精密铸造产品流程翻译

工程铸造中英文术语对照

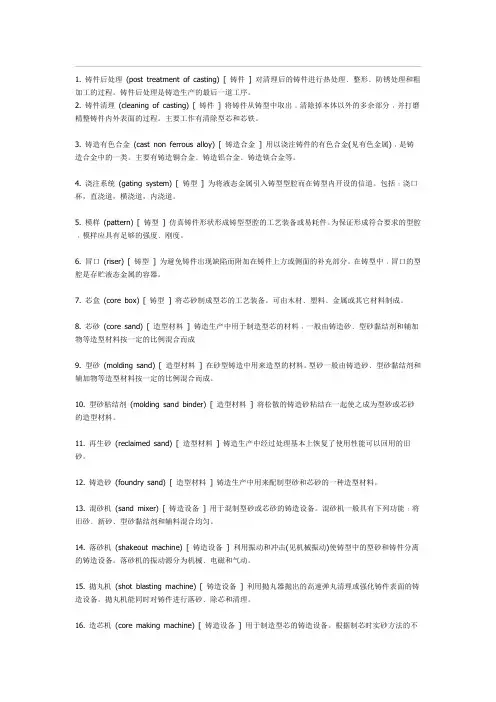

1. 铸件后处理(post treatment of casting) [ 铸件] 对清理后的铸件进行热处理﹑整形﹑防锈处理和粗加工的过程。

铸件后处理是铸造生产的最后一道工序。

2. 铸件清理(cleaning of casting) [ 铸件] 将铸件从铸型中取出﹐清除掉本体以外的多余部分﹐并打磨精整铸件内外表面的过程。

主要工作有清除型芯和芯铁。

3. 铸造有色合金(cast non ferrous alloy) [ 铸造合金] 用以浇注铸件的有色合金(见有色金属)﹐是铸造合金中的一类。

主要有铸造铜合金﹑铸造铝合金﹑铸造镁合金等。

4. 浇注系统(gating system) [ 铸型] 为将液态金属引入铸型型腔而在铸型内开设的信道。

包括﹕浇口杯,直浇道,横浇道,内浇道。

5. 模样(pattern) [ 铸型] 仿真铸件形状形成铸型型腔的工艺装备或易耗件。

为保证形成符合要求的型腔﹐模样应具有足够的强度﹑刚度。

6. 冒口(riser) [ 铸型] 为避免铸件出现缺陷而附加在铸件上方或侧面的补充部分。

在铸型中﹐冒口的型腔是存贮液态金属的容器。

7. 芯盒(core box) [ 铸型] 将芯砂制成型芯的工艺装备。

可由木材﹑塑料﹑金属或其它材料制成。

8. 芯砂(core sand) [ 造型材料] 铸造生产中用于制造型芯的材料﹐一般由铸造砂﹑型砂黏结剂和辅加物等造型材料按一定的比例混合而成9. 型砂(molding sand) [ 造型材料] 在砂型铸造中用来造型的材料。

型砂一般由铸造砂﹑型砂黏结剂和辅加物等造型材料按一定的比例混合而成。

10. 型砂粘结剂(molding sand binder) [ 造型材料] 将松散的铸造砂粘结在一起使之成为型砂或芯砂的造型材料。

11. 再生砂(reclaimed sand) [ 造型材料] 铸造生产中经过处理基本上恢复了使用性能可以回用的旧砂。

12. 铸造砂(foundry sand) [ 造型材料] 铸造生产中用来配制型砂和芯砂的一种造型材料。

铸造流程英文

铸造流程英文The process of casting is a method of forming metal objects by pouring molten metal into a mold and allowing it to cool and solidify. This process is used to create a wide variety of metal objects, ranging from small decorative items to large industrial parts. The casting process can be broken down into several key steps, each of which is essential to producing a high-quality metal casting.Step 1: PatternmakingThe first step in the casting process is patternmaking.A pattern is a replica of the object to be cast, and it is used to create the mold into which the molten metal will be poured. Patterns can be made from a variety of materials, including wood, plastic, and metal. Skilled patternmakers use precise measurements and techniques to create patterns that accurately represent the final product.Step 2: MoldingOnce the pattern is complete, it is used to create a mold. The mold is a cavity that will be filled with molten metal to create the casting. There are several differenttypes of molds, including sand molds, plaster molds, and investment molds. Each type of mold has its own advantages and is used for different types of casting.Step 3: Melting and PouringAfter the mold is prepared, the next step is to melt the metal. The metal is heated in a furnace to its melting point, and then it is poured into the mold. Care must be taken during this step to ensure that the metal is poured at the correct temperature and in the proper manner to avoid defects in the final casting.Step 4: Cooling and SolidificationOnce the molten metal is poured into the mold, it begins to cool and solidify. The cooling process can take varying amounts of time depending on the size and complexity of the casting. As the metal cools, it takes on the shape of the mold and forms the final casting.Step 5: Shakeout and FinishingAfter the metal has solidified, the mold is removed to reveal the casting. Any excess material, known as the gating system, is removed from the casting, and any roughedges or imperfections are smoothed out. The casting may also undergo additional finishing processes, such as machining or surface treatment, to achieve the desiredfinal product.铸造流程是一种通过将熔化的金属倒入模具中,使其冷却并凝固而形成金属物品的方法。

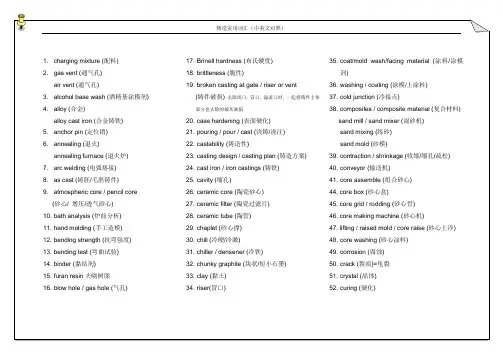

铸造实用词汇(中英文)

120.residual stress (残留应力/铸造应力)

121. roll over machine (翻转机)

122.sag core (砂心下垂)

123.sand blast (喷砂)

124.sand inclusion (夹砂)

125.short pours / short run (浇注不足)

138.surface fold / gas run (皱皮/流缝/冷隔)

139.surface roughness (表面粗糙度)

140.surface treatment (表面处理)

141.tensile strength (抗拉强度)

142.tensile test (拉伸试验)

143.test piece/test lug(试片)

69.flake graphite cast iron (片状石墨铸铁)

70.flow chart (流程图)

71.CE meter(热分析)

72.full size/full dimension(全尺寸)

73.graphitic carbon / graphite carbon (石墨碳)

74.gray cast iron (灰口铸铁/普通铸铁/片状石墨铸铁)

65.open shrinkage / external shrinkage (外缩孔)

66.ferritic spheroidal graphite cast iron

(肥粒体球状石墨铸铁)

67.ferrite (肥粒铁)

68.machining allowance / finishing allowance (加工余量)

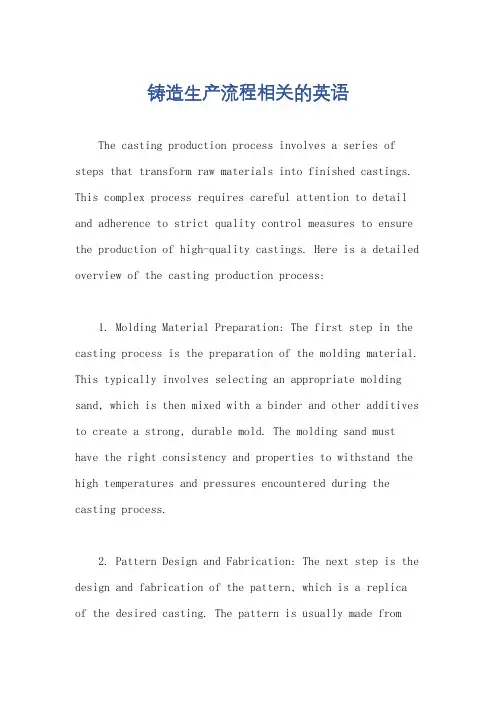

铸造生产流程相关的英语

铸造生产流程相关的英语The casting production process involves a series of steps that transform raw materials into finished castings. This complex process requires careful attention to detail and adherence to strict quality control measures to ensure the production of high-quality castings. Here is a detailed overview of the casting production process:1. Molding Material Preparation: The first step in the casting process is the preparation of the molding material. This typically involves selecting an appropriate molding sand, which is then mixed with a binder and other additives to create a strong, durable mold. The molding sand must have the right consistency and properties to withstand the high temperatures and pressures encountered during the casting process.2. Pattern Design and Fabrication: The next step is the design and fabrication of the pattern, which is a replica of the desired casting. The pattern is usually made fromwood, metal, or plastic and is used to create the mold cavity. The design of the pattern must take into account the dimensions, complexity, and material properties of the final casting.3. Mold Assembly: Once the pattern is ready, it is used to assemble the mold. This involves packing the molding sand around the pattern, creating a cavity that will hold the molten metal during the casting process. The mold must be assembled tightly to prevent leaks and ensure uniform metal distribution.4. Melting and Pouring: The next step is the melting of the metal, which is typically done in a furnace. The metal is heated to a high temperature until it reaches a liquid state. Once the metal is fully melted and ready, it is poured into the mold cavity through a gating system. The gating system controls the flow of metal into the mold and ensures that the casting is filled uniformly.5. Cooling and Solidification: After the metal is poured into the mold, it cools and solidifies, taking theshape of the mold cavity. The cooling process can take several hours or even days, depending on the size and complexity of the casting. During this time, it is crucial to maintain a controlled environment to prevent warping or other defects.6. Mold Removal and Casting Extraction: Once the metal has solidified completely, the mold is removed, and the casting is extracted. This step requires careful handling to avoid damaging the casting. The casting may require further cleaning and finishing to remove any excess sand or imperfections.7. Post-Casting Processes: After the casting is removed from the mold, it undergoes various post-casting processes to enhance its properties and appearance. These processes may include heat treatment, machining, grinding, painting, or coating. The specific processes used depend on the requirements of the final product.8. Quality Control and Inspection: Throughout the casting process, strict quality control measures areimplemented to ensure the production of high-quality castings. This includes regular inspections and testing at various stages of the process to identify and correct any defects or imperfections.In conclusion, the casting production process is a complex and meticulous task that requires careful attention to detail and adherence to strict quality control measures. From material preparation to mold assembly, metal melting, cooling, mold removal, and post-casting processes, each step plays a crucial role in the production of high-quality castings. By understanding and mastering this process, manufacturers can produce castings that meet their specific requirements and applications.。

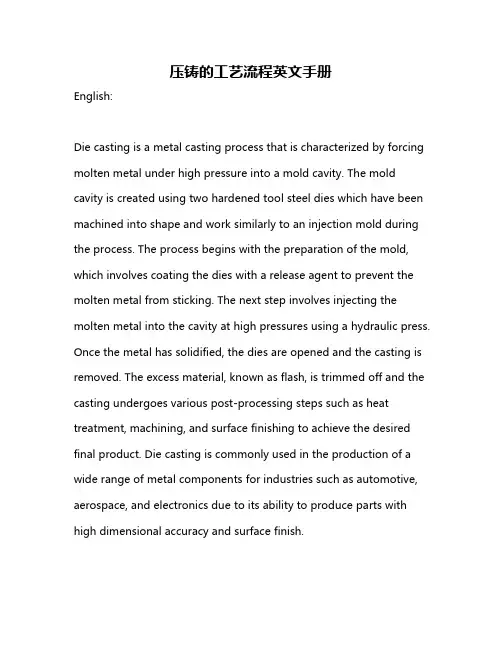

压铸的工艺流程英文手册

压铸的工艺流程英文手册English:Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. The process begins with the preparation of the mold, which involves coating the dies with a release agent to prevent the molten metal from sticking. The next step involves injecting the molten metal into the cavity at high pressures using a hydraulic press. Once the metal has solidified, the dies are opened and the casting is removed. The excess material, known as flash, is trimmed off and the casting undergoes various post-processing steps such as heat treatment, machining, and surface finishing to achieve the desired final product. Die casting is commonly used in the production of a wide range of metal components for industries such as automotive, aerospace, and electronics due to its ability to produce parts with high dimensional accuracy and surface finish.中文翻译:压铸是一种金属铸造工艺,其特点是将熔融金属在高压下注入模腔。

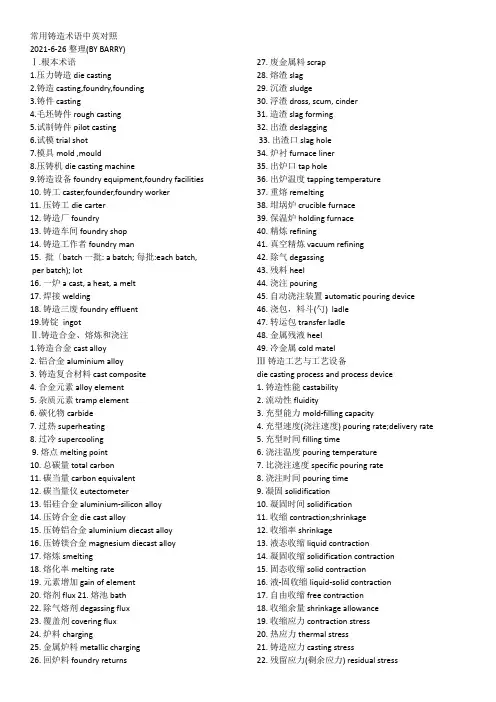

常用铸造术语中英对照

常用铸造术语中英对照2021-6-26整理(BY BARRY)Ⅰ.根本术语1.压力铸造die casting2.铸造casting,foundry,founding3.铸件casting4.毛坯铸件rough casting5.试制铸件pilot casting6.试模trial shot7.模具mold,mould8.压铸机die casting machine9.铸造设备foundry equipment,foundry facilities10.铸工caster,founder,foundry worker11.压铸工die carter12.铸造厂foundry13.铸造车间foundry shop14.铸造工作者foundry man15.批〔batch一批:a batch;每批:each batch, per batch);lot16.一炉a cast,a heat,a melt17.焊接welding18.铸造三废foundry effluent19.铸锭ingotⅡ.铸造合金、熔炼和浇注1.铸造合金cast alloy2.铝合金aluminium alloy3.铸造复合材料cast composite4.合金元素alloy element5.杂质元素tramp element6.碳化物carbide7.过热superheating8.过冷supercooling9.熔点melting point10.总碳量total carbon11.碳当量carbon equivalent12.碳当量仪eutectometer13.铝硅合金aluminium-silicon alloy14.压铸合金die cast alloy15.压铸铝合金aluminium diecast alloy16.压铸镁合金magnesium diecast alloy17.熔炼smelting18.熔化率melting rate19.元素增加gain of element20.熔剂flux21.熔池bath22.除气熔剂degassing flux23.覆盖剂covering flux24.炉料charging25.金属炉料metallic charging26.回炉料foundry returns 27.废金属料scrap28.熔渣slag29.沉渣sludge30.浮渣dross,scum,cinder31.造渣slag forming32.出渣deslagging33.出渣口slag hole34.炉衬furnace liner35.出炉口tap hole36.出炉温度tapping temperature37.重熔remelting38.坩埚炉crucible furnace39.保温炉holding furnace40.精炼refining41.真空精炼vacuum refining42.除气degassing43.残料heel44.浇注pouring45.自动浇注装置automatic pouring device46.浇包,料斗(勺)ladle47.转运包transfer ladle48.金属残液heel49.冷金属cold matelⅢ铸造工艺与工艺设备die casting process and process device1.铸造性能castability2.流动性fluidity3.充型能力mold-filling capacity4.充型速度(浇注速度)pouring rate;delivery rate5.充型时间filling time6.浇注温度pouring temperature7.比浇注速度specific pouring rate8.浇注时间pouring time9.凝固solidification10.凝固时间solidification11.收缩contraction;shrinkage12.收缩率shrinkage13.液态收缩liquid contraction14.凝固收缩solidification contraction15.固态收缩solid contraction16.液-固收缩liquid-solid contraction17.自由收缩free contraction18.收缩余量shrinkage allowance19.收缩应力contraction stress20.热应力thermal stress21.铸造应力casting stress22.残留应力(剩余应力)residual stress23.热裂倾向性tendency to hot tearing24.铸造工艺设计casting process design25.铸造工艺计算机辅助设计Computer-aided design for the casting process;casting process CAD26.实体造型constructive solid geometry;solid modeling27.充型分析mold filling analysis28.铸造工艺设备设计foundry tools design29.铸造工艺卡casting process card;foundry process card30.铸型装配图mold assembly drawing31.铸件图(毛坯图)drawing of rough casting32.铸造工艺准备preparation of casting technique33.铸件设计casting design34.铸件基准面reference face for machining of casting35.分型面parting face;(mold joint;mold parting)36.不平分型面irregular parting;(irregular joint;match parting)37.阶梯分型面stepped parting;stepped joint38.浇注位置pouring position39.交接壁intersection40.十字交接X-junction41.圆角fillet42.热节(点)hot spot43.加强筋stiffening ribs44.拨模斜度draft45.型腔mold cavity46.工艺孔technological hole47.浇注系统gating system;running system48.直浇道sprue49.横浇道runner50.内浇口ingate,gate51.溢流槽overflow well52.排气槽air vent53.分流锥sprue spreader;spreaderⅣ压力铸造〔特种铸造〕die-casting1.压铸机die casting machine2.冷室压铸机cold chamber die casting machine3.冷室卧式压铸机(卧式压铸机)horizontal(cold chamber)die casting machine4.冷室立式压铸机〔立式压铸机〕vertical(cold chamber)die casting machine5.热室压铸机hot chamber die casting machine6.真空压铸evacuated die casting;vacuum die casting7.压射injection;shot8.压射机构injection system9.压室injection chamber10.压射冲头injection ram;plunger11.压射速度injection speed12.压射比压injection pressure13.增压pressurization 14.充填率rate of filling15.锁型(合型)die locking16.合型机构(锁型机构)die closing mechanism17.锁型力die locking force;clamping force18.拉杆tie bar;tie rod19.压铸模die;die casting die20.定模(定型)fixed die;cover die half21.动模(动型)moving die;ejection die half22.浇口套sprue bush23.留型时间opening time24.顶出机构ejection mechanism25.顶杆ejector pin26.抽芯机构core puller27.余料biscuit;slug28.压铸涂料coating of diecasting;releaseagent29.充型压力mold filling pressure30.充型速度filling speed31.保压压力dwell pressure32.保压时间dwell timeⅤ压铸后加工及其工具1.喷砂清理sand blasting cleaning2.喷丸清理shot blasting cleaning3.抛丸清理wheel blasting cleaning4.滚筒清理tumbling5.抛丸清理机wheel blasting machine6.除浇口degating;trimming7.除毛刺deburring8.去氧化皮descaling9.打磨grinding10.弹丸shot11.抛丸器shot wheel12.喷丸器shot blaster13.砂轮机grinder14.浸渗处理impregnantion15.浸渗剂impregnant16.矫型rectification;straightening coining;17.外表处理surface treatment18.砂带打磨belt sanding19.钻孔;镗孔boring20.脱脂degreasing21.电镀electroplating;electrostatic coating22.夹具clamp;fixture23.机加工machining24.铣milling25.台式铣床bench milling machine26.数控加工中心CNC27.铸件机加工余量machining allowance of casting28.切削液mineral cutting oil29.抛光polishing30.粗加工rough working31.喷涂painting32.冲孔punching33.外表处理surface treatment34.洗净rinse35.车床lathe36.磨床grinder,grinding machine37.铣床milling machine38.钻床drill press39.刨床planerⅥ检测方式/设备/工具量具inspection equipment/facility1.合格质量水平acceptable quality level(AQL)2.气密性试验air tightness test3.大气暴露试验atmospheric corrosion test4.成分分析试验chemical analysis5.破坏性检测destructive inspection6.非破坏性检测nondestructive inspection7.尺寸检测dimensional test8.硬度试验hardness test9.冲击试验impact test10.逐件检查individual check11.抽样检查sampling inspection12.三座标检测microcode13.耐压试验pressure test14.盐雾试验salt spray test15.盐雾试验机salt spray test machine16.拉力测量机tensile test machine17.平面度检测仪flatness inspection guage18.检漏机leakage test machine19.普通检具normal guage20.抽样检查sampling inspection21.耐气候试验weathering test22.x光探伤x-ray test23.X光机X-ray machine24.塞规plug guage25.丝攻screw tap26.锥度规conical guage27.螺纹塞规thread plug guage28.游标卡尺vernier caliper29.半径规radius guage30.测角器/量角器bevel guage31.测径规,厚簿规calliper guage32.高度尺height guage33.深度尺depth guage34.三座标CMM35.光谱仪spectrographⅦ.包装packaging1.护边edge protection2.中间夹层intermediate layer3.多插入口式托盘multiple-entry pallet4.一次性托盘throw-away pallet5.耐气候wether resistanceⅧ图纸相关Drawing Related1.喷砂清理abrasive cleaning2.研磨剂abrasive3.依据according to/Acc to4.阳极氧化anodic oxidation5.外观appearance6.踏板autowalk pallet7.底座基座基准base8.盲孔blind hole9.气孔,气泡blow hole10.孔径hole diameter11.凸台boss12.基准面datum plane13.模定位面cast locator datum plane14.铸造应变casting strain15.中心孔center bore16.外圆角,倒角chamfer17.内圆角fillet18.同心度concentricity19.平面度flatness20.平行度parallel21.粗糙度roughness22.垂直度perpendicularity23.清洁度cleanness24.符合conform to25.残留物,污物contamination26.抽芯孔,铸孔core hole27.耐腐蚀corrosion resistance28.沉孔counterbore29.盖板cover30.关键尺寸critical dimension31.横切试验cross-cut test32.脱炭decarburize33.拔模斜度draft angle/draft34.导电性electric conductivity35.电动扶梯梯级escalator step36.外径〔大径〕external diameter37.内径(小径)internal diameter38.外螺纹external thread39.加工余量machining allowance40.法兰flange41.披锋flash42.自由状态free state43.通用公差〔未注公差〕general tolerance44.符合in accondance with45.来料检验incoming inspection46.标识indication,marking47.绝缘性isolation characteristics48.金属互化物intermetallic compound49.内螺纹internal thread50.每per51.边缘periphery52.永久伸长permanent stretch53.垂直于perpendicular to54.针孔,销孔pin hole55.平面图plan,plane figure56.磨光剂polish agent57.聚酯纤维polyester58.容许应力proof stress59.剩余应力residual stress60.试生产铸件prototype casting61.质量保证quality assurance62.散热器radiator63.耐磨性resistance to abrasion64.肋;筋条rib65.滚丝攻通roll thread thru66.剖面图section67.模具寿命service life of dies68.螺距pitch69.阴影毛坯区域shaded area cast70.收缩shrink71.缩孔shrinkage porosity72.碎片sliver73.烧伤soldering mark74.标准standard/std.75.强度范围strength division76.分层;剥落stripped mark;peeling77.清理外表;外表加工;外表抛光surface finish78.抗拉强度tensile strength79.未注unless otherwise specified/unspecified/unmarked80.凸纹/直纹vein grain81.壁厚wall thickness82.屈服点yield pointⅨ压铸报价Quotation1.适用检测标准acceptable inspection standard2.压铸附加费additional casting cost3.铸造费用casting cost4.折扣价depreciation expenses5.估价estimated price6.离岸价free on board(FOB)7.到岸价cost insurance freight(CIF)8.信用证letter of credit(LC)9.后加工费finishing cost10.定率法fixed rate method11.先行生产go-ahead of produce 12.铝锭价格ingot price13.插件费insert cost14.检测费inspection cost15.熔炼费melting cost16.制造间接(额外)费overhead manufacturing expense17.附加利益profit added18.废品比例rejection percentage19.废品率standard rejection rate20.报废时价值,剩余价值,剩余价值residual value/scrap value21.机器运转费;机器运营本钱running cost of machine22.卖价selling expense23.销售间接费selling overhead24.寿命service life25.(合金)掺合比例standard alloying ratio26.标准价格standard price27.试铸时间time of trial shot28.总价格total cost29.试铸费trial casting cost30.除浇口费trimming cost31.生产yield32.生产率yield rate33.后加工合格率yield rate of finishing34.熔炼生产率yield rate of melting35.压铸成品率overall yield of castingⅩ压铸质量和缺陷casting quality and defect1.废品reject2.化学成分不合格chemical consistenceabnormal3.飞边joint flash4.毛刺veining;burr5.气孔blowhole6.气泡blister7.气泡bubble8.激冷区chill zone9.冷脆性cold shortness10.冷隔cold shut;cold filling11.裂纹crack12.铸点dot13.花纹flower msrk;stripping for shot blast14.外部材料foreign material。

铸造件的工序流程

铸造件的工序流程Manufacturing processes for castings play a crucial role in the production of various components for industries such as automotive, aerospace, and machinery. These processes involve a series of steps that transform raw materials into finished products through various methods like molding, melting, pouring, solidifying, and finishing. 铸件的制造工艺在汽车、航空航天和机械等产业的各种组件生产中发挥着至关重要的作用。

这些工艺涉及一系列步骤,通过成型、熔炼、浇铸、固化和整理等各种方法,将原材料转化为成品。

The first step in the process involves creating a pattern or mold, which is then used to shape the molten metal into the desired form. Patterns can be made from various materials such as wood, plastic, or metal, depending on the complexity of the design and the quantity of castings needed. Once the pattern is completed, it is placed in a molding material to create a cavity into which the molten metal will be poured. 过程的第一步是创建一个模具或铸型,然后用它将熔融金属塑造成所需的形式。

铸造业一定要掌握的专业英语单词

铸造业一定要掌握的专业英语单词铸造业一定要掌握的专业英语单词1. fundamental a. 基础的,基本的3. process n. 工序、过程 vt. 使经历某一过程4. molding(美)n. 造型 moulding(英)n. 造型5. casting n. 铸造(法)、浇注、铸件8. mold(美)n. 铸型,型 mould(英)n. 铸型,型9. govern vt.vi. 支配,决定(be)governed by 取决于……;由……决定,以……为转移。

10. green sand mold n. 湿(砂)型12. pour vi. Vt. 浇注13. dry sand mold n. 干(砂)型14. mixture n. 混合物,混合料15. ram vi. Vt. 冲紧,紧实16. bake vt. Vi. 烘烤,焙烤17. moisture n. 水分,潮气,湿度18. firm a. 坚硬的19. coremaking n. 制芯20. cavity n. 空腔,空洞,孔21. project vt. Vi. 伸出,突出23. binding material n. 粘结材料,粘结剂25. melt vi. Vt. n. 熔化,熔炼,溶液30. burner n. 燃烧器,燃烧炉32. brass n. 黄铜,铜锌合金bronze n. 黄铜,铜锡合金34. crucible furnace n. 坩埚炉35. cast iron n. 铸铁36. cupola n. 冲天炉37. electric arc furnace n. 电弧炉38. open hearth furnace n. 平炉39. converter n. 转炉41. container n. 容器42. ladle n. 浇包43. cleaning n. 清理,清砂44. finishing n. 打磨45. solidify vt. Vi. 使凝固47. gate n. 浇口,内浇口48. riser n.冒口49. adhere vi. 粘附,粘着50. department n. 工段,车间,部门51. inspect vi. Vt. 检查,检验,部门52. heat treatment n. 热处理。

精密铸造 英文词汇

精密铸造英文词汇Precision Casting: A Technical Overview.Precision casting, also known as lost-wax casting or investment casting, is a metalworking process that produces complex and intricate parts with exceptional accuracy and surface finish. This process is suitable for a wide range of materials, including ferrous and non-ferrous metals, and is widely used in various industries, such as aerospace, automotive, medical, and energy.The precision casting process begins with the creation of a wax pattern, which is a replica of the desired part. This pattern is then coated with several layers of a refractory material, typically ceramic, to form a mold. Once the mold is dry, the wax pattern is removed through a process called dewaxing, leaving an empty cavity within the mold.The mold is then placed in a furnace and heated to ahigh temperature, causing the ceramic to harden and the wax to melt and be removed. The resulting cavity is then filled with molten metal, which is poured into the mold through a sprue, a small hole in the top of the mold. The metal cools and solidifies within the mold, taking the shape of the original wax pattern.After the metal has solidified, the mold is broken away, revealing the cast part. The sprue and any excess metal are then trimmed away, and the part is ready for further processing, such as machining, finishing, or heat treatment.The precision casting process offers several advantages. Firstly, it allows for the production of complex geometries and intricate details that would be difficult or impossible to achieve with other casting methods. Secondly, theprocess provides excellent dimensional accuracy and surface finish, making it suitable for applications that require high precision and low tolerances. Additionally, precision casting can produce parts with thin walls and intricate internal features, making it an ideal choice for parts with complex internal geometries.In terms of materials, precision casting is suitablefor a wide range of metals, including steel, copper, bronze, aluminum, and titanium. The choice of material depends onthe specific requirements of the application, such as strength, corrosion resistance, and weight.The precision casting process is also highly versatile and can be used to produce parts of various sizes, from small, delicate components to large, heavy-duty parts. This flexibility makes precision casting an attractive optionfor manufacturers seeking to produce complex parts in small batches or large-scale production.However, while precision casting offers many advantages, it also has some limitations. One of the main limitationsis the cost, which can be higher compared to other casting methods due to the complexity of the process and the needfor specialized equipment and skilled labor. Additionally, the process can be time-consuming, as it involves multiple steps and requires careful attention to detail.Despite these limitations, precision casting remains a popular choice for manufacturers seeking to produce high-quality, complex parts. With the advent of new technologies and improvements in the process, precision casting islikely to continue to evolve and find new applications in various industries.In conclusion, precision casting is a highlyspecialized metalworking process that produces complex and intricate parts with exceptional accuracy and surface finish. Its versatility, precision, and ability to produce parts with complex geometries make it an ideal choice for a wide range of applications, particularly in industries that require high-quality, precision-made components. While the process has some limitations, its advantages outweigh these, making precision casting a valuable addition to any manufacturer's toolbox.。

铸造工艺流程英文

铸造工艺流程英文《The Process of Casting Technology》The process of casting technology is a crucial manufacturing method used to produce complex shapes and components. It involves the pouring of molten metal into a mold, where it solidifies to form the desired shape. This process can be used to create a wide variety of products, ranging from simple household items to intricate machine parts.The first step in the casting process is the creation of the mold. This can be done using a variety of materials, including sand, metal, or ceramic. The mold is designed to have a cavity that matches the shape of the final product. Once the mold is prepared, it is then coated with a release agent to ensure that the solidified metal can be easily removed after the casting process.Next, the metal is melted in a furnace at high temperatures. Once it reaches the desired temperature, it is poured into the prepared mold. The molten metal is left to cool and solidify, taking on the shape of the mold cavity. After cooling, the solidified metal is removed from the mold, and any excess material is trimmed off to produce the final product.There are several different types of casting methods, each with its own unique advantages and disadvantages. For example, sand casting is a commonly used method that involves the use of a sand mold, while investment casting utilizes a wax pattern that is coated with a ceramic material. Each method has its own set of parameters that makes it suitable for specific applications.Overall, the casting process is a versatile and efficient manufacturing method that allows for the production of complex and intricate parts. It is a crucial process in various industries, including automotive, aerospace, and construction. With advancements in technology, the casting process continues to evolve, allowing for the production of even more intricate and high-quality products.。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

从射蜡到沾浆制壳阶段工艺流程的英文翻译(其他部分待完成)低温蜡射蜡工艺规范Low temperature wax wax injection process specification1、蜡料的配制石蜡和硬脂酸按1∶1(质量分数)进行配制,蜡料不允许混入水及其它脏物1, 1:1 preparation of paraffin wax and stearic acid (concentration) ,formulated wax does not allow mixed with water and other dirt2、蜡膏的配制取保温缸中的蜡水与蜡屑按1∶2(质量分数)在蜡糊搅拌机上进行充分的搅拌;蜡糊搅拌机的温度设定在60~65℃之间,要求配制的蜡膏具有一定的流动性,手感均匀、细腻、无碎块2, Preparation of insulating cylinder of wax and wax chips by 1:2 (concentration) in fully on wax paste mixer mixing; which temperature setting are between 60~65℃, wax paste needs to has a certain degree of mobility, fine and smooth, no fragments3、蜡样收缩率的控制压注ф100蜡样的收缩率控制在0.9~0.11%之间,要求每工作日检测一次3, controlling shrinkage of wax: :wax injection Diameter 100millimetre ,shrinkage of wax needs to be control I between 0.9~0.11%, C heck once a day4、蜡料温度的控制蜡料溶化缸温度设定在90±5℃,不允许超过95℃;保温缸温度控制在80±5℃;射蜡保温缸温度控制在48~50℃,射蜡嘴温度控制在54~60℃范围内。

4, material temperature control of wax,Wax melting cylinder temperature set at 90 ± 5 ° c,not exceeding 95 ° c; insulation cylinder temperature set at 80 ± 5 ℃; wax injection insulation cylinder temperature is 48~50℃,.Wax injection nozzle temperature control within the scope of 54~60℃6、射蜡工艺参数射蜡压力0.2~0.4Mpa,保压时间1~3分钟,根据蜡件的尺寸大小及壁厚、结构状况进行选定6 wax injection process parameters Injection pressure 0.2~0.4Mpa, 1-3 minutes holding time, process parameters selected according to size and wall thickness and the structural condition of the wax,7、对于具有盲孔的蜡件,为便于抽芯,允许在平厚处扎穿1~2个直径3~5mm的空洞,然后用红蜡修补上。

7, for the wax with a blind hole, for ease of extracting core, allow tie to wear 1~2 at the thick diameter3~5mm hollow, then with red wax on the patch.8、应经常清洁模具上各接合面,以保证蜡件的尺寸精度8, clean the mould on the joint surface regularly, to ensure that the wax pieces size precision9、蜡件冷却水温度控制在20~25℃之间Wax cooling water temperature control between 20~25℃蜡件的检验及修补Inspection and repair of wax1 蜡件必须逐个进行清理,修除批缝、毛刺及污物。

Wax must clear them one by one, in addition to sewing, burrs and dirt.2、蜡件允许用红蜡进行修补,但必须保证表面的光洁度2 Patch wax allows the use of red wax, but must ensure that the surface finish、蜡件的几何尺寸在每班生产过程中进行抽检,但对重要尺寸要求的蜡件需100%检验。

Wax geometry in each sampling during production, but the wax 100% required inspection of critical size requirements.组树tree assembly1、按工艺要求选择合适的模头及组树方法进行组树。

1, according to technological requirements, select the appropriate model and set of tree method for group trees.2、组焊蜡件时要求排列整齐、间距匀称,间隔应不小于一指头。

2, welding wax requires neat, spacing well proportioned, the interval should be not less than a finger. 3、组焊时要防止虚焊,蜡瘤要刮干净3, when welding to prevent cold solder joint, wax tumors to shave小工件的蜡型须以人工的方式逐件地焊粘于浇流导上面组装成蜡树这是脱蜡铸造濧全工程中最耗费时间的一导步骤组树时系用平头型的电烙铁热熔树干或基板和蜡型再予以粘合。

装配时应注意的事项如下S mall workpieces by way of artificial wax type of piece by piece welding sticking above the water flow with investee trees investee which are assembled into wax lost wax casting and clearance works one of the most time consuming steps in investee group tree at the time of using a flat-iron stem or base plate of hot melt and wax investee be bonded. Points to note when Assembly is as follows1尽量将多个蜡型组装成一群1 multiple wax to be assembled into a group of part2组装时应使蜡型于熔融时易于沿着树干或基座流出2 Assembly should make the wax to melt easily along the trunk or base out of3装配成品部份应最先凝固浇池最后凝固3 the Assembly of finished products should be the first solidification casting pool final solidification4浇注、凝固后工件易于从树干或基座上切断4 after casting, solidification piece easily from the trunk or base cut浆的配置Slurry preparation沾浆与淋砂制壳操作Staining sand pulp and hung operation 涂挂前应将浆料搅拌均匀,然后将模组徐徐浸入浆料至模组浇口杯上缘,取出模组用毛刷或压缩空气将尖角、凹孔、窄缝及难涂部位涂刷(或吹)一遍,根据涂挂情况重复此工序1~2次James should stir the slurry before hanging, modules are then slowly deep into a slurry to the module on the basin margin, remove the module with a brush or compressed air to a sharp corner, button holes, narrow and hard coated parts brush (or blowing) again, repeat this process as painting hanging 1~2 times组树先以丙酮或酒精洗净蜡型表面的离型剂、油脂等接着浸泡入粘结剂与微粉耐火材料泡成之浆液滴尽过剩的附着浆液然后淋撒耐火物小粒予以干燥这项操作的重点在于均匀涂浆于蜡型表面并且不使气泡附着、残留Group tree first washed with acetone or alcohol,release agents, such as oil on the surface , then ,immersion into binders and refractory bubbles into a slurry of micro-powder drops excess grout and shower of sub fire Coffea , this operation focused on uniform slurry in wax-coated and does not make bubbles on the surface attachment, persistence如此反复多次直到获得预定的厚度操作的次数及陶壳的厚度系视工件的尺寸与重量而定其厚度须能支撑浇注时金属熔液的重量与挣压力而不致破裂many times repeatedly just like this until you get the thickness of your scheduled,the number operations and thickness of the ceramic shell depending on the workpiece size and weight 。