专业英语大作业样本

专业英语作业

Be My GirlfriendSun Dec 16,10:00 PM ETBy Gao XiangpingXinxiang(Students News Agency)—"Be my girlfriend!" A boy named Yang Fan from College of Physical Education shouted. The Sunday night at December 16 ,2012—a special and unforgettable night for Yang witnessed his success in showing his love to Ye Qing, a girl from College of Liberal Arts, at the fourth west building in our school.At about nine in the evening, there was a bustle in front of the fourth west building. Boy`s jeer noisy mixed into the girl`s screaming. The open space packed by a group of people before the fourth west building placed numerous candles those make up a big heart. Yang with huge bouquet of roses in his hands stood in the middle of the heart. He shouted facing a window :"Ye Qing ,I love you." Meanwhile, the people cheer up. Even male students next to Yang yelled the name of Ye Qing together. Suddenly, someone opened the window on the fifth floor. A girls appeared at the window."Ye qing is there." someone said. "Ye Qing,Be my girlfriend. " Yang lifted up the roses. Most windows were crowed with heads this time. But that girl disappeared.A few minutes later, the girl got swept along by thecrowd .She must be Ye Qing!Ye standing outside the heart looked at Yang. Yang put the flowers into his chest and said,"Will you please be my girlfriend? "" OK quick ,quick,quick……"The crowd cried. Ye nodded sightly and ran righted into inside of the heart. A burst of applause went up right for the couple.Ye took the roses.Yang held of Ye`s hand. Yang wooed and won Ye.专业英语作业:Be My Girlfriend学院名称:文学院专业名称:广播电视新闻学年级班别:2010级二班姓名:高香萍学号:10093240062012年12月。

专业外语大作业word精品文档15页

专业英语大作业专业:电子信息工程班级:学号:姓名:2011——2012(2)晶体管的工作原理晶体管的设计使它的功能相当于一个放大器或一个开关。

它的作用是实现用少量的电能去控制大量的电源供应,就像转阀控制水的供应一样。

晶体管是由三个部分组成——基极、集电极和发射极。

基极是大供电的门控制器部分,集电极是提供更大的电力的部分,,发射极供电的输出部分。

通过发送不同范围的基极电流,从而调节流经集电极的电流。

这样,就像放大器一样,一个非常小的电流就可以用来控制较大的电流。

这个过程被用来为数字处理器创建二进制代码,但需5伏特的门槛电压才能正常工作。

因此,晶体管常被用作门限开关:开关闭合;不超过5伏特时,开关断开。

半导体材料的应用使晶体管的制作成为可能。

人们习惯把材料分为导电和绝缘两种。

金属通常被认为是良导体,而木材、塑料、玻璃、陶瓷等材料通常被认为是不导电的,即绝缘体。

19世纪40年代末,一组在新泽西州的贝尔实验室工作的科学家在研究半导体的特性时,发现了如何制作某些类型的晶体,并把它们作为电子控制装置。

大多数非金属晶体都会被视为绝缘体。

但通过迫使在锗或硅晶体中掺杂硼或磷等杂质,会使晶体获得完全不同的导电性能。

通过在两个导电板(发射极和集电极) 间加入这种材料,晶体管就做好了。

利用基极电流来控制电流的流向。

约翰。

巴丁,沃尔特。

布拉顿和威廉萧克利对晶体管的发明做出了卓越的贡献,他们的专利被称为:“利用半导体材料三电极电路元件。

”现在主要有两种类型的晶体管——双极结型晶体管(BJT)和场效应晶体管。

它们以不同的方式进行工作。

但任何晶体管的用处都在于它能用较弱的电压去控制很大的电流。

例如, 在公共广播系统利用电晶体放大(即加强)人的声音经麦克风形成的弱电压,经晶体管放大后的电源已足够操作扩音器,使之产生比人声响亮的多的声音。

双极结型晶体管双极结型晶体管是在两层厚介质间填充一种稍薄的半导体材料的晶体管类型。

例如,若中间的介质为P型,那么外边的两层介质必须为N型,这样就构成了一个NPN晶体管。

专业英语作业4.doc

MetalsMan fist began using metals at least 5000 years ago. He found that they could be hammered into tools and weapons that remained sharp. From small beginnings the use of metals has brown to such an extent that civilization as we know it today could not exist with them.Metals make up a large part of the earth's outer layer, or crust. But only a few of them appear in the metal form we are familiar with. Most metals, such as iron and tin, are found combined with other chemical elements. Most of these compounds do not look anything like metals. They are often lumps of rocks. But many of them can be treated to produce metals. These are called ores.Not many metals are used widely in their pure state. Other metals are usually added to them to form mixtures called alloys. Sometimes chemical elements other than metals are included in alloys. The most important is carbon. In engineering, metals and alloys are usually called metals. Metals are divided into tow groups, the ferrous, which contain a large percentage of iron, and the nonferrous, which contain no iron.Steel, our most useful metals is alloy of iron and carbon. Because of its strength, steel is used in large buildings and bridges. It is also used to make motor cars, railways and ships. Most of the machinery that makes practically everything we use is made of iron or steel.Many other metals are important to us, too. The spoons, knives and forks we eat with are made of stainless steel. We cook in aluminum boilers. Copper cables carry electricity to factories and families. The coins we carry in our pockets contain copper, nickel, and zinc. The list of the uses of metals is endless.Pure iron is quite a weak metal, and it is not very hard, either. But add a little carbon as well as traces of certain other metals, and it becomes both strong and hard. According to what is added, the iron can be given other desirable properties as well. Adding other substances to a metal to change its properties is called alloying, and the product an alloy.Most of the alloys of iron are better known to us as steels. Many other metals form useful alloys, too. Brass and bronze are common alloys of copper. Solder is a well-known lead alloy. Aluminum and zinc alloys are also in widespread use. However, it is the iron alloys that are by far the most important.The pig iron that is made in the blast furnace can be considered one kind of iron alloy, but it is a very crude one. It contains far too many impurities and other materials as well as being uneven in composition. By only slight refining , it can be made into cast iron. Cast iron is an ideal material formaking engine blocks and machine frames. It is strong, hard, rigid, and absorbs shock well. Its main disadvantage is that it is brittle.Wrought iron is a more refined form of pig iron which is quite pure iron (0.1 〜0.2 per cent carbon) with threads of slag running through it. Wrought iron is made by heating the pig iron with iron oxide in a “puddling" furnace. The oxygen in the oxide combines with the impurities, which either boil away as gas or form a slag. But the temperature of the furnace is not high enough to make the metal melt. That is why it contains threads of slag. Wrought iron is seldom used directly in industry.Refining pig iron in the various steelmaking furnaces reduces the carbon content and removes other unwanted substance. The steel-maker stops the refining process when the metal has reached the carbon content he wants. Then he adds controlled amounts of other elements to bring the steel to the desired composition.There are two principal kinds of steels, carbon steels and alloy steels. The properties of carbon steels depend mainly on the amount of carbon present. Mild steel (up to 0.25 per cent carbon) is the ordinary kind of steel that is used for girders, automobile bodies, bicycle frames, and so on. Medium-carbon steel (0.25〜0.45 per cent) is stronger than mild steel and is used for bridge members, nuts and bolts, and tools of many kinds. High-carbon steel (0.45〜1.5 per cent) is hard and tough, and is used for cutting tools, drill bits, saws, and so on.The properties of alloy steels depend not on the carbon they contain, but on other alloying elements. One of the most familiar alloys is stainless steel. As we all know, ordinary steel corrodes, or rusts if it is left out in the rain, is stained by fruit juices, and so on. But adding chromium and nickel to steel makes it resist corrosion and stains. Both chromium and nickel resist corrosion well, and they tend to impart that property to their alloys. One of the most common kinds of stainless steels contains about 18 percent chromium and 8 percent nickel.Exercises1.Mark the following sentences with T(true) of F(false) according to the article.(1)The civilization could exist without metals.(2)Many metals appear in the metal form we are familiar with.(3)Only a few of metal are used in their pure state.(4)Metal mixtures are called alloys.(5)Carbon is the most important element to form alloy.(6)Solder is a well-known iron alloy.(7)The pig iron is a kind of iron alloy.(8)Iron alloys are the most important alloys in engineering.(9)Most engine blocks and machine frames are made of cast iron.(10)Wrought iron can be used directly in industry.(11)The properties of alloy steels depend mainly on the amount of carbon present.(12)Carbon steels and alloy steels are two main kinds of steels.(13)Cutting tools and drill bits are made of medium-carbon steel.2.Answer the following questions according to the article・(1)When did man first begin using metals?(2)How many groups of metals? What are they?(3)What kind of metal is most useful in engineering?(4)Is steel an alloy? What is it made from?(5)Please list the usages of iron and steel in daily life.3.Translate the following sentences into Chines・(1)In the old days, man found that metals could be hammered into tools and weapons that remainedsharp.(2)Most metals, such as iron and tin, are found combined with other chemical elements.(3)Other metals are usually added to pure metals to form mixtures called alloys.(4)Metals are divided into two groups, the ferrous, which contain a large percentage of iron, and thenonferrous, which contain no iron.(5)Most of the machinery that makes practically everything we use is made of iron or steel.4.Fill in the blanks with the words or expressions given below and change the forms wherenecessary.Corrosion, contain, element, stain, property, corrode, depend, leave, alloy, add The properties of alloy steels (1) not on the carbon they contain, but on other alloying (2) . One of the most familiar (3) is stainless steel. As we all know, ordinary steel(4) , or rusts if it (5) out in the rain, (6) by fruit juices, and so on but (7)chromium and nickel to steel makes it resist (8) and stains. Both chromium and nickel resist corrosion well, and they tend to impart (9) to their alloys. One of the most common kinds of stainlesssteels (10) about 18 percent chromium and 8 per cent nickel.。

英语大作业

Research on ways of acquiring scientificknowledgeMember: xxXx000000000Report about ways of acquiring scientific knowledge 1.IntroductionOur project is to find out the way how students acquire scientific knowledge. The purpose of the project we do is to optimize the ways student acquire knowledge.2.SubjectThe subjects are freshmen from Harbin Institute of Technology, who respectively come from different provinces of China. Altogether 60 students participated in the completion of the questionnaires on ways of acquiring scientific knowledge. But only 54 were resumed, ofwhich 50 were selected. And they are from different disciplines, they may represent theopinions of all students.3.instrumentThe instrument for the research is a questionnaire, which consists of 8 questions. The first question is about the specialties, which I think would affect the result. The next sevenquestions are the main part. such as” How long do you read a textbook for knowledge every day?” I think it will do a favor to students’ self-understanding.4.Analysis of the ways student acquire knowledgeour results were statistically.In the second question,“Where you always get the knowledge they need?”,20 students (40%) chose internet, and 22(44%) chose library, and 3(6%) chose teachers, then 4(8%)chose schoolmates ,while only 1(2%) chose bookstore.And for the third one, facing the options A,B,C,D and E, the answer distribution is 19(38%), 26(52%), 2(4%) ,2(4%) and 1(2%).It comes to the fourth question. 6 persons(12%) chose life practice to be their most likely way to acquire knowledge. While 29 students(58%) chose book-leaning, and 30% of the 50 students chose online enquiry.For the fifth question, in the 50 students, 8% study less than 2 hours per day, and 20% study 2 to 4 hours a day, while 61% are so hard-working that they study 5 to 7 hours a day, another 10% who I think spend too much time studying study more than 7 hours.As for question six, 29 students agree that college students get knowledge still mainly from the teachers. While 31 students disagree.In question seven, only 1 student think the university courses are of no value. And 17 students chose a little, another 17 don’t know, the 15 left think it quite useful.The last question, when students are questioned whatis the fastest way to get knowledge,7(14%), 5(10%) ,26(52%) and 12(24%) students chose different questions A B C and D.5.conclusionfirstly, with science developing so fast, it’s a kind of competence to searching for scientific knowledge. So that’s why we make the project, and we find some usefulinformation.Secondly, we find that book-learning and internet are the two main ways for students to acquire scientific knowledge, And students usually prefer going to the library to buying a book. So the school library should do all they can to make the library friendly to us, which means we can easily find whatever we wanna.Lastly, we can find not a lot of students like to consult teachers. This tell us teachers may have gaps in communicating with students, which I think we should work it out together.Appendix:Ways of acquiring scientific knowledge1.Your specialty is?A. Liberal arts B, Science C. Engineering2.Where you always get the knowledge they need?A. InternetB. libraryC. schoolmatesD. teachersE. bookstoreually do not understand the problems encountered in the classroom, where you tend to find the answers?A. internetB. libraryC. schoolmatesD. teachersE. bookstore4.Which of the following you are most likely way to acquire knowledgeA. Life practiceB. Book-learningC. Online Enquiry5.Every day you read a textbook knowledge of the time is how long?A.less than 2 hours.B.2-4 hoursc.5-7 hoursD.more than 7 hours6.You agree that college students are still mainly from the teachers get knowledge?A. AgreeB. Disagree7.Do you think University courses can acquire knowledge to set it?A. NoneB. a littleC.I don’t knowD. So much8.what do you think is the fastest way to get knowledge?A. teachersB. studentsC internetD, books。

英语大作业参考

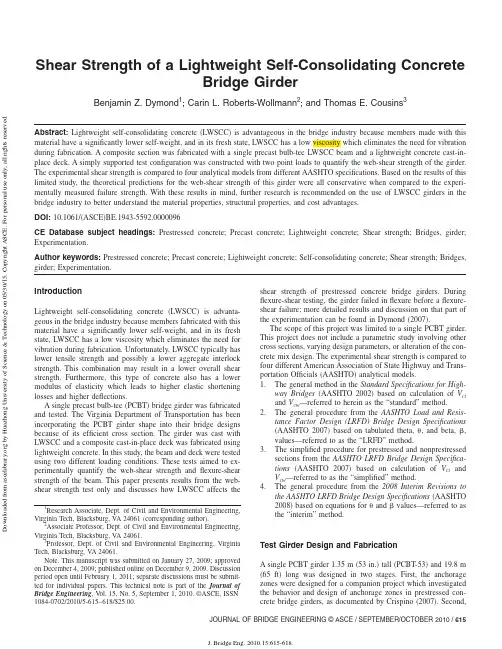

Shear Strength of a Lightweight Self-Consolidating ConcreteBridge GirderBenjamin Z.Dymond 1;Carin L.Roberts-Wollmann 2;and Thomas E.Cousins 3Abstract:Lightweight self-consolidating concrete ͑LWSCC ͒is advantageous in the bridge industry because members made with this material have a significantly lower self-weight,and in its fresh state,LWSCC has a low viscosity which eliminates the need for vibration during fabrication.A composite section was fabricated with a single precast bulb-tee LWSCC beam and a lightweight concrete cast-in-place deck.A simply supported test configuration was constructed with two point loads to quantify the web-shear strength of the girder.The experimental shear strength is compared to four analytical models from different AASHTO specifications.Based on the results of this limited study,the theoretical predictions for the web-shear strength of this girder were all conservative when compared to the experi-mentally measured failure strength.With these results in mind,further research is recommended on the use of LWSCC girders in the bridge industry to better understand the material properties,structural properties,and cost advantages.DOI:10.1061/͑ASCE ͒BE.1943-5592.0000096CE Database subject headings:Prestressed concrete;Precast concrete;Lightweight concrete;Shear strength;Bridges,girder;Experimentation .Author keywords:Prestressed concrete;Precast concrete;Lightweight concrete;Self-consolidating concrete;Shear strength;Bridges,girder;Experimentation .IntroductionLightweight self-consolidating concrete ͑LWSCC ͒is advanta-geous in the bridge industry because members fabricated with this material have a significantly lower self-weight,and in its fresh state,LWSCC has a low viscosity which eliminates the need for vibration during fabrication.Unfortunately,LWSCC typically has lower tensile strength and possibly a lower aggregate interlock strength.This combination may result in a lower overall shear strength.Furthermore,this type of concrete also has a lower modulus of elasticity which leads to higher elastic shortening losses and higher deflections.A single precast bulb-tee ͑PCBT ͒bridge girder was fabricated and tested.The Virginia Department of Transportation has been incorporating the PCBT girder shape into their bridge designs because of its efficient cross section.The girder was cast with LWSCC and a composite cast-in-place deck was fabricated using lightweight concrete.In this study,the beam and deck were tested using two different loading conditions.These tests aimed to ex-perimentally quantify the web-shear strength and flexure-shear strength of the beam.This paper presents results from the web-shear strength test only and discusses how LWSCC affects theshear strength of prestressed concrete bridge girders.During flexure-shear testing,the girder failed in flexure before a flexure-shear failure;more detailed results and discussion on that part of the experimentation can be found in Dymond ͑2007͒.The scope of this project was limited to a single PCBT girder.This project does not include a parametric study involving other cross sections,varying design parameters,or alteration of the con-crete mix design.The experimental shear strength is compared to four different American Association of State Highway and Trans-portation Officials ͑AASHTO ͒analytical models.1.The general method in the Standard Specifications for High-way Bridges ͑AASHTO 2002͒based on calculation of V ci and V cw —referred to herein as the “standard”method.2.The general procedure from the AASHTO Load and Resis-tance Factor Design (LRFD)Bridge Design Specifications ͑AASHTO 2007͒based on tabulated theta,,and beta,,values—referred to as the “LRFD”method.3.The simplified procedure for prestressed and nonprestressedsections from the AASHTO LRFD Bridge Design Specifica-tions ͑AASHTO 2007͒based on calculation of V ci and V cw —referred to as the “simplified”method.4.The general procedure from the 2008Interim Revisions tothe AASHTO LRFD Bridge Design Specifications ͑AASHTO 2008͒based on equations for and values—referred to as the “interim”method.Test Girder Design and FabricationA single PCBT girder 1.35m ͑53in.͒tall ͑PCBT-53͒and 19.8m ͑65ft ͒long was designed in two stages.First,the anchorage zones were designed for a companion project which investigated the behavior and design of anchorage zones in prestressed con-crete bridge girders,as documented by Crispino ͑2007͒.Second,1Research Associate,Dept.of Civil and Environmental Engineering,Virginia Tech,Blacksburg,V A 24061͑corresponding author ͒.2Associate Professor,Dept.of Civil and Environmental Engineering,Virginia Tech,Blacksburg,V A 24061.3Professor,Dept.of Civil and Environmental Engineering,Virginia Tech,Blacksburg,V A 24061.Note.This manuscript was submitted on January 27,2009;approved on December 4,2009;published online on December 9,2009.Discussion period open until February 1,2011;separate discussions must be submit-ted for individual papers.This technical note is part of the Journal of Bridge Engineering ,V ol.15,No.5,September 1,2010.©ASCE,ISSN 1084-0702/2010/5-615–618/$25.00.D o w n l o a d e d f r o m a s c e l i b r a r y .o r g b y H u a z h o n g U n i v e r s i t y o f S c i e n c e & T e c h n o l o g y o n 05/30/15. C o p y r i g h t A S CE .F o r p e r s o n a l u s e o n l y ; a l l r i g h t s r e s e r v e d .the vertical and horizontal shear reinforcements were designed using the AASHTO LRFD bridge design specifications ͓Ameri-can Association of State and Highway Transportation Officials ͑AASHTO ͒2007͔for the shear testing of the PCBT-53.The ver-tical shear design of the beam was based on an assumed angle of inclination of diagonal compressive stresses of 38°–39°.The PCBT-53girder cross section included 32pretensioned 12.7mm ͑0.5in.͒diameter,1.86GPa ͑270ksi ͒,seven-wire low relaxation strands,stressed to 75%of the ultimate stress,approxi-mately 138kN ͑31kips ͒each.The strand manufacturer provided an ultimate stress of 1,960MPa ͑284ksi ͒and a yield stress of 1,785MPa ͑259ksi ͒from material testing.Six of the strands were harped at the end of the girder;the harping points were 762mm ͑30in.͒from each side of the center line of the girder.The LWSCC girder,with a density of 1,920kg /m 3͑120pcf ͒,was designed using a compressive strength of 55MPa ͑8,000psi ͒and release strength of 38MPa ͑5,500psi ͒.Beam details,including a final composite cross section view and an elevation,are shown in Figs.1and 2.The final cross section included a composite deck which was cast in the laboratory with lightweight concrete.The deck was designed with a compressive strength of 34.5MPa ͑5,000psi ͒and the deck reinforcement was designed for a fictitious bridge in which the beams were spaced 2.7m ͑9ft ͒center to center and the deck had a thickness of 229mm ͑9in.͒.For ease of constructionand testing,the deck was only built with a 2.13m ͑7ft ͒width.For calculations,a total self-weight of 19.7kN/m ͑1.35k/ft ͒was used.At the time of web-shear testing,the PCBT girder had a com-pressive strength of 72.4MPa ͑10,500psi ͒,a splitting tensile strength of 5.5MPa ͑800psi ͒,and a modulus of elasticity of approximately 22.8GPa ͑3,300ksi ͒.Furthermore,the cast-in-place deck had a compressive strength of 52.4MPa ͑7,600psi ͒,a splitting tensile strength of 4.7MPa ͑680psi ͒,and a modulus of elasticity of approximately 20GPa ͑2,900ksi ͒.These material properties were used for shear strength calculations because they provide a more accurate estimate of actual behavior versus pre-dicted behavior.Experimental Setup and ResultsDuring web-shear testing,the PCBT girder was simply supported with a center span of 19.2m ͑63ft ͒.The supports were placed to create an overhang of 305mm ͑1ft ͒from the end of the beam.Two hydraulic actuators,acting as point loads shown in Fig.2,were initially placed at a distance of 2.3m ͑7.5ft ͒and 6.6m ͑21.5ft ͒from the end of the beam to simulate the AASHTO design truck rear axle spacing;the tire patch was created using steel reinforced neoprene pads.Several different types of instru-mentation were used to monitor load,deflection,strain,and strand slip during each test.This paper only discusses the applied load and visible web-shear cracks since it pertains to the shear strength calculations.Further information regarding other types of data and analysis can be seen in Dymond et al.͑2009͒.After incremental loading,the first vertical cracks ͑possibly due to flexural effects ͒crossed the bottom of the bulb at approxi-mately 690kN ͑155kips ͒per actuator.The loading process pro-ceeded until the first web shear crack,shown in Fig.3with the corresponding crack angle,in the PCBT-53occurred at approxi-mately 800kN ͑180kips ͒per actuator which is equivalent to a support reaction of 1.45MN ͑327kips ͒.New flexural and web cracks formed and extended as more load was applied.The initial test setup did not produce a high-enough shear force in the girder web because the ultimate strength of the steel load frame bolted connections was reached.For this reason,the point loads were moved to 2.3m ͑7.5ft ͒and 3.2m ͑10.5ft ͒from the end of the beam as shown in Fig.2.After further incremental loading beyond the previous stopping point,the ultimate strength64229#16mm25Fig.1.Final composite cross sectionInitial &Harpingmmm Initial Final 19.2m Center-to-Center of BearingsOverhang 305mmFig.2.Final composite half-elevationD o w n l o a d e d f r o m a s c e l i b r a r y .o r g b y H u a z h o n g U n i v e r s i t y o f S c i e n c e & T e c h n o l o g y o n 05/30/15. C o p y r i g h t A S CE .F o r p e r s o n a l u s e o n l y ; a l l r i g h t s r e s e r v e d .of the steel load frame bolted connections was again reached.The testing was stopped at a load of 1.57MN ͑353kips ͒per actuator.This is equivalent to a support reaction ͑taken as the factored shear force,V u ͒of approximately 2.94MN ͑660kips ͒.The final test setup produced clear evidence of concrete spal-ling in the web of the PCBT-53which indicated a web crushing failure was imminent.McGowan ͑2007͒stated that during tests of two normal weight self-consolidating PCBT-45bridge girders,it was observed that full compression failure occurs soon after evi-dence of concrete spalling in the web is detected.For comparison to AASHTO predicted behavior,ultimate strength of the girder was assumed to have occurred when the final load of 1.57MN per actuator ͑2.94MN shear ͒was reached.Analysis of ResultsThe experimental shear strength was compared to four different AASHTO analytical models currently used in practice for shear design.The standard method and the simplified method are both based on the calculation of the concrete contribution to shear strength,V c ,which is the load at which diagonal cracking is ex-pected to occur.In these methods,V c is taken as the lesser of the shear required to cause web-shear cracking,V cw ,or flexure-shear cracking,V ci .In the LRFD method,the longitudinal strain at mid-depth,x ,and thus and are functions of the factored shear force,V u .Evaluating shear strength is iterative and requires an estimate of the strength,evaluation of the required parameters and the nomi-nal shear resistance,V n ,and then a check that V n is equal to V u .With this in mind,the interim method eliminates much of the iterative process by introducing equations for evaluation of and that replace the LRFD tables.Additionally,a new equation for the longitudinal strain that is not a function of was introduced.The shear strength calculations were done at half of the shear span ͑between the point load 2.3m from the beam end and the support ͒which is very close to where the girder experienced spal-ling in the web.All load and resistance factors were taken as oneand the final analytical results were calculated without using the recommended reduction factor of 0.85for sand-lightweight con-crete due to the fact that the lightweight concrete had a high tensile strength.Additionally,a calculated effective prestress of 1.22GPa ͑177ksi ͒was used during analysis.Table 1presents the results of the web-shear test in a ratio of experimental shear strength divided by the corresponding analytical prediction of shear strength.This allows for a comparison of how conserva-tively each method calculates the shear strength of LWSCC PCBT girders.Further investigating the web-shear strength values in Table 1,it can be seen that both the standard method and the simplified method provided conservative results in the same range.Addi-tionally,the LRFD methods using values of and provided conservative results.These calculations were done in two differ-ent ways.First,as shown by the ratio of 1.32,the shear strength calculations were done using the AASHTO table for both and and the final strength was found through an iterative process ͑in this case,was 34.6°and was 2.25͒.Second,the ratio of 1.44was calculated using the experimental crack angle observed dur-ing testing and the value of was determined using the AASHTO table ͑was found to be 2.74͒.Finally,the experimental shear strength was compared to the interim method which also provided a conservative estimate ͑in this case and were calculated as 36°and 1.9,respectively ͒.The analytical predictions and corresponding ratios of web-shear strength using these four methods are in accordance with test result ratios found by Hawkins et al.͑2005͒during an inves-tigation of high-strength normal weight concrete for the National Cooperative Highway Research Program.This study compared results for prestressed concrete members to the four methods de-scribed herein ͑the interim method is essentially the Canadian Standards Association method ͒.Furthermore,the ratios from this test were also in agreement with structural research on normal weight self-consolidating concrete bridge girders done by Hamil-ton and Labonte ͑2005͒for the Florida Department of Transpor-tation ͑FDOT ͒;this FDOT project specifically compared results to the LRFD method.Conclusions and RecommendationsBased on the results of this limited study,the theoretical predic-tions for the web-shear strength of this girder were all conserva-tive when compared to the experimentally measured failure strength.With this in mind,use of either the LRFD or the interim procedure ͑one based on tabulated and and one based on equations ͒and use of the simplified method provides conservative results for designing LWSCC PCBT girders similar to the one tested.Due to the limits of this single test,further research at different shear-to-depth ratios and shear reinforcement amounts is recommended and necessary before girders are to be designed for public bridges.This will aid in supporting the use of LWSCC girders in the bridge industry because of advantages such aslowerFig.3.Initial web-shear cracksTable 1.Shear Strength Results MethodStandardLRFD a LRFD b Simplified Interim V n ,MN ͑kips ͒2.15͑484͒ 2.22͑500͒ 2.04͑459͒ 2.13͑478͒ 2.08͑468͒V u /V n1.36 1.321.441.381.41aUsing LRFD tabulated .bUsing experimental crack .D o w n l o a d e d f r o m a s c e l i b r a r y .o r g b y H u a z h o n g U n i v e r s i t y o f S c i e n c e & T e c h n o l o g y o n 05/30/15. C o p y r i g h t A S CE .F o r p e r s o n a l u s e o n l y ; a l l r i g h t s r e s e r v e d .self-weight and the lack of vibration during fabrication.Repeat-able results will help to better understand the material properties,structural properties,and cost advantages.ReferencesAmerican Association of State and Highway Transportation Officials ͑AASHTO ͒.͑2002͒.Standard specifications for highway bridges ,17th Ed.,Washington,D.C.American Association of State and Highway Transportation Officials ͑AASHTO ͒.͑2007͒.AASHTO LRFD bridge design specifications ,4th Ed.,Washington,D.C.American Association of State and Highway Transportation Officials ͑AASHTO ͒.͑2008͒.2008interim revisions to the AASHTO LRFD bridge design specifications ,4th Ed.,Washington,D.C.Crispino,E.D.͑2007͒.“Anchorage zone design for pretensioned bulb-tee bridge girders in Virginia.”MS thesis,Virginia Tech,Blacksburg,Va.Dymond,B.Z.͑2007͒.“Shear strength of a PCBT-53girder fabricated with lightweight,self-consolidating concrete.”MS thesis,Virginia Tech,Blacksburg,Va.Dymond,B.Z.,Roberts-Wollmann,C.L.,and Cousins,T.E.͑2009͒.“Shear strength of a PCBT-53girder fabricated with lightweight,self-consolidating concrete.”Rep.No.09-CR11,Virginia Transportation Research Council ͑VTRC ͒,Charlottesville,Va.Hamilton,H.R.,and Labonte,T.͑2005͒.“Self-consolidating concrete ͑SCC ͒structural investigation.”Rep.No.BD545-21,Florida Depart-ment of Transportation ͑FDOT ͒,Gainesville,Fla.Hawkins,N.M.,Kuchma,D.A.,Mast,R.F.,Marsh,M.L.,and Reineck,K.H.͑2005͒.“Simplified shear design of structural concrete mem-bers.”National Cooperative Highway Research Program (NCHRP)Report 549,Transportation Research Board,National Research Coun-cil,Washington,D.C.McGowan,P.D.͑2007͒.“Proposal for a rational shear design model for prestressed concrete bulb-T bridge beams.”MS thesis,Univ.of Vir-ginia,Charlottesville,Va.D o w n l o a d e d f r o m a s c e l i b r a r y .o r g b y H u a z h o n g U n i v e r s i t y o f S c i e n c e & T e c h n o l o g y o n 05/30/15. C o p y r i g h t A S CE .F o r p e r s o n a l u s e o n l y ; a l l r i g h t s r e s e r v e d .。

专业英语大作业优选10篇(英文原文)

杜孟远PILOTING THE SMART GRIDAhmad Faruqui, Ryan Hledik and Sanem Sergici1The transformative power of the smart grid is enormous. It is receiving much consideration frutilities and commissions across North America. Several members of the European UniChina, Japan and other nations are also engaged in the same endeavor.The smart grid has the potential for revolutionizing the way we produce and consume electric but because it contains so many new elements; its core value proposition remains untested.The unanswered questions include:What new services will the smart grid provide customers?Do customers want these new services?Will they respond by changing their energy use patterns?The answers to these questions will help policymakers in federal and state government determine whether the benefits of the smart grid will cover its costs.It is widely understood that the new services enabled by the smart grid will include different rate designs that encourage curtailment of peak loads and make more efficient use of energy. Examples include dynamic pricing and inclining block rates.2These innovative rate designs will be enhanced by various automating technologies such as Energy Orbs, programmable communicating thermostats (PCTs), whole building energy management systems (Auto DR), and in-home displays (IHDs).The smart grid will of course go beyond smart meters and rate design and enable renewable energy resources to be connected to the grid. This will allow optimal use of intermittent resources, such as wind, which often reach their peak generating capacity during off-peak hours. New off-peak loads, such as plug-in hybrid electric vehicles, which reduce overall energy consumption and improve the carbon footprint, will be energized by the smart grid.To address the likely impact of the smart grid on customers, utilities, and society as a whole, it may be necessary to conduct a pilot. When should a pilot be conducted and how should it be conducted? To be useful, a pilot must yield credible results. This requires that the pilot satisfy various validity criteria. These issues form the focus of this paper. We provide examples from several recent pilots that involved dynamic pricing, a key element of the smart gird. The concluding section discusses how a hypothetical company, SMART POWER, should go about designing its own pilot. Should a Pilot be Conducted?3Policymakers should consider implementing a pilot if there is much uncertainty in the cost-benefit analysis of proceeding with full-scale deployment. A powerful method for resolving uncertainty is to assess the value of information that would be generated from a pilot. This point is best illustrated with a case study.California suffered the worst energy crisis in its history in 2001. Most analysts attributed the crisis in part to the lack of demand response in the market design. When prices rose in wholesale markets, there was no incentive for retail customers to lower demand. In the summer of 2002, the California Public Utilities Commission initiated proceedings on demand response, advanced metering, and dynamic pricing. Early in the proceedings, it became clear that the decision to deploy advanced metering was fraught with risk. The deployment would be costly and the benefits uncertain, as they depended on the customers’ price elasticity of demand.龚畅Electricity from the Oceans: Will It Really HappenAnytime Soon?By Doug PeeplesSGN News EditorGovernments and private industry have been casting a wide net to find alternative sources of sustainable power to meet accelerating demand and reduce greenhouse gas emissions. And electric power from ocean waves, tides and currents has been getting a lot more attention —and money — than ever before.But what are the chances that marine and hydrokinetic technologies (let's just call it ocean power to keep it short and sweet) are really going to take their place alongside more mature and relatively well-funded renewable energy sources such as wind and solar to feed the need for more greener power?We can't answer that question to a certainty, but we can round up a lot of the big issues: What's good about it, what's bad and what needs to happen to make ocean power a reality?The Good∙Oceans cover about 70% of the planet, and waves and tides offer a more predictable, reliable source of energy than wind and solar. And energy storage isn't an issue. The oceans are always on.∙ A British company built a large-scale tidal turbine in 2008 that's since been getting good reviews, and several countries have jumped onto the ocean power bandwagon.Globally, according to Pike Research, there are more than 300 ocean power projects"in the works." A New Jersey company has big plans for a pilot buoy project off theOregon coast and much bigger plans for a commercial-scale wave project there.∙ A January report from Pike said ocean power could generate 200 GW of electricity by 2025. A new analysis from Frost & Sullivan pegs global resources at more like2,000 to 4,000 TWh annually. The Frost & Sullivan analysis also anticipates thecommercialization of ocean power within the next 5-10 years as technology improves and production costs drop.∙In the U.S., attitudes of the federal government and private industry are taking a positive tack, too. The DOE and the Interior Department in June signed amemorandum of understanding to collaborate on commercial-scale development of offshore renewable energy projects, including wave power. The DOE has pouredmillions of dollars into hydrokinetic R&D and has put the technological and strategic muscle of its national laboratories behind it.The Bad∙Ocean power is still in the proof-of-concept phase, and initial deployments require unimaginably massive investments. Will investors bet on technologies with nosignificant track record and sky high upfront costs?∙While wave power is more reliable than wind and solar, the actual power in waves fluctuates a lot, as does the state of the oceans in general. Durability is a big issue.Pelamis Wave Power, which operated a highly regarded commercial-scale wave farm in Portugal, shut down its operations last year because of persistent technicalproblems and dwindling financing.∙How will regulations to protect aquatic ecosystems and fisheries evolve? The permitting and siting process for land-based renewable energy projects is complicated enough. The marine environment is more complex, so it seems reasonable thatpermitting and siting for ocean projects will be even more complicated.∙Standardizing technologies, connecting wave power to the electric grid and transmission also present obstacles.That Said, What's It All Mean?Who wouldn’t want to see a new, reliable, secure and green energy source? But even the most optimistic reports and analyses come with heavy disclaimers, most of them pointing at exceptionally high upfront costs and technological nightmares similar to those facing the new deepwater wind farm sector. While the future of ocean power looks a little brighter, it still looks like a long slog to the light at the end of the tunnel.What do YOU think? Will be generating significant amounts of electricity from ocean waves anytime soon ... if ever?甘凯元Radioactive Water Leaking From Crippled Japan Plantby The Associated PressWorkers spray resin on the ground near the reactor buildings to prevent the spread of radioactive substances at the Fukushima Dai-ichi nuclear power plant.April 2, 2011Highly radioactive water was leaking into the sea Saturday from a crack discovered at a nuclear power plant destabilized by last month's earthquake and tsunami, a new setback as frustrated survivors of the disasters complained that Japan's government was paying too much attention to the nuclear crisis.The contaminated water will quickly dissipate into the sea and is not expected to cause any health hazard. Nevertheless, the disturbing discovery points at the unexpected problems that can crop up and continue to hamper technicians trying to control the crisis.Word of the leak came as Prime Minister Naoto Kan toured the town of Rikuzentakata, his first trip to survey damage in one of the dozens of villages, towns and cities slammed by the March 11 tsunami that followed a magnitude 9.0 earthquake."The government has been too focused on the Fukushima power plant rather than the tsunami victims. Both deserve attention," said 35-year-old Megumi Shimanuki, who was visiting her family at a community center converted into a shelter in hard-hit Natori, about 100 miles from Rikuzentakata.The double disaster is believed to have left nearly 25,000 dead — 11,800 confirmed. More than 165,000 are still living in shelters, and tens of thousands more still do not have electricity or running water.Although the government had rushed to provide relief, its attention has been divided by the efforts to stabilize the Fukushima Dai-ichi nuclear plant, which suffered heavy damage and has dragged the country to its worst nuclear crisis since the atomic bombings of Hiroshima and Nagasaki during World War II.The plant's reactors overheated to dangerous levels after electrical pumps — deprived of electricity — failed to circulate water to keep the reactors cool. A series of almost daily problems have led to substantial amount of radiation leaking in the atmosphere, ground and sea.On Saturday, workers discovered an 8-inch long crack in a maintenance pit that was leaking highly radioactive water into the Pacific Ocean, said Japan Nuclear and Industrial Safety Agency spokesman Hidehiko Nishiyama.He said the water contaminated with levels of radioactive iodine far above the legal limit found inside the pit could be one of the sources of recent spikes in radioactivity in sea water."There could be other similar cracks in the area, and we must find them as quickly as possible," he told reporters.Soon after the discovery, the plant's operator, Tokyo Electric Power Co., started filling the pit with cement to seal the crack and prevent more contaminated water from seeping into the ocean.Nuclear safety officials said the crack was likely caused by the quake and may be the source of radioactive iodine that started showing up in the ocean more than a week ago.People living within 12 miles of the plant have been evacuated and the radioactive water will quickly dissipate in the sea, but it was unclear if the leak posed any new danger to workers. People have been uneasy about seafood from the area despite official reassurances that the risk of contamination is low.The cracked pit houses cables for one of the six nuclear reactors, and the concentration of radioactive iodine was the same as in a puddle of contaminated water found outside the reactor earlier in the week. Because of that, officials believe the contaminated water is coming from the same place, though they are not sure where.A nuclear plant worker who fell into the ocean Friday while trying to board a barge carrying water to help cool the plant did not show any immediate signs of being exposed to unsafe levels of radiation, nuclear safety officials said Saturday, but they were waiting for test results to be sure.Radiation worries have compounded the misery for people trying to recover from the tsunami. Kan's visit Saturday to Rikuzentakata did little to alleviate their worries."The government fully supports you until the end," Kan told 250 people at an elementary school serving as an evacuation center. He earlier met with the mayor, whose 38-year-old wife was swept away.He bowed his head for a moment of silence in front of the town hall, one of the few buildings still standing, though its windows are blown out and metal and debris sit tangled out front.Kan also stopped at the sports complex being used as a base camp for nuclear plant workers, who have been hailed as heroes for laboring in dangerous conditions. He had visited the nuclear crisis zone once before, soon after the quake.Workers have been reluctant to talk to the media about what they are experiencing, but one who spent several days at the plant described difficult conditions in an anonymous interview published Saturday in the national Mainichi newspaper.When he was called in mid-March to help restore power at the plant, he said he did not tell his family because he did not want them to worry. But he did tell a friend to notify his parents if he did not return in two weeks."I feel very strongly that there is nobody but us to do this job, and we cannot go home until we finish the work," he said.Early on, the company ran out of full radiation suits, forcing workers to create improvised versions of items such as nylon booties they were supposed to pull over their shoes."But we only put something like plastic garbage bags you can buy at a convenience store and sealed them with masking tape," he said.He said the tsunami littered the area around the plant with dead fish and sharks, and the quake opened holes in the ground that tripped up some workers who could not see through large gas masks. They had to yell at one another to be heard through the masks."It's hard to move while wearing a gas mask," he said. "While working, the gas mask came off several times. Maybe I must have inhaled much radiation."Radiation is also a concern for people living around the plant. In the city of Koriyama, Tadashi and Ritsuko Yanai and their 1-month-old baby have spent the past three weeks in a sports arena converted into a shelter. Baby Kaon, born a week before the quake, has grown accustomed to life there, including frequent radiation screenings, but his parents have not. Their home is fine, but they had to leave because it is six miles from the nuclear plant.Asked if he had anything he would like to say to the prime minister, Tadashi, a32-year-old father, paused to think and then replied: "We want to go home. That's all, we just want to go home."In Natori, where about 1,700 people are living in shelters, others had stronger words for Kan. Toru Sato, 57, lost both his wife and his house in the tsunami and said he was bothered that Kan's visit to the quake zone was so brief about a half day."He's just showing up for an appearance," Sato said. "He should spend time to talk to various people, and listen to what they need."黄松强AEP, ITC Transmission to perform technical study on expanding 765-kV transmission into MichiganCOLUMBUS, Ohio, Nov. 6, 2006 – American Electric Power (NYSE: AEP) has signed a memorandum of understanding (MOU) with ITC Transmission, a subsidiary of ITC Holdings Corp. (ITC), to perform a technical study to evaluate the feasibilityof extending AEP’s 765-kilovolt (kV) transmission infrastructure through Michigan to enhance reliability and support a competitive market of generation supply.The study will explore the merit and benefits of building a 765-kV transmission network in Michigan’s Lower Peninsula that would link to AEP’s 765-kV transmission system in the Midwest. The study will be shared with the Midwest ISO (MISO) and the Michigan Public Servic e Commission’s (MPSC) 21st Century Energy Planning team.The study is projected to be complete in late 2006, in time for it to be shared with the MPSC 21st Century Planning team before they complete their deliberations. The MOU signed with ITC Transmission does not include provisions to build or operate transmission. Any future activities regarding Michigan transmission will be determined after the completion of the study.―Through this agreement, we will work with ITC Transmission to determine the benefits of enhancing the Michigan transmission grid by introducing 765-kV lines, the most robust transmission in the U.S., and linking it to AEP’s 2,100-mile 765-kV transmission network in the Midwest. After the completion of the study, we will provide our analysis to the Michigan Public Service Commission, Midwest ISO and other parties to help them determine the best way to serve Michigan’s future electric reliability needs and support a successful competitive marketplace,‖ said Michael G. Morris, AEP’s chairm an, president and chief executive officer.―ITC Transmission continues in its mission to invest in the transmission infrastructure as a means to improve electric reliability for its customers and lower the overall cost of delivered energy,‖ said Joseph L. Welch, president and chief executive officer of ITC Transmission. ―The transmission grid in Michigan has suffered after a 30-year trend of underinvestment, and we must begin actively looking to implement a long-term solution that will address Michigan’s current electric reliability needs now and for years to come.‖―ITC Transmission, a subsidiary of ITC Holdings Corp. (NYSE: ITC), is the first independently-owned and operated electricity transmission company in the United States. ITC Holdings Corp. is in the business of investing in electricity transmission infrastructure improvements as a means to improve electric reliability, reduce congestion and lower the overall cost of delivered energy. Through its operating subsidiaries, ITC Transmission and METC, it is the only publicly traded company engaged exclusively in the transmission of electricity in the United States. ITC is also the largest independent electric transmission company and the tenth largest electric transmission company in the country based on transmission load served. ITC Transmission and METC operate contiguous, fully regulated, high-voltage systems in Michigan´s Lower Peninsula, an area with a population of approximately 9.8 million people, that transmit electricity to local electricity distribution facilities fromgenerating stations throughout Michigan and surrounding areas. For more information on ITC Holdings Corp., please visit . For more information on ITC Transmission or METC, please visit or , respectively.American Electric Power is one of the largest electric utilities in the United States, delivering electricity to more than 5 million customers in 11 states. AEP ranks among the nation’s largest generators of electricity, owning nearly 36,000 megawatts of generating capacity in the U.S. AEP also owns the nation’s largest electricity transmission system, a nearly 39,000-mile network that includes more 765 kilovolt extra-high voltage transmission lines than all other U.S. transmission systems combined. AEP’s utility units operate as AEP Ohio, AEP Texas, Appalachian Power (in Virginia and West Virginia), AEP Appalachian Power (in Tennessee), Indiana Michigan Power, Kentucky Power, Public Service Company of Oklahoma, and Southwestern Electric Power Company (in Arkansas, Louisiana and east Texas). American Electric Power, based in Columbus, Ohio, is celebrating its 100th anniversary in 2006.杨萌Siemens Residential Surge Protection —Implementing the Right Line of Defense on the Home FrontUnexpected voltage spikes, surges and other electrical disturbances can ruin or severely damage computers, VCRs, televisions, fax machines, scanners and copiers, disrupt satellite signals, degrade the performance of audio/video components, and wreak havoc with telecommunications systems.Because no single device can protect an entire home or office against all electrical surges, the best way to prevent damage is by implementing a systematic, tiered surge protection plan that monitors every possible incoming signal path and protects against internally generated power fluctuations, providing protection at the service entrance and at the point of use.Protection at the point of entryThe first line of defense is protection at the point of entry where electricity,surges and voltage spikes from lightning hits can enter the electrical system. This requires an electrician-installed secondary surge arrestor or transient voltage surge suppressor installed at the service entrance to limit surge voltage by diverting and conducting large surge currents safely to ground. If an AC surge arrestor does its job right, it shields motor-driven appliances like refrigerators, dishwashers, electric washers, and dryers from damage. Additional specialized service entrance protectors can be added to protect cable TV and telephone lines, and minimize damage to TVs and modems. Homeowners also can arrange for installation of branch circuit feeder devices or trips in circuit breaker panels to prevent surges from damaging equipment on specific circuit branches.Protection at the point of useThe second line of defense is the point of use. Here, homeowners can reinforce point-of-entry protection by installing plug-in surge protectors (strips) into grounded wall receptacles where sensitive electronic equipment is located. These plug-in protectors, which generally have much lower limiting voltages than entry protectors, defend against externally and internally generated surges that travel through power, phone, data, and coaxial lines. Plug-in power strips should minimally include AC power protection and appropriate signal line protection and should protect against both catastrophic and small surges. These devices should be installed wherever expensive or sensitive electronic equipment like computers, VCRs, fax machines, PCs with modems, satellite systems, stereo systems, copiers and scanners are located. All types of equipment with signal lines, such as phones, cable TV, and satellites should be equipped with multi-port protectors, which protect signal and AC lines.If you have any questions or are interested in purchasing our surge protection products, please contact us via e-mail or call 1-800-964-4114.胡嘉滨Energy Storage: Can It Replace Transmission?Grid-scale storage offers potential benefits to transmission and distribution systems of utilities in regulated and market environments. These benefits derive from cost reductions due to the time and location shifting of energy for congestion relief, reliability via enhanced stability and outage response, and incremental voltage support—once the storage device and its power electronics are in place. .Between the transmission and distribution systems, at the subtransmission or distribution substation, storage can defer capital expenditures for power transformer upgrades to meet peak load conditions. In remote areas served by radial subtransmission, storage can also be a vehicle for reliability improvement as a way to ride through un-cleared faults on the transmission line(s) that serve the substation.The potential T&D CapEx deferral angle is an interesting area to explore. One example for a substation application is to support power transformer contingency operations during peak load periods that have grown in excess of the N-1 contingency capacity of the station.This potential application, however, suffers from the same barriers today as the transmission congestion relief application:•The planning and operational methodologies are not established•The regulatory process for approval is nonexistent•It, again, crosses the boundary between transmission and distribution regulated functionality and merchant functionality, because it potentially shifts off-peak energy to on-peak delivery.In addition, as this typical substation application is likely to be in the range of 1-10 MW, it may not require centralized storage systems, but rather distributed or utility-scale devices. As previously noted, these could be portable or semi-portable in nature.One More Hurdle … For Now, At LeastAn additional hurdle that needs to be mentioned is costs. One reason multiple roles are applied to a storage device is for a means to create additional revenue that can defer initial cost for the technologies. However, this hurdle needs to be evaluated in the context of an emerging technology and not ―set‖ at current levels.Advanced energy storage technologies are still in a rapid state of evolution and development. Hence, when comparing options, solutions for areas such as CapEx deferral need to be weighed not only against today’s current options, but also with expected prices of future technologies. The intent isn’t to mask cost as a hurdle; rather, there are a number of diffe rent technologies nearing demonstration stages that have potential to alter the current cost of devices. This perceived ―cost‖ hurdle may become a moot point in the near future.Storage is not yet in widespread use to the point that it could serve as a consistent application to defer new transmission. As challenges of siting new transmission continue though, additional modeling of energy storage going forward can help to understand its benefits for a given capacity challenge better.梁诗密A secure energy future requires that we use energy more efficiently and responsibly and improve the performance of the energy delivery system. We launched gridSMART® in 2007 to give customers greater control over their energy usage, increase the efficiency of the electric grid, improve service to our customers and lead us to a new era of energy delivery.From a technology standpoint, gridSMART® incorporates a two-way communications system between AEP and our customers that facilitates the more efficient use of electricity. For example, gridSMART® may allow us to send price signals to customers so they can decide when to run home appliances. It can also allow us to adjust customer thermostats automatically, with their pre-approval, when demand is high and we need to lessen the stress on the electric grid.AEP Ohio is pursuing a comprehensive gridSMART® project involving 110,000 smart meters and distributed grid management technologies on 70 circuits. The $150 million project was funded with a $75 million grant from the DOE, in-kind contributions from vendors and regulatory recovery support from Ohio regulators. The project features smart meters,time-of-use tariffs, home energy use display devices, smart grid-enabled appliances, plug-in electric vehicles, distributed automation equipment, community energy storage devices and a cyber security center.Our most extensive smart meter deployment project is in Texas, where we are installing close to 1 million smart meters. In addition, Indiana Michigan Power Co. (I&M) and Public Service Company of Oklahoma (PSO) are deploying smart grid technology pilots in their states.Our initial goal was to install 5 million smart meters by 2015 throughout the AEP system. Through our early deployments we hope to determine if the expense of the meters is offset by the benefits. We will continue to pursue the deployment of these smart grid technologies where regulators are supportive and there is a proven business case. We believe modernizing the grid is critical to reducing demand and energy consumption, contributing to energy reliability and security, and preparing for the future needs of customers.Get a state-by-state breakdown of gridSMART initiativesWe believe gridSMART® will transform our relationship with our customers and through our current projects we are learning more about how that will occur. For example, we have learned that:The technology that allows us to manage the grid from our back office systems, such as remote operation of the meter and distribution automation equipment, works asexpected. The technology that goes beyond the meter, into the customers’ home, is still evolving.A significant number of customers who participated in the time-of-day rate plan didshift their demand to different times. In a larger scale deployment, this program could provide relief to the distribution systems during peak times.Better system management, fewer crew trips, reduced fuel consumption, better energy theft detection and streamlined billing can create cost savings.When customers agree to the program, we can directly control electric use through wireless technology (e.g. a two-way communicating thermostat) which allows us to raise the temperature in homes to ease stress on the grid and help customers save energy during the cooling season.More education of consumers will be needed in future projects.For more data, please see indicators EU1 through EU12 of AEP's Global Reporting Initiative Electric Utility Sector Supplement.吕思颖Are geothermal power plants safe?For all our hand-wringing over the oil supply, it might shock you to realize that the solution to our dependence on fossil fuels lies right under our feet. In Western states like California, Nevada, Idaho, Alaska and Hawaii, underground pockets of geothermal energy — hot rock, superheated water and steam — can be tapped to generate electricity. According to backers of geothermal technology like Google, this carbon-neutral, inexhaustible energy source could meet 15 percent of America's electricity needs by 2030.Harnessing SteamIn the simplest geothermal power plant, called a dry steam plant, a well is drilled into the rock to tap a steam reservoir. The steam escapes the well under great pressure, which is used to turn a turbine and generate electricity.Since steam deposits aren't as common as hot water and hot rock reserves, the most promising geothermal technology is called a binary-cycle power plant. In this system, hot water from a deep well circulates through a heat exchanger. There, the。

专业英语期末大作业格式

专业英语

译文及原稿译文题目:[单击此处添加译文题目]

原稿题目:[单击此处添加原稿题目]

原稿出处:[单击此处添加原稿出处]

姓名

学号

班级

目录

[单击此处添加译文题目]

[单击此处添加译文正文]

以下是说明文字,正式成文后请删除。

1、模板的使用方法

(1)请不要删除任何具有格式的模板文字。

(2)按照提示直接单击或单击后选择“编辑”→“选择性粘贴”—“无格式文本”就可添加相应内容。

2、在“原稿出处”中对原稿的来源进行说明,包括作者姓名、出处、出版信息等。

网上来源,则放上网址。

3、要求:

(1)题材与信息相关即可,不局限于通信。

(2)外文翻译字数应达到1500字以上(翻译成中文后的汉字字数)。

(3)正文行间距1.3,首行缩进,字体小四宋体,正文对齐方式两端对齐。

(格式排版占30%分数)

(4)按毕业设计的标题要求。

1级黑体3号;2级黑体小三号;3级宋体小四。

然后第二页自动生成目录。

(5)正文所有的英文和数字都用New Times字体。

(6)翻译的语句通顺性、逻辑性以及连贯性是评分主要的标准,切记用了机器翻译后,要改成“人话”。

(7)尽量不要选相同文章!如果多篇翻译内容雷同,则做不及格处理。

[单击此处添加外文原稿题目] [单击此处添加外文原稿正文]。

专业英语翻译

C. Manufacturing Cells (Group Technology)(Familyof Parts Concept)The use of manufacturing cells represents a particular kind of factory layout for manufacturing equipment. The essence of the concept is that, when manufacturing a particular part or family of similar parts in substantial quantities, the equipment for successive operations on the part should be grouped together. The operator - or team of operators who make that part (or the family of parts) - operate all the equipment in the cell. This arrangement is in contrast to a more traditional factory layout that groups like equipment together in departments. Then parts move from departmentto department for each operation. The advantage of the cell layout is that lines of communication and transportation are made very short. The factory's through-put rate is speeded; work-in-process inventory is greatly reduced; when problems arise at one operation, their effect on subsequent operations is immediately recognized. Route sheets to control movement of parts through the factory are greatly simplified or not needed. Operators learn what is needed at each operation to avoid problems at subsequent operations and have the satisfaction of seeing the results of their efforts.Quality tends to improve. The dis-advantage is that C.制造单元(成组技术)(零件族概念)制造单元的使用代表生产设备一种特殊的工厂布局方式。

专业英语大作业

数控技术应用专业英语2011-2012年度第二学期补考姓名:______________________学号:______________________专业:______________________班级:______________________成绩:______________________一、Translate the following sentences into Chinese. (20×2.5=50分)·1.The CNC concept was proposed in the late 1940s.数控的概念,提出了在20世纪40年代末。

C lathes are primarily used to rotate body workpieces with turning.数控车床主要用于旋转与旋转体工件。

3.The program cannot be stored in some media.该方案不能被储存在一些媒体上。

4.The world’s major industrialized countries don’t pay attention to the research and development of NC machining technology.世界主要工业化国家不重视数控加工技术的研究和发展。

5.Vertical CNC lathes are used to turn large diameter disc -type workpieces.立式数控车床是用来打开大直径圆盘型工件。

6.In the fifity years from the time the first NC machine tools came out to now, itexperienced six generation NC systems.从第一数控机床出来到现在的时间fifity年,它经历了六代数控系统。

专业英语作业

龙岩学院化学与材料学院专业英语翻译专业及班级:材料2班姓名及学号:石文艺2013061631Part I. Translate the following English sentences into Chinese.1. One reactant is delivered to the other in a series of known amounts. The equivalence point (specified as a volume of reactant added —— sometimes called the equivalence volume) of the titration is that point when the reaction mixture has the reactants present in stoichiometric equivalence.将一种反应物加入到其他的一系列已知物当中。

滴定的等量点(定义为加入反应物的体积——有时又被称为当量体积)是指当反应混合物中具有以化学计量的反应物的点。

2. A functional group is a chemically reactive atom or group of atoms that imparts characteristic properties to the family of organic compounds containing it. The site of reaction in an organic molecule is often a functional group, a multiple covalent bond, or a polar single bond. An electron-poor atom or group that will bond with an atom that has an available electron pair is called an electrophile. An electron-rich atom or group that will bond with an electron-deficient atom is called a nucleophile.一个官能团是一个化学反应的原子或原子团,它能使包含这些原子团的一类有机化合物显示特殊的性质。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

lesson 10P1 P2The mould designer is frequently confronted with a component design that incorporates a recess or projection which prevents the simple removal of the molding from the mould. The mould design for this type of component is inevitably more complex than for the in line of draw component, as it necessitates the removal of that part of the impression which forms the undercut prior to ejection①.The splits can be incorporated in the mould design in several ways. The designer considers more complex systems where the splits are retained on the mould plate and actuated automatically. There are two basic designs: sliding and angled-lift splits. In both designs there are moving parts and it is necessary to arrange for (i) guiding the splits in the desired direction, (ii) actuating the splits, and (iii) securely locking the splits in position prior to the material being injection into the moul d②.模具设计师经常面临的一个组成部分的设计,包括凹槽或投影,防止简单去除成型模具。

因为脱模前要先抽出形成侧型芯的那部分型腔,这类零件的模具设计比直接脱模的零件复杂的多。

滑块可纳入模具设计的几种方法。

设计师认为,更复杂的系统,滑块将自动保留并驱动在模板中。

有两个个基本的设计思路:滑动和斜滑块。

在两者的设计中都有活动零件,而且有必要安排:沿着正确方向导向滑块,驱动滑块,在材料注射进模具之前安全地锁紧滑块。

Lesson 1The injection molding and machine1.1The injection molding2Injection molding is principally used for the production of the thermoplastic parts, although some progress has been made in developing a method for injection molding some thermosetting materials. The problem of injecting a melted plastic into a mold cavity from a reservoir of melted material has been extremely difficult to solve for thermosetting plastics which cure and harden under such conditions within a few minute s①. The principle of injection molding is quite similar to that of die-casting. The process consists of feeding a plastic compound in powdered or granular from a hopper through metering and melting stages and then injecting it into a mol d②. After a brief cooling period, the mold is opened and the solidified part ejected. Injection-molding machines can be arranged for manual operation, automatic single-cycle operation, and full automatic operation. The advantage of injection molding are: (i) a high molding speed adapted for mass production is possible; (ii) there is a wide choice of thermoplastic materials providing a variety of useful properties; (iii) it ispossible to mold threads, undercuts, side holes, and large thin sections.2.1注塑成型主要用于生产热塑性塑料配件,虽然已经取得了一些进展,在发展中国家的一些热固性材料注塑成型的方法。

问题的注射熔融塑料在模腔的熔融材料的容器已极难处理热固性塑料固化和硬化,在这种情况下,几分钟内①。

注塑成型原理很相似,压铸。

这个过程包括喂养塑料复合粉末或颗粒从料斗通过计量和融化阶段,然后注射到模具②。

经过短暂的冷却时间,打开模具和固化部分弹出。

注塑机可设置为手工操作,自动循环操作,全自动操作。

利用注射成型是:(一)高成形速度为适应大规模生产是可能的;(二)有多种可供选择的热塑性材料提供各种有用的性质;(三)是有可能的模具,削弱,侧孔,和大的薄片。

Lesson2 Mould for threaded components2.2 Stripping internal threadsThe internally thread component may be stripped from the core using the basic stripper plate design providing the plastic material has sufficient elasticity during the ejection phase②. The same principle applies here as to stripping any internal undercut, i.e. the molding must be free to expand during ejection to permit the molded undercut to ride over the restriction on the core③. This means that the outside form of the component must be such that it can be formed in a cavity which is fully contained in one half of the mould.Amould of this type is illustrated in Figure 2-1. This diagram shows a single impression mould for an internally threaded cap. The mould opens initially and, because of molding shrinkage and the undercut form, the molding is withdrawn from the cavity. During the latter stages of opening the stripper plate’s movement is checked, thereby causing the second opening to occur at B. The molding is, therefore, progressively stripped as the core is withdrawn through the stripper plate. The aperture in the stripper plate must be slightly larger in diameter than the major diameter of the thread in order to prevent scoring of the thread.内螺纹组件可能被剥夺的核心采用推板设计提供塑料材料有足够的弹性在弹射阶段②。

同样的原则适用于这里作为剥离的任何内部削弱,即成型必须自由扩大在弹射允许成型凹穴通过限制的核心③。

这意味着,外部组件形式必须是这样的:它可以形成一个腔是完全包含在一个半的模具。

模具这种类型是说明了在图2 - 1。

这个图显示了一个单一的印象模具内螺纹帽。

模具打开了最初,因为成型收缩和削弱形式,成型退出腔。

在后期的开放料板检查,从而造成二开口发生在B成型,因此,逐步剥离为核心撤回通过卸料板。

光圈在料板必须稍微比直径大的大直为防止得分线。

Lesson 3 Basic underfeed mouldP1 P2 P3The moving half consists of the moving mould plate assembly, support blocks, backing plate, ejector assembly and the pin ejection system. Thus the moving half in this design is identical with the moving half of basic moulds.The floating cavity plate, which may be of the integer or insert-bolster design, is located on substantial guide pillars (not shown) fitted in the feed plate. These guide pillars must be of sufficient length to support the floating cavity plate over its full movement and still project to perform the function of alignment between the cavity and core when the mould is being close d. Guide bushes are fitted into the moving mould plate and the floating cavity plate respectively.The maximum movement of the floating cavity plate is controlled by stop bolts or similar devices. The moving mould plate is suitably bored to provide a clearance for the stop bolt assembly. The stop bolts must be long enough to provide sufficient space between the feed plate and the floating cavity plate for easy removal of the feed system. The minimum space provided for should be 65mm just sufficient for an operator to remove the feed system by hand if necessary.一个简单的模具,这种类型是显示在图3 - 1,并说明设计和开放序列如下。