IECEx认证体系基本介绍

IECEx 相关设备认证系统 - Ex ‘s’ 设备评估说明书

IECEx OD 233Edition 2.0 2017-02IECExIEC System for Certification to Standards relating to Equipment for use in Explosive Atmospheres (IECEx System)IECEx Operational DocumentIECEx Certified Equipment Scheme - Assessment of Ex “s” EquipmentO D 233: 2017 (e )Copyright © 2017 IEC, Geneva, SwitzerlandAll rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or IEC's member National Committee in the country of the requester.If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local IEC member National Committee for further information.IEC Central Office3, rue de VarembéCH-1211 Geneva 20SwitzerlandEmail:*************Web: www.iec.chAbout the IECThe International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes International Standards for all electrical, electronic and related technologies.About IEC publicationsThe technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the latest edition, a corrigenda or an amendment might have been published.▪ Catalogue of IEC publications:www.iec.ch/searchpubThe IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text,technical committee). It also gives information on projects, withdrawn and replaced publications.▪ IEC Just Published: www.iec.ch/online_news/justpubStay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available on-line and also by email.▪ Electropedia: The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical Vocabulary online.▪ Customer Service Centre: www.iec.ch/webstore/custservIf you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service Centre FAQ or contact us:Email: **********Tel.: +41 22 919 02 11Fax: +41 22 919 03 00Edition 2.0 2017-02IECEx Certified Equipment Scheme - Assessment of Ex “s” EquipmentINTERNATIONALELECTROTECHNICALCOMMISSIONINTERNATIONAL ELECTROTECHNICAL COMMISSION____________IECEx Operational Document 233IECEx Certified Equipment SchemeAssessment of Ex “s” EquipmentINTRODUCTIONThis IECEx Operational Document OD 233 provides a framework within the IECEx Equipment Certification Scheme for the procedures to be followed when an ExCB receives an application for certification to the requirements of IEC 60079-33 Explosive atmospheres - Part 33: Equipment Protection by special protection “s”, through to the point of delivery of the certificate and for subsequent surveillance of the manufacturing process.Document HistoryDate 2015 03 SummaryOriginal Issue (Version 1)2017 02 Edition 2.0 – Removal of previous Annex B and reference to IEC 60079-33 for competence of verifiers and removal of the IECExExecutive from the process according to comments received byclose of voting on ExMC/1200/DV.Contact address:IECEx Secretariat Tel: +61 2 4628 4690Level 33, 264 George StreetSydney NSW 2000 E-mail:**************Australia Web Site: 1. Purpose and ScopeThe purpose of this document is to provide a framework within the IECEx Equipment Certification Scheme for the procedures to be followed when an ExCB receives an application for certification to the requirements of IEC 60079-33 Explosive atmospheres - Part 33: Equipment Protection by special protection “s”, through to the point of delivery of the certificate and for subsequent surveillance of the manufacturing process.The Ex “s” Standard IEC 60079-33 was developed by IEC TC31 in response to a request from industry to enable a degree of innovation in the way that products can be designed, whilst still providing a level of protection equivalent to that obtainable from the established types of protection. This issue was raised within the IECEx Management Committee and support for an International Standard conveyed to IEC TC 31.IEC 60079-33 gives the technical requirements to be met by the equipment to be certified and introduces the notion of more than one Independent Verifierindependent verifier responsible for verification of conformity to the standard. It also outlines the role of one or more “independent verifiers” in the conformity assessment process. (The Independent VerifiersThe independent verifiers are referenced in IEC 60079-33 as Verifier 1, Verifier 2 and Verifier 3independent verifier (1), independent verifier (2) and independent verifier (3).respectively).This Operational Document confirms that, for IECEx purposes, an ExCB must identify experts that are classified as “Independent Verifiers”independent verifiers in accordance with and as defined by IEC 60079-33, noting that up to three Independent Verifiersindependent verifers may be required. These independent verifiers maybe may be drawn from experts within or outside both the ExCB and their integral or associated ExTL(s) ExCBs shall have documented procedures of the process to be followed by those verifiers when operating within the IECEx Equipment Certification Scheme.This document augments and should be read in conjunction with OD 009 as it contains details and requirements additional to those in OD 009.Annex A to this document provides the procedure to be used when assessing the applications from an ExCB and its associated ExTL to operate to this Operational Document.Annex B to this document provides the specific minimum criteria to be used when assessing the competence of an expert person as Independent Verifier 1, Independent Verifier 2 and Independent Verifier 3 to operate to this Operational Document.2. General PrincipleEx “s” standard IEC 60079-33 provides a framework to demonstrate how essential safety requirements can be met by an innovative design. But before proceeding to special protection “s”, a manufacturer should consider the possibilities for design of electrical equipment using existing techniques and methods with the following order of preference:- Recognized types of protection- Combination of recognized types of protection- Methods provided by existing standard IEC 60079-26- Other applicable international standards recognized by the IECEx systemWhen conditions and/or requirements are not completely met by existing techniques as given above, enough documented analysis, evaluation, testing and verification arerequired to demonstrate how the essential safety requirements have been met against the claimed EPL of the equipment under assessment.According to IEC 60079-33, equipment with special protection “s” shall have levels of protection “sa” (EPL “Ma”, "Ga", “Da”), or “sb” (EPL “Mb”, "Gb", “Db”), or “sc” (EPL “Gc”, "Dc”).The number of iI ndependent vV erifiers involved in the conformity assessment process depends on the required level of protection:- One iI ndependent vV erifier for Level “sc”, this means that Verifier (1)shall be involved only.- Two independent verifiers for Level “sb”, this means that Verifier (1)as well as Verifier (2) shall be involved.- Three independent verifiers for Level “sa”, this means that Verifier (1), Verifier (2) and Verifier (3) shall be involved.ExCBs shall maintain a current list of Independent Verifiers independent verifiers as Independent Verifier 1, 2, or 3 within their own Training training records as part of a Competency competency or Task Matrix Tabletask matrix table. This matrix shall be reviewed as part of the IECEx peer assessment process.According to IEC 60079-33, there shall be a leadan independent verifier plus possible additional independent verifiers as follows:IEC EPL Gc or Dc Lead Independent independent Verifier verifier(1) onlyIEC EPL Mb, Gb or Db Lead Independent Verifierindependent ver if ier(1) and plus one additionalindependent verifier(2)IEC EPL Ma, Ga or Da Lead Independent Verifier plus two additionalindependent verif i er (1) plus independent verifier (2) plus independent verifier (3)IEC 60079-33 requires that the independent verifiers shall have had sufficient experience, including access to or involvement in the standards development process, to be aware of any currently discussed issues that might be applicable to the equipment. Familiarity with published standards alone is not considered sufficient. Accordingly the project shall be allocated for certification management purposes to an individual who has standards development experienceaccess to or involvement in the most applicable standards development for the concept for the equipment. Similar approaches shall be taken for the independent verifiers.The appointed ExCB project manager shall ensure that the work of any engineer is closely monitored in line with knowledge of developments in standards and related discussions.Where a second or third Independent Verifier is required, the appointed ExCB project manager shall select an individual who is independent but also has standards development experience.3. Procedures for the issuing of an IECEx Test and Assessment Report(ExTR)The procedure outlined in Section 2 of OD 009 is augmented as follows. The step references are as used in Section 2, with additional steps identified with additional suffix letters. Where only one Independent Verifierindependent verifier is required (i.e. for level of protection sc), the steps related to the additional independent verifiers shall be ignored. The Steps of Section 2 in IECEx OD 009 shall be varied as follows:OD 009 Step 1:The manufacturer’s application shall include a draft ignition hazard assessment prepared in accordance with Clause 9 of IEC 60079-33 and a draft assessment and test specification prepared in accordance with Clause 8 of IEC 60079-33 in addition to the data normally required.OD 009 Step 2:The contract review shall specifically include an evaluation of the competence of the ExCB and its associated ExTL to complete the work on the specific methods of protection identified by the manufacturer in the draft assessment and test specification (in relation to the ExCB/ExTL scope accepted by IECEx).The ExCB in conjunction with its ExTL shall review the draft assessment and testing specification and either accept the proposal or initiate communication with the manufacturer to revise the document.Additional Step 2a:The ExCB shall determine the required independent verifiers (Independent Verifier 2 and Independent Verifier 3) to be involved in the process according to the required EPL of Ex “s” equipment, from within its listing of Independent Verifierindependent verifier s.The ExCB shall appointnominate to the ExMC Secretary independent verifiers Verifiers 2 and 3 from the ExCB’s internal ExCB / ExTL list, maintaining a record ofproviding name, details of experience and how the requirements of Annex B of this document have been met.IEC 60079-33 are met.The ExMC Secretary shall arrange for the IECEx Executive to review the nominated Independent Verifiers on a project by project basis. The decision of the IECEx Executive shall be arrived by consensus and where full agreement cannot be reached, the IECEx Chairman shall determine the course of action.Where the IECEx Executive does not agree with the ExCB nominated Independent Verifiers for a specific project, the ExCB may seek to nominate alternative Verifiers for consideration by the IECEx Executive.NOTE: As introduction of Ex s is a new concept for IECEx Certification, assigning the review and approval of Verifiers on a project by project basis is being assigned to the IECEx Executive, however it is envisaged that in the future a dedicated IECEx panel or forum will be established based on experience gained from this process.Additional Step 2b:Should the ExCB not have the required number of independent Verifiers verifiers according to IEC 60079-33 and approved by the IECEx Executive, then the ExCB shall inform the applicant and withdraw from the application.OD 009 Step 4:This shall be a refinement of the draft plan accepted at Step 2. According to the Category EPL as specified in IEC 60079-33 all Independent Verifiersindependent verifiers, (1), (2)IECEx OD 233 © IEC: 2017(E) and (3) where more than 1 one Independent Verifierindependent verifier is required,) shall agree on the test/assessment plan prior to commencing test and assessment.OD 009 Step 6:Once the Test/Assessment Plan has been agreed by all Independent Verifiersindependent verifiers the ExTL, associated with the ExCB to whom the application has been made, may then undertake the test s/assessments.OD 009 Step 7:A draft ExTR, as prepared by the ExTL shall be reviewed and agreed by all the Independent Verifiersindependent verifiers with Verifiers 1, 2 and 3 all reaching agreement (when more than 1 Independent Verifier one independent verifier is required by IEC 60079-33) prior to the ExTR being finalised for final endorsement by the ExCB.Additional Step 9a:The ExCB shall prepare “QA” requirements as an Annex to the ExTR detailing any specific issues related to quality surveillance of the manufacturing activity for the product. This shall, in principle, stand as an additional part of the Annex to IECEx OD 005-1 or ISO/IEC 80079-34 prescribing the specific additional information necessary to be assessed when completing the QAR activity related to the product. Refer to Annex B for an example of the Reporting Form to be attached to the ExTR.Additional Step 9b:The ExTR, including the Annex of “QA” requirements, is also to be reviewed and, if acceptable, approved by the additionalall independent verifiers.4.Procedures for the Issuing of an IECEx Certificate of Conformity(IECEx CoC)According to OD 009 it is possible for an ExCB responsible for the work to issue a new IECEx CoC by using a previous QAR for an Ex “s” product issued within validity date, providing:- Manufacturing location is the same- Ex protection techniques that are to be listed on the CoC are the same as covered by the previous audit and QAR- The product is of a similar general nature of those covered by the previous audit and QAR- The “QA” requirements annexed to the ExTR covering the product(s) that are to be listed on the CoC are similar to the specific issues covered by the previous audit and QAR- That the manufacturer commits that the same production management system is being used for the new productHowever, as producing product according to Ex “s” IEC 60079-33 requires special attention which would not normally be covered by any previously issued QARs, the ExCB shall assess whether or not an on-site assessment of the manufacturer is required prior to the issue of a new CoC covering Ex “s”. The decision taken by the ExCB shall be formally recorded. A possible occasion where this on-site visit may not be necessary is where theIECEx OD 233 © IEC: 2017(E) applicant seeks a new Issue of the IECEx CoC to cover changes, of Ex products and where the ExCB determines by assessment of the manufacturer’s quality documentation that a site visit is not requiredTherefore the procedure outlined in Section 1 of OD 009 is followed, with the addition that the QAR shall make specific reference to each individual product that is to be certified Ex “s” and that this shall be checked before issuing the certificate.5. Procedures for the Issuing of an IECEx Quality Assessment Report(QAR)The procedure outlined in Section 3 of OD 009 is followed, with the addition that the ExCB responsible for the work shall take into account the QAR Annex from the ExTR of any Ex “s” equipment that is to be included, and shall specifically include a reference to each Ex “s” certificate in the QAR.Note that there are no additional competence requirements for an ExCB conducting the QAR assessment as the relevant details to be assessed are included in the QAR Annex to the ExTR. The manufacturer shall be audited only when the ExTR has been issued, and received by the ExCB conducting the IECEx quality assessment of manufacturer.IECEx OD 233 © IEC: 2017(E)ANNEX AAdditional Requirements for ExCB and ExTLs to be assigned IEC 60079-33 within their IECEx Scope of Acceptance(Normative)This annex is used for assessing the competence of an ExCB and ExTL to hold IEC 60079-33 within their scope within the IECEx Certified Equipment Scheme.Within the IECEx system, all the candidate bodies must present an application to IECEx secretariat for scope coverage of IEC 60079-33, and should be able to demonstrate the relevant competence of their Staff to undertake assessments according to IEC 60079-33, by an IECEx Assessor.The application information to be submitted to the IECEx Secretariat by the ExCB shall include:a)Completed scope extension Declaration Form (currently ExMC/251B/Q)b)Copy of the ExCB’s internal procedures (in English) for handling applications for Exs according to both IEC 60079-33 and this Operational Documentc)Copy of the ExCB’s internal procedure/criteria for appointing experts as IndependentVerifierindependent verifier s according to Annex B of this documentd)Agreement that the ExCB will appointsubmit to the IECEx Executive,, on a project byproject basis, independent verifiers, maintain records of their copies of the list of ExCB’s nominated Independent Independent Verifiers, showing name, details of experience and how the requirements of Annex B of this document have been petencies in IEC 60079-33 have been met.The IECEx assessment of the ExCB and ExTL may be undertaken as part of an on-site assessment or via an “off-site” assessment of the ExCBs procedures and interview with staff via Web based Conferencing, arranged and managed by the IECEx Secretary. IECEx Assessors for IEC 60079-33 shall be appointed by the IECEx ExecutiveSecretary. The assessments of ExCBs and/or ExTLs are aimed at demonstrating compliance with this document and IEC 60079-33, as well as IECEx 02, ISO/IEC Guide 6517065 and/or ISO/IEC 17025, and particularly including verification of the following knowledge, skills and competence:- A broad knowledge of Ex philosophies, including the principle of explosion prevention, the properties, mechanisms and control of ignition- Active involvement in IEC or national standardization committees (for example, by participating in document review and commenting processes)The following aspects may also be relevant in a limited number of cases and the ExCB should only accept projects where these are relevant if they have the necessary experience and facilities:-- In depth knowledge of risk reduction, reliability theory, reliability anticipation, reliability analysis, reliability test as well as calculation of FMEA and PFH **- Knowledge and experience in evaluation and certification on safety integrity level (SIL) of equipment’s hardware and software **- Having necessary test facilities, equipment (for example, EMC, climate, mechanical), procedures and personnel **- Having national accreditation on testing and/or evaluation of reliability, functional safety and EMC **- Having full scope of Ex concepts covered by IEC 60079 and ISO/IEC 80079 series standards within IECEx certified equipment program for both ExCB and its associated ExTL.** Note: Where the IECEx Secretariat, in conjunction with the assessment team, believes it appropriate to issue a restricted scope in relation to Ex s equipment, they may do so.ANNEX BRequirements for the Competence of Persons declared as Independent Verifiers(Normative)This annex is to be used by ExCBs for assessing the competence of expert persons being appointed as Independent Verifier 1, Independent Verifier 2 and Independent Verifier 3 of Ex “s” equipment.The detailed requirements for a qualified expert person are as follows:- Employed or under permanent contract by an ExCB and its associated ExTL(s) which is previously accepted within IECEx for the purpose of Ex s certification,according to Annex A of this document- An experienced member of the ExCB and/or ExTL, deeply involved in the testing and certification of equipment used in hazardous location for ten years at least- Having additional knowledge and experience on evaluation of risk control, reliability and functional safety- Active involvement in IEC or national standardization committees, preferably on explosion protection, functional safety and reliability- Officially nominated for the purpose by the ExCB and/or ExTL,- Officially registered in the ExCB’s internal Competency or Skills matrix Table as an Independent Verifier for the purpose of this operational documentAnnex CBQA Related Aspects of IEC 60079-33 Certification(Informative)Customer Number: Customer Name:Project Number: Equipment:ExTR Reference Number:Basis of Protection (list applicable concepts plus additional details):Special QA Audit Requirements: Yes ☐No ☐Details:Prepared by:Accepted by independent verifier (1):Accepted by (Independent Verifier 2)independent verifier (2): Accepted by independent verifier (3)(Independent Verifier 3): Countersigned (Certification Manager):。

atex和iecex体系培训办理流程

atex和iecex体系培训办理流程

ATEX和IECEx体系是欧洲和国际上关于防爆设备认证的两个主要体系。

由于其在防爆领域的广泛应用,越来越多的企业和个人开始关注和学习这两个体系。

下面介绍一下ATEX和IECEx体系的培训办理流程。

1.了解培训内容和方式:在进行ATEX和IECEx体系的培训前,需要首先了解培训的内容和方式。

这些培训内容通常包括防爆设备的选型、安装和维护等方面,培训方式则有线上和线下两种。

2.选择培训机构或培训师资:根据自己的需求和情况,选择一家合适的培训机构或培训师资进行培训。

在选择时,可以考虑一些因素,如培训机构或师资的资质、培训内容的全面性和实用性等。

3.申请培训:选择好培训机构或师资后,需要进行培训的申请。

在申请时,需要提供一些相关证件和材料,如身份证明、工作证明和培训费用等。

4.缴纳培训费用:完成申请后,需要缴纳相应的培训费用。

费用大小根据不同的培训机构和师资而有所不同,需要根据实际情况进行选择。

5.参加培训:缴纳费用后,即可参加ATEX和IECEx体系的培训。

在培训中,需要认真听讲,掌握相关知识和技能。

一般来说,培训周期为数天或数周,具体时间根据培训机构和培训师资的不同而有所不同。

6.颁发证书:完成培训后,培训机构或师资会颁发相应的证书。

这些证书可以作为企业或个人在防爆领域的资质和能力的证明,也是进一步学习和发展的基础。

以上就是ATEX和IECEx体系的培训办理流程。

通过认真学习和实践,企业和个人可以更好地了解和应用这两个重要的防爆设备认证体系,提高在防爆领域的能力和竞争力。

全球防爆认证分析及差异应对

国际 IECEx 欧盟ATEX

拉丁美洲 INMETRO

韩国KCs

日本TIIS

澳洲 ANZEx

中国 CCC Ex

北美 UL/FM/ NEMA/CSA

独联体 CU-TR

沙特 SASO

阿联酋 ECASEx

台湾 Ts

防爆体系发展史

19

美国电工法规标准 NEC

德国电机电子工程协会标准 VDE

2

北美防爆安全体系HazLoc-NA(NEC体系)

北美防爆安全体系 NEC Hazardous Location-North America 范围:北美(加拿大、美国、墨西哥) 体系标准:NEC500 北美本地体系,和IEC体系在规定要求上有很大的差异

NEC505 以IEC为基础制定的标准,基本等效于IEC标准 如果客户制定需要执行NEC标准的防爆电机,需明确规定执行NEC500还是NEC505 认证机构:UL认证(美国北美) FM认证(美国工厂联合研究会认证) CSA认证(加拿大标准协会) 证明文件:CSA证书

(22区)

4

NEC500对危险场所划分

Class Ⅰ Class Ⅱ

Group A Group B Group C Group D Group E Group F Group G

(相当于IEC标准中的ⅡC,乙炔) (相当于IEC标准中的ⅡC/ ⅡB ,氢、丁二烯、氧化乙烯) (相当于IEC标准中的ⅡB,环丙烷、乙醛、乙烯、乙醛) (相当于IEC标准中的ⅡA,丙酮、乙醇、氨、笨、丁/丙烷、汽油) (相当于IEC标准中的爆炸性粉尘,金属粉尘:镁和铝) (相当于IEC标准中的可燃性粉尘,碳、煤或焦炭粉尘) (相当于IEC标准中的可燃性粉尘,面粉、淀粉或谷物粉尘)

防爆合格证和IECEx、ATEX证书的区别和转化

目前,全球的防爆合格证认证大致有:欧盟的ATEX认证,采用EN60079系列标准;国际电工委员会的IECEx认证,采用IEC60079系列标准;北美地区的UL和FM防爆认证,主要采用NEC标准;中国防爆合格证的GB3836系列标准大部分是直接引用国际IEC60079系列标准。

目前欧洲的防爆合格证ATEX和防爆合格证IECEx的标准内容几乎一致,一个主要标准是EN60079系统,一个主要标准是IEC60079系列。

产品取得ATEX, 欧盟成员国互认,可以在欧盟国家销售;取得IECEx,理论上说可以在国际电工委员会成员国销售,如某国家既是欧盟的又是国际电工委员会成员国,可以不申请IECEx,只申请ATEX即可,因ATEX为CE范畴下,是强制性认证,而IECEx不是强制性认证。

澳大利亚、新西兰和新加坡等国已经完全接受IECEx国际认证证书,取得IECEx的防爆合格证产品可以直接进入这些国家国内市场,而不再需要申请该国的防爆认证。

按照IECEx体系的规定,由于国家差异等原因目前还不能接受IECEx证书的成员国,在进行国家的Ex防爆认证活动时应承认IECEx体系中其他成员国的Ex认证机构(Ex CB)签发的Ex检验报告和工厂质量条件检查报告(QAR),仅仅对标准中的差异部分进行补充试验或检查,为持有IECEx证书的其他成员国的制造商申请其国家和地区性认证提供快速通道。

比如,中国,也是IEC成员国,但是防爆产品在中国需要申请中国的防爆合格证或者煤安认证,这都是不能用IECEx替代的。

总之,如果某个国家虽然是IEC成员国,但也有自己国家的强制性防爆认证,通常是一定要申请自己国家的强制性防爆认证的,而不能仅仅用IECEx防爆认证代替。

当然,某些时候,可以拿已经获得的IECEx 测试报告(可能需要额外增加一些测试项目)来转化成国内强制性防爆认证证书,但一定需要通过申请机构的确认和审核。

为了加强防爆电气产品的管控,市场监管总局在2019年发布了《市场监管总局关于防爆电气等产品由生产许可转为强制性产品认证管理实施要求的公告》,明确将防爆电气产品由生产许可转为强制性产品认证(CCC认证)管理,并于2019年10月1日正式实施。

ECE认证网络安全

ECE认证网络安全ECE认证网络安全随着互联网技术的不断发展和普及,网络安全问题正在成为全球范围内的重要关注点。

为了更好地保护和管理网络安全,许多国家都建立了相应的网络安全认证体系。

ECE认证(European Certification Entity)是欧洲范围内的网络安全认证体系,旨在评估和认证企业的网络安全防护能力和管理水平。

ECE认证网络安全是一个多维度的认证体系,涵盖了安全策略制定、身份认证与访问控制、网络防护与监测、安全事件响应等多个方面。

在进行认证过程中,评估员会对企业的安全策略进行审查,包括战略目标的制定、风险评估与管理、安全政策与规程等。

此外,评估员还会对企业的身份认证与访问控制机制进行评估,包括密码策略、访问控制权限管理等。

在网络防护与监测方面,评估员会对企业的防火墙、入侵检测系统等安全设备进行评估,并测试其在阻止未授权访问、识别和防止恶意攻击等方面的能力。

此外,评估员还会评估企业的安全事件响应能力,包括安全事件的报告与响应机制、漏洞管理与修复等。

通过ECE认证网络安全,企业能够提高其网络安全防护能力和管理水平,减少网络安全风险,提升企业的竞争力和信誉度。

认证的企业可以获得ECE认证标志,并被列入ECE认证的企业名单中,为企业赢得客户和合作伙伴的信任。

此外,ECE认证网络安全也有助于推动网络安全技术和产业的发展。

认证过程中,评估员会对企业的网络安全技术和解决方案进行评估,并针对其存在的问题提出改进意见和建议。

这为企业提供了改进和创新的机会,推动了网络安全技术的不断发展和完善。

然而,ECE认证网络安全也存在一些挑战和限制。

首先,认证过程需要企业投入大量的时间和资源,包括人力、技术和财务等方面。

对于一些中小型企业来说,这可能是一个较大的负担。

其次,认证只是一个评估企业网络安全能力的过程,并不能完全保证企业的网络安全。

因此,认证后的企业仍需持续改进和完善网络安全措施。

综上所述,ECE认证网络安全是一个综合性的认证体系,通过对企业的安全策略、身份认证与访问控制、网络防护与监测、安全事件响应等方面进行评估,提高企业的网络安全防护能力和管理水平。

IECEx认证的可爆性氛围设备说明书

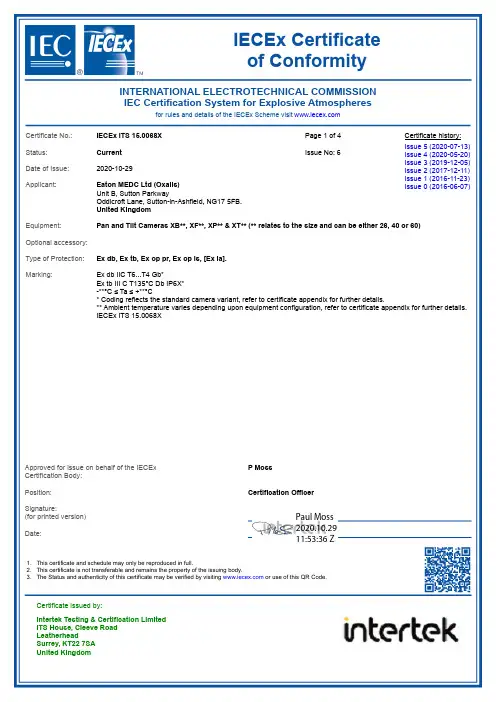

Paul Moss 1ntertek2020.10.2911:53:36 ZCertificate No.:IECEx ITS 15.0068X Date of issue:2020-10-29Page 2 of 4Issue No: 6Manufacturer:Eaton MEDC Ltd (Oxalis)Unit B, Sutton Parkway, Oddicroft Lane, Sutton-in-Ashfield, NG17 5FB. United KingdomAdditional manufacturing locations:This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the IEC Standard list below and that the manufacturer's quality system, relating to the Ex products covered by this certificate, was assessed and found to comply with the IECEx Quality system requirements.This certificate is granted subject to the conditions as set out in IECEx Scheme Rules, IECEx 02 and Operational Documents as amendedSTANDARDS :The equipment and any acceptable variations to it specified in the schedule of this certificate and the identified documents, was found to comply with the following standards IEC 60079-0:2017 Edition:7.0Explosive atmospheres - Part 0: Equipment - General requirementsIEC 60079-1:2014-06 Edition:7.0Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"IEC 60079-11:2011 Edition:6.0Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i"IEC 60079-28:2015 Edition:2Explosive atmospheres - Part 28: Protection of equipment and transmission systems using optical radiation IEC 60079-31:2013 Edition:2Explosive atmospheres - Part 31: Equipment dust ignition protection by enclosure "t"This Certificate does not indicate compliance with safety and performance requirementsother than those expressly included in the Standards listed above.TEST & ASSESSMENT REPORTS:A sample(s) of the equipment listed has successfully met the examination and test requirements as recorded in:Test Reports:Quality Assessment Reports:Cooper Yuhua (Changzhou) Electronic Equipment Manufacture Co., Ltd.No. 60 Hehuan Road, Zhonglou Development Zone; Changzhou, Jiangsu Province, CN-213023 P .R. CHINA ChinaGB/ITS/ExTR15.0063/00GB/ITS/ExTR15.0063/01GB/ITS/ExTR15.0063/02GB/ITS/ExTR15.0063/03GB/ITS/ExTR15.0063/04GB/ITS/ExTR15.0063/05GB/ITS/ExTR15.0063/06GB/BAS/QAR06.0023/09NO/NEM/QAR13.0008/05Certificate No.:IECEx ITS 15.0068X Date of issue:2020-10-29Page 3 of 4Issue No: 6EQUIPMENT:Equipment and systems covered by this Certificate are as follows:SPECIFIC CONDITIONS OF USE: YES as shown below:The Camera Housing is constructed from stainless steel AISI316L with glass windows and designed to accommodate a range of CCTV cameras, infra-red cameras, lenses and associated ancillary equipment to allow their deployment in harsh environmental conditions. Thehousing has facilities for optional items such as window demister/heater, internal window wiper mechanism, integral window washer pump and external sunshield.For full equipment description refer to Annex.••••••••• No modifications must be made to the flamepaths of the unit without consultation of the drawings listed on the schedule.Temperatures could exceed 70°C at the cable gland or 80°C at the branching point, suitably rated cable must be e only hex socket head fasteners with property class of A4-70 for securing end covers & shafts to housings.When fitted, the optical fibre output from the camera housing must always be terminated within a suitably certified enclosure or safe area.Only armoured cable or conduit is to be utilized when fitted with a fibre optic output in order to protect the fibre optic cable.Precautions must be taken to avoid dust from forming layers on the equipment.Antennas used with equipment shall be passive with a nominal impedance of 50Ω and have a minimum degree of protection of IP6X. If the antenna utilises a wire conductor the minimum diameter shall be 0.1mm. Alternatively if a track antenna is used, the tracking shall have a minimum width of 0.4mmThe antenna circuit does not meet the dielectric strength requirements of Clause 6.3.13. Refer to the manufacturers’ instruction manual for further details.Dual Imager Housing variants only: Housings must only be installed in areas where there is a low risk of mechanical impact.Certificate No.:IECEx ITS 15.0068X Date of issue:2020-10-29Page 4 of 4Issue No: 6DETAILS OF CERTIFICATE CHANGES (for issues 1 and above)Annex:IECEx ITS 15.0068X Iss 06 - Annex for IECEx Certificate of Conformity.pdfIssue 1:Change of company name and address to:Oxalis Group LtdOxalis House, Masons Road, Stratford upon Avon, Warwickshire,CV37 9NB.toEaton MEDC Ltd (Oxalis)Unit B, Sutton Parkway, Oddicroft Lane, Sutton-in-Ashfield, NG17 5FB.Issue 2:1. Option of alternative design of Dual Imager Window Assembly (with circlip and raised guard).2. Option of alternative design of 260 housing base plate.Issue 3:Adition of alternative lens guard design.Issue 4:Additional manufacturing name and address.Issue 5:1. Changes to gearbox shaft and Pan & Tilt Mk 2 Base as follows (Modified base to be known as the Mk3 Base):i) Increased shaft diameter and flamepath diameter (flamepath length and gap remains the same).ii) Change of inner bearing set with sleeve bearings.iii) Use of a threaded joint between the gearbox shaft and base.iv) Option of welded top cover for base.v) Option of a brushless gearbox motor.vi) Change of O-ring position.2. Changes to T Body as follows:i) Option of reduced height and width.ii) Option of welded internal earth tag.3. Changes to camera housings as follows:i) Increase length of options with welded blank end cover to same as the flange design.ii) Option of M32 thread gland entry for mounting flange.iii) T6 / Tamb +59°C rating for IR Illuminator version and XP & XF units.4. Changes to the camera covers as follows:i) Option of mounting IR light assembly in wiper window (but without wiper hole).ii) Option of fixed camera rear flange.iii) Addition of PCB mounting holes in Pan & Tilt cover.5. Update from IEC 60079-0:2011 Ed 6 to IEC 60079-0:2017 Ed 7.6. Consolidation of existing GA drawings into one GA drawing covering all necessary certification requirements.7. Exemption Overpressure Testing of Blank Covers, Blank Covers with Cable Entries and Gearbox Shaft/Flange Assemblies.Issue 6:Update of certification to include Class 1 Laser Illuminator option.Annex No. 1Certificate issued by:Intertek Testing & CertificationLimitedIntertek House, Cleeve Road,Leatherhead, Surrey, KT22 7SATel: +44 (0)1372 370900 Fax: +44(0)1372 370977Registered No 3272281.Registered Office: Academy Place,1-9 Brook Street, Brentwood,Essex, CM14 5NQPage 1 of 4 SFT-IECEx-OP-19f (26 October 2018)Technical DocumentsTitle: Drawing No.: Rev. Level: Date:*CERTIFICATION DRAWINGS FOR ALL HOUSINGS AND PANAND TILT COMBINATIONS9 SheetsOXCT-0001 6 8/9/2020ATEX/IECEX CERTIFICATION LABEL DRAWINGS FOR UNITSWITH NO FIBRE OPTICS FITTEDOXCT-0002 007 26/06/2020ATEX/IECEX CERTIFICATION LABEL DRAWINGS FOR UNITSWITH FIBRE OPTICS FITTEDOXCT-0003 007 26/06/2020ATEX/IECEX CERTIFICATION LABEL DRAWINGS FORILLUMINATOR UNITSOXCT-0004 007 26/06/2020ATEX/IECEX CERTIFICATION LABEL DRAWINGS FOR UNITSCONTAINING WIRELESS TRANSMISSION WITH IS BARRIEROXCT-0006 006 26/06/2020Series X (XF, XP & XT) flame proof camera units – Installation& Maintenance InstructionsIMI+70-XF-XP-XT 9.0 13/07/2020Series XF flame proof camera units – Installation & Maintenance Instructions XF CAMERACHANZHOU I.MA 13/07/2020Product Description:The Camera Housing is constructed from stainless steel AISI316L with glass windows and designed to accommodate a range of CCTV cameras, infra-red cameras, lenses and associated ancillary equipment to allow their deployment in harsh environmental conditions. The housing has facilities for optional items such as window demister/heater, internal window wiper mechanism, integral window washer pump and external sunshield.The unit is 260mm to 600mm in length (dependant on model) and is constructed from 139.7mm diameter cylindrical tube and 154mm diameter end covers. The unit has a cemented window assembly in one end cover, with the opposite end cover being either a blank end plate, end plate with up to five cable entries available in M20, M25, ½” or ¾” NPT thread forms. The cable entry to the camera housing is either via a cable entry adaptor in the side of the housing tube or via the tilt motor shaft attachment flange when mounted to a Pan/Tilt unit. When fitted with Germanium windows, for use with infra-red cameras, a protective guard plate is factory fitted on the window end cover and secured in place.The Camera Housing has welded joints and is therefore to be subjected to routine overpressure tests. The IR model is fitted with an infrared LED Illuminator which is fitted in place of a camera.The Class 1 Laser Illuminator may be fitted in conjunction with a camera into a single housing.Annex No. 1Certificate issued by:Intertek Testing & CertificationLimitedIntertek House, Cleeve Road,Leatherhead, Surrey, KT22 7SATel: +44 (0)1372 370900 Fax: +44(0)1372 370977Registered No 3272281.Registered Office: Academy Place,1-9 Brook Street, Brentwood,Essex, CM14 5NQPage 2 of 4 SFT-IECEx-OP-19f (26 October 2018)The integrated Pan & Tilt Unit would be used in conjunction with the Camera Housing where installations require a moveable camera.This Pan & Tilt Unit is also constructed from AISI316L stainless steel and can be fitted with either AC fixed speed or DC variable speed motors. The Pan & Tilt Unit with integral base mount is between approx. 190mm & 282mm wide and between approx. 370mm and 430mm high. There is up to three cable entries in the base mount (dependent on model) in M20, M25, ½” or ¾” NPT thread forms. There are four spigot flamepaths, two wher e the end covers fit into the housing and two where the motor/gearbox assemblies connect to the housing. In addition there are 2 cylindrical flamepaths for the motor shafts allowing for the pan and tilt movement. The Mk2 and Mk3 base unit can also be provided with a M110x1.5 threaded cover for readily accessing wiring terminals. This is secured with a hexagonal grub screw . Additionally, the MK3 base includes a fixed top cover with threaded M32 entry for mounting of the associated T-Body.The Pan & Tilt Unit has welded joints and is therefore to be subjected to routine overpressure tests.Internal and external earthing points are provided.Options are also available fitted with an optical output for data transmission purposes and antennas with associated barriers.Only suitably certified cable glands, thread adaptors or blanking elements to be utilized as detailed on the certificate.The coding the equipment is marked with is dependent upon the assembly configuration, internal power dissipation and optical accessories installed. A breakdown of the coding is given below.Standard variants (including Laser Illuminator option);Ex db IIC T6...T3* GbEx tb IIIC T135°C Db IP6X**-##°C ≤ Ta ≤ +##°COptions fitted with fibre optic outputs are marked;Ex db op pr IIC T6...T3* GbEx tb op pr IIIC T135°C Db IP6X**-##°C ≤ Ta ≤ +##°CIR Illuminator module variants are marked;Ex db op is IIC T6 or T4* GbEx tb op is IIIC T135°C Db IP6X**-##°C ≤ Ta ≤ +##°CAnnex No. 1Certificate issued by:Intertek Testing & CertificationLimitedIntertek House, Cleeve Road,Leatherhead, Surrey, KT22 7SATel: +44 (0)1372 370900 Fax: +44(0)1372 370977Registered No 3272281.Registered Office: Academy Place,1-9 Brook Street, Brentwood,Essex, CM14 5NQPage 3 of 4 SFT-IECEx-OP-19f (26 October 2018)All of the variants above may additionally be marked [Ex ia Ga], which refers to an intrinsically safe antenna connection. The antenna accessory has only been considered for use in the 20W versions of the camera. Refer to the Table below for the suitable ambient temperature ranges of equipment incorporating an antenna.*Note: T class and ambient temp is dependent on the assembly configuration and maximum internal power dissipation.** Note: When fitted with an internal dissipation of 60W and upper ambient temperature of 70°C the maximum marked temperature should be marked T140°C.The following table denotes the temperature classification for products which do not contain an antenna.Integrated Pan and Tilt StandaloneT-Class Maximum AmbientRange^Pan & Tilts MaxWatts DisHousing MaxWatts DisHousing Max Watts DisT6 -60°C ≤ Ta ≤ +40°C20 W 20 W 20 WT5 -60°C ≤ Ta ≤ +40°C40 W 40 W 40 WT5 -60°C ≤ Ta ≤ +65°C20 W 20 W 20 WT4 -60°C ≤Ta ≤ +65°C60 W 60 W 60 WT4 -60°C ≤ Ta ≤ +70°C 60 W 40 W 40 WT4 -60°C ≤ Ta ≤ +70°C50 W 50 W 50 WT3 -60°C ≤ Ta ≤ +70°C60 W 60 W 60 WDustT135°C-60°C ≤ Ta ≤ +65°C60 W 60 W 60 W DustT140°C-60°C ≤ Ta ≤ +70°C 60 W 60 W 60 WThe IR Illuminator variant may either be marked T4 in accordance with the ambient limitations detailed in the table above or T6/Tamb +59°C when the internal power dissipation is limited to the following:IR Illuminator Housing: ≤ 8W, Camera Housing: ≤ 14W, Base/P&T Housing: ≤ 16WThe XF and XP units may also be marked T6/Tamb +59°C when the internal power dissipation is limited to the following:Camera Housing: ≤ 14W, Base/P&T Housing: ≤ 16WThe following table lists the permitted upper ambient temperatures when using a certified RF barrier.Integrated Pan and Tilt Standalone Barrier fitted T-Class Maximum Pan & Tilts Max Housing Max Housing Max WattsAnnex No. 1Certificate issued by:Intertek Testing & CertificationLimitedIntertek House, Cleeve Road,Leatherhead, Surrey, KT22 7SATel: +44 (0)1372 370900 Fax: +44(0)1372 370977Registered No 3272281.Registered Office: Academy Place,1-9 Brook Street, Brentwood,Essex, CM14 5NQPage 4 of 4 SFT-IECEx-OP-19f (26 October 2018)Ambient Range^ Watts Dis Watts Dis DisExtronics & Solexy T6-40°C ≤ Ta ≤+40°C20 W 20 W 20 WExtronicsT5 -40°C ≤ Ta ≤+50°C20 W 20 W 20 WSolexyT5 -40°C ≤ Ta ≤+55°C20 W 20 W 20 WExtronics DustT135°C -40°C ≤ Ta ≤+50°C20 W 20 W 20 WSolexy DustT135°C -40°C ≤ Ta ≤+55°C20 W 20 W 20 W^ The manufacturer has requested that this limit may be marked from the evaluated lower ambient to 0°C to ensure correct functionality of the equipment. This does not affect the protection offered by the enclosure. Routine Tests:• A routine overpressure test in accordance with IEC 60079-1:2014 Clause 16.1 shall be carried out on all enclosures, including all cemented window assemblies, at a pressure of 30.12bar for a period of between 10 and 60 seconds.• There shall be no deformation or damage to the enclosures and no leakage through the cement of any of the window assemblies integrity of the welded construction shall also be verified during routine overpressure testing. • Empty enclosures may be tested.• The individual parts of a flameproof enclosure (for example, cover and base) can be tested separately. The test conditions shall be such that the stresses are comparable to those to which these parts are exposed in the complete enclosure.• If required during the construction, thread inserts need to withstand the routine overpressure test also.Details must be recorded and records maintained.Note: The following items, as referenced on drawing OXCT-0001, are exempt from routine testing:1. Item F – End Cover with Gland Entries2. Item G – PCB Mounting End Cover3. Item H – End Cover Blank4. Item I – Combined Cover5. Item U – Motor Gearbox M32 Thread (Shaft and Flange)6. Item V – Free Shaft (Twin Head) M32 Thread7. Item S & T – Motor Gearbox/Free Shaft Spigot (Shaft and Flange)。

iecex防爆认证流程

iecex防爆认证流程英文回答:IECEx Certification Process.The IECEx Certification Process is a globallyrecognized system for certifying electrical equipment for use in hazardous areas. It is based on the IEC 60079 series of standards, which cover all aspects of electrical equipment design, construction, and testing for use in hazardous areas.The IECEx Certification Process is managed by the IECEx Certification Body (CB), which is a not-for-profit organization based in the United Kingdom. The CB is responsible for developing and maintaining the IECEx Scheme, which is the framework for the certification of electrical equipment for use in hazardous areas.The IECEx Certification Process consists of thefollowing steps:1. Application The manufacturer of the electrical equipment submits an application to the CB. The application must include all of the necessary technical documentation, including drawings, specifications, and test reports.2. Review The CB reviews the application and supporting documentation to ensure that the electrical equipment meets the requirements of the IEC 60079 standards.3. Testing The CB may require the manufacturer to submit the electrical equipment for testing. The testing is carried out by an independent test laboratory that is accredited by the CB.4. Certification If the electrical equipment passes the testing, the CB will issue a certificate of conformity. The certificate of conformity is valid for a period of five years.The IECEx Certification Process is a rigorous processthat ensures that electrical equipment is safe for use in hazardous areas. The IECEx certification mark is a globally recognized symbol of quality and safety.中文回答:IECEx 防爆认证流程。

陕西地区iecex认证体系培训申请

陕西地区iecex认证体系培训申请

您好!我司将于近期举行陕西地区IECEx认证体系培训,现向贵公司发出培训申请。

IECEx是由国际电工委员会(IEC)设立的认证体系,主要针对爆炸危险环境下使用的设备和防爆系统进行认证。

该认证体系是全球范围内最为权威的防爆认证体系之一,具有广泛的国际认可度和可靠性。

陕西地区作为我国西部地区的重要经济中心和技术创新基地,其爆炸危险环境使用设备和防爆系统的需求日益增长。

因此,IECEx认证体系的应用和推广显得尤为重要。

本次培训将由IECEx认证机构专业的讲师主讲,内容涵盖IECEx 认证体系的基本知识、标准和流程等方面。

培训结束后,参训人员将获得IECEx认证体系的深入理解和实践经验,有利于提升贵公司在防爆领域的竞争力和市场份额。

希望贵公司能够积极参与该培训,共同推动IECEx认证体系在陕西地区的应用和发展。

谢谢!

此致

敬礼!

- 1 -。

地区atex和iecex体系培训办理流程

地区atex和iecex体系培训办理流程地区Atex和IECEx体系是针对危险性较高的行业所采用的一种防爆体系,该体系是指符合欧洲Atex标准和国际IECEx标准的防爆设备及产品。

为了确保企业的设备能够符合这两项标准,需要进行Atex和IECEx体系的培训,并对设备进行防爆认证。

下面介绍地区Atex和IECEx体系的培训办理流程。

1. 培训准备:首先,需要确定需要培训的人员以及培训内容,然后为他们寻求一家合适的Atex和IECEx体系认证机构。

2. 接收培训:培训过程通常需要3-5天时间,根据不同的行业和参与者,培训课程内容也不同,主要包括:(1) Atex和IECEx体系的基础知识和标准。

(2)风险评估和防爆设计:包括如何执行有效的风险评估,并利用正确的防爆设备进行防爆设计。

(3)防爆设备的要求和防爆部件的选用:讲解具体的防爆设备要求以及如何选择适合的防爆部件。

(4)防爆现场操作技能:讲解防爆现场的基本要求,培训现场操作技能。

3. 考试和评估:除了培训,参加者还需要参加考试以测试其收获,并获得Atex和IECEx体系的认证。

4. 审核和审批:在考试和评估完成后,需要审核并批准认证资格,审核和审批的程序通常需要2-4周时间。

5. 维护和更新:Atex和IECEx体系的认证是有期限的,企业需要按时进行体系维护和更新,确保设备符合最新的国际标准。

二、注意事项1. Atex和IECEx体系认证准备过程需要比较长时间,需要提前关注并安排好计划,以便安排人员的时间。

2. 防爆设备的设计、选型和使用需要人们进行高度重视,在防爆现场操作时,需要遵循相关规定,确保工作人员的安全。

3. 在培训和认证过程中,需要严格遵守Atex和IECEx体系的相关规定和标准,确保认证过程的合法性和权威性。

三、结论地区Atex和IECEx体系的培训和认证,对于在危险行业从事业务的企业来说是非常重要的。

在此过程中,人们需要了解相关的规定,确保设备安全,并培训相关工作人员掌握正确的操作技巧,使防爆设备能够达到应有的效果。

防爆产品需要办理哪些防爆认证

现如今,随着经济以及企业发展的需要,大多数企业需要生产防爆产品进行销售,由于防爆产品用于危险环境下,需要办理防爆认证,防爆认证的种类繁多,以下列举出几种防爆产品需要取得的防爆认证。

1.防爆合格证GB3836.1-2010中3.6术语,防爆合格证:用于确定设备符合标准的要求、型式试验和适应的例行试验的文件。

证书可针对Ex设备或Ex元件。

2.防爆CCC认证CCC认证全称为“中国强制性产品认证”,是通过制定强制性产品认证的产品目录和实施强制性产品认证程序,对列入强制性产品认证目录中的产品实施强制性的检测和审核。

没有获得指定认证机构的认证证书,没有按规定加施认证标志,一律不得进口、不得出厂销售和在经营服务场所使用。

3.欧盟ATEX认证1994年3月23日,欧洲委员会采用了“潜在爆炸环境用的设备及保护系统”(94/9/EC)指令。

这个指令覆盖了矿井及非矿井设备,与以前的指令不同,它包括了机械设备及电气设备,把潜在爆炸危险环境扩展到空气中的粉尘及可燃性气体、可燃性蒸气与薄雾。

该指令是通常称之为ATEX 100A的“新方法”指令,即现行的ATEX 防爆指令。

它规定了拟用于潜在爆炸性环境的设备要应用的技术要求——基本健康与安全要求和设备在其使用范围内投放到欧洲市场前必须采用的合格评定程序。

4.IECEx认证IECEx国际电工委员会防爆电气产品认证体系的简称,指专门用于石油、化工、煤矿、轻纺、粮食加工以及军工等工业部门中可能聚集爆炸性气体、蒸气、粉尘或纤维等爆炸危险场所的电气设备的认证。

Ex产品必须取得防爆认证,才允许在爆炸危险场所使用。

认证制度对保证Ex产品的使用安全是十分必要的,但是另一方面,由于Ex产品进入不同的国家或地区需要进行重复的防爆检验和认证,对Ex产品的国际贸易造成了许多障碍。

为了消除国际间对Ex产品不必要的重复检验和重复认证,促进国际贸易,1992 年国际上开始在国际电工委员会范围内筹建防爆电气产品国际认证组织。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

IECEx,英文IEC Scheme for Certification to Standards for Electrical Equipment for Explosive Atmospheres,是国际电工委员会防爆电气产品认证体系的简称。

IECEx认证是指专门用于石油、化工、煤矿、轻纺、粮食加工以及军工等工业部门中可能聚集爆炸性气体、蒸气、粉尘或纤维等爆炸危险场所的电气设备的认证。

IECEx认证体系的成立背景

防爆电气产品也称为Ex产品,是指专门用于石油、化工、煤矿、轻纺、粮食加工以及军工等工业部门中可能聚集爆炸性气体、蒸气、粉尘或纤维等爆炸危险场所的电气设备,主要有防爆电动机、防爆开关电器、防爆灯具、防爆仪表、成套设备和附件等。

由于这些设备的安装和使用场所是爆炸危险环境,例如油库、化工厂、煤矿井下等,如果由于电气设备制造质量等原因降低或丧失防爆性能,则电气设备运行或故障中产生的火花、电弧或高温就会点燃环境中的爆炸性混合物,形成工业爆炸或火灾,造成巨大的经济损失和众多人员伤亡。

世界上煤矿井下每年都发生多起瓦斯、煤尘爆炸事故,重大事故一次就死伤数十人;石油化工企业也曾多次发生过爆炸和火灾事故,损失惨重。

由于防爆电气设备的安全质量与许多重要工业部门的安全生产有密切关系,因此包括我国在内的世界各个国家和地区对防爆电气产品的制造和使用都采取严格的管理措施。

早期的管理措施主要是对防爆电气产品进行型式检验或型式认可, 八十年代后期,一些工业国家,例如西欧国家先后开始对防爆电气产品实施防爆安全认证制度。

Ex产品必须取得防爆认证,才允许在爆炸危险场所使用。

认证制度对保证Ex产品的使用安全是十分必要的,但是另一方面,由于Ex产品进入不同的国家或地区需要进行重复的防爆检验和认证,对Ex产品的国际贸易造成了许多障碍。

为了消除国际间对Ex产品不必要的重复检验和重复认证,促进国际贸易,

1992 年国际上开始在国际电工委员会范围内筹建防爆电气产品国际认证组织。

经过几年的筹备,1996年正式成立了国际电工委员会防爆电气产品认证组织,简称IECEx认证体系。

IECEx体系的最终目标是全世界范围内接受

一个标准---- IEC TC31制订的爆炸危险环境用电气设备系列标准;

一个证书---- IECEx 认证证书(IECEx Certification of Conformity);

一个标志---- IECEx 认证标志(IECEx Mark of Conformity)。

澳大利亚、新西兰和新加坡等国已经接受IECEx国际防爆认证证书,取得IECEx的防爆合格证产品向这些国家出口不需要再申请该国的防爆认证。

IECEx认证证书的转化

目前,IECEx认证是由标准驱动的,即属于自愿性认证。

但在国际市场上IECEx认证的认可度较高,大部分IECEx体系成员国直接或者间接认可IECEx认证。

如果产品已经取得IECEx认证,提供有效的检测报告(IECEx体系中其他成员国的Ex认证机构(Ex CB)签发的Ex检验报告和工厂质量条件检查报告(QAR)),只需要进行一部分的差异性测试或评估,即可持有IEC Ex证书的其他成员国的制造商申请其国家和地区性认证提供快速通道。

比如,中国,也是IEC成员国,但是防爆产品在中国需要申请中国的防爆合格证或者煤安认证,这都是不能用IECEx替代的。

总之,如果某个国家虽然是IEC成员国,但也有自己国家的强制性防爆认证,通常是一定要申请自己国家的强制性防爆认证的,而不能仅仅用IECEx防爆认证代替。

当然,某些时候,可以拿已经获得的IECEx 测试报告(可能需要额外增加一些测试项目)来转化成国内强制性防爆认证证书,但一定需要通过申请机构的确认和审核。

深圳中诺检测技术有限公司立足于华南地区,是一家专注防爆认证和煤安认证的第三方检测机构,业务涵盖防爆3C认证、防爆合格证、防爆检测、ATEX认证、IECEx认证、防爆设计、现场防爆检查、防爆工程、防腐等级测试、煤安&矿安认证、防爆培训、SIL认证等。

为客户提供从防爆设计、检测、认证、安装、检修、现场检查、防爆施工、防爆改造等一站式防爆技术咨询和服务。