南阳二机石油装备(集团)有限公司钻机设备安全警示(中英文)

钻井安全操作规程中英文

1. Reeving on Drilling Line1.1 Operational RequirementsA. Pre-job meeting must be held before the reevingoperations commence.B. Direct communication among all personnel isessential during this operation.C. The drawworks anchor clamp assembly on thefast line end must be changed out, as a whole, each time a new one is installed.D. Traveling block hanging strops and shackle,snake and safety harness must be inspected before this operation commences.E. All crew members working in derrick must wearsafety harness.F. A visual inspection of the drilling line shall be donebefore the procedure commences.G. Check and ensure the proper size andspecifications of the replacement drilling line.H. Avoid scrubbing the new drilling line against thederrick and the substructure.I. The new drilling line must be reeved onto thedrawworks drum under tension.J. The new drilling line should never be allowed to touch the ground where dirt or sand could be picked up.K. Inspect crown sheaves for wear prior to installation of drilling line.Special care should be taken to ensure the drilling line is not kinked.1.2 Reeving on Drilling Line from New Spool to Replace Existing Drilling LineA. Hang off the drill string in slips and install the Kellycock (in the open position), on the drill pipe.B. Disengage the crown-o-matic.C. Hang off and secure the traveling block with thededicated hang-off line.D. Cut off the excess drilling line from the old storagespool using the hydraulic line cutter; leave a sufficient length to attach a snake to the old drilling line. 1. 穿大绳1.1操作要求A. 在穿大绳作业开始之前,必须先召开工前会。

安全告知牌(中英文对照)

安全生产纪律Safety Work Rules1.进入现场必须戴好安全帽、系好帽带、并正确使用(穿好)个人劳动保护用品。

Enter construction site requires correctly wear a helmet with chinstrap fastened and the use of other personal protection equipments.2.二米以上的高处作业、悬空作业、无安全设施的,必须系好安全带、扣好保险钩。

For aloft work above two meters height,dangling work and work without safety protection, workers should wear safety belts and buttoned insurance hook.3.高处作业时,不准往下或向上乱抛材料和工具等物件。

Worker on site are prohibited to throw material and tools to upside or downside.4.各种电动机械设备必须有可靠有效的安全接零(地)和防雷装置、才能开动使用。

All electrical machinery and equipment must be reliable and have effective safety grounding and lightning protection devices which then can be start to use.5.不懂电气和机械的人员,严禁使用和玩弄机电设备。

Unprofessional electrician and mechanical personnel Prohibit operating and playing with electrical and mechanical equipment.6.吊装区域非操作人员严禁入内、吊装机械必须完好、吊臂垂直下方不准站人。

南阳二机直升飞机吊装石油钻机通过评审

本 刊讯 , 久 前 , 台钻 井 深 度 可 达 50 m 的 不 一 00 石 油钻 机 , 大模块 仅重 2 7吨 , 种 吊运 模块 全球 最 . 这 最 轻 的直升 飞机 吊装钻 机技术 方案 及全套 图纸 在南 阳二机 集 团问世 , 被 巴西 直 升 飞机 吊装 钻 机专 家 并 誉 为“ 世界一 流 的方 案 和技 术 ”顺 利 通 过 了专家 评 ,

多个模 块 , 0 以上 的模 块 被 控 制在 2 4 以下 , 9 .t 所

在 巴西亚 马逊 热带 雨林道 路条 件不好 和环 境敏

感 的富 油 区 , 把钻机 合理 分解 为多个 吊运 模块 , 使用

有模块均不超过 2 7, .t使用小型直升机即可轻松 吊

运 , 品整体 性能 达到 国际先 进水 平 。 产

大项 目的总 体 目标 是研 发 出先 进 实用 的航 空地 球物 理 勘查 技术 系统 , 以满足 我 国矿产 资源勘 查对 快速 、

谱仪的硬、 软件上却依赖进 口。研制开发出具有我 国 自主知识产权的航空伽玛能谱勘查 系统 , 以打 可 破 国外 公 司的垄 断 和技 术 封 锁 , 升 我 国航 空 地 球 提

能产 品 , 经过 严格 的测试 和试 验飞 行 , 具 备 了用 确认

于勘查 的条件, 即将应用 于地质矿产资源保障工程

的地质 找矿 工作 。

国家 8 3 6 计划 “ 空地球 物理 勘查技 术 系统” 航 重

国外航空伽玛能谱测量产 品被欧美 大公 司所垄断,

其关键 性技 术在 国际上 是 保 密 的 , 且存 在 技 术 封 而 锁 。我 国虽 然在 航空伽 玛 能谱测 量 的数 据处 理 和成 果 解 释方 面处 于 国际先 进 行 列 , 是 在航 空 伽 玛 能 但

外资企业(国企)国标安全警示禁止提示系统标识中英文可打印

1-9禁止转动1-10禁止叉车和厂内机动车辆通行1-11禁止乘人1-12禁止靠近1-13禁止入内1-14禁止推动1-15禁止停留1-16禁止通行1-17禁止跨越1-18禁止攀登1-19禁止跳下1-20禁止伸出窗外1-21禁止倚靠1-22禁止坐卧1-23禁止蹬踏1-24禁止触摸1-25禁止伸入1-26禁止饮用1-27禁止抛物1-28禁止戴手套1-29禁止穿化纤衣服1-30禁止穿带钉鞋1-31禁止开启无线移动通讯设备1-32禁止携带金属物或手表1-33禁止佩戴心脏起搏器者靠近1-34禁止植入金属材料者靠近1-35禁止游泳1-36禁止滑冰1-37禁止携带武器及仿真武器1-38禁止携带托运易燃及易爆物品1-39禁止携带托运有毒物品及有害液体1-40禁止携带托运放射性及磁性物品国家标准(GB 2894-2008)安全标识中国国家标准GB2894-2008《安全标志》是由中华人民共和国劳动部制定,经国家技术监督局批准,自2008年开始实施。

该标准提醒人们注意不安全因素、防止事故发生。

标准规定了传递安全信息的标志,适用于工矿企业、建筑工地、厂内运输和其他有必要提醒人们注意安全的场所。

安全标志共分为:禁止标志、警告标志、指令标志和提示标志四大类型。

设置范围和地点易发生坠落事故的作业地点,如:脚手架、高出平台、地面的深沟(池、槽)、建筑施工、高出作业场所等。

警示类标识警示类:提醒人们对周围环境引起注意,以避免可能发生危险的图形标识幻灯片11幻灯片3禁止烟火NO BURNING幻灯片4禁止带火种NO KINDING幻灯片5禁止用水灭火NO EXTINGUISHING WITH WATER 幻灯片6禁止放置易燃物NO LAYING INFLAMMABLE THING 幻灯片7禁止堆放NO STOCKING 幻灯片8禁止启动NO STARTING 幻灯片9禁止合闸NO SWITCHING ON幻灯片10禁止转动NO TURNING 幻灯片11禁止叉车和厂内机动车辆通行NO ACCESS FOR FORK LIFT TRUCKS AND OTHERINDUSTRIAL VEHICLES幻灯片12。

中石化胜利油田安全生产禁令英文版翻译

中石化胜利油田安全生产禁令英文版翻译一、严禁在禁烟区吸烟,在酒后上岗。

First, is prohibited in the smoking area in the drink posts.二、严禁高处作业不系安全带。

Second, high operating without a seatbelt is strictly prohibited.三、严禁无操作证从事电气、起重、电气焊作业。

Third, is strictly prohibited without operating certificate in electrical, crane, electric welding operations.四、严禁违反操作规程用火、进入受限空间、临时用电、破土作业、点燃加热炉。

Fourth, in violation of the rules prohibited the use of fire, confined space entry, temporary power, ground-breaking work, lit the furnace.五、严禁油气装卸人员违规作业擅离岗位。

Fifth,Prohibited illegal operation of oil and gas handling personnel absent without leave.六、严禁不停机进行抽油机维修、保养工作。

Non-stop pumping machine repair and maintenance work.七、严禁不使用绝缘防护器具进行电气操作。

Non-insulated protective equipment is not used for electrical operation.八、严禁带高温、高压检维修设备设施。

Prohibited with high temperature and pressure inspection and maintenance of equipment and facilities.九、严禁不佩带安全防护器具进行含硫化氢井操作。

钻机设备译文

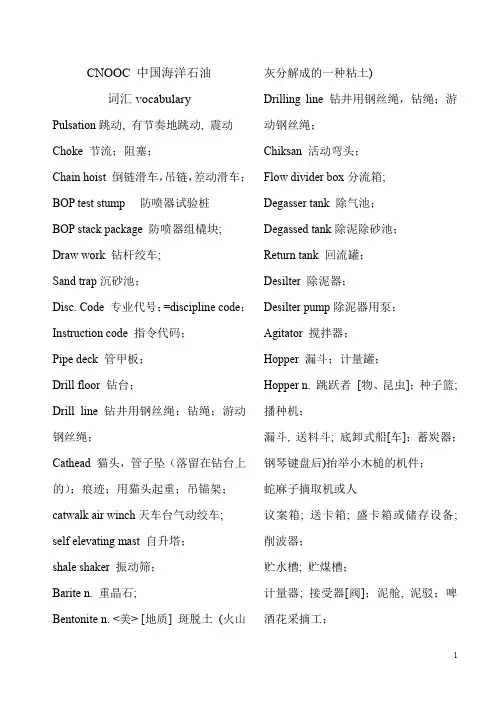

CNOOC 中国海洋石油词汇vocabulary Pulsation跳动, 有节奏地跳动, 震动Choke 节流;阻塞;Chain hoist 倒链滑车,吊链,差动滑车;BOP test stump 防喷器试验桩BOP stack package 防喷器组橇块; Draw work 钻杆绞车;Sand trap沉砂池;Disc. Code 专业代号;=discipline code;Instruction code 指令代码;Pipe deck 管甲板;Drill floor 钻台;Drill line 钻井用钢丝绳;钻绳;游动钢丝绳;Cathead 猫头,管子坠(落留在钻台上的);痕迹;用猫头起重;吊锚架;catwalk air winch天车台气动绞车;self elevating mast 自升塔;shale shaker 振动筛;Barite n. 重晶石;Bentonite n. <美> [地质] 斑脱土(火山灰分解成的一种粘土)Drilling line 钻井用钢丝绳,钻绳;游动钢丝绳;Chiksan 活动弯头;Flow divider box分流箱;Degasser tank 除气池;Degassed tank除泥除砂池;Return tank 回流罐;Desilter 除泥器;Desilter pump除泥器用泵;Agitator 搅拌器;Hopper 漏斗;计量罐;Hopper n. 跳跃者[物、昆虫];种子篮; 播种机;漏斗, 送料斗; 底卸式船[车];蓄炭器;钢琴键盘后)抬举小木槌的机件;蛇麻子摘取机或人议案箱; 送卡箱; 盛卡箱或储存设备; 削波器;贮水槽; 贮煤槽;计量器; 接受器[阀];泥舱, 泥驳;啤酒花采摘工;自动播种机;有倾斜斗的小推车;厕所;[澳]袋鼠;Hopper-cooled adj. 连续水冷却的;Hopperdozer n. 灭蝗机;hopper feed n.料斗供料机;Hopperman n. 自卸泥驳的船员;自卸泥驳维修工;。

南阳二机集团将低碳钻机进行到底

机 研 制 成 功 并 顺 利 通 过 验 收 , 始 发 往 用 开

“ 过去钻机试验完成后 , 中残油直接 罐

石油钻 井行 业 走进绿 色低 碳新 时代

户 。该设备能够直接利用井场当地现有的 随钻机发往用户 , 不仅 白白浪费掉 , 而且还 电网为交流 电动机供 电 , 每钻一 口井 比柴 增 加 了 产 品 运 输 重 量 , 可 惜 了 。 现 在 把 太

井 装 备 国产 化基 地 ”南 阳二机 石 油装 备 ,

( 团 ) 限公 司在节能减 排 集 有

上 硕果 累 累 :

南 阳二机 技术负 责人介绍 , 国现阶 不超过 1 , 场 占地少 , 家 时可 比传 我 5吨 井 搬 段 生 产 的石 油钻 机 几乎 全部 统钻机 节约一半 时间和车次 , 大幅提高 了 采用 柴油机 或 柴油 发 电机作 工作效率 。 为主动力 , 能耗 大 、 污染 大 、 噪 在我 国出 口欧盟 的首 台 70 0 0 米橇装 声大 。 随着 我 国对 各行 业节 钻机 发运前 , 阳二机集 团总装二分 厂 二 南 三

目2 项 , 得 省 级 以上 科 技 进 步 奖 1 项 ; 编成册 , 2 获 9 对博 士后进 站 、 在站 、 出站管理 及 成系列化 , 并实现批量 出口俄罗斯 、 加拿大

获得 专 利 16 , 中获 国家 1项 其 发 明专利 1 项 ; 0 先后制定 国家

行业标准 4 项。 5 地 引 进 和 使 用 高 层

2 1 年 1 5日 , 内 首 台 2 0 米 节 油 为动力源 的常规钻 机节能 3%以上 , 02 月 国 0 0 0 同 这些残油 回收 、 过滤后 , 还可以当作 铸锻分

能经济型网电钻机在南 阳二机集团研 制成 时 又减少 了柴油机的维护费及大量用油的 厂锻造 加热炉 的燃 油用 , 一举 两得呀 。 采 ”

南阳二机产品(英文)

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manuf acturers f or petroleum drilling equipment in China. It is a stoc k company, reorganized f rom Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manuf acturing Plant of National P etroleum Industrial Ministry of China). As a f ormer national technical equipment production base, authorized by f ormer national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product tri al production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.RG PETRO-MACHINERY (GROUP) CO. LTD, w ith its technical center, inf ormation center and quality inspection center at provincial level, has possessed 16 production plants f or f orging, metal machining, heat treatment, steel-structure manuf acturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites f or drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.RG PETRO-MACHINERY (GROUP) CO. LTD has established a complete quality assurance system and HSE system. It is one of the f irst companies that got the certif ication of ISO9001 /2000 in the industry of Chin a and now its products are licensed w ith API spec 8A, 8C, 11E, 4F,7K and pass the “3C” compulsory certif ication of China.RG PETRO-MACHINERY (GROUP) CO. LTD provides 110 types of products in 10series, including: 1000m-4000m truc k-mounted drilling ri gs, 1000m-7000m skid-mounted drilling rigs,1000m-4000m trailer-mounted drilling rigs,25T-225T onshore worko ver rigs,60T-225T off shore workover rigs,4000m-7500m well-logging equipment, 50T-70T heavy-duty trailers, top-drive unit, petroleum special vehicles and wellhead tools.By Firmly holding the principle of “Customer First”, RG PETRO-MACHINERY (GROUP) CO. LTD has established a professional service organization in all the domestic major oilfields to provide all-around after-sales services ranging from equipment installation, debugging, maintenance, training and spare parts supply. The products of RG PETRO-MACHINERY (GROUP) CO. LTD are in great demand in all the oilfields of China and have been exported to about 20 countries and regions across the world, such as: The United States of America, Canada, Mexico, Russia, Turkmenistan, Kazakhstan, India, Iraq, Egypt, Sudan, Nigeria and Venezuela.石油钻井装备-车装钻机This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1、4F、7k、8C and RP500,GB3826.1,GB3836.2,GB7258,SY6584 Standards as well as “3C”compulsory standard.* The whole rig has a compact structure, which requires a small installation space due to kits high integration.* The heavy-duty and self-propelled chassis: 8×6、10×8、12×8,14×8、14×12、16×12 and hydraulic steering system are utilized respectively, which ensures the drilling rig a good passage and cross-country capability.* The reasonable assembly of CATERPILLAR engine and ALLISON transmission box can ensure high driving efficiency and working reliability.* The main brake adopts hydraulic disc brake or band brake and Air brake or hydromatic brake or FDWS brake can be applied as auxiliary brake.* The rotary table transmission box can realize forward-reverse shift, which can be suitable for all kinds of DP rotary operations, and the anti-torque releasing device can be used to make the DP deformation force released safely.* The mast, which is front –open and double-section type with an inclination angle or erective double-section type, can be erected or lowered and telescoped hydraulically.* The drill floor is twin-body telescopic type or with parallelogram structure, which is convenient for easy hoist and transportation. The height of the drill floor can be designed according to the client’s requirements.* The perfect configurations of solid control system, well control system, high-pressure manifold system, generator house, engine & mud pump house, doghouse and other auxiliary facilities can meet user’s different requirements.Truck-mounted drilling rig 1000m Truck-mounted drilling rig 3000mTruck-mounted drilling rig 1500m 3000m Truck-mounted drilling rig (VFD-drive)Truck-mounted drilling rig 2000m Truck-mounted drilling rig 4000mVFD drilling rigs 石油钻井装备-橇装钻机* This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1、4F、7k、8C、9A and RP500,GB3826.1、GB3836.2 ,SY5609 standards.* These drilling rigs adopt an advanced AC-VFD-AC or AC-SCR-DC drive system and a non-step speed adjustment can be realized on the drawworks, rotary table and mud pump, which can obtain a good well-drilling performance with the following advantages: calm startup, high transmission efficiency and auto load distribution.* One -to -one control is designed for the VFD system and one-to –two control is designed for the SCR system., The intellectual control of the drillerover the drilling rigs can be realized by PLC system and the integrated design of touch screen parameters of gas, electricity, fluid and drilling instrumentation.* K type mast and the swing-up/sling-shot substructure have a good stability and provide a large working space. The mast and the equipment on the drill floor can be assembled on the ground and raised integrally.* The skid module structure can make the whole unit very compact and quick for movement, which can meet the requirements of the whole-unit-trucked transportation and of cluster-type-well drillings.* The drawworks will be driven by a single-shaft gear with a non-step speed adjustment. The transmission is simple and reliable.* The drawworks is equipped with a hydraulic disc brake and a motor-energy-consumption braking, and the braking torques can be controlled via the computer.* An auto bit feeder is equipped individually to realize real-time monitoring to the dropping process and drilling process of the DP.* Safety and inspection measures are strengthened under the guidance of the design concept of “Humanism Above All” to meet the requirements of H SE.The trailer-mounted drilling rigs 石油钻井装备-拖挂钻机* This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1、4F、7k、8C and RP500,GB3826.1、GB3836.2 GB7258,SY6584 standards as well as“3C”compulsory standard.* These drilling rigs have following advantages: reasonable design structures and high integration, a small working space and a reliable transmission.* The heavy-duty trailer is equipped with some desert tires and large-span axles to improve the moveability and the cross-country performance.* A high transmission efficiency and performance reliability can be maintained by a smart assembly and a utilization of two CAT 3408 diesels and ALLISON hydraulic transmission box.* The drawworks is double- drum type, with which the hydraulic disc brake is equipped as main brake and air water-cooling disc brake (Model EATON WCB324) is equipped as auxiliary brake.* The derrick which is front -open type and has two –section structure with an inclination angle or erective sections can be lifted up or fallen down and telescoped.* The substructure has a parallelogram integral structure for easy transportation and installation, which can be risen by 6 setbacks spirally.* This kind of drilling rigs with desert adaptability design also have good anti-dust and high/low- temperature-proof performances.* Safety and inspection measures are strengthened under the guidance of the design concept of “Humanism Above All” to meet the requirements of HSE.石油修井装备-大吨位陆地修井机* This kind of workover rigs are designed and manufactured in accordance with API Spec Q1、4F、7k、8C and technical standards of RP500,GB3826.1、GB3836.2 GB7258,SY5202 as well as“3C”compulsary standard.* The whole rig structure is compact, highly integrated, and requires a small space for installation.* The heavy-duty chassis are 8×6、10×8、12×8、14×8 constant- drive and self-propelled, equipped with hydraulic steering system and have a good capability of passage and cross country.* A good and reasonable assembly of CATERPILLAR engine and ALLISON transmission box can supply a high driving efficiency and increase safe performance.* Band brake or disc brake is applied for the main brake and the air disc brake/water brake or FDWS is used for auxiliary brake.* The compound box for rotary table has a function of forward-reverse speed shift gears, which can be suitable for DP’s rotary operations. The anti-torque releasing device can be used to release the deformation energy of the DP safely.* The mast is front –open type, with double- section structure, which can be telescoped, raised and extended hydraulically.* The drill floor is twin-body telescopic type or with parallelogram structure, which is convenient for installation and transportation. The dimension and height of the drill floor can be designed according to the user’s requirements.* Safety and inspection measures are strengthened under the guidance of the design concept of “Humanism Above All” to meet the requirements of HSE.XJ100石油修井装备-小吨位陆地修井机* This kind of workover rigs are designed and manufactured in accordance with API Spec Q1、4F、7k、8C and technical standards of RP500,GB3826.1、GB3836.2 GB7258,SY5202 as well as“3C” compulsory standard.* The whole unit structure is compact and adopts hydraulic + mechanical driving mode, with high comprehensive efficiency.* The workover rigs adopt II-class or self-made chassis with various to meet the user’s different requirements.* The mast is front-open type and with single-section or double-section structure, which can be raised and telescoped hydraulically or mechanically.* Safety and inspection measures are strengthened under the guidance of the design concept of “Humanism Above All” to meet the requirements of HSEXJ30XJ40XJ50石油修井装备-特殊环境用修井机Desert workover rig 沙漠修井机Swamp workover rig 滩涂修井机Slant-well workover rig 斜井修井机The offshore workover rigs: 海洋钻修设备-海洋修井机* This kind of workover rigs are designed and manufactured in accordance with API Spec Q1、4F、7k、8C and technical standards of RP2A-LRFD,2Z,14F,14G,500,GB3826.1、GB3836.2 GB7258,SY5202.* A reasonable assembly of Caterpillar engine and Allison hydraulic transmission box can insure safety. The offshore workover rigs can be driven by VFD or SCR, which has a high driving efficiency and are easy to control.* The derrick is erective and front open, which can be structured with two sections or with T-type or telescopic multi sections without ropes for fixing. The effective height of the derrick is 29m, 31m and 33m.* According to the finite element structure analysis, the whole unit can fully meet the customer’s requirements of wind-resistance and anti-vibration capabilities* The surface of structural parts are treated with sand blasting, spray-painting baked painting, spray-aluminum and spray-zinc to meet the requirements of ocean environment and climate.* The rotary equipment, solid-control equipment and well-control equipment are equipped to meet the requirements of drilling and workover operations. The whole unit can be moved horizontally and longitudinally to meet cluster-well operation requirements.* Safety and inspection measures are strengthened under the guidance of the design concept of “Humanism Above All” to meet the requirements of HSE.HXJ60 HXJ80HXJ100 HXJ125石油专用车辆Mast-carrying truckWell flushing truck Pump-carrying truck Pipe-carring truckTubing elevator Iron roughman提升系统及旋转设备Hook block Swivel Power swivelDeadline anchor Kelly drive bushingRotary table Hydraulic disc brake·Cementing Truck压裂固井设备-固井车Max. Working pressure: 35MPa~100MPa Max. discharge capacity: 1600L ~ 3700L/min Inc. Trailer model, Truck Model, Skid modelThe mud mixing control system is designed as Auto mud mixing density control, manual control and numeric display system.·Fracturing truck压裂固井设备-压裂车FRAC truck is the truck model design inc, engine, transmission, drive system. Plunger pump, control system, lubrication system, low/high pressure pipe lines.The unit can be working independently and in group.Main pressure:·Sand Mix Truck压裂固井设备-混砂车Full hydraulic drive system for the sand transfer and sand mixing equipment, Stepless speed control, hydraulic centralized operation.Main parameter:·Snubbing Unit石油修井装备-不压井修井机Full hydraulic snubbing unit consists of carrier system, power system, BOP system, raising and downward system, control system. The power system is installed on the front-middle of the axle. The raising and downward system adopts hydro-cylinder and sheave set structure, and each component become in series by multiplication lines and then integrated install on the rotary platform. The lifting up and laying down of the whole raising and downward system is done after rotating around the rear support with the help of lifting hydro-cylinder, thus, the raising and downward system is under the following two condition: running and transport. Wellhead tools (hydraulic slip, BOP stacks, etc) are fixed on the working platform by bolts, and transported along with working platform. Except the working platform and wellhead tools, the other systems are integrated on the self-propelled carrier, The unit can run with any auxiliary device, raising up or laying down a tubing at one time, with the performance of quick raising and high working effective.Main parameter:1.Model: YYBYJ80/212. Depth: 4000m (3 1/2″EUE)3. Max. Lifting load: 800KN4. Lifting speed: 1m/s5. Max. pull down: 200KN6. Pull down speed: 0.4m/s7. Lifting stroke: 16mm8. Hydraulic working pressure: 21MPa9. Dynamic working pressure: 14MPa10. Static working pressure: 21MPa·Coiled Tubing Unit连续油管作业车The CTU designed according to the USA and Canada technology is the main product of the company. And already be used in USA, Canada, Mid-east, South American, Russia and China.MAIN TECHNICAL PARAMTERS•Coiled Tubing Diameter: 1-1/ 1-3/•Coiled Tubing WT: Variable, according attached design (20 KLbs overpull).•Coiled Tubing Yield Strength: 90 Kpsi•Maximum Working Pressure: 10 Kpsi• Continues Pull Power: 60 KLbs/80 KLbs/100 KLbs•Continues Push Power: 30 KLbs/40 KLbs/50 KLbs•Coiled Tubing maximum Speed: Variable up to 185 ft/min | 120 Ft/Min @ 50,000 lbs•Steady Running Speed: 0.5 Ft/Min•Working temperature: -20°C~+ 45°CTRAILERCAT ENGINEPOWER PACK UNIT, INJECTOR HEAD HOSE REELSCOILED TUBING REELCOILED TUBING 1-1/ 1-3/WELL CONTROL EQUIPMENT, CONTROL CABINTechnical parameters:1. Fast operation speed, high efficiency and save the working time, mobility and save cost.2. Can be used for drilling, cementing, sanding, fishing, logging, workover/service, and well complete.。

ZJ40L钻机使用说明书

2.1 TC225-00 天车 -------------------------------------------------------------------------------- 8 2.2 JJ225/43D-K 井架 ---------------------------------------------------------------------------- 9 2.3 JC40 绞车 -------------------------------------------------------------------------------------10 2.4 转盘驱动装置 -------------------------------------------------------------------------------14 2.5 DZ225/6.0 底座 ------------------------------------------------------------------------------15 2.6 动力系统 -------------------------------------------------------------------------------------17 2.7 气控系统 -------------------------------------------------------------------------------------18 2.8 液控系统 -------------------------------------------------------------------------------------20 2.9 司钻房 ----------------------------------------------------------------------------------------21 2.10 司钻偏房------------------------------------------------------------------------------------22 2.11 井口机械化工具 ---------------------------------------------------------------------------22 2.12 机泵组及高压泥浆管汇 ------------------------------------------------------------------23 2.13 智能化参数仪表 ---------------------------------------------------------------------------23 2.14 电控系统------------------------------------------------------------------------------------24

钻井设备及工具中英文对照ok

钻井设备及工具中文名称English name中文名称English name 储能器accumulator刮管器casing scraper循环池active tank套管鞋casing shoe(刹把)调节螺栓adjusting bole套管卡瓦casing slip进气管admission pipe套管打捞矛casing spear搅拌器agitator套管四通casing spool空气包air chamber套管大钳casing tong气管线air line锚头绳cat line气动绞车air-operated hoist锚头绳爪cat line grip交流电驱动alternating current drive锚头轴cat shaft环形BOP annular BOP锚头cat-head消音器ato-muffler井口甲板cellar deck水泥cement球阀ball valve水泥伞cement basket井口喇叭管bell nipple水泥塞cement plug老虎钳bench vise水泥阻流环cement retainer钻头bit固井质量检查cementing bond log钻头装卸器bit breaker水泥头cementing head钻头规bit gauge固井管线cementing line盲板防喷器blind ram preventer固井泵cenmenting pump剪切闸板防喷器blind shear ram preventer链chain防喷器blow-out preventer链钳chain pipe tong螺栓bolt链钳chain tong防喷器控制盘BOP control pannel房间,寝室chamber防喷器平台BOP deck阀箱,闸室chamber gate底塞bottom piug灌注泵charge pump母扣box止回阀、回压凡尔check valve刹把brake level(brake handle)节流阀、阻流器choke刹带brake line (brake staple)阻流管线choke line桥塞bridge plug节流阀位置指示器choke position indicator 梯形扣buttress节流阀choke valve蝶阀butterfly valve阻流管汇choke-line manifold旁通by-pass离合器clutch旁通塞by-pass plug导管conductor牙轮cone卡钳callipers牙轮打捞器cone fisher套管打捞筒casing bowl牙轮卡死cone lock套管接箍casing coupling冷却水泵cooling-water pump套管隔刀casing cutter取心筒鞋core barrel shoe套管吊卡casing elevator取心爪core basket套管悬挂器casing hanger取心钻头core bit套管头casing head岩心爪core catcher套管平台casing monkey board 岩心爪外套core catecher case岩心烘箱core drying oven 外部割刀external cutter变换接头crossover joint(x/o)吊耳、吊环eye plate天车crown block绳套、接环eye splice天车梁crown block beam灌泥浆管线fill up line死绳dead line失水测定仪filtration test apparatus死绳固定器膜片dead line diaphragm指梁finger board死绳固定器dead line anchor打捞钩fishing hook除气器degasser打捞头fishing head井架derrick打捞震击器fishing jars除砂(泥)器desander(desilter)打捞颈fishing neck直流电驱动direct current drive打捞公锥fishing nipple排出管线discharge line打捞作业sishing operation排出阀discharge valve打捞母锥fishing socket双闸板防喷器double ram type preventer打捞矛fishing spear入井工具down hole tool打捞管柱fishing string绞车draw works打捞公锥fishing tap(taper)绞车电机drawworks motor打捞工具fishing tool通径规drift mandrel法兰flange钻铤drill collar扁锉flat(round,square)file钻铤卡瓦drill collar slip扁嘴钳flat bit tongs钻杆drill pipe平地铣鞋flat bottom mill钻杆卡瓦drill pipe slip绕性接头flexible joint钻杆刮泥器drill pipe wiper 浮鞋float shoe钻柱drill string浮阀float valve司钻控制台driller's console浮箍floating collar司钻监视器driller's monitor四通阀four-way valve钻井大绳drilling line(workline)卡点测定仪free point indicator钻杆防喷器drilling stem valve贯眼钻杆接头full hole joint驱动轴drive shaft漏斗粘度计funnel viscometer从动轴driven shaft传动链条driving chain 储气筒gas holdre(tank)滚筒drum大门gate滚筒容量drum capacity闸门阀gate valve滚筒离合器drum clutch鹅颈管goose neck pipe滚筒高速(低速)drum hight air clutch空气离合器drum low air clutch锤子hammer分级箍DV collar加重钻杆heavey weight drill pipe厚壁钻杆heavy wall drill pipe涡磁刹车eddy current brake高压管线hagh pressure line吊卡elevator开眼器hole opener吊卡耳环elevator link大钩hook吊卡-卡盘elevator-spider大钩弹簧hook spring应急牙嵌离合器emergency jaw clutch水龙带hose(刹带的)平衡杠equalizing yoke卸扣液缸hydraulic break-out cylinder 外卡钳external cutter液压锚头hydraulic catwork液压泵hydraulic pump上扣猫头make out catchead液压油箱hydraulic reserviur手摇钻manual drill液压大钳hydraulic tibg手动阀manual valve液动阀hydraulic valve转盘大补心master bushing液动试压泵hydraulic (press)test pump铣鞋millingshoe液压绞车hydraulic-powered winch铣具milling tool混合漏斗mixing hopper惯性inertia混合泵mixing pump惯性刹车inertia brake猴台monkey board入口inlet电机,马达motor内岩心筒inner core barrel小鼠洞mouse hole中间套管intermediate casing泥浆比重计mud balance钻刚内防喷器intermnal blowout preventer泥浆清洁器mud cleaner内卡钳internal callipers泥浆槽mud ditch内外加厚internal external upset挡泥板mud guard内平钻杆接头internal flush joint泥浆枪 mud gun泥浆泵mud pump震击器jar泥浆泵安全阀mud relieg valve牙嵌离合器jaw cluth泥浆返出管线mud rutern line接头,单根joint泥浆池mut pit笼式打捞篮junk basket打捞爪junk catcher钉子nail打捞杯junk sub近钻头扶正器near-bit stabilizer针形阀needle valve方补心kelly bushing扳手加长套筒nigger-head方钻杆考克kelly cock镊子nipper方保接头kelly pretective sub非磁钻铤non-magnetic drilling collar 方钻杆旋转短节kelly spinner常闭阀normal close valve键槽破坏器key seat reamer常开阀normal open valve压井管线kill line水眼nozzle弯管knee pipe螺帽nut带帽螺栓nut bolt梯子laddre自动螺母扳手nut spinner水平仪level提伸短节listing plug油位oil level滑车装绳数lifting sub油位检查丝堵oil level check plug缸套line reeving油柜oil tank尾管liner油尺oil-level dipstick锁紧螺栓liner开口扳手open-ended spanner锁紧法兰lock bolt外岩心筒outer core barrel低压管线locking flange出口outlet润滑油泵low pressure line加油孔lube oil pump油漆刷paint brush磁力打捞工具lubrication hole领眼钻头pilot bit公扣pin卸扣猫头magnetic fishing tool销子pin钳子pincers螺钉screw撬杠pinch bar螺丝刀screw driver活塞piston无缝钢管seamless pipe活塞皮碗piston up立根盒容量setback capacity活塞杆piston rod沉砂池setting pit手钳子pliers轴shaft旋塞阀plug valve振动筛shalc shaker气动工具pneumatic tool减震器shock absorber硅酸盐水泥portland cement 倒开门吊卡side door elevator动力卡瓦power slip单根吊卡single join elevator动力供应设备power supply unit单闸阀防喷器single ran type preventer 动力大钳power tong计算尺slide rule动力扳手power wrench管钳slide tongs缓冲罐pressure snubbling tank吊索sling生产层套管production casing卡瓦slip滑轮pulley卡瓦补心slip bushing反循环接头pump-out reversing sub卡瓦牙板slip dog短钻杆pup pipe joint 卡瓦槽slip groove卡瓦牙slip insert快速联结quikck connection 卡瓦打捞筒slip socket(卡瓦)锥形座slip socket bowl(井架大门处)坡板ramp套筒扳手socket大鼠洞rat hole卡盘spider正规钻杆接头regular tool joint螺旋钻铤spiral drill collar调节阀regulator valve钢丝绳打捞钩spud spear放压管线relief line开眼钻头spudding bit承托环retaining ring (support ring)插入式注水泥stab-in cementing反循环阀reverse circulation valve对扣台(下套管用)stabbing board反循环打捞篮reverse circulation junk basket扶正器stabilizer反循环孔reverse circulation port不锈钢stainless steel导档齿轮reverse gear立管stand pipe倒扣工具reversing tool插人头stinger钢圈ring gasket(内管)注水泥管柱stinger strings梅花扳手ring spanner双端螺栓stud铆钉river双头螺栓stud bolt转盘rotary table盘根盒stuffing box转盘电机rotary table motor 接头sub转盘风机rotary table motor blower 吸入管线suctionline吸入阀suction valve安全卡瓦safety clamp(slips)表层套管surface casing安全接头safety jont水龙头swivel安全限位档块safety stop安全开关safety switch卷尺tape measure安全带safty -strap(belt)三通tee捞砂滚筒sand reel丝扣thread筛布screen cloth丝扣油thread dope护丝thread protector先行水ahead water三牙轮钻头three-cone bit环空流速annular velocity大钳tong表观黏度apparent viscosity大钳平衡器tong bucket倒扣back off大钳牙板tong dies回压back pressure钳头tong head打好背钳back up attachment大钳刻痕tong mark泥包ball up大钳搭绞部位tong space压舱水ballast water工具接头tool joint尾水behind water工具钢tool steel宾汉模型bingham model顶(底)塞top(bottom) plug钻头成本bit cost水泥面top of the cement钻头直径bit diameterTOTCO承托环TOTCO ring baffle plate 钻头进尺bit footage游动滑车traveling block钻头IADC编码bit IADC code泥浆计量罐trip-tank钻头寿命bit lift两通阀two way valve钻头位置bit position钻头系列号bit series number井架大门v-door钻头齿bit teeth阀门valve钻头时间bit time阀,凡尔valve钻头类型bit type凡尔体valve body钻头磨损bit wear阀盖,阀帽valve bonnet吹扫作业blow job凡尔座balve cup(seat)扫线用管线blow line阀面valve face吹压压力blowing pressure阀杆valve lever井喷blowout阀密封valve seal 防喷bolwout control起阀座器valve seat grab防喷设备blowout control equipment 阀弹簧valve spring装卸防喷器BOP handling灵敏指针vernier沉砂bottom fill虎钳vice(=vise)井底压力bottom-hole pressure双母接头box-box connection壁钩wall hook套管程序casing program冲管wash pipe套管尺寸casing size耐磨补心wear bushing阳离子表面活性剂cationic surface active agent 井口装置well-head equipment烧碱caustic soda造斜器whip stock水泥胶结cement bond翼状扶正器wing stabilizer水泥串槽cement channeling 20"“ L”型接头type "l" connector固井失败cement failure水泥冲洗cement flush水泥浆cement slurry固井配方cementing formulation循环circulation粘土泥浆clay base mud控制钻进control drilling岩心取样coring sample腐蚀corrosion临界速度critical velocity气显示gas showing天车防碰装置crown block protector硬地层hard formation天车防碰装置crown block saver井眼尺寸hole size割大绳cut off drilling line井眼纠斜hole straightening危险品danderous objects大钩负荷hook load除垢剂degasser efficiency大钩位置hook position井斜测量deviation survey初切力initial gel-strength压差卡钻differential pressure sticking内管注水泥inner string cementing定向钻井directional drilling表面活性剂interface level indicator定向井directional well方入kelly down狗腿dog leg方入深度kelly dowm depth狗腿率dog leg ratio方入kelly in停工时间down time方余kelly up通径drifting键槽卡钻key-seating sticking钻具组合drilling assembly井涌kick钻进突变drilling break 控制井涌kick control钻进承包商drilling contractor压井kill well钻井成本drilling cost甩钻杆lay down the drill pipe钻进时间drilling hours漏失实验leak-offtest钻井作业drilling operation左旋“J”型槽left-hand J-slot钻井程序drilling preogram迟到时间log time钻井报表drilling report低固相泥浆low solid mud钻井日报drilling daily report最小速度maximum pressure钻井水drilling water平均海平面maximum speed钝钻头分级dull bit grading平均潮面mean sea level戴纳钻具dyna-drill泥浆添加剂mean tide level乳化剂emulsifying agent泥浆柱mud additive刺坏erode out泥浆柱mud column评估井evaluation well调节泥浆mud conditioning初探井exploratory well泥浆处理材料mud conditioning materials 疲劳极限fatigue limit泥线mud line自动灌浆浮鞋fill-up float shoe泥浆录井mud logging泥饼filter cake泥浆量mud volume降失水剂filtration-reducing agent不漏no leak絮凝作用flocculation无返出no return流压flowing pressure水眼效率nozzle efficiency失水fluid loss水眼尺寸nozzle size地层formation离开井底off-bottom地层测试formation test海上offshore地层水formation wter漏油oil leak淡水fresh water油层压力oil reservoir pressure功能测验function test耐油橡胶oil resistant gom气含量gas content油封oil seal气侵gas cut油页岩oil shale泥浆中的气gas in mud油基泥浆oil-base mud气层gas reservoir接触井底on bottom裸眼open hole开钻spud in作业者operator开钻泥浆spud mud上提,遇卡overpull挤水泥squeeze cement上扣过紧overtonging分级注水泥squeeze cementing钟摆钻具组合pendulum bottom hole assembly待命stand-by机械钻速penetration rate待命费stand-by rate塑性黏度plastic viscosity启动(泵)start ip(pump)塑料plastics静压static pressure水泥回堵plugging back卡钻sticking管内压降pressure loss in pipe卡点sticking point压力试验pressure test泵冲stoke泵入水泥塞pump down plug抽吸压力swab pressure泵效pump efficiency抽吸swabbing泵压pump pressure 转盘高度table height泵速pump speed转盘扭矩table torque泵冲pump stroke试纸test paper额定流量rated flow绸化时间thicking time划眼reaming错扣thread alternating记录record造扣thread making记录纸recording paper脱扣thread off松开捞矛releasing spear滑扣thread slipping缓凝剂retarder缩径井眼tight hole反循环reverse circulation大钳扭矩tong torque钻台rig floor起下钻trip转盘转速fotary speed起下钻时间tripping time下套管run casing事故troubles运转时间running time垂深vertical depth下入工具running tool增稠剂viscosifier砂桥sand bridge侯凝wait on cementing饱和盐水泥降saturated salt-water mud壁厚wall thickness晕船sea sick开泵循环下放wash dowm海水泥浆seawater mud冲刷井段wash out section坐卡瓦setting slip水击water hammer浅层气shallow gas钻压weight on bit泥质砂岩shaly sand加重材料weighting materials短起下short trip井口流压well head flow pressure 关井shut-in井位well location关井套压shut-in casing pressure通井wiper trip关井钻杆压力shut-in drill pipe pressure作业指令working instruction请病假sick leave工作压力working pressure侧钻side tracking倒大绳slip drilling line坍塌sloughing ,caving苏打soda软地层soft formation固相含量solid content锚anchor救生圈life buoy抛锚船anchor boat救生衣life jacket风速表anemometer救生艇lifeboat重晶石barite照明lighting气压计barometer水位报警器liquid level alarm般土bentonite定位浮标locating buoy锅炉boiler人孔、检修孔manhole爬杆boom人孔盖manhole cover防喷演习BOP drill指示灯、标志灯marker lamp手提式CO2灭火器CO2 hand-portable fire-extingusisher隔膜泵membrane pump空压机compressor锚泊系统mooring system冷凝器condenser马达油motor oil吊车crane拖航灯navigation lights甲板deck空载、空车no load柴油机diesel engine障碍灯obstruction light吃水线draft line超载overload电动机electrical motor泥浆池测定演习pit drill排烟管engine exhaust line 可移动式1211灭火器portable 1211 extinguisher柴油engine oil手提式干粉灭火器portable dry powder fire extinguisher 逃生呼吸器escape bresthing apparatus生活水(淡水)portable water (fresh water)传真facsimile压载水preload water消防报警系统fire alarm system压载preloading消防演习fire drill通风设备rrentilation太平门fire escape软(绳)梯rope laddre消防斧fire hatchet接线盒rosette消防管线fire line安全网safety net消防面罩fire mask卫生水管线sanitary line消防服fireman's suit海水淡化装置swawater distillation unit急救设备first-aid equipment海水管线seawater line急救箱first-aid kit分离器seperator泡沫灭火系统foam fire extinguishing sysem值班船stand-by boat燃油(柴油)fuel(diesel oil)担架stretcher防毒面具gas mask潜水泵submerged pump发电机generator救生服survival suit砂轮机grinder电话telephone硫化氢气体检测系统H2S gas detection system电传打字机teletype热交换器heat exchanger电传打字电报telex加热盘管heating coil试运转、试车test run直升机平台helicopter port温度计thermometer可膨胀式救生阀inflatable liferaft可控硅thyristor升降室jack house计时器、秒表timer升船jacking 气焊torch升降系统jacking system拖缆towing line信号、信号灯lantern收发报机transceiver车床lathe变压器transformer桩腿leg打字机typewriter卸载unload可变载荷variable load排气孔vent hole电焊条welding electrode绞盘、绞机windlass工作救生衣work life jacket气压表air pressure gauge流量警报器flow alarm流量指示器flowing indicator流量计flowing meter泥浆流量计mud flow meter泥浆体积指示器mud volume indicator 油压表oil pressure guage泥浆液位计pit level meter位置指示器position indicator压力表pressure gauge泵冲数计数器pump stroke counter 泵冲数指示器pump stroke indicator 泵冲数传感器pump stoke sensor转盘转速表rotary speed indicator 转盘扭矩表rotary torque indicator 灵敏度sensitivity指重表weight indicator。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

特别提醒:

●调整检修发动机、液力变矩器、分动箱绞车等传动系统前,务必先停

止发动机。

●操作人员进入井场,应戴好安全帽,穿好劳动防护用品。

●加注发动机燃油或气路系统酒精时,严禁明火及吸烟。

●发动机启动后,不宜立刻重载运行,应空载或轻载运行一段时间,待

各部分温度正常润滑良好后,方可进行重载工作动作。

●主机就位后,将分动箱挂合手柄置于作业状态,在钻机作业时,严禁

摘挂装置。

●作业时,发动机转速不低于1200r/min工作,以使液力变速箱有足够的

润滑油量。

●严禁挂合倒档起下钻。

●钩载超过1150kN时,采用双机并车,摘挂并车装置时,发动机必须

熄火。

●液力变速箱采用气控换档方式。

主机装有多种电气元件。

当主机需要

电焊维修时,必须切断车辆电源,防止烧坏电气元件。

●洗车时不要淋湿电气控制箱。

●井架竖立安装后,务必拉好各绷绳,确保井架安全。

作业中,在任何

情况下不得松卸绷绳。

●井架在竖立状态下,严禁动作支腿油缸,以防止发生井架倾翻的严重

事故。

●井架伸缩时(仅用于二层井架),各扶正器工作必须正确。

●井架起升、下落及伸缩前,必须清理现场,清除油缸活塞、柱塞杆异

物,理顺各绷绳。

●井架起升、下落及伸缩前,必须排放液压系统空气,起升、伸缩油缸

空气;井架在伸出过程中,大钩要置于井架下部,扶正器要完全打开。

●井架起升、下落及伸缩时,井架上、井架前后不得有人。

●发动机重载运行后,要怠速运转五分钟后方可熄火。

●大钩负荷接近最大钩载时,要对井架进行安全检查。

O P E R A T E N O R M A L L Y A N D S T A N D A R D L Y!

S A F E T Y A T T E N T I O N!

★Stop the engine if any repairs or adjustments are required for transmission system , such as engine, hydraulic torque converter, transfer case, Drawworks and so on.

★It is forbidden for operators without labour safety devices and safety helmet to be in the well site.

★Open fire and smoking are forbidden when filling fuel oil for the engine or filling alcohol for pneumatic system.

★It is forbidden for engine to run with full load as soon as starting. Engine should run without load or with light load till every part get normal temperature and good lubrication.

★Putting the switch-on handle of the transfer case to the WORKING position.

When operation, disengaging transfer case is forbidden. Engine of the working drilling rig running with a speed less than 1200r/min is forbidden, otherwise, lubricant oil of the hydraulic torque converter won't be enough.

★Tripping operation with back motion is forbidden.

★Stop engine when starting the hydraulic pump. Only need to start one pump when the drilling rig is working.

★Two engine paralleling method is used when the load of the hook-block is over 129US.t, Engine should stopped when user engages the compound box.

★Hydraulic gear box adopts a pneumatic speed control method. In order to ensure electrical components safety, electric circuits for the main unit should be cut off if any welding repairs are required for the main unit.

★It is forbidden for all electric control consoles to get wet when cleaning the main unit.

★In order to ensure the mast safely, please tighten each guy line after the mast has been upright installed. It is forbidden for all guy lines to be removed when the drilling rig is working.

★It is forbidden for hydraulic cylinder to move in the situation of mast upright, otherwise, serious accidents of mast abnormal falling will be occured.

★Every centralizer should normally work when the mast is telescoping. (only for

double section mast)

★Before the mast raising, dropping or telescoping, please clean all obstacles (including obstacles of all cylinder piston rods and plunger rods) and make each guy line separately if some guy lines got tangled up.

★Before the mast raising, dropping and telescoping, please exhaust all air of the hydraulic

system, raising cylinders and telescoping cylinders. Hook-block should place on the mast lower section and all centralizers should fully open during the period of the mast extending out.

★Before the mast raising, dropping and telescoping, Loiterers keep away.

★After engine has been run with high duty load, don’t stop the engine till it idly run for 5 minutes

★Mast safely checks should be performed when the hook-block works with a load approach the maximum capacity of the hook-block.。