Delrin POM 100STE NC010 物性表

DELRIN 150NC010

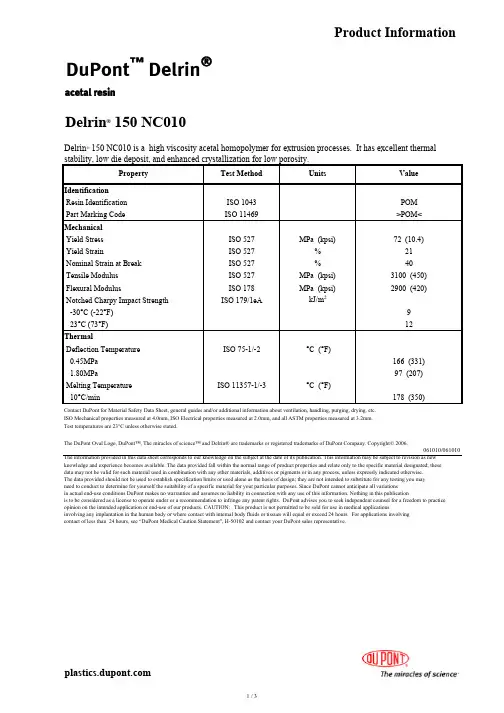

DuPont™ Delrin®acetal resinDelrin® 150 NC010Delrin® 150 NC010 is a high viscosity acetal homopolymer for extrusion processes. It has excellent thermal stability, low die deposit, and enhanced crystallization for low porosity.Property Test Method Units ValueIdentificationResin Identification ISO 1043POMPart Marking Code ISO 11469>POM< MechanicalYield Stress ISO 527MPa (kpsi)72 (10.4)Yield Strain ISO 527%21Nominal Strain at Break ISO 527%40Tensile Modulus ISO 527MPa (kpsi)3100 (450)Flexural Modulus ISO 178MPa (kpsi)2900 (420)Notched Charpy Impact Strength ISO 179/1eA kJ/m2-30°C (-22°F)923°C (73°F)12ThermalDeflection Temperature ISO 75-1/-2 °C (°F)0.45MPa166 (331)1.80MPa97 (207)Melting Temperature ISO 11357-1/-3 °C (°F)10°C/min178 (350)Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061010/061010 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.Delrin® 150 NC010Property Test Method Units ValueThermalCLTE, Parallel ISO 11359-1/-2E-4/C (E-4/F)-40 - 23°C (-40 - 73°F) 1.0 (0.56)23 - 55°C (73 - 130°F) 1.1 (0.61)55 - 100°C (130 - 212°F) 1.4 (0.78)CLTE, Normal ISO 11359-1/-2E-4/C (E-4/F)-40 - 23°C (-40 - 73°F)0.9 (0.5)23 - 55°C (73 - 130°F) 1.0 (0.56)55 - 100°C (130 - 212°F) 1.5 (0.83) RheologicalMelt Mass-Flow Rate ISO 1133g/10 min190°C, 2.16kg 2.4 FlammabilityFlammability Classification IEC 60695-11-101.5mm HB3.0mm HBFlammability Classification UL941.5mm HB3.0mm HB Temperature IndexRTI, Electrical UL 746B°C1.5mm503.0mm50RTI, Impact UL 746B°C1.5mm503.0mm50RTI, Strength UL 746B°C1.5mm503.0mm85Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061010/061010 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.Delrin® 150 NC010Property Test Method Units ValueOtherDensity ISO 1183kg/m3 (g/cm3)1420 (1.42)Water Absorption ISO 62, Similar to%Immersion 24h0.39Molding Shrinkage ISO 294-4%Normal, 2.0mm 2.0Parallel, 2.0mm 1.8Processing - Injection MoldingMelt Temperature Range °C (°F)210-220 (410-430)Melt Temperature Optimum °C (°F)215 (420)Mold Temperature Range °C (°F)80-100 (175-210)Mold Temperature Optimum °C (°F)90 (195)Hold Pressure Range MPa (kpsi)90-110 (13-16) Processing - ExtrusionMelt Temperature Range °C (°F)195-205 (385-400)Melt Temperature Optimum °C (°F)200 (395)Processing Moisture Content%<0.2 ProcessingDrying Time, Dehumidified Dryer h2-4Drying Temperature °C (°F)80 (175)Processing Moisture Content%<0.2Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061010/061010 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.。

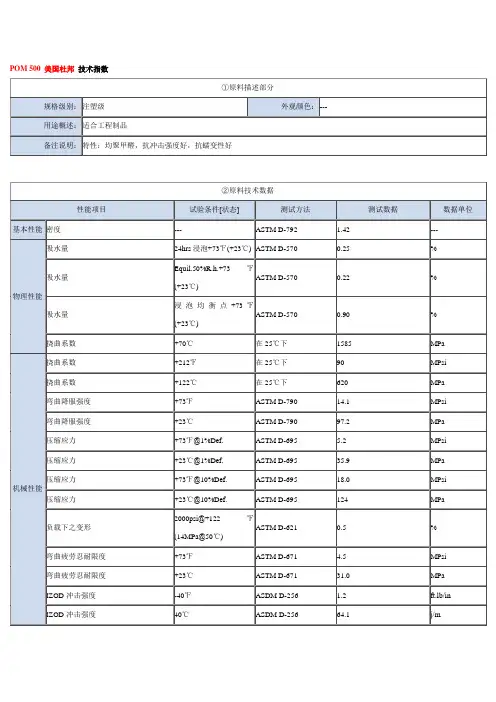

POM 500 美国杜邦 物性表

Sec.

伸张强度

+23℃

ASTM D-638

68.9

MPa

热性能

熔点

---

ASTM D-2133

347

℉

热变形温度

264psi

ASTM D-648

277

℉

热变形温度

1.8MPa

ASTM D-648

136

℃

热变形温度

66psi

ASTM D-648

342

℉

热变形温度

0.5MPa

ASTM D-648

172

℃

可燃烧性

---

UL-94

94HB

---

线性热膨胀系数

-40 to Βιβλιοθήκη 85℉ASTM D-696

5.8

10-5in/in.℉

线性热膨胀系数

-40 to +29℃

ASTM D-696

10.4

10-5m/m.℃

线性热膨胀系数

+85 to +140℉

ASTM D-696

6.8

10-5in/in.℉

ASDM D-256

1.2

ft.lb/in

IZOD冲击强度

40℃

ASDM D-256

64.1

j/m

IZOD冲击强度

+73℉

ASDM D-256

1.4

ft.lb/in

IZOD冲击强度

+23℃

ASTM D-256

74.7

j/m

拉力冲击抵抗力

+73℉

ASTM D-1822

100

ft.lb/in2

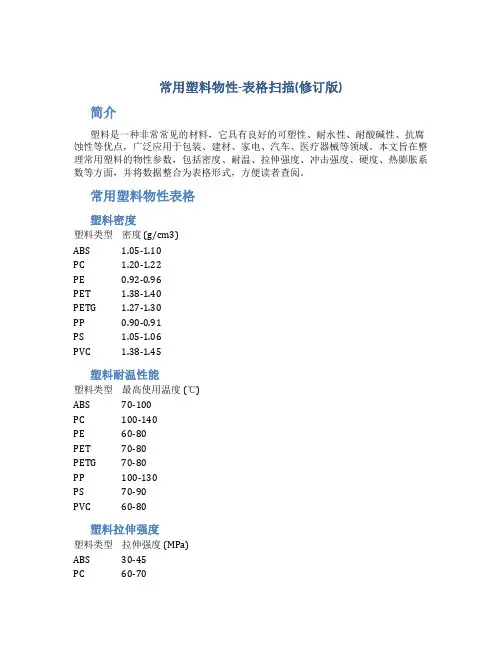

常用塑料物性-表格扫描(修订版)(DOC)

常用塑料物性-表格扫描(修订版)简介塑料是一种非常常见的材料,它具有良好的可塑性、耐水性、耐酸碱性、抗腐蚀性等优点,广泛应用于包装、建材、家电、汽车、医疗器械等领域。

本文旨在整理常用塑料的物性参数,包括密度、耐温、拉伸强度、冲击强度、硬度、热膨胀系数等方面,并将数据整合为表格形式,方便读者查阅。

常用塑料物性表格塑料密度塑料类型密度 (g/cm3)ABS 1.05-1.10PC 1.20-1.22PE 0.92-0.96PET 1.38-1.40PETG 1.27-1.30PP 0.90-0.91PS 1.05-1.06PVC 1.38-1.45塑料耐温性能塑料类型最高使用温度 (℃)ABS 70-100PC 100-140PE 60-80PET 70-80PETG 70-80PP 100-130PS 70-90PVC 60-80塑料拉伸强度塑料类型拉伸强度 (MPa)ABS 30-45PC 60-70PE 12-25PET 55-75PETG 50-70PP 30-40PS 38-48PVC 20-60塑料冲击强度塑料类型冲击强度 (kJ/m2)ABS 10-40PC 60-90PE 15-25PET 10-30PETG 20-25PP 5-20PS 2-10PVC 10-50塑料硬度塑料类型硬度 (shore)ABS 70-110PC 70-90PE 40-70PET 50-120PETG 70-105PP 65-110PS 70-95PVC 70-95塑料热膨胀系数塑料类型热膨胀系数 (10^-5 K^-1) ABS 9-19PC 6-7PE 12.5-20PET 5-6.5PETG 8-10PP 12-20PS 6-8PVC 7-9结论通过以上表格,我们可以看出不同种类的塑料在密度、耐温、拉伸强度、冲击强度、硬度、热膨胀系数等方面有所差别,如在最高使用温度方面,ABS的最高使用温度为70-100℃,而PC的最高使用温度高达100-140℃。

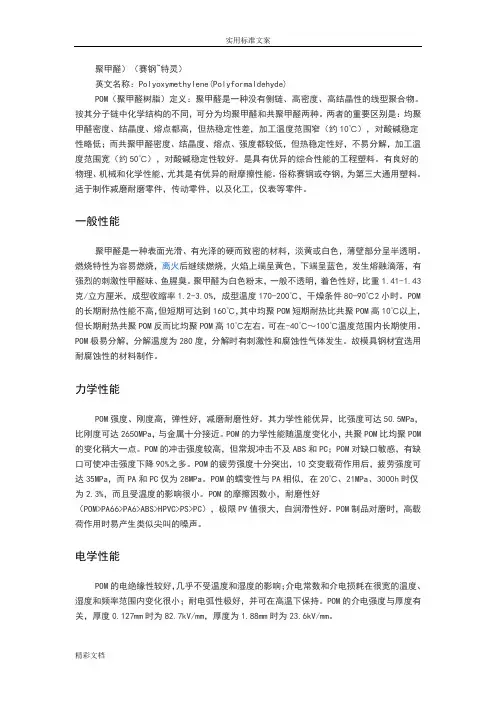

POM赛钢

聚甲醛)(赛钢~特灵)英文名称:Polyoxymethylene(Polyformaldehyde)POM(聚甲醛树脂)定义:聚甲醛是一种没有侧链、高密度、高结晶性的线型聚合物。

按其分子链中化学结构的不同,可分为均聚甲醛和共聚甲醛两种。

两者的重要区别是:均聚甲醛密度、结晶度、熔点都高,但热稳定性差,加工温度范围窄(约10℃),对酸碱稳定性略低;而共聚甲醛密度、结晶度、熔点、强度都较低,但热稳定性好,不易分解,加工温度范围宽(约50℃),对酸碱稳定性较好。

是具有优异的综合性能的工程塑料。

有良好的物理、机械和化学性能,尤其是有优异的耐摩擦性能。

俗称赛钢或夺钢,为第三大通用塑料。

适于制作减磨耐磨零件,传动零件,以及化工,仪表等零件。

一般性能聚甲醛是一种表面光滑、有光泽的硬而致密的材料,淡黄或白色,薄壁部分呈半透明。

燃烧特性为容易燃烧,离火后继续燃烧,火焰上端呈黄色,下端呈蓝色,发生熔融滴落,有强烈的刺激性甲醛味、鱼腥臭。

聚甲醛为白色粉末,一般不透明,着色性好,比重1.41-1.43克/立方厘米,成型收缩率1.2-3.0%,成型温度170-200℃,干燥条件80-90℃2小时。

POM 的长期耐热性能不高,但短期可达到160℃,其中均聚POM短期耐热比共聚POM高10℃以上,但长期耐热共聚POM反而比均聚POM高10℃左右。

可在-40℃~100℃温度范围内长期使用。

POM极易分解,分解温度为280度,分解时有刺激性和腐蚀性气体发生。

故模具钢材宜选用耐腐蚀性的材料制作。

力学性能POM强度、刚度高,弹性好,减磨耐磨性好。

其力学性能优异,比强度可达50.5MPa,比刚度可达2650MPa,与金属十分接近。

POM的力学性能随温度变化小,共聚POM比均聚POM 的变化稍大一点。

POM的冲击强度较高,但常规冲击不及ABS和PC;POM对缺口敏感,有缺口可使冲击强度下降90%之多。

POM的疲劳强度十分突出,10交变载荷作用后,疲劳强度可达35MPa,而PA和PC仅为28MPa。

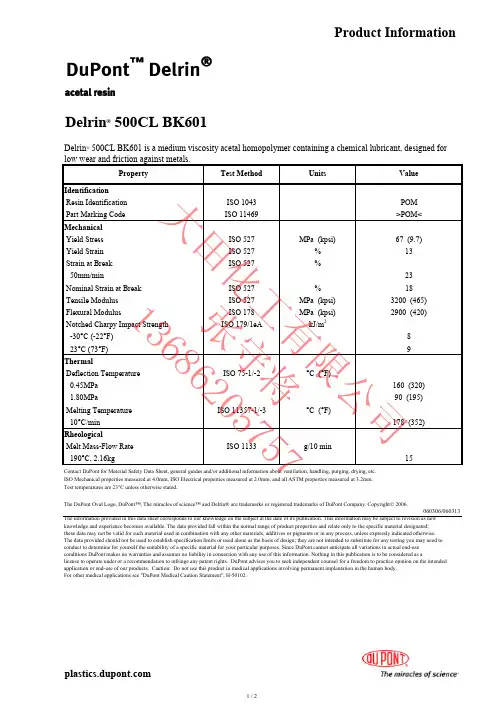

POM 500CL BK601物性表

DuPont ™ Delrin®acetal resinDelrin ®500CL BK601Identification Resin Identification ISO 1043POM Part Marking Code ISO 11469>POM<Mechanical Yield Stress ISO 527MPa (kpsi)67 (9.7) Yield Strain ISO 527%13Strain at Break ISO 527%50mm/min 23Nominal Strain at BreakISO 527%18Tensile Modulus ISO 527MPa (kpsi)3200 (465)Flexural Modulus ISO 178MPa (kpsi)2900 (420)Notched Charpy Impact StrengthISO 179/1eAkJ/m2-30°C (-22°F)8 23°C (73°F)9Thermal Deflection TemperatureISO 75-1/-2 °C (°F)0.45MPa 160 (320) 1.80MPa 90 (195)Melting TemperatureISO 11357-1/-3 °C (°F)10°C/min 178 (352)RheologicalMelt Mass-Flow Rate ISO 1133g/10 min190°C, 2.16kg15Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.060306/060313The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as alicense to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102.Delrin ® 500CL BK601 is a medium viscosity acetal homopolymer containing a chemical lubricant, designed for low wear and friction against metals.PropertyTest MethodUnitsValue大田化工有限公司 张守将 13686205757Delrin ®500CL BK601Electrical CTI IEC 60112V 600FlammabilityFlammability Classification IEC 60695-11-100.75mm HB 1.5mm HB 3.0mmHBTemperature Index RTI, Electrical UL 746B°C0.75mm 50 1.5mm 100 3.0mm 100 RTI, Impact UL 746B°C0.75mm 50 1.5mm 80 3.0mm 80 RTI, Strength UL 746B°C 0.75mm 50 1.5mm 85 3.0mm 85ProcessingMelt Temperature Range°C (°F)210-220 (410-430) Melt Temperature Optimum °C (°F)215 (420) Mold Temperature Range°C (°F)80-100 (175-210)Mold Temperature Optimum °C (°F)90 (195) Drying Time, Dehumidified Dryer h 2-4 Drying Temperature°C (°F)80 (175)Processing Moisture Content %<0.2Hold Pressure RangeMPa (kpsi)80-100 (12-15)Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.060306/060313The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as alicense to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102.PropertyTest Method Units Value大田化工有限公司 张守将 13686205757。

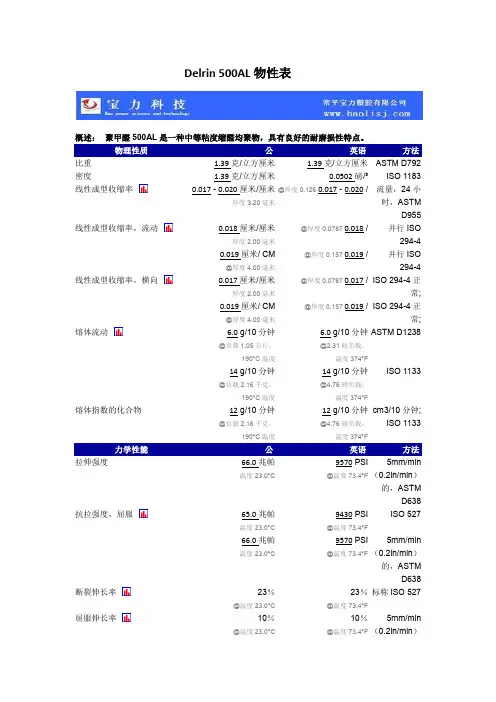

POM耐磨损 Delrin 500AL

@厚度 0.0787 0.017 / ISO 294-4 正

厚度 2.00 毫米

常;

0.019 厘米/ CM

@厚度 0.157 0.019 / ISO 294-4 正

@厚度 4.00 毫米

常;

熔体流动

6.0 g/10 分钟

6.0 g/10 分钟 ASTM D1238

@负载 1.05 公斤,

@2.31 磅负载,

ISO 11469 ISO 1043

169 °C

热变形温度在 1.8 兆帕(264 磅)

97.0 °C 108 °C

UL RTI,电气 UL RTI,机械冲击

UL RTI,机械无冲击 易燃性,UL94

加工性能 熔体温度

50.0 °C

@厚度 0.750 毫米

50.0 °C

@厚度 0.750 毫米

85.0 °C

@厚度 1.50 毫米

90.0 °C

1.00E +6 @频率(Hz)

温度 73.4°F

600 V UL 746A

@ 0118 厚度,

温度 73.4°F

英语

方法

278 μin/in-°F ASTM E 831

温度 73.4 - 131°F

55.6 μin/in-°F

ISO

温度-40.0 - 73.4°F 11359-1/-2 352 °F。 ASTM D3418

温度 73.4°F

431 ksi 的 ASTM D790

温度 73.4°F

1.09 ft-lb/in ASTM D256

@温度 73.4°F

2.38 ft-lb/in² ISO 180/1A

@温度-40.0°F

2.86 ft-lb/in² ISO 180/1A

C-POM物性表

%

抗挠强度

---

ASTM D-790

88

MPa

抗挠系数

---

ASTM D-790

2600

MPa

悬臂梁式缺口冲击强度

---

ASTM D-256

59

J/m

洛氏硬度

---

ASTM D-785

80

M-Scale

洛氏硬度

---

ASTM D-785

115

R Scale

热性能

热变形温度

1.82MPa

ASTM D-648

ASTM D-638

61

MPa

延伸率

---

ASTM D-638

50

%

抗挠强度

---

ASTM D-790

90

MPa

抗挠系数

---

ASTM D-790

2630

MPa

悬臂梁式缺口冲击强度

---

ASTM D-256

59

J/M

洛氏硬度

---

ASTM D-785

80

M scale

洛氏硬度

---

ASTM D-785

0.2

%

熔体流动速率

---

TMA

10

×10-5cm/cm/℃

物理性能

磨耗率

---

ASTM D-1044

14

mg/1000cycles

成型收缩率

---

旭化成方法

1.6-2.0

%

比重

---

ASTM D-792

1.41

---

机械性能

拉伸强度

---

ASTM D-638

POM 500P物性表

101

MPA

拉伸强度

23℃

ASTM D-638

69

MPa

拉伸强度

70℃

ASTM D-638

48

MPa

拉伸强度

100℃

ASTM D-638

36

MPa

拉伸强度

122℃

ASTM D-638

26

MPa

破裂点拉伸变形量

-55℃

ASTM D-638

15

%

破裂点拉伸变形量

23℃

ASTM D-638

MPa

挠曲系数

70℃

ASTM D-790

1720

MPa

挠曲系数

100℃

ASTM D-790

1030

%

挠曲系数

122℃

ASTM D-790

755

MPa

挠曲变形强度

23℃

ASTM D-790

97

MPa

压缩应力

23℃,1%变形

ASTM D-695

35

MPa

压缩应力

23℃,10%变形

ASTM D-695

123

MPa

抗剪强度

23℃

ASTM D-732

66

MPa

挠曲疲劳忍耐限度

50%RH,23℃,106周期

ASTM D-671

31

MPa

负载变形量

140kg/cm2,50℃

ASTM D-621

0.5

%

抗拉伸冲击强度

长试片23℃

ASTM D-1822

420

kj/பைடு நூலகம்2

IZOD冲击试验

无缺口23℃

PBT 杜邦 S600F10 物性表

PBT杜邦DUPONT S600F10物性表:产品提供久隆塑胶原料tEL134********PBT DUPONT Crastin®S600F10NC010是未增强聚对苯二甲酸乙二醇酯纯树脂,润滑,高粘度,注塑成型。

特别适宜成型厚壁产品。

加工方法:注塑,异型材挤出成型,其它挤出成型,表面涂层.Crastin®S600F10is an unreinforced,lubricated,high viscosity polybutylene terephtalate for injection molding.熔体体积流动速度(MVR)10cm³/10min ISO1133温度250°C ISO1133载荷 2.16kg ISO1133模塑收缩率(平行) 1.7%ISO294-4,2577模塑收缩率(垂直) 1.6%ISO294-4,2577拉伸模量2700MPa ISO527-1/-2屈服应力57MPa ISO527-1/-2屈服伸长率4%ISO527-1/-2名义断裂伸长率>50%ISO527-1/-2拉伸蠕变模量(1h)2300MPa ISO899-1拉伸蠕变模量(1000h)1800MPa ISO899-1无缺口简支梁冲击强度(+23°C)N kJ/m²ISO179/1eU无缺口简支梁冲击强度(-30°C)N kJ/m²ISO179/1eU简支梁缺口冲击强度(+23°C) 5.4kJ/m²ISO179/1eA简支梁缺口冲击强度(-30°C)4kJ/m²ISO179/1eA熔融温度(10°C/min)225°C ISO11357-1/-3玻璃化转变温度(10°C/min)55°C ISO11357-1/-2热变形温度(1.80MPa)50°C ISO75-1/-2热变形温度(0.45MPa)115°C ISO75-1/-2维卡软化温度(50°C/h50N)175°C ISO306线性热膨胀系数(平行)130E-6/K ISO11359-1/-2线性热膨胀系数(垂直)130E-6/K ISO11359-1/-21.5mm名义厚度时的燃烧性HB class IEC60695-11-10测试用试样的厚度 1.5mm IEC60695-11-10UL注册UL--厚度为h时的燃烧性HB class IEC60695-11-10测试用试样的厚度0.8mm IEC60695-11-10UL注册UL--燃烧性-氧指数22%ISO4589-1/-2相对介电常数.(100Hz) 3.8-IEC60250相对介电常数.(1MHz) 3.2-IEC60250介质损耗因子(100Hz)20E-4IEC60250介质损耗因子(1MHz)200E-4IEC60250体积电阻率>1E13Ohm*m IEC60093表面电阻率1E15Ohm IEC60093介电强度26kV/mm IEC60243-1相对漏电起痕指数600-IEC60112吸水性0.5%类似ISO62吸湿性0.2%类似ISO62密度1300kg/m³ISO1183熔体密度1110kg/m³-熔体0.21W/(m K)-熔体的比热2100J/(kg K)-注塑成型参数:干燥温度110-130°C干燥时间,除湿机=2-4小时处理水分含量<0.04%熔体温度处理最佳=250°C熔体温度范围240-260°C模具温度最佳=80°C模具温度范围30-130°C型材挤出参数:干燥温度110-130°C干燥时间,除湿机=2-4小时处理水分含量<0.04%熔体温度处理最佳=250°C熔融温度范围为240-260°C。

塑料原料物性表

kJ/m2

N. B. 0.25

℃ ℃ ℃

42 120 90 0.42 2 3 0.0001 > 1014 > 1011 45 HB

DIN 11359 ISO 11359 IEC 60250 IEC 60250 IEC 60093 IEC 60093 IEC 602431 UL 94

W/(K*m) 10-4 * K-1 106 Hz 106 Hz Ohm (Ω) * cm Ohm (Ω) kV/mm Class

NOTE: 1 g/cm3 = 1,000 kg/m3, 1 Mpa = 1 N/mm2, 1kV/mm = 1 MV/m

工程塑膠 防靜電塑膠 鋼 1.39 0.25 45 ≧ 20 1,400 1,450 M84 N. B. 0.2 105 140 100 0.3 0.65 109-11 ≦ 1011 HB 70 N. B. 0.5 88 100 75 0.17 0.8 3.3 0.015 ≧ 1015 ≧ 1013 22 HB ABS 1.06 0.4 45 2,400 82 N. B. 0.38 75 160 100 0.23 0.85 3.5 0.031 ≧ 1013 > 1012 50 HB 尼龍6A 1.13 3 90 ≧ 50 3,000 84 N. B. 0.36 95 180 105 0.23 0.8 3.7 0.03 ≧ 1015 ≧ 1013 50 HB MC尼龍 1.15 2.5 80 3 3,300 83 180 100 0.9 HB MC尼龍-含 油 1.15 2.5 70 20 2,500 R93 75 105 1.1 1010-12 HB 防靜電尼龍 尼龍66 1.15 1.6 52 162 1.14 2.8 90 40 3,100 2,830 82 N. B. 0.35 85 150 80 0.28 0.8 3.3 0.02 ≧ 1014 ≧ 1013 27 HB 鋼氟龍 1.79 < 0.05 50 46 ≧ 50 2,000 2,000 78 N. B. 0.34 104 150 150 0.13 1.2 7.25 0.18 ≧ 1013 ≧ 1014 22 V-0 55 - 60 N. B. 0.08 260 260 0.25 1.2 2.1 0.0002 > 1016 > 1016 48 V-0 鐵氟龍 2.18 < 0.05 25 > 50 700