运营管理》-课后习题答案

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

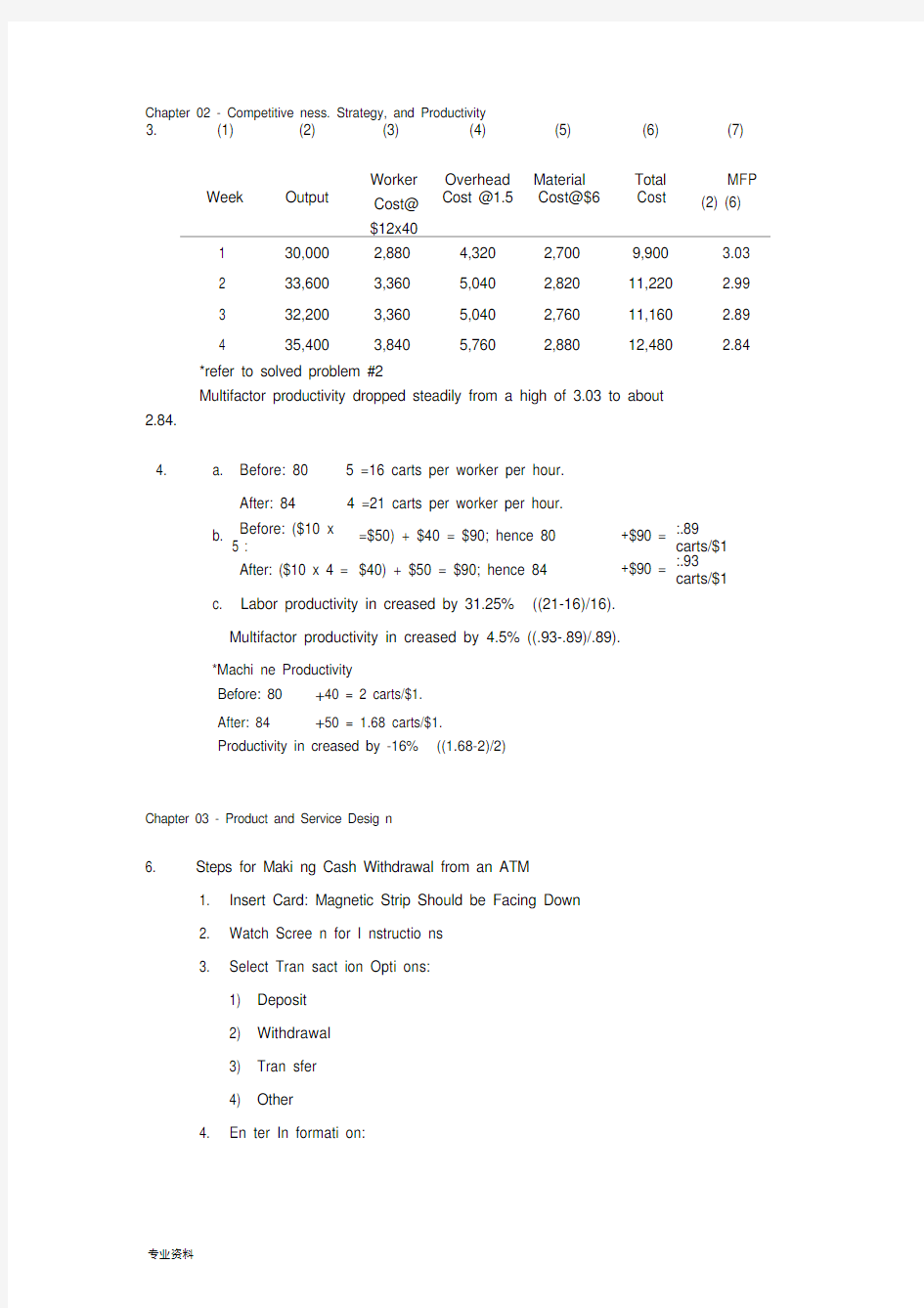

Chapter 02 - Competitive ness. Strategy, and Productivity

3. (1) (2) (3) (4) (5) (6) (7)

Worker Overhead Material Total MFP Week Output Cost@

$12x40

Cost @1.5 Cost@$6 Cost (2) (6)

1 30,000 2,880 4,320 2,700 9,900 3.03

2 33,600 3,360 5,040 2,820 11,220 2.99

3 32,200 3,360 5,040 2,760 11,160 2.89

4 35,400 3,840 5,760 2,880 12,480 2.84

*refer to solved problem #2

Multifactor productivity dropped steadily from a high of 3.03 to about

2.84.

4. a. Before: 80 5 =16 carts per worker per hour.

After: 84 4 =21 carts per worker per hour.

b. Before: ($10 x

5 : =$50) + $40 = $90; hence 80 +$90 = :.89

carts/$1

After: ($10 x 4 = $40) + $50 = $90; hence 84 +$90 = :.93

carts/$1

c. Labor productivity in creased by 31.25% ((21-16)/16).

Multifactor productivity in creased by 4.5% ((.93-.89)/.89).

*Machi ne Productivity

Before: 80 +40 = 2 carts/$1.

After: 84 +50 = 1.68 carts/$1.

Productivity in creased by -16% ((1.68-2)/2)

Chapter 03 - Product and Service Desig n

6. Steps for Maki ng Cash Withdrawal from an ATM

1. Insert Card: Magnetic Strip Should be Facing Down

2. Watch Scree n for I nstructio ns

3. Select Tran sact ion Opti ons:

1) Deposit

2) Withdrawal

3) Tran sfer

4) Other

4. En ter In formati on:

1) PIN Number

2) Select a Tran sacti on and Acco unt

3) En ter Amount of Tran sact ion

5. Deposit/Withdrawal:

1) Deposit ——place in an envelope (which you ' ll find near or in the

ATM) and insert it into the deposit slot

2) Withdrawal —lift the “Withdrawal Door, ” being careful to remove all cash

6. Remove card and receipt (which serves as the tra nsact ion record)

8.

Chapter 04 - Strategic Capacity Pla nning for Products and

Services

2. Efficiency Actual output8Q% Effective capacity

Actual output = .8 (Effective capacity)

Effective capacity = .5 (Desig n capacity)

Actual output = (.5)(.8)(Effective capacity)

Actual output = (.4)(Desig n capacity)

Actual output = 8 jobs

Utilizati on = .4

Utilizatio n Actual output Desig n

capacity

Design Capacity

Actual output 8 Effective capacity .4

20 jobs

5

10. a. Given: 10 hrs. or 600 min. of operating time per day.

250 days x 600 min. = 150,000 min. per year operating time. Total process ing time by machi ne Product

A B C 1 48,000 64,000 32,000 2 48,000 48,000 36,000 3 30,000 36,000 24,000 4

60,000 60,000 30,000 Total

186,000

208,000

122,000

You would have to buy two “A machines at a total cost of $80,000, or two

“ B' machines at a total cost of $60,000, or one

“ C "

machi ne at $80,000.

b. Total cost for each type of machi ne:

A (2): 186,000 min 60 = 3,100 hrs. x $10 = $31,000 + $80,000 = $111,000

B ⑵:208,000 60 = 3,466.67 hrs. x $11 = $38,133 + $60,000 = $98,133 C(1): 122,000

60 = 2,033.33 hrs. x $12 = $24,400 + $80,000 = $104,400

Buy 2 Bs — these have the lowest total cost.

Chapter 05 - Process Selecti on and Facility Layout

3.

N A 186,000 150,000

N B

208,000 150,000

N C 122,000 150,000

1.24 2 machi ne 1.38 2 machine .81 1 mach ine

7

4