通用 APQP常用缩写

Glossary of Terms

术语

Glossary of Terms术语

AAR: Appearance Approval Report 外观批准报告

A/D/V: Analysis/Development/Validation 分析/开发/验证

A/D/V–DV: ADV Design Validation ADV设计验证

A/D/V P&R: Analysis/Development/Validation Plan and Report. This form is used to summarize the plan and results for validation testing. Additional information can be found in the GP-11 procedure.

分析/开发/验证计划和报告

A/D/V–PV: ADV Product Validation ADV产品验证

AIAG: Automotive Industries Action Group, an organization formed by General Motors, Ford and

Daimler-Chrysler to develop common standards and expectations for automotive suppliers. 汽车工业行动集团

AP: Advance Purchasing 先期采购

APQP: Advanced Product Quality Planning 产品质量先期策划

APQP Project Plan: A one-page summary of the SGM APQP process that describes the tasks and the timeframe in which they occur. APQP项目策划

AQC:Attribute Quality Characteristic 属性质量特性

ASQE: Advanced Supplier Quality Engineer 先期供应商质量工程师

BIW: Body in White. Usually the bare metal shell of the body including doors and deck lid prior to paint and trim. 白车身

BOM: Bill of Materials 材料清单

BOP:Bill of Process 过程清单

Brownfield Site: An expansion of an existing facility. 扩建场地

CMM: Coordinate Measuring Machine 三坐标测试仪

Cpk: Capability Index for a stabile process 过程能力指数

CTC: Component Timing Chart (DRE document) 零部件时间表(DRE文件)

CTS: Component Technical Specifications 零部件技术规范

CVER: Concept Vehicle Engineering Release 概念车工程发布

DC: Design Complete 设计完成

Defect outflow detection: A phrase used in the Supplier Quality Statement of Requirements that refers to in-process or subsequent inspection used to detect defects in parts. 缺陷检测

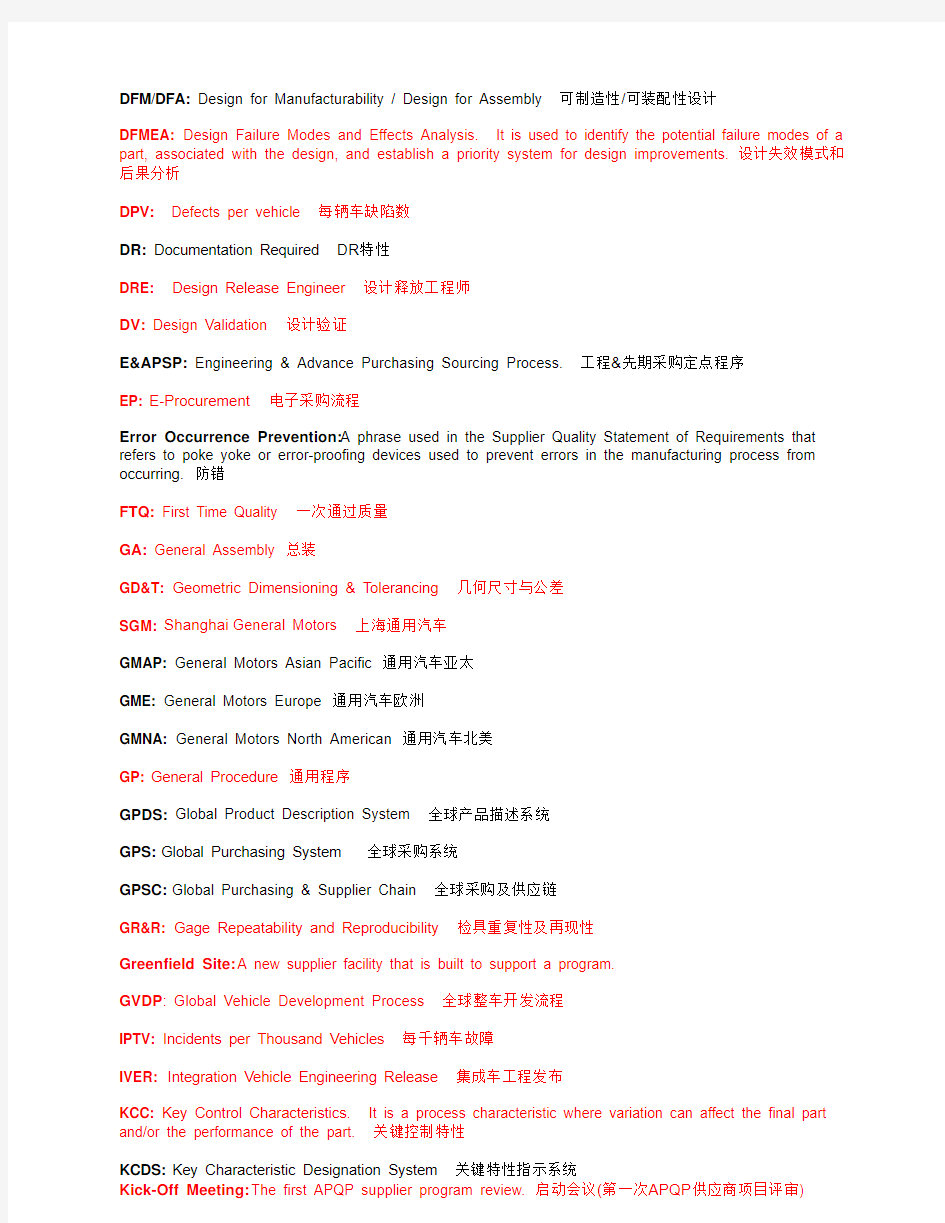

DFM/DFA: Design for Manufacturability / Design for Assembly 可制造性/可装配性设计

DFMEA: Design Failure Modes and Effects Analysis. It is used to identify the potential failure modes of a part, associated with the design, and establish a priority system for design improvements. 设计失效模式和后果分析

DPV: Defects per vehicle 每辆车缺陷数

DR: Documentation Required DR特性

DRE: Design Release Engineer 设计释放工程师

DV: Design Validation 设计验证

E&APSP: Engineering & Advance Purchasing Sourcing Process. 工程&先期采购定点程序

EP: E-Procurement 电子采购流程

Error Occurrence Prevention: A phrase used in the Supplier Quality Statement of Requirements that refers to poke yoke or error-proofing devices used to prevent errors in the manufacturing process from occurring. 防错

FTQ: First Time Quality 一次通过质量

GA: General Assembly 总装

GD&T: Geometric Dimensioning & Tolerancing 几何尺寸与公差

SGM: Shanghai General Motors 上海通用汽车

GMAP: General Motors Asian Pacific 通用汽车亚太

GME: General Motors Europe 通用汽车欧洲

GMNA: General Motors North American 通用汽车北美

GP: General Procedure 通用程序

GPDS: Global Product Description System 全球产品描述系统

GPS: Global Purchasing System 全球采购系统

GPSC: Global Purchasing & Supplier Chain 全球采购及供应链

GR&R: Gage Repeatability and Reproducibility 检具重复性及再现性

Greenfield Site: A new supplier facility that is built to support a program.

GVDP: Global Vehicle Development Process 全球整车开发流程

IPTV: Incidents per Thousand Vehicles 每千辆车故障

IVER: Integration Vehicle Engineering Release 集成车工程发布

KCC: Key Control Characteristics. It is a process characteristic where variation can affect the final part and/or the performance of the part. 关键控制特性

KCDS: Key Characteristic Designation System 关键特性指示系统

Kick-Off Meeting: The first APQP supplier program review. 启动会议(第一次APQP供应商项目评审)

KPC: Key Product Characteristic. It is a product characteristic for which reasonably anticipated variation could significantly affect safety, compliance to governmental regulations, or customer satisfaction. 关键产品特性

LAAM: (General Motors) Latin American, Africa & Meddle East (通用汽车)拉丁美洲、非洲及中东

LCR: Lean Capacity Rate. It is the GM daily capacity requirement. 正常生产能力

MCR: Maximum Capacity Rate. It is the GM maximum capacity requirement. 最大生产能力

MOP: Make or Purchase 制造/采购

MPC: Material Production Control 物料生产控制

MPCE: Material Production Control Europe 欧洲物料生产控制

MRD: Material Required Date; date material must be delivered in order to allow a build event to begin. 物料需求日期

MSA: Measurement Systems Analysis 测量系统分析

MVBns: Manufacturing Validation Build non-saleable 非销售车制造验证

MVBs: Manufacturing Validation Build saleable 销售车制造验证

NBH: New Business Hold 停止新业务

N.O.D.: Notice of Decision 决议通知

OEM: Original Equipment Manufacturer 主机客户

PAD: Production Assembly Documents 生产装配文件

PC&L: Production Control & Logistics 生产控制&物流

PDT: Product Development Team 产品开发小组

PFMEA: Process Failure Modes and Effects Analysis. It is used to identify potential failure modes associated with the manufacturing and assembly process. 过程失效模式和后果分析

PPAP: Production Part Approval Process 生产件批准程序

Ppk: Performance index for a stable process 过程能力指数

PPM: 1) Program Purchasing Manager, 2) Parts per Million (rejects and returns to suppliers) 1)项目经理2)每百万件的产品缺陷数

PPV: Product & Process Validation 产品及过程验证

PQC: Product Quality Characteristic 产品质量特性

PR/R: Problem Reporting & Resolution 问题报告及解决

PSA: Potential Supplier Assessment, a subset of the Quality System Assessment (QSA) 潜在供应商评审PV: Product Validation 产品验证

QSA: Quality System Assessment 质量体系评审

QSB: Quality Systems Basics 质量体系基础

QTC: Quoted Tool Capacity 工装报价能力

RASIC: Responsible, Approve, Support, Inform, Consult 负责、批准、支持、通知、讨论

R@R: Run at Rate 按节拍生产

RFQ: Request For Quotation 报价要求

RPN: Risk Priority Number related to FMEA development 风险顺序数

RPN Reduction Plan: An action plan that describes what is being done to reduce the risk priority number for items listed in the DFMEA or PFMEA.降低RPN值计划

SDE: Supplier Development Engineer 供应商开发工程师

SFMEA: System Failure Mode and Effects Analysis 系统失效模式分析

SMT: System Management Team 系统管理小组

SOA: Start of Acceleration 加速开始

SORP: Start of Regular Production 正式生产

SOR: Statement of Requirements 要求声明

SPC: Statistical Process Control 统计过程控制

SPO: (General Motors) Service and Parts Operations (通用汽车)零件与服务分部

SQ: Supplier Quality 供应商质量

SQE: Supplier Quality Engineer 供应商质量工程师

SQIP: Supplier Quality Improvement Process 供应商质量改进过程

SSF: Start of System Fill 系统填充开始

SSTS: Sub-system Technical Specifications 子系统技术规范

Sub-Assembly/ Sub-System: An assembly of sub-components delivered to the SGM main production line for installation to the vehicle as a single unit.

Subcontractor: The supplier of a sub-component to a Complex System/Subassembly supplier (Tier 2, 3, etc). 分供方

SVE: Sub-System Validation Engineer 子系统验证工程师

SVER: Structure Vehicle Engineering Release. 结构车工程发布

Team Feasibility Commitment: An AIAG APQP form that is provided with the Request for Quotation. It is the suppli er’s concerns with the feasibility of manufacturing the part as specified.小组可行性承诺TKO: Tooling Kick-Off 模具启动会议

UG: Unigraphics UG工程绘图造型系统

VLE: Vehicle Line Executive 车辆平台负责人

VTC: Validation Testing Complete 验证试验完成EWO: Engineering Work Order 工程工作指令