(B5/R9)K,12,0,HK,13,B5,H-(R9-R9*COS(ANGI)) LARC,12,13,1,R9DX1=B4-B5+R8*SIN(ANGI)ANGI1=ASIN(DX1/R8)Y1=R8*COS(ANGI)-R8*COS(ANGI1) K,14,B4,KY(13)-Y1LARC,13,14,1,R8!5.倒角或弧线连接LFILLT,1,2,R1LFILLT,2,3,R2LFILLT,3,4,R3LPTN,4,5LFILLT,17,18,R4LFILLT,8,9,R10LPTN,9,11LFILLT,20,22,R7LDELE,15,16,1,1LDELE,19,21,2,1LSYMM,X,ALLNUMMRG,ALLNUMCMP,ALLAL,ALLASUMVOFFST,1,300!EX2.9B 斜向圆台建模finish/clear/prep7r0=3r1=2h=4cyl4,,,r0wpoff,r1,,hcyl4,,,r1*do,i,1,4askin,i,i+4*enddova,all!斜向延伸创建圆台vgen,1,1,,,,3*r0,,,,1wpcsyscyl4,,,r0vext,7,,,r1,,h,r1/r0,r1/r0!EX2.9B 已知函数方程时的建模!玫瑰线1==================================== !极坐标方程为ρ=asin(4Φ/3)finish/clear/prep7a=20csys,1*do,i,0,360*3fei=i*acos(-1)/180r0=a*sin(fei*4/3)k,,r0,i*enddo*do,i,1,360*3l,i,i+1*enddo!玫瑰线2=================================== !极坐标方程为ρ=asin(4Φ)finish/clear/prep7a=20csys,1*do,i,0,360fei=i*acos(-1)/180r0=a*sin(fei*4)k,,r0,i*enddo*do,i,1,360l,i,i+1*enddo!长辐圆内旋轮线============================ !参数方程x=(a-b)cost+λcos(a-b)/bt!参数方程y=(a-b)sint-λsin(a-b)/btfinish/clear/prep7a=50b=5lmda=15*afun,deg*do,i,0,360x1=(a-b)*cos(i)+lmda*cos((a-b)/b*i)y1=(a-b)*sin(i)-lmda*sin((a-b)/b*i)k,,x1,y1*enddo*do,i,1,360l,i,i+1*enddo!椭圆抛物面================================ !方程为z=x*x/a/a+y*y/b/b!使用蒙皮方法finish/clear/prep7a=20b=10n=20*do,i,1,niz=i/10lsel,nonewpoff,,,izcyl4,,,1adele,alllsscale,all,,,a*sqrt(iz),b*sqrt(iz),,,,1*enddoallsel*do,i,1,4*(n-1),4askin,i,i+4askin,i+1,i+5askin,i+2,i+6askin,i+3,i+7*enddo!EX2.9C 旋转图素建模!类花瓶建模--------------------finish/clear/prep7K,1K,2,100K,3,300,400K,4,150,550k,5,130,880K,6,300,1150k,7,400,1100k,8,500,1150bsplin,allk,1001,,1000arotat,all,,,,,,1,1001,360,5!类轮建模----------------------finish/clear/prep7!先创建类轮结构的一个断面,然后旋转之blc4,,,4,6cyl4,2,6,1.5asba,1,2k,100,-3k,101,-3,10vrotat,all,,,,,,100,101!EX3.1 自定义箱形截面finish/clear/prep7k,1k,2,2k,3,2,2.2k,4,3,2.3k,5,3,2.5k,6,0,2.5a,1,2,3,4,5,6blc4,,0.2,1.7,2asba,1,2wpoff,1.7wprota,,,90asbw,allwpoff,,,0.3asbw,allwpoff,,0.2wprota,,90asbw,allwpoff,,,-2asbw,allarsym,x,allwpcsysaglue,allet,1,plane82lesize,all,,,1amesh,allsecwrite,myboxfinish/clear/prep7et,1,beam189mp,ex,1,3.0e10mp,prxy,1,0.167sectype,1,beam,mesh secread,mybox,,,meshk,1k,2,10k,100,5,5l,1,2lesize,all,,,20latt,1,,1,,100,,1lmesh,all/eshape,1Eplot!EX3.2 自定义多种材料截面finish/clear/prep7Ro=1.5Ri=1.0csys,1cyl4,,,ricyl4,,,roaptn,allwprota,,90asbwa,allwprota,,,90asbw,allwpcsyset,1,plane82mymat1=4mymat2=7mp,ex,mymat1,1.0mp,ex,mymat2,2.0asel,s,loc,x,0,riaatt,mymat1,,1asel,s,loc,x,ri,roaatt,mymat2,,1allselesize,0.25mshape,0,2dmshkey,1amesh,allsecwrite,mycsolid,sectfinish/clear/prep7et,1,beam189mym1=4mym2=7mp,ex,mym1,3.0e10mp,prxy,mym1,0.167 mp,ex,mym2,2.1e11mp,prxy,mym2,0.3 sectype,1,beam,mesh secread,mycsolid,sect,,mesh k,1k,2,,,10l,1,2lesize,all,,,20latt,,,1,,,,1lmesh,all/eshape,1/pnum,mat,1eplot!EX3.3A 单个方位关键点示例FINISH/CLEAR/PREP7ET,1,BEAM189MP,EX,1,2.1E5MP,PRXY,1,0.3SECTYPE,1,BEAM,ISECDATA,100,40,160,10,10,8K,1K,2,,,1000L,1,2K,100,,500,500LATT,1,,1,,100,,1LGEN,4,1,,,500LESIZE,ALL,,,10LMESH,ALL/ESHAPE,1EPLOT!EX3.3B 同时使用KB和KE方位关键点示例FINISH/CLEAR/PREP7ET,1,BEAM189MP,EX,1,2.1E5MP,PRXY,1,0.3SECTYPE,1,BEAM,ISECDATA,100,40,160,10,10,8L0=1000DL=500DXC=400K,1K,2,,,L0L,1,2K,100,,DLK,200,DXC,-DLK,300,2*DXC,DLK,301,2*DXC+DLK,400K,500,8*DXCLGEN,5,1,,,DXCLATT,1,,1,,100,,1LSEL,S,,,2LATT,1,,1,,200,,1LSEL,S,,,3LATT,1,,1,,300,301,1LSEL,S,,,4LATT,1,,1,,400,,1LSEL,S,,,5LATT,1,,1,,500,,1LSEL,ALLLESIZE,ALL,,,50LMESH,ALL/ESHAPE,1EPLOT!EX3.3C 双方位关键点翻转示例FINISH/CLEAR/PREP7ET,1,BEAM189MP,EX,1,2.1E5MP,PRXY,1,0.3SECTYPE,1,BEAM,I SECDATA,100,40,160,10,10,8L0=1000DL=500DXC=400K,1K,2,,,L0K,3,DXCK,4,DXC,,L0/2K,5,DXC,,L0L,1,2L,3,4L,4,5K,100,,DLk,101,,-DLK,200,DXC,DLk,201,2*DXCK,202,DXC,-DLLATT,1,,1,,100,101,1lesize,all,,,100LSEL,S,,,2LATT,1,,1,,200,201,1lesize,all,,,50LSEL,S,,,3LATT,1,,1,,201,202,1lesize,all,,,50LSEL,ALLLMESH,ALL/ESHAPE,1EPLOT!EX3.4A 两种单元形状和两种网格划分比较finish/clear/prep7et,1,plane82k,1k,2,8k,3,7,6k,4,1,6a,1,2,3,4esize,1mshape,0mshkey,0!mshape,0!mshkey,1!mshape,1!mshkey,0!mshape,1!mshkey,1amesh,all!EX3.4B 中间节点位置控制网格划分比较finish/clear/prep7cyl4,,,4,,8,60lesize,all,,,2mshape,0mshkey,1mshmid,0!mshmid,1!mshmid,2amesh,all!EX3.5 线上单元尺寸设置示例!下边密上边稀finish/clear/prep7et,1,plane82blc4,,,10,10lsel,s,tan1,ylesize,all,,,10lsel,s,loc,x,0lesize,all,,,9,1/8lsel,s,loc,x,10lesize,all,,,9,8lsel,allmshape,0mshkey,1amesh,all!中间密外边稀finish/clear/prep7et,1,plane82blc4,,,10,10lsel,s,tan1,ylesize,all,,,10,-1/5lsel,s,tan1,xlesize,all,,,9,-1/8lsel,allmshape,0mshkey,1amesh,all!EX3.6 合并线和连接线以进行映射网格划分finish/clear/prep7et,1,plane82k,1,5k,2,10k,3,11,6k,4,6,15k,5,-1,8k,6,,4l,1,2l,2,3l,3,4larc,4,5,3,10l,5,6l,6,1al,allesize,3mshape,0mshkey,1lccat,1,2lcomb,4,5amesh,all!EX3.7 合并线或连接线的网格划分设置finish/clear/prep7et,1,plane82k,1,5k,2,10k,3,11,6k,4,6,15k,5,-1,8k,6,,4l,1,2l,2,3l,3,4larc,4,5,3,10l,5,6l,6,1al,allesize,,10lesize,6,,,8lesize,1,,,4lesize,2,,,3lesize,4,,,5lesize,5,,,2mshape,0mshkey,1lcomb,1,2!lccat,1,2!如采用lcatt,1,2则采用7个划分数lcomb,4,5amesh,all!EX3.7B 简化映射网格划分finish/clear/prep7et,1,plane82k,1,5k,2,10k,3,11,6k,4,6,15k,5,-1,8k,6,,4l,1,2l,2,3l,3,4larc,4,5,3,10l,5,6l,6,1al,allesize,,6mshape,0amap,1,2,5,3,4!EX3.8A 过渡四边形映射网格finish/clear/prep7k,1k,2,10,-1k,3,8,6k,4,1,3a,1,2,3,4lesize,1,,,8lesize,3,,,3lesize,4,,,7lesize,2,,,2mshape,0,2dmshkey,1amesh,all!EX3.8B 过渡四边形映射网格finish/clear/prep7et,1,plane42k,1k,2,10,-1k,3,8,6k,4,1,3a,1,2,3,4lesize,1,,,11lesize,3,,,3lesize,4,,,2lesize,2,,,2mshape,0,2dmshkey,1amesh,all!EX3.9A 过渡六面体映射网格划分finish/clear/prep7et,1,95blc4,,,8,8,8lesize,all,,,3lesize,5,,,15allselmshape,0,3dvmesh,all!EX3.9B 过渡六面体映射网格划分finish/clear/prep7et,1,95blc4,,,8,8,8lesize,all,,,4lesize,7,,,12mshape,0,3dmshkey,1vmesh,all!EX3.9C 过渡六面体映射网格划分finish/clear/prep7et,1,95blc4,,,8,8,8lsel,s,,,1,8,7lesize,all,,,6lsel,s,,,2,7,5lesize,all,,,3lsel,s,,,4,5lesize,all,,,7lsel,s,,,3,6,3lesize,all,,,2lsel,s,,,9,12,1lesize,all,,,5allselmshape,0,3dmshkey,1vmesh,all!EX3.9D 过渡六面体映射网格划分finish/clear/prep7et,1,95blc4,,,8,8,8lesize,2,,,2lesize,4,,,2lesize,5,,,2lesize,1,,,3lesize,3,,,3lesize,7,,,6lesize,6,,,7lesize,11,,,7lesize,9,,,3lesize,10,,,3lesize,12,,,3allselmshape,0,3dmshkey,1vmesh,all!EX3.10 带两孔的长方体的扫掠网格划分finish/clear/prep7a=10r=2et,1,mesh200,6et,2,solid45blc4,,,2*a,a,acyl4,a/2,a/2,r,,,,awprota,,90cyl4,1.5*a,a/2,r,,,,-avsbv,1,2vsbv,4,3wprota,,,90wpoff,,,a/2vsbw,allwpoff,,,a/2vsbw,allwpoff,,,a/2vsbw,allwpcsyswpoff,,a/2,a/2vsbw,allwprota,,90vsbw,allwpcsysesize,1amap,105,15,16,26,63amap,107,16,13,60,26amap,108,13,14,28,60amap,103,15,14,28,63lesize,94,,,4lesize,79,,,5vsel,s,loc,x,0,avsweep,allasel,s,loc,y,aasel,r,loc,x,a,2*alccat,2,45lccat,57,71lccat,68,78lccat,65,72mshape,0,2dmshkey,1amesh,allvsel,s,loc,x,a,2*avsweep,allallsel/view,1,1,2,3Eplot!EX3.11 拉伸类命令生成体单元网格finish/clear/prep7et,1,82et,2,95blc4,,,4,4blc4,6,,4,4blc4,12,,4,4blc4,18,,4,4esize,1amesh,allesize,,8vrotat,1,,,,,,1,4,90vext,2,,,,,10,0.5,0.5voffst,3,10vdrag,4,,,,,,35!EX3.12 圆的网格划分finish/prep7et,1,plane82r0=10cyl4,,,r0cyl4,3*r0,,,,r0 wprota,,90asbw,allwprota,,,90asbw,allwpoff,,,3*r0asbw,allwpcsys,-1asel,s,loc,x,-r0,r0lsla,slesize,all,,,8mshape,0,2dmshkey,1amesh,allallselasel,s,loc,x,2*r0,4*r0 lesize,all,,,8lsel,r,length,,r0lesize,all,,,8,0.1,1 amesh,allallsel!EX3.13 圆环的网格划分finish/clear/prep7et,1,plane82r0=10cyl4,,,r0/3,,r0,90cyl4,2*r0,,r0/10,,r0,90 asel,s,loc,x,-r0,r0lsla,slesize,all,,,8lsel,r,length,,r0*2/3 lesize,all,,,3,,1 mshape,0,2dmshkey,1amesh,allasel,s,loc,x,2*r0,4*r0lesize,5,,,12lesize,7,,,6lsel,s,length,,r0*9/10lesize,all,,,7amesh,all!EX3.14 圆柱面和圆柱体的网格划分!圆柱面finish/clear/prep7r0=10h0=50et,1,shell63cyl4,,,r0adele,1cm,l1cm,linek,50k,51,,,h0l,50,51adrag,l1cm,,,,,,5lsel,s,loc,z,0lesize,all,,,6lsel,s,length,,h0lesize,all,,,8mshape,0,2dmshkey,1amesh,all!圆柱体finish/clear/prep7r0=10h0=50et,1,solid95cyl4,,,r0,,,,h0wprota,,90vsbw,allwprota,,,90vsbw,allmshape,0,3dmshkey,1lsel,s,loc,z,0lsel,s,length,,h0lesize,all,,,8vmesh,all!EX3.15 圆锥的网格划分!扫掠网格划分finish/clear/prep7cone,10,,,15,,90et,1,200,7et,2,95lsel,s,,,5,6lesize,all,,,12,0.5lsel,alllesize,3,,,6mshape,0,2dmshkey,1amesh,3vsweep,1,3,4vsymm,x,allvsymm,y,allvglue,all!六面体映射网格划分finish/clear/prep7cone,10,,,15,,90et,2,95lesize,all,,,8mshape,0,3dmshkey,1vmesh,allvsymm,x,allvsymm,y,allvglue,all!EX3.16 正多边形面的通用网格划分finish/clear/prep7ns=11rpr4,ns,,,10kp0=100+nsk,kp0*if,mod(ns,2),eq,0,then*do,i,1,ns/2l,kp0,2*i-1*enddo*else*do,i,1,nsl,kp0,i*enddo*endiflsel,s,,,ns+1,2*nscm,l1cm,lineallselasbl,1,l1cm*if,mod(ns,2),eq,0,then cmsel,s,l1cmlesize,all,,,8lsel,invelesize,all,,,4*elselesize,all,,,8*endifallselmshape,0mshkey,1amesh,all!EX3.17 球体及球面网格划分finish/clear/prep7r0=10sphere,,r0,,90vsbw,allvdele,2,,,1esize,2et,1,solid95mshape,0,3dmshkey,1vsymm,x,all vsymm,y,all vsymm,z,allvglue,allfinish/clear/prep7r0=10sphere,,r0,,90 vsbw,allvdele,2,,,1vdele,allasel,s,loc,x,0asel,a,loc,y,0asel,a,loc,z,0adele,all,,,1allselesize,2et,1,shell63 mshape,0,2d mshkey,1amesh,allarsym,x,allarsym,y,allarsym,z,all nummrg,all!EX3.18 孔板网格划分finish/clear/prep7a0=300b0=800r0=15blc4,,,a0,b0cyl4,a0/4,b0/8,r0 agen,2,2,,,a0/2 agen,2,2,3,1,,b0/8 agen,2,2,5,1,,b0*5/8 asel,s,,,2,9,1cm,a2cm,areaallselwprota,,-90*do,i,1,5wpoff,,,b0/16asbw,all*enddowpoff,,,b0*5/16*do,i,1,5wpoff,,,b0/16asbw,all*enddowprota,,,90*do,i,1,3wpoff,,,a0/4asbw,all*enddowpcsys,-1numcmp,alllsel,s,radius,,r0lesize,all,,,8lsel,invelesize,all,,,4lsel,allet,1,82mshape,0,2dmshkey,1asel,u,loc,y,b0/16,b0*5/16 asel,u,loc,y,b0*11/16,b0*15/16 lsla,slsel,r,tan1,xlesize,all,50,,,,1amesh,allallselamap,21,30,31,54,62 amap,22,31,32,54,64 amap,32,29,30,62,76 amap,33,29,32,64,76amap,42,34,35,76,82 amap,43,35,36,76,84 amap,41,33,34,53,82 amap,44,33,36,53,84amap,19,22,23,49,64 amap,20,23,24,49,60 amap,9,21,22,64,74 amap,31,21,24,60,74amap,38,26,27,74,84 amap,39,27,28,74,80 amap,37,25,26,50,84 amap,40,25,28,50,80amap,17,14,15,43,59 amap,18,15,16,43,63 amap,7,13,14,59,73 amap,8,13,16,63,73amap,34,18,19,73,79 amap,30,17,18,79,44 amap,35,19,20,73,83 amap,36,17,20,44,83amap,15,6,7,39,63amap,16,7,8,39,58amap,4,6,5,63,71amap,5,5,8,58,71amap,27,10,11,71,83 amap,28,11,12,71,78 amap,26,9,10,83,40 amap,29,9,12,40,78!EX3.19 角支架的网格划分finish/clear/prep7blc4,,,150,50blc4,100,,50,-50cyl4,,25,25cyl4,125,-50,25aadd,allnumcmp,allcyl4,,25,10cyl4,125,-50,10 asel,s,,,2,3cm,a1cm,area asel,allasba,1,a1cm lcomb,1,6lfillt,1,2,20 asbl,4,6adele,1,,,1lfillt,3,4,20al,18,19,20 aadd,all numcmp,all!---------------------- wprota,,90 wpoff,,,-25 asbw,all wpoff,,,75 asbw,all wprota,,,90 asbw,all wpoff,,,125 asbw,all wpcsys,-1 wpoff,25 wprota,,,90 asbw,all kwpave,18 asbw,all kwpave,3 wprota,,90 asbw,all kwpave,21 wprota,,-45 asbw,8 wpcsys,-1!-------------------- et,1,plane82 mshape,0,2d mshkey,1 esize,6lesize,33,,,6 lesize,37,,,6 lesize,42,,,6amesh,3,5,2amap,6,9,10,4,23amap,7,9,12,1,23amesh,11,13,2amesh,1,9,8amesh,2,4,2amap,16,3,18,26,28amap,12,14,15,5,28amap,15,13,14,6,28lcomb,19,22lcomb,27,46amesh,10,14,4!========================= !EX3.20 大板小孔的网格划分A finish/clear/prep7a0=100blc4,,,a0,a0cyl4,,,a0/100asba,1,2csys,1k,50,a0/20k,51,a0/20,90l,50,51asbl,all,1wprota,,90,45asbw,allet,1,plane82mshape,0,2dmshkey,1lsel,s,loc,x,0,a0/20lesize,all,,,8lsel,alllesize,7,,,12,0.1lesize,8,,,12,0.1lesize,9,,,12,10amesh,allcsys,0arsym,x,allarsym,y,allnummrg,all!============================= !EX3.20 大板小孔的网格划分Bfinish/clear/prep7a0=100blc4,,,a0,a0cyl4,,,a0/100asba,1,2csys,1k,50,a0/20k,51,a0/20,90l,50,51asbl,all,1et,1,plane82mshape,0,2dmshkey,1lesize,5,,,8lesize,1,,,10lesize,4,,,8,5lesize,6,,,8,5amesh,1lesize,7,,,20,0.1lesize,8,,,20,0.1amap,2,50,51,2,4csys,0arsym,x,allarsym,y,allnummrg,all!EX3.21 Z形面网格划分及局部细分finish/clear/prep7blc4,,,15,10blc4,10,6,14,12aadd,allwprota,,-90wpoff,,,6asbw,allwpoff,,,4wprota,,,90wpoff,,,10asbw,allwpoff,,,5asbw,allwpcsys,-1et,1,82esize,2mshape,0,2dmshkey,1amesh,allkrefine,9,10,1,1,,off !不光滑处理(节点位置不变)aclear,allamesh,allkrefine,9,10,1,1,,smooth !光滑处理,节点位置可改变,但既有单元不删除aclear,allamesh,allkrefine,9,10,1,1 !光滑处理,可删除既有单元重细分,节点位置改变!EX3.22 分布小孔环形面的网格划分finish/clear/prep7r1=15r2=25r3=3n=8cyl4,,,r1,,r2,180/ncyl4,0.5*(r1+r2),,r3asba,1,2kl,2larc,6,8,4,0.5*(r1+r2)asbl,all,4lesize,4,,,4lesize,10,,,4lesize,6,,,8lesize,3,,,6lesize,8,,,4lesize,5,,,8lesize,9,,,4lesize,7,,,4et,1,plane82mshape,0,2damap,2,6,7,4,8amap,1,5,6,8,1!lrefine,5,6,1,1,smootharsym,y,allcsys,1agen,n,all,,,,360/nnummrg,all!EX3.23 同心圆轴体的网格划分finish/clear/prep7cylind,50,0,100,150cylind,40,0,200,250cylind,30,0,100,250cylind,20,0,50,250cylind,10,0,0,250vptn,allwprota,,,90vsbw,allwprota,,90vsbw,allet,1,95csys,1lsel,s,length,,50lesize,all,,,5lsel,invelsel,u,radius,,10,50lesize,all,,,4n1=6n2=6n3=8n4=10n5=12lsel,r,loc,x,0,10lesize,all,,,n1,,1lsel,s,radius,,10lesize,all,,,n1lsel,s,radius,,20lsel,s,radius,,30lesize,all,,,n3lsel,s,radius,,40lesize,all,,,n4lsel,s,radius,,50lesize,all,,,n5allselmshape,0,3dmshkey,1vmesh,all!EX3.24A 圆柱与长方体组合模型的网格划分!采用六面体映射网格划分finish/clear/prep7a0=30h1=15h2=25r0=7blc4,,,a0/2,a0/2,h1cyl4,,,r0,,,90,h1+h2vptn,allaccat,4,6et,1,95esize,3mshape,0,3dmshkey,1vmesh,allasel,s,accaadele,alllsel,s,lccaldele,allallselvsymm,x,allvsymm,y,allnummrg,all!EX3.24B 圆柱与长方体组合模型的网格划分!采用过渡六面体映射网格划分finish/cleara0=30h1=15h2=25r0=7blc4,,,a0/2,a0/2,h1cyl4,,,r0,,,90,h1+h2vptn,alllsel,s,radius,,r0lsel,a,length,,r0lesize,all,,,6lsel,s,loc,z,0lsel,a,loc,z,h1lesize,all,,,7asel,s,loc,x,a0/2asel,a,loc,y,a0/2accat,allallselet,1,95esize,3mshape,0,3dmshkey,1vmesh,allasel,s,accaadele,alllsel,s,lccaldele,allallselvsymm,x,allvsymm,y,allnummrg,all!EX3.25-任意圈数圆柱形螺旋弹簧的扫略网格划分FINISH/CLEAR/PREP7!1.定义弹簧参数(同上)D=4C=8DZ=C*DT=DZ/6N=4.7*IF,T,LT,D,THEN*ENDIFTKPD=90!2.创建全部螺旋线CSYS,1TDEG=N*360TDEG1=MOD(TDEG,TKPD) N0=(TDEG-TDEG1)/TKPD+1 *AFUN,DEG*DO,I,1,N0CTA=(I-1)*TKPDZ=T/360*CTAK,I,DZ/2,CTA,Z*ENDDO*IF,TDEG1,LT,1.0E-2,THEN *ELSEN0=N0+1CTA=CTA+TDEG1Z=T/360*CTAK,N0,DZ/2,CTA,Z*ENDIF*DO,I,1,N0-1L,I,I+1*ENDDOCM,L1,LINE!3.在螺旋线端部创建簧丝截面CSYS,0WPOFF,DZ/2 WPROTA,,90CYL4,,,D/2wprota,,90asbw,allwprota,,,90asbw,allcm,a1cm,areaVDRAG,a1cm,,,,,,L1et,1,mesh200,7et,2,solid95cmsel,s,a1cmlsla,slesize,all,,,6amesh,allallselesize,d/2vsweep,all!EX3.26 具坑缺陷圆柱的网格划分finish/clear/prep7l0=50r0=10r1=5r2=1h0=5et,1,solid45cyl4,,,r0,,,,l0wpave,0,r0,l0/2wprota,,90con4,,,r1,r2,h0vsbv,1,2wprota,,90vsbw,allwpoff,,,r1+3vsbw,allwpoff,,,-2*(r1+3)vsbw,allwprota,,,90vsbw,allwpoff,,,r1+1vsbw,allwpoff,,,-2*(r1+1)vsbw,allwpcsys,-1wprota,,90vsbw,allwpoff,,,-r1vsbw,allwpoff,,,2*r1vsbw,allwpcsys,-1numcmp,allksel,s,loc,z,l0/2ksel,r,loc,x,0ksel,u,loc,y,0*get,kp1,kp,0,num,min kp2=kpnext(kp1) ksel,s,loc,z,l0/2+r2*get,kp3,kp,0,num,min allselk,1000,,-r0,l0/2+5l,kp3,1000asel,none*get,l1,line,0,num,max arotat,l1,,,,,,kp1,kp2 cm,a1cm,areaallselvsba,all,a1cm!vsel,s,loc,z,17,33!vsel,r,loc,x,-6,6!aslv,s!aplotaccat,128,61accat,160,138 accat,224,202 accat,183,35accat,31,134accat,151,164 accat,215,231 accat,82,195accat,130,5accat,162,145 accat,229,209 accat,192,89accat,12,123accat,117,155 accat,109,219 accat,14,178mshape,0,3d mshkey,1esize,1vmesh,all!EX3.27长方体开圆柱槽的网格划分finish/clear/prep7blc5,,,20,10,30wpoff,,5,5cyl4,,,8,,,,10wpoff,,,10cyl4,,,4,,,,12vsel,s,,,2,3cm,v1cm,voluallselwpcsys,-1vsbv,1,v1cmvoffst,15,5voffst,16,3voffst,17,15vptn,allwprota,,,90vsbw,allwpcsys,-1wpoff,,,5vsbw,allwpoff,,,10vsbw,allwpoff,,,12vsbw,allet,1,mesh200,7esize,2mshape,0,2dmshkey,1asel,s,loc,z,30lccat,6,74lccat,8,68amesh,allasel,s,loc,z,0lccat,3,73lccat,1,67amesh,allallselet,2,solid95mshape,0,3dmshkey,1vsweep,all!ex4.1累加节点自由度约束值finish/clear/prep7et,1,beam3k,1k,2,10l,1,2esize,1lmesh,alld,1,ux,1e-2,,,,uyd,1,rotzd,2,alldlistnsel,s,d,u,0,0.1dofsel,s,uydscale,2.5dlistdofsel,alldcum,addd,1,ux,2e-2dlistdcum,ignod,2,uy,1.0dlist!ex4.2 对线施加约束并转换finish/clear/prep7et,1,95blc4,,,10,10,10dl,7,,ux,0.1dl,5,,alldl,11,6,symmdl,10,6,asymdl,6,,symmdllistesize,2vmesh,alldtrandlist!ex4.3 施加集中荷载与节点坐标系finish/clear/prep7et,1,beam4k,1k,2,5k,3,10l,1,2l,2,3local,12,0,,,,90nrotat,alldk,1,allfk,2,fy,-1000esize,1lmesh,allnrotat,alllplotfk,3,fy,1000f,6,fx,-1000sbctraneplot!ex4.4a 3d单元sf加载示例finish/clear/prep7et,1,95blc4,,,10,10,20esize,,4vmesh,allasel,s,loc,y,10sf,all,pres,1000asel,s,loc,z,20nsla,s,1sf,all,pres,1000!ex4.4b 2d单元sf加载示例finish/clear/prep7et,1,82blc4,,,100,200blc4,30,60,40,80asba,1,2wprota,,-90wpoff,,,60asbw,allwpoff,,,80asbw,allwprota,,,90wpoff,,,30asbw,allwpoff,,,40asbw,allwpcsys,-1esize,5amesh,all/psf,pres,norm,2sf,all,pres,100sfdele,all,presnsel,s,loc,x,0sf,all,pres,100nsel,s,loc,x,15,20esln,s,1nsel,r,loc,x,15sf,all,pres,110nsel,s,loc,x,40,60nsel,r,loc,y,10,30esln,s,1sf,all,pres,100lsel,s,loc,x,100nsll,s,1esln,snsel,s,loc,x,95sf,all,pres,-100eplot!ex4.5 节点号及其荷载函数finish/clear/prep7et,1,45blc4,,,10,10,20esize,5vmesh,all*dim,mypres,,100*do,i,1,100mypres(i)=i*10.0*enddosffun,pres,mypres(1)nsel,s,loc,y,10sf,all,pres,10sflist*do,i,1,100mypres(i)=i*50.0*enddonsel,s,loc,z,20sf,all,pres,0allselsflist!ex4.6a 2d平面单元plane82 finish/clear/prep7et,1,82blc4,,,10,50esize,2amesh,allsfe,1,4,pres,,100,50sfe,6,4,pres,,200,40nsel,s,loc,x,10esln,ssfe,all,2,pres,,-100/psf,pres,norm,2,0,1eplot!ex4.6b 3d体单元solid95 finish/clear/prep7et,1,95blc4,,,10,10,30esize,5vmesh,all/psf,pres,norm,2,0,1sfe,22,3,pres,,100sfe,22,6,pres,,100,110,120,130 sfelist!ex4.6c 3d壳单元shell63 finish/clear/prep7et,1,63wprota,,90blc4,,,10,10esize,5amesh,all/psf,pres,norm,2,0,1sfe,1,1,pres,,100sfe,1,3,pres,,100sfe,1,6,pres,,100sfe,4,1,pres,,100,110,120,130!ex4.7 在梁单元上施加荷载finish/clear/prep7et,1,beam3k,1k,2,10l,1,2esize,,10lmesh,all/pnum,elem,1sfbeam,3,1,pres,50,100 sfbeam,5,1,pres,100 sfbeam,7,1,pres,50,100,,,0.2,0.1sfbeam,9,1,pres,100,,,,0.4,-1sfbeam,3,2,pres,50,100,,,0.2,0.1!ex4.8a 在线上施加面荷载finish/clear/prep7et,1,82blc4,,,10,30esize,5amesh,all/psf,pres,norm,2sfl,4,pres,10,60sfl,2,pres,60sftraneplot!ex4.8b 在线上施加面荷载finish/clear/prep7et,1,shell63wprota,,90blc4,,,10,30esize,5amesh,allsfl,3,pres,100sftraneplot!ex4.9 利用荷载梯度在直角坐标系下的施加方法finish/clear/prep7et,1,82blc4,,,10,60esize,2amesh,all/psf,pres,norm,2sfgrad,pres,,y,0,-5nsel,s,loc,x,0nsel,r,loc,y,0,40sf,all,pres,600sfgrad,pres,,y,30,-20nsel,s,loc,x,10sf,all,pres,0allseleplot!ex4.10利用荷载梯度在柱坐标系下的施加方法finish/clear/prep7csys,1k,1,10,-90k,2,10,90k,3,10,90,30l,1,2l,2,3adrag,1,,,,,,2ldele,2,,,1numcmp,allet,1,63esize,2amesh,allsfgrad,pres,1,y,-90,1sfa,all,2,pres,400sftran!可考察下述命令及其施加方法!①!sfgrad,pres,1,y,270,1sfa,all,2,pres,400sftran!②!local,12,1cscir,12,1sfgrad,pres,12,y,270,1sfa,all,2,pres,400sftran!ex4.11 ldread命令的示例finish/clear/filname,ldtest1/prep7et,1,plane82mp,ex,1,2.1e5mp,prxy,1,0.3blc4,,,10,40esize,2amesh,alld,all,allsfl,3,pres,100/solusolve/post1prrsolfinish/filename,ldtest2/solulsclear,allnsel,s,loc,y,0d,all,allallselldread,reac,,,,,ldtest1,rst solve/post1plnsol,s,y!ex4.12 初应力荷载finish/clear/filname,colu1/prep7et,1,plane82mp,ex,1,2e5mp,nuxy,1,0.3blc4,,,1,10esize,2amesh,allnsel,s,loc,y,0d,all,uyd,1,uxnsel,s,loc,y,10sf,all,pres,-10。

ANSYS分析实例与工程应用命令流学习笔记

ANSYS分析实例与工程应用命令流学习笔记1大纲静力分析:2杆、3梁、5薄膜和板壳、4实体单元梁单元:简化计算,结构总体受力情况实体单元:较复杂的结构,局部细节的受力情况稳定性分析:6振动、模态分析:7简单振动和梁的振动、8膜板和实体振动2杆系结构的静力分析2.1铰接杆在外力作用下的变形二维杆单元LINK1*AFUN,DEG:三角函数默认为弧度,改为角度后处理:结构变形图、显示节点位移和杆件应力2.2人字形屋架的静力分析后处理:杆单元的轴力、轴向应力、轴向应变2.3超静定拉压杆的反力计算后处理:节点反力2.4平行杆件与刚性梁连接的热应力问题定义3点的UY为耦合自由度,即三者的UY位移相等温度(增量)后处理:寻找特定位置的节点和单元,并从单元表中提取它们的内力2.5端部有间隙的杆的热膨胀二维带厚度的平面应力单元PLANE42、二维接触单元CONTACT26温度(始、末)后处理:定义水平应力和铅直应力单元表,并提取3号单元的应力结果*Status,ParmFINISH定义数组变量,将计算结果通过数组变量输出到文件3梁的弯曲静力分析3.1单跨等截面超静定梁的平面弯曲二维弹性梁单元BEAM3后处理:定义以两端弯矩和剪力的单元表,并列出单元表数据并用单元表数据绘制剪力图和弯矩图更细的节点划分方案,更精细3.2四跨连续梁的内力计算体素建模:keypoint, line, area, volume便于细分单元3.3七层框架结构计算3.4工字形截面外伸梁的平面弯曲3.5矩形截面梁的纵横弯曲分析考虑应力强化效应后处理:迭代过程3.6空间刚架静力分析三维梁单元BEAM43.7悬臂梁的双向弯曲三维8节点耦合场实体单元SOLID5三维20节点固体单元SOLID92三维10节点耦合场实体单元SOLID98三维结构实体自适应单元SOLID147定义宏程序,对应四种工况,各种结果差别不大3.8圆形截面悬臂杆的弯扭组合变形三维直管单元PIPE16(只定义外直径,不定义内直径)3.9悬臂等强度梁的弯曲四边形壳单元SHELL63(这里用退化的三角形单元,并使用节点耦合自由度保证模型的对称变形)三维非对称锥形梁单元BEAM44(定义横截面主轴,单元宽度线性变化)计算结果都很好,但壳体单元更能模拟出等强度梁的实际几何形状,更直观,截面定义更简单。

ansys命令流实例

ansys命令流实例1.结构静力分析--梁分析/PREP7 !进入前处理器ET,1,BEAM3 !定义单元类型R,1,0.25,0.0052,0.5 !定义实常数MP,EX,1,210E6MP,PRXY,1,0.3 !定义材料属性N,1,0N,2,1N,3,5N,4,7N,5,7N,6,9N,7,11N,8,11N,9,13N,10,14 !定义节点E,1,2E,2,3E,3,4E,5,6E,6,7E,8,9E,9,10 !生成单元CP,1,UX,4,5CP,2,UY,4,5CP,3,UX,7,8CP,4,UY,7,8 !耦合节点FINISH/SOLU !进入求解器D,2,UXD,2,UYD,3,UYD,6,UYD,9,UY !施加位移约束F,10,FY,-4 !施加集中约束SFBEAM,1,1,PRES,4,4SFBEAM,2,1,PRES,4,4 !施加均布力SOLVE !求解/POST1 !进入后处理器PLDISP !绘制结构变形图PRDISP !列出各节点的位移ETABLE,IMOMENT,SMISC,6ETABLE,JMOMENT,SMISC,12ETABLE,ISHEAR,SMISC,2ETABLE,JSHEAR,SMISC,8 !将节点弯矩、剪力制表PRETAB !列表显示单元的弯矩、剪力/TITLE,SHEAR FORCE DISTRIBUTION !设置剪力分布图的标题PLLS,ISHEAR,JSHEAR !绘制剪力分布图/TITLE,BENDING MOMENT IDSTRIBUTION !设置弯矩分布图的标题PLLS,IMOMENT,JMOMENT !绘制弯矩分布图流固耦合实例RAD=0.8 !底面半径H=1G=9.8OMEGAR=2ROU=1000 !定义参数变量/PREP7 !进入前处理器ET,1,FLUID79 !选择单元类型KEYOPT,1,3,1 !设置单元关键字MP,EX,1,2E9 !设置杨氏模量MP,DENS,1,ROU !设置材料密度K,1K,2,RADK,3,RAD,HK,4,,H !生成关键点A,1,2,3,4 !连接关键点生成面积LESIZE,ALL,,,10 !设置网格划分精度AMESH,ALL !将面积划分网络/SOLU !进入求解器DL,2,,UXDL,1,,UYNSEL,S,LOC,XDSYM,SYMM,XD,ALL,UXNSEL,ALL !施加位移约束ACEL,,GOMEGA,,OMEGAR !施加惯性力SOLVE !求解/POST1SET,LAST !进入通用后处理器PLNSOL,U,X,0,1 !绘制应力云图UCENT=UY(22)UEDGE=UY(12)UELEV=UEDGE-UCENT !提取节点位移结构静力分析--壳结构内力分析LENGTH=100YOUNG=200000THICKNESS=2FORCE=1000DENSITY=9E-6 !将材质、载荷、板的几何尺寸等参数化/PREP7 !进入前处理器MP,EX,1,YOUNGMP,NUXY,1,0.3MP,DENS,1,DENSITY !定义材质ET,1,SHELL63 !定义单元类型R,1,THICKNESS,THICKNESS,THICKNESS,THICKNESS !定义实常数!构建结构的几何模型K,1,0,0K,2,LENGTH,0K,3,LENGTH,LENGTHK,4,0,LENGTH !定义关键点A,1,2,3,4!通过关键点生成面LSEL,ALLLESIZE,ALL,,,16AMESH,ALL !设定网格划分参数,划分网格FINISH/SOLU !进入求解器NSEL,S,LOC,X,0,0D,ALL,ALL,0 !选择X=0的节点将其固定NSEL,S,LOC,X,LENGTH,LENGTHD,ALL,ALL,0 !选择X=LENGTH的节点将其固定NSEL,S,LOC,X,0.5*LENGTH,0.5*LENGTHNSEL,R,LOC,Y,0.5*LENGTH,0.5*LENGTHF,ALL,FZ,FORCEALLSEL !捕捉板的中心点并在中心点处施加集中力荷载SOLVE !求解FINISH/POST1 !进入后处理器/DSC,,10PLNSOL,U,Z,0,1 !绘图显示板的竖向变形NSEL,ALL !提取板的最大竖向变形NSORT,U,Z,1,1 !将节点的位移绝对值以升序排序*GET,MAXDEFLECTION,SORT,0,MAX !提取位移最大值并赋给变量NSEL,S,LOC,X,0NSEL,A,LOC,X,LENGTH,LENGTH !选择固定边节点NSORT,S,EQV,1,1 !将节点等效应力的绝对值以升序排序*GET,MAXSTRESS,SORT,0,MAX !提取等效应力最大值并赋给变量结构静力分析--平面桁架分析/PREP7 !进入前处理器ET,1,LINK1 !选择单元R,1,0.1 !定义实常数MP,EX,1,30E6MP,PRXY,1,0.3 !定义材料属性N,1,0N,2,4N,3,8N,4,12N,5,0,3N,6,4,3N,7,8,3 !生成节点E,1,2E,2,3E,3,4E,4,7E,3,7E,2,7E,2,6E,2,5E,1,5E,5,6E,6,7 !生成单元FINISH/SOLU !进入求解器D,1,UXD,1,UYD,5,UX !实加位移约束F,2,FY,-15F,3,FY,-15F,4,FY,-15 !施加集中力SOLVE !求解/POST1 !进入能用后处理器PRESOL,FORC !列表显示反力。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

ANSYS 结构稳态(静力)分析之经典实例-命令流格式.txt两人之间的感情就像织毛衣,建立的时候一针一线,小心而漫长,拆除的时候只要轻轻一拉。

/FILNAME,Allen-wrench,1 ! Jobname to use for all subsequent files/TITLE,Static analysis of an Allen wrench/UNITS,SI ! Reminder that the SI system of units is used/SHOW ! Specify graphics driver for interactive run; for batch! run plots are written to pm02.grph! Define parameters for future useEXX=2.07E11 ! Young's modulus (2.07E11 Pa = 30E6 psi)W_HEX=.01 ! Width of hex across flats (.01m=.39in)*AFUN,DEG ! Units for angular parametric functions定义弧度单位W_FLAT=W_HEX*TAN(30) ! Width of flatL_SHANK=.075 ! Length of shank (short end) (.075m=3.0in)L_HANDLE=.2 ! Length of handle (long end) (.2m=7.9 in)BENDRAD=.01 ! Bend radius of Allen wrench (.01m=.39 in)L_ELEM=.0075 ! Element length (.0075 m = .30 in)NO_D_HEX=2 ! Number of divisions on hex flatTOL=25E-6 ! Tolerance for selecting nodes (25e-6 m = .001 in)/PREP7ET,1,SOLID45 ! 3维实体结构单元;Eight-node brick elementET,2,PLANE42 ! 2维平面结构;Four-node quadrilateral (for area mesh)MP,EX,1,EXX ! Young's modulus for material 1;杨氏模量MP,PRXY,1,0.3 ! Poisson's ratio for material 1;泊松比RPOLY,6,W_FLAT ! Hexagonal area创建规则的多边形K,7 ! Keypoint at (0,0,0)K,8,,,-L_SHANK ! Keypoint at shank-handle intersectionK,9,,L_HANDLE,-L_SHANK ! Keypoint at end of handleL,4,1 ! Line through middle of hex shapeL,7,8 ! Line along middle of shankL,8,9 ! Line along handleLFILLT,8,9,BENDRAD ! Line along bend radius between shank and handle! 产生一个倒角圆,并生成三个点/VIEW,,1,1,1 ! Isometric view in window 1/ANGLE,,90,XM ! Rotates model 90 degrees about X! 不用累积的旋转/TRIAD,ltop/PNUM,LINE,1 ! Line numbers turned onLPLOT! Line numbers off!/PNUM,KP,1KPLOTL,1,4 ! Hex section is cut into two quadrilateralsASBL,1,7,,,KEEP ! to satisfy mapped meshing requirements for bricks! 减线从面中CM,BOTAREA,AREA ! Component name BOTAREA for the two areas! Generate area mesh for later drag/PNUM,KP,0LPLOTLESIZE,1,,,NO_D_HEX ! Number of divisions along line 1 为线指定网格尺寸LESIZE,2,,,NO_D_HEXLESIZE,6,,,NO_D_HEXTYPE,2 ! PLANE42 elements to be meshed firstMSHAPE,0,2D ! Mapped quad mesh 指定单元要划分的形状和维数MSHKEY,1 ! 指定了映射网格划分SAVE ! Save database before meshingAMESH,ALL/TITLE,Meshed hex wrench end to be used in vdragEPLOT! Now drag the 2-D mesh to produce 3-D elementsTYPE,1 ! Type pointer set to SOLID45ESIZE,L_ELEM ! Element sizeVDRAG,2,3,,,,,8,10,9 ! Drag operation to create 3-D mesh面掠生成体/TYPE,,HIDP ! Precise hidden line display 显示要求是精确/TITLE,Meshed hex wrenchEPLOTCMSEL,,BOTAREA ! Select BOTAREA component and! 选择一个子集ACLEAR,ALL ! delete the 2-D elements! 清楚选择单元的几点和单元ASEL,ALLFINISH ! Apply loads and obtain the solution/SOLUANTYPE,STATIC ! Static analysis (default)/TITLE,Allen wrench -- Load step 1! First fix all nodes around bottom of shankCMSEL,,BOTAREA ! Bottom areas of shank 选择以前建立的一个单元面积的组合LSEL,,EXT ! Exterior lines of those areas 显示线NSLL,,1 ! Nodes on those linesD,ALL,ALL ! Displacement constraintsLSEL,ALL/PBC,U,,2 ! Displacement symbols turned on 显示位移约束的符号/TITLE,Boundary conditions on end of wrenchNPLOT!Now apply pressure on handle to represent 100-N (22.5-lb) finger forceASEL,,LOC,Y,BENDRAD,L_HANDLE ! Areas on handleASEL,R,LOC,X,W_FLAT/2,W_FLAT ! Two areas on one side of handle...NSLA,,1 ! ...and all corresponding nodesNSEL,R,LOC,Y,L_HANDLE+TOL,L_HANDLE-(3.0*L_ELEM)-TOL ! Reselects nodes at 位置 ! back end of handle (3 element lengths)*GET,MINYVAL,NODE,,MNLOC,Y ! Get minimum Y value of selected nodes预处理中的结点项;问题是得到一个什么样的值,结点的什么?*GET,MAXYVAL,NODE,,MXLOC,Y ! Get maximum Y value of selected nodes是中心位置的值吗?PTORQ=100/(W_HEX*(MAXYVAL-MINYVAL)) ! Pressure equivalent to 100 NSF,ALL,PRES,PTORQ ! PTORQ pressure on all selected nodes 指定节点上的表面力的载荷ALLSEL ! Restores full set of all entities/PSF,PRES,,2 ! Pressure symbols turned on 以箭头显示载荷/TITLE,Boundary conditions on wrench for load step 1NPLOTLSWRITE ! Writes first load step/TITLE, Allen wrench -- load step 2! Downward pressure on top of handle, representing 20-N (4.5 -lb) forcePDOWN=20/(W_FLAT*(MAXYVAL-MINYVAL))ASEL,,LOC,Z,-(L_SHANK+(W_HEX/2)) ! Area on top flat of handle...NSLA,,1 ! ...and all corresponding nodesNSEL,R,LOC,Y,L_HANDLE+TOL,L_HANDLE-(3.0*L_ELEM)-TOL ! Reselects nodes at! back end of handle (3 element lengths)SF,ALL,PRES,PDOWN ! PDOWN pressure at all selected nodesALLSEL/TITLE,Boundary conditions on wrench for load step 2NPLOTLSWRITE ! Writes second load stepSAVE ! Save database before solutionLSSOLVE,1,2 ! Initiates solution for load step files 1 and 2!Review the resultsFINISH/POST1SET,1 ! Reads load step 1 resultsPRRSOL ! Reaction solution listing/PBC,DEFA ! No BC symbols 重新安排规格说明/PSF,DEFA ! No surface load symbols 重新安排载荷的显示/EDGE,,1 ! Edges only, no interior element outlines 只显示边缘单元的显示/TITLE,Deformed allen wrench caused by torquePLDISP,2 ! Deformed shape overlaid with undeformed edge plot 显示结构转移/GSAVE,pldisp,gsav ! Saves graphics specifications on pldisp.gsav 保存为此图形文件,稍后再用/PLOPTS,INFO,ON ! Turns on entire legend column 打开边框形式;开启全部的图形圆柱/PLOPTS,LEG1,OFF ! Turns off legend header 关闭图形轮廓线的标题(头部)/ANGLE,,120,YM,1 ! Additional rotation about model Y (to see high stress areas)/TITLE,Stress intensity contours caused by torquePLNSOL,S,INT ! Stress intensity(应力强度) contours 组元应力/GSAVE,plnsol,gsav ! Saves graphics specifications to plnsol.gsavSET,2 ! Reads load step 2 resultsPRRSOL ! Reaction solution listing/GRESUME,pldisp,gsav ! 恢复pldisp文件;Resumes graphics specifications from pldisp.gsav/TITLE,Deformed allen wrench caused by torque and forcePLDISP,2/GRESUME,plnsol,gsav ! Resumes graphics specifications from plnsol.gsav/TITLE,Stress intensity contours caused by torque and forcePLNSOL,S,INTWPOF,,,-0.067 ! 把工作平面在Z方向偏移,达到后面要的截面的位置Offset the working plane for cross-section view从Z轴方向偏移工作平面/TYPE,1,5 ! Capped hidden display 显示剖面/CPLANE,1 ! 以共工作平面来剪切截面 Cutting plane defined to use the WP 把平面切开/VIEW, 1 ,WP ! View will be normal to the WP正切于当前的工作平面/DIST,1,.01 ! Zoom in on the cross section 指定详细的扩大倍数进行查看/TITLE,Cross section of the allen wrench under torque and force loading PLNSOL,S,INT! ***********************************GUI操作后的一些log文件命令流的解释说明***********************************/BATCH/COM,ANSYS RELEASE 11.0SP1 UP20070830 15:05:16 02/20/2009/TITLE,Static Analysis of an Allen Wrench*AFUN,DEG*SET,EXX, 2.07E11*SET,W_HEX, .01*SET,W_FLAT, W_HEX*TAN(30)*SET,L_SHANK, .075*SET,L_HANDLE, .2*SET,L_ELEM, .0075*SET,NO_D_HEX, 2*SET,TOL, 25E-6*SET,BENDRAD, .01/PREP7ET,1,SOLID45ET,2,PLANE42MPTEMP,,,,,,,,MPTEMP,1,0MPDATA,EX,1,,EXX ! 与温度相对应的材料属性MPDATA,PRXY,1,,0.3RPOLY,6,W_FLAT, ! 创建规则的多边形K,7,,,,K,8,,,-L_SHANK,K,9,,L_HANDLE,-L_SHANK,!*/VIEW, 1 ,1,1,1/ANG, 1/REP,FAST!*/ANGLE,1,90,XS,0 ! 不用累积的旋转LSTR, 4, 1 ! 两点定义一条直线LSTR, 7, 8LSTR, 8, 9LFILLT,8,9,BENDRAD, , ! 产生一个倒角圆,并生成三个点SAVEAPLOTFLST,2,1,5,ORDE,1FITEM,2,1LPLOTFLST,3,1,4,ORDE,1FITEM,3,7ASBL,P51X,P51X, , ,KEEP ! 减线从面中CM,BOTAREA,AREA ! 创建一个面的组合FLST,5,3,4,ORDE,3FITEM,5,1FITEM,5,-2FITEM,5,6CM,_Y,LINELSEL, , , ,P51XCM,_Y1,LINECMSEL,,_YLESIZE,_Y1, , ,NO_D_HEX, , , , ,1TYPE, 2MAT, 1 REAL,ESYS, 0 SECNUM,TSHAP,LINE!*MOPT,AMESH,DEFA MOPT,QMESH,DEFA MOPT,VMESH,DEFA MOPT,TIMP,1 MOPT,PYRA,ON MOPT,AORD,0 MOPT,SPLIT,1 MSHKEY,1MSHMID,0 MSHPATTERN,0 KEYW,ACCEPT,0!*MSHAPE,0,2D MSHAPE,0,3D!*SAVEFLST,5,2,5,ORDE,2 FITEM,5,2 FITEM,5,-3CM,_Y,AREAASEL, , , ,P51X CM,_Y1,AREA CHKMSH,'AREA' CMSEL,S,_Y!*AMESH,_Y1!*CMDELE,_Y CMDELE,_Y1 CMDELE,_Y2!*EPLOTTYPE, 1MAT, 1 REAL,ESYS, 0TSHAP,LINE!*ESIZE,L_ELEM,0, ! 指定线的份数LPLOTFLST,2,2,5,ORDE,2FITEM,2,2FITEM,2,-3FLST,8,2,4FITEM,8,8FITEM,8,10VDRAG,P51X, , , , , ,P51X/AUTO,1/REP,FASTEPLOTSAVECMSEL,S,BOTAREA ! 选择一个子集FLST,2,2,5,ORDE,2FITEM,2,2FITEM,2,-3ACLEAR,P51X ! 清楚选择单元的几点和单元ALLSEL,ALLEPLOTCMSEL,S,BOTAREALSEL,S,EXTNSLL,S,1FINISHFLST,2,18,1,ORDE,4FITEM,2,1FITEM,2,-10FITEM,2,17FITEM,2,-24/soluD,P51X, , , , , ,ALL, , , , ,LSEL,ALLASEL,S,LOC,Y,BENDRAD,L_HANDLEASEL,R,LOC,X,W_FLAT/2,W_FLATNSEL,R,LOC,Y,L_HANDLE+TOL,L_HANDLE-(3.0*L_ELEM)-TOL !**GET,minyval,NODE,,MNLOC,Y, , , ,*GET,maxyval,NODE,,MXLOC,X, , ,,*SET,PTORQ,100/(W_HEX*(MAXYVAL-MINYVAL))ALLSEL,ALLFLST,2,364,1,ORDE,2FITEM,2,1FITEM,2,-364SF,P51X,PRES,PTORQALLSEL,ALLNPLOTSAVELSWRITE,1,*SET,PDOWN,20/(W_FLAT*(MAXYVAL-MINYVAL))ASEL,S,LOC,Z,-(L_SHANK+(W_HEX/2))NSLA,S,1NSEL,R,LOC,Y,L_HANDLE+TOL,L_HANDLE-(3.0*L_ELEM)-TOL ALLSEL,ALLFLST,2,364,1,ORDE,2FITEM,2,1FITEM,2,-364SF,P51X,PRES,PDOWNALLSEL,ALLNPLOTLSWRITE,2,SAVELSSOLVE,1,2,1,FINISH/POST1SET,FIRSTPRRSOL,/PBC,ALL, ,0/REP/EDGE,1,1,45/GLINE,1,0PLDISP,1/GSAVE,'pldisp','gsa',' ' !*/ANGLE,1,120,YM,1/REPLOT/EFACET,1PLNSOL, S,INT, 0,1.0/GSAVE,'plnsol','gsa',' 'SET,NEXTPRRSOL,/GRESUME,'pldisp','gsa',' ' PLDISP,1/GRESUME,'plnsol','gsa',' ' !*/EFACET,1PLNSOL, S,INT, 0,1.0wprot,0,0,-0.067/GRAPHICS,POWER!*/TYPE,1,5/CPLANE,1/SHADE,1,1/HBC,1,0/REPLOT!*/VIEW, 1 ,WP/REP,FAST/REPLOT,RESIZE/VIEW,1,1,2,3/ANG,1/REP,FASTFINISH! /EXIT,NOSAV。