数控机床英文操作面板

FANUC系统数控机床MDI操作面板按键的详细说明

FANUC系统数控机床MDI操作面板按键得详细说明:1 ALTER 修改程序及代码2 INSRT插入程序3 DELET删除程序4 EOB完成一句 (END OF BLOCK)5 CAN 取消(EDIT 或MDI MODE情况下使用)6 INPUT输入程序及代码7 OUTPUT START 输出程序及指令8 OFFSET 储存刀具长度、半径补当值9 AUX GRAPH 显示图形10 PRGRM 显示程序内容11 ALARM 显示发生警报内容或代码12 POS 显示坐标13 DGONS PARAM 显示自我诊断及参数功能14 RESET 返回停止15 CURSOR 光标上下移动16PAGE上下翻页17 O程序号码由 O0001~O999918 N 顺序号码由N0001~N999919 G 准备功能代码20 X 坐标轴运动方向指令21 Y 坐标轴运动方向指令22 Z 坐标轴运动方向指令23H长度补偿功能代码24 F 进给(FEED)指令25 R圆弧半径指令26M辅助功能指令27 S主轴指速指令28 T 刀具号码29 D 半径补偿功能代码30 I 、J 、K 圆弧起点至圆弧中心距离(分别在X,Y,Z轴上)31 P 子程序调用代码32 PROGRAM PROTECT程序记忆保护开关33 MEMORY 自动执行程序34 EDIT 编辑35 MDI 手动编辑36 SINGL BLOCK单句执行37 BLOCKDELET 指定不执行单句程序 (与 / 键共享)38 OPT STOP 选择性停止 (与M01码共享)39 DRY RUN 空运行40 PRGTEST不执行M、S、T、码指令41 CYCLE START循环动(执行程序)42CYCLE STOP 循环停止(暂停程序)43 PRG STOP 程序停止(与M00共享)44HOME 返回X、Y、Z、各轴机械原45 JOG 手动进给(行位或切削)46 MPG 手动驱动器50 HIGH 手动快速进给51 SPDL DEC 主轴(RPM)速52 SPDL100%执行程序中S指令速53 SPDL CW 主轴顺时钟转动54 SPDLSTOP 主轴停止55 SPDL CCW主轴逆时钟转动56 SPDL INC主轴(RPM)增速57 Z+,Y+,X+机床X、Y、Z、轴往正方向移动58 Z-,Y-,X- 机床X、Y、Z、轴往负方向移动59 4-,4+ 机床第四轴60 TRVRS执行机床各轴移动指令61 CLNT ON 供应切削液62 CLNT OFF 停止供应切削液63 CLNT AUTO 自动执行供应切削液64 OVERRIDE切削速度随控0—-150%65 EMERGENCY STOP 紧急停止66 THERMAL ALARM 主轴负荷过热报警67 LUB ALARM 润滑油不足报警68 X_MIRROR IMAGE X轴镜像加工功能69Y_MIRROR IMAGE Y轴镜像加工功能70 RAPID OVERRIDE 快速行程?控71 DNC 直接数控:由于外部接口设备输入程序至数控机床,而又因子控机床本身记忆容量有限,需要执行边读边做(即同时执行收取程序与执行程序指令动作),称为DNC操作。

数控系统操作面板介绍

3. 设置参数

• G54—G59参数设置 • 在MDI键盘上点击 键,按菜单软键

[坐标系],进入坐标系参数设定界面,

• 利用MDI键盘输入通过对刀所得到的工 件坐标原点在机床坐标系中的坐标值。 设通过对刀得到的工件坐标原点在机床 坐标系中的坐标值(如-500,-415,404)

• 1.机床位置界面

点击 进入坐标位置界面。点击菜单软键[绝 对]、菜单软键[相对]、菜单软键[综合],对 应CRT界面将对应相对坐标(如图14-2-1)、 绝对坐标(如图14-2-2)、和综合坐标(如 图14-2-3)。

• 2.程序管理界面

• 点击编辑键进入程序管理界面,点击菜 单软键[LIB],将列出系统中所有的程序 (如图14-3-1所示),在所列出的程序列表 中选择某一程序名,点击 将显示该

用于输入字母到

输入区域,按

shift键可进行小

字母输入

回车换行键。结 束一行程序的输 入并且换行。

控制CRT坐 标显示

控制CRT参数设置显 示,对数控系统参数 进行设置

控制CRT程序 及程序输入显 示

控制CRT坐 标显示

控制CRT参数设置显 示,对数控系统参数 进行设置

控制CRT程序 及程序输入显 示

• 点击操作面板上的编辑键,编辑状态指 示灯变亮,此时已进入编辑状态。按菜 单软键[操作],在下级子菜单中按菜单 软键[Punch],在弹出的对话框中输入文 件名,选择文件类型和保存路径,按 “保存”按钮,如图14-5-4-1所示 。

• 2) 变更刀具长度和刀尖半径:“选择车 刀”完成后,该界面的左下部位显示出 刀架所选位置上的刀具。其中显示的 “刀具长度”和“刀尖半径”均可以由 操作者修改。

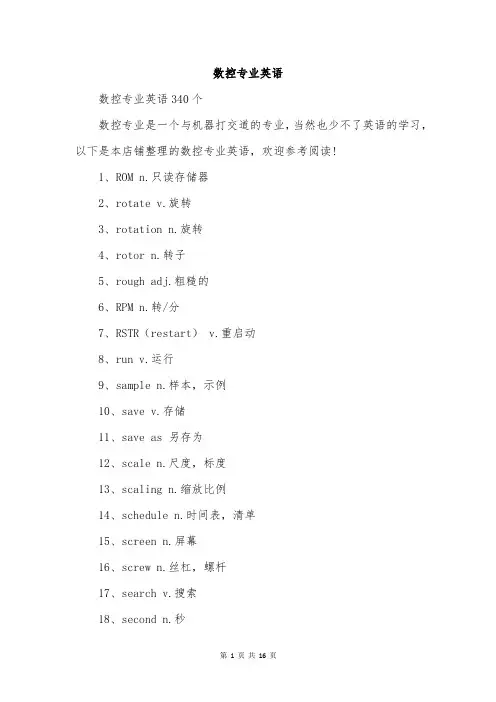

数控专业英语

数控专业英语数控专业英语340个数控专业是一个与机器打交道的专业,当然也少不了英语的学习,以下是本店铺整理的数控专业英语,欢迎参考阅读!1、ROM n.只读存储器2、rotate v.旋转3、rotation n.旋转4、rotor n.转子5、rough adj.粗糙的6、RPM n.转/分7、RSTR(restart) v.重启动8、run v.运行9、sample n.样本,示例10、save v.存储11、save as 另存为12、scale n.尺度,标度13、scaling n.缩放比例14、schedule n.时间表,清单15、screen n.屏幕16、screw n.丝杠,螺杆17、search v.搜索18、second n.秒19、segment n.字段20、select v.选择21、selection n.选择22、self-diagnostic 自诊断23、sensor n.传感器24、sequence n.顺序25、sequence number 顺序号26、series n.系列,adj.串行的27、series spindle n.数字主轴28、servo n.伺服29、set v.设置30、setting n.设置31、shaft n.轴32、shape n.形状33、shift v.移位34、SIEMENSE(德国)西门子公司35、sign n.符号,标记36、signal n.信号37、skip v,n.跳步38、slave adj.从属的39、SLC n.小型逻辑控制器40、slide n.滑台,v.滑动41、slot n.槽42、slow adj.慢43、soft key n.软键盘44、software n.软件45、space n.空格,空间46、SPC n.增量式脉冲编码器47、speed n.速度48、spindle n.主轴49、SRAM n.静态随机存储器50、SRH(search) v.搜索51、start v.启动52、statement n.语句53、stator n.定子54、status n.状态55、step n.步56、stop v.停止,n.挡铁57、store v.储存58、strobe n.选通59、stroke n.行程60、subprogram n.子程序61、sum n.总和62、surface n.表面63、SV(servo) n.伺服64、switch n.开关65、switch off v.关断66、switch on v.接通67、symbol n.符号,标记68、synchronous adj.同步的69、SYS(system) n.系统70、system n.系统71、tab n.制表键72、table n.表格73、tail n.尾座74、tandem adv.一前一后,串联75、tandem control n.纵排控制(加载预负荷的控制方式)76、tank n.箱体77、tap n,v.攻丝78、tape n.磁带,纸带79、tape reader n.纸带阅读机80、tapping n.攻丝81、teach in 示教82、technique n.技术,工艺83、temperature n.温度84、test v,n.测试85、thread n.螺纹86、time n.时间,次数87、tolerance n.公差88、tool n.刀具,工具89、tool pot n.刀杯90、torque n.扭矩91、tower n.刀架,转塔92、trace n.轨迹,踪迹93、track n.轨迹,踪迹94、tranducer n.传感器95、transfer v.传输,传送96、transformer n.变压器97、traverse v.移动98、trigger v.触发99、turn v转动,n转,回合100、turn off v.关断101、turn on v.接通102、turning n.转动,车削103、unclamp v.松开104、unit n.单位,装置105、unload n.卸载106、unlock v.解锁107、UPS n.不间断电源108、user n.用户109、value n.值110、variable n.变量,adj.可变的111、velocity n.速度112、velocity loop n.速度环113、verify v.效验114、version n.版本115、vertical a.垂直的116、voltage n.电压117、warning n.警告118、waveform n.波形119、wear n,v.磨损120、weight n.重量,权重121、wheel n.轮子,砂轮122、window n.窗口,视窗123、workpiece n.工件124、write v.写入125、wrong n.错误,adj.错的126、year n.年127、zero n.零,零位128、zone n.区域129、increment n.增量130、incremental adj.增量的131、indeX 分度,索引132、initial adj.原始的133、initialization n.C523初始化134、initialize v.初始化135、input n.v.输入136、INS() v.插入137、v.插入138、instruction n.说明139、interface n.接口140、internal adj.内部的141、interpolate v.插补142、interpolation n.插补143、interrupt v.中断144、interruption n.中断145、intervent n.间隔,间歇146、involute n.渐开线147、ISO n.国际标准化组织148、jog n.点动149、jump v.跳转150、key n.键151、keyboard n.键盘152、label n.标记,标号153、ladder diagram 梯形图154、language n.语言155、lathe n.车床156、LCD n.液晶显示157、least adj.最小的158、length n.长度159、LIB(library) n.库160、library n.库161、life n.寿命162、light n.灯163、limit n.极限164、limit switch n.限位开关165、line n.直线166、linear adj.线性的167、linear scale n.直线式传感器168、link n,v.连接169、list n,v.列表170、load n.负荷,v.装载171、local adj.本地的172、locate v.定位,插销173、location n.定位,插销174、lock v.锁定175、logic n.逻辑176、look ahead v.预,超前177、loop n.回路,环路178、LS n.限位开关179、LSI n.大规模集成电路180、machine n.机床,v.加工181、macro n.宏182、macro program n.宏程序183、magazine n.刀库184、magnet n.磁体,磁185、magnetic a.磁的186、main program n.主程序187、maintain v.维护188、maintenance n.维护189、MAN(manual) n.手动190、management n.管理191、manual n.手动192、master adj.主要的193、maX adj.最大的,n.最大值194、maXimum adj.最大的,n.最大值195、MDI n.手动数据输入196、meaning n.意义197、measurement n.测量198、memory n.存储器199、menu n.菜单200、message n.信息201、meter n.米202、metric adj.米制的203、mill n.铣床,v.铣削204、min adj.最小的,n.最小值205、minimum adj.最小的,n.最小值206、minus v.减,adj.负的207、minute n.分钟208、mirror image n.镜像209、miscellaneous function n.辅助功能210、MMC n.人机通讯单元211、modal adj.模态的212、modal G code n.模态G代码213、mode n.方式214、model n.型号215、modify v.修改216、module n.模块217、MON(monitor) v.监控218、monitor v.监控219、month n.月份220、motion n.运动221、motor n.电机222、mouse n.鼠标223、MOV(移动) v.移动224、move v.移动225、movement n.移动226、multiply v.乘227、N number n.程序段号228、N.M n.牛顿。

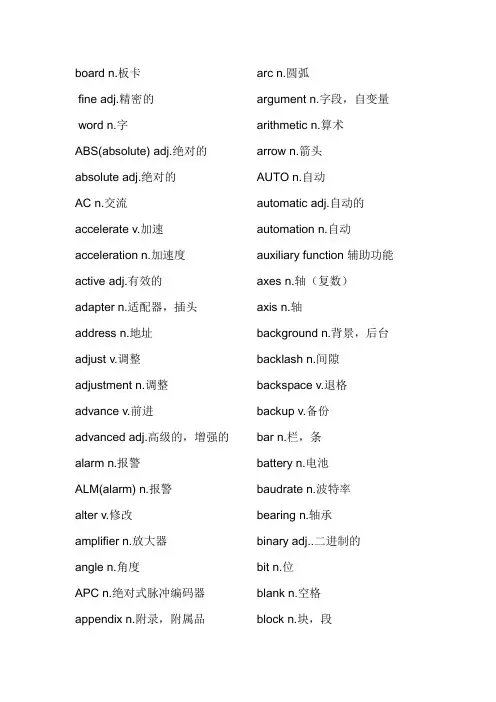

常用数控设备英文词汇.

board n.板卡fine adj.精密的word n.字ABS(absolute) adj.绝对的absolute adj.绝对的AC n.交流accelerate v.加速acceleration n.加速度active adj.有效的adapter n.适配器,插头address n.地址adjust v.调整adjustment n.调整advance v.前进advanced adj.高级的,增强的alarm n.报警ALM(alarm) n.报警alter v.修改amplifier n.放大器angle n.角度APC n.绝对式脉冲编码器appendix n.附录,附属品arc n.圆弧argument n.字段,自变量arithmetic n.算术arrow n.箭头AUTO n.自动automatic adj.自动的automation n.自动auxiliary function 辅助功能axes n.轴(复数)axis n.轴background n.背景,后台backlash n.间隙backspace v.退格backup v.备份bar n.栏,条battery n.电池baudrate n.波特率bearing n.轴承binary adj..二进制的bit n.位blank n.空格block n.块,段block n.撞块,程序段blown v.熔断bore v.镗boring n.镗box n.箱体,框bracket n.括号buffer n.v.缓冲bus n.总线button n.按钮cabient n.箱体calbe n.电缆calculate v.计算calculation n.计算call v.调用CAN(cancel) v.清除cancel v.清除canned cycle 固定循环capacity n.容量card n.板卡carriage n.床鞍,工作台cassette n.磁带cell n.电池CH(chanel) n.通道change v.变更,更换channel n.通道check v.检查chop v.錾削chopping n.錾削circle n.圆circuit n.电路,回路circular adj.圆弧的clamp v.夹紧clear v.清除clip v.剪切clip board n.剪贴板clock n.时钟clutch n.卡盘,离合器CMR n.命令增益CNC 计算机数字控制code n.代码coder n.编码器command n,v.命令communication n.通讯compensation n.补偿computer n.计算机condition n.条件configuration n.配置configure v.配置connect v.连接connection n.连接connector n.连接器console n.操作台constant n.常数,adj.恒定的contour n.轮廓control v.控制conversion n.转换cool v.冷却coolant n.冷却coordinate n.坐标copy v.拷贝corner n.转角correct v.改正,adj.正确的correction n.修改count v.计数counter n.计数器CPU n.中央处理单元CR n.回车cradle n.摇架create v.生成CRT n.真空射线管CSB n.中央服务板current n.电流,当前的,缺省的current loop n.电流环cursor n.光标custom n.用户cut v.切削cutter n.(元盘形)刀具cycle n.循环cylinder n.圆柱体cylindrical adj.圆柱的data n.数据(复数)date n.日期datum n.数据(单数)DC n.直流deceleration n.减速decimal point n.小数点decrease v.减少deep adj.深的define v.定义deg. n.度degree n.度DEL(delete) v.删除delay v,n.延时delete v.删除deletion n.删除description n.描述detect v.检查detection n.检查device n.装置DGN(diagnose) v.诊断DI n.数字输入DIAG(diagnosis) n.诊断diagnosis n.诊断diameter n.直径diamond n.金刚石digit n.数字dimension n.尺寸,(坐标系的)维DIR n.目录direction n.方向directory n.目录disconnect v.断开disconnection n.断开disk n.磁盘diskette n.磁盘display v,n.显示distance n.距离divide n,v除,v.划分DMR n.检测增益DNC 直接数据控制DO n.数字输出dog switch n.回参考点减速开关DOS n.磁盘操作系统DRAM n.动态随机存储器drawing n.画图dress v.修整dresser n.修整器drill v.钻孔drive v.驱动driver n.驱动器dry run 空运行duplicate v.复制duplication n.复制dwell n,v.延时edit v.编辑EDT(edit) v.编辑EIA n.美国电子工业协会标准electrical adj.电气的electronic adj.电子的emergency n.紧急情况enable v.使能encoder n.编码器end v,n.结束enter n.回车,v.输入,进入entry n.输入equal v.等于equipment n.设备erase v.擦除error n.误差,错误,故障esc=escape v.退出exact adj.精确的example n.例子exchange v.更换execute v.执行execution n.执行exit v.退出external adj.外部的failure n.故障FANUC n.(日本)法那克fault n.故障feed v.进给feedback v.反馈feedrate n.进给率figure n.数字file n.文件filt(filtrate) v.过滤filter n.过滤器fin(finish) n.完成(应答信号)fine adj.精密的fixture n.夹具FL (回参考点的)低速flash memory n.闪存flexible adj.柔性的floppy adj.软的foreground n.前景,前台format n.格式,v.格式化function n.功能gain n.增益GE FANUC GE法那克gear n.齿轮general adj.总的,通用的generator n.发生器geometry n.几何gradient n.倾斜度,梯度graph n.图形graphic adj.图形的grind v.磨削group n.组guidance n.指南,指导guide v.指导halt n,v.暂停,间断handle n.手动,手摇轮handy adj.便携的handy file 便携式编程器hardware n.硬件helical adj.螺旋上升的help n,v.帮助history n.历史HNDL(handle) n.手摇,手动hold v.保持hole n.孔horizontal a.水平的host n.主机hour n.小时hydraulic adj.液压的I/O n.输入/输出illegal adj.非法的inactive adj.无效的inch n.英寸increment n.增量incremental adj.增量的index 分度,索引initial adj.原始的initialization n.C523初始化initialize v.初始化input n.v.输入INS(insert) v.插入insert v.插入instruction n.说明interface n.接口internal adj.内部的interpolate v.插补interpolation n.插补interrupt v.中断interruption n.中断intervent n.间隔,间歇involute n.渐开线ISO n.国际标准化组织jog n.点动jump v.跳转key n.键keyboard n.键盘label n.标记,标号ladder diagram 梯形图language n.语言lathe n.车床LCD n.液晶显示least adj.最小的length n.长度LIB(library) n.库library n.库life n.寿命light n.灯limit n.极限limit switch n.限位开关line n.直线linear adj.线性的linear scale n.直线式传感器link n,v.连接list n,v.列表load n.负荷,v.装载local adj.本地的locate v.定位,插销location n.定位,插销lock v.锁定logic n.逻辑look ahead v.预,超前loop n.回路,环路LS n.限位开关LSI n.大规模集成电路machine n.机床,v.加工macro n.宏macro program n.宏程序magazine n.刀库magnet n.磁体,磁magnetic a.磁的main program n.主程序maintain v.维护maintenance n.维护MAN(manual) n.手动management n.管理manual n.手动master adj.主要的max adj.最大的,n.最大值maximum adj.最大的,n.最大值MDI n.手动数据输入meaning n.意义measurement n.测量memory n.存储器menu n.菜单message n.信息meter n.米metric adj.米制的mill n.铣床,v.铣削min adj.最小的,n.最小值minimum adj.最小的,n.最小值minus v.减,adj.负的minute n.分钟mirror image n.镜像miscellaneous function n.辅助功能MMC n.人机通讯单元modal adj.模态的modal G code n.模态G代码mode n.方式model n.型号modify v.修改module n.模块MON(monitor) v.监控monitor v.监控month n.月份motion n.运动motor n.电机mouse n.鼠标MOV(移动) v.移动move v.移动movement n.移动multiply v.乘N number n.程序段号N.M n.牛顿.米name n.名字NC n.数字控制NCK n.数字控制核心negative adj.负的nest v,n.嵌入,嵌套nop n.空操作NULL n.空number n.号码numeric adj.数字的O number n.程序号octal adj.八进制的OEM n.原始设备制造商OFF adv.断offset n.补偿,偏移量ON adv.通one shot G code 一次性G代码open v.打开operate v.操作operation n.操作OPRT(operation) n.操作origin n.起源,由来original adj.原始的output n,v.输出over travel 超程over voltage 过电压overcurrent 过电流overflow v,n.溢出overheat n.过热overload n.过负荷override n.(速度等的)倍率page n.页page down 下翻页page up 上翻页panel n.面板PARA(parameter) n.参数parabola n.抛物线parallel adj.平行的,并行的,并联的parameter n.参数parity n.奇偶性part n.工件,部分password n.口令,密码paste v.粘贴path n.路径pattern n.句型,式样pause n.暂停PC n.个人电脑PCB n.印刷电路板per prep.每个percent n.百分数pitch n.节距,螺距plane n.平面PLC n.可编程序逻辑控制器plus n.增益,prep.加,adj.正的PMC n.可编程序逻辑控制器pneumatic adj.空气的polar adj.两极的,n.极线portable adj.便携的POS(position) v,n.位置,定位position v,n.位置,定位position loop n.位置环positive adj.正的power n.电源,能量,功率power source n.电源preload v.预负荷preset v.予置pressure n.压力preview v.予览PRGRM(program) v.编程,n.程序print v.打印printer n.打印机prior adj.优先的,基本的procedure n.步骤profile n.轮廓,剖面program v.编程,n.程序programmable adj.可编程的programmer n.编程器protect v.保护protocol n.协议PSW(password) n.密码,口令pulse n.脉冲pump n.泵punch v.穿孔puncher n.穿孔机push button n.按钮PWM n.脉宽调制query n.问题,疑问quit v.退出radius n.半径RAM n.随机存储器ramp n.斜坡ramp up v.(计算机系统)自举range n.范围rapid adj.快速的rate n.比率,速度ratio n.比值read v.读ready adj.有准备的ream v.铰加工reamer n.铰刀record v,n.记录REF(reference) n.参考reference n.参考reference point n.参考点register n.寄存器registration n.注册,登记relative adj.相对的relay v,n.中继remedy n.解决方法remote adj.远程的replace v.更换,代替reset v.复位restart v.重启动RET(return) v.返回return v.返回revolution n.转rewind v.卷绕rigid adj.刚性的RISC n.精简指令集计算机roll v.滚动roller n.滚轮ROM n.只读存储器rotate v.旋转rotation n.旋转rotor n.转子rough adj.粗糙的RPM n.转/分RSTR(restart) v.重启动run v.运行sample n.样本,示例save v.存储save as 另存为scale n.尺度,标度scaling n.缩放比例schedule n.时间表,清单screen n.屏幕screw n.丝杠,螺杆search v.搜索second n.秒segment n.字段select v.选择selection n.选择self-diagnostic 自诊断sensor n.传感器sequence n.顺序sequence number 顺序号series n.系列,adj.串行的series spindle n.数字主轴servo n.伺服set v.设置setting n.设置shaft n.轴shape n.形状shift v.移位SIEMENSE (德国)西门子公司sign n.符号,标记signal n.信号skip v,n.跳步slave adj.从属的SLC n.小型逻辑控制器slide n.滑台,v.滑动slot n.槽slow adj.慢soft key n.软键盘software n.软件space n.空格,空间SPC n.增量式脉冲编码器speed n.速度spindle n.主轴SRAM n.静态随机存储器SRH(search) v.搜索start v.启动statement n.语句stator n.定子status n.状态step n.步stop v.停止,n.挡铁store v.储存strobe n.选通stroke n.行程subprogram n.子程序sum n.总和surface n.表面SV(servo) n.伺服switch n.开关switch off v.关断switch on v.接通symbol n.符号,标记synchronous adj.同步的SYS(system) n.系统system n.系统tab n.制表键table n.表格tail n.尾座tandem adv.一前一后,串联tandem control n.纵排控制(加载预负荷的控制方式)tank n.箱体tap n,v.攻丝tape n.磁带,纸带tape reader n.纸带阅读机tapping n.攻丝teach in 示教technique n.技术,工艺temperature n.温度test v,n.测试thread n.螺纹time n.时间,次数tolerance n.公差tool n.刀具,工具tool pot n.刀杯torque n.扭矩tower n.刀架,转塔trace n.轨迹,踪迹track n.轨迹,踪迹tranducer n.传感器transfer v.传输,传送transformer n.变压器traverse v.移动trigger v.触发turn v转动,n转,回合turn off v.关断turn on v.接通turning n.转动,车削unclamp v.松开unit n.单位,装置unload n.卸载unlock v.解锁UPS n.不间断电源user n.用户value n.值variable n.变量,adj.可变的velocity n.速度velocity loop n.速度环verify v.效验version n.版本vertical a.垂直的voltage n.电压warning n.警告waveform n.波形wear n,v.磨损weight n.重量,权重wheel n.轮子,砂轮window n.窗口,视窗workpiece n.工件write v.写入wrong n.错误,adj.错的year n.年zero n.零,零位zone n.区域。

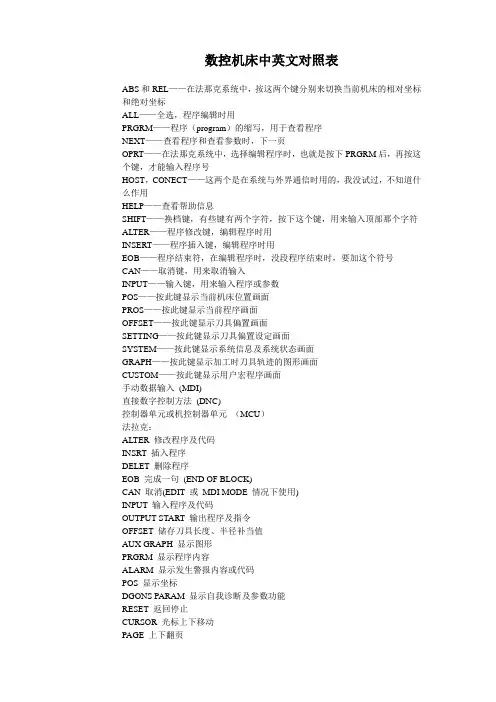

数控机床中英文对照表

数控机床中英文对照表ABS和REL——在法那克系统中,按这两个键分别来切换当前机床的相对坐标和绝对坐标ALL——全选,程序编辑时用PRGRM——程序(program)的缩写,用于查看程序NEXT——查看程序和查看参数时,下一页OPRT——在法那克系统中,选择编辑程序时,也就是按下PRGRM后,再按这个键,才能输入程序号HOST,CONECT——这两个是在系统与外界通信时用的,我没试过,不知道什么作用HELP——查看帮助信息SHIFT——换档键,有些键有两个字符,按下这个键,用来输入顶部那个字符ALTER——程序修改键,编辑程序时用INSERT——程序插入键,编辑程序时用EOB——程序结束符,在编辑程序时,没段程序结束时,要加这个符号CAN——取消键,用来取消输入INPUT——输入键,用来输入程序或参数POS——按此键显示当前机床位置画面PROS——按此键显示当前程序画面OFFSET——按此键显示刀具偏置画面SETTING——按此键显示刀具偏置设定画面SYSTEM——按此键显示系统信息及系统状态画面GRAPH——按此键显示加工时刀具轨迹的图形画面CUSTOM——按此键显示用户宏程序画面手动数据输入(MDI)直接数字控制方法(DNC)控制器单元或机控制器单元(MCU)法拉克:ALTER 修改程序及代码INSRT 插入程序DELET 删除程序EOB 完成一句(END OF BLOCK)CAN 取消(EDIT 或MDI MODE 情况下使用)INPUT 输入程序及代码OUTPUT START 输出程序及指令OFFSET 储存刀具长度、半径补当值AUX GRAPH 显示图形PRGRM 显示程序内容ALARM 显示发生警报内容或代码POS 显示坐标DGONS PARAM 显示自我诊断及参数功能RESET 返回停止CURSOR 光标上下移动PAGE 上下翻页常见机床报警信息中英文对照T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERRORSPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR MAGAZINE NOT IN POSITION OR SENSOR ERRORAIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW(液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTESINNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZ NOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC电池SIEMENS常用缩略语A Output 输出ASCII American Standard Code for Information Interchange 美国信息交换标准代码AV Preparation for work 运行准备BA Operating mode 运行方式BAG Operating mode groups 运行方式组BB Ready for operation 准备好运行BCD Binary Coded Decimals 二-十进制BHG Hand-held terminal 手提终端BOF User interface 用户接口CNC Computerized Numerical Control 计算机化数字控制CP Communication Processor 通迅处理器CPU Central Processing Unit 计算机中央处理装置CR Carriage Return 托架折回CSB Central Service Board(PLC module) 中央维护板,PLC 模块CTS Clear To Send 发送使能DAU Digital-Analog Converter 数模转换器DB Data Block 数据块DIN German Industrial Standards 德国工业标准DIO Data Input/Output 数据输入/输出DRF Differential Resolver Function 差分功能DRY Dry Run 空运行DSB Decoding Single Block 译码单段DSR Data Send Ready 备用输入DW Data Word 数据字E Input 输入EIA-Code Special tape code,number of holes per characters alwaysodd 特殊纸带码,每个字符的孔数为奇数EPROM Programm memory with fixed program 有固定程序的程序存储器E/R Controlled Supply and Energy Recovery Module 可控电源和能量恢复模块ETC ETC key:Extension of the softkey bar in the same menuETC 键:同级菜单扩展键FDB Product designation database 产品指定数据库FIFO First in First Out 先进先出FRA Frame module 帧频模块FRAME Coordinate conversion with the components zerooffset,rotation,scaling,mirror-imaging 坐标换算,具有零点偏置,坐标旋转,标度功能和镜向功能FRK Cutter radius compensation 铣刀半径补偿FST Feed Stop 停止进给GUD Global User Data 全体用户数据HMS High-Resolution Measuring System 高分辨率测量系统HSA Main Spindle Drive 主轴驱动HW Hardware 硬件IM Interface Module 接口模块IM-S/R Interface Module(S=send/R=receive) 接口模块,S=发送/R=接收INC Increment 步进增量ISO-Code Special tape code,number of holes per character always even特殊纸带码,每个字符的孔数为偶数K1...k4 Channel 1 to Channel 4 通道1 到通道4KOP Ladder Diagram 梯形图KV Loop-Gain Factor 增益系数KUE Transformation Ratio 传动比LCD Liquid Crystal Display 液晶显示LED Light Emitting Diode 发光二极管显示LUD Local User Data 局部用户数据MB Megabyte 兆字节MD Machine Data 机床数据MK Measuring Circuit 测量回路MDA Manual Data Automatic 手动输入,自动执行MLFB Machine-readable product designation 机器可识别的产品代号MMC Man Machine Communication:User interface of the numerical controlsystem for operation,programming and simulation 人机通讯:系统操作界面,用操作,编程和模拟MPF Main Program File:NC part program(main program)NC 零件程序,主程序MPI Multi Point Interface 多点通讯接口MSTT Machine control panel 机床控制面板NC Numerical Control 数字控制NCK Numerical Control Kernel(numerical krnel with block preparation, traversing range etc.) 数字控制核心:具有程序段预处理,运行范围等等NCU Numerical Control Unit 数控单元NURBS Non Uniform Rational B Spline 非均值有理B样条NV Zero Offset 零点偏置OEM Original Equipment Manufacturer 原设备制造商OP Operator Panel 操作面板OPI Operator Panel Interface 操作面板接口PC Personal Comprter 个人计算机PCMCIA Personal Computer Menory Card International Association接口协议PG Programming Device 编程器PLC Programmable Logic Control 可编程逻辑控制器PRT Program Test 程序测试RAM Random Access Memory 随机存取存储器RISC Reduced Instruction Set Computer 处理器,具有指令组小、通过能力强ROV Rapid Override 快速修调RPA R Parameters Active(NCK memoty area for R parameter numbers) R 参数有效,NCK 中用于R 参数号的存储器区RTS Request To Send(control signal from serial data interfaces)发送请求:来自串行接口的控制信号SBL Single Block 单段SBL2 Single Block Decoding 译码单段SEA Setting Data Active(memory area for setting data in NCK)设定数据有效:用于NCK 中设定数据的存储区SD Setting Data 设定数据SKP Skip Block 程序段跳跃SM Signal Module 信号模块SPF Sub Program File 子程序文件SPS Programmable Logic Controller 可编程逻辑控制器SRK Cutter Radius Compensation 刀尖半径补偿SSFK Leadscrew Error Compensation 丝杠螺距误差补偿SSI Serial Synchronous Interface 串行同步接口SW Software 软件TEA Testing Data Active(with reference to the machine data) 测试数据有效:与机床数据有关TO Tool Offset 刀具补偿TOA Tool Offset Active(memory area for tool offset) 刀具补偿有效,用于刀补的存储区TRANSMIT Transform Milling into Turning(coordinate conversion on turning machines for milling)铣床转换为车床:车床坐标换算用于铣削加工VSA Feed drive(spindle) 主轴进给驱动V Bit type PLC variable PLC变量类型:位VB Byte type PLC variablePLC变量类型:字节WKZ Tool 刀具WZ Tool 刀具WZK Tool offset 刀具补偿ZOA Zero Offset Active(memory area for zero offsets) 零点偏置有效:零点偏置存储区。

数控机床操作面板图文详解

数控车床编程和操作(一)熟悉机床操作面板图-1 GSK980T面板1.方式选择EDIT:用于直接通过操作面板输入数控程序和编辑程序。

AUTO:进入自动加工模式。

MDI:手动数据输入。

REF:回参考点。

HNDL:手摇脉冲方式。

JOG:手动方式,手动连续移动台面或者刀具。

置光标于按钮上,点击鼠标左键,选择模式。

2.数控程序运行控制开关单程序段机床锁住辅助功能锁定空运行程序回零手轮X轴选择手轮Z轴选择3.机床主轴手动控制开关手动开机床主轴正转手动关机床主轴手动开机床主轴反转4.辅助功能按钮冷却液润滑液换刀具5.手轮进给量控制按钮选择手动台面时每一步的距离:毫米、毫米、毫米、1毫米。

置光标于旋钮上,点击鼠标左键选择。

6.程序运行控制开关循环停止循环启动 MST选择停止7.系统控制开关NC启动NC停止8.手动移动机床台面按钮选择移动轴,正方向移动按钮,负方向移动按钮。

快速进给9.升降速按钮主轴升降速/快速进给升降速/进给升降速10紧急停止按钮(12)手轮(二)熟悉GSK980T数控系统的输入面板图-1 GSK980T输入面板1.按键介绍(1)数字键(2)字母键数字/字母键用于输入数据到输入区域(如下图所示),系统自动判别取字母还是取数字。

图-2(3)编辑键位参数,位诊断含义显示方式的切换。

消除输入到键输入缓冲寄存器中的字符或符号。

键缓寄存器的内容由CRT显示。

例:键输入缓冲寄存器的显示为:N001时,按(CAN)键,则N001被取消。

用于程序的删除的编辑操纵。

用于程序的修改的编辑操纵。

用于程序的插入的编辑操纵。

(4)页面切换键按下其键,CRT显示现在位置,共有四页[相对],[绝对],[总和],[位置/程序],通过翻页键转换。

程序的显示、编辑等,共有三页,[MDI/模],[程序],[目录/存储量]。

显示,设定补偿量和宏变量,共有两项,[偏置],[宏变量]。

显示报警信息。

显示,设置各种设置参数,参数开关及程序开关。

数控机床专业英语(超级棒).

3-Jaws indexing spacers 三爪、分割工具头A.T.C.system 加工中心机刀库Aluminum continuous melting & holding furnaces 连续溶解保温炉Balancing equipment 平衡设备Bayonet 卡口Bearing fittings 轴承配件Bearing processing equipment 轴承加工机Bearings 轴承Belt drive 带传动Bending machines 弯曲机Blades 刀片Blades,saw 锯片Bolts,screws & nuts 螺栓,螺帽与螺丝Boring heads 搪孔头Boring machines 镗床Cable making tools 造线机Casting,aluminium 铸铝Casting,copper 铸铜Casting,gray iron 铸灰口铁Casting,malleable iron 可锻铸铁Casting,other 其他铸造Casting,steel 铸钢Chain drive 链传动Chain making tools 造链机Chamfer machines 倒角机Chucks 夹盘Clamping/holding systems 夹具/支持系统CNC bending presses 电脑数控弯折机CNC boring machines 电脑数控镗床CNC drilling machines 电脑数控钻床CNC EDM wire-cutting machines 电脑数控电火花线切削机CNC electric discharge machines 电脑数控电火花机CNC engraving machines 电脑数控雕刻机CNC grinding machines 电脑数控磨床CNC lathes 电脑数控车床CNC machine tool fittings 电脑数控机床配件CNC milling machines 电脑数控铣床CNC shearing machines 电脑数控剪切机CNC toolings CNC刀杆CNC wire-cutting machines 电脑数控线切削机Conveying chains 输送链Coolers 冷却机Coupling 联轴器Crimping tools 卷边工具Cutters 刀具Cutting-off machines 切断机Diamond cutters 钻石刀具Dicing saws 晶圆切割机Die casting dies 压铸冲模Die casting machines 压铸机Dies-progressive 连续冲模Disposable toolholder bits 舍弃式刀头Drawing machines 拔丝机Drilling machines 钻床Drilling machines bench 钻床工作台Drilling machines,high-speed 高速钻床Drilling machines,multi-spindle 多轴钻床Drilling machines,radial 摇臂钻床Drilling machines,vertical 立式钻床drills 钻头Electric discharge machines(EDM) 电火花机Electric power tools 电动刀具Engraving machines 雕刻机Engraving machines,laser 激光雕刻机Etching machines 蚀刻机Finishing machines 修整机Fixture 夹具Forging dies 锻模Forging,aluminium 锻铝Forging,cold 冷锻Forging,copper 铜锻Forging,other 其他锻造Forging,steel 钢锻Foundry equipment 铸造设备Gear cutting machines 齿轮切削机Gears 齿轮Gravity casting machines 重力铸造机Grinder bench 磨床工作台Grinders,thread 螺纹磨床Grinders,tools & cutters 工具磨床Grinders,ultrasonic 超声波打磨机Grinding machines 磨床Grinding machines,centerless 无心磨床Grinding machines,cylindrical 外圆磨床Grinding machines,universal 万能磨床Grinding tools 磨削工具Grinding wheels 磨轮Hand tools 手工具Hard/soft and free expansion sheet making plant 硬(软)板(片)材与自由发泡板机组Heat preserving furnaces 保温炉Heating treatment funaces 熔热处理炉Honing machines 搪磨机Hydraulic components 液压元件Hydraulic power tools 液压工具Hydraulic power units 液压动力元件Hydraulic rotary cylinders 液压回转缸Jigs 钻模Lapping machines 精研机Lapping machines,centerless 无心精研机Laser cutting 激光切割Laser cutting for SMT stensil 激光钢板切割机Lathe bench 车床工作台Lathes,automatic 自动车床Lathes,heavy-duty 重型车床Lathes,high-speed 高速车床Lathes,turret 六角车床Lathes,vertical 立式车床Lubricants 润滑液Lubrication Systems 润滑系统Lubricators 注油机Machining centers,general 通用加工中心Machining centers,horizontal 卧式加工中心Machining centers,horizontal & vertical 卧式与立式加工中心Machining centers,vertical 立式加工中心Machining centers,vertical double-column type 立式双柱加工中心Magnetic tools 磁性工具Manifolds 集合管Milling heads 铣头Milling machines 铣床Milling machines,bed type 床身式铣床Milling machines,duplicating 仿形铣床Milling machines,horizontal 卧式铣床Milling machines,turret vertical 六角立式铣床Milling machines,universal 万能铣床Milling machines,vertical 立式铣床Milling machines,vertical & horizontal 立式与卧式铣床Mold & die components 模具单元Mold changing systems 换模系统Mold core 模芯Mold heaters/chillers 模具加热器/冷却器Mold polishing/texturing 模具打磨/磨纹Mold repair 模具维修Molds 模具Nail making machines 造钉机Oil coolers 油冷却器Overflow cutting machines for aluminium wheels 铝轮冒口切断机P type PVC waterproof rolled sheet making plant P型PVC高分子防水PCB fine piecing systems 印刷电器板油压冲孔脱料系统Pipe & tube making machines 管筒制造机Planing machines 刨床Planing machines vertical 立式刨床Pneumatic hydraulic clamps 气油压虎钳Pneumatic power tools 气动工具Powder metallurgic forming machines 粉末冶金成型机Presses,cold forging 冷锻冲压机presses,crank 曲柄压力机Presses,eccentric 离心压力机Presses,forging 锻压机Presses,hydraulic 液压冲床Presses,knuckle joint 肘杆式压力机Presses,pneumatic 气动冲床Presses,servo 伺服冲床Presses,transfer 自动压力机Pressing dies 压模Punch formers 冲子研磨器Quick die change systems 速换模系统Quick mold change systems 快速换模系统Reverberatory furnaces 反射炉Rollers 滚筒Rolling machines 辗压机Rotary tables 转台Sawing machines 锯床Sawing machines,band 带锯床Saws,band 带锯Saws,hack 弓锯Saws,horizontal band 卧式带锯Saws,vertical band 立式带锯shafts 轴Shapers 牛头刨床Shearing machines 剪切机Sheet metal forming machines 金属板成型机Sheet metal working machines 金属板加工机Slotting machines 插床spindles 主轴Stamping parts 冲压机Straightening machines 矫直机Switches & buttons 开关与按钮Tapping machines 攻螺丝机Transmitted chains 传动链Tube bending machines 弯管机Vertical hydraulic broaching machine 立式油压拉床Vises 虎钳Vises,tool-maker 精密平口钳Wheel dressers 砂轮修整器Woven-Cutting machines 织麦激光切割机Wrenches 扳手Assembly line组装线Layout布置图Conveyer流水线物料板Rivet table拉钉机Rivet gun拉钉枪Screw driver起子Electric screw driver电动起子Pneumatic screw driver气动起子worktable 工作桌OOBA开箱检查fit together组装在一起fasten锁紧(螺丝)fixture 夹具(治具)pallet栈板barcode条码barcode scanner条码扫描器fuse together熔合fuse machine热熔机repair修理operator作业员QC品管supervisor 课长ME制造工程师MT制造生技cosmetic inspect外观检查inner parts inspect内部检查thumb screw大头螺丝lbs. inch镑、英寸EMI gasket导电条front plate前板rear plate后板chassis 基座bezel panel面板power button电源按键reset button重置键Hi-pot test of SPS高源高压测试Voltage switch of SPS电源电压接拉键sheet metal parts 冲件plastic parts塑胶件SOP制造作业程序material check list物料检查表work cell工作间trolley台车carton纸箱sub-line支线left fork叉车personnel resource department 人力资源部production department生产部门planning department企划部QC Section品管科stamping factory冲压厂painting factory烤漆厂molding factory成型厂common equipment常用设备uncoiler and straightener整平机punching machine 冲床robot机械手hydraulic machine油压机lathe车床planer、plein刨床miller铣床grinder磨床driller床linear cutting线切割electrical sparkle电火花welder电焊机staker=reviting machine铆合机position职务president董事长general manager总经理special assistant manager特助factory director厂长department director部长deputy manager、vice manager副理section supervisor课长deputy section supervisor、vice section superisor副课长group leader/supervisor组长line supervisor线长assistant manager助理to move, to carry, to handle搬运be put in storage入库pack packing包装to apply oil擦油to file burr 锉毛刺final inspection终检to connect material接料to reverse material 翻料wet station沾湿台Tiana天那水cleaning cloth抹布 to load material上料to unload material卸料to return material/stock to退料scraped 报废scrape 刮;削deficient purchase 来料不良 manufacture procedure 制程rotating speed, revolution 转速deficient manufacturing procedure 制程不良delivery deadline交货期oxidation 氧化scratch 刮伤dents 压痕defective upsiding down抽芽不良defective to staking 铆合不良embedded lump 镶块feeding is not in place 送料不到位stamping-missing 漏冲production capacity 生产力education and training 教育与训练proposal improvement 提案改善spare parts、buffer 备件forklift叉车trailer、long vehicle拖板车compound die合模die locker锁模器pressure plate、plate pinch压板bolt螺栓name of a department部门名称administration/general affairs dept总务部automatic screwdriver电动启子thickness gauge厚薄规gauge(or jig)治具power wire电源线buzzle蜂鸣器defective product label不良标签identifying sheet list标示单screwdriver holder起子插座pedal踩踏板stopper阻挡器flow board流水板hydraulic handjack油压板车forklift叉车pallet栈板glove(s)手套glove(s) with exposed fingers割手套thumb大拇指forefinger食指midfinger中指ring finger无名指little finger小指band-aid创可贴garbage can垃圾箱garbage bag垃圾袋chain链条jack升降机production line流水线chain链条槽magnetizer加磁器lamp holder灯架to mop the floor拖地to clean the floor扫地to clean a table擦桌子air pipe 气管packaging tool打包机packaging打包missing part漏件wrong part错件excessive defects过多的缺陷critical defect极严重缺陷major defect主要缺陷minor defect次要缺陷not up to standard不合规格dimension/size is a little bigger尺寸偏大(小) cosmetic defect外观不良slipped screwhead/slippery screw head螺丝滑头slipped screwhead/shippery screw thread滑手speckle斑点mildewed、moldy、mouldy发霉rust生锈deformation变形burr(金属)flash(塑件)毛边poor staking铆合不良excesssive gap间隙过大grease/oil stains油污inclusion杂质painting peel off脏污 shrinking/shrinkage缩水 mixed color杂色scratch划伤 poor processing 制程不良poor incoming part事件不良fold of pakaging belt打包带折皱painting make-up补漆discoloration羿色water spots水渍polishing/surface processing表面处理exposed metal/bare metal金属裸露 garbage container灰箕cost成本engineering工程die repair模修enterprise plan、enterprise expansionprojects企划QC品管die worker模工production, to produce生产equipment设备 to start a press开机stop/switch off a press关机classification整理regulation整顿cleanness清扫conservation清洁culture教养qualified products, up-to-grade products良品defective products, not up-to-grade products不良品waste废料board看板feeder送料机sliding rack滑料架defective product box不良品箱die change 换模to fix a die装模to take apart a die拆模to repair a die修模packing material包材basket蝴蝶竺plastic basket胶筐isolating plate baffle plate; barricade隔板 carton box纸箱to pull and stretch拉深to put material in place, to cut material, to input落料to impose lines压线to compress, compressing压缩character die字模to feed, feeding送料transportation运输(be)qualfied, up to grade合格not up to grade, not qualified不合格material change, stock change材料变更feature change 特性变更manufacture management制造管理abnormal handling异常处理production unit生产单位lack of painting烤漆不到位safety安全quality品质evaluation评估prepare for, make preparations for 准备parameters参数vaccum cleaner吸尘器rag 抹布lots of production生产批量steel plate钢板roll material卷料manufacture procedure制程operation procedure作业流程to revise, modify修订to switch over to, switch、to throw、over switching over切换engineering, project difficulty 工程瓶颈stage die工程模automation自动化to stake, staking, reviting铆合add lubricating oil加润滑油shut die架模shut height of a die架模高度analog-mode device类模器die lifter举模器argon welding氩焊vocabulary for stampingiudustrial alcohol工业酒精alcohol container沾湿台head of screwdriver起子头sweeper扫把mop拖把pneumatic 气动的,空气的,pneumatic control 气动控制electromechanical 机电的governor 操纵杆,控制器electronic governor 电子调速器screw machine 车丝机relay 继电器timer定时器counter 计数器inherent固有的,本质的,inherent problem本质问题versatile通用,多用途的filter out过滤ladder diagram梯形图symbology符号体系contact dot接点,触点instantaneously瞬时地magnet-opened contact switch 电磁触点开关architecture构造,结构,组织implementation工具,仪器,实现thumbwheel switch指轮(微调)开关breadboard实验电路板Hardwired relay panel分立(硬连线)延时,控制面板relay module继电模块capability性能,耐受力category分类single throw单掷开关double throw switch双掷开关double-pole双极(刀开关)double-pole single throw双刀单掷开关selector switch选择开关push-button switch按钮开关proximity switch接近开关level switch (信号)液位开关thumbwheel拨轮debug调试be population for……application在……应用很广泛electromechanical control机电控制exce pt that ……除……之外be available可利用的wiring out布线图milling cutter铣刀profile轮廓,外形,断面machine tool机床perforated tape穿孔带mature成熟hard-wire硬线连接punched tape冲孔带magnetic tape磁带lathe车床turning machine车削中心punch冲床significant显著encoder编码器resolve分解,决定utilize利用magnetic磁的photoelectric光电的binary code二进制码execution cycle执行循环electronic pulse脉冲spindle主轴,转轴lead screw丝杠,螺杆turret转台,转塔刀架servomotor伺服电机machining center加工中心electric discharge machine (EDM) 电火花机床grinder磨床testing and inspection equipment测试和检测设备conventional machining常规加工recommendation for…… 关于……推荐值scrap rate废品率incorporate插(引,加,编)入quality assurance质量保证spot check点检,抽查set up安装set up method安装方法set up time按照时间assembly装配,组装件notation符号,符号表示法binary二进制accomplish完成,实现sensing传感graduate刻度backlash后座力adjacent毗连的radius半径,范围intersection交叉,交集slide刀架,滑板,滑移fluid servomotor液压伺服器open-loop开环close-loop闭环direct current (DC) 直流电alternative current (AC)交流电gear mechanism齿轮机构pneumatic motor气动马达(气泵)processed with继续(更新)discrepancy偏(误)差,不同speed discrepancy转速差transducer传感器,转换器magazine链式刀库,杂志magazine feed自动传输带(送料带)magazine tool刀库magazine attachment机床送料装置retrieve检索,查询retrieval data检索数据retrieval program检索程序。

数控面板英语——中英对照大全

数控面板英语ABS和REL——在法那克系统中,按这两个键分别来切换当前机床的相对坐标和绝对坐标ALL——全选,程序编辑时用PRGRM——程序(program)的缩写,用于查看程序NEXT——查看程序和查看参数时,下一页OPRT——在法那克系统中,选择编辑程序时,也就是按下PRGRM后,再按这个键,才能输入程序号HOST,CONECT——这两个是在系统与外界通信时用的,我没试过,不知道什么作用HELP——查看帮助信息SHIFT——换档键,有些键有两个字符,按下这个键,用来输入顶部那个字符ALTER——程序修改键,编辑程序时用INSERT——程序插入键,编辑程序时用EOB——程序结束符,在编辑程序时,没段程序结束时,要加这个符号CAN——取消键,用来取消输入IMPUT——应该是INPUT吧,输入键,用来输入程序或参数POS——按此键显示当前机床位置画面PROS——按此键显示当前程序画面OFFSET——按此键显示刀具偏置画面SETTING——按此键显示刀具偏置设定画面SYSTEM——按此键显示系统信息及系统状态画面GRAPH——按此键显示加工时刀具轨迹的图形画面CUSTOM——按此键显示用户宏程序画面专业数控英语词汇1)计算机数值控制(Computerized Numerical Control, CNC)用计算机控制加工功能,实现数值控制。

2)轴(Axis)机床的部件可以沿着其作直线移动或回转运动的基准方向。

3)机床坐标系(Machine Coordinate Systern )固定于机床上,以机床零点为基准的笛卡尔坐标系。

4)机床坐标原点(Machine Coordinate Origin )机床坐标系的原点。

5)工件坐标系(Workpiece Coordinate System )固定于工件上的笛卡尔坐标系。

6)工件坐标原点(Wrok-piexe Coordinate Origin)工件坐标系原点。

数控机床操作面板结构及功能说明

12,MACHINE RESET机床复位按钮

机床通电后,释放急停按钮,如机床正常运行的条件均以具备,按下此按钮,强电复位并接通伺服。

13.PROGRAM PROTECT程序保护开关(带锁)

此开关处于“0”的位置可保护内存程序及参数不被修改,需要执行存入或修改操作时,此开关应置“l”。

数控机床操作面板结构及功能说明

Saturday, September 29, 2007 12:38:14 AM 发布:sunlight

机床操作面板由大小两块组成,小面板上安装有主轴负载表及控制器电源通断按钮,大操作面板位于操作下部,装有各种按钮,指示灯及操作部件,以下主要对人操作面板进行说明。

6)LUBE ALARM (橙)润滑泵液面低报警

7)AIR ALARM (橙)气压低报警

8)ATC ALARM (橙)自动换刀报警

9)X HOME (红)X轴机床回零指示

10)Y HOME (红)Y轴机床回零指示

11)Z HOME ห้องสมุดไป่ตู้红)Z轴机床回零指示

12)HOME (红)第四轴机床回零指示

自动,MDI或JOG操作时,此按钮接通,即禁止所有轴向运动已(进给的轴将减速停止)但位置显示仍将更新M,S,T功能不受影响。

10. OPS程序段选择停功能按钮(带灯)

此按钮接通,所执行的程序在遇有M01指令处,自动停止执行。

11. E-STOP急停按钮

机床操作过程中,出现紧急情况时按下此按钮伺服进给及主轴运行立即停止,CNC进入急停状态。

自动操作执行程序时,每按一下CYCLESTART按钮,只执行一个程序段。

7.DRN空运行功能按钮(带灯)

自动或MDI方式时,此按钮接通,机床按空运行方式执行程序。

数控车床操作面板介绍

数控车床操作面板介绍数控车床的类型和数控系统的种类很多,以及各生产厂家设计的操作面板也不尽相同,但操作面板中各种旋钮、按钮和键盘上键的基本功能与使用方法基本相同。

本节通过数控车床型号HM-077,以选用FANUC0-TC系统为例,介绍数控车床的操作。

操作面板1.CRT/MDI面板(CRT∕MDI面板由CRT显示器和MDI键盘组成)图1是上海第二机床厂生产的HM-077数控卧式车床操作面板,上半部分是弱电操作面板,直接与数控系统连接与通讯,称其为CRT/MDI面板(数控车床的类型和数控系统的种类很多,以及各生产厂家设计的操作面板也不尽相同,但操作面板中各种旋钮、按钮和键盘上键的基本功能与使用方法基本相同。

本节通过数控车床型号HM-077,以选用FANUC 0-TC系统为例,介绍数控车床的操作。

操作面板1. CRT/MDI面板(CRT∕MDI面板由CRT显示器和MDI键盘组成)图1是上海第二机床厂生产的HM-077数控卧式车床操作面板,上半部分是弱电操作面板,直接与数控系统连接与通讯,称其为CRT/MDI面板(图2);下半部分是强电操作面板,通过面板上的按扭与开关直接控制机床工作,又称其为机械操作面板(图3)。

图3-5-1 数控车床操作面板图3-5-2 CRT∕MDI面板图3-5-3 机械操作面板1)主功能键CRT∕MDI面板上键盘的各主功能键功能见表1。

表1 主功能键的功能键名称功能说明RESET复位键按下此键,复位CNC系统。

包括取消报警、主轴故障复位、中途退出自动操作循环和中途退出输入、输出过程等。

CURSOR光标移动键移动光标至编辑处PAGE页面转换键CRT画面向前变换页面CRT画面向后变换页面地址和数字键按下这些键,输入字母、数字和其它字符POS位置显示键在CRT上显示机床现在的位置PRGRM程序键在编辑方式,编辑和显示内存中的程序在MDI方式,输入和显示MDI数据在自动方式,指令值显示MENU OFFSET偏置值设定和显示DGNOS PARAM自诊断参数键参数设定和显示,诊断数据显示OPR ALARM报警号显示键报警号显示及软件操作面板的设定和显示AUX GRAPH图形显示键图形显示功能INPUT输入键用于参数或偏置值的输入;启动I/O设备的输入;MDI方式下的指令数据的输入OUTPT START输出启动键输出程序到I/O设备ALTER修改键修改存储器中程序的字符或符号INSRT插入键在光标后插入字符或符号CAN取消键取消已键入缓冲器的字符或符号DELET删除键删除存储器中程序的字符或符号2)子功能键CRT显示器下有五个子功能键,与显示器屏幕内下方的五个软键位置相互对应,随主功能状态不同,相应的软键有不同的含义,故称其为主功能状态下的子功能键。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

数控机床的英文操作面板

1.EMERGENCY STOP 紧急制动

2.MODE SELECT 模式选择

3.EDIT 编辑

4.MEMORY 存储

5.MDI 人工数据输入

6.HANDLE 手动

7.JOG 点动

8.CYCLE START 循环启动

9.FEED HOLD 进给锁定

10.SINGLE BLOCK 单程序段

11.DRY RUN 空运行

12.REFERENCE RETURN 零点返回

13.FEED RATE OVERRIDE 进给倍率

14.RAPID TRAVERSE OVERRIDE 快速进给倍率

15.MACHINE LOCK 机床面板

16.CONTROL PANEL 控制面板

17.POWER ON AND POWER OFF 电源开和关

18.RESET 复位

19.CRT CHARACTER DISPLAY 显示

数控技术常用术语中英文大全

1.计算机数值控制:Computerized Numerical Control, CNC

2.轴:(Axis)

3.机床坐标系:Machine Coordinate System

4.机床坐标原点:Machine Coordinate Origin

5.工件坐标系:Work-piece Coordinate System

6.工件坐标原点:Work-piece Coordinate Origin

7.机床零点:Machine Zero

8.参考位置:Reference Position

9.绝对尺寸(Absolute Dimension)/绝对坐标值(Incremental

Coordinates)

10.增量尺寸(Incremental Dimension)/增量坐标(Incremental

Dimension)

11.最小输入增量:Least Input Increment

12.命令增量:Least Command Increment

13.插补:Interpolation

14.直线插补:Line Interpolation

15.圆弧插补:Circular Interpolation

16.顺时针圆弧:Clockwise Arc

17.逆时针圆弧:Counterclockwise Arc

18.手工零件编程:Manual Part Programming

19.计算机零件编程:Computer Part Programming

20.绝对编程:Absolute Programming

21.增量编程:Increment Programming

22.字符:Character

23.控制字符:Control Character

24.地址:Address

25.程序段格式:Block Format

26.指令码:Instruction Code

27.程序号:Program Number

28.程序名:Program Name

29.指令方式:Command Mode

30.程序段:Block

31.零件程序:Part Program

32.加工程序:Machine Program

33.程序结束:End of Program

34.数据结束:End of Data

35.程序暂停:Program Stop

36.准备功能:Preparatory Function

37.辅助功能:Miscellaneous Function

38.刀具功能:Tool Function

39.进给功能:Feed Function

40.主轴速度功能:Spindle Speed Function

41.进给保持:Feed Hold

42.刀具轨迹:Tool Path

43.零点偏置:Zero Offset

44.刀具偏置:Tool Offset

45.刀具长度偏置:Tool Length Offset

46.刀具半径偏置:Tool Radius Offset

47.刀具半径补偿Cutter Radius Compensation

48.刀具轨迹进给速度:Tool Path Feed Rate

49.固定循环:Fixed cycle, Canned cycle

50.字程序:Subprogram

51.工序单:Planning Sheet

52.执行程序:Executive Program

53.倍率:Override

54.伺服机构:Servo-Mechanist

55.误差:Error

56.分辨率:Resolution。