FC400B新风系统前置电子式空气净化机

北星空气净化器开始套件用户指南说明书

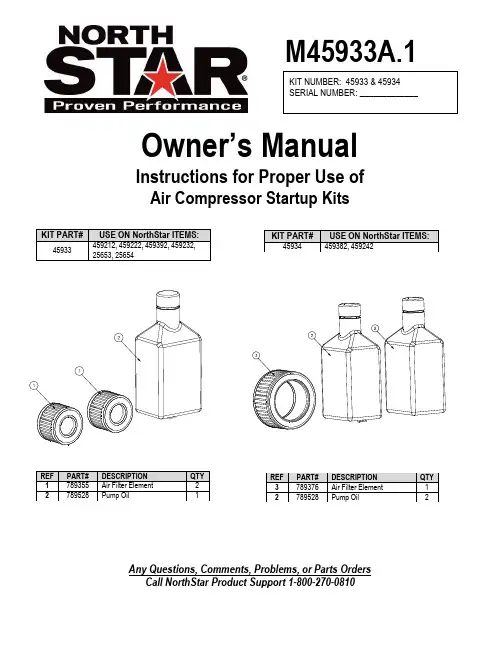

Any Questions, Comments, Problems, or Parts Orders Call NorthStar Product Support 1-800-270-0810TABLE OF CONTENTS (2)INITIAL SET-UP (3)Kit# 45933 (3)Kit# 45934 (3)MAINTENANCE & REPAIR (4)MAINTENANCE SCHEDULE SUMMARY (4)DETAILED INSTRUCTIONS – MAINTENANCE & REPAIR (4)Inspect Safety/Relief Valve (4)Inspect Air Filter (4)Change Air Filter Element (5)Inspect Compressor for Air Leaks (5)Engine Maintenance (5)Change Pump Oil (5)Drain Receiver Tank and Inspect Tank (5)Check Drive Belt for Tension and Alignment (5)Inspect & Clean Spark Arrestor (if Equipped) (6)Keep Compressor Clean (6)APPENDIX A: LUBRICANTS AND COMPATIBILITY (7)Alternate Lubricants. (7)LIMITED WARRANTY (8)See detailed instructions for each maintenance item below.No modifications. Never modify or alter the compressor in any way. Modifications can create serious safety hazards and will also void the warranty.Inspect Safety/Relief ValveThis valve should be inspected on a weekly basis if used regularly or the first time it is being used after a prolonged period of storage. The safety valveautomatically releases air if the tank pressure exceeds the preset maximum.∙ Check the safety/relief valve by pulling the rings.∙Replace safety/relief valve that do not operate freely.Inspect Air FilterInspect the compressor’s air filter element on a weekly basis if used regularly or the first time it is being used after a prolonged period of no use. A dirty air filter will not allow the air compressor to operate at full capacity. ∙ Clean air filter when necessary.∙ Every 12 months or 1000 hours, replace the air filter element.Change Air Filter ElementThe compressor’s air filter element should be changed every 12 months or after 1000 hours of use.Figure 11. Unscrew wingnut and washer used to hold cover in place.2.3.Replace new air filter element and cover,removed previously.Note: Keep the air filter clean. Do not operate with the air filter removed.Inspect Compressor for Air LeaksInspect system for air leaks on a monthly basis, or again, at the first use after a prolonged period of storage.∙ Squirt soapy water around joints duringcompressor operation and watch for bubbles. Developing bubbles indicate a leak is present. ∙ Tighten fittings if necessary.Engine MaintenancePerform engine maintenance as specified in the engine Owner’s Manual. Items include:∙ Change oil after the first 20 operating hours, and at least every 100 operating hours thereafter and oi l filter, as directed in engine Owner’s Manual.∙ Air filter check/replacement∙ Spark plug cleaning/replacement ∙ Fuel filter check/replacement ∙Fuel tank cleaningChange Pump OilNorthern Tool recommends using synthetic oil after the first 50 hour break in period . See “MaintenanceSchedule Summary” for recommended frequency of oilchanges. See “Appendix A: Lubricants ” for suitable alternatives. 1. Remove the oil fill and drain plugs. Collect the oilin a suitable container.2. Clean and replace the oil drain plug and refill compressor crankcase with clean oil.3. Replace the oil fill plug. increasing the risk of tank rupture.Northern Tool recommends a tank inspection after every 2 years of service. See “Inspection of Unfired Pressure Vessels ,” volumes 2-9, August 2001, Bill McStraw (available on-line at NTIS).”Check Drive Belt for Tension and AlignmentBelts will stretch from normal use. When properly adjusted, a 5 lb. force applied to the belt between the engine pulley and the pump will deflect the belt about ½”.To align and adjust drive belt tension: 1. Remove the belt guard cover. Base BodyAir Filter Element Cover WasherWingnut2. Loosen the four fasteners holding theengine/motor to the compressor.3. Shift the engine/motor in the proper direction. Thebelt must be properly aligned when adjustment is made.4. To align belt, lay a straight edge against the faceof the flywheel touching the rim at two places.(Figure 3)Figure 35. Adjust flywheel or engine pulley so that the beltruns parallel to the straight edge.6. If necessary, use a gear puller to move the pulleyon the motor shaft. Tighten set screw after pulley is positioned.7. Check for proper belt tension. (Figure 4)Figure 48. Tighten the four fasteners holding the engine tothe top plate while tension and alignment ismaintained.9. Attach the belt guard cover.Inspect & Clean Spark Arrestor (if equipped) Equip engine with spark arrestor if machine will be used near any ignitable forest, brush, or grassy land. (See engine Owner’s Manual provided to determine if the engine is already equipped.) Make sure you comply with applicable local, state, and federal codes.If the engine is equipped with a spark arrester, clean and inspect it regularly following manufacturer’s service instructions. Replace if damaged.Keep Compressor CleanDo not allow air intakes to become blocked. If dust or debris accumulates in the compressor, clean the compressor with a damp cloth or soft bristle brush.Note: Do not spray compressor with a garden hose orpressure washer. Water may enter the compressorand cause damage to the engine and pump.Contact NorthStar Product Support at 1-800-270-0810 For any questions, problems, or parts orders.The following table lists materials that are suitable or not recommended for use with synthetic oil. As some oil escapes into the compressed air, all components that come into contact with the air (i.e., piping, filters, hoses, tools, etc) must be compatible with synthetic oil. Northern Tool recommends using synthetic oil after the first 50 hour break in period.Alternate LubricantsYou may use a petroleum-based lubricant that is premium quality, does not contain detergents, contains only anti-rust, anti-oxidation, and anti-foam agents as additives, has a flashpoint of 440ºF (227ºC) or higher, and has an auto-ignition point of 650ºF (343ºC) or higher.See the petroleum lubricant viscosity table below. The table is intended as a general guide only. Heavy-duty operating conditions require heavier viscosities. Refer specific operating conditions to NorthStar Product Support at 1-800-270-0810.Dear Valued Customer:The NorthStar Product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits from its high performance. By purchasing a NorthStar product, you show a desire for quality and durability. Like all mechanical equipment, the air compressor you purchased requires a due amount of care. This startup kit will help you treat your air compressor like the high quality piece of machinery it is. Neglect and improper handling may impair its performance. Please thoroughly read the instructions and understand the operation before using your product. Always contact NorthStar Product Support at 1-800-270-0810 prior to having any service or warranty work performed, as some services performed by parties other than NorthStar approved service centers may void this warranty. This warranty is in lieu of any other warranty expressed or implied and NorthStar assumes no other responsibility or liability outside that expressed within this warranty.Limited WarrantyStartup kit and NorthStar air compressor must be purchased coincidentally to receive extended limited warranty on pump. NorthStar shall warranty any piece of equipment manufactured, or parts of equipment manufactured, to be free from defects in material or workmanship for a period of:“Consumer use” means personal residential household use by a consumer. “Commercial use” means all other uses, including use f or commercial, income producing or rental purposes or when purchased by a business.This warranty applies to the original purchaser of the equipment (verification of purchase, in the form of a receipt, is the responsibility of the buyer), is non-transferable, and covers parts and labor.Parts will be replaced or repaired at no charge, except when the equipment has failed due to lack of proper maintenance. If a part is no longer available, the part may be replaced with a similar part of equal function. Any misuse, abuse, alteration or improper installation or operations will void warranty. Determining whether a part is to be replaced or repaired is the sole decision of NorthStar. NorthStar will not provide for replacement of complete products due to defective parts. Any costs incurred due to replacement or repair of items outside of a NorthStar approved facility is the responsibility of the buyer and not covered under warranty. Transportation costs to and from service center is the responsibility of the customer.This warranty specifically excludes the following; failure of parts due to damage caused by accident, fire, flood, windstorm, acts of God, applications not approved by NorthStar in writing, corrosion caused by chemicals, use of replacement parts which do not conform to manufacturer’s specifications, damage to accessory parts such as starting batteries, damage related to rodent and/or insect infestation and damage caused by vandalism. Additional exclusions: loss of running time, inconvenience, loss of income, or loss of use, including any implied warranty of merchantability of fitness for a specific use. Also, Outdoor Power Equipment needs periodic parts and service to perform well, and this warranty does not cover instances when normal use has exhausted the life of a component or the engine.This warranty does not cover any personal injury or damage to surrounding property caused by failure of any part. Repair or replacement of parts does not extend the warranty period.Please fill in the following information and have it on hand when you call in on a warranty claim.Customer Number: ______________________________________________________________Date of Purchase: _______________________________________________________________NorthStar Serial Number: _________________________________________________________Item Number: __________________________________________________________________This page has been left intentionally blankManufactured by Northern Tool + Equipment Co., Ltd Burnsville, MN 55306。

净水先锋400内部结构

净水先锋400内部结构

净水先锋400的内部结构。

1、PE水管

PE水管是净水先锋400水源流通的唯一配件,一般品质好的PE水管使用的都是食品级材质聚乙烯制作而成,安全无毒、耐磨耐腐,使用寿命大概在三年左右。

2、前置颗粒炭滤芯

多用本质、煤质、果壳(核)等含碳物质通过化学法或物理活化法制成。

它有非常多的微孔和比表面积,因而具有很强的吸附能力,能有效地吸附水中的有机污染物。

此外在活化过程中,活性碳表面的非结晶部位形成一些含氧官能团,这些基团使活性碳具有化学吸附和催化氧化、还原性能,能有效去除水中一些金属离子。

3、进水电磁阀

进水电磁阀:整机停止工作时切断水路,a防止后续滤芯继续受到水压的作用;b防止自来水经过RO膜废水通道导致废水流不停,c滤芯寿命降低。

4、冲洗电磁阀

提供RO膜废水快速流动的通道,提高RO膜表面水的流动速度,达

到冲洗RO膜的作用。

5、电脑板

净水先锋400电脑版用来控制整个机器的中枢系统。

近两年全球人工智能技术发展迅速,不少净水先锋400品牌也开始在净水先锋400电脑板上嵌入各种智能芯片,通过手机APP对净水先锋400所有参数和运行实施控制

6、增压泵

市政自来水进入用户家中通常都有一定压力,但是压力达不到净水先锋400所需额定压力,增压泵就是在原有压力上,再加大压力,让水进入净水先锋400内。

7、压力桶

压力桶:储存净水机用,缓解RO膜单位时间内制水量小与用户单位时间内需水量大之间的矛盾。

空气净化器用户使用手册

Scqair1苍穹空气净化器用户使用手册P01 目录企业简介 (2)整机及配件 (3)产品部件介绍 (4)快速使用指南 (5)注意事项............................................................ 6-7 操作说明............................................................ 8-9 净化功能.. (10)技术创新 (11)工作原理 (12)技术参数 (13)保养维护 (14)故障排除 (15)使用前操作事项 (16)售后服务 (17)产品合格证 (17)售后服务卡 (18)感谢您使用苍穹空气净化器,使用前请仔细阅读使用手册并妥善保管。

企业介绍P02上海苍穹环保科技有限公司致力于健康型高科技事业,专注空气净化系列产品的研发、生产、安装和销售。

公司的“圆孔通道均场空气净化装置”、“高频高压除尘灭菌装置“等专利技术,“符合国际上高压静电空气净化技术的发展方向”,属国内领先,并达到国际同类技术的先进水平“。

此技术最重要的特点是,能在有人场所连续同步高效除尘、除菌、除放射性氡子体。

此外,这一技术与一种新型的纳米催化剂材料配合使用,能高效去除空气中的甲醛、苯TVOC等有害气体。

静电式空气净化器技术已经列入卫生部《医疗卫生机构消毒规范》。

苍穹空气净化器通过国家疾控中心检测、获得卫生部(消)字号批文。

苍穹空气净化器已在地铁、机场、医院、学校、宾馆、商场、办公大楼、公交车等公共场和食品、药品、化妆品厂等对空气洁净度有苛刻要求的领域,得以成功应用。

苍穹“静电式车用空调配套空气净化装置”是中华人民共和国科技部创新基金支持项目,这项技术产品在2010年世博会专用申沃大巴成功推广。

它能同时除尘杀菌出醛、去除PM2.5,是目前洁净车内空气、保障司乘人员健康呼吸的最为便捷有效的技术。

首创的苍穹“除氡”专利技术,改变了原来的空气净化器不能去除空气中放射性污染认识。

FC400-User Manual

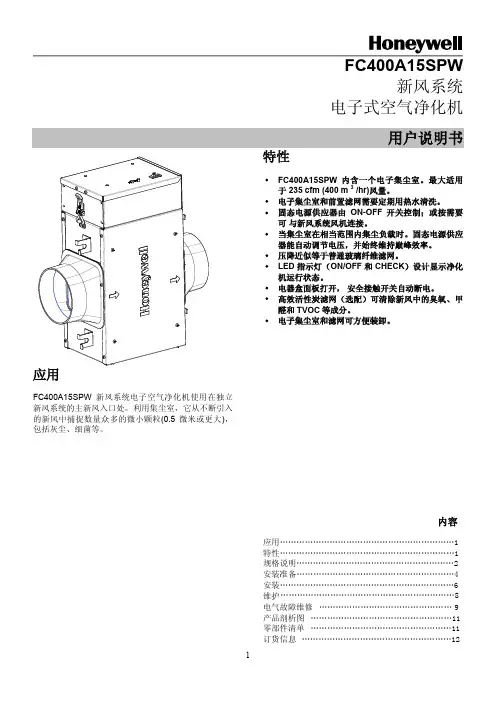

FC400A15SPW 新风系统电子空气净化机

规格说明

重要申明:

于此刊物中所列示之规格并不包含一般制造公差。故真 正实品单位与所列之规格可能有制造公差的差异。而且 本产品是在严密控制下测试测定的,如果这些条件有所 改变,可预期在其性能表现上有微小差异。

安装:

安装在新风入口,新风机进风口的前端,特别适合天花 吊顶。

图 8. 接线

FC400A15SPW接线图

BLACK RED

P4 HV2 P3 HV1 POWER SUPPLY ELECTRONIC CELL

P8

CHECK ON/OFF BROWN BLACK

1 2 3 4

ON/OFF开关 互锁开关 与电源连接 LED指示灯

L N P1 P2

4

P10

N L

220VAC, 50Hz

8

FC400A15SPW 新风系统电子空气净化机

电气故障检修

开关灯

开关灯可从前面板上看见,电源供应器为其提供高电 压。当开关灯亮,其指示空气净化机处于通电状态,电 源供应器工作正常。

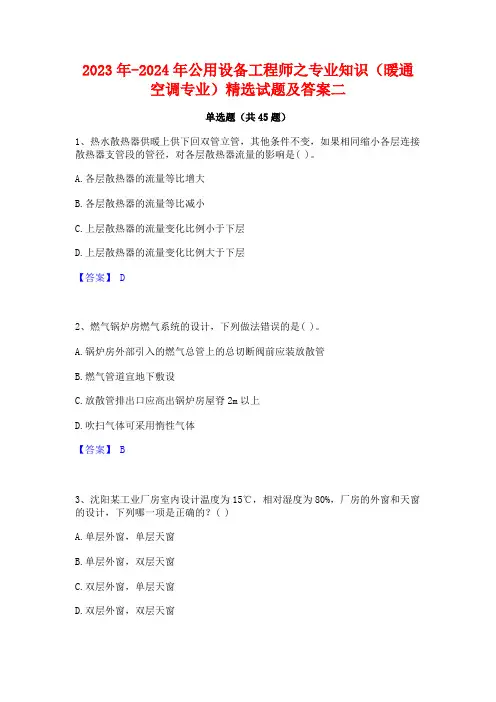

2023年-2024年公用设备工程师之专业知识(暖通空调专业)精选试题及答案二

2023年-2024年公用设备工程师之专业知识(暖通空调专业)精选试题及答案二单选题(共45题)1、热水散热器供暖上供下回双管立管,其他条件不变,如果相同缩小各层连接散热器支管段的管径,对各层散热器流量的影响是( )。

A.各层散热器的流量等比增大B.各层散热器的流量等比减小C.上层散热器的流量变化比例小于下层D.上层散热器的流量变化比例大于下层【答案】 D2、燃气锅炉房燃气系统的设计,下列做法错误的是( )。

A.锅炉房外部引入的燃气总管上的总切断阀前应装放散管B.燃气管道宜地下敷设C.放散管排出口应高出锅炉房屋脊2m以上D.吹扫气体可采用惰性气体【答案】 B3、沈阳某工业厂房室内设计温度为15℃,相对湿度为80%,厂房的外窗和天窗的设计,下列哪一项是正确的?( )A.单层外窗,单层天窗B.单层外窗,双层天窗C.双层外窗,单层天窗D.双层外窗,双层天窗4、在风机盘管十新风系统中,新风机组为定风量系统,各房间的设计新风量均相同,各房间的新风支管均无风阀。

关于不同的新风接入室内方法的表述中,下列哪一项是错误的?A.新风接入风机盘管回风,口处,风机盘管高速运行房间的新风多于低速运行的房间B.新风接人风机盘管送风管处,风机盘管停机的房间送入的新风量最大C.新风单独接人室内,送入的新风量不随风机盘管的运行与否而改变D.三种新风接入方法送入的新风量完全一样【答案】 D5、某地的室外设计干球温度为36℃、相对湿度为80%,送风干球温度为15℃,相对湿度为30%的直流式全新风系统,冷水供回水温度为7/12℃。

该系统的空气处理过程,下列哪一项是正确的?A.新风→一级冷却→二级冷却B.新风→一级冷却→一级转轮除湿C.新风→一级转轮除湿→一级冷却D.新风→一级冷却→一级转轮除湿→二级冷却【答案】 D6、燃气冷热电三联供系统中,哪种发电装置获得的高温余热量最大?( )A.内燃机型发电机组B.燃气轮机型发电机组C.微燃气轮机型发电机组D.都差不多7、设置集中采暖的民用建筑物,其室内空气与围护结构内表面之间的允许温差与下列何项无关?( )。

新风换气机20110101

新风入口 (OA)

新风出口 (SA)

污风出口 (EA)

污风入口 (RA)

倒置安装时检修口位置

型号

新风量 (m3/h)

机外静压 (Pa)

焓回收率(%)

制冷

制热

温度回收率 (%)

噪声 dB(A)

额定 电压

(V) 低 高 特高 低 高 特高 低 高 特高 低 高 特高 低 高 特高 低 高 特高

XHBQ-D1.5TP 115 150 150 34 58 75 67 63 63 74 70 70 77 75 75 22 24 26 220

小型高效系列新风换气机 small TP series, suspended type

XHBQ-D1.5TP~D10TP

特 点:

节能明显 交叉逆流板式热交换器的使用,提高了能量回收率,降低 了空气阻 力,节能效果更加明显;

规格更多 风量范围115~2000m3/h,适合住宅、会议室、实验室、 办公室、 机房、餐饮及健身等场所使用;

20110101 本公司产品不断改进求新,文件数据如有变更,恕不另行通知

北京环都人工环境科技有限公司

Beijing Holtop Artificial Environment Technology Co.,Ltd

地址:北京市海淀区韩家川158号

邮编 P.C:100094

Address:No.158 Hanjiachuan Road,Haidian District,Beijing China

11

小型壁挂系列

Wall type

13

高效节能的热交换器

Brief introduction to heat exchanger

14

开利BFP变风量空气处理机组

320 270

1

485 630

67.0

1

355 500

67.0

43.12 64.20 33.10 8.28 81.87* 92.80 72.60 13.32

380 350

1

595 740

72.5

2

205 380

61.0

45.66 67.60 35.60 8.64 93.46* 103.00 74.50 14.04

箱体内部

过滤网

安装方便,利于维修

机组结构合理,外形美观、性能优异、质量可靠,由于采用先进的数控机床 加工设备,零部件的互换与组合质量得以充分保证,便于现场拆装。

4

BFP性能参数

机组 型号

风量 m³/h

BFP2 2000 BFP2I 2000 BFP3 3000 BFP3I 3000 BFP4 4000 BFP4I 4000 BFP5 5000 BFP5I 5000 BFP6 6000 BFP6I 6000 BFP7.5 7500 BFP7.5I 7500 BFP8 8000 BFP8I 8000 BFP9 9000 BFP9I 9000 BFP10 10000 BFP10I 10000 BFP12 12000 BFP12I 12000 BFP15 15000 BFP15I 15000 BFP16 16000 BFP16I 16000 BFP18 18000 BFP18I 18000 BFP22 22000 BFP22I 22000 BFP24 24000 BFP24I 24000 BFP27 27000 BFP27I 27000 BFP30 30000 BFP30I 30000 BFP36 36000 BFP36I 36000 BFP40 40000 BFP45 45000 BFP50 50000

飞利浦 三合一智能凉暖风空气净化器 8000i 用户手册说明书

用户手册Air Performer8000i 系列三合一智能凉暖风空气净化器AMF870目录1 重要事项 (1)安全 (1)电磁场 (EMF) (3)回收 (3)2 您的三合一智能凉暖风空气净化器 (4)产品概述 (4)显示概述 (5)遥控器概述 (6)3 使用入门 (7)安装滤网 (7)首次使用遥控器 (7)了解 Wi-Fi 指示灯 (7)Wi-Fi 连接 (8)4 使用三合一智能凉暖风空气净化器 (9)了解空气质量指示灯 (9)打开和关闭 (10)摇摆送风 (11)功能切换 (11)设置风速/温度 (12)劲速模式 (12)模式切换 (13)设置童锁 (14)设置定时 (14)光传感器 (14)5 清洁和保养 (14)清洁计划 (15)清洁机身 (15)清洁微粒传感器 (15)清洁滤网表面 (16)更换滤网 (16)滤网重置 (18)更换电池 (18)6 存放 (19)7 故障排除 (20)8 保修和支持 (21)1 重要事项安全使用本产品之前,请仔细阅读本用户手册,并妥善保管以备日后参考。

为了确保实现出色的性能,请务必将三合一智能凉暖风空气净化器升级到最新版本。

您可以通过智慧家App进行此升级。

危险• 切勿让任何液体或易燃性清洁剂进入产品,以免发生触电和/或火灾。

• 为了避免过热和火灾,请勿盖住设备。

警告• 本产品的某些部件可能会变得很热且造成烫伤。

对于有儿童和脆弱人群的场合,必须提供持续监督。

• 本产品不适合由肢体不健全、感觉或精神上有障碍或缺乏相关经验和知识的人(包括儿童)使用,除非有负责其安全的人对他们使用本产品进行监督或指导。

• 3 岁到 8 岁之间的儿童只有在产品已放置或安装在其预期的正常工作位置,并已得到有关安全使用产品的监督或指示且了解可能产生的危险时,才可开启/关闭该产品。

• 3 岁到 8 岁之间的儿童不得插入、调节和清洁产品或进行用户维护。

• 3 岁以下儿童应远离,除非持续监督。

空气净化器说明书

空气净化器说明书 Document serial number【KKGB-LBS98YT-BS8CB-BSUT-BST108】专利产品 仿冒必究 安阳振动器有限责任公司(集团)为确保产品的正确、安全使用,请在使用前仔细阅读本说明书产品简介◆ 产品简介.................................................................................1 ◆ 使用范围.................................................................................1 ◆ 系统组成.................................................................................1 ◆ 技术参数 (1)使用维护◆ 使用注意事项 (2)联合制造 安阳安振环境高科有限公司 智能空气净化新风系统产品使用说明书◆空气净化流程图............................................................... (4)◆操作使用说明............................................................... . (5)◆常见故障............................................................... .. (11)◆温馨提示............................................................... .. (12)◆接线图............................................................... (13)附件◆智能空气净化新风系统保修卡此标志表示禁止之事项此标志表示必须遵循事项注:使用电源220V/50Hz使用注意事项使用本智能空气净化新风系统时,请注意以下事否则会损坏新风系统。

关于高层办公楼空调方式

诱导器系统(IUS)

顶式诱导器(欧洲称“冷梁”)的应用实践

作为热湿分别控制的方式,国内已有应用

北京全国工商联大厦(与苏宁集团联合投资),深井水经板交,二次 水可直接进干盘管。新风系统分层设置,从井水源热泵得到的制冷水

供OAAHU,窗边用FCU(一般可不开)

国家环保局签约中心(3万m2,地上9F) 西门子大楼

特点

灵活性大 可系统化应用

经冷却水系统(水侧)—— WLHP

经冷剂管道 —— VRF

型式发展

风冷:一体型:窗式、穿墙式(TWU)

分体型:一拖一、一拖多(多联机)、VRF 功能:舒适性、全新风、低温型

性能

空调机组性能曲线

空调机组冷风比

性能系数:COP / EER / SEER / IPLV (对APF),总体比“大机”小;

传统方式 —— 为了空气处理过程中

获得必要的去湿量,制冷机蒸发温度 较低,使机组效率降低

新方式 —— 由DESICA机组仅对新

风用固体吸湿法去湿(利用热泵型机 组与干式去湿法相结合),循环风部 分用传统制冷(或供热)方式处理空

气,二者结合组成系统

两种方式的主体区别见下图

DESICA机组的构造

(2002年)

空气-水系统的温湿度独立处理

风机盘管+新风系统(FCU+FA)

民用建筑(医院) 大型微电子生产车间

诱导器系统(IUS)

特点

高速诱导一次风,能耗大 个别调节影响系统工况 高速喷口噪声处理问题 无新风室内就不能供冷——优点

应用

我国上世纪70年代研发(应用: 和平饭店、延安饭店、华山医院 等),80年代后被FCU取代, 欧洲仍用