2014机械制造英语练习答案

机械英语试题及答案解析

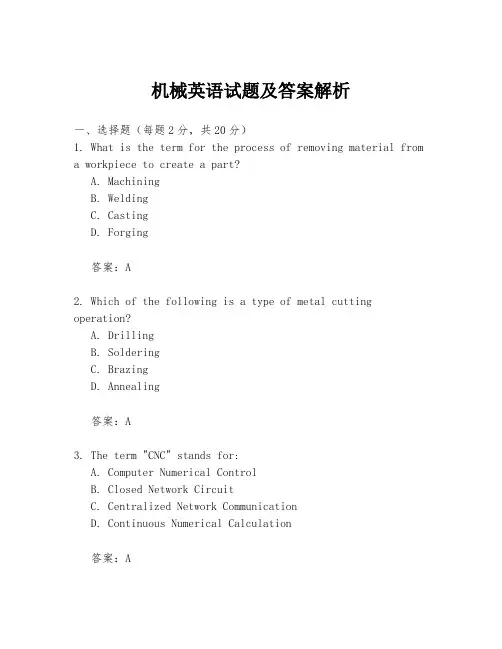

机械英语试题及答案解析一、选择题(每题2分,共20分)1. What is the term for the process of removing material froma workpiece to create a part?A. MachiningB. WeldingC. CastingD. Forging答案:A2. Which of the following is a type of metal cutting operation?A. DrillingB. SolderingC. BrazingD. Annealing答案:A3. The term "CNC" stands for:A. Computer Numerical ControlB. Closed Network CircuitC. Centralized Network CommunicationD. Continuous Numerical Calculation答案:A4. What is the primary function of a lathe?A. To shape woodB. To cut threads on a workpieceC. To bend metal sheetsD. To forge metal答案:B5. In the context of manufacturing, what does "CAD" refer to?A. Computer Aided DesignB. Computer Aided DraftingC. Computer Aided DevelopmentD. Computer Aided Diagnosis答案:A6. Which of the following is a common material used in the production of machine parts?A. PlasticB. CeramicC. AlloyD. Glass答案:C7. The process of joining two pieces of metal by heating them to their melting point is known as:A. SolderingB. BrazingC. WeldingD. Gluing答案:C8. What is the role of a milling machine in the manufacturing process?A. To cut internal threadsB. To shape the surface of a workpieceC. To drill holesD. To create a smooth finish on a surface答案:B9. The term "tolerance" in mechanical engineering refers to:A. The maximum weight of a partB. The acceptable variation in size or shape of a partC. The minimum strength of a materialD. The standard size of a part答案:B10. What is the purpose of a jig in manufacturing?A. To hold workpieces in place during machiningB. To measure the dimensions of a partC. To cut threads on a workpieceD. To provide power to a machine tool答案:A二、填空题(每空1分,共10分)11. The process of shaping metal by applying pressure is known as _______.答案:Forging12. A _______ is a tool that holds a cutting tool and guides it through a specific path.答案:Cutter13. In machining, the term "feed rate" refers to the _______ of the tool relative to the workpiece.答案:Speed14. The _______ is a device that can be used to measure the internal diameter of a hole.答案:Micrometer15. The process of hardening a metal to increase its strength is called _______.答案:Quenching16. A _______ is a machine tool used for shaping a workpiece by removing material.答案:Milling Machine17. The _______ is the process of cutting a workpiece along a straight line.答案:Sawing18. The _______ is a type of machine tool used for cutting internal threads.答案:Tapping Machine19. The _______ is the process of heating and cooling a metalto alter its physical properties.答案:Heat Treatment20. A _______ is a device that holds a workpiece in place during machining.答案:Vise三、简答题(每题5分,共10分)21. Explain the difference between a milling machine and a lathe.答案:A milling machine is used for shaping the surfaceof a workpiece by removing material with a rotating multi-toothed cutter, whereas a lathe is used for shaping a workpiece by rotating it and cutting it with a stationary tool.22. What is the purpose of a jig in the manufacturing process?答案:A jig is a device used in manufacturing to hold a workpiece in a specific position while it is being machined, ensuring accuracy and repeatability in the production process.四、论述题(每题15分,共15分)23. Discuss the importance of precision in mechanical engineering and how it affects the performance of a machine.答案:Precision in mechanical engineering is crucial asit ensures that components fit together correctly andfunction as intended. Inaccurate parts can lead to poor performance, increased wear, and even failure of the machine. Precision is achieved through the use of。

机械制造专业英语课后翻译标准答案

应力与应变第一单元That branch of scientific analysis which motions, times and forces is called mechanicsand is made up of two parts, statics and dynamics.研究位移、时间和力运动乘力是科学分析法的一个分歧,被称作力学,力学由两大部静力学和动力学。

分组成,For example, if the force operating on a sleeve bearing becomes too high, it will squeeze outthe oil film and cause metal-to-metal contact, overheating and rapid failure of the bearing.例如:如果止推轴承上的作用力过大的话,会挤出油膜,引起金属和金属之间的相互接触,轴承将过热而迅速失效。

and of place application, direction, concept Our intuitive of force includes such ideas asmagnitude, and these are called the characteristics of a force.。

力的直观概念包括力的作用点、大小、方向,这些被称为力的三要素All bodies are either elastic or plastic and will be deformed if acted upon by forces. When thedeformation of such bodies is small, they are frequently assumed to be rigid, i.e., incapableof deformation, in order to simplify the analysis.的,如果受到力的作用就产生变形。

机械制造专业英语课后答案(部分)

专业英语翻译一stress and strain(应力与应变)1the fundamental concepts 基本概念cross section 横截面 the internal stresses produced in the bar 杆的内应力continuous distribution of hydrostatic pressure 流体静压力 the tensile load 拉伸载荷 a uniform distribution over the cross section 在横截面均匀分布arbitrary cross-sectional shape 任意截面形状 tensile stresses 拉应力 compressive stresses 压应力 a normal stress 正应力through the centroid of the cross sectional area 通过横截面形心the uniform stress condition 压力均匀分布 the stress distribution at the ends of the bar 杆末端应力分布 high localized stresses 高度应力集中 an axially loaded bar 轴向载荷杆件 a tensile strain 拉应变 an elongation or stretching of the material 材料拉伸 a compressive strain 压应变 the ratio of two lengths 两个长度的比值 purely statical and geometrical considerations 从纯静态以及几何角度考虑 1.That branch of scientific analysis which motions, times and forces is called mechanics and ismade up of two parts, statics and dynamics. 研究位移、时间和力运动乘力是科学分析法的一个分支,被称作力学,力学由两大部分组成,静力学和动力学。

机械制造专业英语--课后答案(部分).(精选)

专业英语翻译一(应力与应变)1 基本概念横截面杆的内应力流体静压力拉伸载荷a在横截面均匀分布任意截面形状拉应力压应力a 正应力通过横截面形心压力均匀分布杆末端应力分布高度应力集中轴向载荷杆件a 拉应变材料拉伸a 压应变两个长度的比值从纯静态以及几何角度考虑1 , , . 研究位移、时间和力运动乘力是科学分析法的一个分支,被称作力学,力学由两大部分组成,静力学和动力学。

2 , a , , . 例如:如果止推轴承上的作用力过大的话,会挤出油膜,引起金属和金属之间的相互接触,轴承将过热而迅速失效。

3 , , , a . 力的直观概念包括力的作用点、大小、方向,这些被称为力的三要素。

4 . , , ., , . 所有的物体既可以是弹性的也可以是塑性的,如果受到力的作用就产生变形。

当变形很小的时候它们被假设成刚体,也就是不产生变形。

5 . . 刚体假设不能应用于内应力和内应变的分析,所以在实际力的分析时,要考虑物体的形变。

6 a , a a .如果作用在质点上所有的力是平衡的,质点将会保持静止或做做匀速直线运动。

21)主要的表现能力2)( )最大单位载荷(应力) 3 ) 应力—应变图4 ) 简单的拉伸试验5) 断裂伸长率6 ) 拉伸试样的两端7 ) 永久变形8 ) 由此产生的载荷位移曲线9 )a 大量产生的物质10 ) 屈服点11) 从弹性到塑性的过度12 ) 材料属性表13 ) 塑性变形14 )a 指定的标准式样长度15) 此刻的破裂16) 短圆柱标本17 ) 韧性材料18 )高应力集中19 ) 极限抗拉强度20 ) 应变硬化区1)A aa . . 拉伸试验包括慢慢加载拉伸载荷直到断裂,拉伸试件两端加粗为了提供装夹区域和避免试件断裂。

2 ) a , ,a . 通常进行试验的方法就是使试件以恒定速度发生变形。

例如,在万能拉伸试验机上,固定端和移动的十字滑块之间的变形是以恒定速度进行的。

3) . FA . 随着实验的进行,用来产生位移的载荷是随位移的变化而变化。

机械设计制造及其自动化专业英语课后题

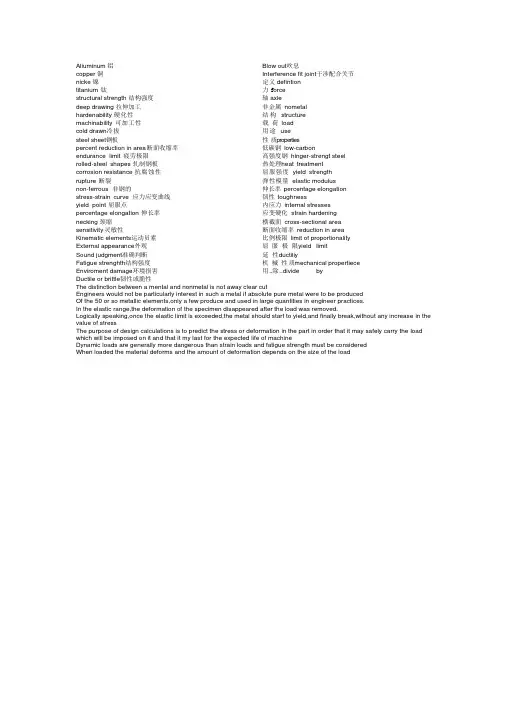

Aliuminum 铝copper 铜nicke 镍titanium 钛structural strength 结构强度deep drawing 拉伸加工hardenability 硬化性machinability 可加工性cold drawn冷拔steel sheet钢板percent reduction in area 断面收缩率endurance limit 疲劳极限rolled-steel shapes 轧制钢板corrosion resistance 抗腐蚀性rupture 断裂non-ferrous 非钢的stress-strain curve 应力应变曲线yield point 屈服点percentage elongation 伸长率necking 颈缩sensitivity 灵敏性Kinematic elements运动员素External appearance外观Sound judgment准确判断Fatigue strenghth结构强度Enviroment damage环境损害Ductile or brittle韧性或脆性Blow out吹息Interference fit joint干涉配合关节定义 defintion力 f orce轴axle非金属nometal结构structure载荷load用途use性质properties低碳钢low-carbon高强度钢hinger-strengt steel热处理heat treatment屈服强度yield strength弹性模量elastic modulus伸长率percentage elongation韧性toughness内应力internal stresses应变硬化strain hardening横截面cross-sectional area断面收缩率reduction in area比例极限limit of proportionality屈服极限yield limit延性ductiliy机械性质mechanical propertiece 用..除..divide byT he distinction between a mental and nonmetal is not away clear cutEngineers would not be particularly interest in such a metal if absolute pure metal were to be producedOf the 50 or so metallic elements,only a few produce and used in large quantities in engineer practices.In the elastic range,the deformation of the specimen disappeared after the load was removed.Logically speaking,once the elastic limit is exceeded,the metal should start to yield,and finally break,without any increase in the value of stressThe purpose of design calculations is to predict the stress or deformation in the part in order that it may safely carry the load which will be imposed on it and that it my last for the expected life of machineDynamic loads are generally more dangerous than strain loads and fatigue strength must be consideredWhen loaded the material deforms and the amount of deformation depends on the size of the load。

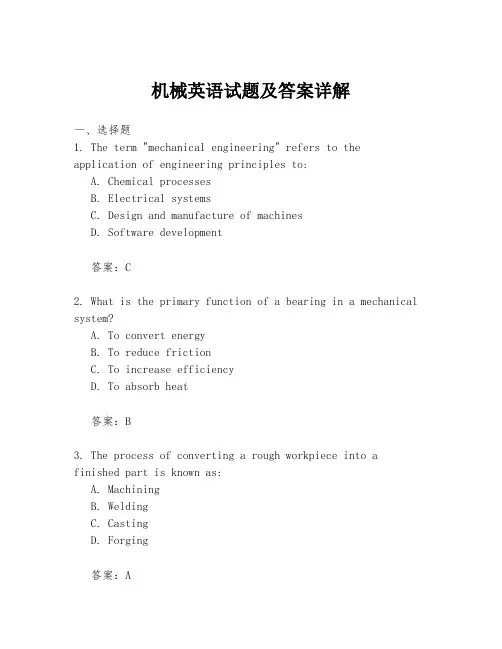

机械英语试题及答案详解

机械英语试题及答案详解一、选择题1. The term "mechanical engineering" refers to the application of engineering principles to:A. Chemical processesB. Electrical systemsC. Design and manufacture of machinesD. Software development答案:C2. What is the primary function of a bearing in a mechanical system?A. To convert energyB. To reduce frictionC. To increase efficiencyD. To absorb heat答案:B3. The process of converting a rough workpiece into a finished part is known as:A. MachiningB. WeldingC. CastingD. Forging答案:A二、填空题4. The formula for calculating the force exerted by a springis known as ________.答案:Hooke's Law5. In mechanical design, the term ________ refers to thestudy of the forces and moments acting on a body.答案:Statics6. The unit of pressure in the International System of Units (SI) is ________.答案:Pascal (Pa)三、简答题7. Explain the difference between static and dynamic friction.答案:Static friction is the force that must be overcometo start moving an object at rest, while dynamic friction is the force that opposes the motion of an object that isalready moving.8. Describe the purpose of a gear in a mechanical system.答案:A gear is used to transmit motion and force from one part of a system to another, often changing the speed and/or direction of the motion.四、计算题9. A hydraulic press has a piston with an area of 0.02 m². If the pressure applied to the piston is 5 MPa, calculate the force exerted by the piston.答案:Force = P ressure × Area = 5 × 10⁶ Pa × 0.02 m²= 100,000 N10. A lever is balanced when the product of the effort force and its distance from the fulcrum is equal to the product of the load force and its distance from the fulcrum. If the effort force is 300 N and the load force is 1200 N, and the effort is applied 2 m from the fulcrum, calculate the distance from the fulcrum to the load.答案:Let the distance from the fulcrum to the load be\( x \). According to the principle of levers, \( 300 N\times 2 m = 1200 N \times x \). Solving for \( x \) gives\( x = \frac{300 N \times 2 m}{1200 N} = 0.5 m \).五、论述题11. Discuss the importance of mechanical vibrations in the context of machinery operation and maintenance.答案:Mechanical vibrations are crucial in machinery for several reasons. They can indicate the health of a machine, with abnormal vibrations often signaling a problem such as imbalance, misalignment, or wear. Monitoring vibrations can help in predictive maintenance, preventing breakdowns and extending the life of machinery.12. Explain the concept of stress concentration in mechanical components and its implications.答案:Stress concentration occurs in mechanical components where the stress is higher than the average stress due to geometrical discontinuities or material defects. This can lead to premature failure of the component under load, as the high-stress areas are more susceptible to fatigue and cracking. Designing to minimize stress concentrations and using materials with good fatigue resistance can mitigate these effects.。

内蒙古第一机械制造集团有限公司第一中学2014-2015学年高二上学期期末考试英语试卷word版含答案

第二节请听下面5段对话或独白,选出最佳选项。

请听第6段材料,回答第6、7题。

6. Why does the woman like the yellow sweater better?A. It looks cool.B. It is less expensive.C. It is more fashionable.7. What will the speakers do next?A. Drink something.B. Go home immediately.C. Try on the sweater. 请听第7段材料,回答第8至9题。

8. Who will cut the man’s hair?A. Kim.B. Tony.C. John.9. When will the man come to have the haircut?A. At 1: 30 pm.B. At 2:30 pm.C. At 3:30 pm.请听第8段材料,回答第10至12题。

10. Where does the woman want to go?A. To a bus station.B. To a bank.C. To a bookshop.11. Which bus should the woman take?A. Bus No. 953.B. Bus No. 14.C. Bus No. 44.12. What does the man tell the woman at the end of the conversation?A. How soon she can get to the bus stop.B. When she should get off the bus.C. Where she can buy a city map.请听第9段材料,回答第13至16题。

13. When will the conference be over?A. On early Wednesday.B. On late Wednesday.C. On early Thursday.14. What is the woman interested in doing?A. Visiting history museums.B. Enjoying something outdoors.C.Visiting some art galleries.15. How will the woman get to the waterfall?A. By car.B. By bus.C. On foot.16. What can we learn from the conversation?A. The woman comes from a beautiful village.B. The man lives on Waterson Street.C. The waterfall is to the west of the town.请听第10段材料,回答第17至20题。

机械制造专业英语答案

第一单元应力与应变That branch of scient ificanalys is whichmotion s, timesand forces is called mechan ics and is mad e up of two parts, static s and dynami cs.研究位移、时间和力运动乘力是科学分析法的一个分歧,被称作力学,力学由两大部分组成,静力学和动力学。

For example, if the force operat ing on a sleeve bearin g become s too high, it will squeeze out the oil film and cause metal-to-metal contac t, overhe ating and rapid failur e of the bearing. 例如:如果止推轴承上的作用力过大的话,会挤出油膜,引起金属和金属之间的相互接触,轴承将过热而迅速失效。

Our intuit ive concep t of forceinclud es such ideasas placeof applic ation, direct ion, and magnit ud e, and theseare called the charac teris ticsof a force.力的直观概念包括力的作用点、大小、方向,这些被称为力的三要素。

All bodies are either elastic or plastic and will be deformed if acted upon by forces. When the deform ation of such bodies is small, they are freque ntly assume d to be rigid , i.e., incapable of deform ation, in ordert o simplify the analysis. 所有的物体既可以是弹性的也可以是塑性的,如果受到力的作用就产生变形。

机械设计制造及其自动化专业英语课后题

机械设计制造及其自动化专业英语课后题第一单元3. Aliuminum铝copper 铜nicke镍titanium 钛structural strength结构强度deep drawing拉伸加工4. 定义defition 力torce 轴axle(roller) 非金属nometal 结构structure 载荷load 用途use(application)性质properties(nature)(character)第二单元4.hardenability硬化性machinability可加工性cold drawn 冷拔steel sheet钢板percent reduction in area断面收缩率endurance limit疲劳极限rolled-steel shapes 轧制钢板corrosion resistance 抗腐蚀性rupture断裂5.低碳钢low-carbon 高强度钢hinger-strengt steel热处理heat treatment屈服强度yield strength弹性模量elastic modulus伸长率percentage elongation韧性toughness内应力internal stresses第三单元4.non-ferrous 非钢的stress-strain curve应力应变曲线yield point屈服点percentage elongation伸长率necking 颈缩sensitivity 灵敏性5.应变硬化strain hardening横截面cross-sectional area断面收缩率reduction in area比例极限limit of proportionality 屈服极限yield limit 延性ductiliy机械性质mechannicalpropertiece用..除..divide…by…第六单元3.tangential notes肤浅的事情flexible manufacturingsystem 柔性制造系统machine instruction机器指令economy of scale规模经济Hardwireyd logic controller硬固线逻辑控制transfer-line运输线,流水线numerically control(NC)数字控制direct numerical control(DNC)直接数字控制computer numerical control(CNC)计算机数字控制4.计算机辅助制造computer-aided manufacturing数控机床手工、半自动化或全自动化manal semiautomatic or full automation 尽管机械制造业一直在持续发展,但知道20世纪50年代才出现又一个重大发展。

机械专业外语_习题集(含答案)

《机械专业外语》课程习题集一、短文翻译(英译汉)1. The solution to most design problems does arise from a set of equations, instead it is a compromise to satisfy a number of design requirements and practical limitations such as available tooling and servicing ease. Designs are often revised to introduce new features, but as much as possible of the old design is retained for economic reasons. Producing a revised design is usually not as difficult as producing a new design because the history of the original is available for evaluation.2. When cutting screw threads, power is provided to the gearbox of the apron by the lead screw. In all other turning operations, it is feed rod that drives the carriage. The lead screw goes through a pair of half nuts, which are fixed to the rear of the apron. When actuating a certain lever, the half nuts are clamped together and engage with the rotating lead screw as a single nut, which is feed , together with the carriage along the bed.3.Generally, grinding is considered to be a finishing process that is usually used for obtaining high-dimensional accuracy and better surface finish. Grinding can be performed on flat, cylindrical, or even internal surfaces by employing specialized machine tools, which are referred to as grinding machines. Obviously, grinding machines differ in construction as well as capabilities, and the type to be employed is determined mainly by the geometrical shape and nature of the surface to be ground. -e.g. cylindrical surfaces are ground on cylindrical grinding machines.4. The dielectric serves to concentrate the discharge energy into a channel of very small crosssectional area. It also cools the two electrodes, and flushes away the products of machining from the gap. The electrical resistance of the dielectric influences the discharge spark energy and time of spark initiation .if the resistance is low , an early discharge spark occurs. If it is large the capacitor will attain a higher value charge before the discharge spark occurs.5. As we previously saw, CNC,DNC and computer-assisted part programming are different kinds of preplanned computerized control of machine tools. In all cases, the tool path has to be established beforehand through a program, the person who prepares the programs employs his or her experience in order to bring the processing time to minimum and not to cause any damage or distortion to the workpiece. This is, in many cases, a difficult problem that involves many factors, alternatives, and constraints. Obviously, this is exactly where an expert system is needed.6. Equipment productively is improved because of the better utilization of machines whenCIM is implemented. We can see that factors like program ability of equipment and computerized monitoring and control of the whole manufacturing facility would largely improve the efficiency of machine utilization. Higher labor and equipment productivity would certainly result in lower product cost.7. Where loads are due to contact, a pair of equal and opposite forces occur. One force acts as an external load on one contacting member. This action-reaction force pairing is one of the basic natural laws put to practical use by engineers. Tracing these power transmission forces through connected machine linkages is an extremely useful visualization aid for identifying machine component loads.8. Element design is concerned with the proper sizing of machine elements to perform a given function at some stated life criterion. Mechanical designers must also be familiar with properties of materials and machining processes to achieve optimal design. In addition, designers must always contend with the question of cost. The watchword should be simplicity, since a simple device is usually the least expensive.9. The tailstock assembly consists basically of three parts, its lower base, an intermediate part, and the quill. The lower base is a casting that can slide on the lathe bed along the guideways, and it has a clamping device to enable locking the entire tailstock at any desired location, depending upon the length of the workpiece. The intermediate part is a casting that can be moved transversely to enable alignment of the axis of the tailstock with that of the headstock.10. Internal grinding is employed for grinding relatively short holed. The workpiece is held in a chuck or a special fixture. Both the grinding wheel and the workpiece rotate during the operation and feed is applied in the longitudinal direction. Any desired depth of cut can be obtained by the cross feed of the grinding wheel. A variation from this type is planetary internal grinding, which is recommended for heavy workpieces that cannot be held in chucks. In the case, the grinding wheel not only spins around its own axis but also rotates around the centerline of the hole that is being ground.11. The intelligent robot has always been the dream of manufacturing engineers, in order to make the automated factory of the future attainable. It is artificial intelligence that will make that dream come true. By definition, an intelligent robot is one that is able to think, sense, and effect, so that it can cope with a changing environment and learn from experience. Since thinking is a brain function, it is obvious that it would fall within the domain of artificial intelligence if it is to be performed by a computer. An integration between sensing, reasoning, and effecting would unify artificial intelligence and robots, with the final outcome an intelligent robot.12. In recent years, there has been a dramatic increase in the range of media used to convey information. Initially, communication was limited to simple forms of media such as voice and paper. This century, however, has witnessed the introduction of a greater variety of media types such as the telephone and visual forms of media. In the latter part of the century,this trend has accelerated and there is now a wide range of media types available to convey information.13. It is well known that a hot plate of metal will cool faster when placed in front of a fan than when exposed to still air. We say that the heat is convected away and we call the process convection heat transfer. Convection is a much simpler physical process than conduction since it merely consists of the actual motion of a volume of hot fluid from one place to another.14.Around the turn of the twentieth century the steam turbine came into use. Steam turbines are very efficient. They can utilize almost 40 percent of the energy supplied to them. They are three times as efficient as reciprocating engines. Steam turbines power many of the world's ships and the majority of the world's electricity generating stations.15. Most small i.C.engines in common use has four cylinders, which fire in a definite and regular sequence. A flywheel is fitted to the crankshaft to keep it running smoothly. It is essential for the inlet and exhaust valves to open and close at exactly the appropriate moment in relation to the position of the piston. Therefore they are actuated by a cam-shaft running in phase with the crankshaft.16. The alternative to forming method is machining. In machining, a sharpened tool of suitable shape removes material in the form of chips until the desired shape is produced. The use of computer and punched-tape control of machine tools makes it possible forthe machining tool to follow any complex three-dimensional path.17. Perhaps because more high-strength, hard, tough, and exotic materials are used, there isa tendency to use chipless machining despite the progress just noted. There is a trend to reduce the amount of metal that needs to be removed. Often chipless machining is more expensive, but the reduced loss of material results in a saving. The increased use of metal forming, forging, rolling, die-casting and other processes illustrates this trend.18.For the semi-mechanized forging of small to medium-sized components, forging hammers powered by various means are employed. The feature common to all of them is that, like the hand forging hammer, they utilize the energy of a falling weight to develop the pressure needed for shaping the metal. Larger components are forged by means of forging presses operated by steam or compressed air or by hydraulic or electric power. Largely automatic forging machines are used for the quantity production of engineering parts.19. As we know, these are the main tasks of an engineer: to explore new ways, invent new solutions to problems, and design new devices. In the research stage of a project, the engineer usually has found a new way of doing a job and is analyzing it (using mathematics and computers) to see how feasible the idea is and how well it will work. The development stage then follows. Here the idea is carried out in the laboratory. The processes vary among different projects, but the basic point is the same: Turn the idea into a working reality.20.The fact that steel can possess a wide range of useful mechanical properties is of extreme economic importance. This is clearly illustrated in the railroad industry, forex-ample. To move a train from one place to another, we use a locomotive which has the ability to pull a given total load. This load is composed of the weight of the cars and the weight of the freight being transported. If a freight car is made of high strength steel, the structural members can be relatively small and the car will be lighter as well as stronger. This means that the amount of freight can be increased.21.The simplest method of welding two pieces of metal together is known as pressure welding. The ends of metal are heated to a white heat— for iron, the welding temperature should be about 13000C—in a flame, At this temperature the metal becomes plastic. The ends are then pressed or hammered together, and the joint is smoothed off. Care must be taken to ensure that the surfaces are thoroughly clean first, for dirt will weaken the weld. Moreover, the heating of iron or steel to a high temperature causes oxidation, and a film of oxide is formed on the heated surfaces.22. The design of a machine includes many factors other than those of determining the loads and stresses and selecting the proper materials. Before construction or manufacture can begin, it is necessary to have complete assembly and detail drawings to convey all necessary information to the shop men. The designer frequently is called upon to check the drawings before they are sent to the shop. Much experience and familiarity with manufacturing processes are needed before one can become conversant with all phases of production drawings.23. Flat pulleys and belts. This is the oldest and simplest type of pulley and belt. The pulley may be a single pulley, or it may have three or four different diameters. A one-piece pulley having three or four diameters is called a cone pulley. Actually the pulleys are not flat. They are tapered slightly so that the diameter of the pulley is a little larger at its center. We call this a crowned pulley. The pulley is made larger in diameter at the center because a flat belt will always climb to the highest part of a pulley. The crown ensures that the belt will run in the center of the pulley.24.Of course, materials have always been vital to human civilization. Three of humanity’s earliest eras are called the Stone Age, the Bronze Age, and the Iron Age, because the civilization of each was almost entirely dependent on the material after which the era was named. But now, in the twentieth century, materials-not just one, but many-have become a most important factor on which the advance of technology and industry depends. Our progress in space, in electronics, and in atomic energy is directly linked to the solution of crucial materials problems.25.The purpose of the design calculations is of course to attempt to predict the stress or deformation if the part in order that it may safely carry the loads which will be imposed upon it, and that it may last for the expected life of the machine. All calculations are, of course, dependent on the physical properties of the construction materials as determined by laboratory tests. A rational method of design attempts to take the results of relatively simple and fundamental tests and apply them to all the complicated and involved situations encountered in present-day machinery.二、按要求翻译下列句子(略)……答案1.对大多数设计问题的解决并不是来源于一组公式,而是受制于要满足很多设计要求和实际限制诸如可用的工具或使用的舒适性。

- 1、下载文档前请自行甄别文档内容的完整性,平台不提供额外的编辑、内容补充、找答案等附加服务。

- 2、"仅部分预览"的文档,不可在线预览部分如存在完整性等问题,可反馈申请退款(可完整预览的文档不适用该条件!)。

- 3、如文档侵犯您的权益,请联系客服反馈,我们会尽快为您处理(人工客服工作时间:9:00-18:30)。

1.Metals are elements that generally have good electrical and thermal conductivity. Many metals have high

strength, high stiffness, and have good ductility.

金属就是通常具有良好导电性和导热性的元素。

许多金属具有高强度、高硬度以及良好的延展性。

2.Plastic deformation is the ability of bend or deform before breaking. As engineers, we usually design

materials so that they don’t deform under normal conditions.

塑性变形就是在断裂前弯曲或变形的能力。

作为工程师,设计时通常要使材料在正常条件下不变形。

3.The lathe bed is the main frame, involving a horizontal beam on two vertical supports. It is usually made of grey or nodular

cast iron to damp vibrations and is made by casting.

车床床身是包含了在两个垂直支柱上水平横梁的主骨架。

为减振它一般由灰铸铁或球墨铸铁铸造而成。

4.Although small tolerances give higher quality work and a better operating mechanism, the cost of manufacture increases

rapidly as the tolerances are reduced. It is therefore important that the tolerances be specified at the largest values that the operating or functional considerations permit.

虽然较小公差能得到较高加工质量和较好操作机构,但随着公差的减小制造成本会迅速增加。

因此公差被定为从操作或功能考虑允许的最大值是重要的。

5. A tensile test consists of slowly pulling a sample of material with a tensile load until it breaks. The ends of tensile

specimens are usually enlarged to provide extra area for grip-ping and to avoid having the sample break where it is being gripped.

拉伸试验包括慢慢加载拉伸载荷直到断裂。

拉伸试件两端加粗为了提供装夹区域和避免试件断裂。

6.As we look around us we see a world full of “things”, machines, devices, tools, things that we have designed, built, and

used; things made of wood, metals, ceramics, and plastics. We know from experience that some things are better than others; they last longer, cost less, are quieter, or are ease to use.

当我们环顾四周,我们可以看到一个充满“物体”的世界,机器、设备、工具等一切由我们设计、建造和使用的物体;有木头、金属、水泥和塑料制成的物体。

从我们的经验我们知道一些物体会比其他一些物体更好,如使用寿命更长,成本更低,更轻便或者更容易使用。

7. Interchangeability means that identical parts must be interchangeable, i.e., able to replace each other, whether during

assembly or subsequent maintenance work; without the need for any fitting operations.

互换性意味着在相同的零件之间必须能够进行互换。

无论是在装配时还是在其后的维修时,这些零件都可以互相取代而不需任何修配工作。

8.The term operation is defined as when one oprator(or a group of operators) works in a definite position (one machine tool

or clipping table) to achieve the continuous man.

一个或一组工人,在一个工作地(机床设备)上,对同一个或同时对几个工件所连续完成的那一部分工艺过程称为工序。

9. A gear can be gripped axially between a shoulder on the shaft and a spacer, with torque being transmitted

through a key.

一个齿轮可以用轴肩和挡圈进行轴向固定,并通过键来传递。

10.。