卷扬机使用说明书

5吨电动卷扬机设计说明书

对大型卷扬机安装了电器连锁装置,以保证绝对安全可靠。

3.发展手提式卷扬机为提高机械化水平,减轻工人劳动强度,国外大力发展小型手提式卷扬机,如以汽车蓄电池为动力的直流电动小型卷扬机,其电压为12 V,质量为7.7—15.4 kg,拉力为3336—13344 N。

4.大力发展不带动力源装置的卷扬机欧美国家非常重视发展借助汽车和拖拉机动力的卷扬机。

此种卷扬机结构简单,有一个卷筒和一个变速箱即可。

第1章卷扬机的设计参数本设计卷扬机设计的主要参数有:额定起升重量:5吨起升高度:14米起升速度:12.5米/分卷扬机用途:用于5吨桥式吊车起升机构工作条件:频繁启动粉尘量大设计的主要要求:本设计为有轨运行机构;电动机轴到减速器高速轴山齿轮链接盘连接: 起升机构的制动器必须采用常闭式的;制动力矩应保证有足够的制动安全系数。

第2章卷扬机的整体结构概述§2.1电动卷扬机基本结构电动卷扬机III于操作方法不同,其结构相差很大。

我们将其分为电控卷扬机和溜放型卷扬机两类。

§2.1.1电控卷扬机此类卷扬机通过通电或断电以实现卷扬机的工作或制动。

物料的提升或下降曲电动机的正反转来实现,操作简单方便。

其制动型式主要有电磁铁制动器和锥形转子电动机两类,下面就这两种制动型式卷扬机的常见类型作介绍。

此类卷扬机大多是单卷筒的。

§2.1.2带有电磁铁制动器的卷扬机1.圆柱齿轮减速器快速卷扬机,如图2-1。

图2-1圆柱齿轮减速器快速卷扬机简图1 —电动机2—联轴器3—制动器4—减速器5—联轴器6—卷筒7—底座8—支架2.蜗杆减速器慢速卷扬机。

3.圆柱齿轮减速器加开式齿轮传动的卷扬机,如图2-2。

图2-2圆柱齿轮减速器加开式齿轮传功的卷场机简图1 —电动机2—联轴器3—制动器4—减速器5—开式齿轮传动6—卷筒4.蜗杆减速器加开式齿轮传动的卷扬机。

对一些起重量大的卷扬机,为使钢丝绳在卷简上排列整齐,需要安装排绳器。

卷扬机通用说明书-英文

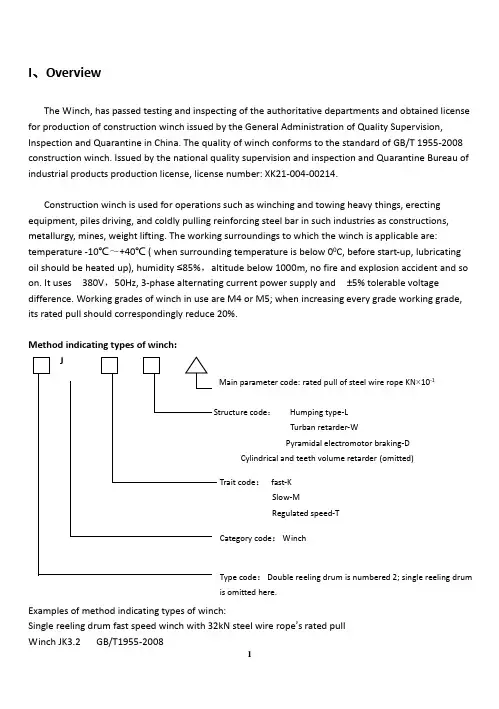

I、OverviewThe Winch, has passed testing and inspecting of the authoritative departments and obtained license for production of construction winch issued by the General Administration of Quality Supervision, Inspection and Quarantine in China. The quality of winch conforms to the standard of GB/T 1955-2008 construction winch. Issued by the national quality supervision and inspection and Quarantine Bureau of industrial products production license, license number: XK21-004-00214.Construction winch is used for operations such as winching and towing heavy things, erecting equipment, piles driving, and coldly pulling reinforcing steel bar in such industries as constructions, metallurgy, mines, weight lifting. The working surroundings to which the winch is applicable are: temperature -10℃~+40℃ ( when surrounding temperature is below 00C, before start-up, lubricating oil should be heated up), humidity ≤85%,altitude below 1000m, no fire and explosion accident and so on. It uses 380V,50Hz, 3-phase alternating current power supply and ±5% tolerable voltage difference. Working grades of winch in use are M4 or M5; when increasing every grade working grade, its rated pull should correspondingly reduce 20%.Method indicating types of winch:Examples of method indicating types of winch:Single reeling drum fast speed winch with 32kN steel wire rope’s rated pullWinch JK3.2 GB/T1955-2008Single reeling drum slow speed winch with 50kN steel wire rope’s rated pullWinch JM5 GB/T1955-2008II、Structure and Working PrincipleStructure Figure maps of JK fast speed winch and JM slow speed winch can be seen in Figure 1 and Figure 2 respectively. Electrically-controlled winch implements its operations or braking through connecting or disconnecting power supply. When connecting electrical source, band-type brake of normally-closed brake(3)arrester will loose; electromotor(1)starts up; Then shaft coupling(2)drives speed retarder(5); After reducing the speed of the speed retarder, through the drive of connecting tray(6)or open-style gear wheel(6), the reeling drum(7)starts to work. When stopping machine, disconnect electrical source and normally-closed brake arrester will hold the braking wheel to make the reeling drum stop revolving, then the winch stops its running. Rising or falling of materials is reached through clockwise revolving and counterclockwise revolving.1-motor 2-shaft coupling 3-brake 4-cam control 5-decelerator 6-inner gear connecting tray 7-reeling drum 8-chassis 1-motor 2- shaft coupling 3- brake 4- cam control 5- deceleraror 6-open-style gear wheel 7-reeling drum 8-chassisFigure 1 JK type electrically-controlled fast speed winch Figure Figure 2 JM type electrically-controlled slow speed winch FigureIII、Technical Parameters tableDiameter(mm)Φ21.5 Φ21.5 Φ26 Φ26 Φ30Electromoto r Type YZR160L-6YZR160L-6 YZR180L-6YZR180L-6 YZR200L-6Power(kW)11 11 15 15 22Brake arrester YWZ B-300/45 YWZ B-300/45YWZ B-300/90YWZ B-300/90 YWZ B-300/90Appearance measurements(length×width × height) 1235×1230×8051620×1260×9451075×1598×9852090×1475×9562090×1475×956Weight of entire machine(kg)1560 1800 2650 2900 3000IV、Installation and Testing1. When installing, dismantling and moving the winch, it is necessary to keep stable and being not overly oblique without any clashes and fierce vibration.2. Installation of winchIts installation should be completed by professionals. The ground for installing the winch should be leveled off and much solid. The connection between winch and base should be reliable.2.1 When mobile using, fix the winch to timber sleepers block, and reliably and tightly connect timber block and chassis to ground anchor with steel wire rope. Be aware of avoiding any looseness.(See Figure 3)Figure 3 horizontal ground anchorSteel wire rope Steel wire ropeRound bar WinchThis installing method is suitable to winch being less than 3 tons. Concrete measurements forinstallation need to refer to such conditions as soil quality, soil specific gravity and earth stamina, and are determined by ground anchor standard pictures appropriate to local use.2.2 When using in a fixed place, make concrete groundwork, and find the horizontal lines by using a gradienter, and leave in advance a square-type hole with a section of 20x20(cm 2) (See Figure 4); number of hole is decided by foundation bolt of the winch(see Figure 4).At first, fixing the foundation bolt, then inject concrete into holes; after ossifying, evenly tighten the nuts. If there are rooms between chassis and lower interface, add adjusting mat so as to prevent partly deforming of chassis. Hole depth of foundation should be determined according to local geological condition and type of winch(L,L1 value in the table only for reference).Figure 4 Layout Figure of concrete foundation boltType Parameter JK0.5 JK1 JK1.6 JK2 JK3.2 JK5 JK8 A(mm) 667 667 956 956 1270 1560 1550 B(mm) 420 420 560 560 900 1090 1218 C(mm) 0 0 0 0 0 545 579 n-d(mm) 4×Φ14 4×Φ14 4×Φ17 4×Φ17 4×Φ22 6×Φ25 6×Φ32 L1(mm) 400 400 450 450 600 700 850 L(mm) 350 350 300 300540640780TypeParameter JM1 JM1.6 JM2 JM3.2(4-bearing style) JM3.2(open-style gear wheel) A(mm)667956956968920motor central lined e c e l e r a t o r c e n t r a l l i n eReeling drum central line2.3 The running direction of steel wire rope of the winch usually is horizontal; the direction of running rope is in accordance with actual situation, from the underside of reeling drum or other directions. The deviation angle αvalue of horizontal reeling and extending of steel wire rope must in conformity with stipulations in Table 1. L value should normally equal 20 times Bt width of reeling drum, but ensuring αvalue to be in line with Table 1, and the location of guiding pulley (see Table 2)to be on vertical bisector (see Figure 5). The ratio of Pitch diameter of all pulleys and diameter of steel wire rope should be less than stipulations in Table 2.2.4 The winch working in the air should be sheltered by a rainproof canopy, which can ’t obstruct operators ’ eyesight and operators should be able to see the commanders and dragging objects. 2.5 Metal shells of structure and electrical devices of the winch should be evenly connected to the earth. Earth connecting resistance should not more than 4Ω.Choosing and installing of earth connecting devices should conform to stipulations of GB/T232. 2.6 When used for winching heavy things, the winch should be fixed with ascending overtravel limit switch.2.7 Notch panel type pulley is prohibited from using when choosing guiding pulley.2.8 The safety circling number of steel wire rope on reeling drum shouldn ’t be less than 3 circles. The end of steel wire rope should be reliably fixed. In order to ensure safety the distance from outside layer of steel wire rope to outside edge of side board of reeling drum should not be less than steel wire rope ’s diameter.2.9 The connection area between brake block andbrake wheel shouldn ’t be less than 80% of the total area. When loosening braking, the brake block mustbe completely separated from braking, and maintain certain clearance. The value of clearance are 1~2.5mm between brake strap and brake wheel, 0.25~1mm between brake block and brake wheel.V 、Choosing of Steel Wire Rope1. Steel wire rope used for winch should conform to stipulations of GB/T20118 and linear contact lay wire rope should be a priority for use. Safety parameter of steel wire rope (specific value between minimum breaking force of steel wire rope and rated load of winch) shouldn ’t be less than Ka value stipulated in Table 3.Table 3 Safety parameter Ka of steel wire rope Grade of workingM1M2 M3 M4 M5 M6 M7 M8 Safety parameter Ka3.15 3.353.554.04.55.67.19.02. The size of pulley rope slot should be about 10% more than nominal diameter of steel wire rope.3. Steel wire rope should have good lubrication; usually adopt lubricating oil with moderate and lowReeling drumGuiding rope pulley Figure 5viscidity; domestically-made oil for steel wire rope is recommended for use.4. In the environment of outdoor, humidity and erosion medium existing, choose galvanized steel wire rope.5. If finding one of the following cases, please use new wire rope.5.1 Surface layer wire diameter of steel wire rope was worn down and erosion rate is up to 40% of its original diameter.5.2 Diameter of steel wire rope has reduced 7%.5.3 Stranded or broken wire is discovered.5.4 The core cord of the entire steel wire rope has been squeezed out.5.5 For any things not detailed, inspect and discard as useless according to stipulations of GB/T 5972. VI、Regulations for OperationPreparation:1. Construction winch should be operated by workers who have been well-trained and are familiar with regulations for safe operation.2. Check out oil quantity and purity in speed retarder and brake arrester and see if there is oil in all lubricating parts (see page 9, Table for machine lubricating scope)3.Confirm the type, scope applied, working grade, rated load, rated speed, rope capacity etc. of the winch are in conformity with conditions for using. Overloading is strictly prohibited.4. Check if steel wire rope has been fixed reliably, and if there are stranded or broken threads in steel wire rope.5. If the electrical device consists of motor, control box and alternating current cam controller, handlebar should be placed on “0”positon.6. Before operating winch, firstly make a test-run for 5 minutes. After satisfying the following requirements, normal operation can be conducted.6.1 Brake is smooth and steady, safe and reliable; its actions are accurate and flexible (regulating method of brake arrester can be seen in detail in users’ manual of brake arrester.6.2 Actions of all driving parts and gliding parts are flexible without such phenomena as overly big noise and being stuck.6.3 No any looseness in all linked partsOperation:1. Turn on electrical source, according needed direction, turn the handwheel of cam control; after running of electromotor is smooth and steady, and turn to next position, up to maximum gear.2.Under normal circumstances, to stop the machine just needs to rotate the brake arrester to“0”position; at that time, resistor’s resistance will be gradually added to rotor circuit, rotating speed of electromotor will decrease, hydraulic pressure brake arrester starts to work, and then main device stops running.3.When in use of weight lifting electrical device, cam control can’t regulate speed; it only can be usedto switch resistance buffer start and can’t work on lower gear; it is required to regularly inspect dampproof condition of the electrical device. Principle drawing of electrical device can be seen in Appendix 2Requirements for use:1. The voltage of motor shouldn’t exceed 5% of rated value. The electromotor cannot be used in exceeding its continuous electric connection rate and maximum number of starting up.2. Don’t connect the braking reversely; when wanting to realize humping placement, don’t manually open the power-controlled brake controller.3. When the winch is in the state of working, operators cannot be off the operating position.4. Do not take the liberty of transforming the winch.5. Maximum load, withstood by datum layer and steel wire rope in various layers within datum layer, is the rated load. Maximum load, withstood by steel wire rope in various levels outside the benchmark level, is less than rated load. For added one layer, the pull force will relatively reduce 10% of rated pull force.6. When operating the host, steel wire rope can’t be dragged running on the ground; if necessary, install supporting roller or grooved roller. When steel wire rope crosses driveways, protective devices should be added so as to avoid persons treading on it and cars crushing on it. It is prohibited for people to cross the running steel wire rope or pass before the winch. Carrying workers on the site by the winch is not allowed.7. When winching by using many winchs, traction speed and weightlifting capability of winchs must be identical. United directing, united action and synchronized operation are necessary.8.During operation, operators should focus all their attentions on working and strictly follow the rules for operation, and, under urgent and risky circumstances, immediately stop their operation against risk signals like crying and calling send out by any people. After making clear the situations, continue their operations.9. When such phenomena as abnormal mechanism, abnormal sound, failure of braking, sharply rising of bearing temperature, etc. has occurred in winch operation, immediately stop running for inspect and repair and remove breakdowns.10. The steel wire rope should be neat and tidy. When overlapping or oblique winding is found, stop the machine to cope with it. When in revolving, pulling or treading on steel wire rope by hand or feet are strictly prohibited.11. When winching heavy things but keeping load for a longer time, please close the stop stopper; before running the machine again, loosen the stop stopper.12. If running the machine with heavy things, Braking by using stop stopper is strictly prohibited, use brake and gradually add force for braking. If adding force abruptly and forcefully, the machine will be possibly damaged.13. After ending work, heavy things must be placed on the ground; hanging heavy things in the air is not allowed.14. Before getting off duty, clean and maintain the winch, cut off the power supply and lock the switch box.VII、Repair and Maintenance1. The driving part of the winch such as reeling drum bearing, hinge of brake arrester and shaft pin of various parts, should be added some lubricant once before each shift’s operation. Every 48 hours of operation by using steel wire rope, the guiding pulley should be lubricated once. The height reached by lubricating oil surface in decelerator box should be within the scope of dipstick; under normal circumstance, check it once every week, and replace it once every half a year.2. After the winch’s running for 300 hours, carry out grade 1 maintenance, lubricate the entire machine again, check and adjust the brake , check the decelerator and replace with or add new lubricating oil to the height designated of oil surface.3. After the winch’s running for an accumulative working of 600 hours, carry out grade 2 maintenance and measure insulated resistance of electromotor; check the state of wearing down for rubbed surface, all involving parts, and rubber loop of connecting parts; check the state of all parts of gear wheel bearing and electrical components. If affecting the use of machine, please replace them at once.4. Every day, running of winch should be recorded in the list for recording running state; the contents of recording daily include working hours and load, and inspection, repair, adjustment and so on.5. Inspection and maintenance of winch should in conformity with the following regulations.5.1 The winch should have everyday inspection and regular inspection. Cycle, items, method and standard of inspection should according to regulations in appendix 1. When frequently using or using ina special place or environment, inspection of winch should add other items.5.2 Inspection, maintenance and repair should be implemented by professionals.5.3 During inspection and repair, pay attention to people’s safety. Apart from items for inspection or repair carried out necessarily in a state of starting up, inspection and repair of other items must be carried out after discharging load, shutting off power supply and locking up the power switch. The items for inspection and repair in a state of starting up, should be carried out at least by two people; one person among them should take charge of watching for safety of the other personnel, and be able to immediately stop the winch’s running under any special circumstances.5.4 After maintenance and repair, please inspect the winch according to inspecting items stipulated in Appendix 1.5.5 After the winch reached the aggregate working hours identified according to its using conditions, it should not be continuously used6. When transporting and maintaining, the winch should be placed in a dry locality. Good dampproof and antisepticising measures should be applied to all parts of it.7. When not using the winch for a long-term period, cut off its power supply; it should be kept in a place which is dry, ventilating, rainproof and without caustic gases; and appropriate antirust disposal should be applied to it.8. If one of the following cases occurs, reeling drum should be discarded as useless.8.1 Cracks or broken edge8.2 The wear abrasion amount of the husk thickness of reeling drum has reached 10% of original thickness.9. Parts of brake and clutch should be replaced if one of the following occurs.9.1 Cracks have occurred on any parts.9.2 The wear abrasion degree for friction liner of brake arrester has reached 50% of its original thickness.9.3 The wear abrasion degree of brake wheel has been up to 2~3mm. (Big diameter is opposed to big value, small diameter to small value)9.4 Plastic deformations related to spring9.5 The wear abrasion degree of shaft pin and shaft hole diameter has been up to 5% of its original diameter.9.6 Elastic components has been damaged or severely worn down.10. When one of the following cases occurs, driving wheel should be replaced.10.1 Cracks or broken gear teeth10.2 Gear surface rippling has reached 30% of field of conjugate action, and 10% of original gear thickness.10.3 The percentage of wear abrasion degree to original gear thickness has reached the following value: 10.3.1 Closed-style gear wheel driving: 10% (grade 1); 20% (other grades)10.3.2 Open-style gear wheel driving: 30%VIII、Common Breakdowns and Handling MethodIX、Table for machine lubricating scopeX、Spare partsSerial No. Names Raw material Quantity Connected parts1 Rubber loop polyurethane 20 shaft coupling2 seal ring Oil resistant rubber 4 gearbox3 Brake shoe 1pair brake4 Carbon brush 1set motor5 bearing 2 Drum support6 Brake tank 1 brakeSpare parts imageSerial No. Names Picture for reference1 Rubber loop2 seal ring3 Brake shoe4 Carbon brush5 bearing6 Brake tankAppendix 1 Cycle, item, method and standard for examinationExamining period Items examined Examiningmethod Examining standardEveryday Onemonth Threemonths1 year√Label Eyeing Make sure thatthe label isreliably fixed √Steel wire rope’s runningrope deviation angleEyeing、MeasuringMake sure thatit conforms tostipulations intable 1√Tightening of base frameand various partsExamining thefixed boltConfirming thatit is not loose√Electricalsystem OperatingswitchCheck switch’sactionConfirming thatactions arenormal√Wiring Check the Confirming thatAppendix 2 Electrical device ’s principle drawing1、Controlling principle drawing for Y series electromotor electrical device2、Controlling principle drawing for YZR weightlifting electromotor electrical deviceNote :Z :brake KT :Cam controller RT :ResistorFalling backwardFalling backward Rising forward Rising forward。

JM5(YZR180L-8单头)卷扬机说明书

5吨慢动卷扬机一、机器的用途:5吨慢动卷扬机适用于机器和大型结构及冶金设备的安装及土木建筑工程中用来起卸或拖曳重物。

二、主要技术性能:1、产品型号JM52、钢丝绳额定拉力 50kN3、钢丝绳额定速度 4.9m/min4、卷筒直径 400 mm5、卷筒宽度 840mm6、总传动比 226.287、钢丝绳规格6×19S+IWR—20—17708、卷筒容绳量 250m9、钢丝绳缠绕层数5层10、制动器YWZ3 250/4511、电动机型号 YZR180L—8 FC=25%功率11kW转数 700r/min电压 380V12、机器外形尺寸(长×宽×高) 1869×1813×933 mm13、机器重量(包括电气)约1770kg三、 机器结构:本机器由机座、蜗轮减速机、传动齿轮、卷筒、制动器和电器等部分构成,全部机件安装在机座上。

电动机通过弹性联轴器经蜗轮减速机和一级开式园柱正齿轮带动卷筒旋转缠绕钢丝绳,钢丝绳应由卷筒下方绕入。

本机器采用液压制动器,能自动制动。

电器全部安装在电器箱内。

机器的全部动作是由可逆鼓形控制器的手轮控制,操作简单方便。

本机带有手摇装置,电机驱动时应绝对保证摇把与减速器轴头的完全脱离。

四、 机器的操作和注意事项:1、工作前先检查重物之重量,应在机器性能规定的范围内,再检查钢丝绳及其捆扎情况。

并在减速箱内注油。

2、检查机器的固定及各部联接的牢固性,并检查电器接线及接地的正确性。

3、检查控制器手轮处在“0”位后,合上控气开关,这时指示灯明亮,以示接通电源。

然后按起动按钮,使交流接触器吸合,再以顺时针方向慢慢地转动鼓形控制器的手轮至最后一挡,使电机启动运转,机器既进行工作。

需要停止时将手轮转回“0”位,制动器自动刹车,机器停止转动。

以逆时针方向转动手轮,机器即可反转。

切勿在起动中途时突然反向。

在紧急状态时,可按动停止按钮开关,交流接触器脱开,以使电机及其它电器与电源立即切断。

卷扬机说明书

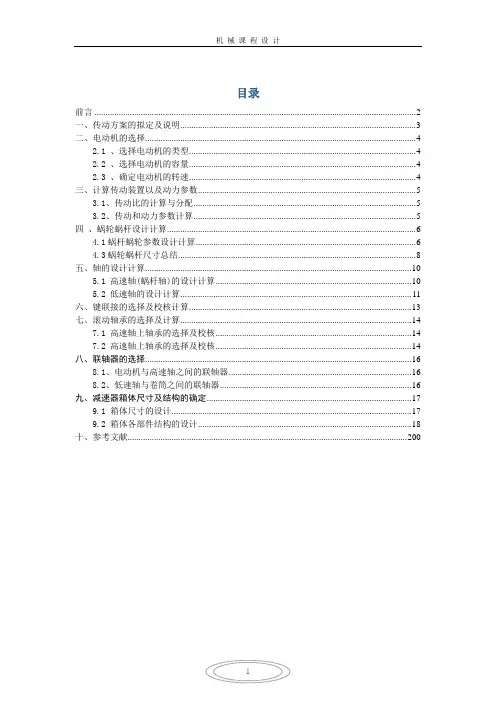

目录前言 (2)一、传动方案的拟定及说明 (3)二、电动机的选择 (4)2.1 、选择电动机的类型 (4)2.2 、选择电动机的容量 (4)2.3 、确定电动机的转速 (4)三、计算传动装置以及动力参数 (5)3.1、传动比的计算与分配 (5)3.2、传动和动力参数计算 (5)四、蜗轮蜗杆设计计算 (6)4.1蜗杆蜗轮参数设计计算 (6)4.3蜗轮蜗杆尺寸总结 (8)五、轴的设计计算 (10)5.1 高速轴(蜗杆轴)的设计计算 (10)5.2 低速轴的设计计算 (11)六、键联接的选择及校核计算 (13)七、滚动轴承的选择及计算 (14)7.1 高速轴上轴承的选择及校核 (14)7.2 高速轴上轴承的选择及校核 (14)八、联轴器的选择 (16)8.1、电动机与高速轴之间的联轴器 (16)8.2、低速轴与卷筒之间的联轴器 (16)九、减速器箱体尺寸及结构的确定 (17)9.1 箱体尺寸的设计 (17)9.2 箱体各部件结构的设计 (18)十、参考文献 (200)前言经过在2011年6月13日-2011年7月1日为期三周的机械设计课程设计,终于完成了这项宏大的工程。

在这为期三周的设计中,使我们了解到课程设计是考察学生全面在掌握基本理论知识的重要环节,根据学院的教学环节,。

本次是设计一个卷扬机减速器,减速器是用于电动机和工作机之间的独立的闭式传动装置。

本减速器属单级蜗杆减速器(电机——联轴器——减速器——联轴器——带式运输机),在袁逸萍老师指导下独立完成的。

该课程设计内容包括:任务设计书,参数选择,传动装置总体设计,电动机的选择,运动参数计算,蜗轮蜗杆传动设计,蜗杆、蜗轮的基本尺寸设计,蜗轮轴的尺寸设计与校核,减速器箱体的结构设计,减速器其他零件的选择,减速器的润滑等和装配图A0图纸一张、零件图A3图纸4张(包括蜗杆轴与蜗轮)。

设计参数的确定和方案的选择通过查询有关资料所得。

该减速器的设计基本上符合生产设计要求,限于作者初学水平,错误及不妥之处望老师批评指正。

JK8F.2508卷扬机说明书

JK8F.2508 单筒快速卷扬机一、按用户要求设计制造二、主要技术性能1、拉力 80kN2、额定速度1-25m/min3、卷筒底径Ф744mm4、卷筒宽度 907 mm5、总速比i=92.216、钢丝绳规格6×37+FC—26—17707、容绳量 70m(1层)8、减速机ZQD85-92.219、制动器2-YWZ3B—315/9010、电动机型号 YZP250M2-6 S3 40% IP54功率 45kW额定转速 982r/min电压 380V11、主令:LKT812、机器外廓尺寸(长×宽×高)2728×2271×114913、机器重量 约3940kg三、机器的结构本机由电动机、联轴器、制动器、减速机、卷筒、松绳装置及底盘等组成。

电机经联轴器、减速机驱动卷筒旋转并缠绕钢丝绳。

钢丝绳应从卷筒上方水平向外出绳。

本机采用双制动装置;采用YZP系列起重电机。

四、机器的操作和注意事项1、工作前,先检查重物之重量应在机器拉力范围以内,检查钢丝绳及其捆扎情况。

2、检查机器的固定及各部联接的牢固性,电器接线及接地的正确性,以及在减速机内注油。

3、检查控制开关,闭合闸刀,按下启动按扭,机器开始运转,按停止按扭,电机停止转动,同时制动器自动刹车。

4、落下重物时,防止钢丝绳张力松懈,在卷筒上保留的钢丝绳不少于三圈。

5、按要求定期加油换油,工作前应空转3—5分钟。

机器润滑范围1、制动器各连杆活动轴(用油壶注油)HJ—30(视需而定)2、轴承(旋盖式油杯)Ⅲ号润滑油脂(每班一次)3、减速机内(箱内换油)齿轮油HL20冬、HL30夏(每季一次)4、卷筒表面(在工作表面涂油)Ⅲ号润滑油脂(视需而定)5、钢绳(用沾油的布擦油)Ⅲ号润滑油脂(视需而定)6、电动机轴承(向滚珠轴承体壳注油)Ⅲ号润滑油脂(视需而定)天津华天传动设备有限公司产品出厂合格证明书产品名称:八吨单筒快速卷扬机产品型号: JK8F.2508出厂编号:本机经检验:拉力、绳速,刹车下滑量、工作电压、电流及摩擦部位温度,均符合GB/T 1955—2002《建筑卷扬机》的相关规定。

SC200、200使用说明书内容

SC200/200多功能施工升降机(变频控制、水塔中应用)使用说明中国建筑科学研究院建筑机械化研究分院廊坊凯博新技术开发公司书目 录1、概述及特点····························1 2、性能参数表····························1 3、构造原理简介··························3 4、升降机的安装··························11 5、升降机使用之前························21 6、升降机的操作··························22 7、升降机的润滑··························24 8、升降机的保养和维修····················24 9、调整及磨损极限························30 10、吊笼坠落试验··························33 11、防坠安全器····························33 12、升降机的拆卸··························36 13、主要易损件明细表······················37 14、主要外构件明细表······················37 15、电器系统说明··························381、概述及特点SC200/200多功能升降机是中国建筑科学研究院建筑机械研究分院与廊坊凯博新技术开发公司共同开发研制的新产品,在国内属首创。

卷扬机说明书

卷扬机说明书(总6页)--本页仅作为文档封面,使用时请直接删除即可----内页可以根据需求调整合适字体及大小--QPQ型卷扬式啓闭机安装使用说明书国电南京自动化股份有限公司用途及特征:本系列启闭机为固定式平面闸门卷扬式启闭机,机架采用工字形结构,机加上装有起升机构。

适用于各种水利工程平面闸门的启闭,在一定的条件下,也可启闭孤形闸门。

其特征是结构紧凑,承载能力大,运行平稳可靠,安装维修方便,工程造价低。

一、主要技术参数启门力电动机起升高度制动器起升速度减速器吊距开式齿轮卷筒直径总传动比钢丝绳最大外形尺寸滑轮倍率工作电源交流380V 50HZ卷筒装置尺寸质量机架最大件尺寸质量二、安装1、安装前的检查(1)检查该启闭机各零部件是否齐全及运输存放过程中有无损伤和丢失。

(2)仔细清除零部件上灰尘,油污或铁屑等杂物,必需时应解体清洗。

2、整机安装(1)启闭机安装应根据起吊中心线找正,其纵横向中心线偏差不应≥3mm;高程偏差不应超过±5mm;水平偏差应大于1000。

(2)钢丝绳型号、长度、穿绕方式、固定螺栓数量、规格均应符合图纸要求。

钢丝绳不应有硬弯曲,纽结和砸压扁平状等缺陷,钢丝绳长度不得有接长。

表面应涂防锈油脂。

钢丝绳固定牢固可靠,当全部放下扬程后,留在卷筒上的钢丝绳每侧应≥圈数。

(3)减速器加油前,应清洗检查,减速器润滑位与油标尺的刻度应相符合。

(4)制动器的调整应灵活可靠,闸瓦退距制动轮的摆动值应符合要求。

制动轮的摩擦表面不星有油污。

(5)40T(包括40T)以上的启闭机设置负何控制器的平衡杠必须处于水平位置。

(6)电器的安装及接线应无误,所有电器保护装置(包括零位保护),负何保护等应动作灵活可靠。

三、启闭机的试动转1、启闭机试动前应进行下列检查:(1)所有电器及动力回路的接线应正确、整齐,有良好的绝缘和可靠的接地。

(2)检查所有机械部件、连接部件和各种保护装置及润滑系统,注油情况应符合要求。

JM0.7F.0301卷扬机说明书

JM0.7F.0301单筒慢速卷扬机一、按用户要求设计、制造:二、主要技术性能:1.卷扬能力:7kN2.卷扬速度:3.01m/min3.卷筒直径: 185 mm4.卷筒宽度:80mm5.总速比: i=2896. 钢丝绳:6×37+FC—9.3—17707. 最大容绳量: 10m(有效行程2m)8. 钢丝绳缠绕层数:2层9. 减速机:型号:XWEDC0.75—53—1/289(电机双出) 10. 电动机:型式YEJ802—4 (电机双出)功率 0.75kW转数 1440 r/min电压 380V11.主令控制器DXZ—4/1(1:13)12.机器外廓尺寸 918×535×48013.机器重量约140kg三、机器的结构:本机由机座、电机、减速机、卷筒、主令控制器等部分构成。

全部机件装在机座上,电动机经减速机而驱动卷筒旋转缠绕钢丝绳。

钢丝绳应由卷筒下方绕出。

自动刹车,机器的全部工作是由按扭开关控制,操作非常简单方便。

卷筒后端装有多功能行程控制器,可做上下极限限位使用。

电机后端有出轴,停电时可供手摇。

当电机驱动时必须绝对保证手轮与电机轴头的分离。

四、机器的操作和注意事项:1.工作前,先检查重物之重量应在机器性能规定的范围内,检查钢丝绳及其捆扎情况。

2.检查机器的固定及各部联接的牢固性,电器接线及接地的正确性。

3.落下重物时,防止钢丝绳张力松懈,在卷筒上保留的钢丝绳不少于三圈。

4.按要求定期加油换油,工作前应空转3~5分钟。

五、 机器润滑范围1.减速机内(箱内换油)工业极压齿轮油 70#。

2.卷筒表面(在工作表面涂油)Ⅲ号润滑油脂(视需而定)3.钢丝绳(用沾油的布擦油)Ⅲ号润滑油脂(视需而定)六、 加换油制度第一次加油运转两周后应更换新油,并将内部油污冲净。

以后可每3―6个月更换一次。

若环境温度较高或潮湿时应适当缩短换油时间。

运转中减速机体内储油量必须保持规定油面高度,不适过多或过少。

卷扬机排绳机构说明书

1 绪论1.1建筑卷扬机的简介随着微机技术在世界的改变及在电路中的智能化,PLC在电路中的运用得到了广泛的应用,而它可靠性高、能经受恶劣环境的考验、使用极方便的巨大优越性,迅速占领工业自控领域,成为工业自动控制的首选产品,与机动人、CDM/CAM 并称为工业生产自动化的三大支柱。

1.2设计方法或技术路线:1.2.1设计要求1)设计一台带排绳机构的卷扬机2)要求能提升5吨的物体1.2.2各零部件的设计1)电动机的功率计算及选用:2)减速箱的参数设计与选用:减速箱的选择主要根据齿面性能,传动比等方面进行选择。

本设计中选择硬齿面及合适的传动比减速器作为卷扬机的选型方案,其传动比需满足设计要求。

3)卷扬机滚筒及排绳机构的设计:卷扬机滚筒的选择主要包括结构设计和强度设计,强度设计主要是考虑弯曲校核、扭矩校核和寿命校核。

4)电动机控制线路的设计及卷扬机钢丝绳的选择:卷扬机绳径的选择依据是JG/T503 1—93《建筑卷扬机设计规范》4.1.1条,根据安全系数来确定的。

控制线路的设计实现三相异步电机的正、反转、快转和慢转的要求。

1.2.3拟采用的方法或技术路线1)动力及传动部分采用合适的三相异步电机,通过减速箱驱动卷扬机转动2)排绳机构设计出排绳机构,以减速箱齿轮提供的动力,驱动排绳机构往复直线运动,使得钢丝绳能在卷扬机卷筒上整齐排列3)卷扬机对卷扬机滚筒进行结构设计和强度、寿命校核4)采用继电器和手动按钮设计三相异步电机的正、反转、快转和慢转,完成控制面板的设计1.3本设计的意义随着卷扬机在工业的广泛应用,所以本设计就是为了更好地改善已往卷扬机在工业中的缺点,如:钢丝绳在工作中由于受到挤压而使其使用寿命下降,而采用排绳机构进行均匀排绳从而提高了钢丝绳的使用寿命。

同样在控制电路中,采用plc来进行控制这样能减少电路中的繁锁,跟据科学技术要从智能化和微型化进行发展。

从而改善了采用继电器来控制电路。

并增强了控制的实时性,更能保证精度要求的产品质量。

卷扬机设计说明书0

目录摘要 (Ⅰ)第一章绪论 (1)卷扬机的分类及特性 (1)卷扬机的常见类型 (3)1.3国内卷扬机开展概况 (4)第二章卷扬机的设计参数 (5)第三章主体零件的设计 (12)3.1钢丝绳的选择 (12)3.2卷筒的结构设计及尺寸确定 (15)卷筒轴的设计计算 (20)3.4电动机选择 (26)3.5减速器的设计计算 (27)3.6制动器,联轴器的选择 (36)第四章小车行走机构设计 (38)4.1轨道 (38)4.2车轮与车轮组 (38)4.3车轮直径的计算 (38)总结 (40)致谢 (41)参考文献 (42)第一章绪论垂直提升、水平或倾斜拽引重物。

卷扬机分为手动卷扬机和电动卷扬机两种。

现在以电动卷扬机为主。

电动卷扬机由电动机、联轴节、制动器、齿轮箱和卷筒组成,共同安装在机架上。

对于起升高度和装卸量大工作频繁的情况,调速性能好,能令空钩快速下降。

对安装就位或敏感的物料,能用较小速度。

随着社会的开展,机械将会越来越取代人力,这也是机械行业飞速开展的后果,在机械的开展历史中,新机械的创造有着举足轻重的作用。

但是,那些很久以前就被利用生产并一直延续到今天的机械,更是起着不可替代的作用,卷扬机就是一例。

卷扬机的开展就像其他机械一样,从开始的简单到现在的复杂,从以前的机械动力到现在的电力动力,从以前的人工操作到现在的电脑操作甚至智能操作。

卷扬机又称绞车,是起重垂直运输机械的重要组成局部,配合井架、桅杆、滑轮组等辅助设备,用来提升物料、安装设备等作业。

由于它结构简单、搬运安装灵活、操作方便、维护保养简单、使用本钱低、对作业环境适应能力强等特点,广泛应用于冶金起重、建筑、水利作业等方面。

本设计就传统的卷扬机说起,一直到现在以及将来的开展。

卷扬机是起重垂直运输机械的重要组成局部,配合井〔门〕架、桅杆、滑轮组等辅助设备,用来提升物料、安装设备等作业。

由于它结构简单、操作方便、维护保养简单、使用本钱低、可靠性高等优点。